Split series solar junction box

A solar energy and junction box technology, applied in semiconductor devices, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of module output power drop, long connection cable of junction box, poor heat dissipation of junction box, etc., to achieve enhanced heat dissipation and stable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

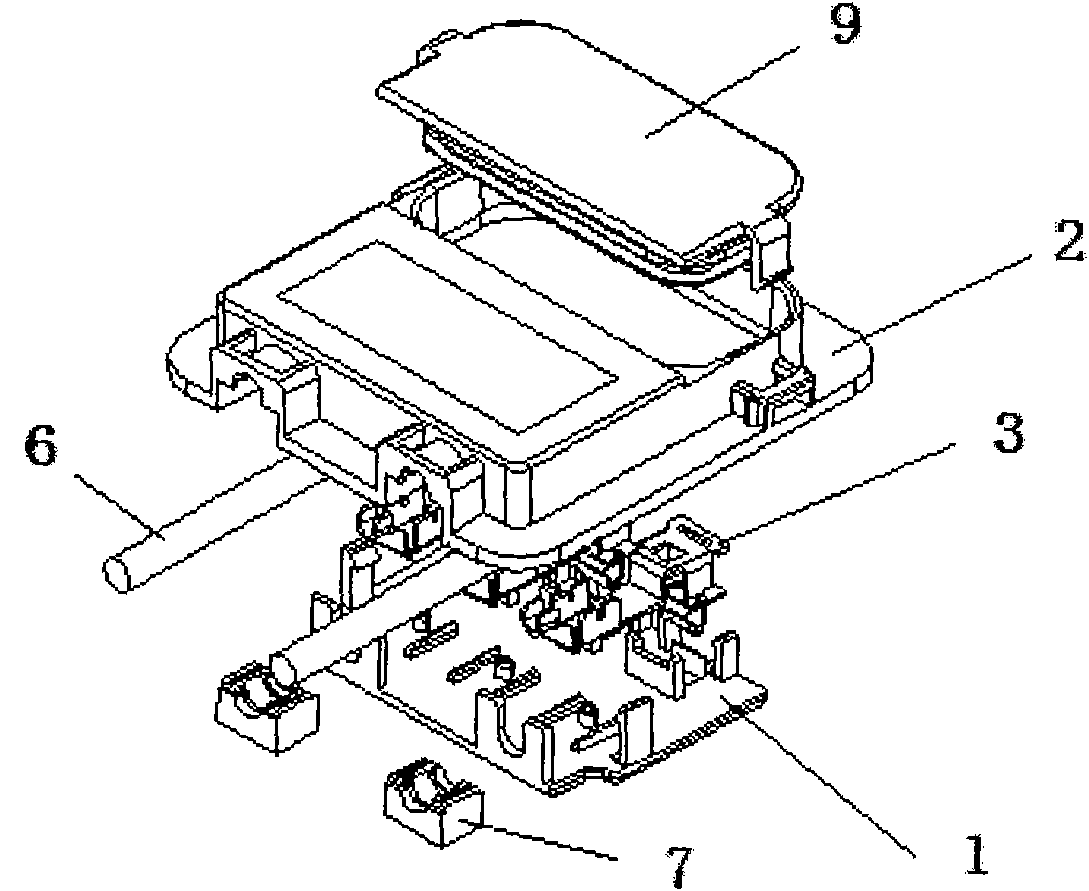

[0021] Embodiment 1, the split series solar junction box drawn from the left, refer to Figure 4 : A solar junction box, comprising a base 1 and a large box cover 2, the base 1 and the large box cover 2 are connected, the base 1 and the large box cover 2 are made of heat-conducting materials, and the base 1 and the large box cover 2 Between them, a plurality of sets of connection terminals 3 are arranged in parallel, and each two opposite terminals are connected through one or more diodes 4 to play a role of bypass protection. Each connection terminal 3 is correspondingly connected to the busbar 8 on the solar module, and the connection terminal 3 and the diode 4 are packaged with conductive glue 5 . The connecting terminal 3 has a relatively large area, which not only serves as a connection, but also as a heat dissipation rib. The sealing function of the conductive glue 5 ensures the sealing of the junction box on the one hand, and on the other hand, when the diode 4 is worki...

Embodiment 2

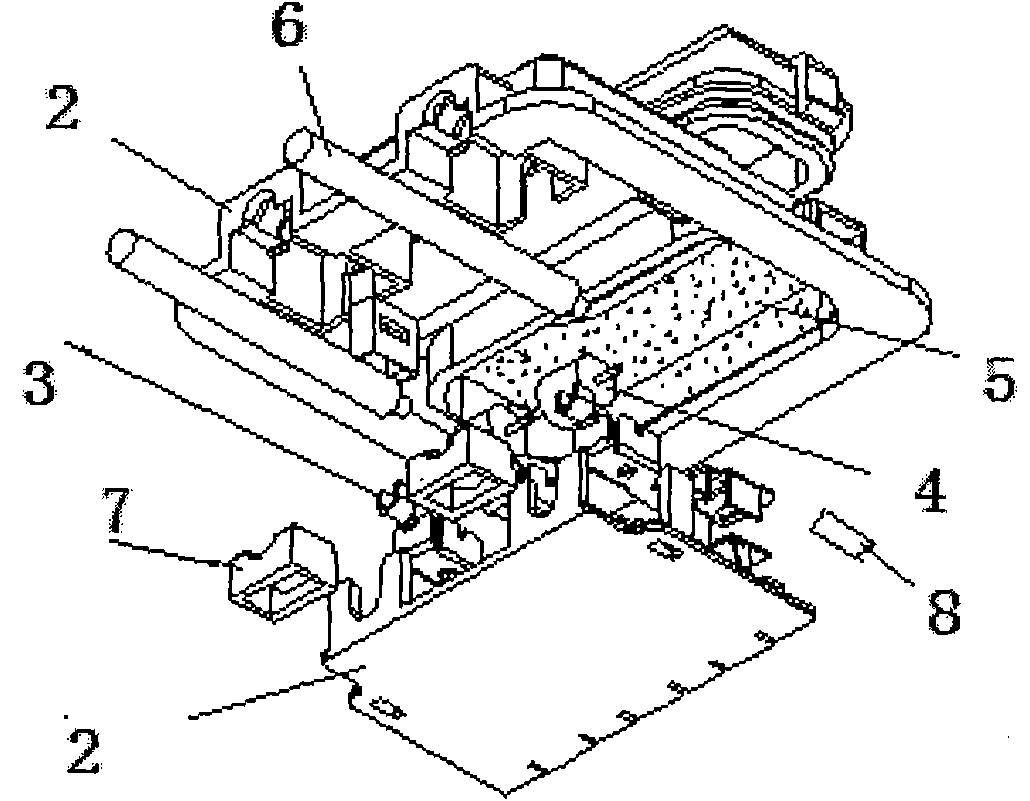

[0024] Embodiment 2, split series solar junction box without lead-out, refer to Figure 5 : A solar junction box, comprising a base 1 and a large box cover 2, the base 1 and the large box cover 2 are connected, the base 1 and the large box cover 2 are made of heat-conducting materials, and the base 1 and the large box cover 2 Between them, a plurality of sets of connection terminals 3 are arranged in parallel, and each two opposite terminals are connected through one or more diodes 4 to play a role of bypass protection. Each connection terminal 3 is correspondingly connected to the busbar 8 on the solar module, and the connection terminal 3 and the diode 4 are packaged with conductive glue 5 . The middle connecting terminal 3 has a relatively large area, which not only serves as a connection, but also as a heat dissipation rib. The sealing function of the conductive glue 5 ensures the sealing of the junction box on the one hand, and on the other hand, when the diode 4 is worki...

Embodiment 3

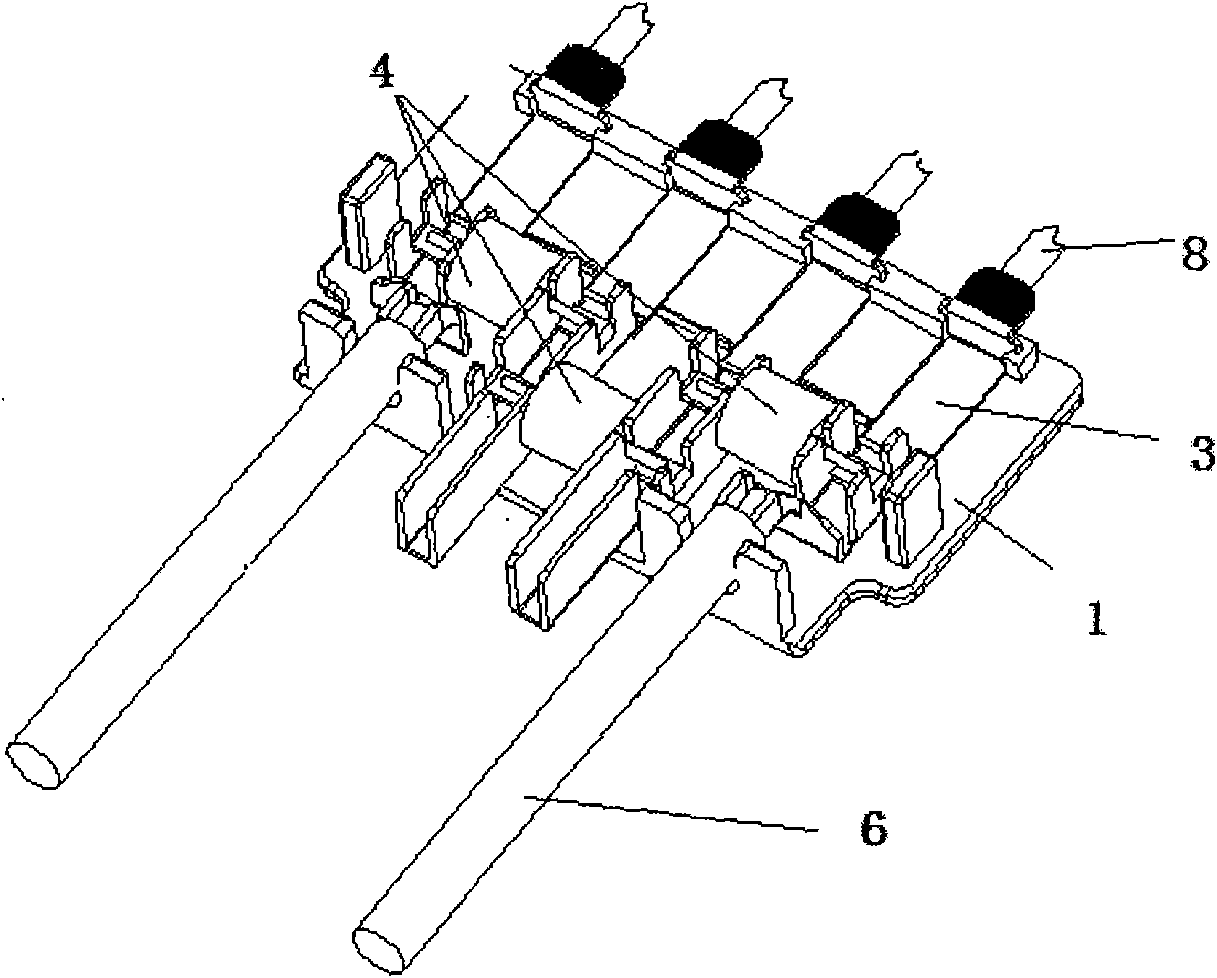

[0027] Embodiment 3, the split series solar junction box drawn from the right, refer to Figure 6 : A solar junction box, comprising a base 1 and a large box cover 2, the base 1 and the large box cover 2 are connected, the base 1 and the large box cover 2 are made of heat-conducting materials, and the base 1 and the large box cover 2 Between them, a plurality of sets of connection terminals 3 are arranged in parallel, and each two opposite terminals are connected through one or more diodes 4 to play a role of bypass protection. Each connection terminal 3 is correspondingly connected to the busbar 8 on the solar module, and the connection terminal 3 and the diode 4 are packaged with conductive glue 5 . The connecting terminal 3 has a relatively large area, which not only serves as a connection, but also as a heat dissipation rib. The sealing function of the conductive glue 5 ensures the sealing of the junction box on the one hand, and on the other hand, when the diode 4 is work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com