Patents

Literature

328 results about "Hirudin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hirudin is a naturally occurring peptide in the salivary glands of blood-sucking leeches (such as Hirudo medicinalis) that has a blood anticoagulant property. This is fundamental for the leeches’ alimentary habit of hematophagy, since it keeps the blood flowing after the initial phlebotomy performed by the worm on the host’s skin.

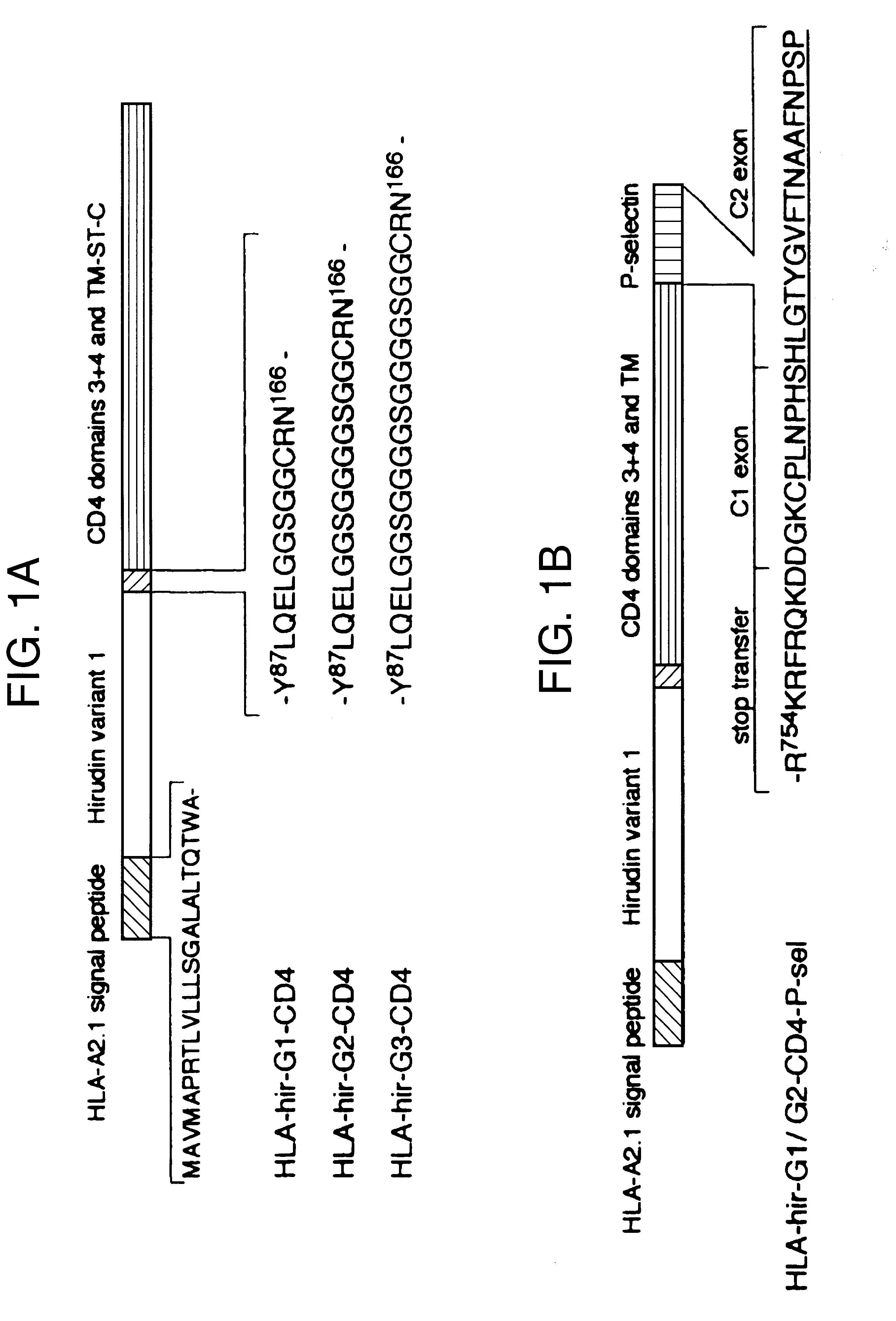

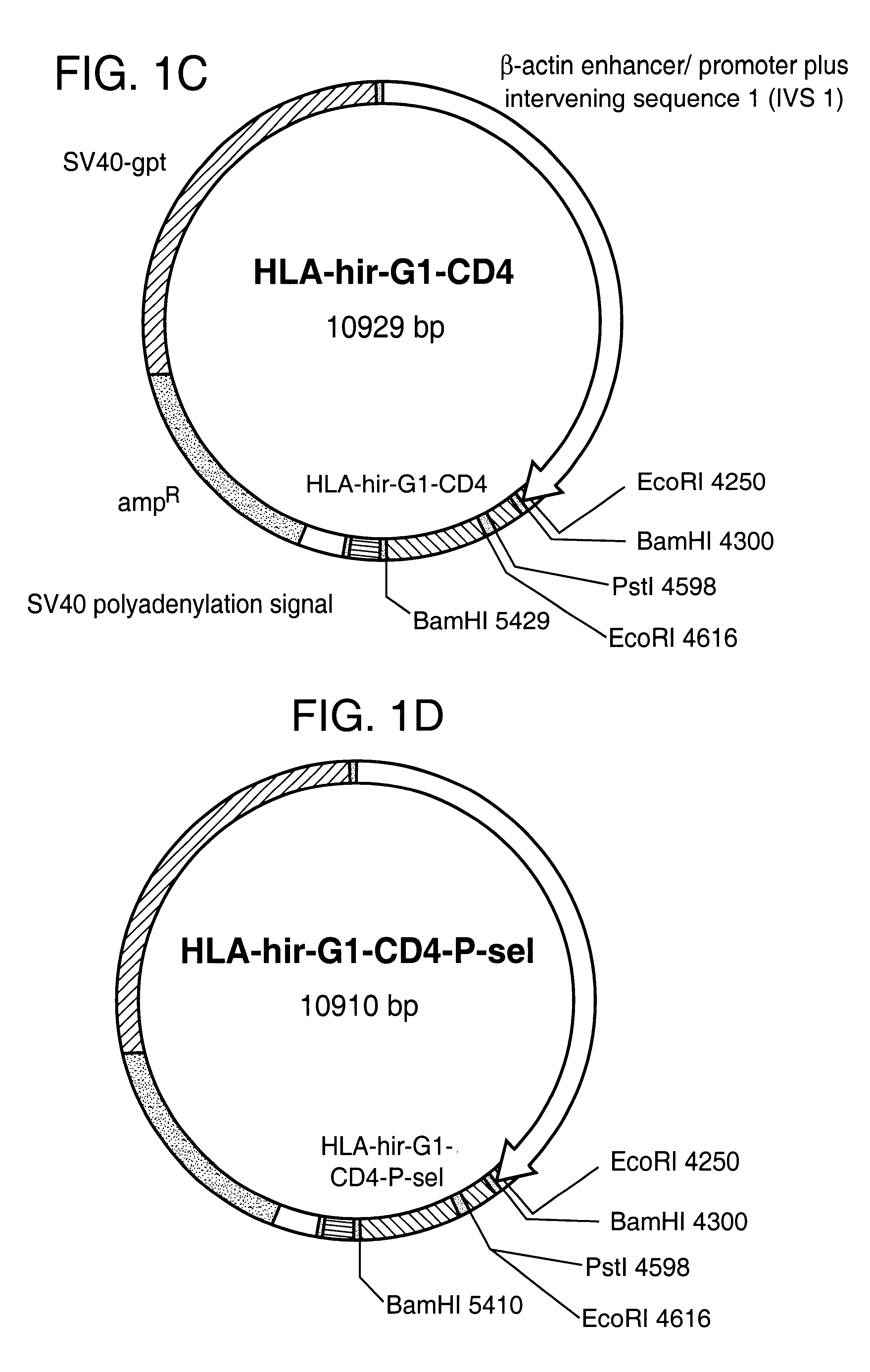

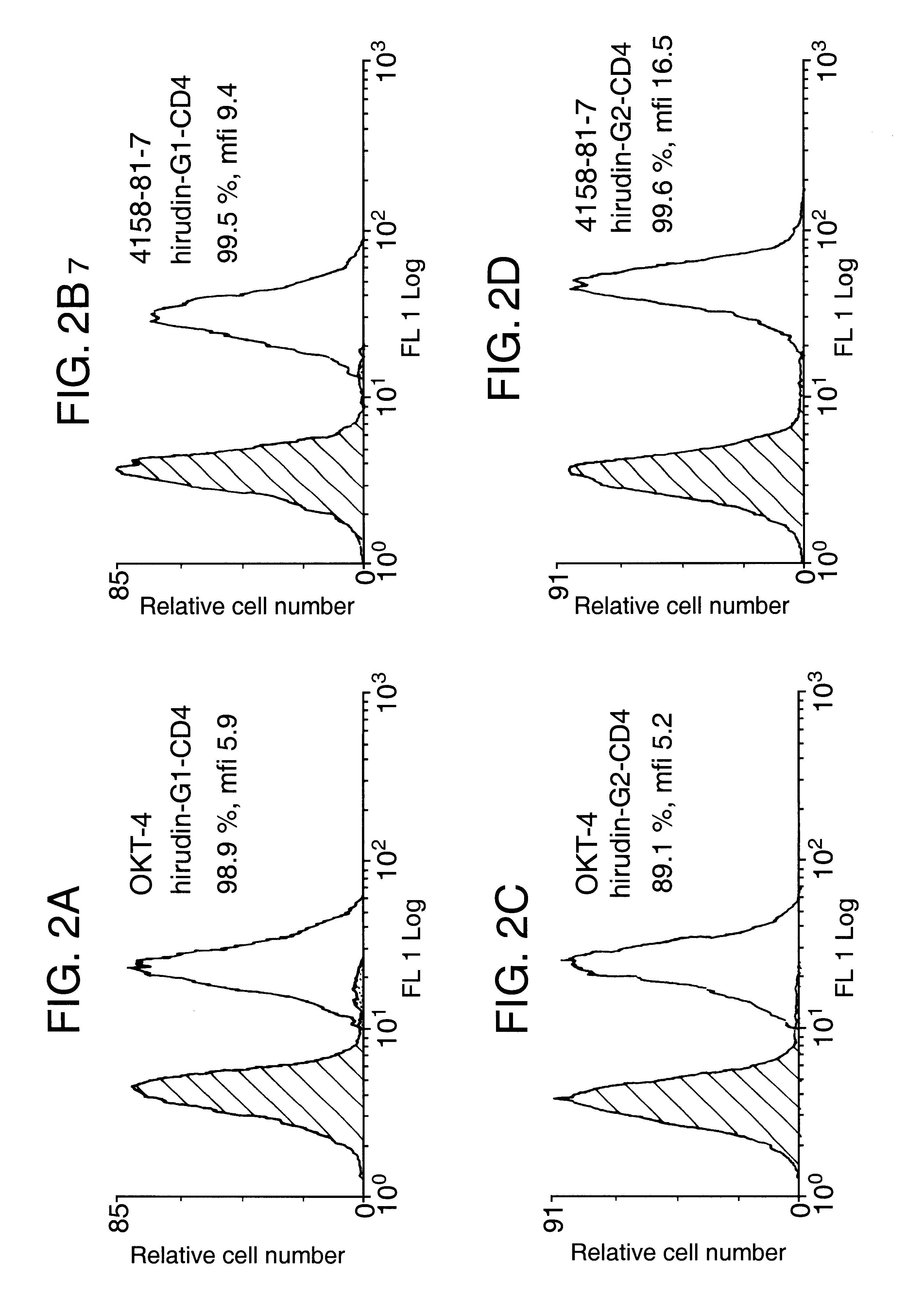

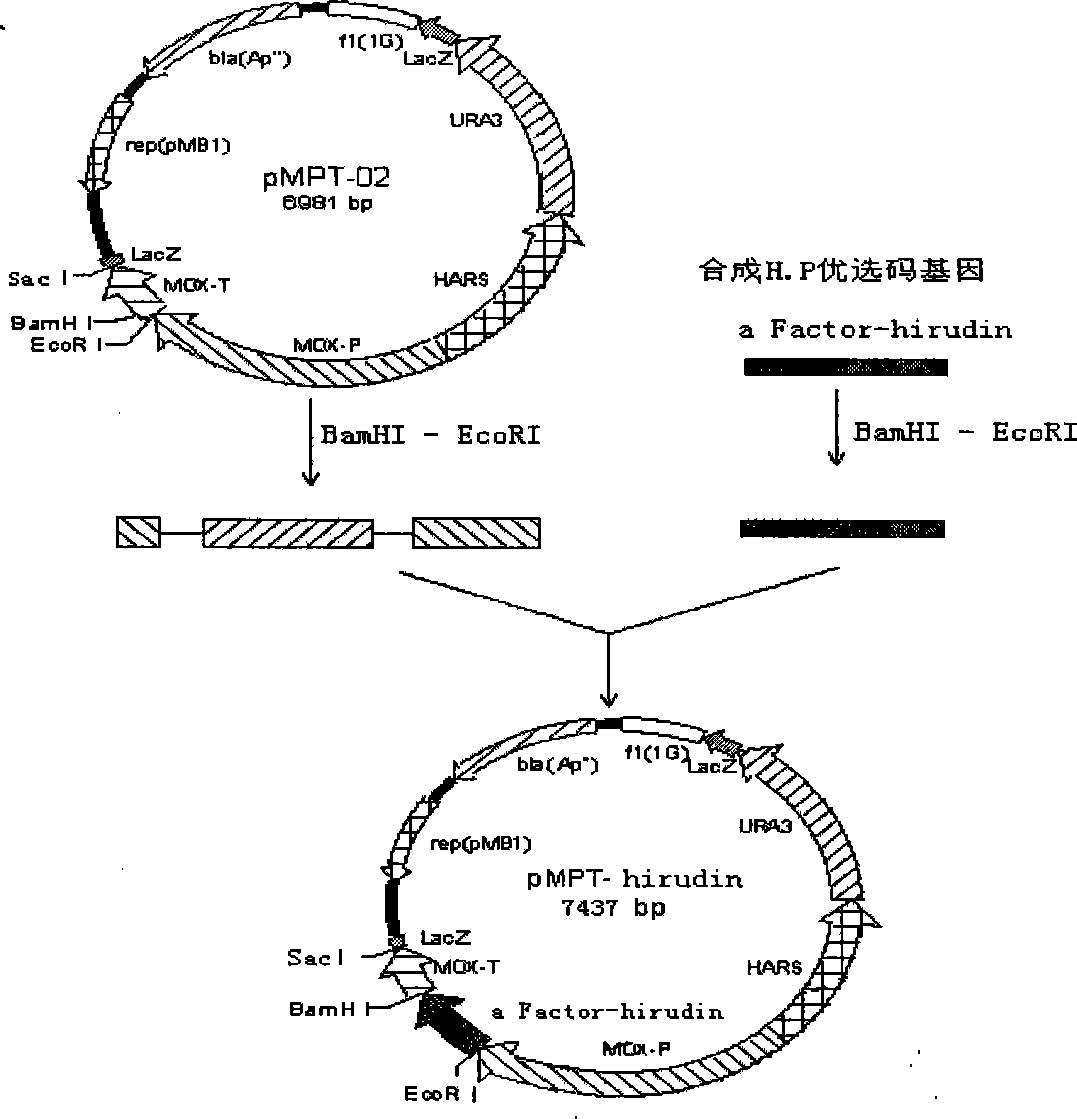

Anticoagulant fusion protein anchored to cell membrane

InactiveUS6423316B1Prolong clotting timeGood curative effectFungiVirusesCell membraneBlood coagulations

The invention relates to the inhibition of blood coagulation, especially during organ rejection, and in particular the inhibition of delayed vascular rejection. The invention provides anticoagulant proteins which are anchored to cell membranes. The anticoagulant function preferably provided by heparin, antithrombin, hirudin, TFPI, tick anticoagulant peptide, or a snake venom factor. These anticoagulant proteins are preferably prevented from being constitutively expressed at the cell surface. In particular, expression at the cell surface is regulated according to cell activation, for instance by targeting the protein to a suitable secretory granule. Expression of these proteins renders cells, tissues and organs less vulnerable to rejection after transplantation (e.g. after xenotransplantation).

Owner:IMPERIAL INNOVATIONS LTD

Method for repeatedly extracting natural hirudin from live vampire leech

ActiveCN102964446ANon-toxic ingredientsNot corrosiveLeech-based protease inhibitorsBiotechnologyBiochemical engineering

The invention provides a method for repeatedly extracting natural hirudin from live vampire leech. The method comprises the steps of: firstly extracting crude natural hirudin from the live vampire leech, then carrying out separation and purification to obtain natural hirudin, wherein the extraction of the crude natural hirudin comprises the steps of: firstly preparing specific induction liquid and then pouring into intestinal canal to obtain specific induction liquid-containing intestinal canal; then feeding the specific inducing liquid-containing intestinal canal to the vampire leech, and extracting the spit of the vampire leech or grinding the vampire leech into slurry, thereby obtaining the crude natural hirudin; and the crude natural hirudin is separated and purified to obtain natural hirudin powder according to a conventional biochemical separation method. The method is simple in process, and high in extraction rate, the death rate of the vampire leeches can be obviously reduced after the crude natural hirudin is extracted, and biological resource utilization rate can be effectively improved, so that the production cost can be obviously lowered; therefore, the method is a convenient approach for extracting the main effective active substance (such as natural hirudin) from the leech body.

Owner:周维官

A kind of production method of natural hirudin

ActiveCN102286098ASimple processHigh extraction ratePeptide preparation methodsLeech-based protease inhibitorsCurative effectBULK ACTIVE INGREDIENT

The invention discloses a production method of natural hirudin. The production method is characterized by comprising the steps of extracting, acid depositing, heating, dehydrating and drying natural hirudin liquid, wherein the content of active ingredients of the obtained natural hirudin powder can be detected through Markwardt direct thrombin titration so that the quality is stable and the curative effect of the product is ensured. The method has the characteristics of simple process, high extraction ratio, low production cost, high product purity, long storage period and the like and can beused for providing safe and high-quality raw materials for foods, health-care foods, medicines or cosmetics.

Owner:广西科康科技集团有限公司

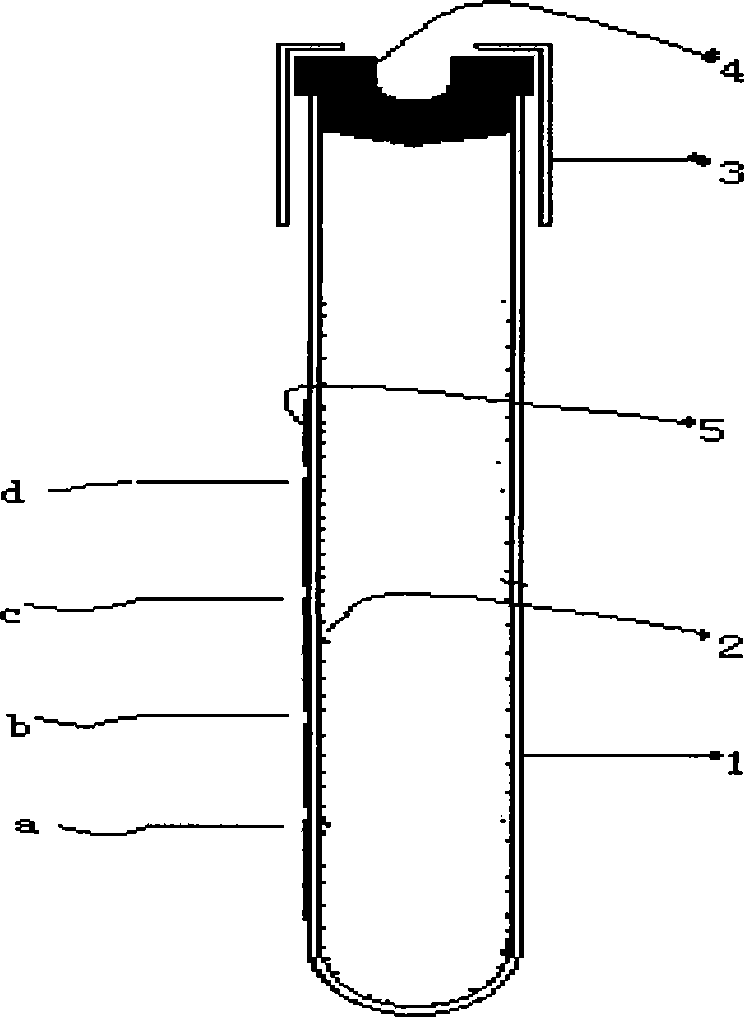

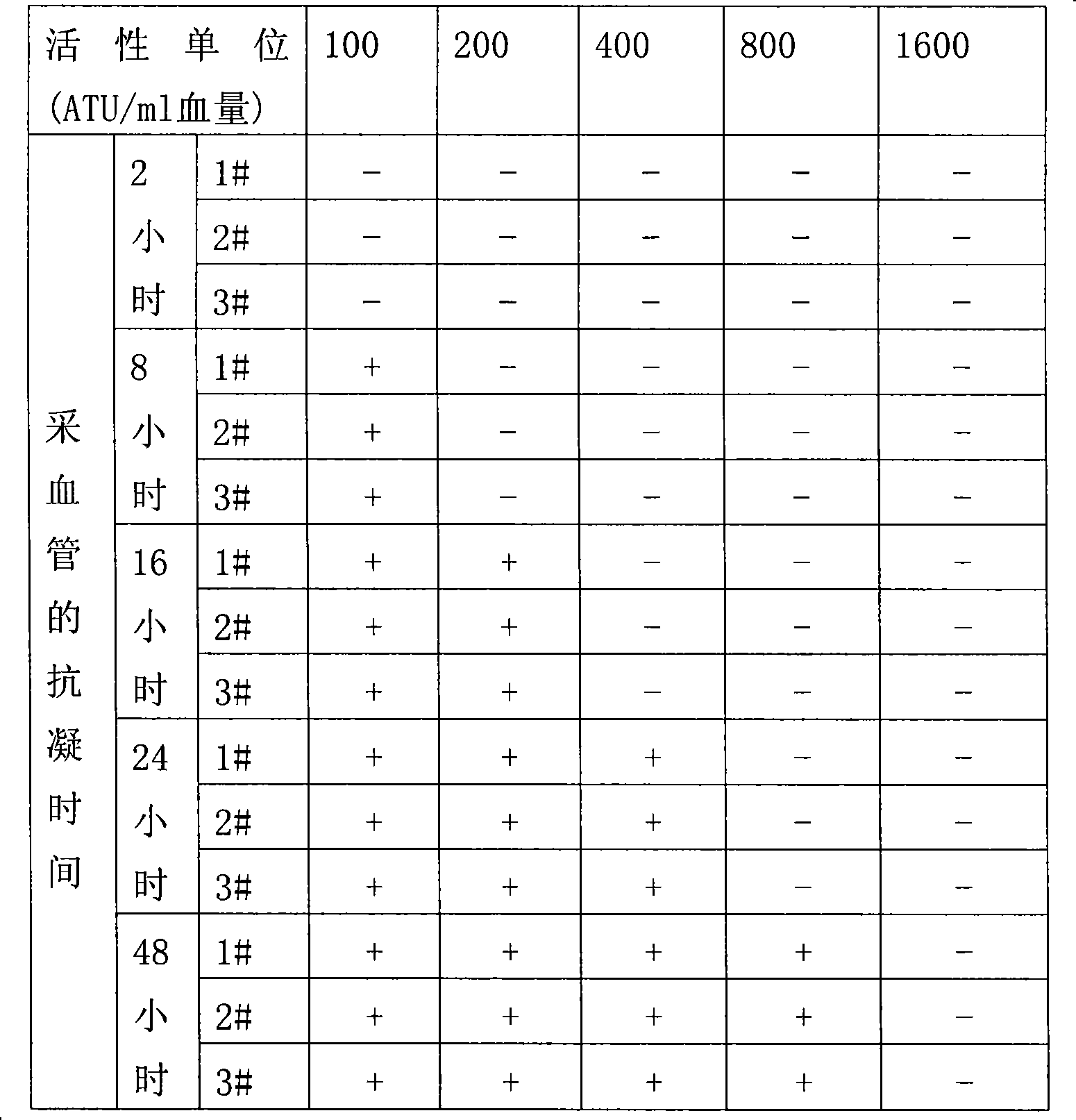

Vacuum hemostix

InactiveCN101248998AKeep original state for a long timeExtended storage timeFungiPeptide/protein ingredientsMedicine.hematologyBlood Collection Tube

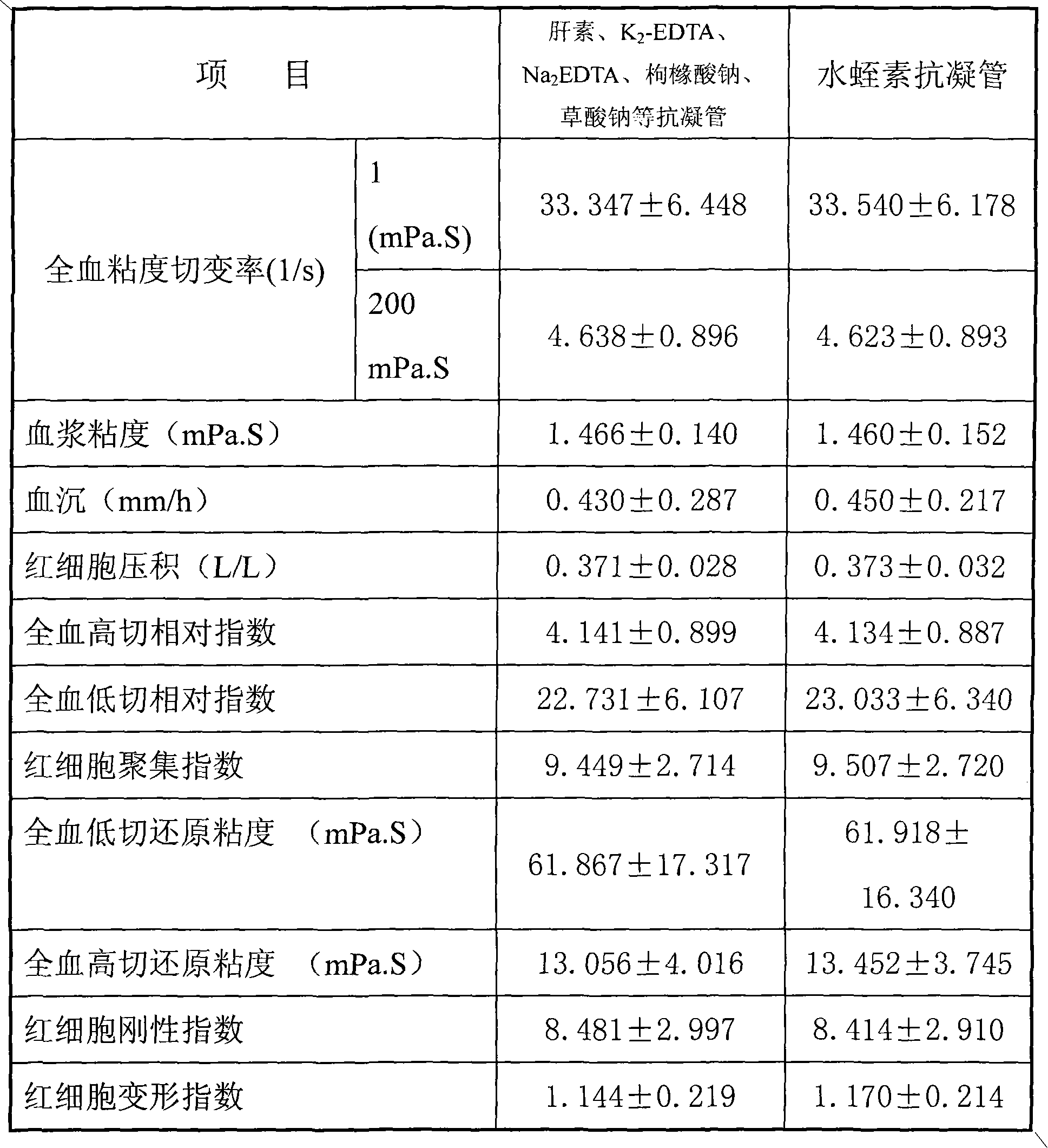

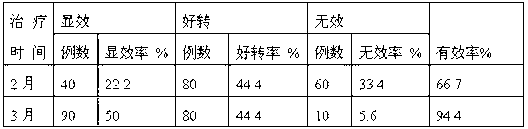

The invention discloses a vacuum test tube which comprises a vacuum tube containing hirudin as anticoagulant therein. The hirudin can be in the form of freeze-dried powder or spray-dried powder or aqueous solution, or modified with polyethylene glycol or encapsulated in liposome. The content of the hirudin in the vacuum tube is 100-2000 ATU per milliliter of blood. The hirudin has an amino acid sequence (see sequence 1 in the sequence table). The vacuum test tube of the invention is used in clinical biochemistry, clinical immunology, clinical hemorheology, immune prototype analysis, RT-PCR detection and clinical hematological examinations (except cruor parameters) and realizes versatility of laboratory examinations.

Owner:汪和睦

Method for extracting active ingredient of natural leech essence

InactiveCN101108879AHighlight substantive featuresSignificant progressLeech/worm material medical ingredientsLeech-based protease inhibitorsRetention periodAqueous acetone

The invention discloses an extract method of the effective constituent of the Natural hirudin. The method is that the blood-sucking leech is washed cleanly by water and is added with the ethanol water with content of 15 per cent to 25 per cent to soak for 30h to 50h, and then is filtered to gain the filter liquor and dregs of a decoction; the Poecilobdella manillensis waste residue is broken into pieces and is added with aqueous acetone solution with content of 15 per cent to 25 per cent to soak, and then is filtered to gain the filter liquor; after recovering ethanol and acetone from the two-time filter liquor in the vacuum, the filter liquor is combined and frozen and dried in the vacuum conventionally to gain the product. The invention is simple in process, low in cost, higher in yield, good in product quality and long in retention period. The ''three wastes'' are not discharged in the whole production process, and the product can work as the raw material in such three fields as medicine, hairdressing and health food.

Owner:滕海英 +2

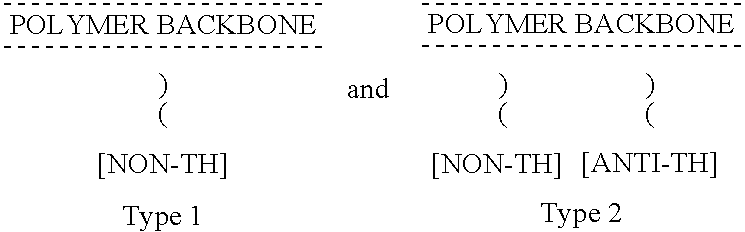

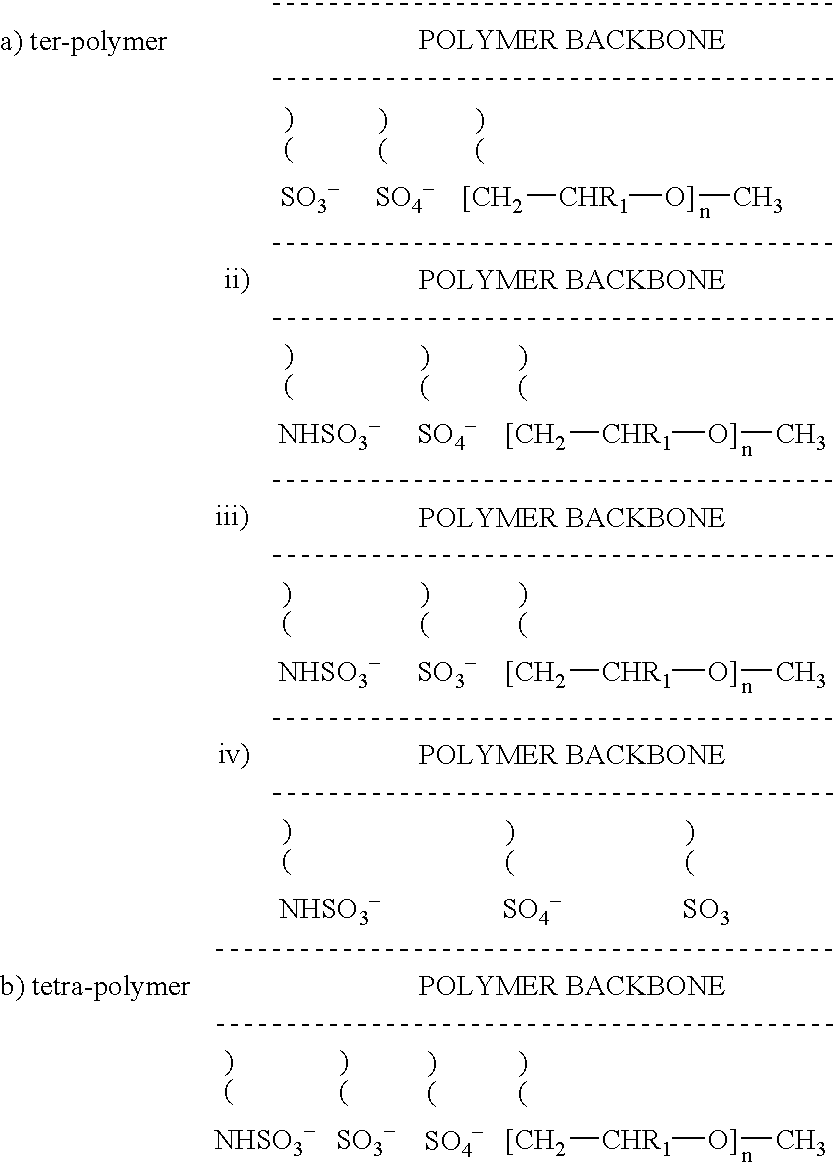

Non-thrombogenic and anti-thrombogenic polymers

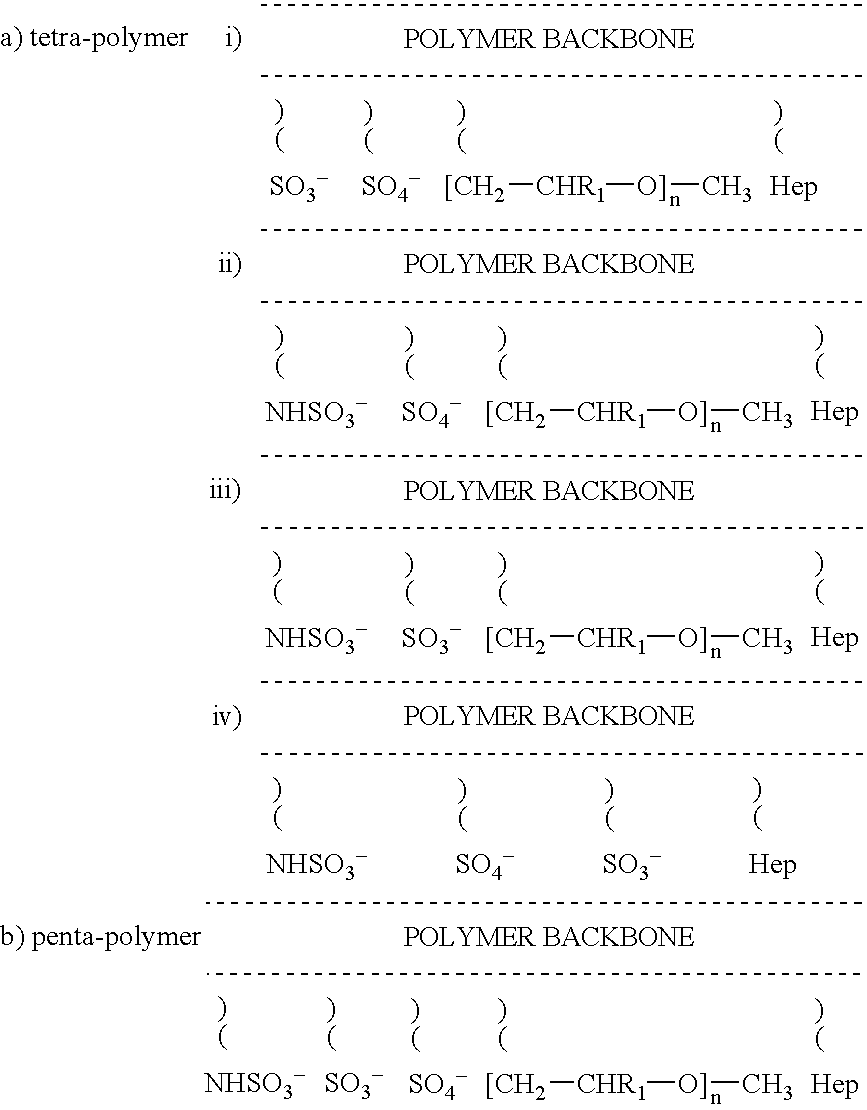

InactiveUS7034061B1Improve attachment stabilityPreferential ionic bondingPeptide/protein ingredientsPharmaceutical non-active ingredientsWarfarinPolymer science

Polymers having non-thrombogenic properties can be prepared by copolymerizing monomers of at least three classes selected from (a) monomers having sulphate groups, (b) monomers having sulphonate groups, (c) monomers having sulphamate groups, (d) monomers having polyoxyalkylene ether groups, and (e) monomers having zwitterionic groups. The polymers can additionally be provided with anti-thrombogenic properties by including an additional comonomer having a pendant heparin (or hirudin, warfarin or hyaluronic acid) group. The polymers can be used as coating materials for medical devices, such as tubing or connectors, in order to provide them with non-thrombogenic, and optionally anti-thrombogenic, properties.

Owner:BIOINTERACTIONS

Compound medicinal formulation with bioactivity

InactiveCN1628845ALiver protectionImprove hemodynamicsPeptide/protein ingredientsMetabolism disorderMedicinal herbsAdjuvant

The invention provides a compound medicinal formulation with bioactivity, which comprises Chinese medicinal herbs and right amount of medicinal or edible adjuvant to obtain pharmaceutically or food acceptable preparation, the herbs includes (by weight ratio) chloris virgata swartz 20-85%, notoginseng 5-30%, ginkgo leaves powder 0-60%, Gaultheria yunnanensis (Franch.) Rehd. 0-50%, safflower 0-35%, Ligusticum wallichii 0-30%, astragalus root 0-32%, borneol 0-5%, hirudin 0-10%, lumbrukinase 0-13%, ancrod 0-3%.

Owner:KUNMING ZIJIAN BIOTECH

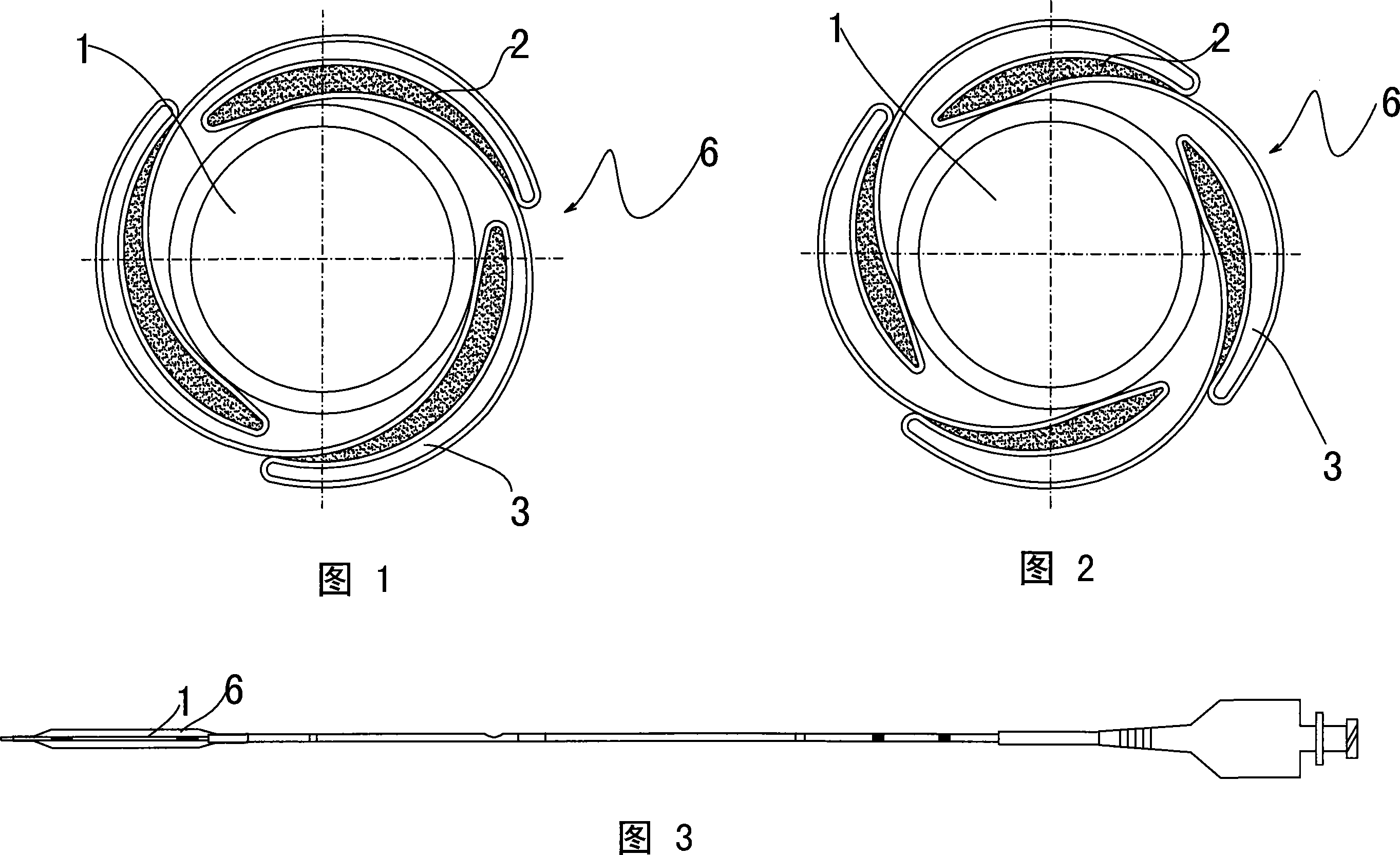

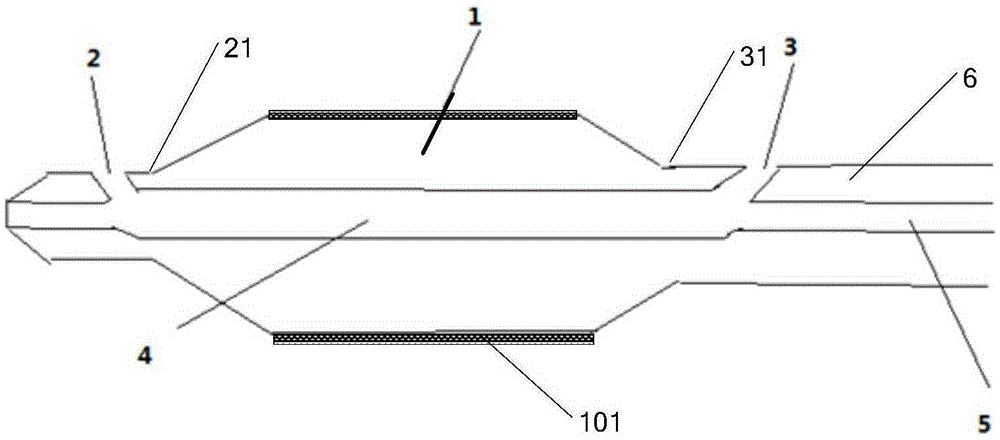

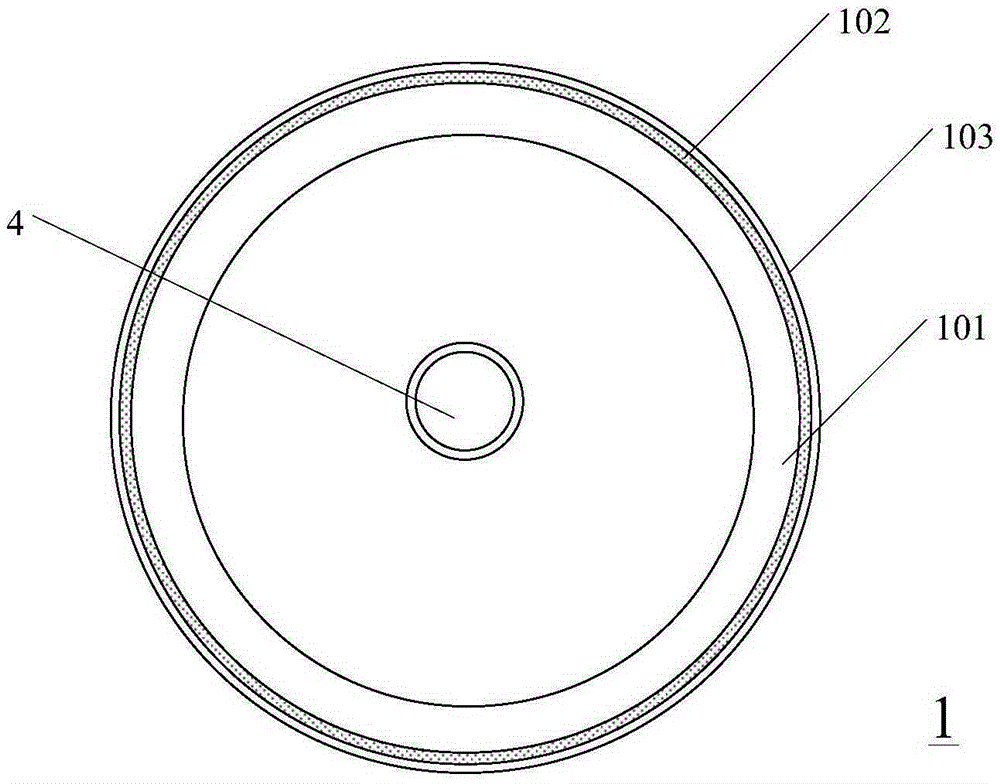

Novel sacculus dilating catheter

The present invention provides a new type balloon dilation catheter which includes ballon and medication material coated on stent. Said medication material comes from one or two and more than two mixtures of heparin sodium, fiber degrading enzyme, serine proteinase, batroxobin, aspirin, genistein, hirudin and its recombined product, colchicine, sirolimus, biolimus, zotarolimus, tracrolimus, pimecrolimus, simvastatin, atorvastatin, pravastatin, ciclosporin, Anti-CD34, dexamethasone, bleomycin, plicamycin, daunomycin, mitomycin C, actinomycin D, taxol, celastrol, methopterin, 5-fluorouracil, cytarabine and 6-purinethol. The balloon is made of macromolecule nylon material, and the stimulation to blood vessel is far lower than the stent with metal structure.

Owner:上海赢生医疗科技有限公司

Method for extracting hirudin from leech saliva

InactiveCN104926937ANot corrosiveEasy extractionAnimal husbandryLeech-based protease inhibitorsFiltrationLiving body

The invention discloses a method for extracting hirudin form leech saliva. The method includes the following steps of a), placing leeches in a container to allow the leeches to be hungered sufficiently, inputting inductive substances to the leeches to allow the same to absorb fully, adding vomitives to allow the leeches to spit the saliva in bodies, taking out blood-sucking leech living bodies to return to a rearing pond to feed continuously, and meanwhile, collecting hirudin crude product liquid in the container; b), freezing above hirudin crude products, adding into precooled cold acetone, stirring prior to placing in a refrigerator for setting overnight, sucking supernatant acetone the next day prior to centrifuging, adding a trichloroacetic acid solution, and centrifuging to remove residues to obtain concentrated liquid; c), eluting the above concentrated liquid with an anion exchange column chromatography method, and performing gel filtration chromatography to obtain finished products. The method has the advantages of reasonable process, convenience and practicability in operation, good quality stability of the finished hirudin products and high yield, one-time pillage on the leeches with a traditional method can be avoided, wild resources of the leeches are protected, and development of leech farming is driven.

Owner:广西复鑫益生物科技有限公司

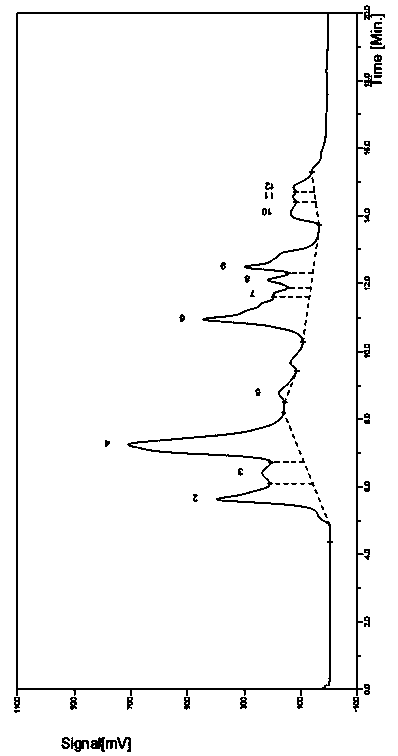

Production technology capable of efficiently separating high-activity hirudin based on anion exchange column

ActiveCN103509105ASimple processHigh extraction ratePeptide preparation methodsLeech-based protease inhibitorsPoecilobdella manillensisBiochemical engineering

The invention discloses a production technology capable of efficiently separating and purifying hirudin based on a novel anion exchange column (DEAE-silica gel separation column). The production technology taking leech powder prepared from Guangxi poecilobdella manillensis as a raw material belongs to the field of traditional Chinese medicine production, relates to extraction of animal effective ingredients and aims at solving the problems that hirudin is complicated to extract, high in cost and difficult to produce industrially. The invention is characterized in that a new hirudin separating and purifying technology is designed aiming at a separating and purifying system of the new DEAE-silica gel separation column with low cost. The technology is simple and speedy and low in cost; besides, the freeze-dried powder of the obtained hirudin is high in activity, recovery rate and purity, and long in storage life, so that safe and good-quality raw materials can be offered for industries of foods, health-care foods, medicines or cosmetics and the like.

Owner:科康生物医药(深圳)有限公司

Freeze dried powder injection of hirudin and its preparation method

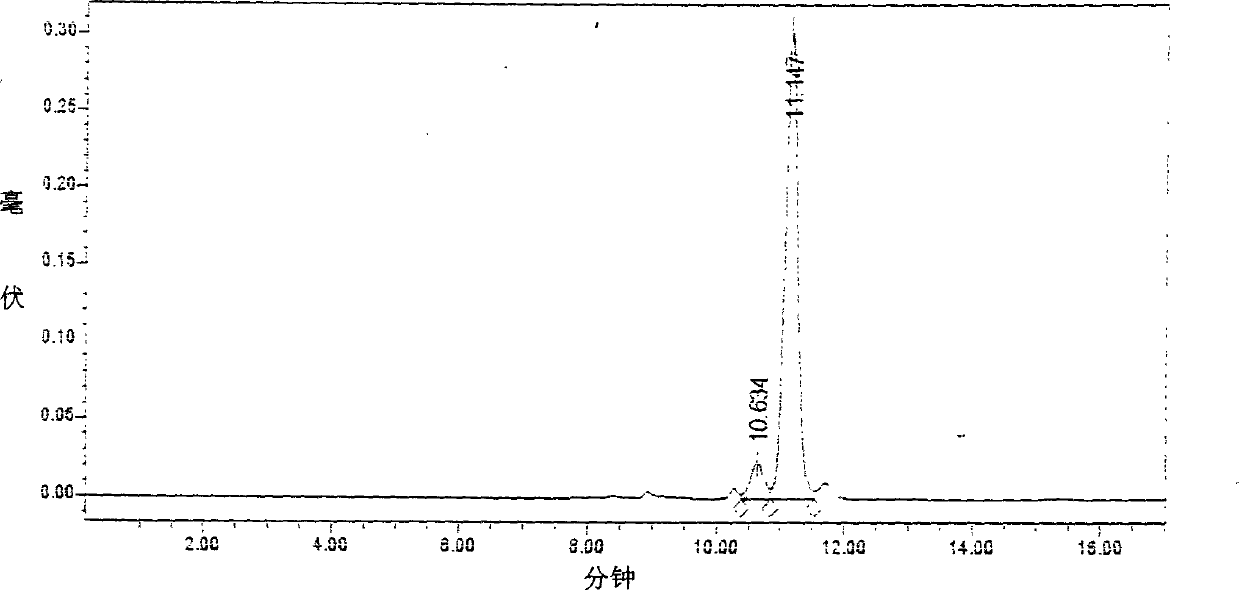

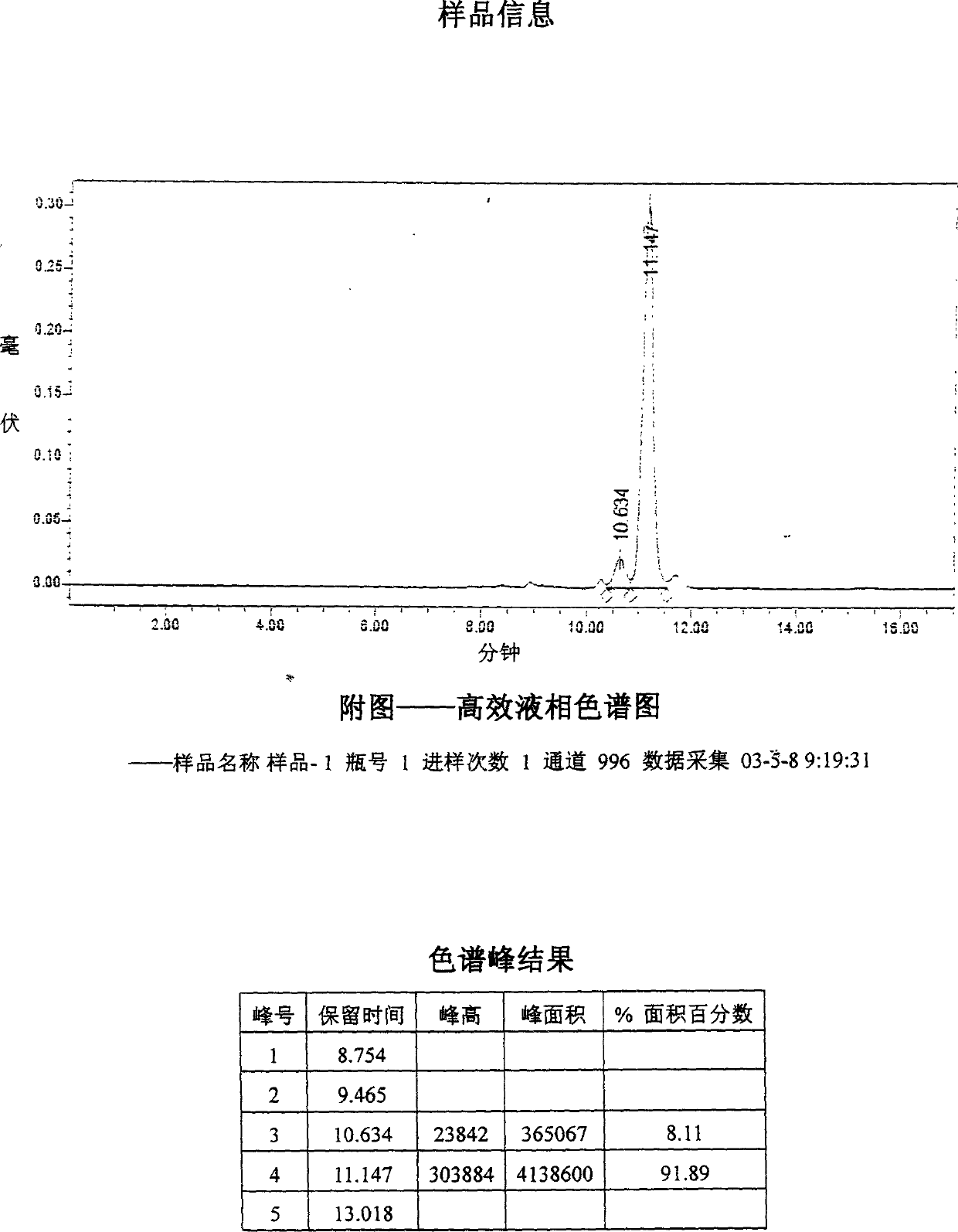

InactiveCN1569226AHigh purityGood curative effectPowder deliveryPeptide/protein ingredientsPurification methodsFreeze-drying

The invention discloses a freeze dry injection of hirudin and its preparation process. It is characterized in that hirudin is extracted from fresh leech, pharmaceutic adjuvant can be added or not added after purification to prepare freeze dry injection formulation of hirudin, the character also lies in not adopting any organic solvent in the preparation method, but adopting purification methods of ultra filtration, ion exchange column chromatography and reverse osmosis condensation to get hirudin with comparative highly purity. The pharmacody experiment result indicates that the freeze dry injection has a favorable pharmacological action.

Owner:北京干露春科技有限公司

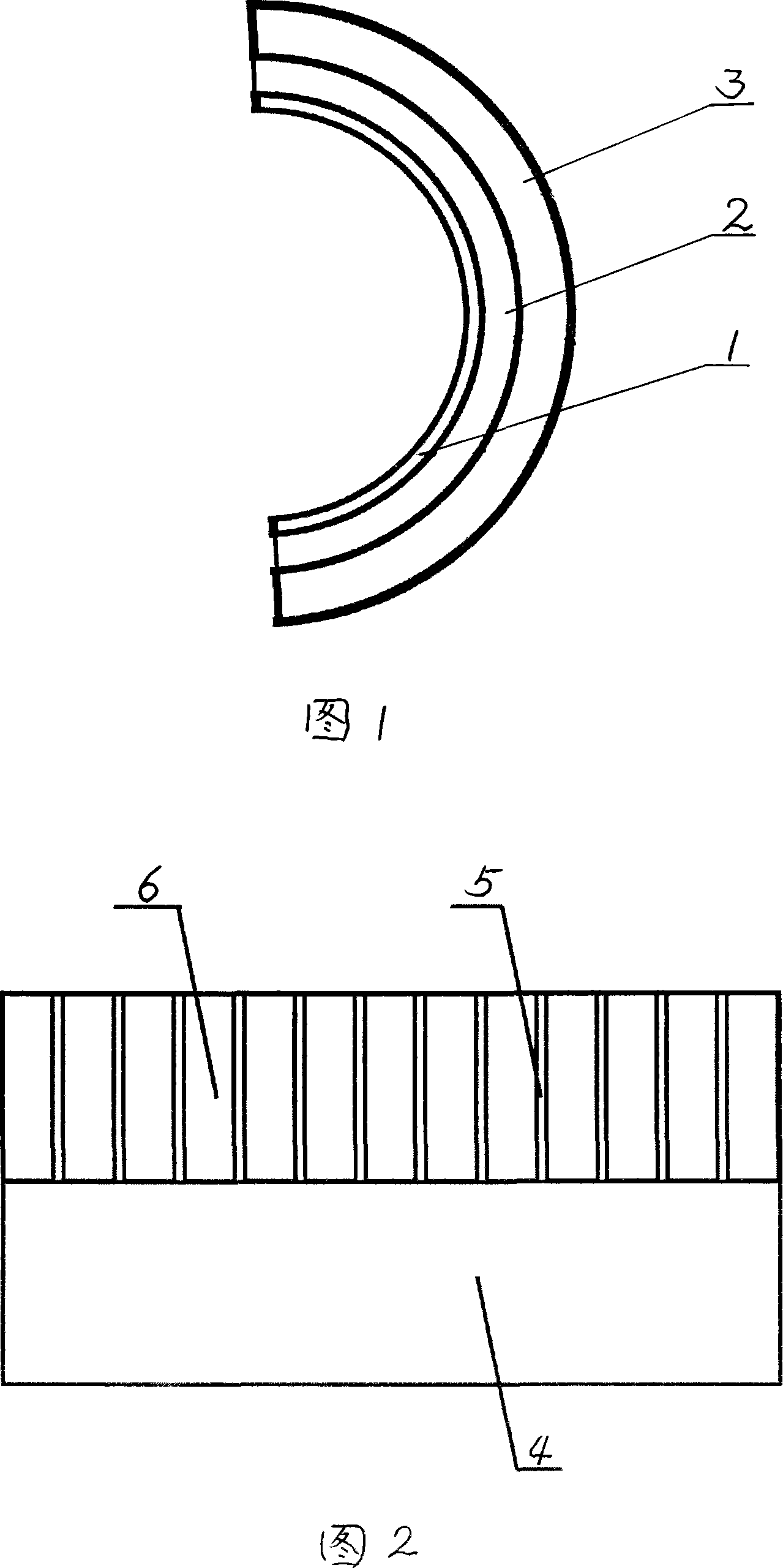

Drug eluting balloon system

InactiveCN105288823APromote absorptionFaster filling timeBalloon catheterCoatingsCurative effectTherapeutic effect

The invention discloses a drug eluting balloon system which comprises a balloon catheter and a drug eluting balloon, wherein the balloon catheter is provided with a wire guide cavity arranged along the axial direction; the drug eluting balloon is arranged along the partial length of the balloon catheter and is expanded by virtue of a pressure medium provided by the balloon catheter; the external surface of the balloon body of the drug eluting balloon is provided with a drug coating; the drug coating comprises an inner layer and an outer layer, wherein the inner layer is a taxol and hirudin mixed drug coating, and the outer layer is a hirudin drug coating; a flow channel is also arranged in the wire guide cavity, and the flow channel is arranged at the partial length position of the balloon catheter; and the flow channel is provided with two openings which are respectively formed in two ends of the drug eluting balloon. When the drug eluting balloon system releases drugs, blood flow can not be blocked and drug release can be prolonged to any time, so that the action time of the drugs is increased and the curative effect is improved.

Owner:王显

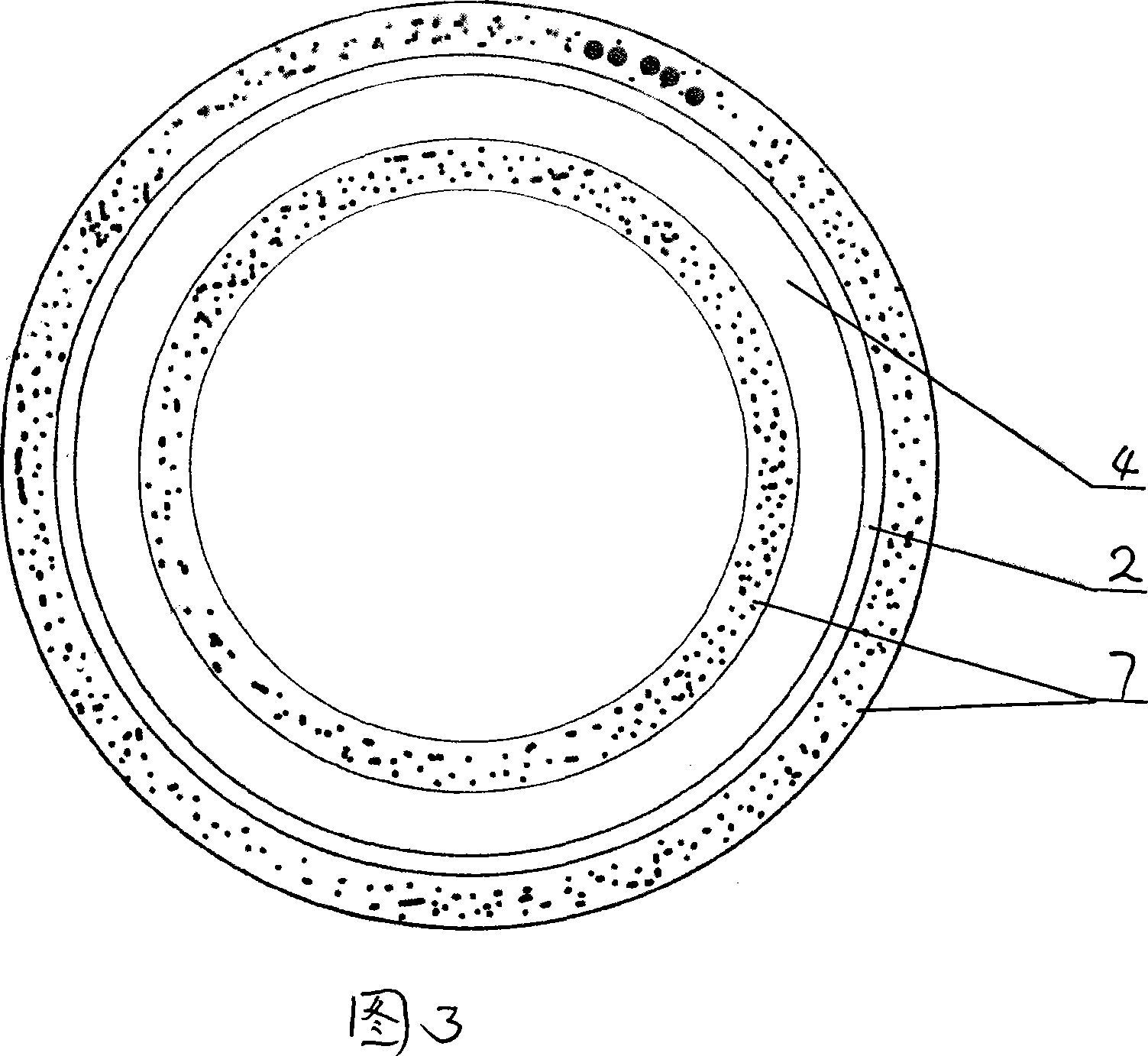

Vascular stent coating with drug sustained-release function and preparation method thereof

InactiveCN106139259AGood biocompatibilityNon-cytotoxicSurgeryCoatingsBiocompatibility TestingThrombus

The invention discloses a vascular stent coating with a drug sustained-release function, which is prepared from the following raw materials: polycaprolactone, chitosan, collagen, medicine, nano magnesium, nano titanium dioxide, dendrobium polysaccharide, tea polyphenol, dopamine, gelatin, nano zirconia, hirudin, and ethanol. The invention also discloses a preparation method of the vascular stent coating with the drug sustained-release function. The binding strength of the vascular stent coating and a substrate is 4.8 to 5.9 MPa, the binding strength of the vascular stent coating and the stent substrate is high, the degradation time of the vascular stent coating is 68 to 86 days, the vascular stent coating can be completely degraded after 90 days, the large-area shedding and swelling phenomena do not occur in the degradation process, the stability and biocompatibility are good, no cell toxicity, coagulation and thrombosis are formed, and no inflammatory response is generated.

Owner:林春梅

Large-scale production method for natural hirudin

ActiveCN104151425AAnticoagulant thrombolysisPromote blood circulationPeptide preparation methodsLeech-based protease inhibitorsClean waterHirudin

The invention discloses a large-scale production method for natural hirudin. The method comprises the following steps: placing a living hematophagous leech body which has thoroughly absorbed an induction liquid into a container and adding a certain amount of an emetic to allow the living hematophagous leech body to vomit saliva in its body, wherein the saliva is a crude natural hirudin product liquid, and the emetic is a zinc sulfate solution or a mixed liquor of zinc sulfate and ethanol; then taking out the living hematophagous leech body, flushing the living hematophagous leech body with clean water and continuing breeding the living hematophagous leech body for subsequent extraction; collecting the crude natural hirudin product liquid in the container; and adding a proper amount of a filler, carrying out mixing and then carrying out drying so as to obtain a finished powder product which is the natural hirudin product. According to the invention, a Markwardt thrombin direct titration method can be used to detect the content of active components in the natural hirudin product so as to guarantee stable quality and the curative effect of the product. The method has the characteristics of capacity of realizing large-scale production, simple process, a high recovery rate, low production cost and is capable of providing a safe and high-quality raw material for food, health food, medicines or cosmetics.

Owner:深圳金康道夫生物科技有限公司

Blood vessel medicine support

InactiveCN101147814AControl release speedReduce hyperplasiaStentsSurgeryBlood vesselBiomedical engineering

The present invention relates to a blood vessel medicine scaffold, including blood vessel scaffold, medicine and carrier, in which the medicine is coated on the surface of said blood vessel scaffold by means of carrier. The described medicine is rolimus medicine or mixture of rolimus medicine and taxol and / or hirudin, and said rolimus medicine is one of sirolimus, tacrolimus and eotarolimus or mixture of more than two kinds of them.

Owner:蔡绪旺

Hirudin skin-whitening moisture-keeping conditioning cream and production process thereof

ActiveCN103006511APromote regenerationPromote absorptionCosmetic preparationsToilet preparationsCuticleSkin color

The invention belongs to the field of cosmetics and particular relates to hirudin skin-whitening moisture-keeping conditioning cream and a production process thereof. The conditioning cream is prepared by oil phase raw materials such as squalane, polyoxyethylene stearyl alcohol ether, jojoba oil, white oil, ferulic acid derivative, cetostearyl alcohol and evening primrose oil, and water phase raw materials such as hirudin, oat polypeptide, a saffron crocus extracting solution, collagen polypeptide, caffeine derivative and an epidermal growth factor. The production process comprises the steps of heating, sterilization, stirring, dissolving, emulsifying, homogenizing, cooling, discharging, sampling, detection, filling, and packaging to obtain the conditioning cream. The conditioning cream can permeate into a corium layer of skin autonomously and directly, can be easily absorbed by the skin, can solve the problems such as the lusterless skin caused by pore blockage, has a better skin-whitening, moisture-keeping and skin-softening effect, and can promote regeneration of the skin and improve the skin quality; as multiple skin-whitening, moisture-keeping and skin-tone-improving raw materials are added, the conditioning cream can improve blood circulation and the skin elasticity, and has very good skin-whitening, moisture-keeping and skin-softening effects; and the production process is simple and easy to operate.

Owner:SHANDONG QIAOPAI GROUP

Anticoagulation fibroin material and preparation method

ActiveCN103285431APlay persistentGood anticoagulant effectSurgeryPharmaceutical containersProtein solutionImide

The invention discloses an anticoagulation fibroin material, which comprises components such as fibroin protein and hirudin. An anticoagulation fibroin material preparation method comprises the following steps: (1) preparing a fibroin protein solution with a concentration of 4-20%; (2) dissolving N-hydroxy succinimide in the fibroin protein solution in the step (1), uniformly stirring, standing, adding hirudin, and uniformly stirring to obtain a mixed solution; and (3) curing the mixed solution obtained from the step (2), adopting a methanol solution or an ethanol solution to carry out a dipping treatment, then soaking in deionized water, taking the obtained material, and carrying out air drying on the material to obtain the anticoagulation fibroin material. Compared with the fibroin material with no hirudin addition, the anticoagulation fibroin material of the present invention has the following advantages that: an anticoagulation performance is significantly increased, and hirudin in the anticoagulation fibroin material and activated fibroin protein can be directly subjected to stable covalent bonding through an amide bond so as to lastingly provide an anticoagulation effect.

Owner:常熟紫金知识产权服务有限公司

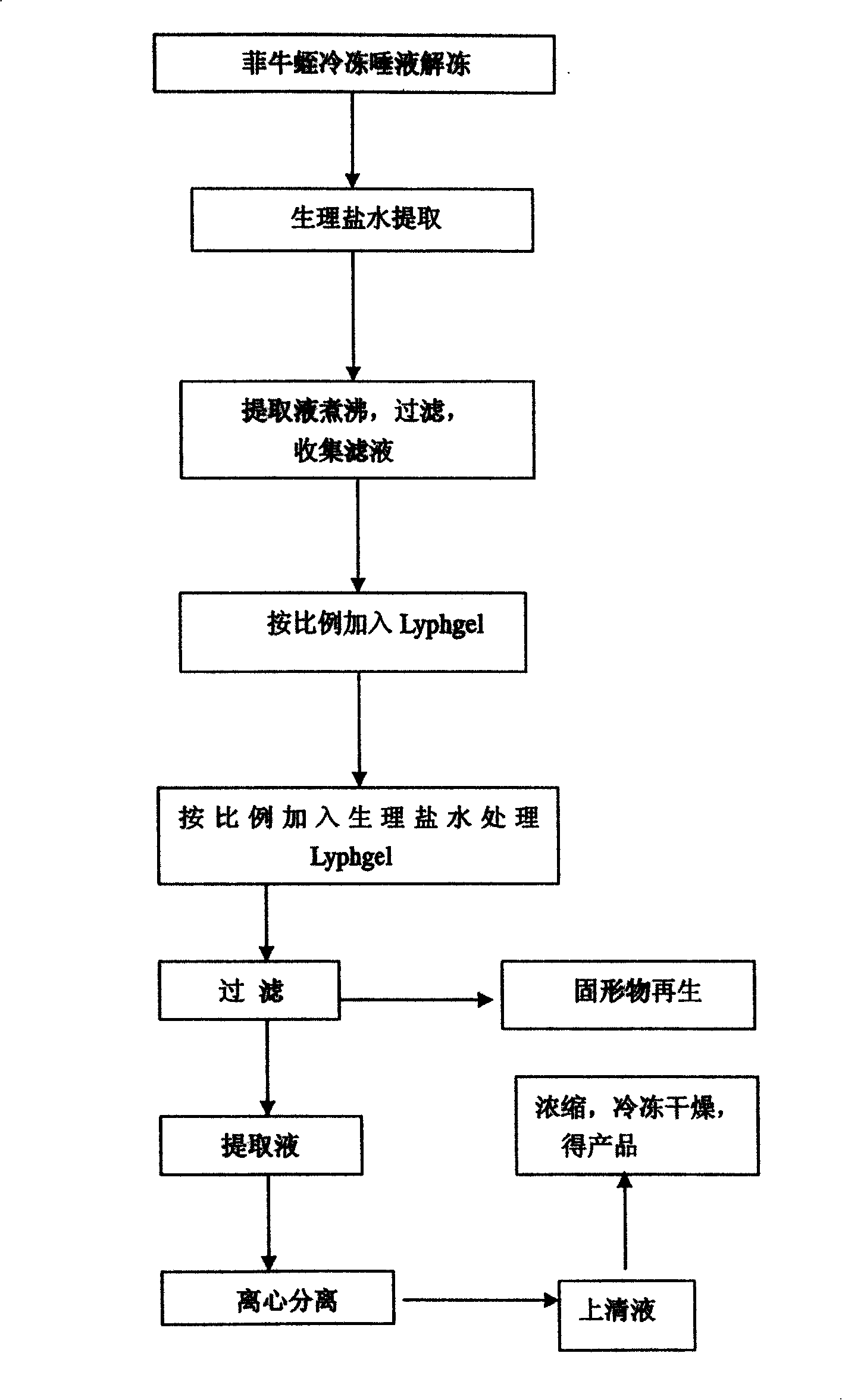

Technique for producing hirudin by using poecilobdella manillensis saliva as raw material

The invention discloses a hirudin manufacturing technique with the saliva of poecilobdella manillensis as the raw material, which belongs to the traditional Chinese medicine pharmacy field, relates to extraction of effective elements of animals, and aims at solving the problem that the traditional hirudin extraction technique is difficult to realize industrialized production. The technique adopts the saliva of poecilobdella manillensis to extract hirudin, and industrialized production can be realized. The saliva of poecilobdella manillensis is extracted through normal saline, the extracting solution is boiled and filtered, and the filter liquor is obtained. The solids is extracted through normal saline, and filtered, and the filter liquor is obtained. All the filter liquor produced in the two steps is combined together, Lyphgel is added to treat for twice, filtering is performed, and the filter liquor is removed. The solids is extracted through normal saline and filtered. After being boiled, the filter liquor is cooled down rapidly, and refrigerated over night. Centrifugation is performed, the supernatant is taken, and the filter liquor is frozen and dried into powder after decompression and condensation. The manufacturing technique is simple, the product activity is high, and has very strong thrombus dissolution function.

Owner:GUANGDONG OCEAN UNIVERSITY

Ointment of natural hirudin

InactiveCN1840175AStrong antithrombin effectNormal metabolismPeptide/protein ingredientsAerosol deliverySkin ulcerationsD ointment

Disclosed is a natural hirudin ointment, wherein the formula contains natural hirudin and conventional ointment matrix, and each 100g of the ointment contains natural hirudin 100-200000 international units. The ointment can be used for treating thrombotic phlebitis, burns, skin cracks, skin ulcer, chilblain, acne, acne and hemorrhoid.

Owner:周维海

Silk fibroin anticoagulant material and preparation method thereof

ActiveCN106730052AInhibition of thrombin activityPrevent neointimal hyperplasiaPharmaceutical containersMedical packagingCross-linkThrombus

The invention provides a preparation method of a silk fibroin anticoagulant material. The preparation method comprises the following steps: (S1) mixing a silk fibroin solution and polyethylene glycol diamine with a cross-linking agent for carrying out a reaction, then carrying out dialysis, and drying to obtain a polyethylene glycol diamine cationized silk fibroin material; (S2) dipping the polyethylene glycol diamine cationized silk fibroin material into a hirudin solution to obtain the silk fibroin anticoagulant material. Compared with the prior art, the preparation method provided by the invention protects a functional group at a thrombin bonding region from being affected by the reaction so as to prevent the influence on a structural domain bonded with the thrombin, and also can enable hirudin to be bonded onto the polyethylene glycol diamine cationized silk fibroin by means of an ionic bond with a stronger bonding force, thus achieving the effect of stably giving play to anticoagulation; therefore, the obtained silk fibroin anticoagulant material has an obvious function of inhibiting the activity of the thrombin, and is especially applied to prevention of the neointimal hyperplasia and postoperative thrombus formation of artificial blood vessels.

Owner:SUZHOU UNIV

Hirudin vacuum blood collection tube

InactiveCN101779959AEasy to operateRelieve painPharmaceutical containersMedical packagingHirudinHeavy metals

The invention discloses a hirudin vacuum blood collection tube. A hirudin coating is coated on the inner wall of a tube body, wherein the hirudin content is 0.005 to 1 milligram per milliliter of blood. The tube has the advantages that: 1, the tube can replace an anticoagulant commonly used in clinic, save the trouble of ordering in blood collection, apply to various kinds of examination, facilitate the operation of doctors and relive pains in patients; 2, as the hirudin used in the tube is a biological reagent, so the examination result is reversible and once the clinic examination fails, examination can be performed again directly without drawing block again for test; 3, the anticoagulation time is as long as more than 7 days; 4, the interference with blood is zero so as not to cause hemolytic reaction; 5, impurities and heavy metals are avoided; 6, more than 300 examination items can be performed; and 7, the biological reagent is environmental-pollution free.

Owner:刘金雪 +1

Polysulfone dialysis membrane as well as preparation method and application thereof

InactiveCN107174983AReduce the amount of adsorptionWill not cause deteriorationSemi-permeable membranesDialysis membranesPolysulfone membrane

The invention provides a polysulfone dialysis membrane as well as a preparation method and application thereof. The polysulfone dialysis membrane is formed by connecting a bioactive molecule onto a polydopamine surface modified polysulfone membrane, wherein the bioactive molecule is any one or a combination of at least two of human serum albumin, bovine serum albumin, natto kinase, lumbrokinase, thrombomodulin and hirudin. The polysulfone dialysis membrane provided by the invention can guarantee the activity of the bioactive molecule and has a good anticoagulation function; the pure water flux is 65L / m<2>.h.bar to 140L / m<2>.h.bar, the retention rate on BSA (Bull Serum Albumin) is 95 percent or above and the retention rate on lysozyme is 25 percent to 35 percent; compared with an unmodified polysulfone membrane, the adsorption amount on the BSA, fibrinogen and blood platelets is remarkably reduced. The method provided by the invention has moderate conditions and a simple preparation process; the deterioration of membrane structure and performance and the inactivation or denaturation of bioactive macromolecules are not caused; the polysulfone dialysis membrane has a wide application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Anti-hyperlipidemia health-care product

InactiveCN102716471ALower blood fatSmall side effectsPeptide/protein ingredientsMetabolism disorderBiotechnologyHirudin

The invention relates to an anti-hyperlipidemia health-care product. The technical scheme disclosed by the invention is that the anti-hyperlipidemia health-care product is prepared from the following crude drugs in parts by weight: 150 parts of nattokinase, 40-60 parts of hirudin, 20-40 parts of lumbricus, 40-60 parts of medlar and 10-30 parts of hawthorn. The crude drugs are evenly mixed in parts by weight to prepare tablets, capsules or pills. According to the anti-hyperlipidemia health-care product, through adopting the technology of homology of medicine and food, blood fat can be lowered, and the blood viscosity reaches within a normal range through the synergistic effect between traditional Chinese medicines and food. As the traditional Chinese medicines are combined with the food, the toxic and side effects are small, whereas the anti-hyperlipidemia curative effect is high.

Owner:童长虹

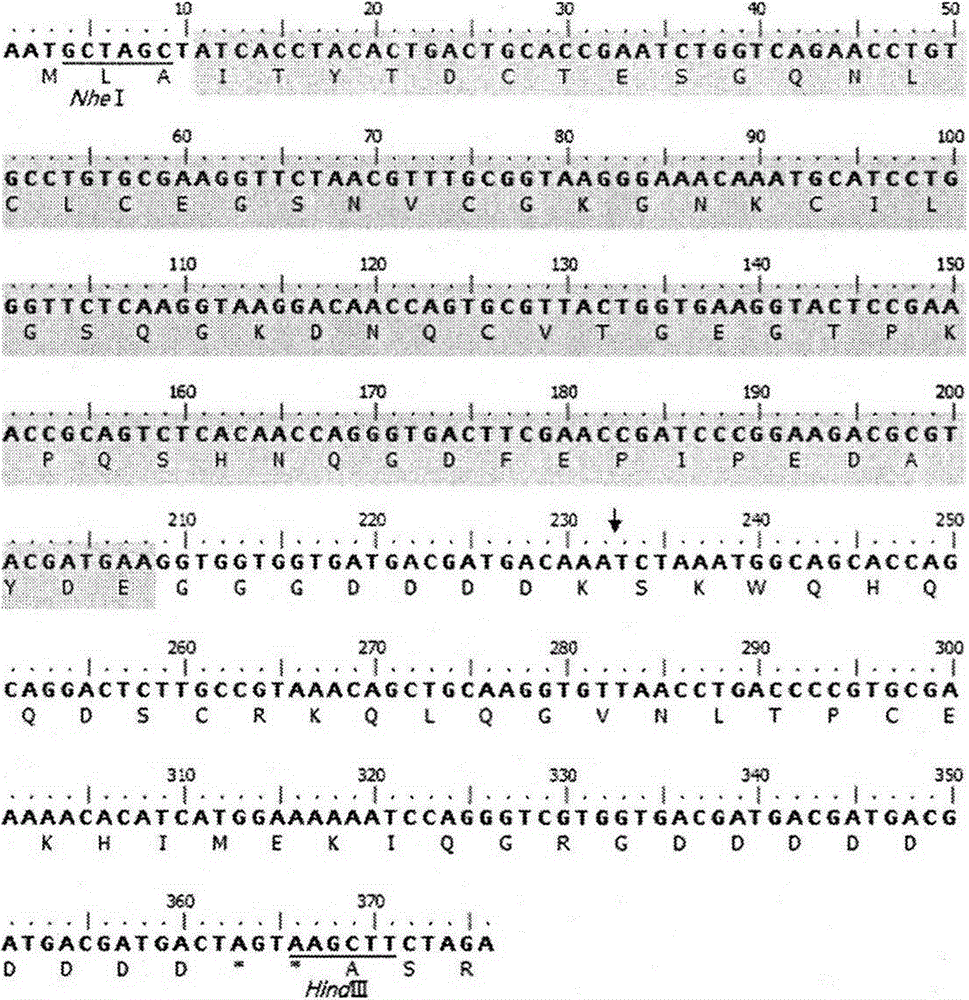

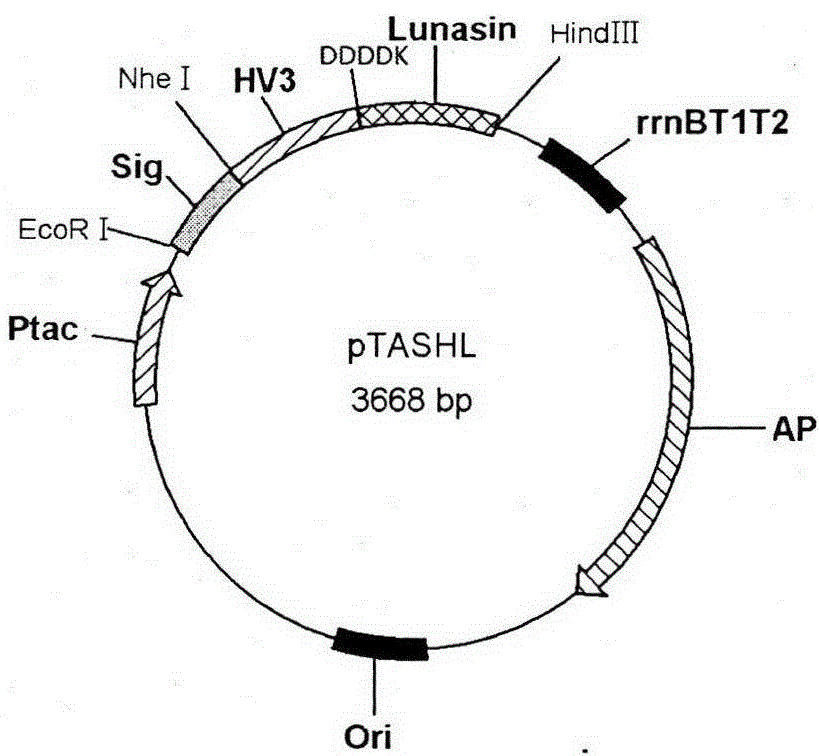

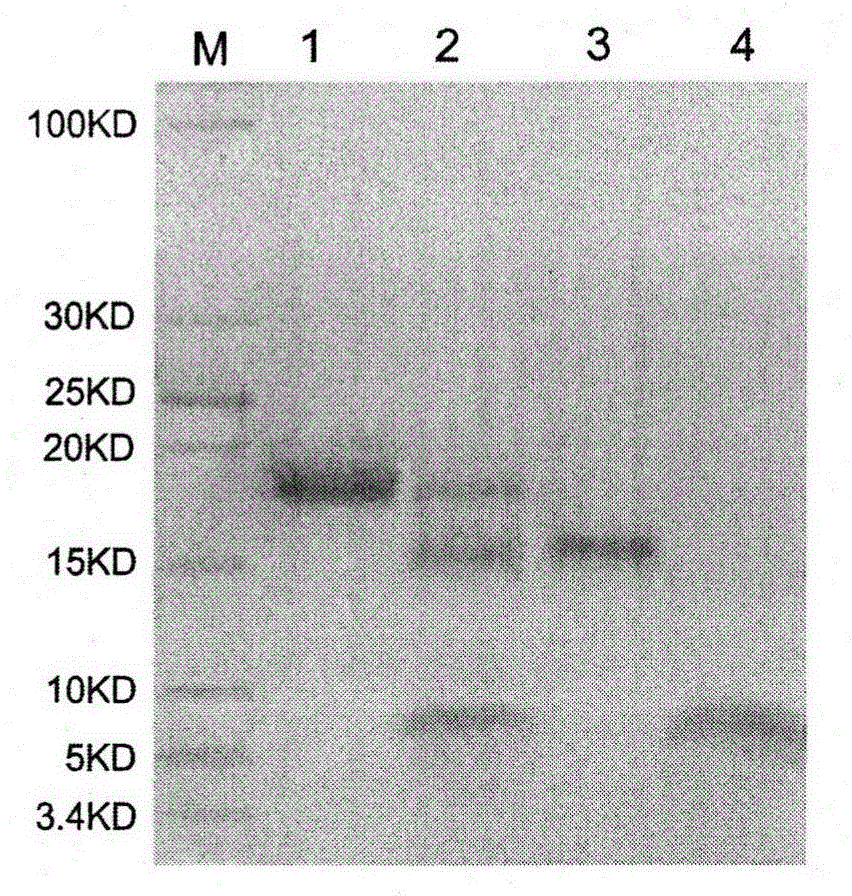

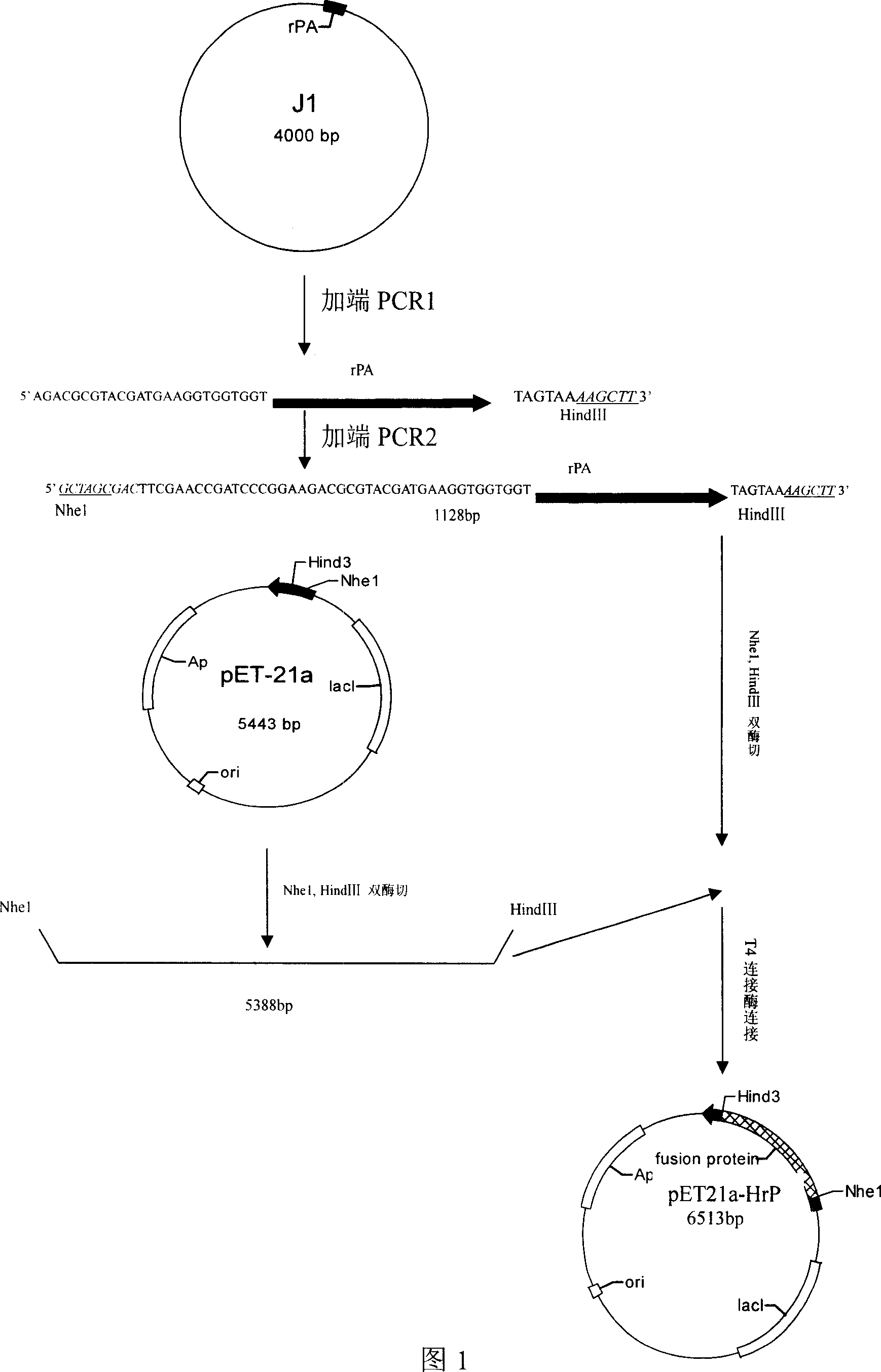

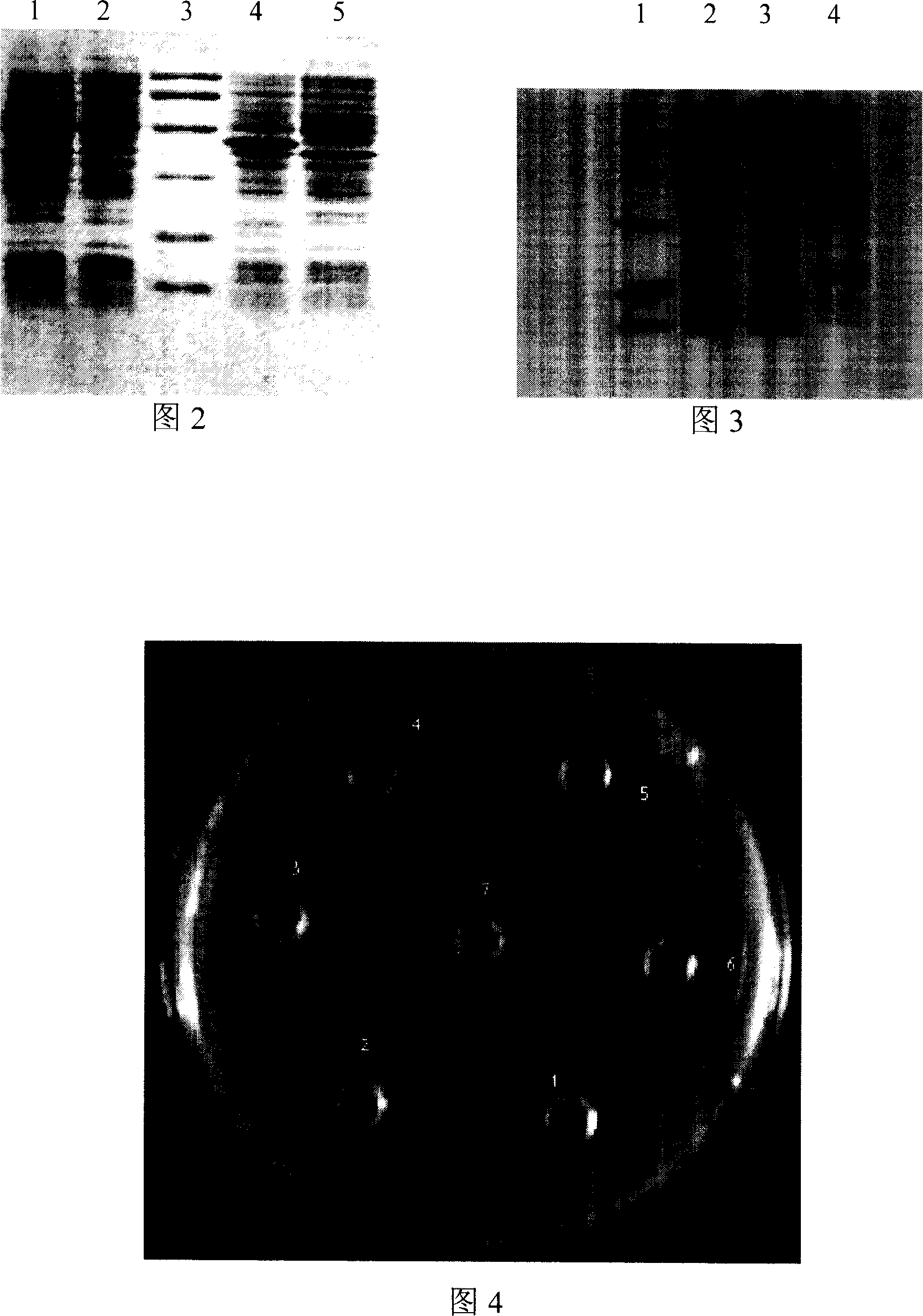

Method of preparing recombinant small molecular protein or polypeptide with hirudin as fusion partner

InactiveCN103819546APlant peptidesFusions for enhanced expression stability/foldingFusion Protein ExpressionProtein target

The invention provides a new method of fusion expressing a small molecular protein (polypeptide). The new method is characterized by comprising the following steps: using hirudin as a fusion partner (label), splicing the protein (polypeptide) with a small molecular mesh to the downstream of the hirudin as the fusion partner to carry out fusion expression, designing a connecting peptide (which contains protease or a chemical cutting site or intein as a self-cuttable protein intron) between the fusion partner and a target protein (polypeptide), and releasing the target protein (polypeptide) by restriction enzyme digestion or chemical cutting or induced self cutting after fusion protein expression. The new method has the advantages that (1) as the hirudin as the fusion partner (label) is smaller (with the molecular weight of 7Kd), the rate of the protein (polypeptide) with the small molecular mesh accounting for a fusion protein can be effectively increased, and the yield of the target small molecular protein (polypeptide) is finally increased; (2) the hirudin still has the anticoagulant activity after being fused as the fusion partner (label), and the expression and the purification of the fusion protein can be conveniently detected and traced in real time.

Owner:CHINA PHARM UNIV

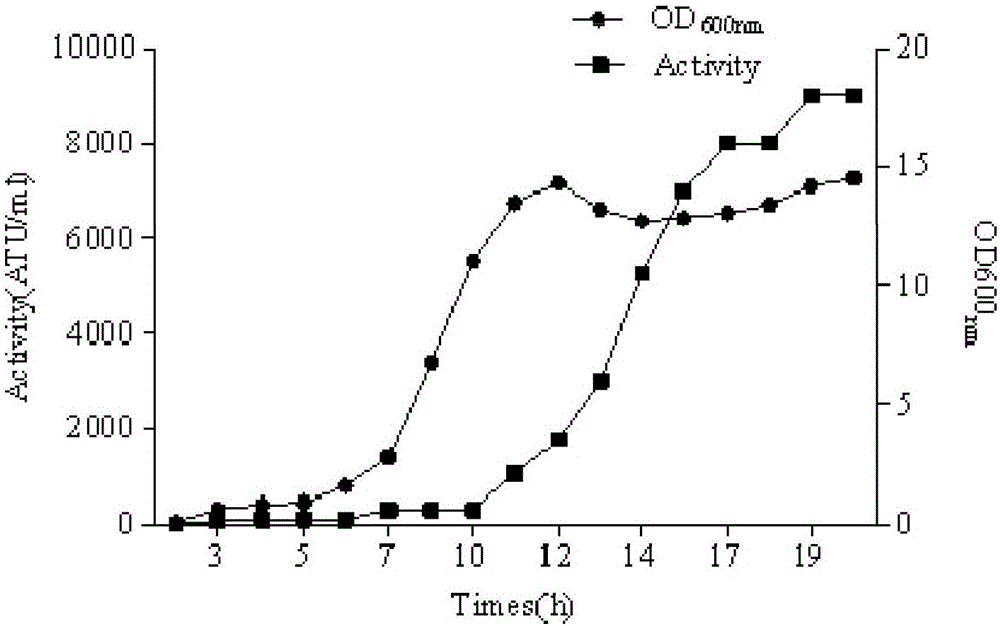

Double function infusion protein for thrombolysis and anticoagulation , its preparation method and uses

The invention discloses a fusing protein with plasminokin and anticoagulant function and DNA sequence to code the fusing protein, carrier with the DNA sequence and making method of fusing protein, which provides the application of fusing protein to prepare functional drug with peptide segment of continuous amino acid sequence as connecting structure, wherein the fusing protein connects 10-12 amino acids in the 55-66th amino acids sequence at IIIC end of hirudin with r-PA as t-PA bobbing mutant.

Owner:CHINA PHARM UNIV

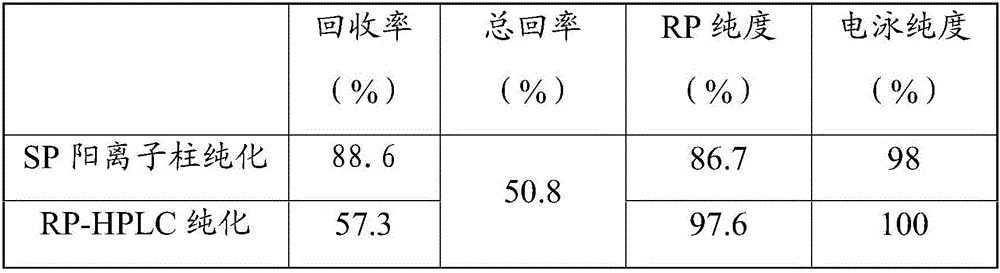

Method for separating and purifying recombined hirudin suitable for industrial production

InactiveCN106834395AHigh puritySuitable for industrial productionPeptide preparation methodsFermentationHigh volume manufacturingFermentation

The invention discloses a method for separating and purifying recombined hirudin suitable for industrial production and belongs to the field of biotechnological pharmaceutics. The method comprises the following steps: taking HV3 glycerinum strain for culturing and fermenting, thereby acquiring fermentation liquor; centrifuging the fermentation liquor, thereby acquiring fermentation liquor supernate; adjusting pH of the fermentation liquor supernate with 12M hydrochloric acid; and putting into a fermentation tank and heating, thereby effectively removing impure protein, greatly reducing the difficulty of the subsequent purifying process and increasing the maneuverability of the large-scale production process. The fermentation liquor is taken out from the tank and is placed at 2-8 DEG C, and then a method for filtering through a filter is adopted, so that the impure protein and lipid matters are removed and the maneuverability of the large-scale production process is promoted. The separating and purifying process designed according to the structural characteristics of hirudin provided by the invention is capable of effectively increasing the protein purity and greatly reducing the pigment content; the process is simple and convenient in operation; and the cost is lower.

Owner:程度胜 +1

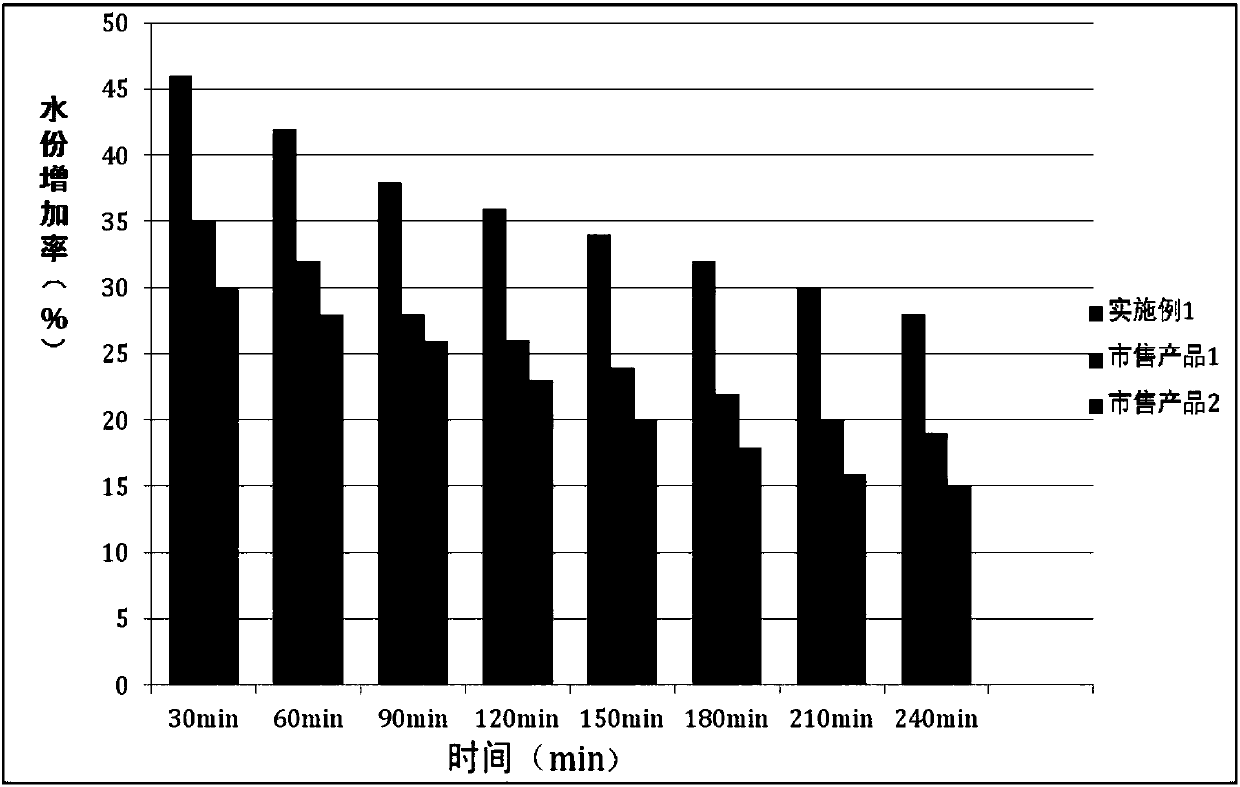

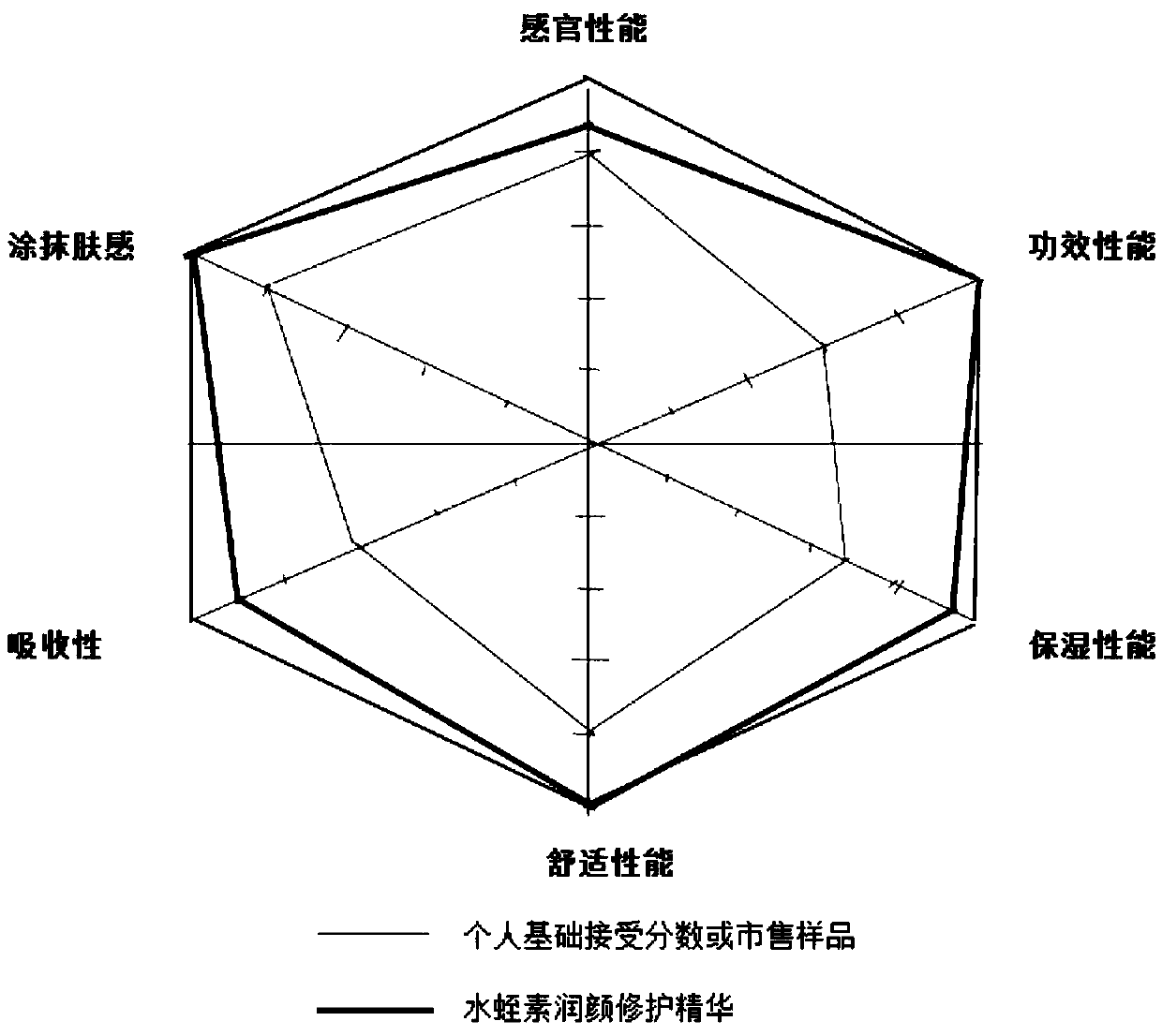

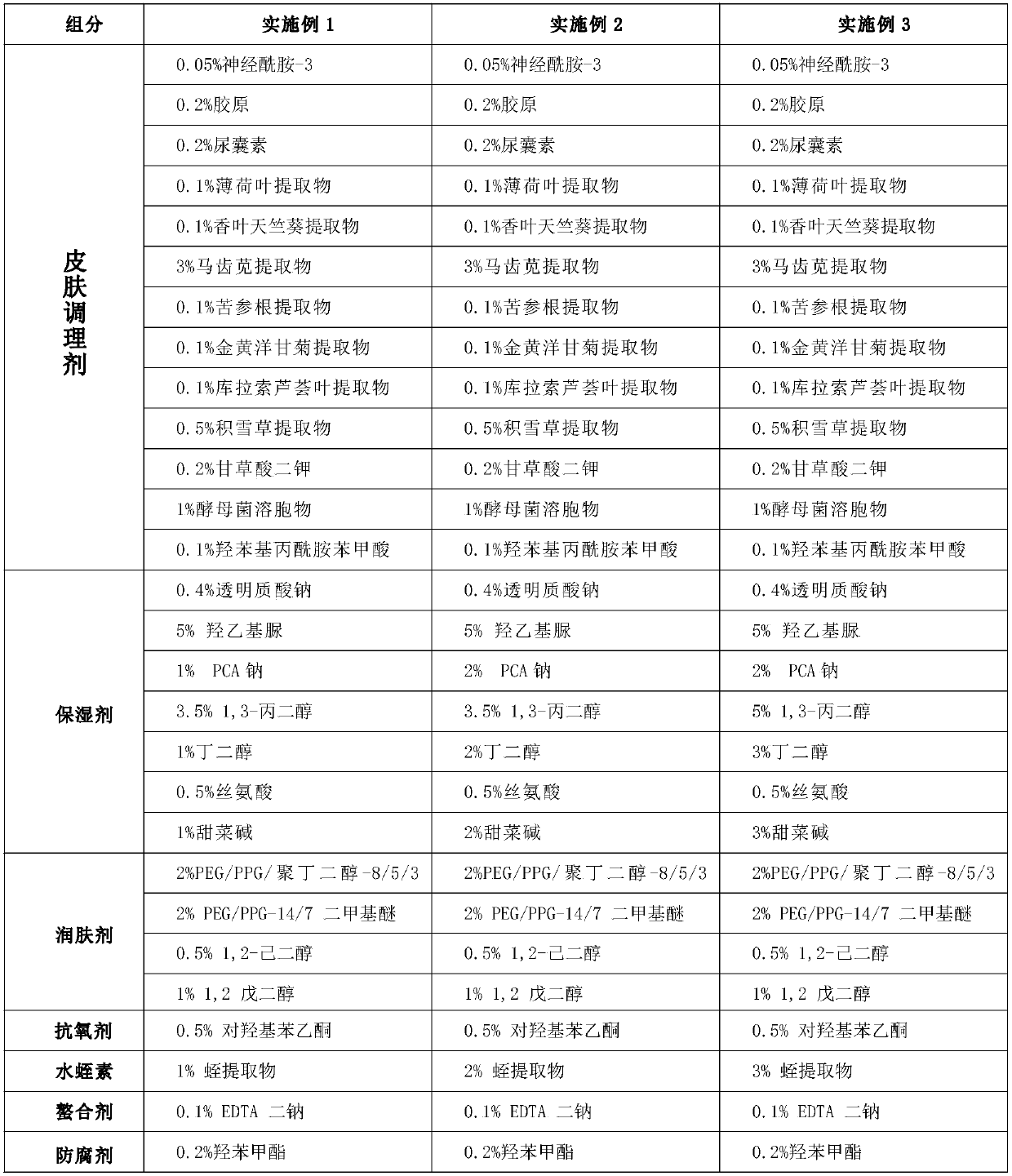

Hirudin repairing essence for skin nourishing and moisture preservation

InactiveCN107854326AEffective absorptionHigh glossCosmetic preparationsToilet preparationsAntioxidantPermeation

The invention relates to the field of professional cosmetic skin care, and specifically relates to a hirudin repairing essence for skin nourishing and moisture preservation. The hirudin repairing essence for skin nourishing and moisture preservation is prepared from 5-20% of skin conditioning agent, 3-10% of moisture preservation agent, 0.5-10% of patent hirudin, 1-10% of skin nourishing agent andthe balance water. The essence can also contain an antioxidant with the mass percent lower than or equal to 1%, a chelating agent with the mass percent lower than 1% and a preservative with the masspercent lower than or equal to 0.5%. The micromolecular hirudin, sodium hyaluronate with superhigh concentration, various natural plant essences and the like are adopted as raw materials, the essencecan permeate into the skin and provide demanded nutrients for the skin under the cooperation of a skin self-permeation technique to facilitate the blood circulation function, smooth fine aging wrinkles, brighten dark skin and achieve the functions of moisture preservation and skin relief.

Owner:乳山寰海生物科技有限公司

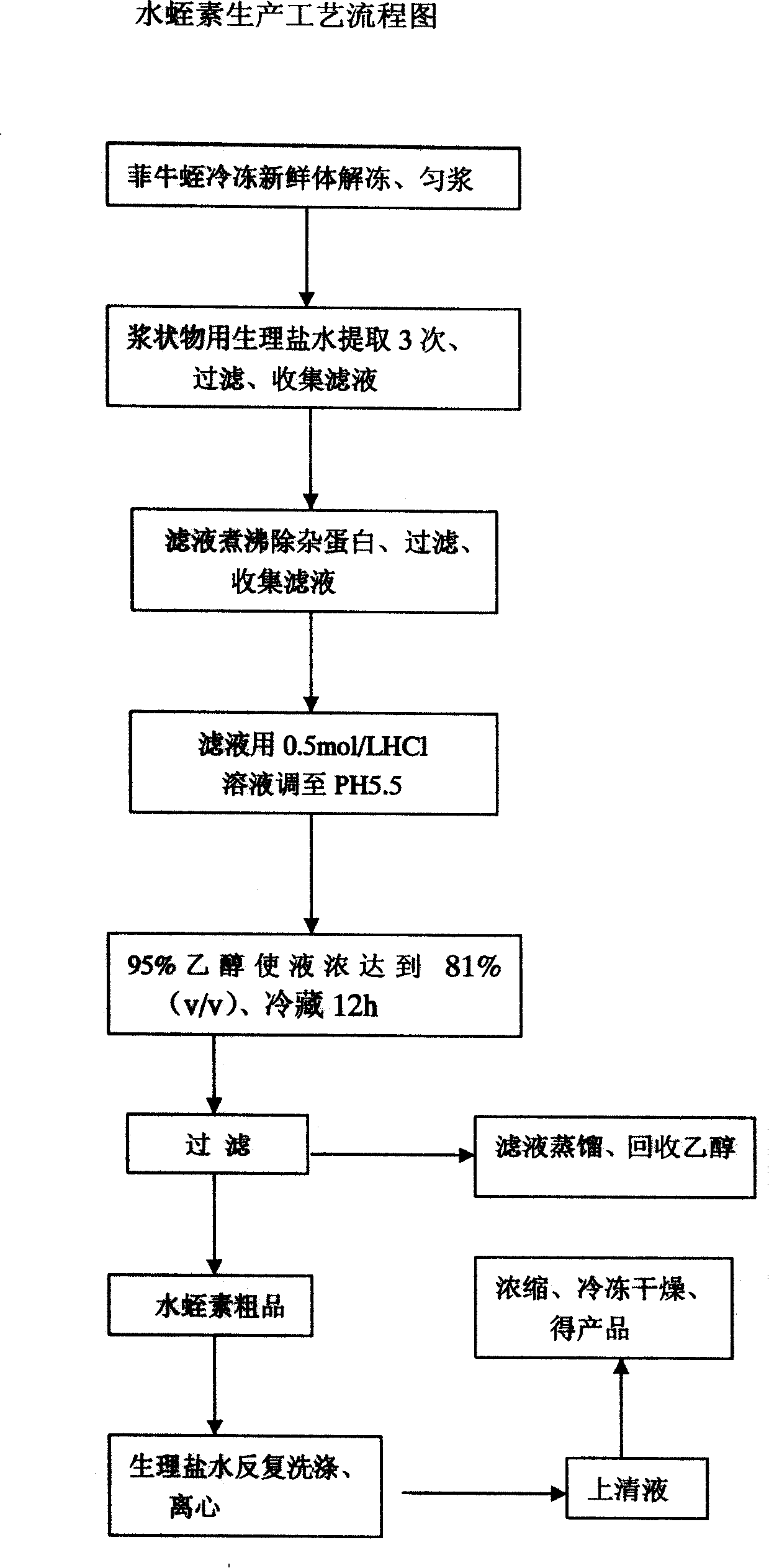

Technique for producing hirudin by using poecilobdella manillensis frozen fresh body as raw material

The invention relates to a hirudin production process that a Hirudinaria manillensis refrigerated fresh body is taken as raw material, which belongs to the pharmaceutical field of the traditional Chinese medicine, and relates to the active constituent extraction of animals. The invention aims at solving the problem that the traditional hirudin extraction process is difficult to be applied to the industrialized production. The process adopts the method that the hirudin is extracted from the whole Hirudinaria manillensis, thus the industrialized production can be operated. The Hirudinaria manillensis is rectified, and the pulp is distilled for three times with normal saline, and filtered. The filtrate is boiled and filtered, and protein is removed from the filtrate. The filtrate is collected, and after freezing, concentration and alcoholization, and the hirudin crude product is obtained. The hirudin crude product is washed with the normal saline, and then washing solution is concentrated, and finally the product is obtained through freezing and drying. The production process method of the hirudin is simple, and the quality of the end product is qualified. The pharmacology experiment result indicates that the hirudin extracted by utilizing the process has good pharmacological action.

Owner:GUANGDONG OCEAN UNIVERSITY

Method for extracting high-anticoagulation-activity hirudin from natural leeches

InactiveCN101974085AIncrease profitPeptide preparation methodsLeech-based protease inhibitorsNeutral proteaseFiltration

The invention relates to a method for extracting high-anticoagulation-activity hirudin from natural leeches, which comprises the steps that two kinds or a plurality of kinds of substances in sodium chloride, acetyl cysteine hydrochloride monohydrate, lysine, neutral protease and papain are combined and dissolved in deionized water to be prepared into stimulation liquid; the weight percentage concentration of each substance in the stimulation liquid is 0.01 to 5%, wherein the enzyme concentration is 100U to 300U / ml; the living leeches are weighed and placed into a container; the stimulation liquid is added according to the weight and volume ratio of the leeches to the stimulation liquid of 1 to (1-5); the leeches secrete exudate after the stimulation is carried out for 3 hours; the exudateis separated to obtain the hirudin crude product through 16000 to 20000r / min centrifugation; the hirudin crude product is micro-filtered through a stainless steel membrane with the thickness of 0.2 micrometer; the micro-filtration is carried out through an organic membrane with the molecular weight of 10000 to 3000 Dalton; the reverse osmosis, the nano-filtration and the concentration are carriedout; starch for drugs is added according to the weight and volume ratio of the solid to the liquid of 1 to (6-10) to allocate the mixture; and the spray drying is carried out to obtain the leech finished product. Finally, the extraction yield of the hirudin is above 30%, and the activity unit of the product is stabilized between 600AT-U / g to 1000AT-U / g.

Owner:南宁市和兰记生物科技有限公司

Method for extracting hirudin by stimulating living leech with electricity

InactiveCN102146136AKeep aliveHigh purityPeptide preparation methodsLeech-based protease inhibitorsElectricityBiological body

The invention relates to a method for extracting hirudin by stimulating a living leech with electricity. By utilizing the simulating effect of current on organism glands, a way for simulating a living leech to extract high-purity hirudin at mass by direct weak current is directly used, and the living character of the leech is maintained, therefore, the production process of hirudin is simplified,the product purity is improved, the wild leech resources are recycled, the production cost is reduced and the problem of seasonal disorder of production is solved. The hirudin extracted by using the method is subjected to nanofiltration water removal and decompression spray drying to be made into powdery hirudin with the antithrombin activity of 800AT-U / g and liquid hirudin with the antithrombin activity of 1,000AT-U / g when protective agents are added in the liquid hirudin.

Owner:南宁乙翔生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com