Patents

Literature

450results about How to "Easy for production management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

InactiveCN103350027AImprove sorting efficiencyFlexible structureWet separationThermodynamicsMagnetic separator

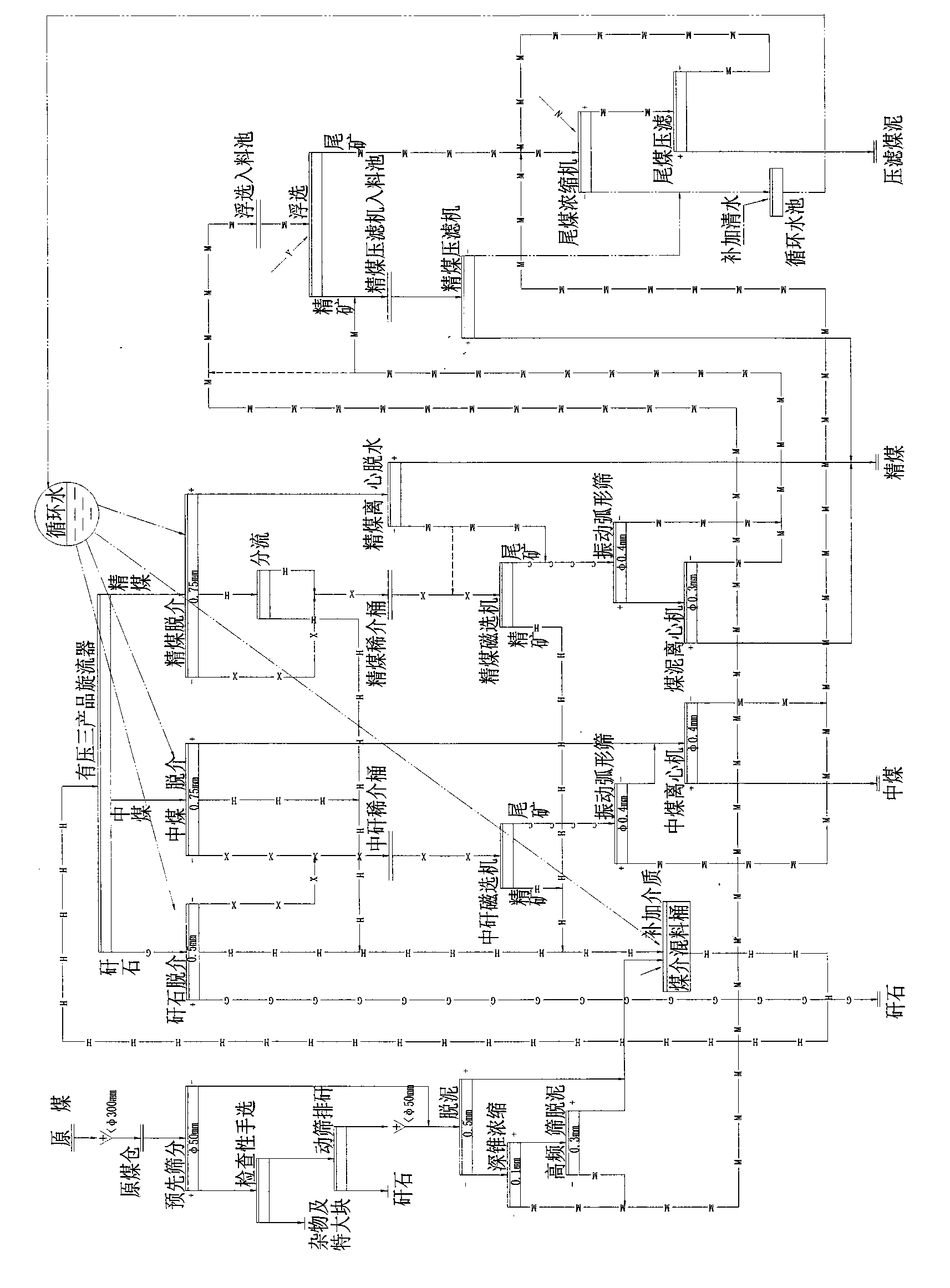

Provided is a classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process. The process comprises the steps that wet classification and primary desliming are carried out on raw coal after prescreening, gangue predischarging and breaking are carried out on the raw coal, secondary desliming is carried out on the screen underflow of the raw coal after the screen underflow is concentrated, the oversize products of the secondary desliming and the screen underflow of the primary desliming are together fed in a pressurized three-product cyclone, three products are obtained after separation, and clean coal, middle coal and gangue are obtained after medium separation and dehydration are carried out on the three products. Part of qualified suspension liquid and dilute suspension liquid are obtained when the medium separation is carried out on the three products, magnetic concentrate is obtained after the dilute suspension liquid is recovered by a magnetic separator, and the magnetic concentrate and the qualified suspension liquid are directly fed in a medium blending barrel. The magnetic tailings of the dilute suspension liquid and the undersize mixtures of pre-desliming, the overflow of concentration classifying equipment and a secondary desliming screen enter a coal slime recovery processing system together. The process is high in separation efficiency, flexible in product structure, low in producing and operating cost and prone to achieving the large-scale single system, the modularization and the integrating intellectualization of plant layout.

Owner:煤炭科学研究总院唐山研究院

Vacuum negative-pressure los mould casting technique

InactiveCN101332501AHigh precisionImprove casting qualityFoundry mouldsFoundry coresLost-foam castingMaterials science

The invention relates to a vacuum negative pressure lost foam casting process, which belongs to the technical field of casting. The process comprises the following steps: an integral mold of a screw is obtained by using resin bonded sand with a nut which has the same inner surface geometric parameters as that of or a little bigger internal diameter than that of a screw hole to be processed; the mold of the screw is taken out, coated with a coating and baked dry; then a hole is cut at the position of the screw hole to be processed on the integrally cast overall mold; finally the screw mold is inserted into the cutting hole and assembled to form the final mold; that is, the vacuum negative pressure lost foam casting process can be directly used for casting a casting with the screw hole, which creates a precedent of directly casting small-aperture screw holes without reprocessing in the casting field. The screw hole processed by the process can ensure precision and needs no reprocessing. The vacuum negative pressure lost foam casting process is especially applicable to the vacuum negative pressure lost foam casting of the casting with a plurality of screw holes, small size and high precision.

Owner:泰州市永昌冶金设备有限公司

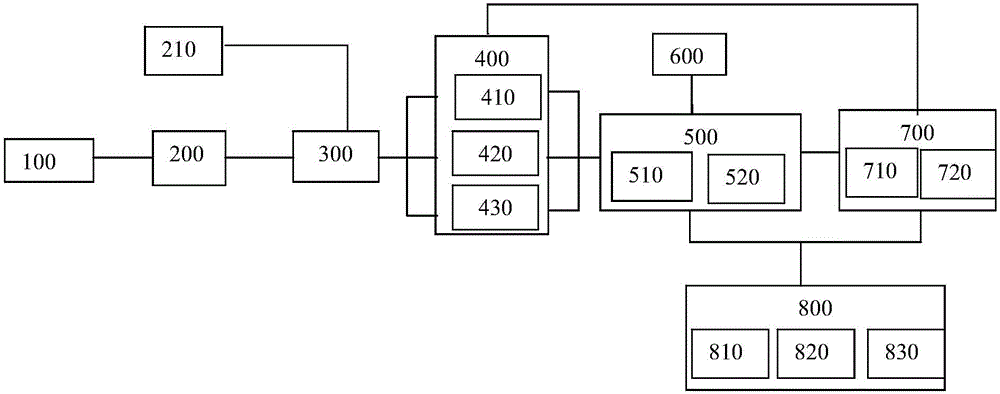

Automatic testing system of production line of vehicle information terminal and testing method of system

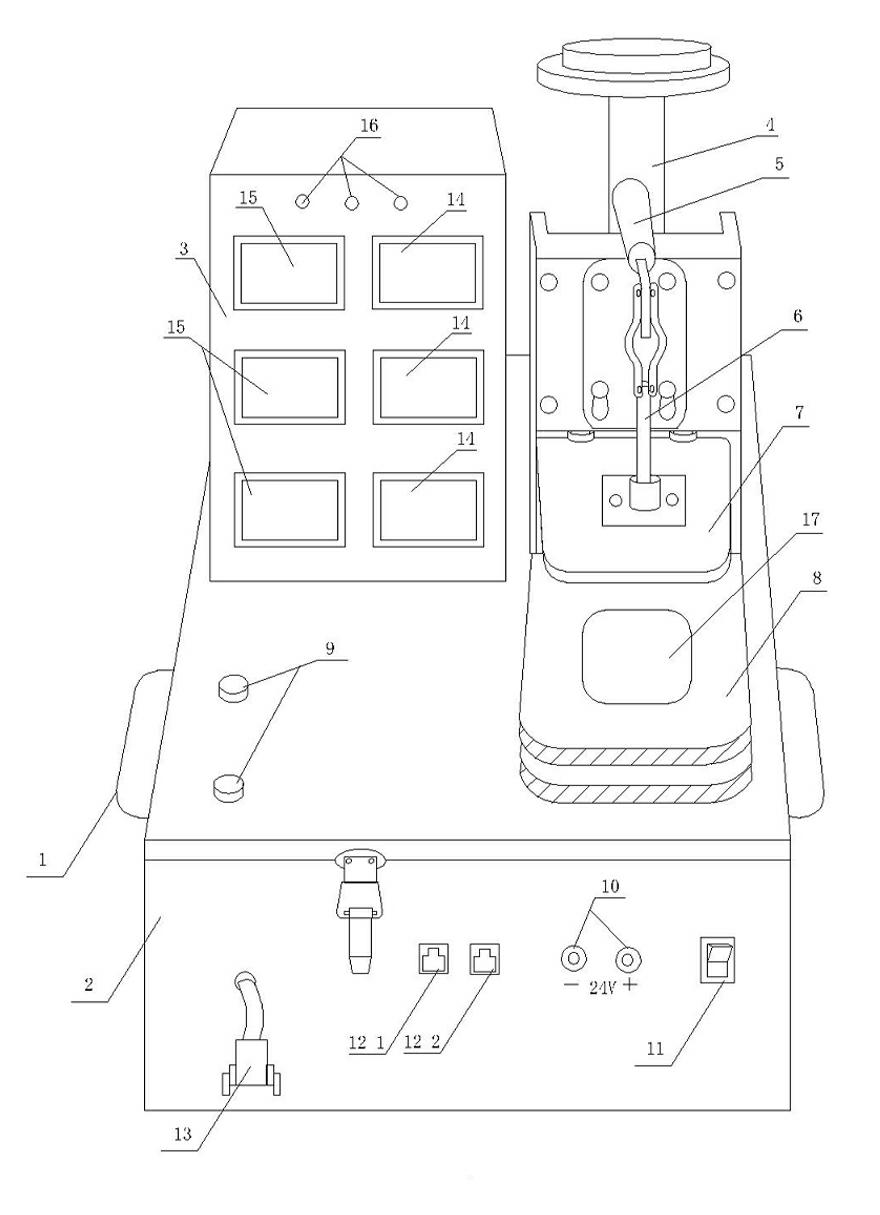

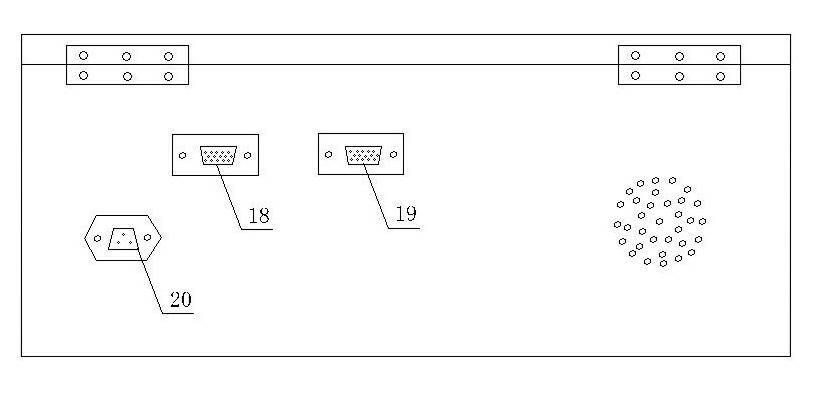

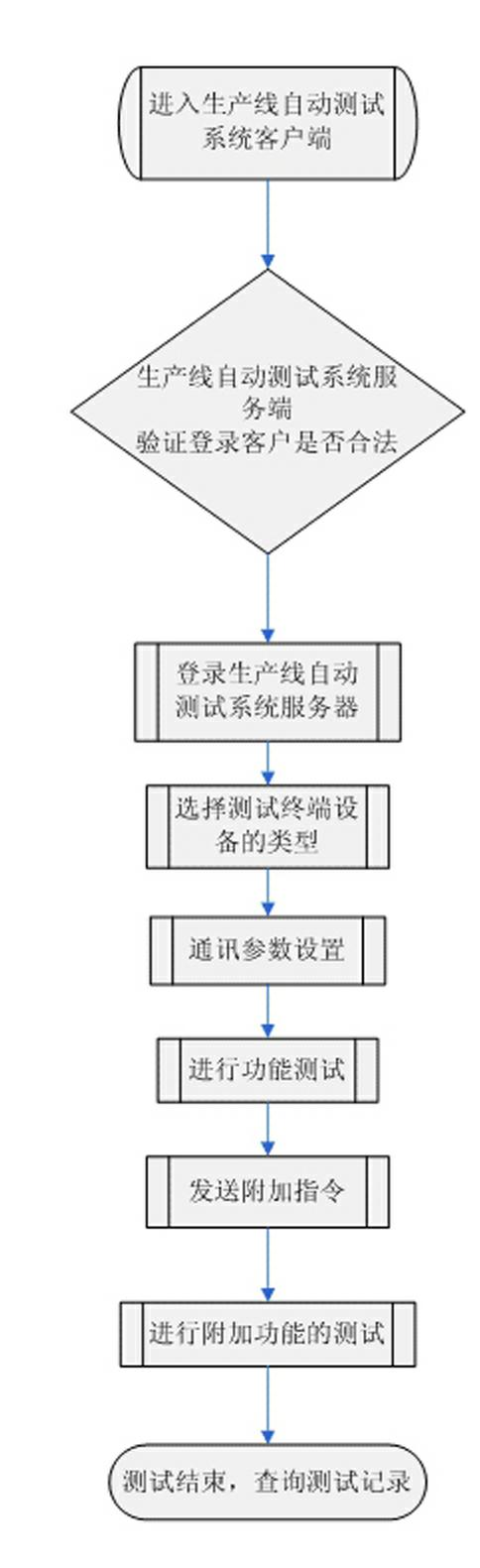

ActiveCN102095448AEasy for production managementSimplify production managementMeasurement devicesTransmission systemsTest fixtureFunctional module

The invention relates to an automatic testing system of the production line of a vehicle information terminal and a testing method of the system. By adopting the system and the method, the state of the test terminal can be obtained according to the test record of the automatic testing system of the production line of the vehicle information terminal, the use condition of each functional module can be analyzed and counted and the reference information can be provided for the enterprises to select the functional modules. The automatic testing system comprises a client of the automatic testing system of the production line, a server of the automatic testing system of the production line, a central database of the system, auxiliary equipment for the automatic testing system of the production line, a test fixture of the automatic testing system of the production line and a computer. The testing method comprises the following steps: 1) entering into the client of the automatic testing system of the production line and selecting the type of the test terminal equipment according to the interface prompt of the terminal testing program before testing the equipment; 2) setting the communication parameters; 3) carrying out functional test; 4) sending extra instructions; 5) testing the extra functions; and 6) inquiring the test record.

Owner:TIANZE INFORMATION IND

High-voltage lithium ion battery cathode material and preparation method thereof

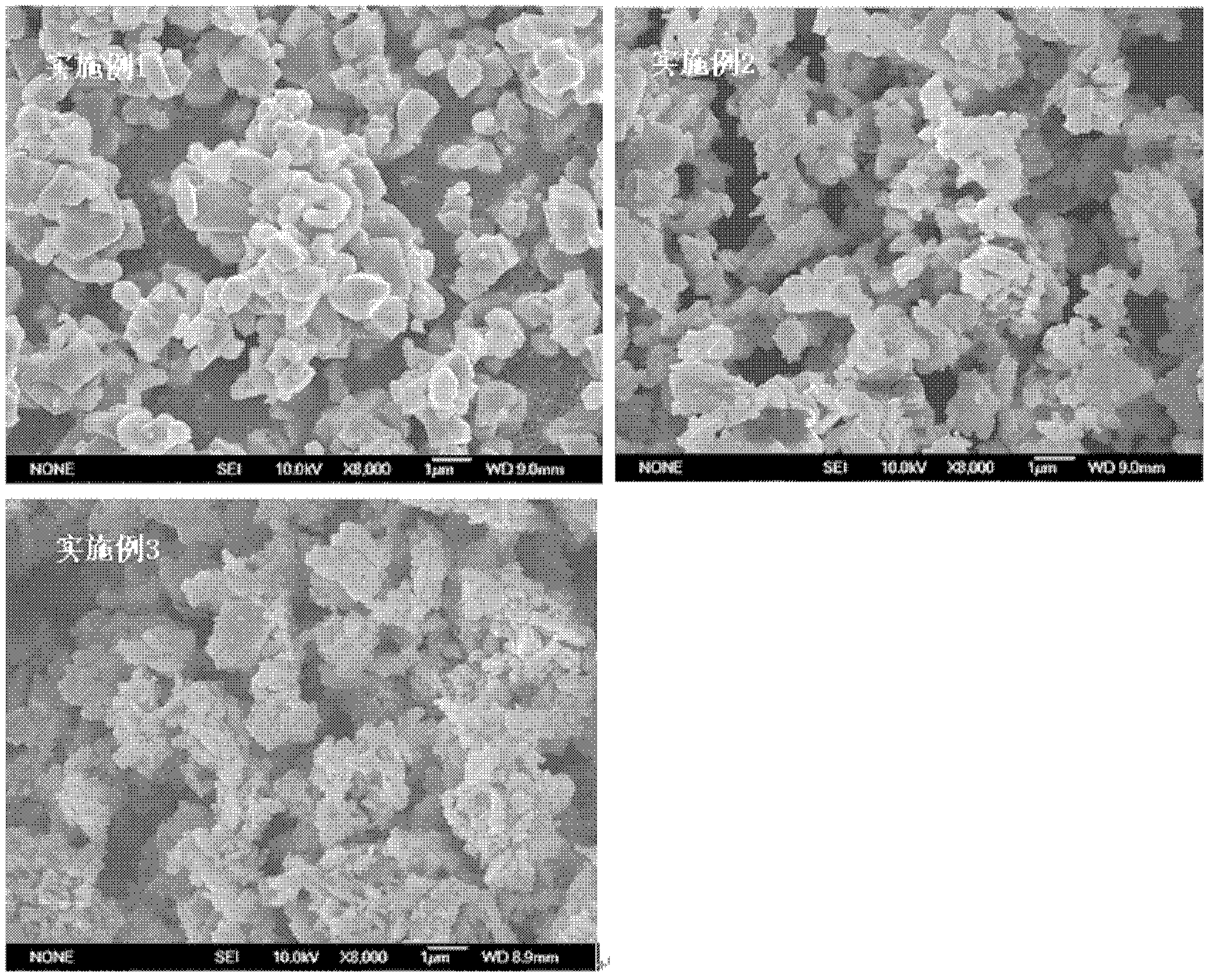

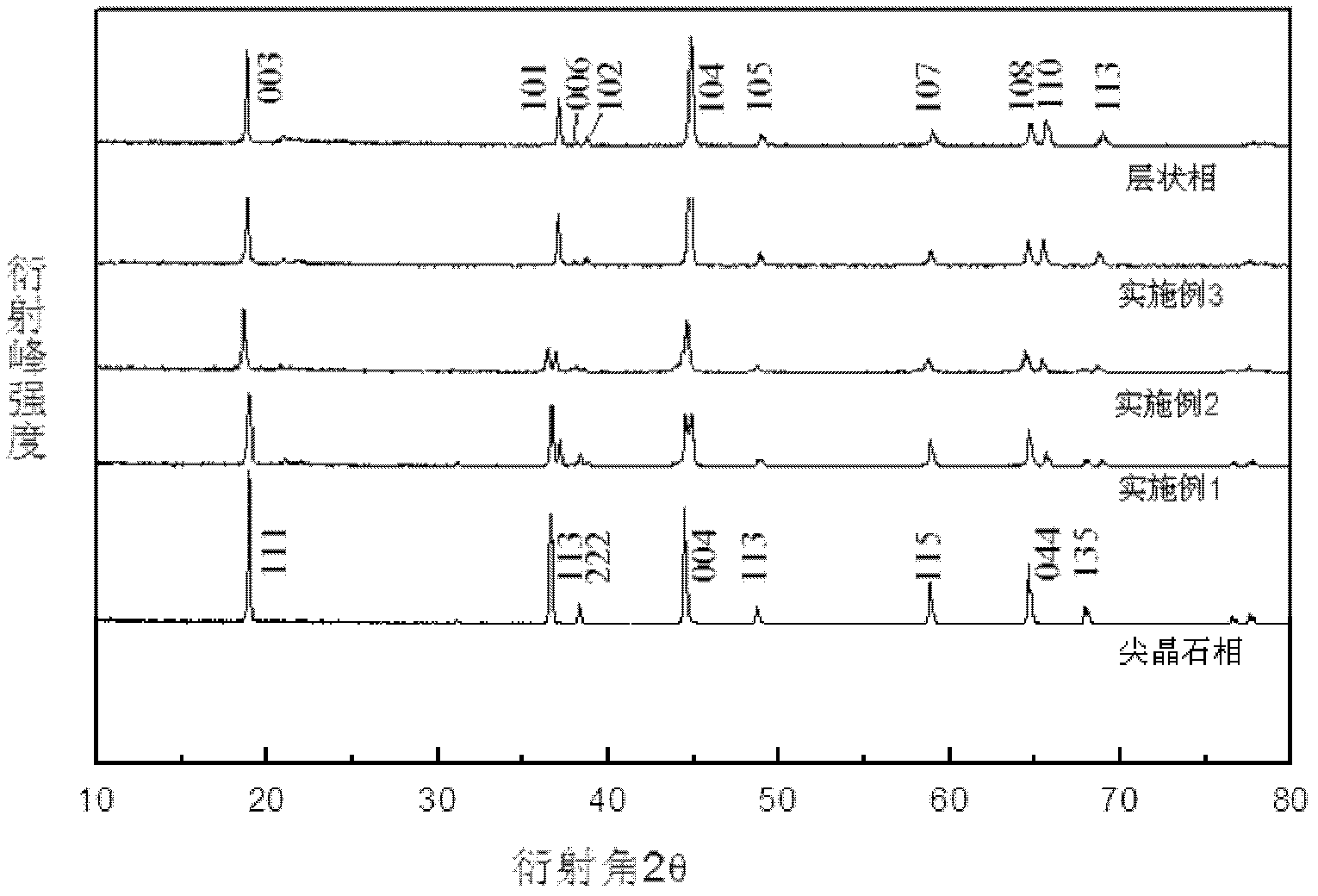

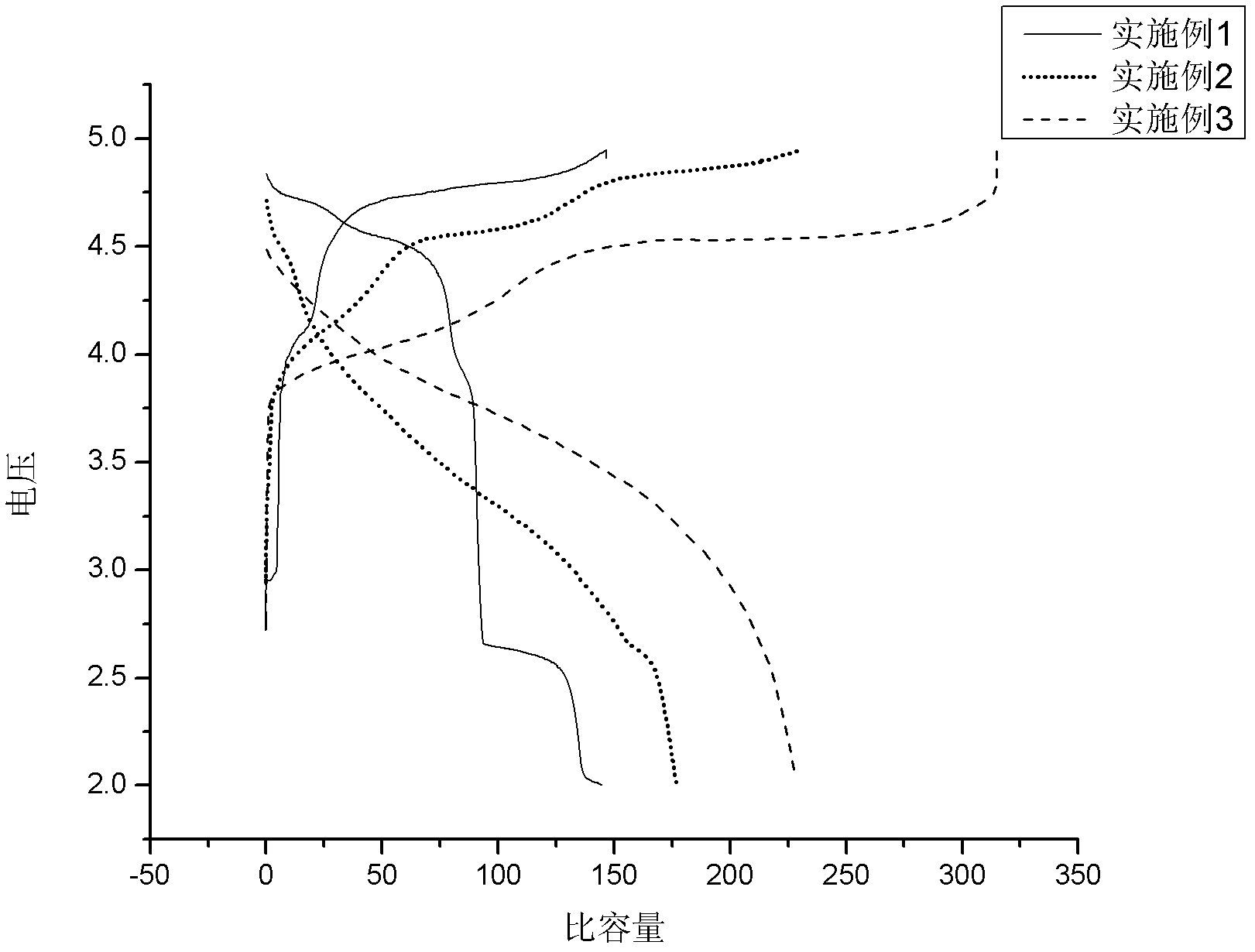

ActiveCN102569781AExpand the voltage application rangeImprove cycle stabilityCell electrodesManganeseLithium-ion battery

The invention discloses a high-voltage lithium ion battery cathode material and a preparation method thereof. The high-voltage lithium ion battery cathode material is a solid solution material with a stratiform and spinel composite structure, and the molecular formula of the cathode material is LixNi0.25-zMn0.75-zM2zOy, wherein M is one or two of doped metals of Co, Al, Cr, Mn and Ga, x is more than 0 and less than 2, y is more than or equal to 2 and less than or equal to 3, and z is more than 0 and less than or equal to 0.25. The invention has the advantages that: the cathode material has the stratiform and spinel composite structure, the high specific capacity advantage of a manganese-based solid solution material is kept, and the cycle stability and the thermal stability of the material are improved; the impedance of the cathode material is reduced by doping, so that the thermal stability of the material is further improved, and the heat release is reduced to improve the comprehensive electrochemical performance of the material; and the preparation process of the material has high controllability, the manufacturing cost is low, and the manufacturing process has high repeatability and high batch stability, production management is facilitated, and the application demands on high-voltage and high-specific-capacity materials on the market are met.

Owner:徐源庆

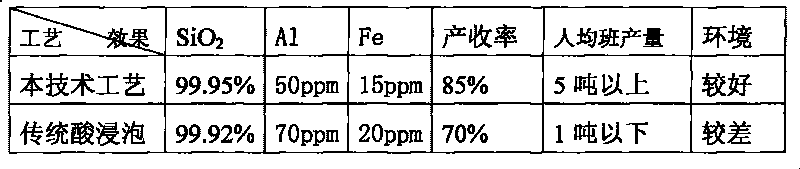

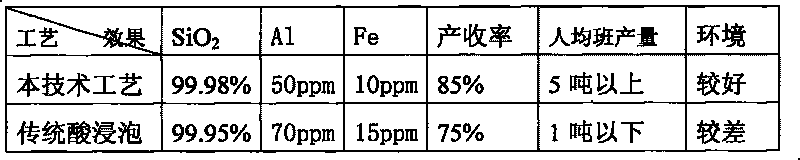

Autogenous grinding and impurity removing method of thermokalite in high-purity quartz sand production

InactiveCN101695680ARelieve stressReduce processing costsCleaning using liquidsWet separationResource utilizationGranularity

The invention relates to an autogenous grinding and impurity removing method of thermokalite in high-purity quartz sand production, which belongs to the technical field of quartz sand production. The method comprises the following steps: breaking quartz ores to reach lumpiness below 10 centimeters or granularity below 0.5 millimeter; uniformly inputting broken quartz lumps below 10 centimeters into an autogenous grinding machine (inputting quartz sand with the granularity being below 0.5 millimeter into a scrubbing machine), and meanwhile, adding an NaOH or Na2CO3 solution with a concentration of 1-2 percent according to a liquid-solid volume ratio of 0.5:1-2:1; at a temperature of 40-100 DEG C (90+ / -5 DEG C for the best), starting the autogenous grinding machine or the scrubbing machine to ensure that the quartz ores are mutually and autogenously ground so as to peel off impurities on the surfaces of the quartz ores; and washing the autogenously ground or scrubbed quartz by clear water or purified water until the pH value of the quartz reaches 7 after the washing. The invention can guarantee the product quality, obviously improve the resource utilization rate and the production efficiency, greatly reduce the pollutant discharge of the whole production process and reduce the cost of waste water treatment.

Owner:江苏阳山硅材料科技有限公司

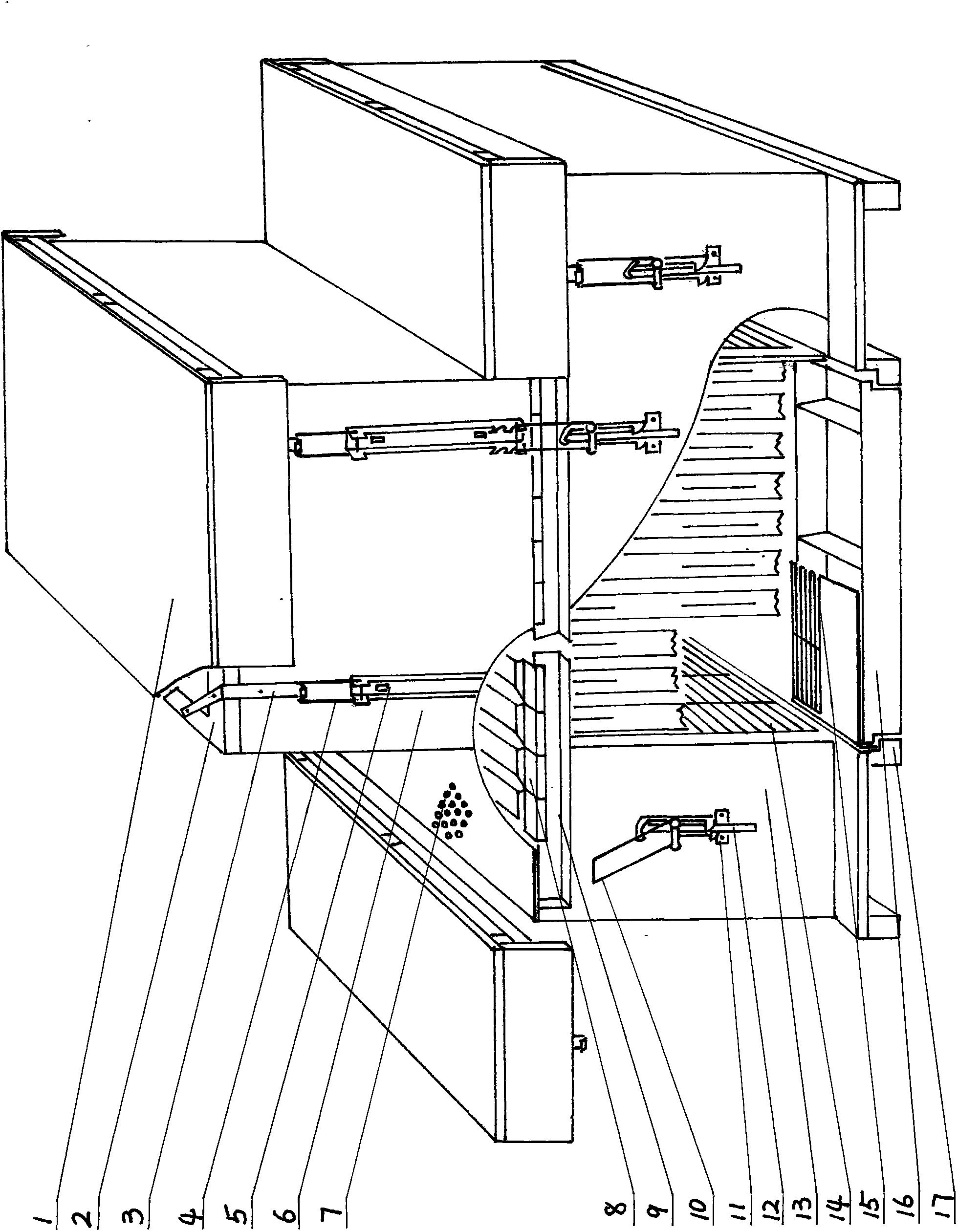

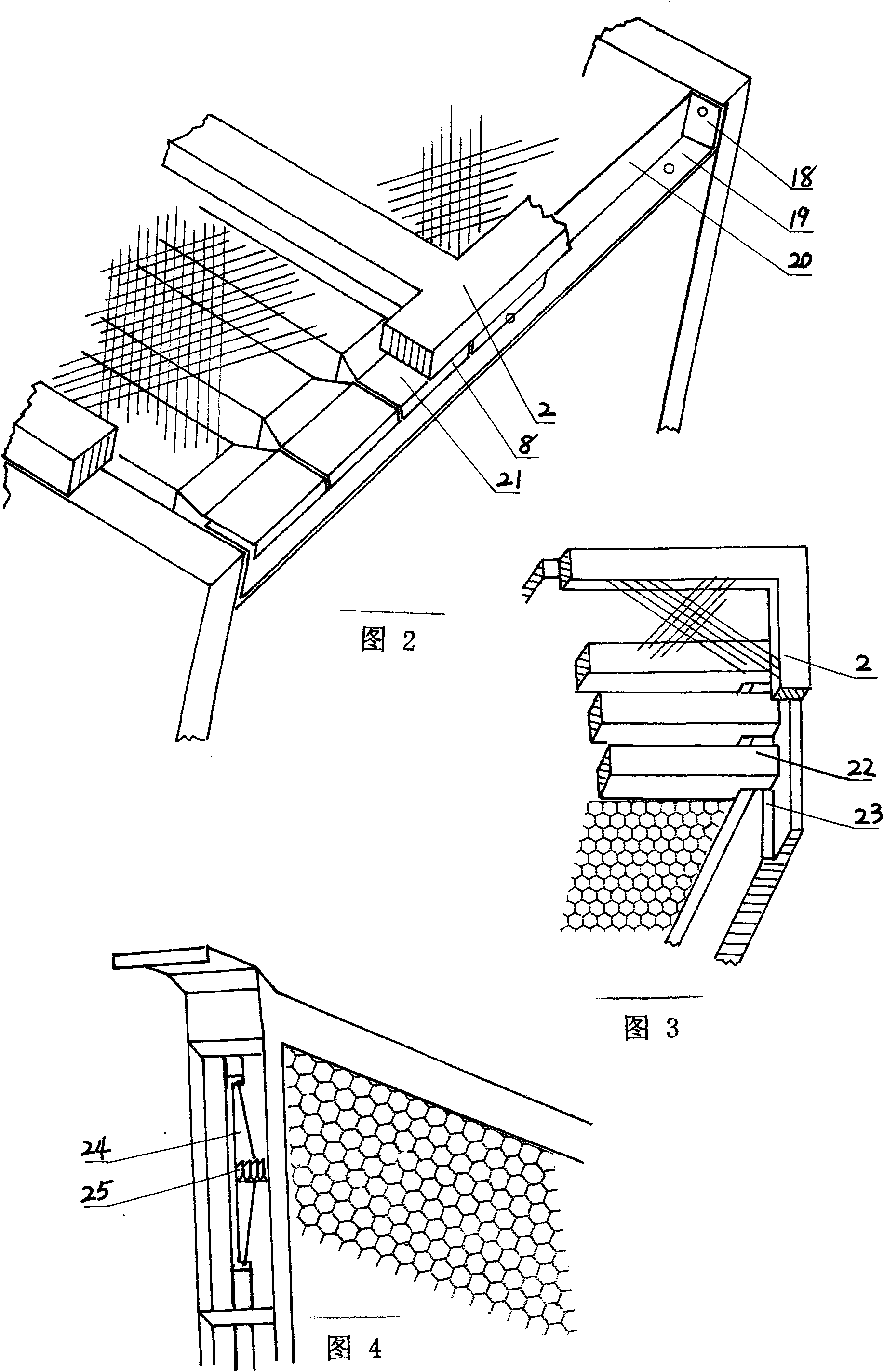

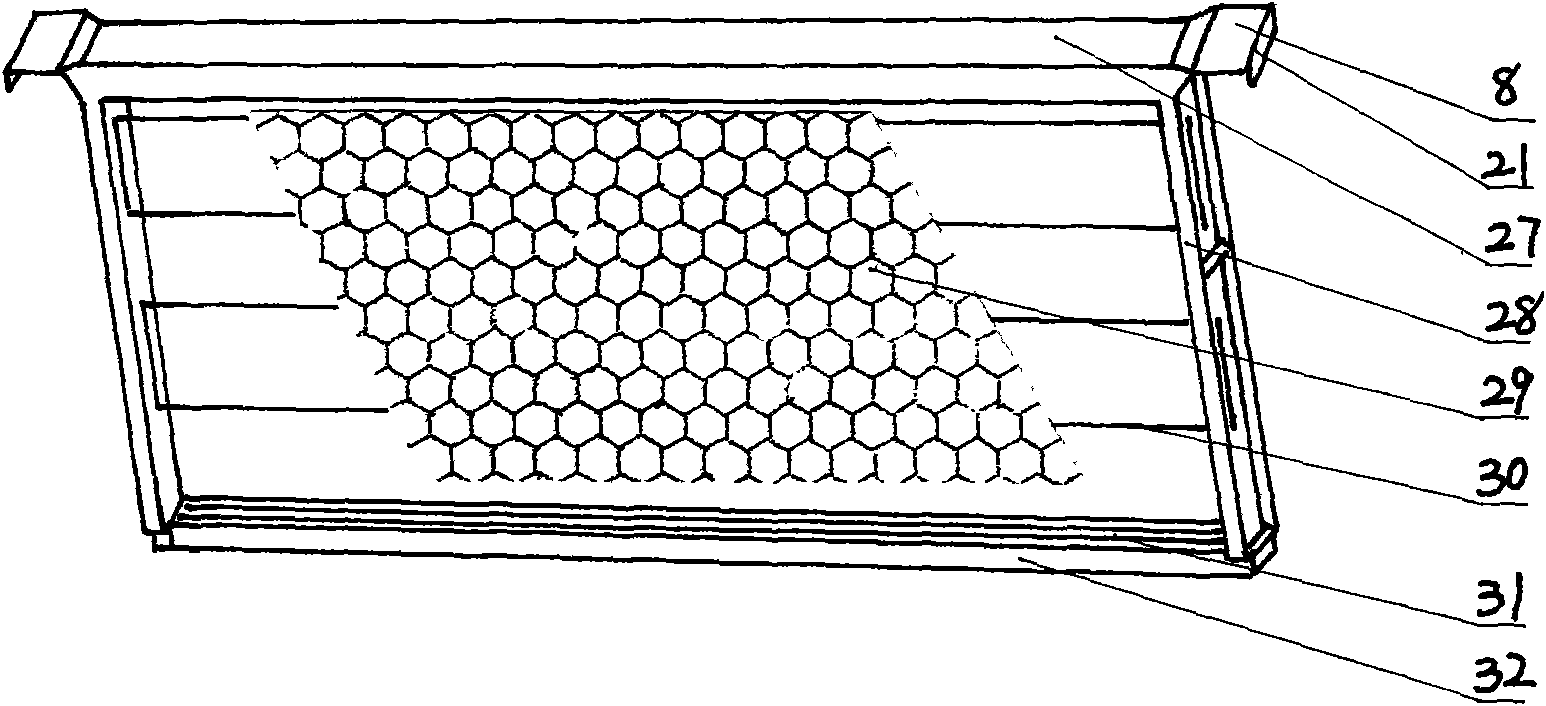

Horizontal and super combined beehive

InactiveCN101897300AImprove work efficiencyIncrease productionBeehivesHoney collectionWaxEngineering

A horizontal and super combined beehive comprises a wide-comb box, a frame support, a powder-releasing cover, a pollen box, a connector, a degummed drape, an inserted frame, an integrated frame and a wax comb foundation with suspension loops. The wide-comb box is characterized in that the both ends of the box are used as the breeding areas for two swarms of bees, a super is supported above the middle production area, frame queen excluders are used to form a working bee centralized production area, the areas are covered; the powder-releasing cover is bottomless, pollens and honey on a powder-leaking railing pedal with anti-theft gantry boxes on both sides directly leak in the pollen box at the bottom; the connected box is coarsely adjusted by a multi-teeth hook and finely adjusted and connected firmly by a screw crow bar through screws; the laps and edgings of the inserted frame are integrated, an upper beam and a lower beam are inserted in the upper and lower grooves of two edgings to integrate, the upper beam is thin, the lower beam and the edgings are provided with grooves to be inserted in the comb foundation; a wide hook with the same width and an adjuster are hung on the wax comb foundation for tightening; the laps are integrated with a frame-distance clip and connected with the upper beam through a downward slope, the tops of comb-forming frame supports are butted to each other and are tightly pressed by the degummed drape and the inner frame of the box cover, the distance of the frames is standard so that people can not stung by bees; and the top of each lap is provided with a handle, thus the laps can be fast gripped outside the box. The wide-comb box can be used to multiply the efficiency, thus being suitable to be used for beekeeping around the world.

Owner:汪修建

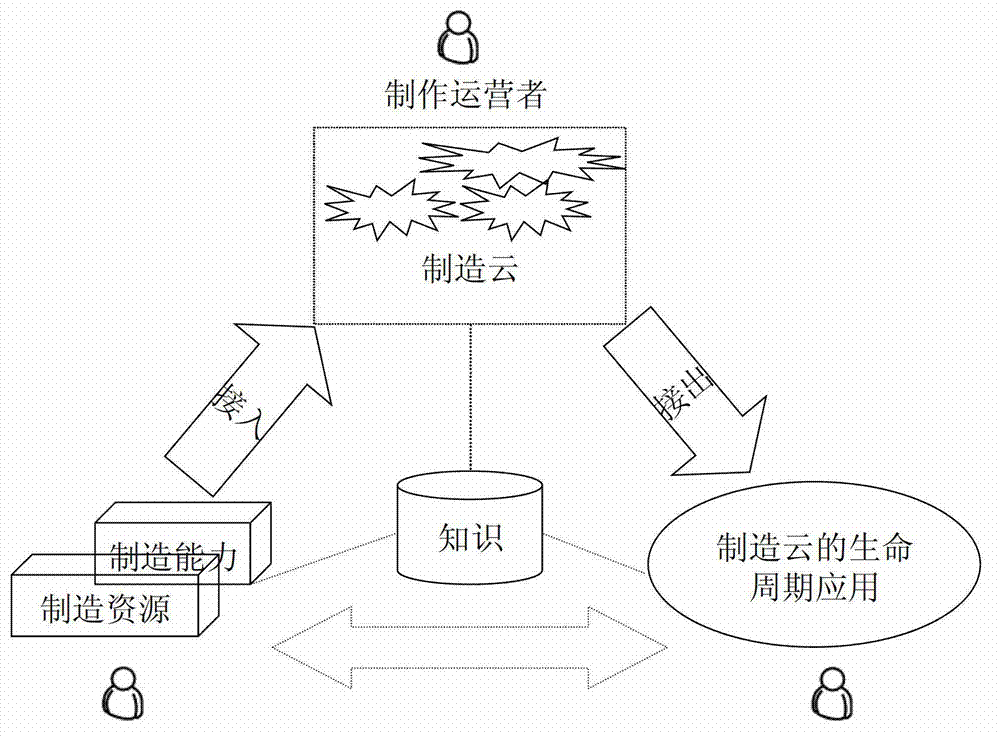

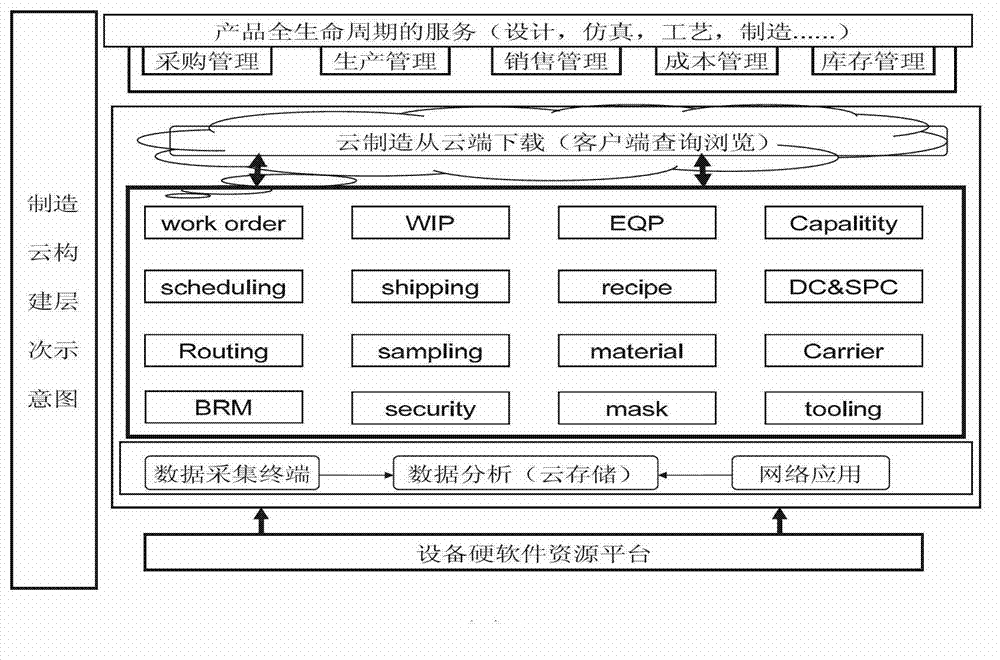

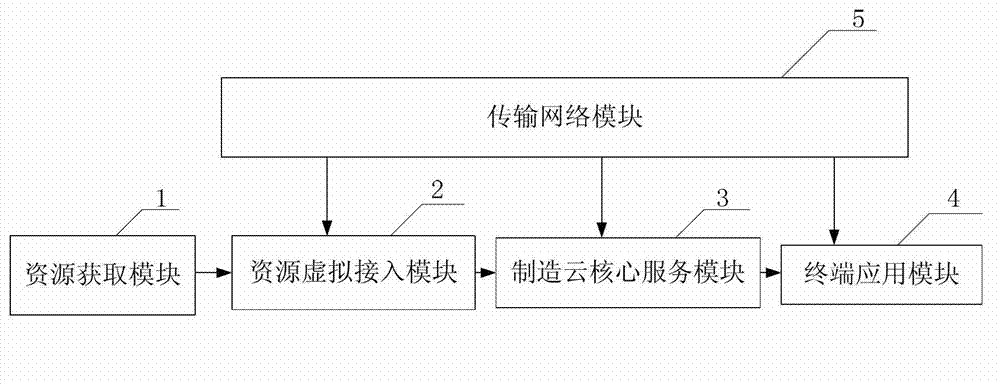

Execution method of computer integrated manufacturing based on cloud manufacturing and system thereof

InactiveCN103095808ARealize informatizationInexpensive and unlimited expansion of storage spaceTransmissionVirtualizationResource pool

The invention discloses an execution method of computer integrated manufacturing based on cloud manufacturing and a system thereof, and relates to the field of virtual network resource sharing. The execution method of the computer integrated manufacturing based on cloud manufacturing comprises the following steps: S1, obtaining product resource information relating to a whole product life cycle provided by a product manufacturer, classifying or integrating the product resource information according to the contents, and obtaining pending input information, S2, collecting the pending input information together to form a virtual resource pool by means of virtualization technology, S3, creating a cloud platform according to the virtual resource pool in a network operation environment so that a user is capable of applying and managing the product with the help of cloud service provided by the manufacturing cloud platform, S4, obtaining the product resource information after interaction with the cloud platform. The execution method of computer integrated manufacturing based on cloud manufacturing and the system thereof have the advantages that automation level and entire production efficiency of a manufacturing industry are improved and group informatization of factories or manufacturing-type enterprises is realized.

Owner:IRICO FOSHAN FLAT PANEL DISPLAY

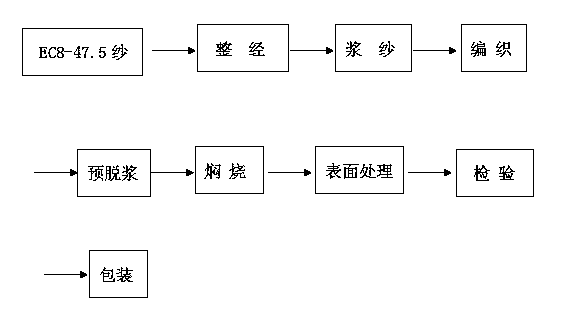

Production technology of glass fiber cloth for insulation

ActiveCN103741319ASolve the production processSimple processFibre treatmentHeating/cooling textile fabricsGlass fiberPolymer science

Provided is a production technology of glass fiber cloth for insulation. The production technology of the glass fiber cloth for insulation comprises the steps that EC8-47.5 glass fiber yarn serves as warp and weft; a warping working procedure technology is carried out, wherein the EC8-47.5 glass fiber yarn is placed on warping creels in sequence; a slashing working procedure technology is carried out; a knitting working procedure technology is carried out, wherein an air jet loom is used for carrying out weaving, drafting, reed insertion, gaiting and weaving are carried out on slashed warp beams in sequence according to plain weave, the warp and weft density is 17.3*14.2 pieces per centimeter, and the cropping length is 2000 meters per roll; a post-processing working procedure is carried out; drying is carried out at the temperature of 200DEG C, and the trimming working procedure, the take-up working procedure, the check working procedure and the packaging working procedure are carried out. The purpose of the production technology for using the EC8-47.5 glass fiber yarn to produce the high-grade glass fiber cloth for insulation is achieved, the warp and weft density of the glass fiber cloth is 17.3*14.2 pieces per centimeter, the thickness of the glass fiber cloth is 0.140mm, the basic weight is 150g / m<2>, the diameter of a filament of the glass fiber cloth is 8 microns, the warp and weft number is 47.5Tex, and the production technology of the glass fiber cloth for insulation has the advantages that the technology is more convenient to use, production management is easy, weaving is convenient, and the foundation is laid for producing the high-grade insulating glass fiber cloth through ordinary devices.

Owner:江西长江化工有限责任公司

Electronic jet drying cylinder dryer

InactiveCN102183128AMeet production needsSatisfy productivityDrying gas arrangementsLiquid/gas/vapor removalTextile printerWaste heat recovery unit

The invention discloses a textile printing and dyeing electronic jet drying cylinder dryer and a jet drying cylinder, waste gas heat recovery and condensate water recovery thereof and a method for setting a moisture regain reference roller. The electronic jet drying cylinder dryer consists of a heat insulating and preserving drying room, the jet drying cylinder, a heat recovery and jet system and an electronic information system, wherein exhaust air is divided into exhausted air and circulating air according to humidity of the exhaust air; heat of the exhausted air is recovered by fresh air; the fresh air is mixed with the circulating air; the heat of condensate water is then recovered and the condensate water is sprayed to a textile; heating is performed and drying conditions are improved; complete on-line detection and control are performed on temperature, tension and moisture regain of the textile and humidity, temperature and speed of an air flow; therefore, heat application efficiency and drying efficiency are increased, production cost is reduced and production requirement of high-grade textiles is met in a scientific, strict, careful and reliable drying mode. The electronic jet drying cylinder dryer can be used for substituting a drying cylinder dryer or is made by modifying the drying cylinder dryer; a waste gas heat recovery system and a condensate water recovery system are suitable for various heating production occasions; and by the method for setting the moisture regain reference roller, reliability and validity of moisture regain control are solved.

Owner:段新顺 +1

Method for cultivating lycium barbarum in fence wall mode

ActiveCN105900770ATimely and efficient control of pests and diseasesFrame stabilityCultivating equipmentsFertilizerPesticide

The invention discloses a method for cultivating lycium barbarum in a fence wall mode. The method for cultivating lycium barbarum in the fence wall mode has the advantages of bringing convenience to production and management of lycium barbarum planting, saving time and labor and being efficient. A fence wall type frame body is stable and firm and can effectively lift or erect various sprinkler irrigation facilities such as drip irrigation belts and mist-spray sprinkler irrigation pipes, the problems of integration of water, fertilizer and pesticide in soil and integration of foliage pesticide spray and top dressing of micro-element fertilizer are solved, damage, caused by planting measures such as weeding and soil loosening, to the drip irrigation belts can be eliminated, and work of top dressing of foliage micro-element fertilizer and unified prevention and control of diseases and insect pests can be conducted conveniently and efficiently in time. Therefore, by means of the brand-new cultivating mode of combining fence walls with agricultural measures such as water-saving irrigation, electrostatic mist spray and pruning, field mechanization management is promoted and is more convenient and rapid, the purposes of saving the labor and achieving high-efficiency production are achieved, and a powerful guarantee is provided for producing high-quality and high-yield lycium barbarum.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

Method for extracting active ingredient of natural leech essence

InactiveCN101108879AHighlight substantive featuresSignificant progressLeech/worm material medical ingredientsLeech-based protease inhibitorsRetention periodAqueous acetone

The invention discloses an extract method of the effective constituent of the Natural hirudin. The method is that the blood-sucking leech is washed cleanly by water and is added with the ethanol water with content of 15 per cent to 25 per cent to soak for 30h to 50h, and then is filtered to gain the filter liquor and dregs of a decoction; the Poecilobdella manillensis waste residue is broken into pieces and is added with aqueous acetone solution with content of 15 per cent to 25 per cent to soak, and then is filtered to gain the filter liquor; after recovering ethanol and acetone from the two-time filter liquor in the vacuum, the filter liquor is combined and frozen and dried in the vacuum conventionally to gain the product. The invention is simple in process, low in cost, higher in yield, good in product quality and long in retention period. The ''three wastes'' are not discharged in the whole production process, and the product can work as the raw material in such three fields as medicine, hairdressing and health food.

Owner:滕海英 +2

Method for reading three-charge rate and four-charge rate electrical energy meter of low voltage carrier wave meter reading collection terminal

ActiveCN101435832AEasy for production managementReduce use costElectric signal transmission systemsSpecial tariff metersElectricityLow voltage

The invention relates to a method for reading a three-rate electric energy meter and a four-rate electric energy meter by the collecting terminal of a low-pressure carrier wave reading meter. The method is characterized in that the electric energy meter receives a 901F instruction emitted from the collecting terminal and returns the 901F instruction to a data frame of the collecting terminal; firstly, the collecting terminal reads L and former data; according to the size of L, the electric energy meter is judged to be the three-rate meter or the four-rate meter; subsequently, according to the judgment on the three-rate meter or the four-rate meter, the collecting terminal is correspondingly provided with different collecting forms of the three-rate meter or the four-rate meter on subsequent data of L, thereby rightly resolving the returned data of electric energy. The method is applied in order that the collecting terminal only needs to produce according to the same specification model and is greatly convenient for production management. When the collecting terminal is mounted on the spot, only one collecting terminal is arranged in one electricity meter box and can read the three-rate meter electric energy meter and the four-rate meter electric energy meter, thereby reducing use cost.

Owner:ANHUI ZENITH ELECTRICITY & ELECTRONICS

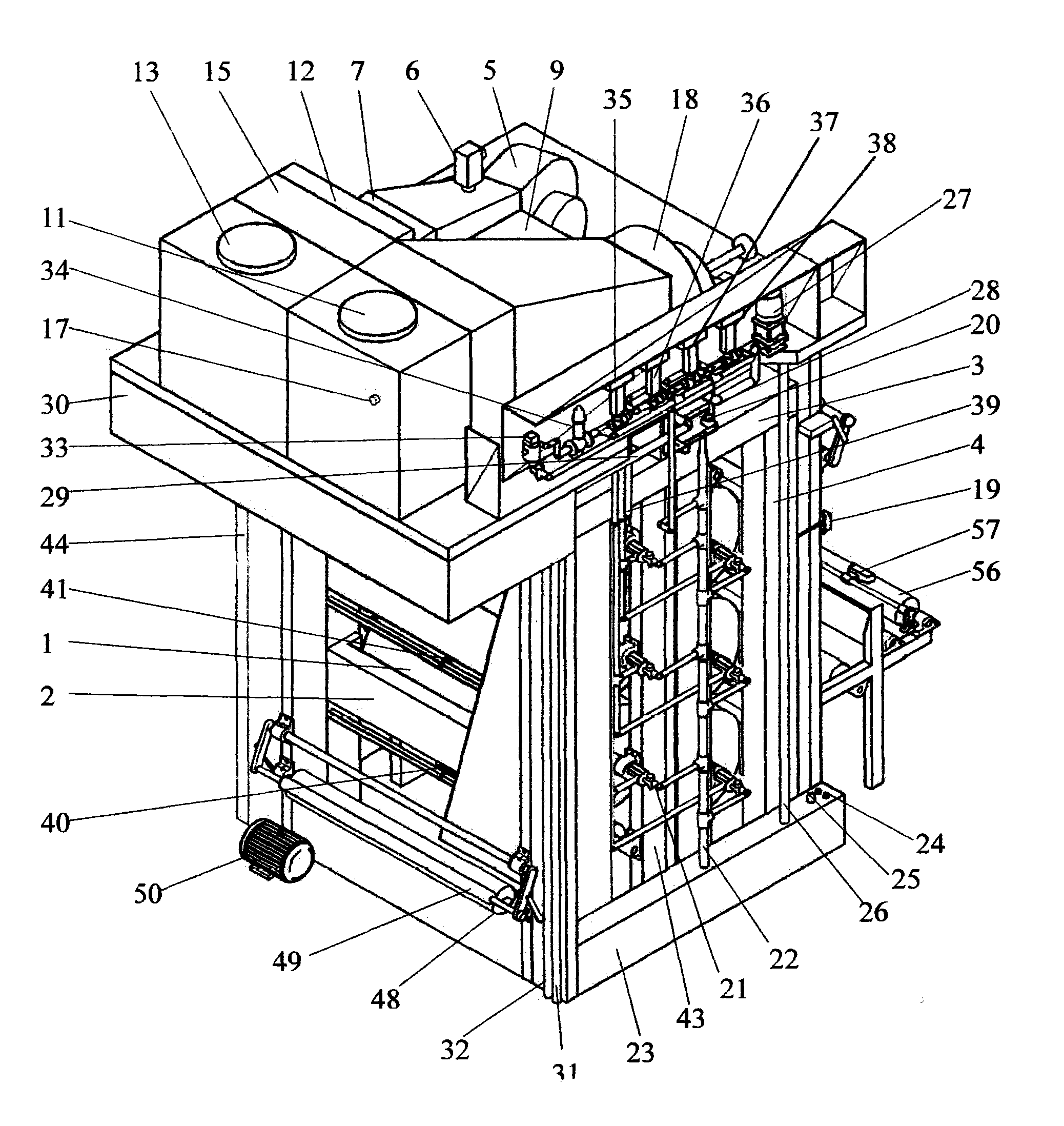

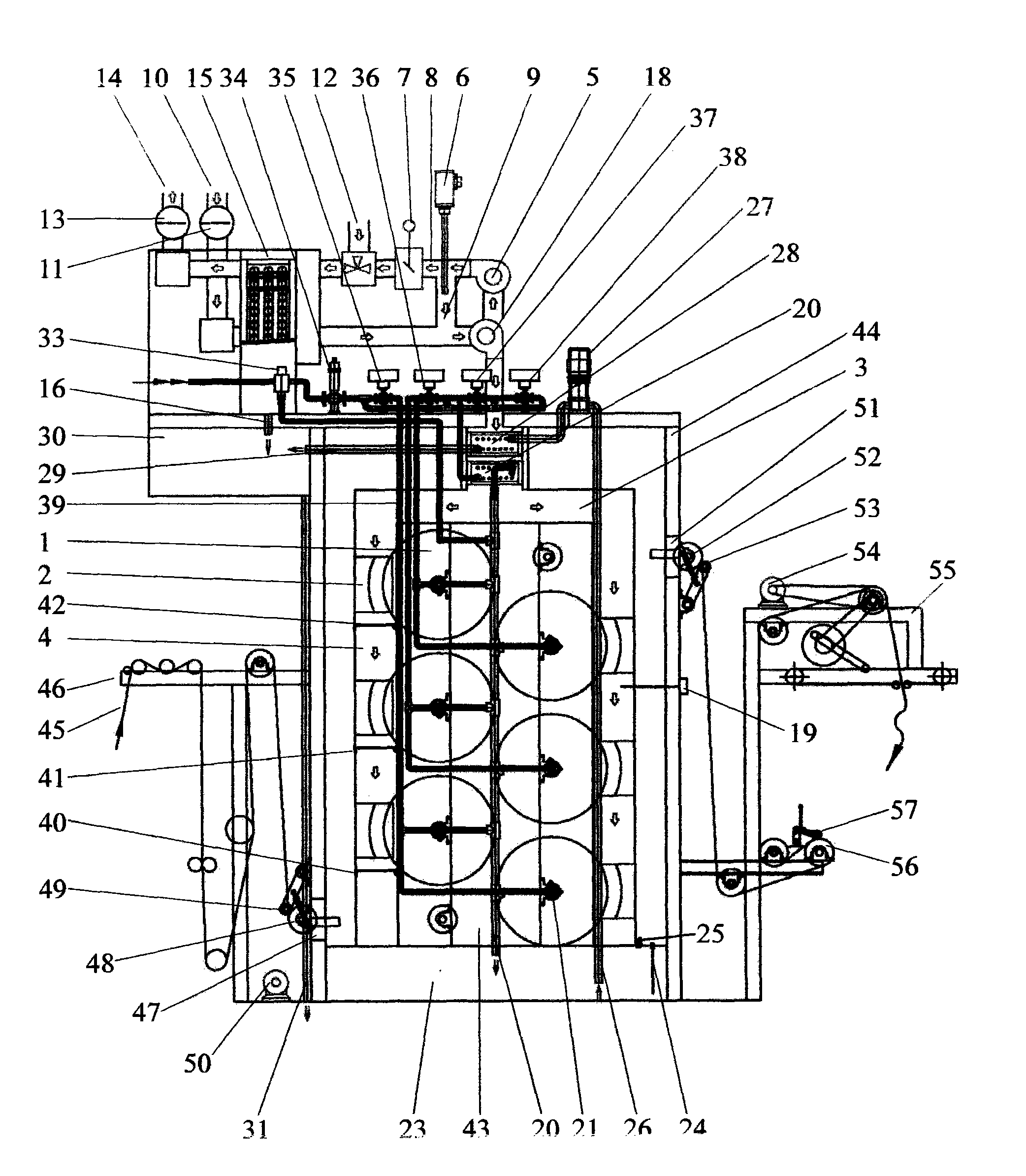

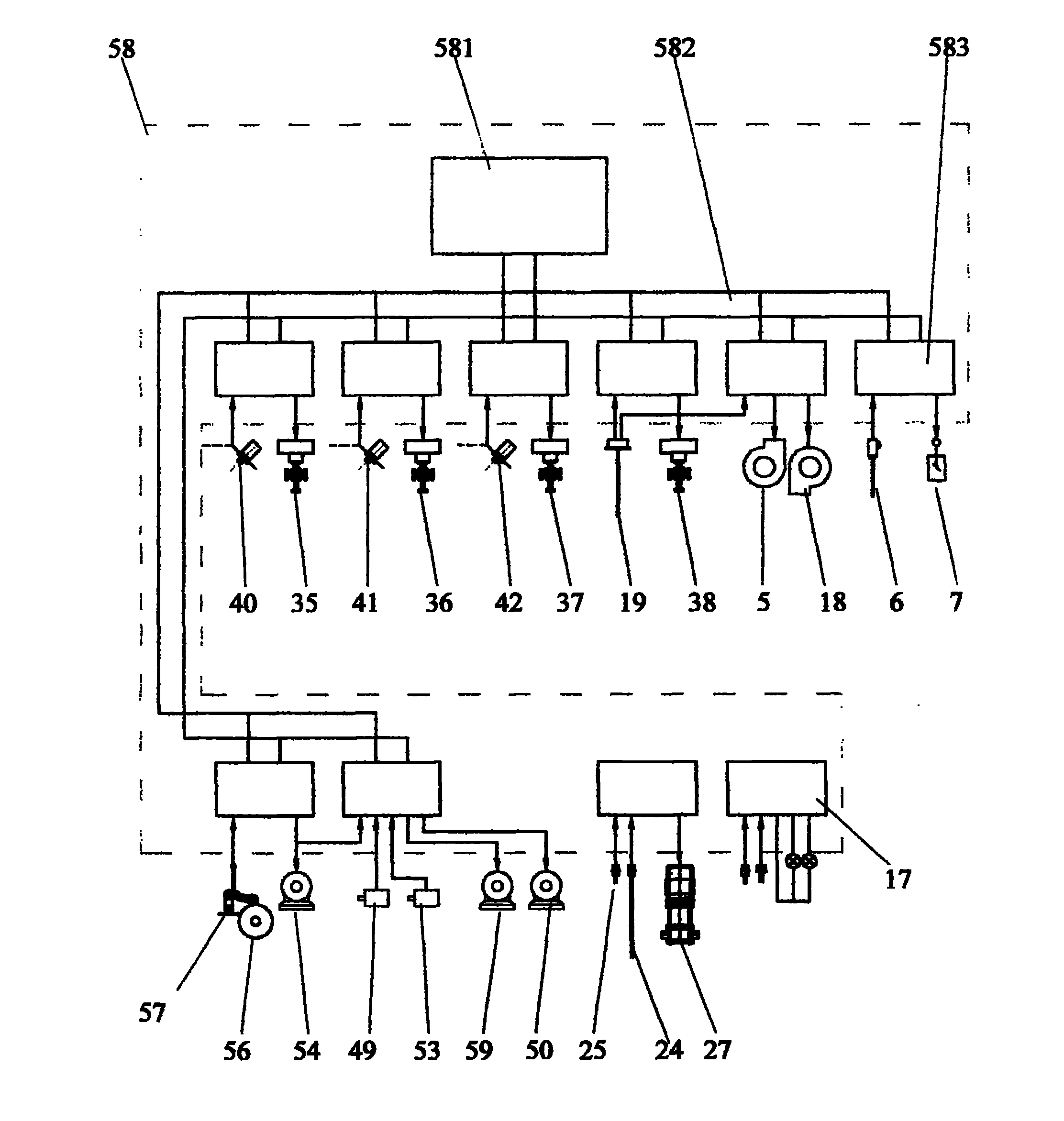

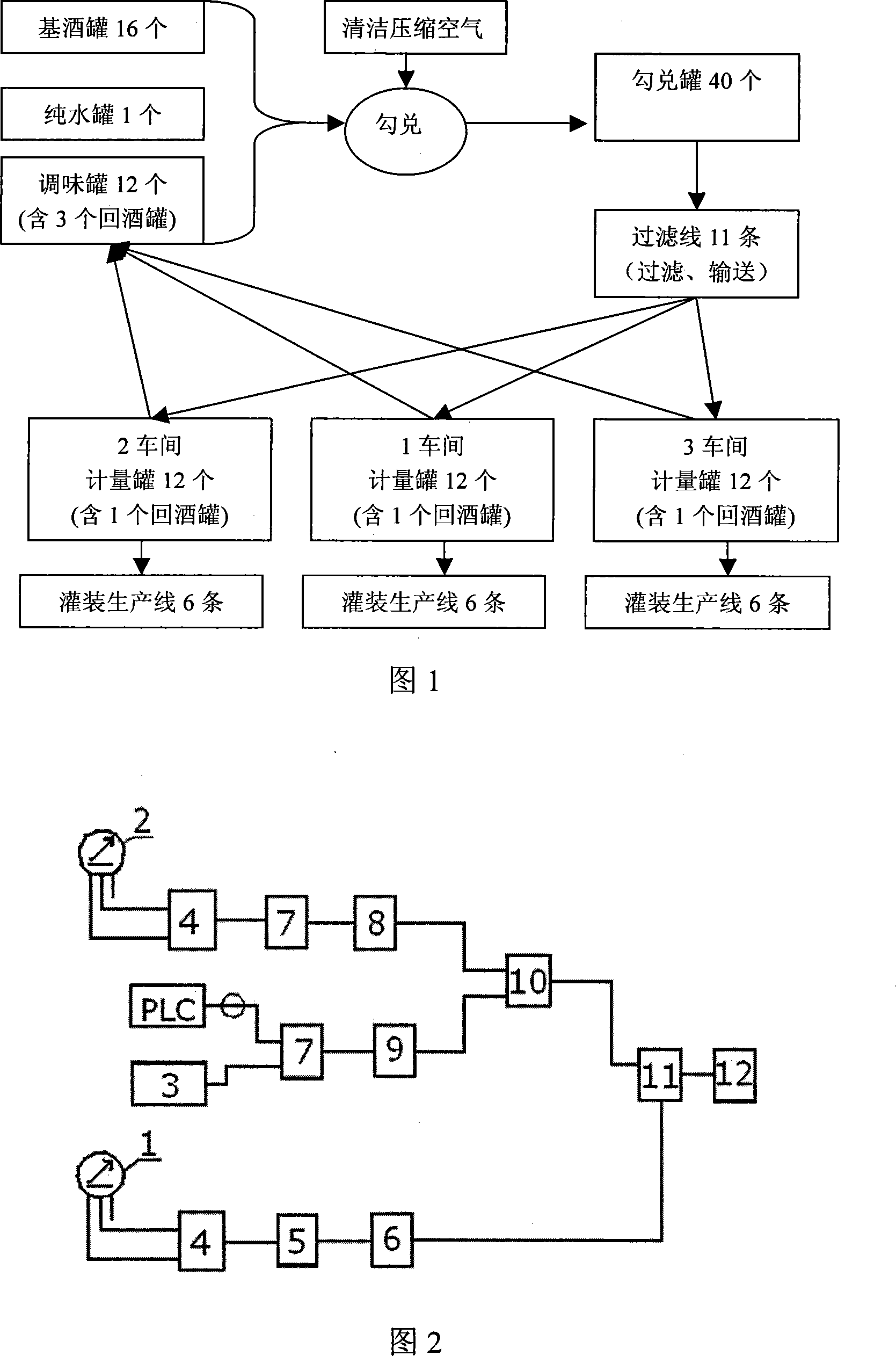

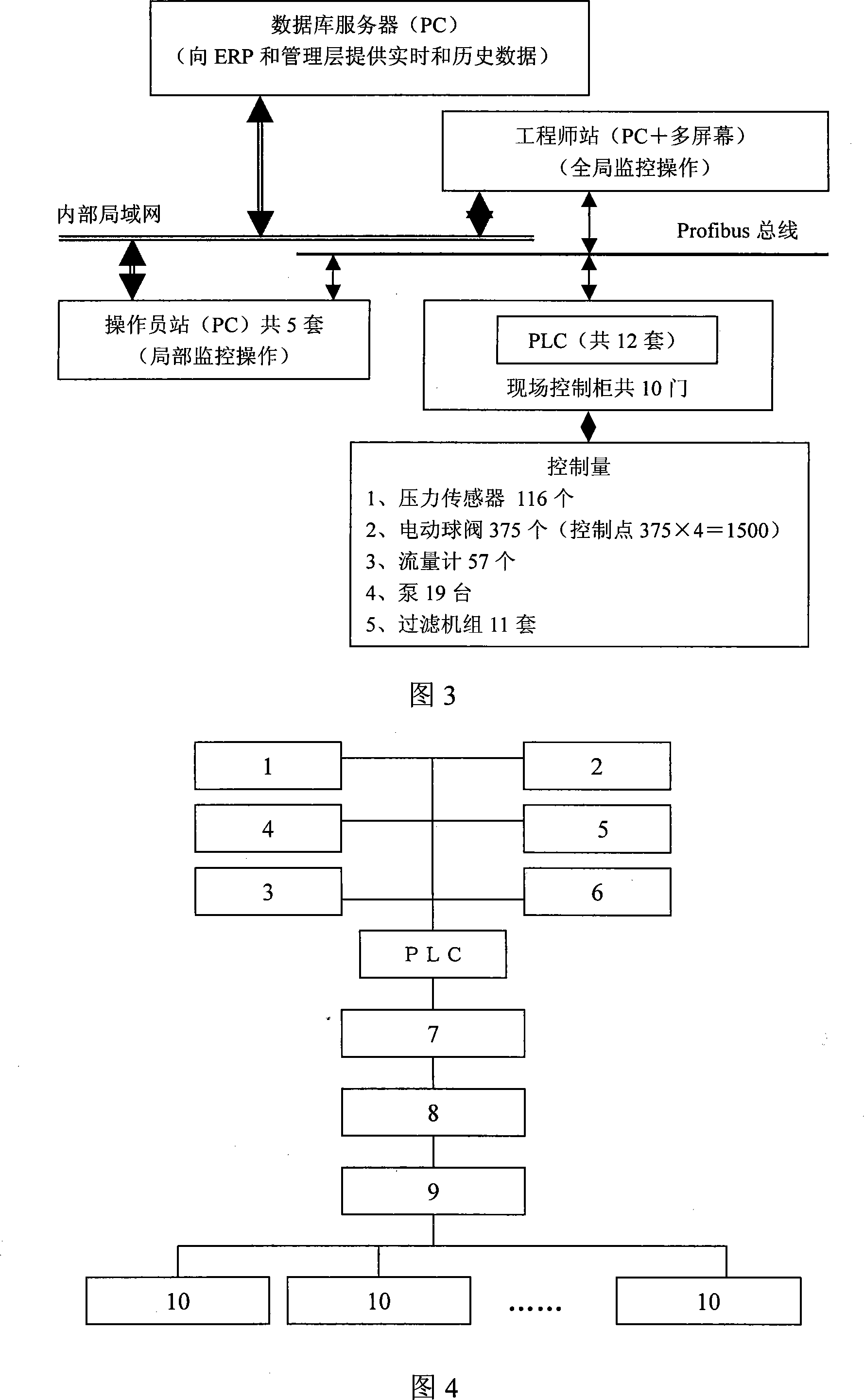

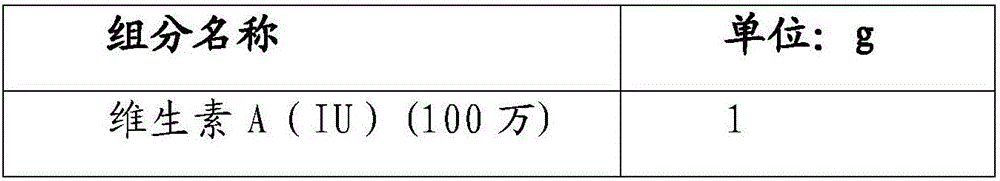

Automatic control system for white spirit blending

ActiveCN101117619AEasy to operateEasy for production managementBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlAir cleaning

The present invention relates to an automatic control system for white spirit blend, and aims at solving the problems of low blend efficiency and low success in the prior art, and comprises a plurality of basal cans and seasoned cans arranged with electro-pneumatic valves, a purified water can arranged with a feeding pump, an air compressor provided with an air compressed and purified device, a plurality of blend cans connected with finished product cans through a filtering system, a programmable logic controller PLC, and a process computer. The basal cans, the seasoned cans, the purified water can, and the blend cans and the finished product cans are arranged with pressure sensors used for measuring the liquid level and temperature sensors, the programmable logic controller PLC is connected with the pressure sensors, a flowmeter, the temperature sensors, the air compressor, the electro-pneumatic valves, the feeding pump, a filter bank, and the process computer. Therefore the present invention has the advantages of strong maneuverability, convenient production management, blend efficiency and high success ratio.

Owner:HUBEI ZONGHENG TECH +1

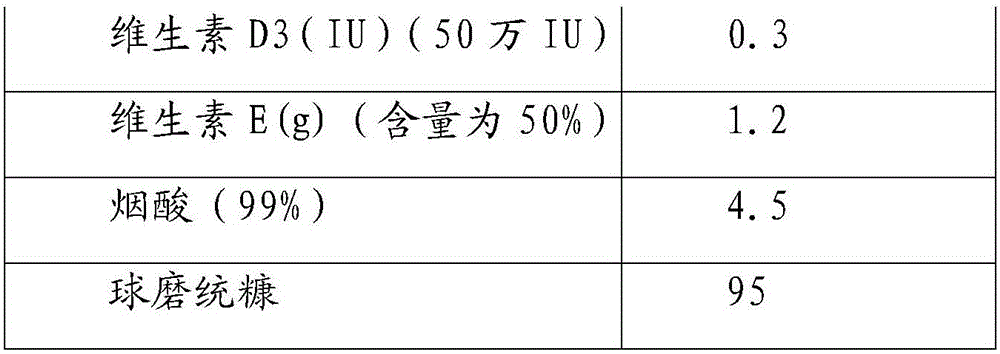

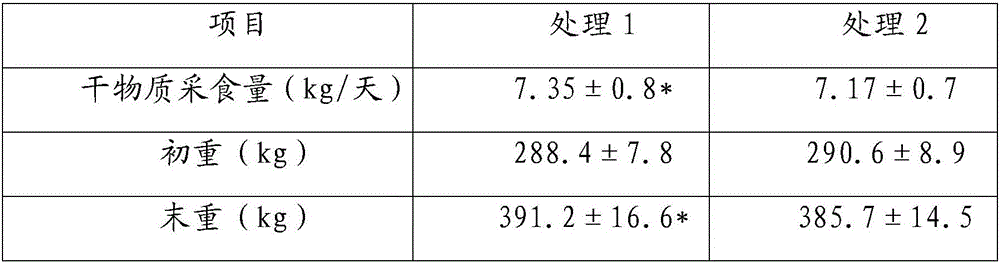

Whole-value grain biological feed for fattening cattle

InactiveCN106071147AIncrease the number ofImprove the environmentFood processingAnimal feeding stuffYeastCorn flour

The invention relates to the technical field of animal feeds, in particular to a whole-value grain material biological feed for fattening cattle and a whole-value grain material for fattening the cattle added with the biological feed. Raw materials of the biological feed comprise the following components by weight: 0.15 to 0.2 g / kg of yeasts, 0.05 to 0.2 g / kg of lactic acid bacteria, 0.05 to 0.2 g / kg of bacillus, 100 to 150 g / kg of extruded dehulled soybean meal, 100 to 250 g / kg of corn flour, 200 to 350 g / kg of wheat bran, and 100 to 350 g / kg of corn straw. 5% to 8% of the whole-value grain biological feed disclosed by the invention is applied to production of the whole-value grain material for fattening the cattle, and the prepared whole-value grain material for fattening the cattle has balanced nutrition and high digestibility, and can effectively improve the utilization of coarse materials, and further has positive significance for the safety and efficiency of beef cattle breeding.

Owner:SICHUAN TQLS IND

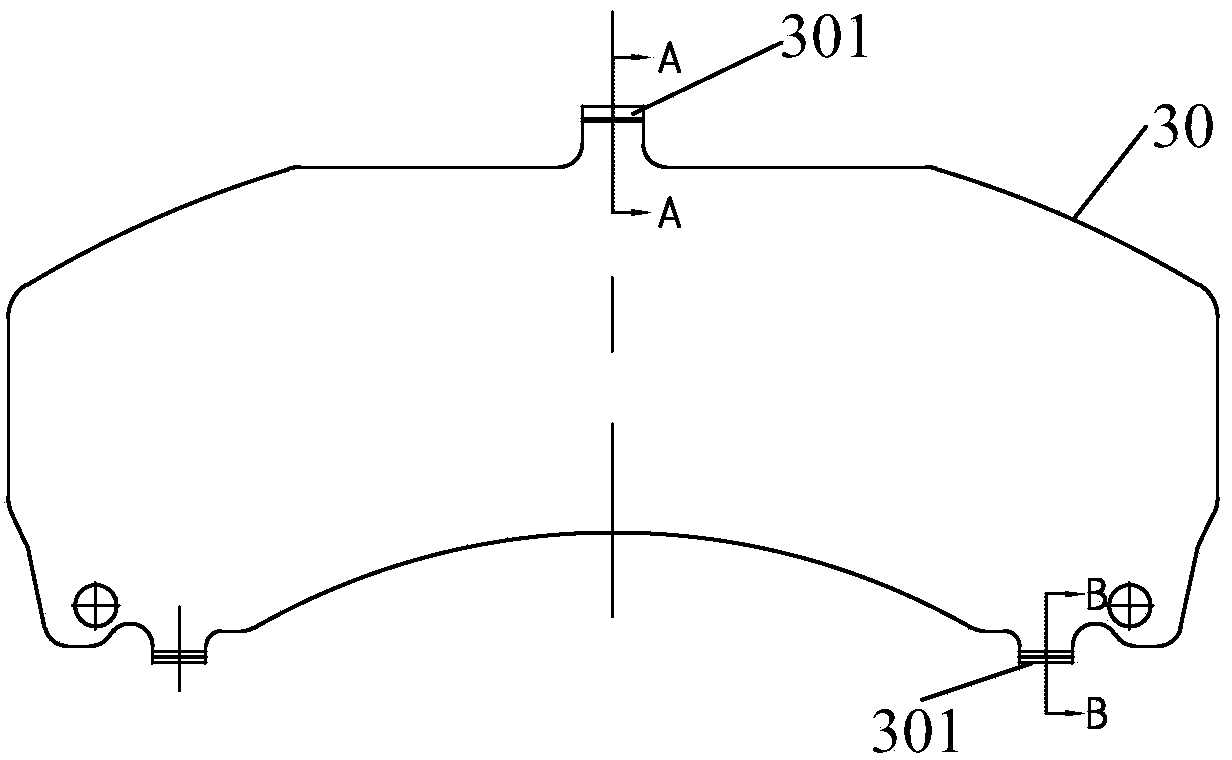

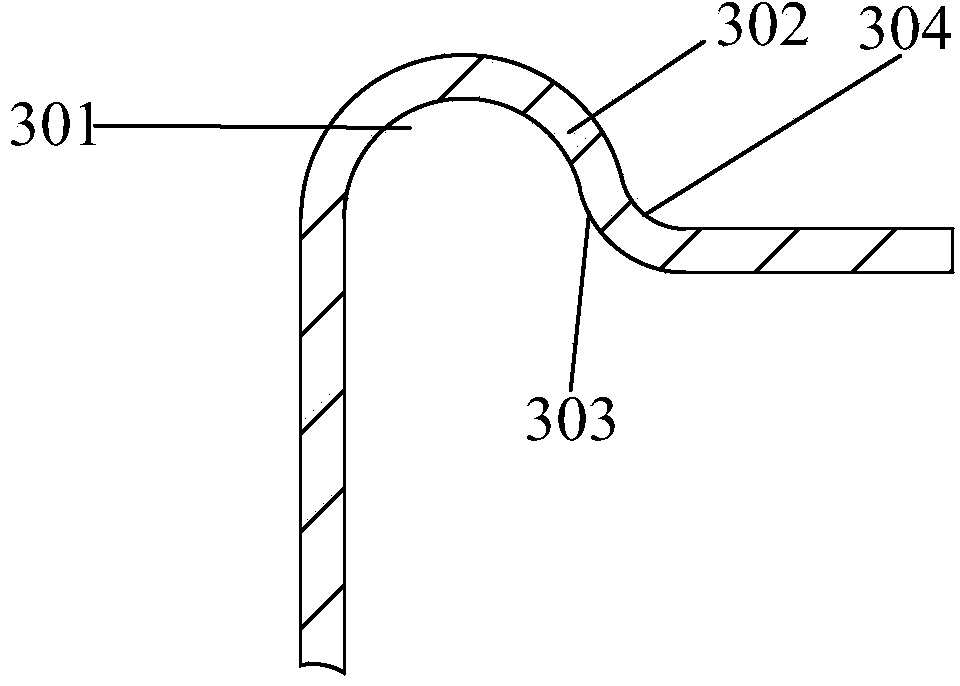

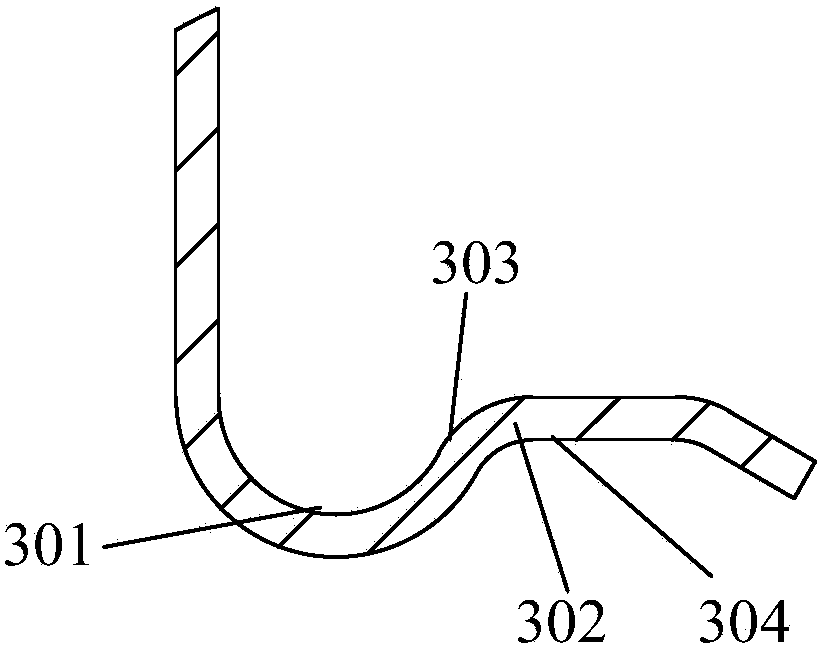

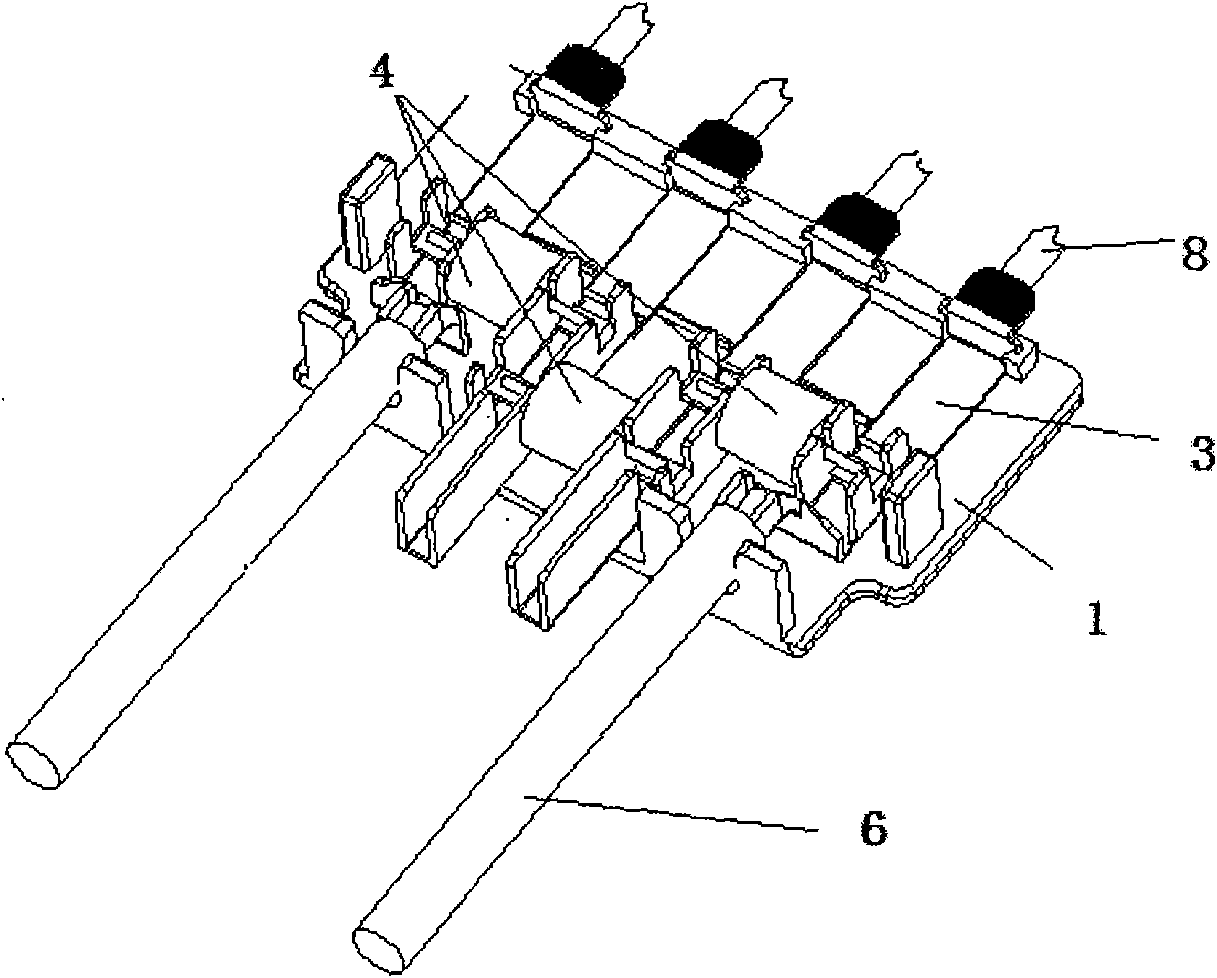

Progressive die of concave bayonet bloop and production method of concave bayonet bloop

ActiveCN103506492AImprove operational safetyStrong order response abilityShaping toolsPunchingEngineering

The invention discloses a progressive die of a concave bayonet bloop and a production method of the concave bayonet bloop. The progressive die of the concave bayonet bloop comprises an upper die and a lower die matched with the upper die, and a bloop material strap goes forward between the upper die and the lower die; in the advancing direction of the bloop material strap, the lower die is sequentially provided with a lower die punching insert core used for punching the bloop material strap, a lower die pre-bending insert core used for concave bayonet half forming, and a lower die blocking foot bending insert core used for blocking foot forming; the upper die is provided with a punching plunger chip matched with the lower die punching insert core, a pre-bending insert core matched with the lower die pre-bending insert core, and a blocking foot bending plunger chip matched with the lower die blocking foot bending insert core. The progressive die is high in production automation degree, productivity and quality of products are greatly promoted, manual operation safety is high, labor intensity is also greatly weakened, manpower and drilling crews are saved, production management is convenient and fast, and customer order response ability is high.

Owner:韶关德嘉汽车零部件有限公司

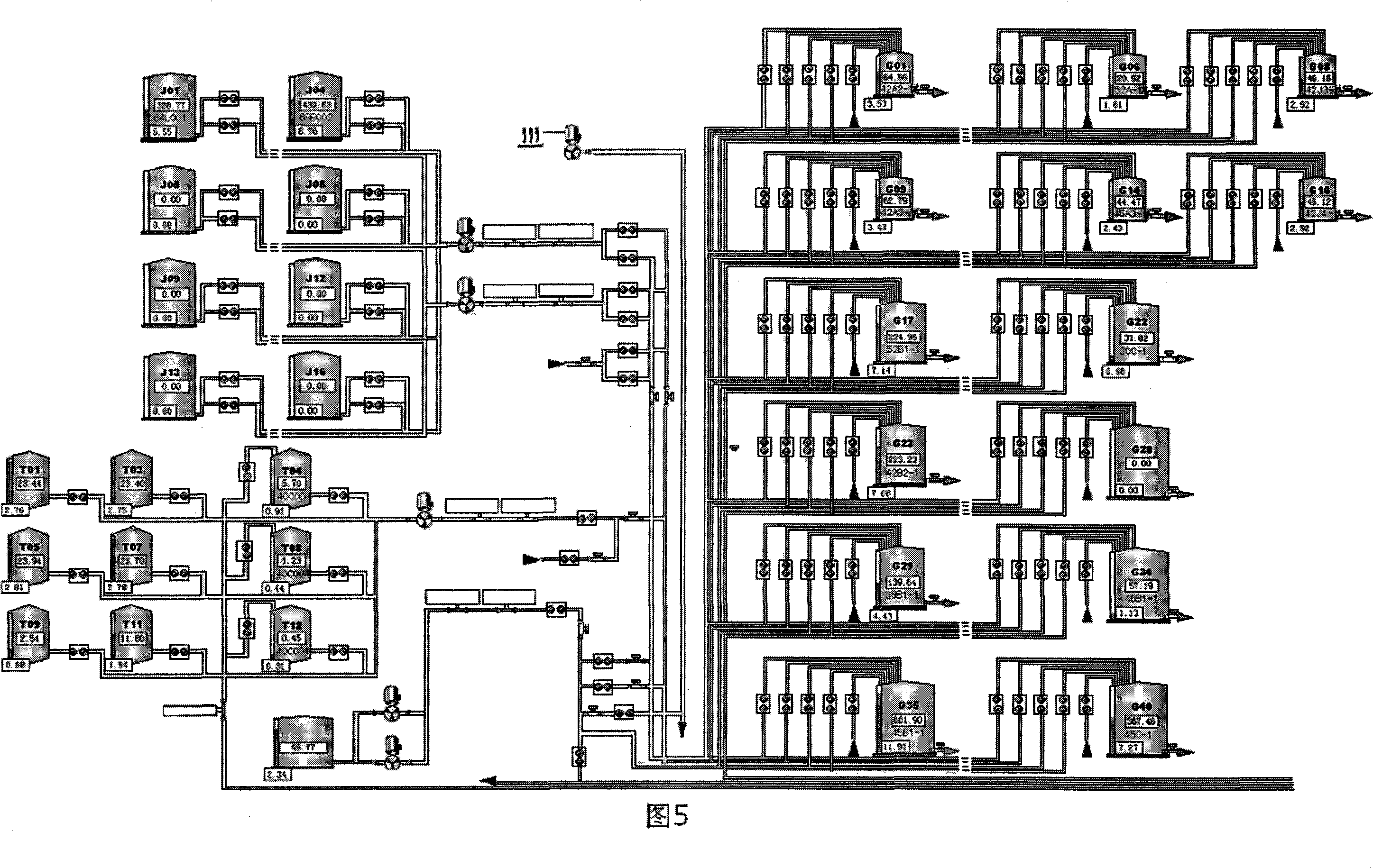

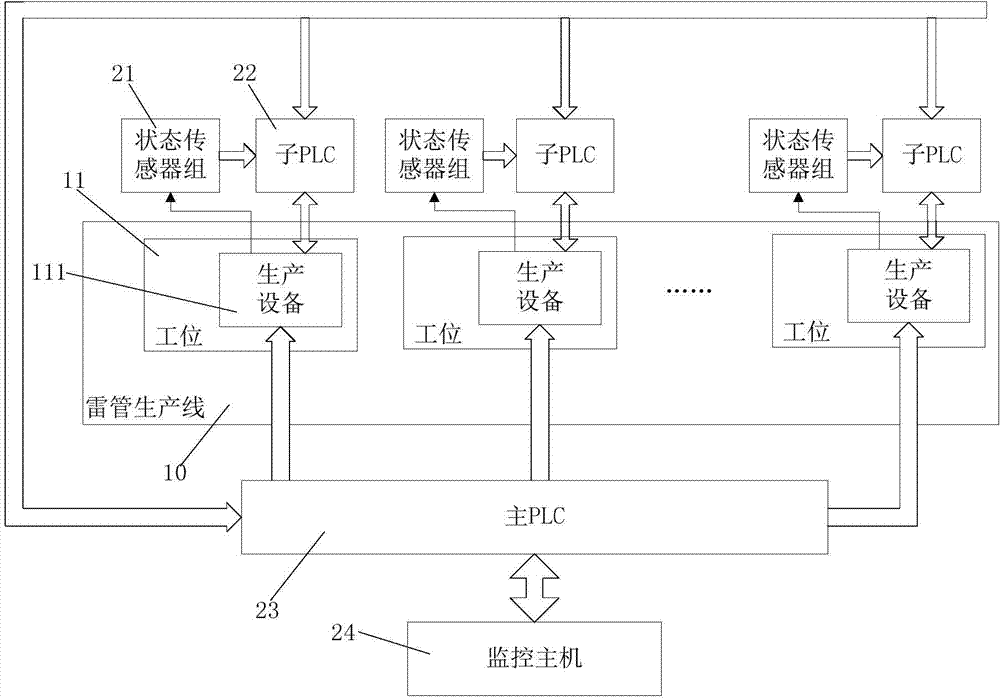

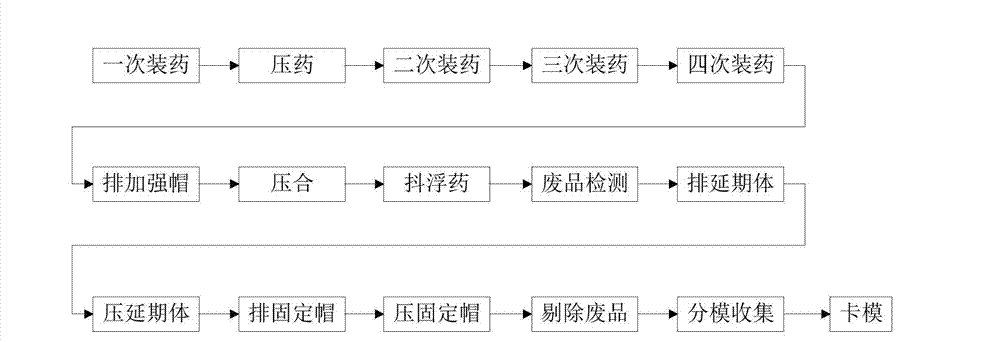

Monitoring system for detonator production line

InactiveCN104503413AEasy for production managementImprove security protectionPIc to applicationsTotal factory controlProgrammable logic controllerEngineering

The invention provides a monitoring system for a detonator production line. The detonator production line comprises a plurality of workstations; and each workstation corresponds to a working procedure. The monitoring system comprises state sensor groups, secondary PLCs (programmable logic controllers), a main PLC (programmable logic controller) and a monitoring host, wherein the state sensor groups and the secondary PLCs are arranged on the workstations; the state sensor groups are used for detecting production states of production equipment on the workstations and transmit state adjusting signals or alarming signals when detecting abnormal production states; the secondary PLCs are used for transmitting the state adjusting signals or the alarming signals to the main PLC and controlling the production equipment on the corresponding workstations to stop running when receiving stopping commands; the main PLC is used for transmitting the stopping commands to the secondary PLCs when receiving the alarming signals, transmitting the alarming signals to the monitoring host and controlling states of the production equipment on the corresponding workstations according to the state adjusting signals when receiving the state adjusting signals; and the monitoring host is used for storing alarming information containing the alarming signals. By the monitoring system for the detonator production line, production of detonators can be monitored in an informatization and centralized manner.

Owner:SICHUAN YIBIN WEILI CHEM CO LED

Purple heart pitaya planting and cultivating method

InactiveCN104604498AGreat tasteIncrease productionCultivating equipmentsHorticultureChemical controlPest control

The invention relates to a purple heart pitaya planting and a cultivating method. The method comprises the steps that 1, seeding stage management: at the early stage of characterization , one time of watering is conducted every 2 to 3 days, and timely drainage is conducted in rainy season; 2, at the initial planting period, emergency crops can be interplanted in a new orchard. Sod culture is adopted to the cultivating management once the pediciel of the pitaya climbs to the top of a pillar. Ridge plowing and root covering are conducted according to the root baring situation after raining, and ridge plowing to protect seeding is conducted in winter in the new orchard; 3, scientific fertilizer and water index; 4, pruning; 5, flower and fruit thinning and fruit bagging; 6, pest control: priority is given to the agricultural, physical and biological control, and chemical control is supplemented; 7, reaping and marketing timely. According to the purple heart pitaya planting and cultivating method, three-dimensional management is adopted into the planting of the purple heart pitaya, the production management is convenient, the taste of the purple heart pitaya is good, and the yield is high.

Owner:YUNNAN YUAN JIANG YALONG PLANTING

High-yield planting method of organic lotus roots

The invention provides a high-yield planting method of organic lotus roots. The method particularly includes the steps that a lotus root cultivation tank is built in an appropriate cultivation field, wherein the depth of the tank is 0.6 m, the width of the tank is 1.2 m, and the length of the tank is not less than 12 m; soil, animal waste, crop straw and mineral substances are used as raw materials to prepare a special cultivation medium; in the cultivation process, the cultivation medium for production is placed in the cultivation tank, then lotus root seeds are buried in the cultivation medium at the same time, the lotus root seeds are buried and smoothly placed along the cultivation tank at the same time, and after the lotus root seeds are completely buried in the cultivation tank, the cultivation tank is irrigated until the tank is fully filled with water, wherein the three lotus root seeds form one set. By the implementation of the method, the cultivation field is divided into a plurality of blocks, nursing, harvesting and the like in production management are very convenient, the growth habit of the lotus roots is fully utilized, and the yield of the lotus roots reaches a highest level through the marginal effect of land and restoration of soil. Due to the fact that the cultivation medium with the high fertilizer efficiency is prepared, no chemical fertilizer is utilized in the whole production process, and therefore the produced lotus roots are good in taste and high in quality.

Owner:广西平果华莲科技研究所

Acrylonitrile butadiene styrene (ABS) laminated composite plate and refrigeration equipment liner

InactiveCN102173159AHigh glossEasy to cleanDomestic cooling apparatusLighting and heating apparatusSurface layerMetallurgy

The invention discloses an acrylonitrile butadiene styrene (ABS) laminated composite plate and a refrigeration equipment liner. The laminated composite plate comprises a surface layer consisting of high gloss ABS, and a corrosion resistant layer consisting of foamer corrosion resistant ABS. According to the ABS laminated composite plate, the surface layer consists of the high gloss ABS, so the ABS laminated composite plate has good glossiness and is easy to clean. Meanwhile, because the corrosion resistant layer consists of the foamer corrosion resistant ABS, so the ABS laminated composite plate is foamer corrosion resistant. In addition, the general high gloss ABS and foamer corrosion resistant ABS are adopted to replace ABS dyeing special materials, so the cost is greatly reduced. Moreover, the requirement on the performance of a single material is reduced, so more material choices are provided, raw materials are convenient to purchase and the localization of the raw materials is realized.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

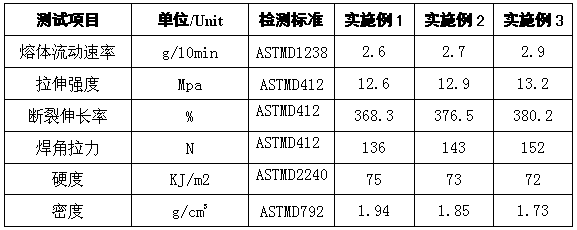

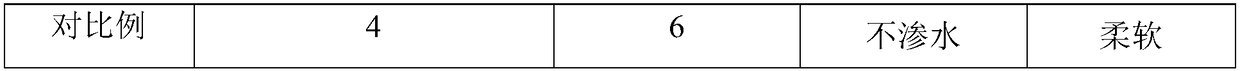

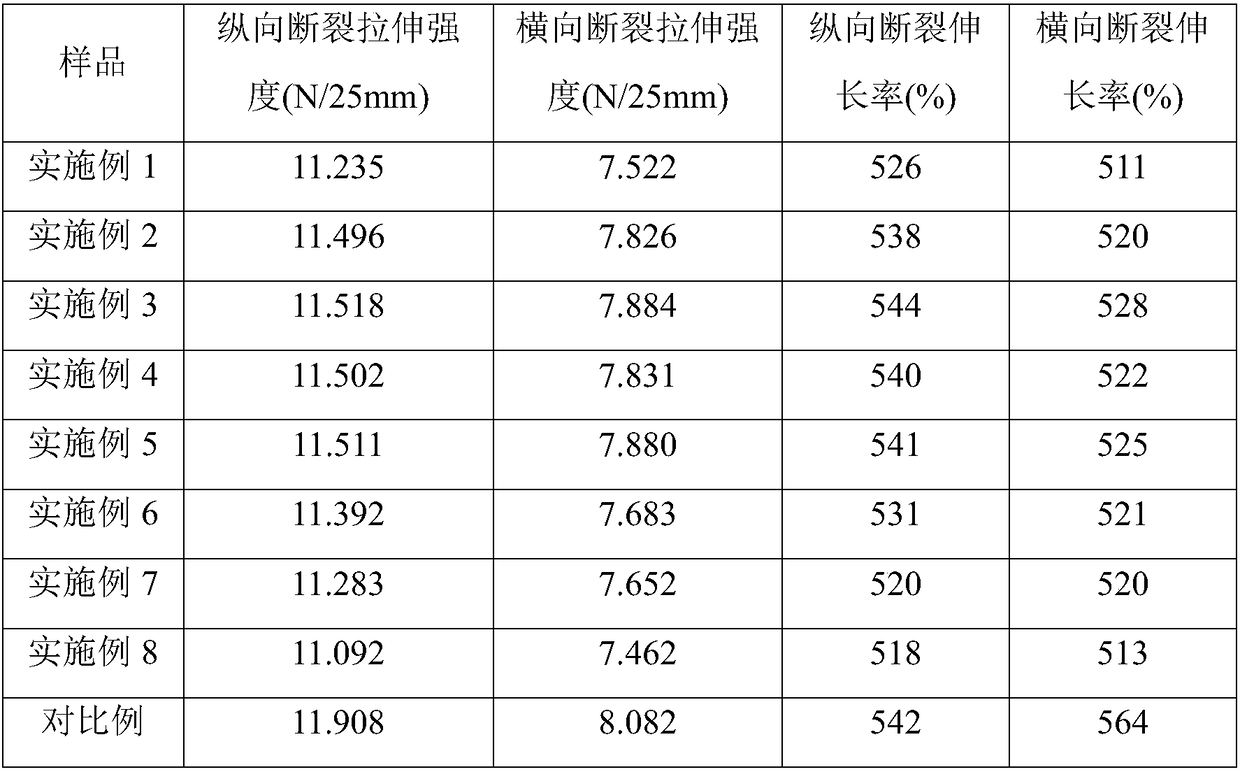

Polyvinyl chloride (PVC) magnetic-plastic blending door gasket and manufacture method thereof

ActiveCN102936384AReduce processing stepsReduce production processDomestic cooling apparatusLighting and heating apparatusThermoplasticPolyvinyl chloride

The invention provides a polyvinyl chloride (PVC) magnetic-plastic blending door gasket and a manufacture method thereof. The PVC magnetic-plastic blending door gasket is obtained by joint extrusion molding of PVC equal heat plasticity plastic and magnetic powder, processing steps of a magnetic stripe and processing steps that the magnetic stripe is inserted in a door gasket rubber sleeve are reduced, manufacturing processes of the magnetic door gasket are effectively shortened, processing time is saved, labor and material cost are reduced, work efficiency is greatly improved, and simultaneously an adsorptive property of the door gasket is improved.

Owner:ANHUI HIGASKET PLASTICS CO LTD

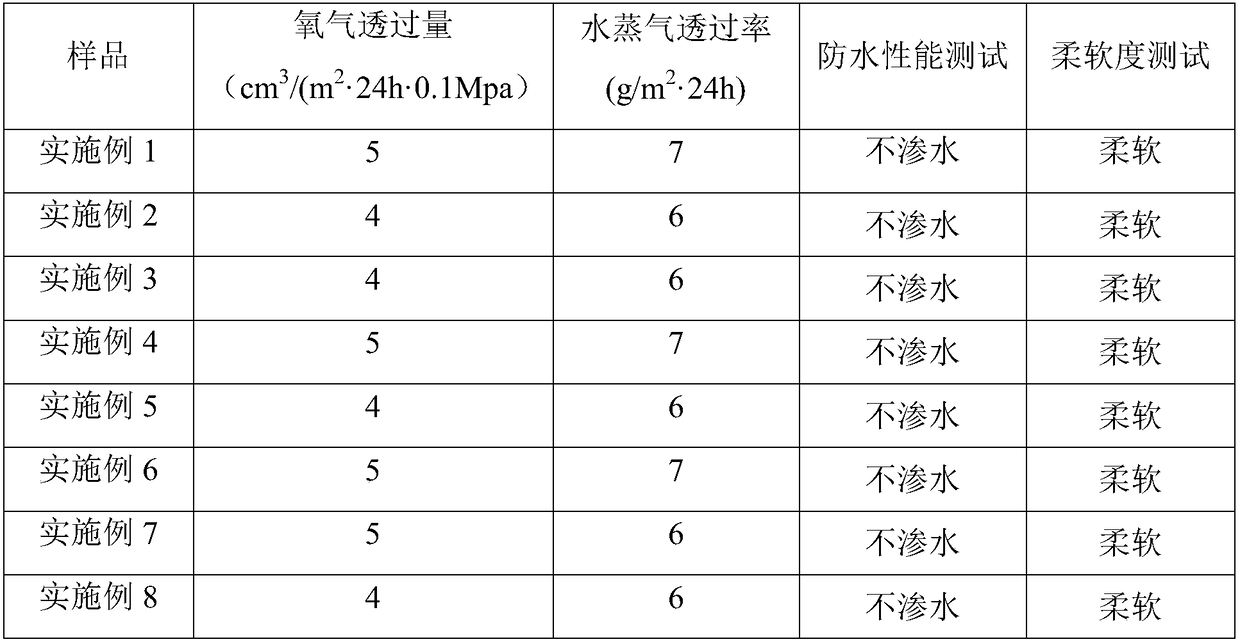

Ultrathin cast film as well as preparation method thereof and application thereof

InactiveCN108129735AImprove water barrier effectEasily brokenFlexible coversWrappersCast filmsMaterials science

The invention discloses an ultrathin cast film. According to the technical scheme, the key point isThe ultrathin cast film is characterized that the ultrathin cast filmby comprises comprising the following components: 7-12 parts of LDPE, 20-25 parts of LLDPE, 30-55 parts of HDPE, 3-5 parts of MLLDPE, 1-3 parts of PP and 5-8 parts of color master batch. The invention further discloses a preparation method for the ultrathin cast film, and the preparation method comprises the following steps: adding materials; performing extrusion plastifying; , extrusion casting, calendaring, setting and cooling; performing corona treatment; and trimming and rolling, wherein during calendaring, setting and cooling, the temperature of a rubber roller is set to be 50-55 DEG C, the temperature of an embossed steel stick is set to be 60-65 DEG C and pulling speed is 60-80 m / min. On the premise of keeping barrier properties, waterproof properties, softness, tensile properties and breakage properties of the cast film, the thickness of the cast film is reduced, the unit weight yield is increased, and the cost is reduced.

Owner:天津市德利塑料制品有限公司

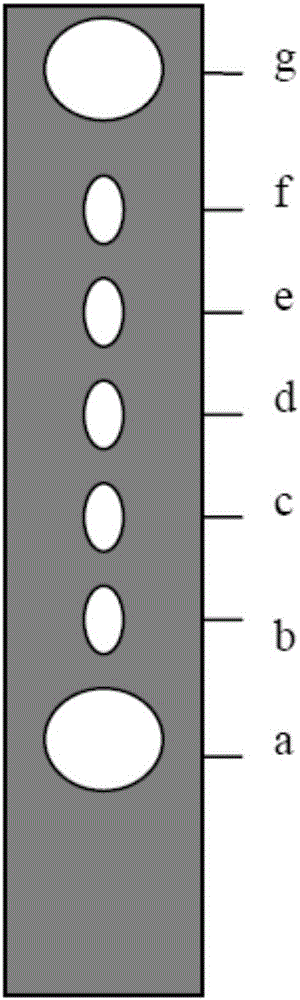

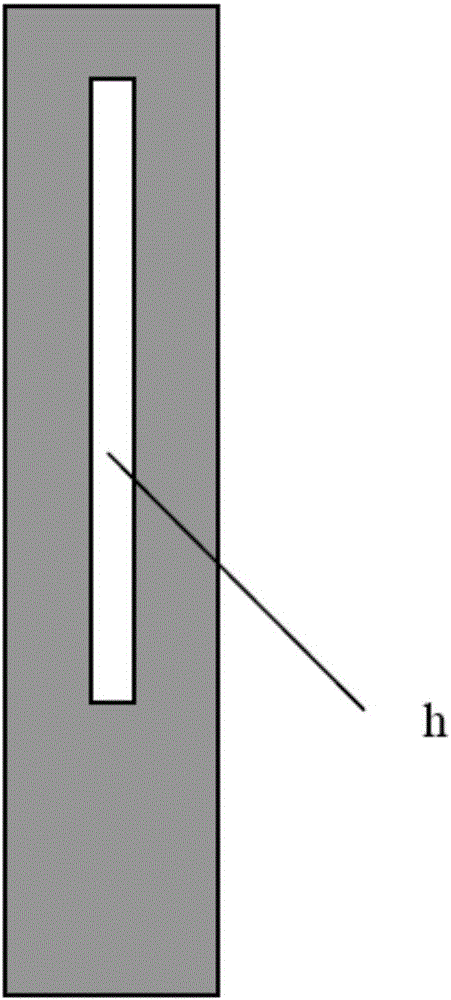

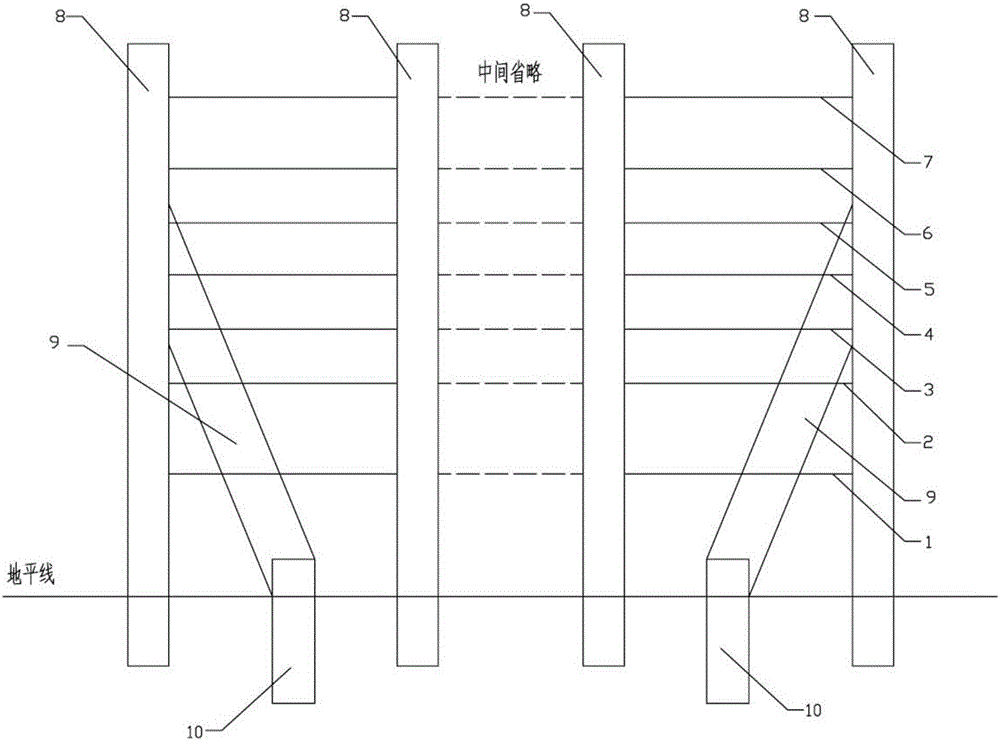

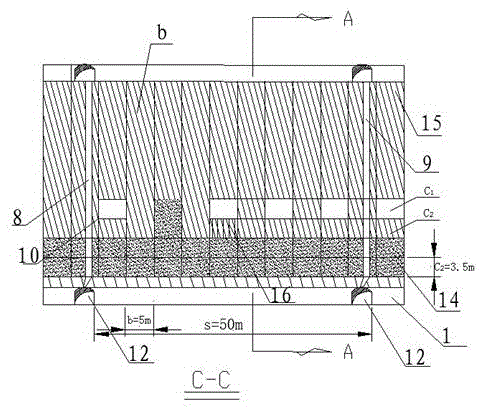

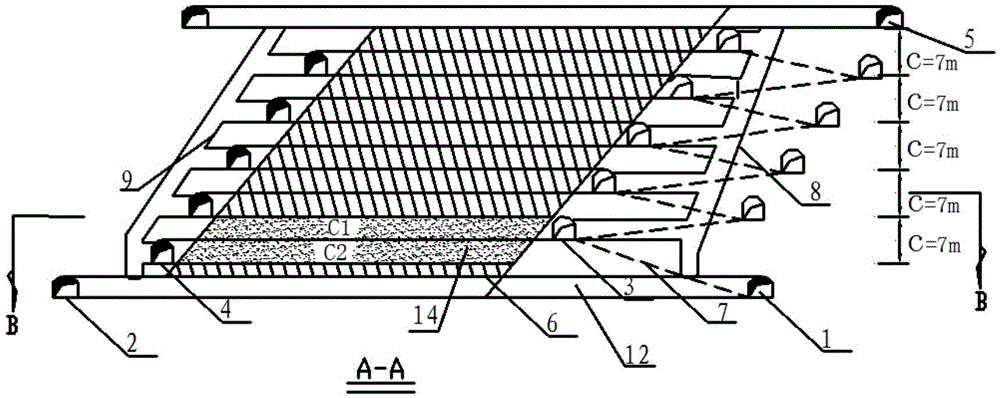

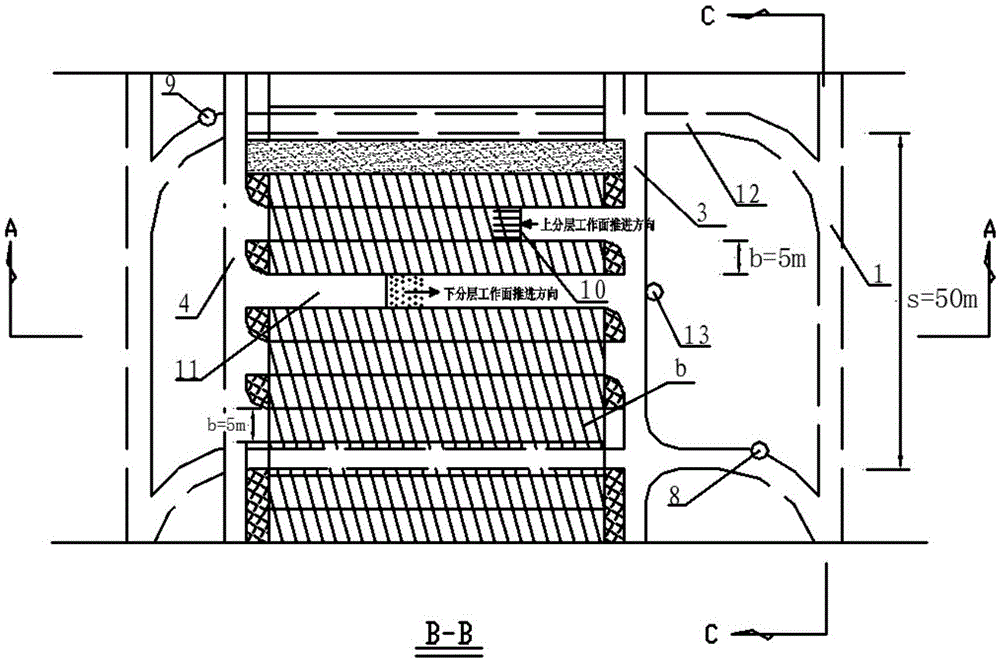

Stope structure for upward slicing whole tailing cemented filling method

ActiveCN106761756ASimplify mining processIncrease productivityUnderground miningSurface miningEngineeringTailings

The invention discloses a stope structure for an upward slicing whole tailing cemented filling method. The height of one section (c) is 6-8 m, and each section (c) is divided into an upper slice (c1) and a lower slice (c2). A footwall intra-reef following-reef connection roadway (3) is arranged on one sides of the footwalls of ore bodies of the upper slices (c1), and a hanging wall intra-reef following-reef connection roadway (4) is arranged on one sides of the hanging walls of ore bodies of the lower slices (c2); the footwall intra-reef following-reef connection roadway (3) serves as an ore removal connection roadway for stoping of the upper slices (c1), and the hanging wall intra-reef following-reef connection roadway (4) serves as an ore removal connection roadway for stoping of the lower slices (c2); and a middle section hanging wall main haulage roadway (2) communicates with a middle section footwall main haulage roadway (1) through an ore loading across-reef connection roadway (12), the footwall intra-reef following-reef connection roadway (3) communicates with the middle section footwall main haulage roadway (1) through a stope slicing connection inclined roadway (7), and therefore a complete transportation system is formed. The stope structure is high in production capacity, small in stope preparation project amount, simple in process, low in stope supporting cost and capable of achieving second-step continuous mining.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

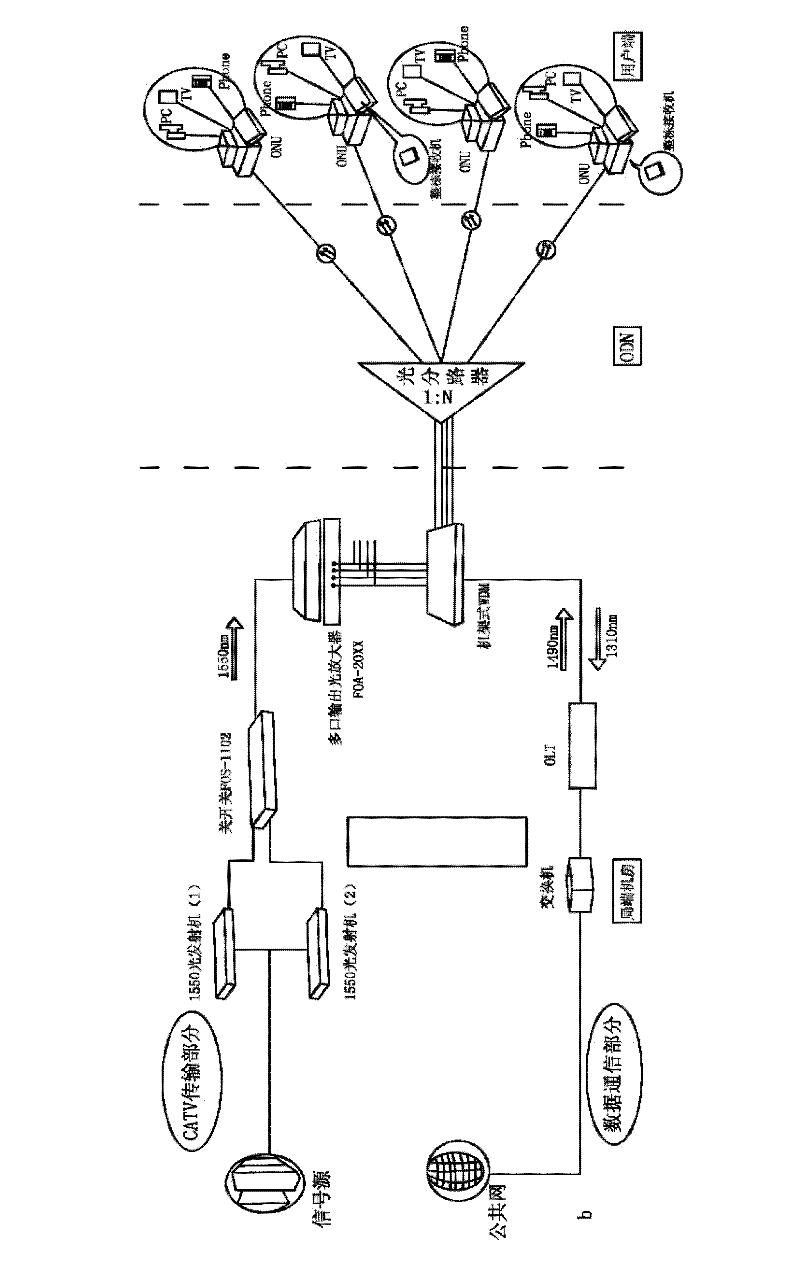

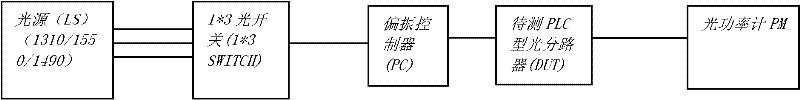

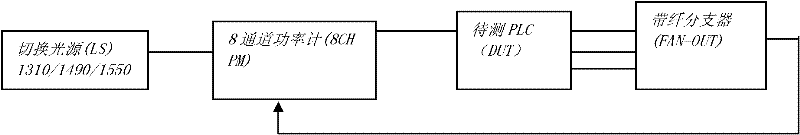

PLC (Programmable Logic Controller) type optical splitter testing method

ActiveCN102192830AEasy to operateReduce labor costsTesting optical propertiesOptical power meterChannel power

The invention relates to a PLC (Programmable Logic Controller) type optical splitter testing method, wherein a light source is output by a light source line; the output light source line enters the eight detection ports of an eight-channel power meter to be respectively calibrated and the initial value pO is tested; the rear light source line is connected with the single fiber of a PLC to be measured; the ribbon fiber of the PLC is connected with a ribbon fiber splitter through a ribbon fiber welding machine; the matched eight connectors are selected for the PLC finished product testing; each connector is respectively connected with the eight-channel power meter; a PDL (Polarization Dependent Loss) mode is selected; the switching of an optical switch in a three-wavelength light source and the action of a polarization controller in the eight-channel power meter are automatically controlled by a computer; and the simultaneous testing of the insertion loss of the three wavelengths corresponding to eight channels and the relevant loss of polarization can be finished once. The PLC type optical splitter testing method provided by the invention has the advantages of simple operation steps and high testing efficiency, ensures that the labor cost of testing personnel is saved and is simultaneously beneficial to the production management of the products, thereby improving the production efficiency and competitiveness of enterprises.

Owner:上海乐通通信设备(集团)股份有限公司 +3

Method for searching data target on basis of spatial-temporal database

ActiveCN106446278AThe search method is simple and convenientEasy for production managementDatabase distribution/replicationSpecial data processing applicationsTemporal databaseManagement object

The invention relates to a method for searching a data target on basis of a spatial-temporal database. The method is characterized by comprising the following steps: according to the temporal state and the spatial state of a target to be managed, performing modularization on the managed target; according to a management model of the target to be managed, setting a specific attribute which is described by using a natural language, of the target to be managed; on the basis of the type of the management model of the managed target, and a temporal attribute and / or spatial attribute which is defined by modularization and is described by using the natural language, performing retrieval, so as to confirm the operation state of the managed target. According to the spatial-temporal database, data information of production monitoring management is described by using three sections of times of history, real time and planning, a user does not need to master a computer language, but only with a spatial-temporal meta language, spatial-temporal data of the managed target can be retrieved and understood, and the spatial-temporal operation state of the managed target can be understood, namely both computer content can be saved and management is facilitated.

Owner:BEIJING WELLINTECH CO LTD

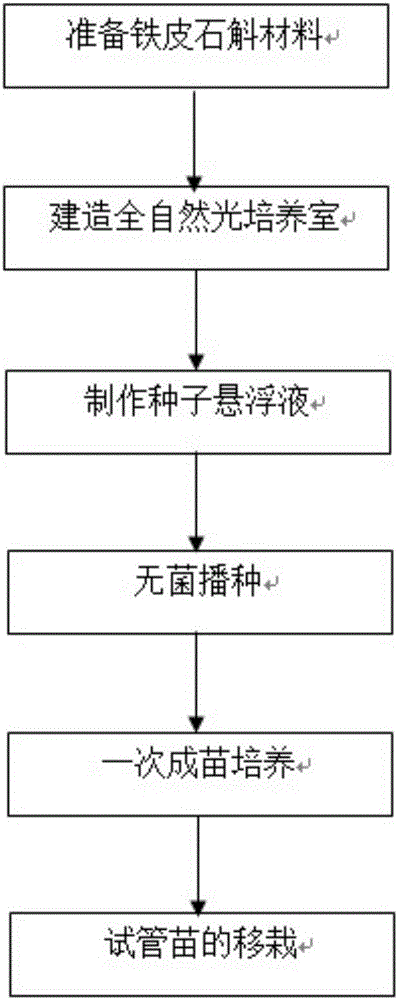

Rapid propagation method of high-quality seedlings of Dendrobium officinale with natural light cultivation for one-step seedling formation

ActiveCN106386482AReduce manufacturing costPromote growthHorticulture methodsPlant tissue cultureExercise treatmentPhacus

The invention discloses a rapid propagation method of high-quality seedlings of Dendrobium officinale with natural light cultivation for one-step seedling formation. The method mainly comprises the following six steps in order: a Dendrobium officinale material is prepared, cultivation rooms only with natural light are established, a fluid suspension of seeds is prepared, aseptic sowing is carried out for seeds, one-step seedling formation cultivation, and transplanting of test-tube seedlings. The one-step seedling formation cultivation is further divided into three phases: induced cultivation of protocorm, cultivation of small plantlets, and cultivation of big seedlings. The invention also comprises a one-step seedling formation medium used in the rapid propagation method. A one-step seedling formation is carried out without artificial transplantation, the cultivation rooms only with natural light are used, positions for cultivation can be changed according to different demands of light in different growth stages, and produced seedlings are healthy and strong as well as are easy to survive; special seedling exercising treatment is not needed before transplantation, after the seedlings are out of bottles, the seedlings can be transplanted directly, and production cost is substantially reduced. The seeds with high germination rate, medium with abundant nutrition and cultivation rooms only with natural light are used, in order to realize large scale production of one-step seedling formation of Dendrobium officinale seedlings.

Owner:NANJING XIANCAOTANG BIOLOGICAL TECH CO LTD

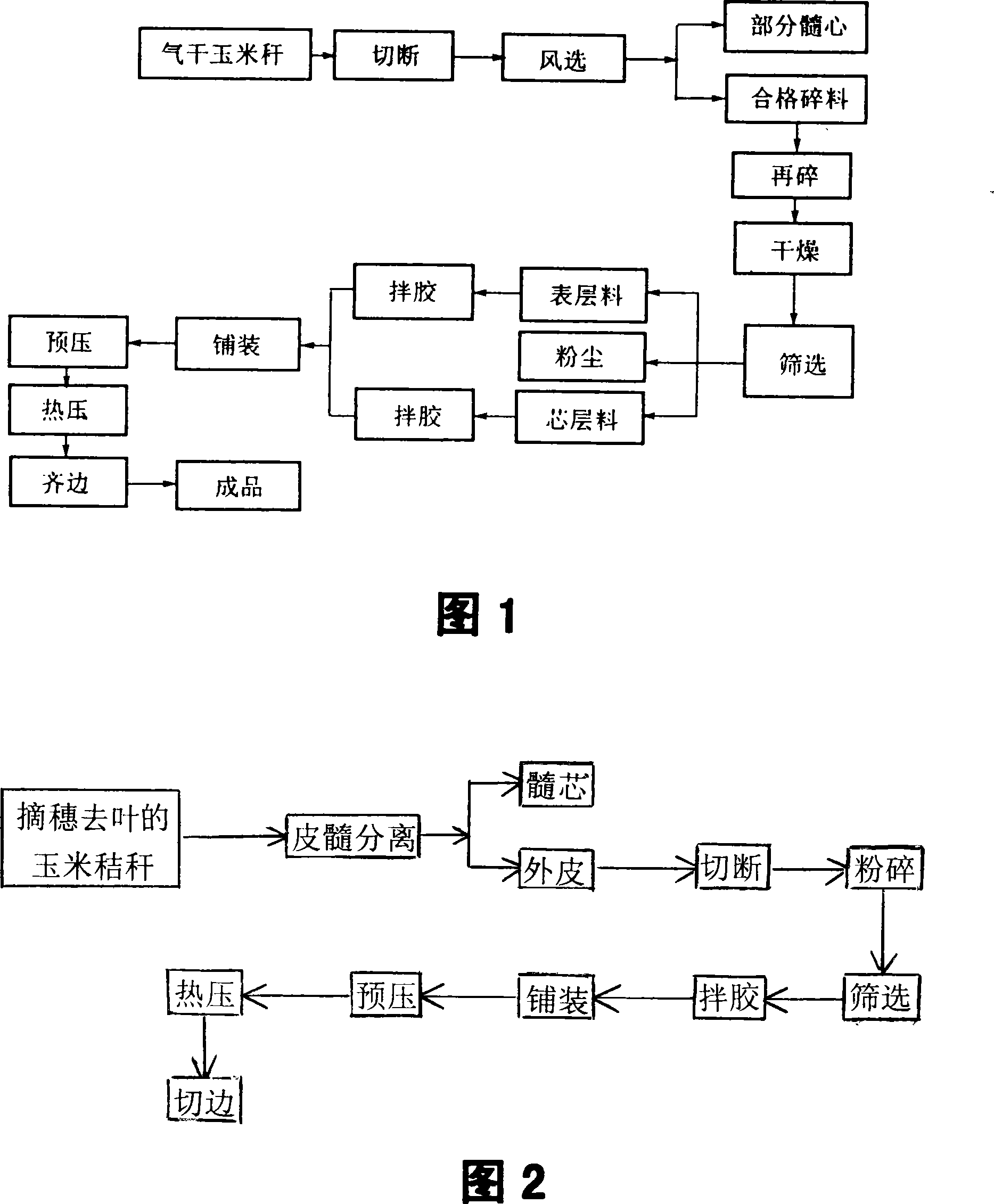

Corn straw particle board and manufacturing method thereof

The invention belongs to the category of cropper straw wood based panel. A maize straw grain plate comprises maize straw broken material and isocyanate adhesive. The invention is characterized in that the maize straw broken material is the grain of the skin of the marrow-removed maize straw; the weight percentage of the grain composition can be seen in the table; the content of the isocyanate is 3.2% to 3.7% times of the weight of the maize straw broken material. The manufacturing method of the maize straw grain plate is that the skin and marrow of the maize straw are removed; the peeled skin of the maize straw is cut off, crushed, screened, glued, paved, pre-pressed, hot pressed under the temperature ranging from 170 DEG C to 175 DEG C and edge cut. The invention solves the technical problems of improving the strength of maize straw crushed grain plate, simplifying gluing and glue mixing process, raising hot pressing temperature and shortening hot pressing time.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

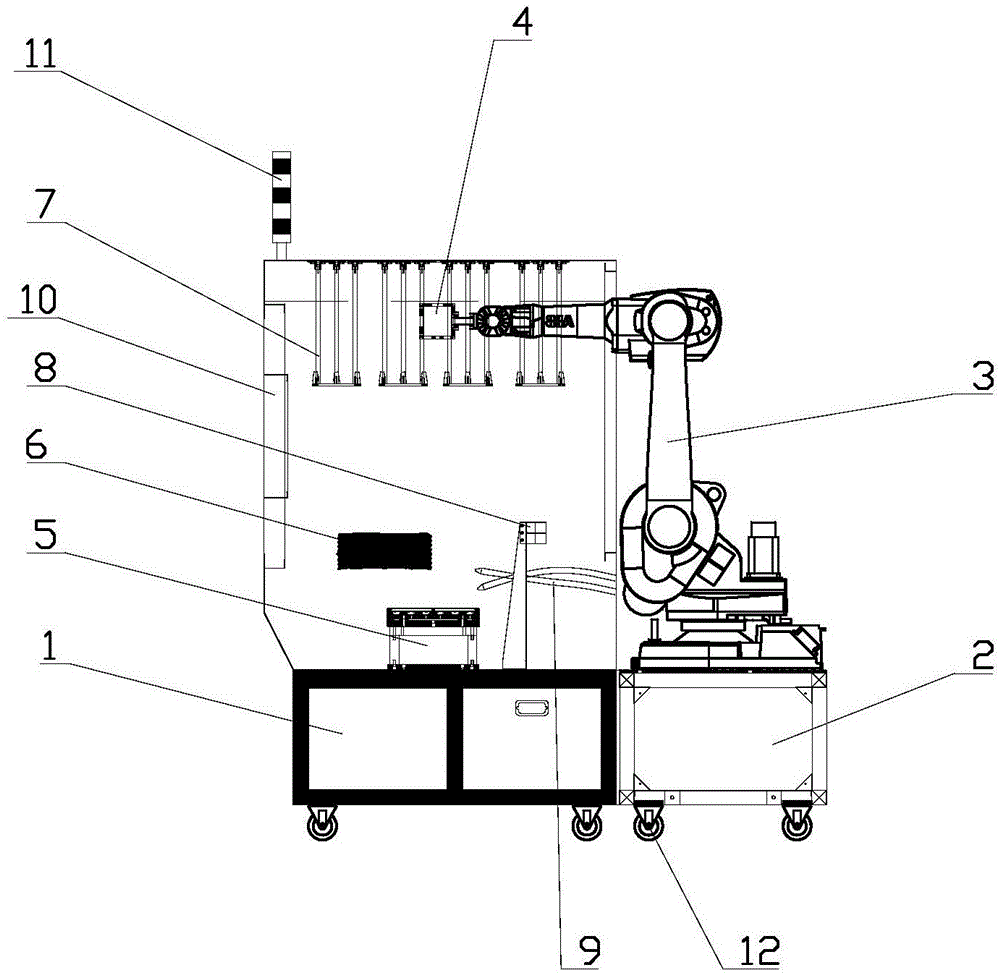

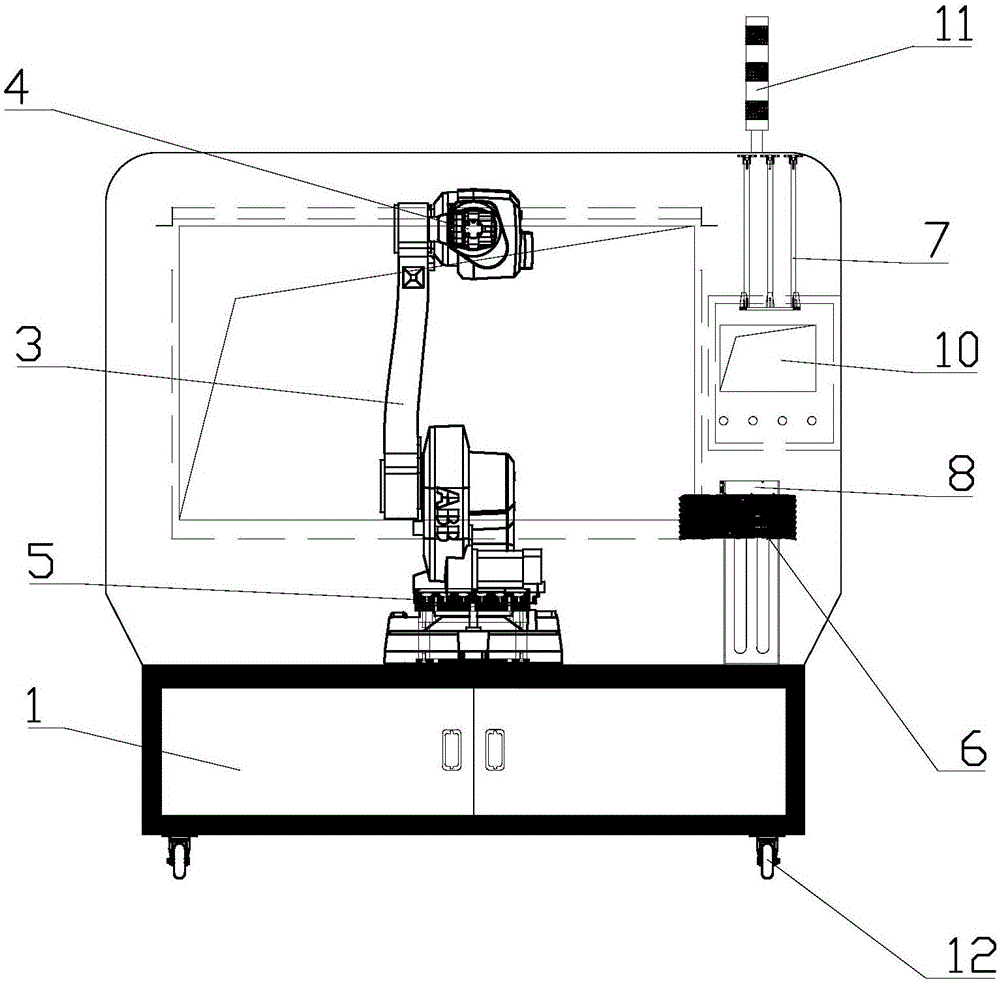

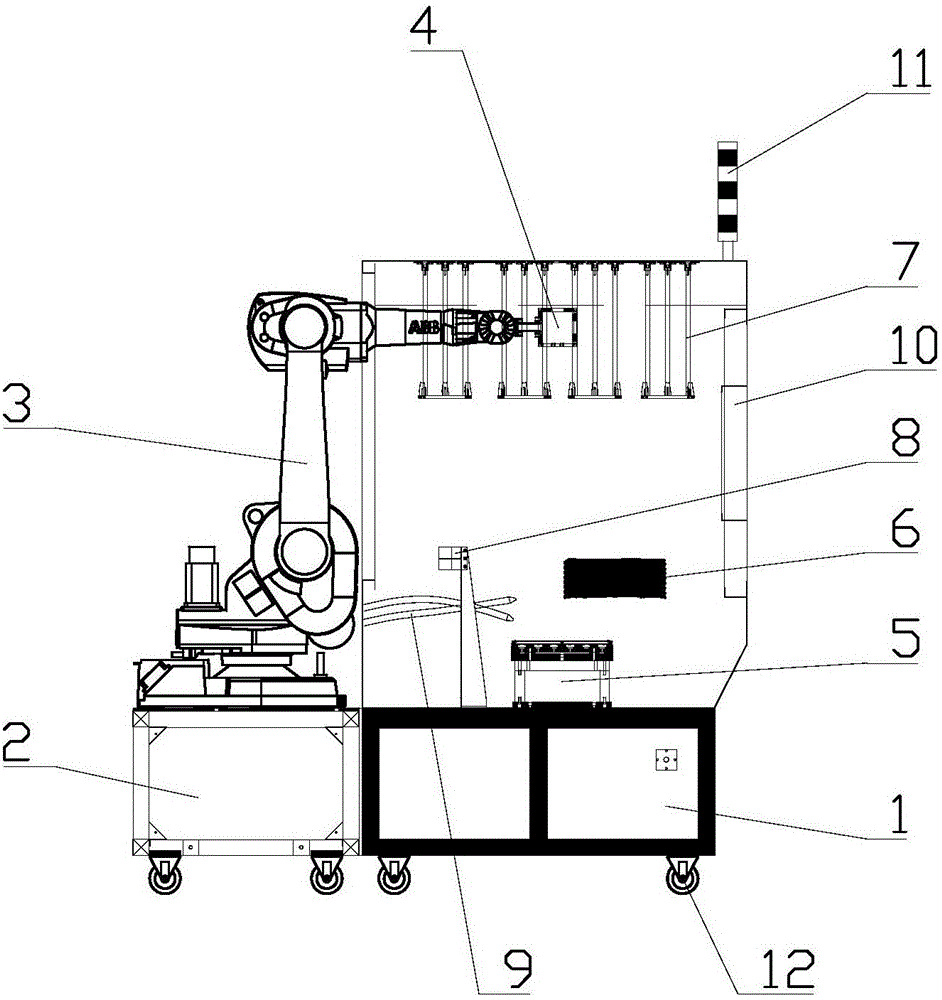

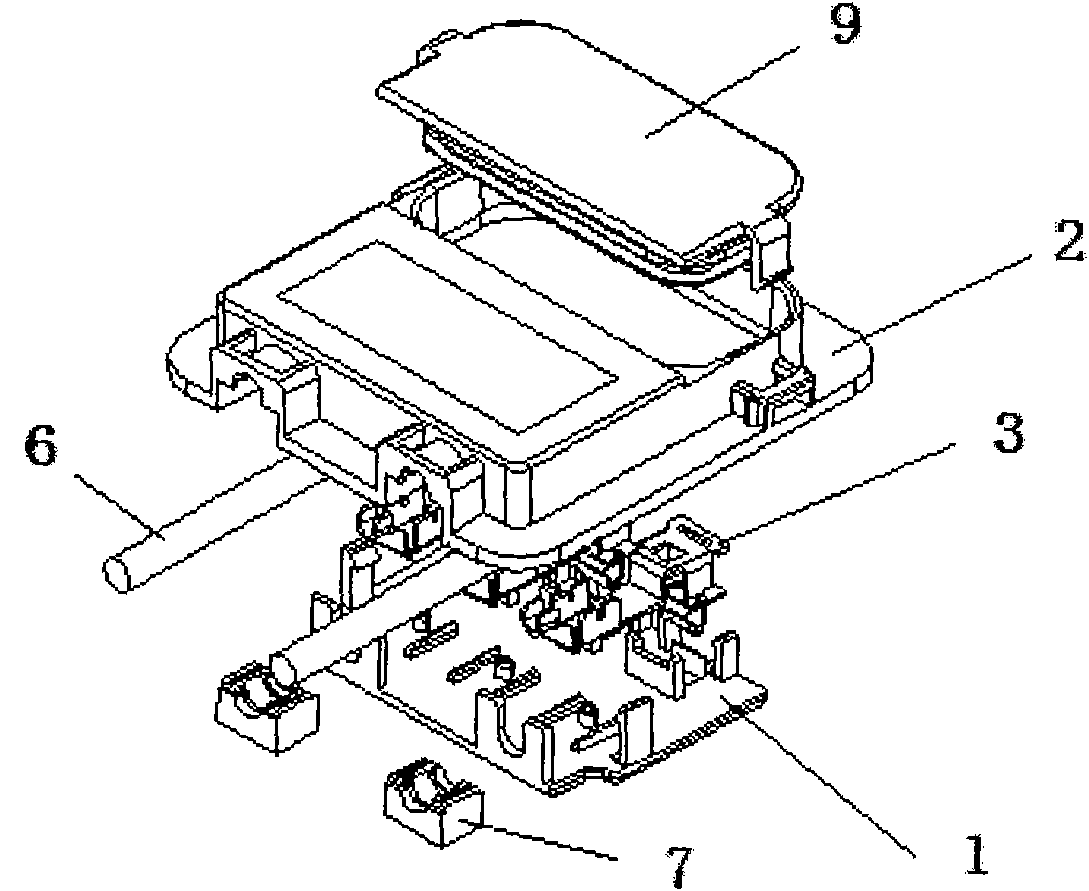

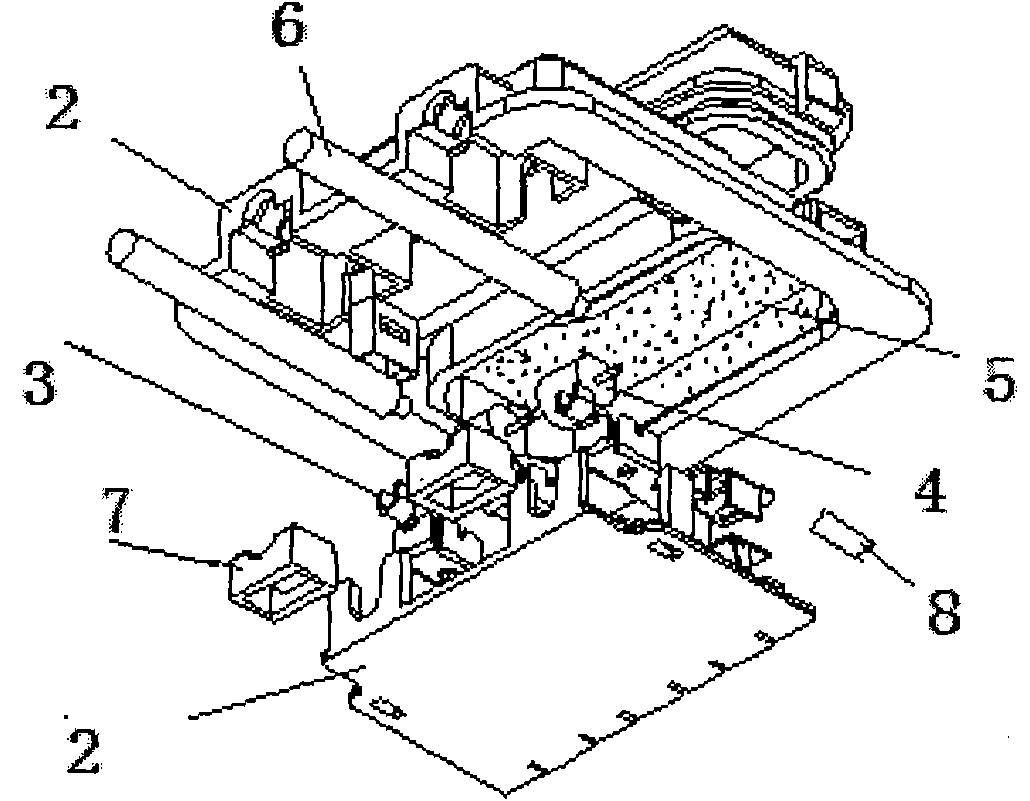

Wet type grinding equipment for automatic robot

InactiveCN106607753AReduce labor costsLow costGrinding feedersGrinding/polishing safety devicesHuman–machine interfacePulp and paper industry

The invention discloses wet type grinding equipment for an automatic robot. The wet type grinding equipment for the automatic robot comprises a grinding machine table body, a robot base, a robot body, a grinding head fixing mechanism, a grinding fixing fixture, an automatic feeding mechanism, an abrasive paper loading mechanism, an automatic abrasive paper tearing mechanism, an automatic water spraying mechanism, a human-computer interface and a three-colour audible and visual alarm; the robot base is tightly pressed against the rear side of the grinding machine table body; the robot body is placed on the robot base; the grinding head fixing mechanism is mounted at the working end part of the robot body; a machine table is arranged at the lower part of the grinding machine table body; a machine case is arranged at the upper part of the grinding machine table body; the grinding fixing fixture is arranged in the central position of the machine table; the automatic feeding mechanism and the automatic abrasive paper tearing mechanism are arranged on one side of the grinding fixing fixture; the abrasive paper loading mechanism is arranged above the automatic abrasive paper tearing mechanism; the automatic water spraying mechanism is arranged on the rear side of the grinding fixing fixture; the human-computer interface is mounted on the outer wall of the front side of the machine chassis; the three-colour audible and visual alarm is mounted at the top of the machine case. The equipment can protect the environment, and can improve the production efficiency.

Owner:SUZHOU HUYOU IND EQUIP

Split series solar junction box

InactiveCN102118011AImprove cooling effectStable jobPhotovoltaicsPhotovoltaic energy generationAdhesiveEngineering

The invention discloses a split series solar junction box which comprises a base and a box body, wherein the base and the box body are connected and are made from heat conduction materials; multiple groups of terminal blocks are distributed in parallel between the base and the box body; and every two terminal blocks are connected through one or multiple diodes so as to perform a bypass protection function. Each terminal block is correspondingly connected with a bus bar on a solar component, and the terminal block and the diode are encapsulated by heat conductive adhesives. According to the junction box disclosed by the invention, the radiating effect of the junction box is enhanced, a solar photovoltaic cell component works more stably, and solar photovoltaic components with different power adopt the same junction boxes of three specifications, thereby being convenient in production and management.

Owner:JIANGSU SHANGKUN BIOLOGICAL EQUIP

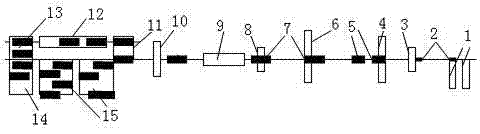

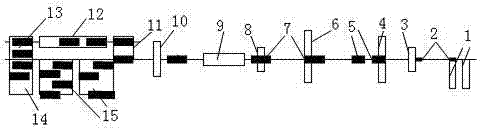

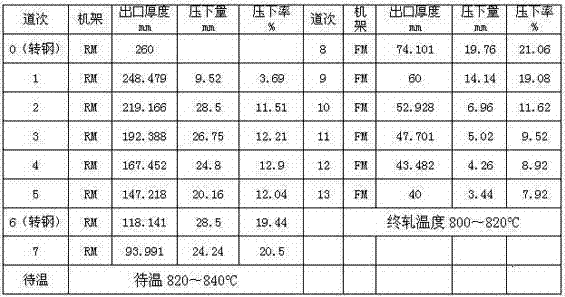

Production process of high-toughness and ultra-high strength steel and production system thereof

The invention relates to a production process of high-toughness and ultra-high strength steel and a production system thereof. The production system comprises a descaling box, a roughing mill, a temperature waiting roller table, a finishing mill, an ultra-fast cooling system, a thermal straightening machine, steel splitting racks and an open flame tempering furnace. The production process comprises the following steps of: fully heating a plate blank, discharging the plate blank from a furnace, descaling the plate blank, sequentially performing rough rolling, temperature waiting, finish rolling, on-line ultra-fast quenching and fast thermal straightening, separating the plate blank from a main production line through the steel splitting racks, fast sending a steel plate into the open flame tempering furnace for heat insulation, performing carbon distribution at PT (carbon distribution temperature), discharging the steel plate from the furnace, and then performing air cooling. The sequential arrangement of equipment of the production line is as follows: the heating furnace, the plate blank, the descaling box, the roughing mill, an intermediate blank, the finishing mill, a pre-straightening machine, an ultra-fast cooling unit, the thermal straightening machine, the first steel splitting rack, the open flame tempering furnace, the second steel splitting rack, a thick plate cooling bed and an intermediate plate cooling bed.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

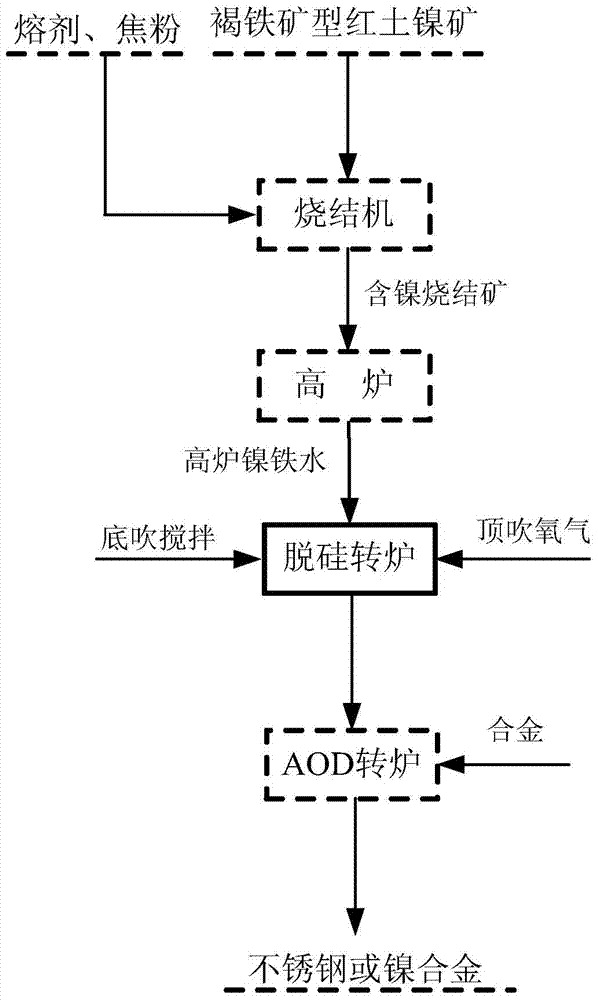

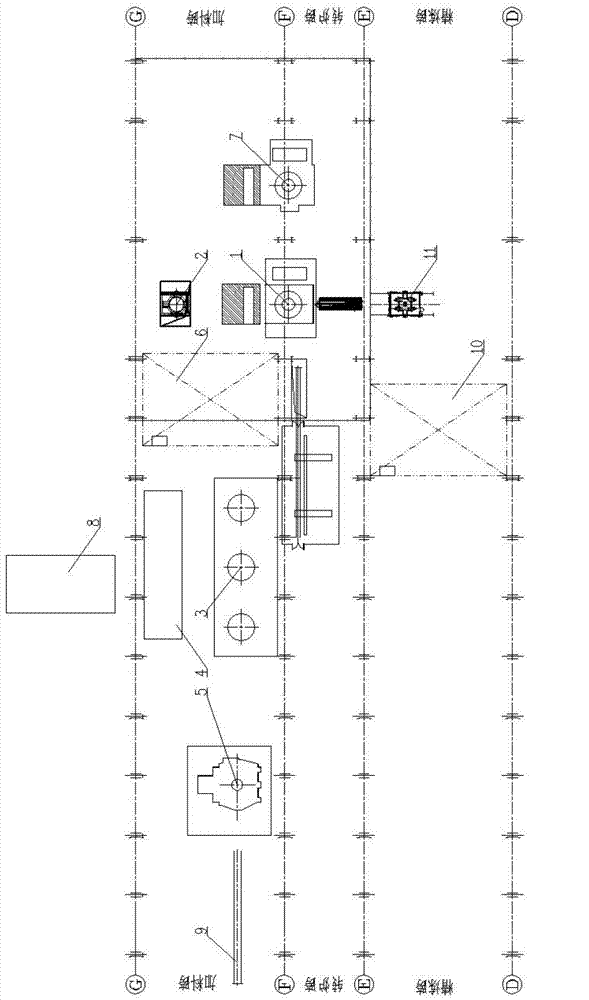

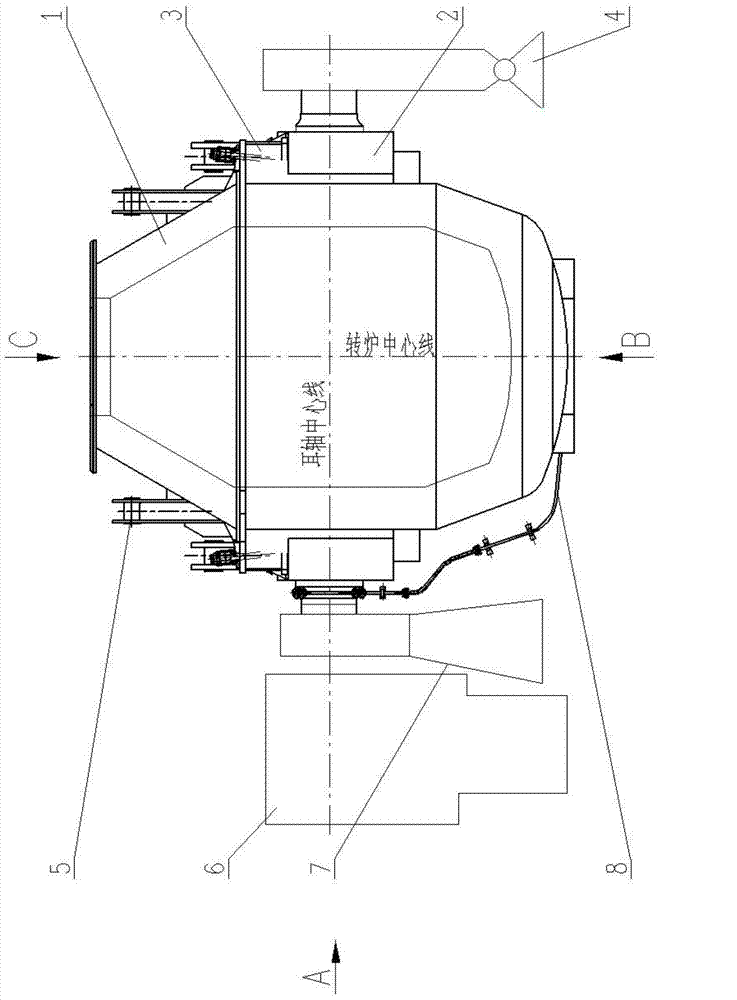

Molten iron desilication method for stainless steel smelting

ActiveCN103614609ALow Si content requirementEnough reaction spaceManufacturing convertersIRON PREPARATIONSFerrosilicon

The invention provides a molten iron desilication method for stainless steel smelting, which comprises the following steps: 1. blast furnace molten iron preparation: mixing and sintering laterite-nickel ore, adding the laterite-nickel ore into a blast furnace, and smelting while ensuring the blast furnace tapping temperature to be at least 1350 DEG C; 2. transportation: transporting the high-temperature nickeliferous high-silicon molten iron of the blast furnace to a desilication converter in the one-step or metal mixer form; 3. carrying out desilication, decarburization, dephosphorization and desulfurization on the nickeliferous high-silicon molten iron in the desilication converter, and carrying out desilication treatment on the molten iron in a top / bottom blowing mode, wherein the mass percent of silicon in the desilicated molten iron is not greater than 0.20%; and 4. final product smelting: after finishing converting, charging the semisteel from the desilication converter into an AOD (argon oxygen decarburization) furnace while adding alloy into the AOD furnace, and finishing the final smelting of stainless steel. The desilication technique has low requirements for Si content in the molten iron, provides sufficient reaction space for desilication, effectively prevents splashing, creates favorable dynamic conditions for desilication, and meanwhile, can perform dephosphorization and desulfurization.

Owner:BERIS ENG & RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com