Back-bolt type dry-hang curtain wall system

A dry-hanging and back-bolting technology, applied in the field of curtain wall systems, can solve the problems of high cost and use of many materials, and achieve the effect of ensuring connection stability, reducing costs and facilitating installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

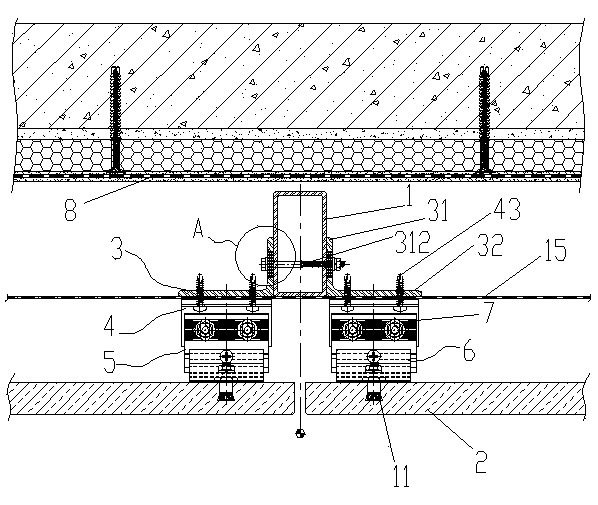

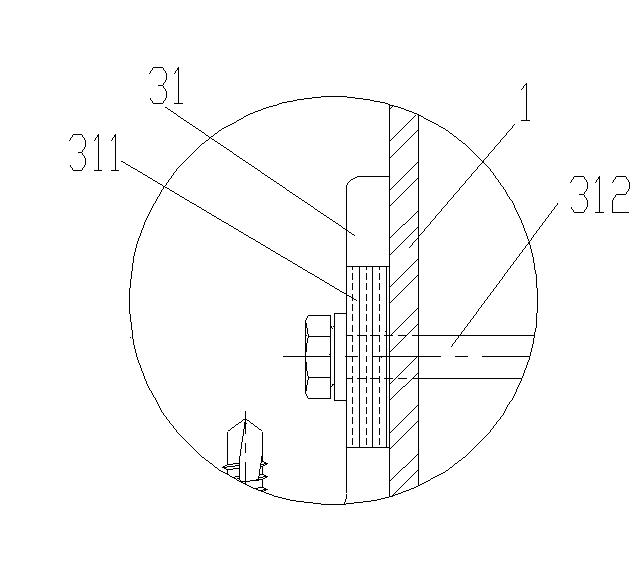

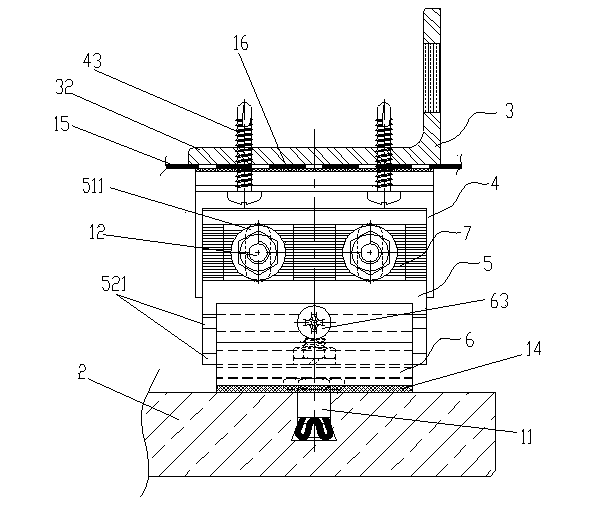

[0047] Such as Figure 1-12 As shown, the back bolt type dry-hanging curtain wall system includes a panel 2, a column 1 arranged on the back of the panel 2, and a dry-hanging assembly connecting the panel 2 and the column 1. The dry-hanging assembly includes a back bolt 11 connected to the panel 2. Both sides of the column 1 are respectively provided with L-shaped supports 3, the L-shaped supports 3 include a first sheet-like portion 31 and a second sheet-like portion 32 perpendicular to each other, the first sheet-like portion 31 is connected with the column 1, the second The sheet part 32 is connected with the hanging assembly.

[0048] Specifically, the panel 2 is composed of a plurality of panel plates. The horizontal ends of each panel plate are connected to two columns 1 respectively, and the horizontal end of each panel plate is connected to the corresponding column 1 through two sets of dry-hanging components. The columns 1 are arranged in the vertical direction. The...

Embodiment 2

[0059] Such as Figure 13-16 As shown, the difference between the back-bolt type dry-hanging curtain wall system and Embodiment 1 is:

[0060]No waterproof board is provided between the L-shaped support 3 and the dry-hanging assembly, instead, a sealing member is provided between each panel plate for sealing. Specifically, the sealing member includes a foam caulking strip 17 embedded between two adjacent panel panels, and a sealing strip 18 arranged between the two panel panels and outside the foam caulking strip 17, and the sealing strip 18 seals , The role of waterproof, specifically, it can be a silicone sealant strip.

[0061] It should be noted that, the panel 2, column 1, L-shaped support 3, dry-hanging assembly and waterproof board 15 of the present invention can all be made of common materials in this industry. Specifically, in Embodiment 1-2, the panel 2 used by the inventor is a stone panel, the column 1 is a steel column, the L-shaped support 3 is an angle steel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com