High-voltage connector with secondary locking structure

A high-voltage connector and secondary locking technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve problems such as easy rotation of cables, poor shielding contact, and uneven contact force, and achieve guaranteed The effect of connection stability, high assembly efficiency and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that the location words "front", "rear" and "end" in the present invention refer to the front of the socket part, and the back and the end of the part far away from the socket part. The socket part refers to the plug The part that is plugged into the socket.

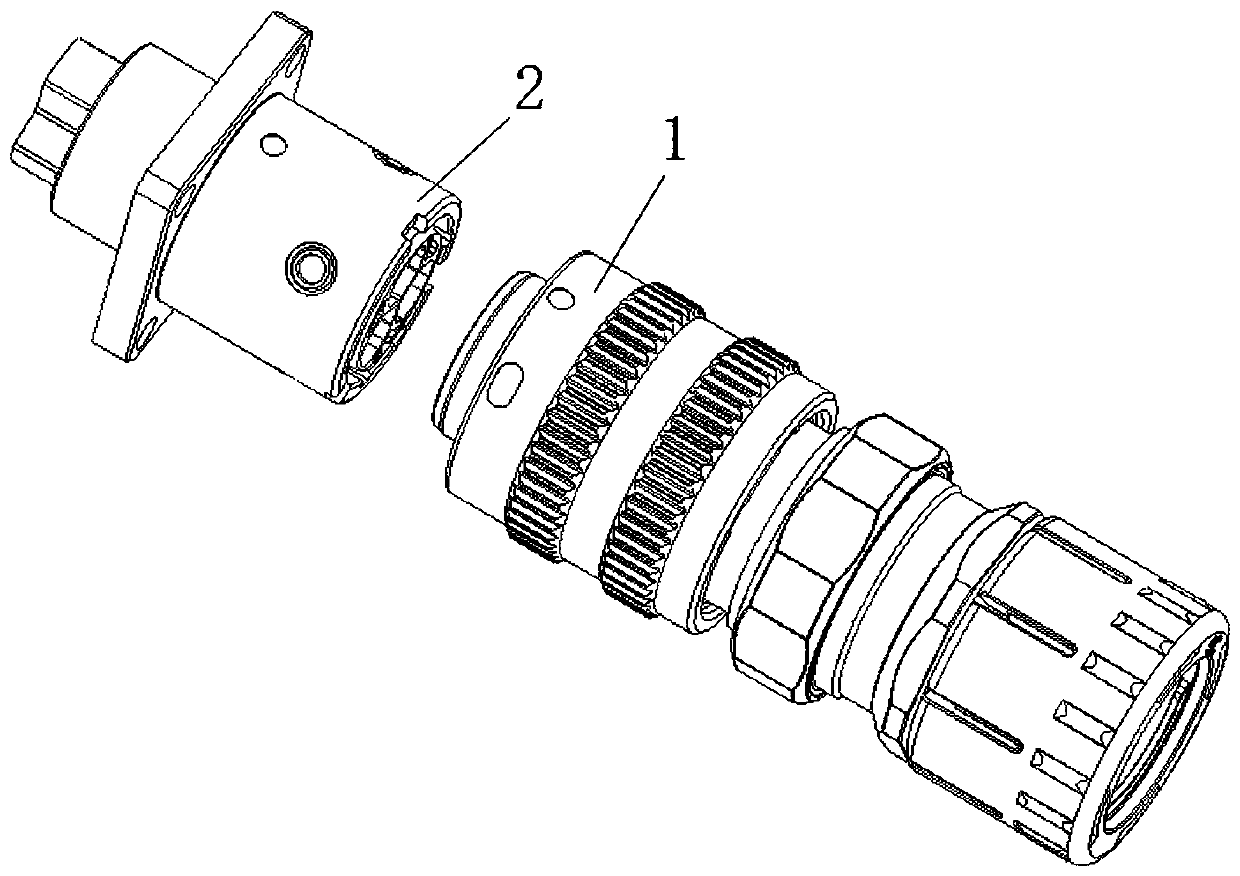

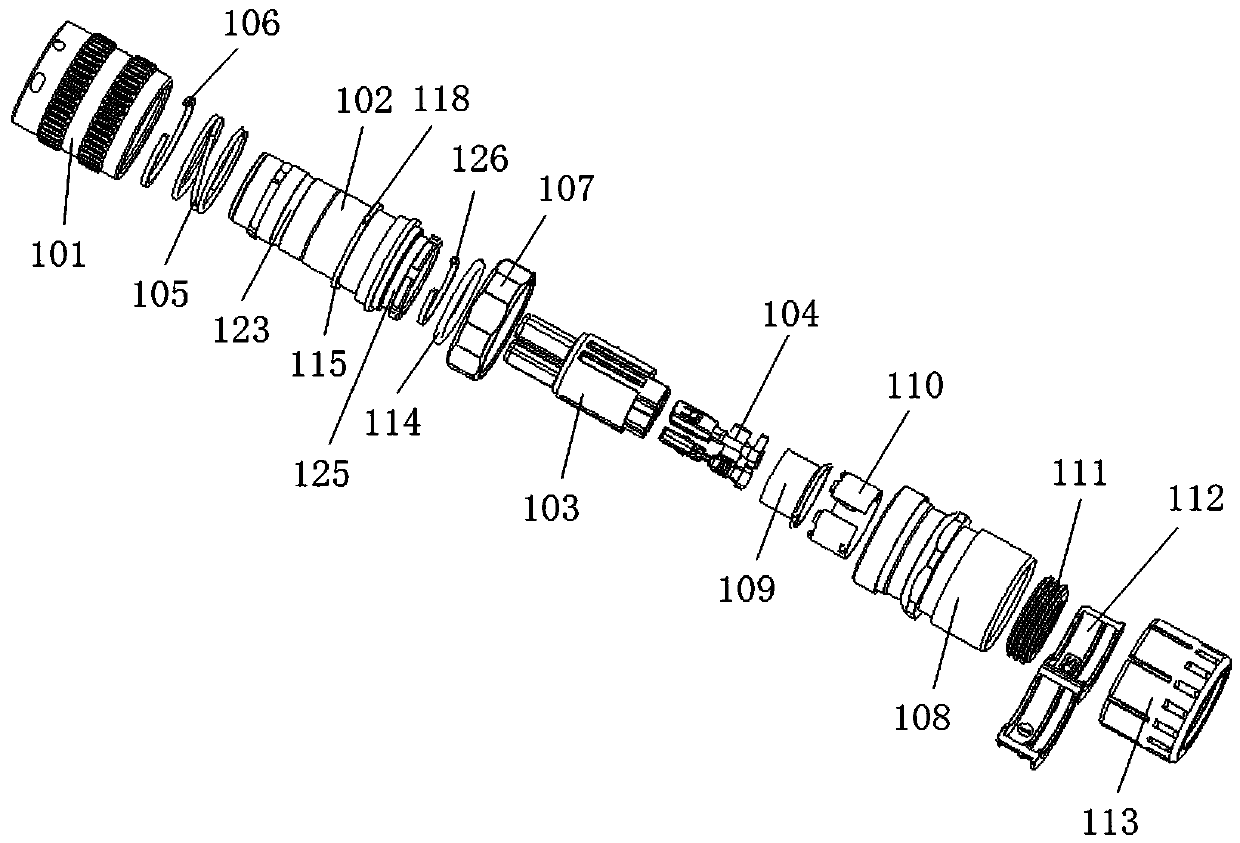

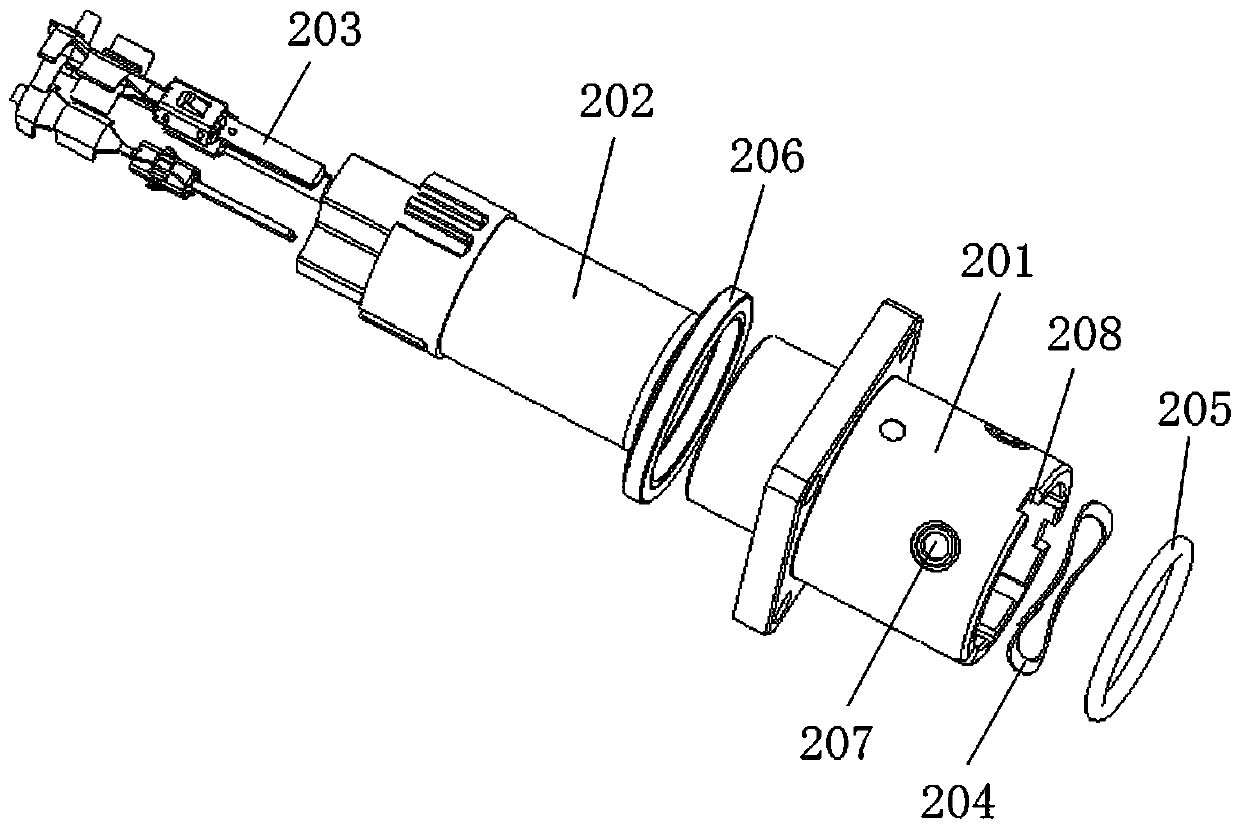

[0032] like Figure 1-14 As shown, a high-voltage connector with a secondary locking structure has a variety of key positions, small size, convenient and fast connection, and has a secondary locking structure to ensure the stability of the connection between the plug 1 and the socket 2; The effective connection with the wiring harness of the corrugated tube saves the process of winding tape or heat shrinkable tube, greatly improves the assembly efficiency, and the assembly holding force is much greater than that of tape winding or heat shrinkable tube, effectively improving the product aesthetics. The high-voltage connector with a secondary locking structure includes a plug 1 and a socket 2 mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com