Patents

Literature

46results about How to "Faster filling time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

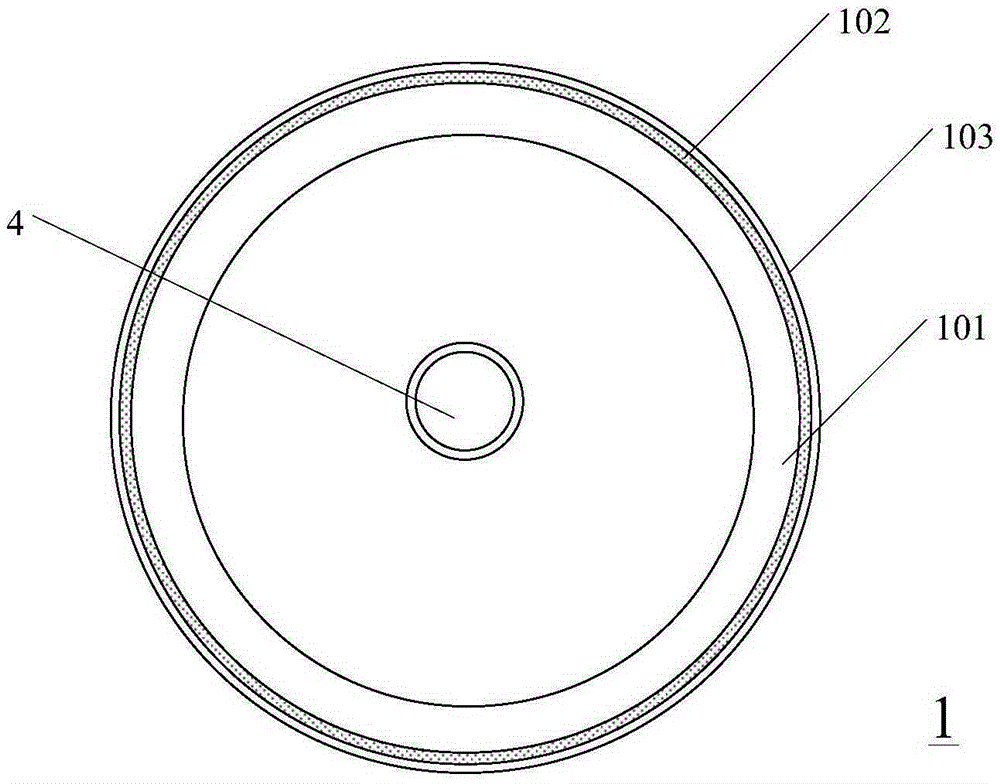

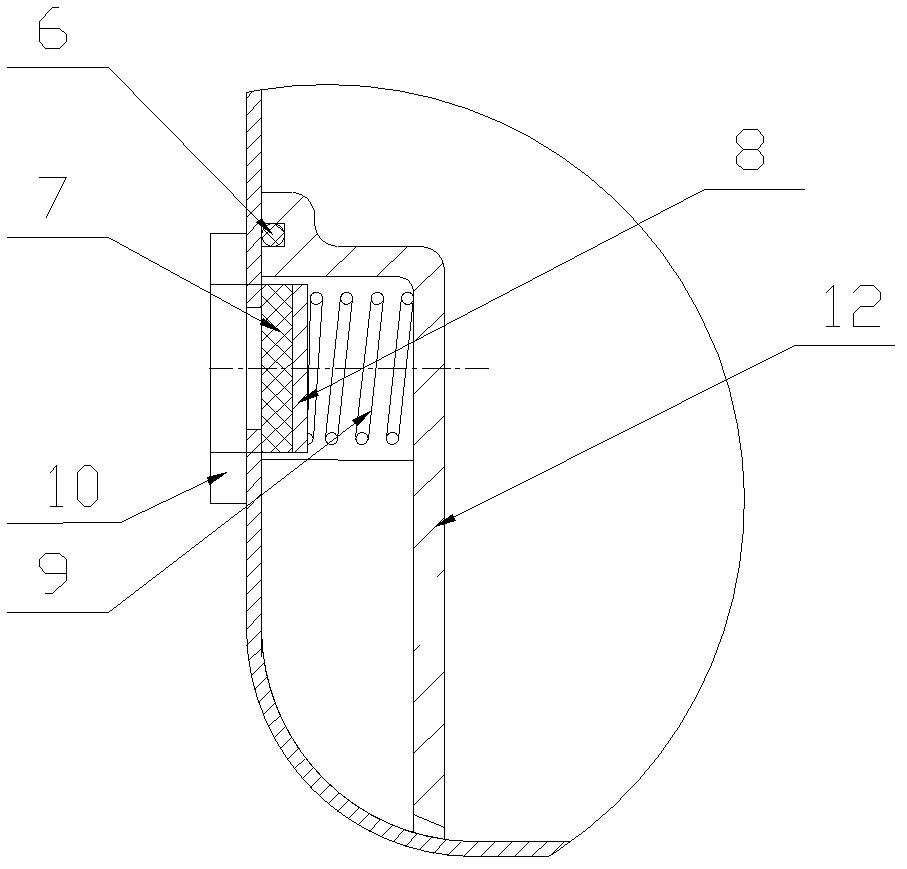

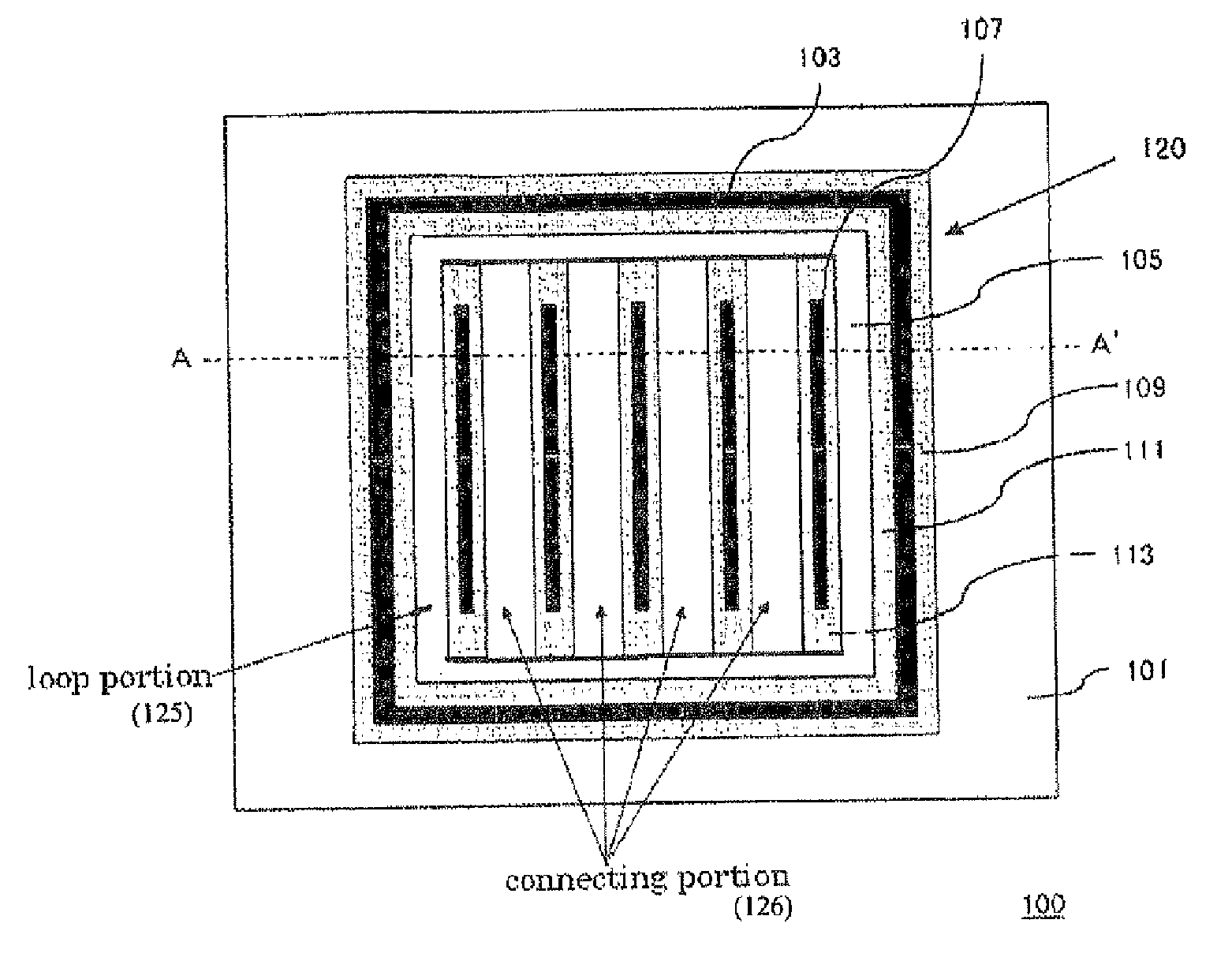

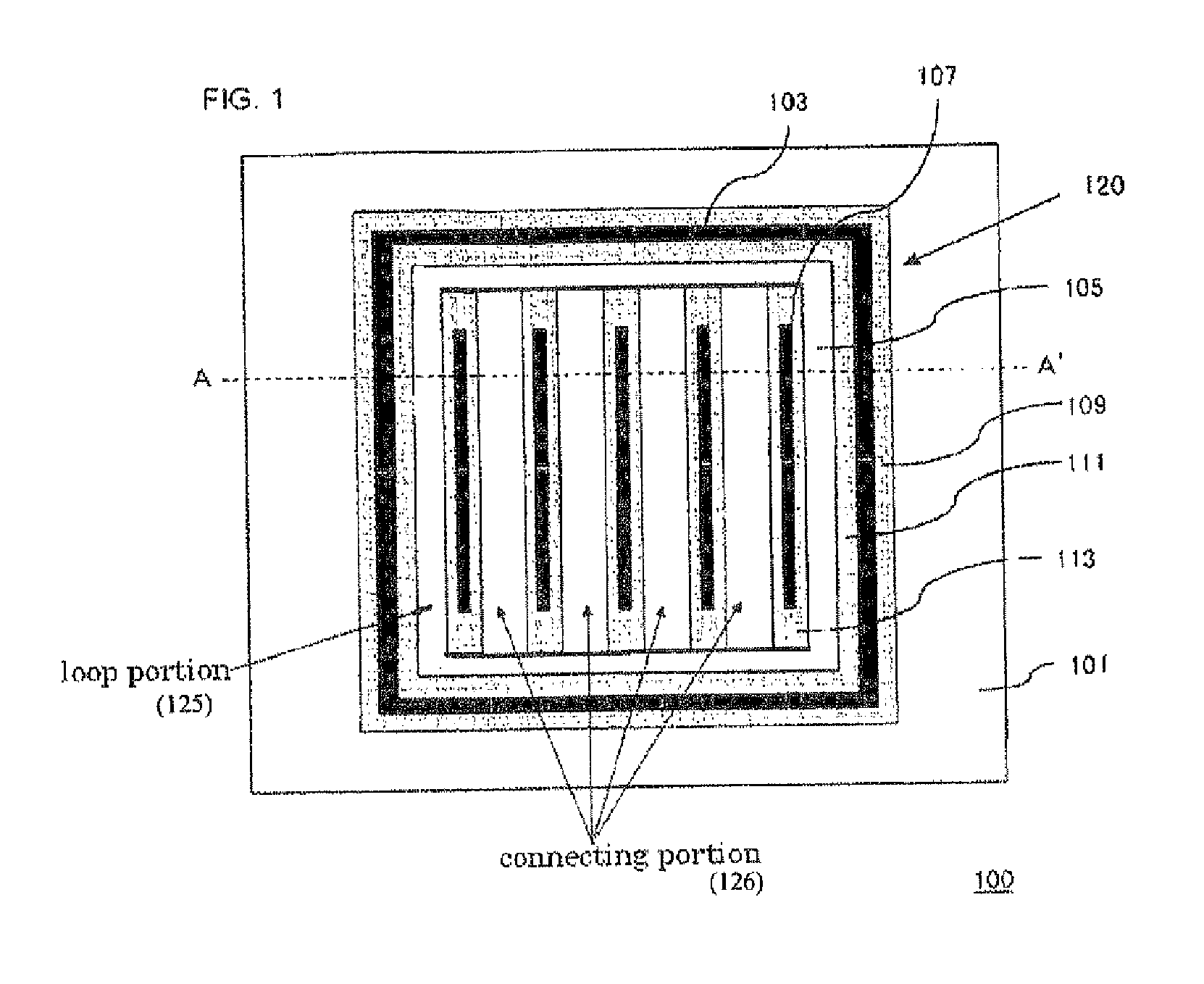

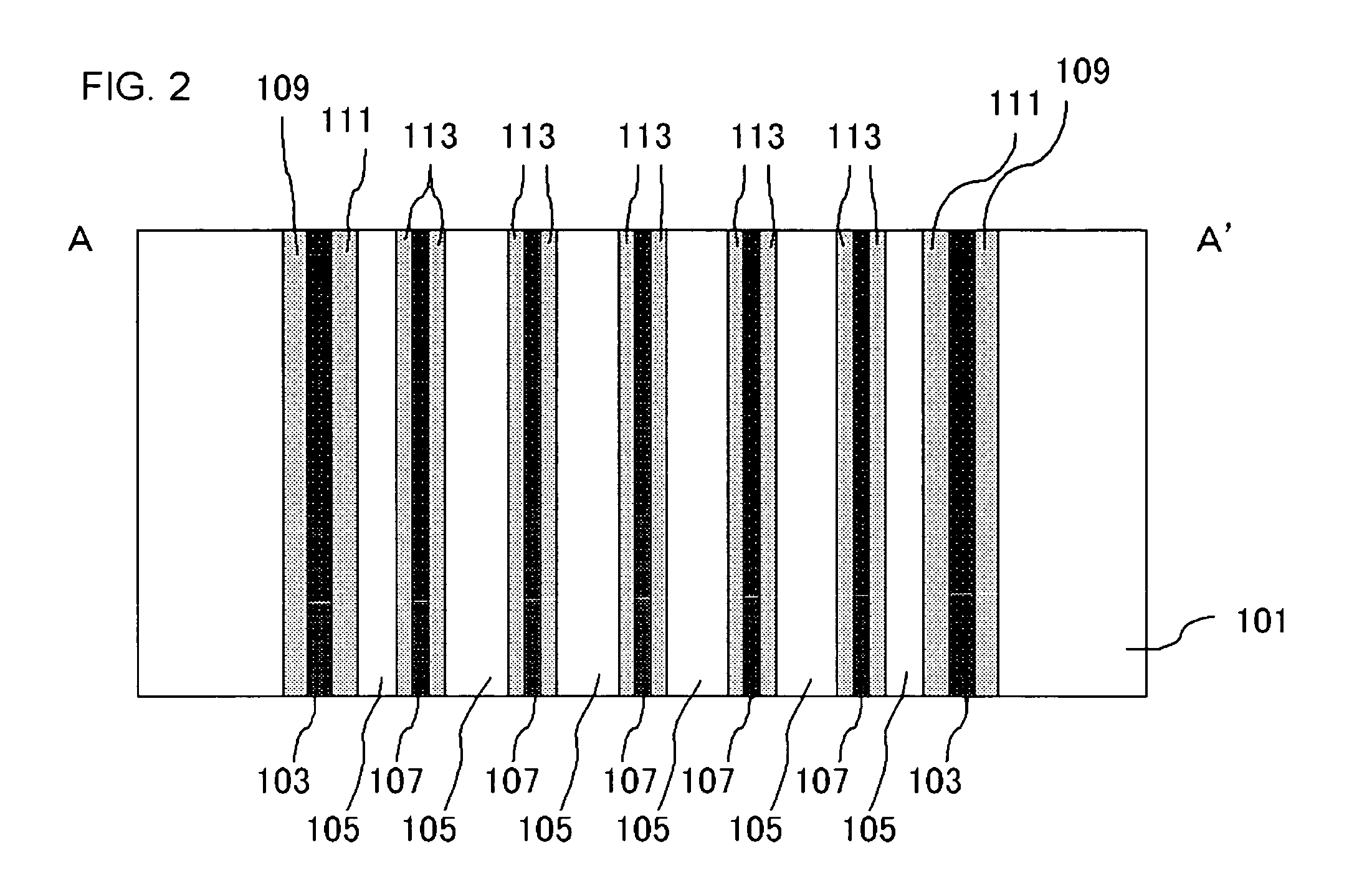

Semiconductor device and semiconductor module employing thereof

ActiveUS20060006539A1High densityReduce areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

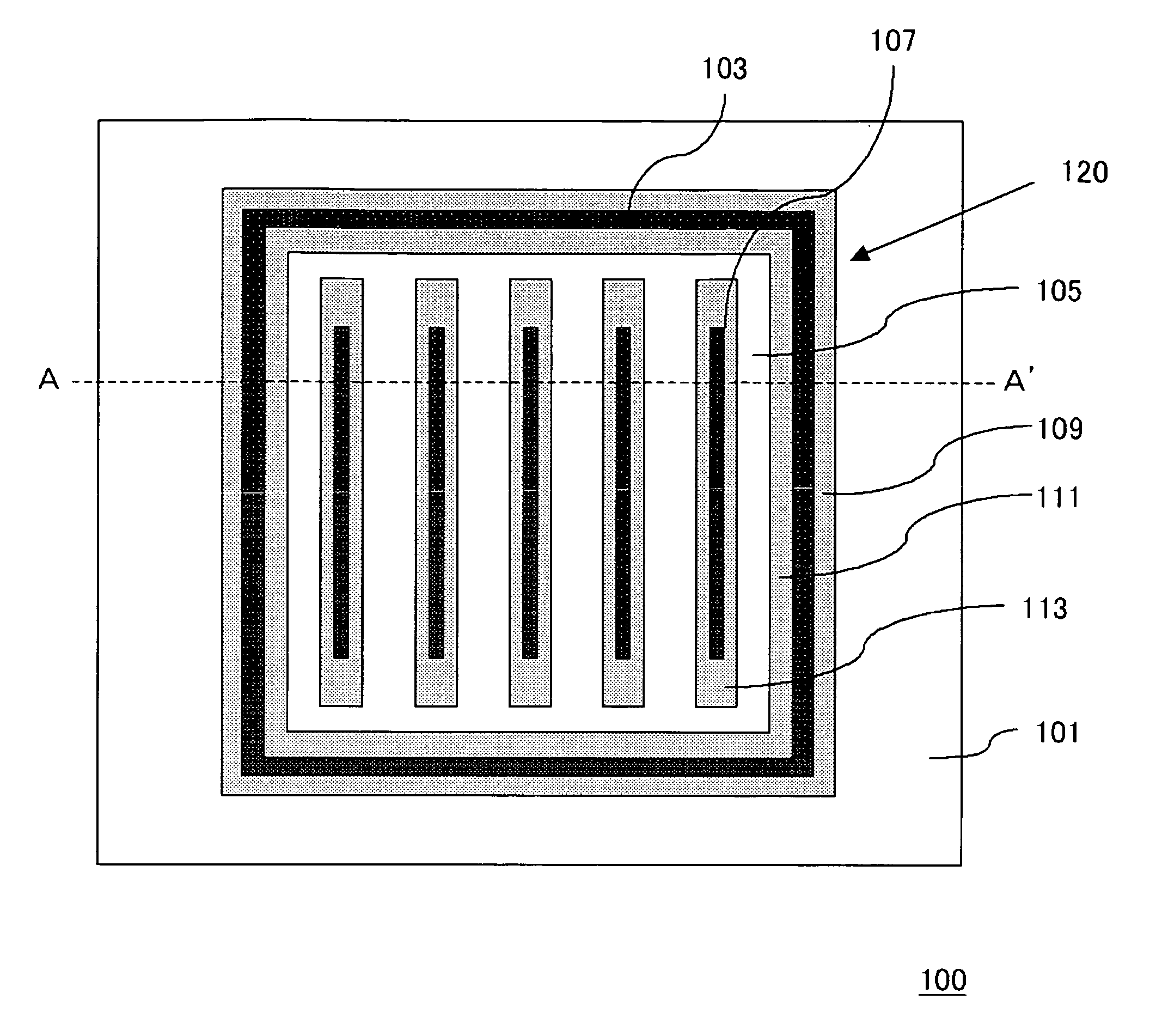

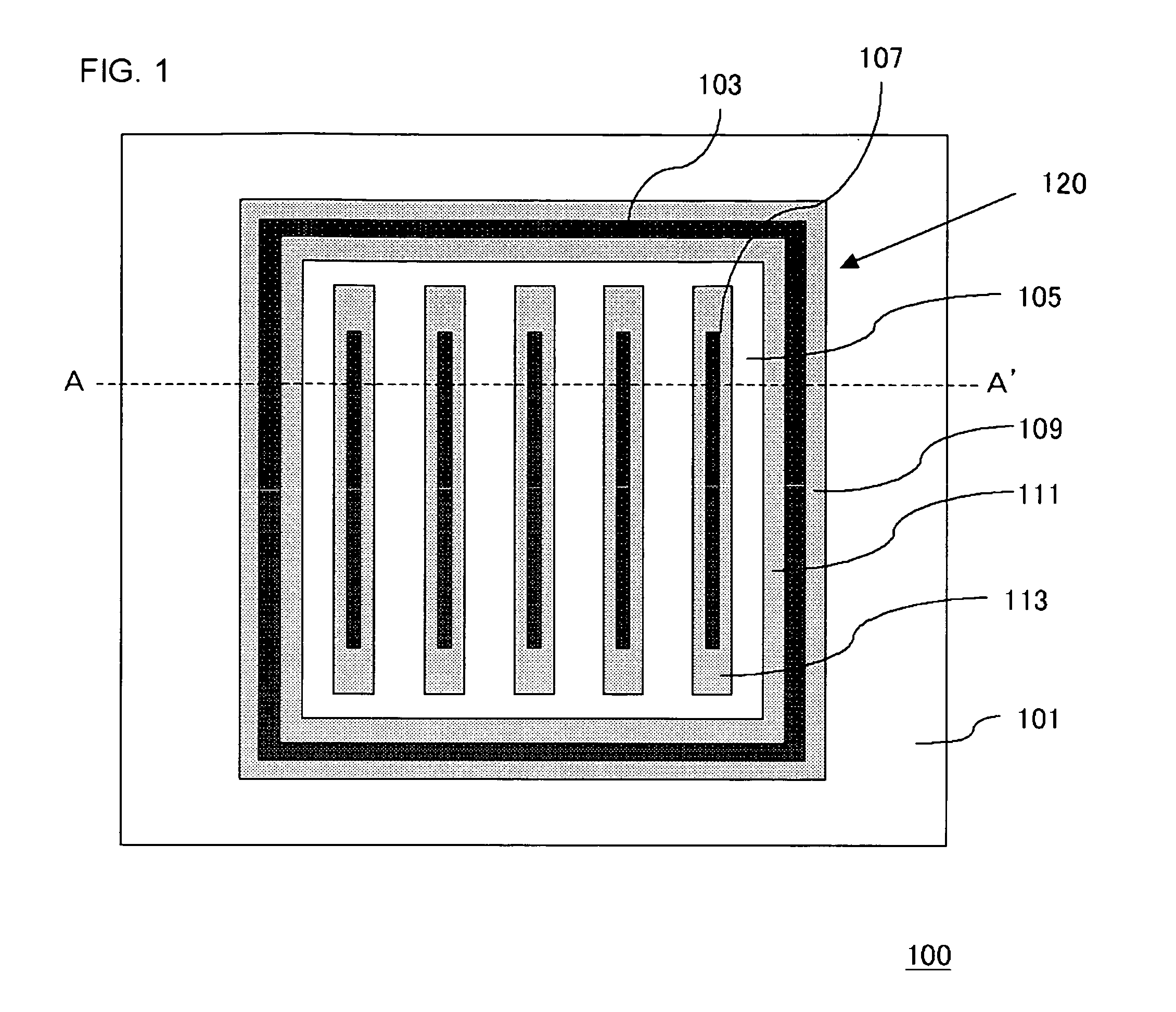

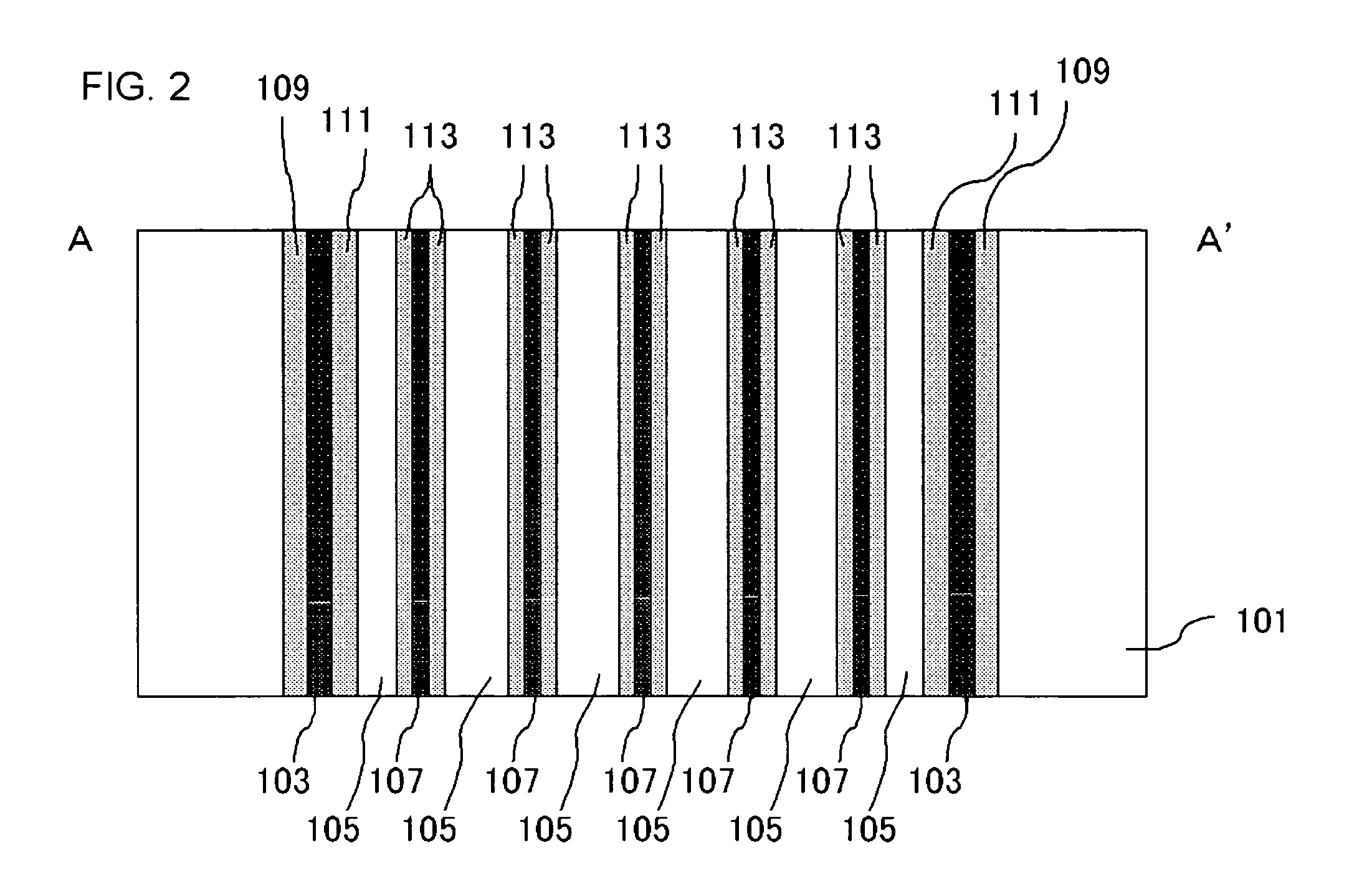

A semiconductor device 100 is provided with a silicon substrate 101 and a structure 120 filled in a through hole that has a rectangular cross section and extends through the silicon substrate 101. The structure 120 comprises a pipe-shaped through electrode 103, stripe-shaped through electrodes 107, silicons 105, a first insulating film 109, a second insulating film 111 and a third insulating film 113. The pipe-shaped through electrode 103 is utilized as a pipe-shaped electric conductor that extends through the silicon substrate 101. In addition, the stripe-shaped through electrodes 107 are provided in the interior of the pipe-shaped through electrode 103 so that the stripe-shaped through electrodes 107 extend through the silicon substrate 101 and is spaced away from the pipe-shaped through electrode 103. A plurality of through electrodes 107 are provided in substantially parallel within the inner region of the pipe-shaped through electrode 103.

Owner:TESSERA ADVANCED TECH

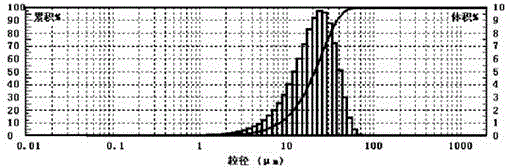

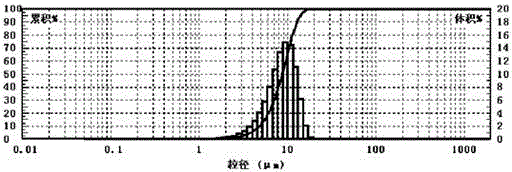

L-polylactide filler for injection and preparation method thereof

ActiveCN105879124AExtended shelf lifeGood stabilityPharmaceutical delivery mechanismProsthesisSodium hyaluronateAloin

The invention discloses an L-polylactide filler for injection and a preparation method thereof. Active ingredients of the filler are L-polylactide particles, honeycomb HA and a synergist, the honeycomb HA is obtained by alcohol precipitation and drying of a water solution formed by mixing sodium hyaluronate high in molecular weight and sodium hyaluronate low in molecular weight in an alkaline condition, and the synergist is mannitol or a mixture of mannitol and aloe polysaccharide with a mass ratio of 1:0.05-0.12. The filler is simple to prepare, shorter in re-suspension time, long in validity period and more convenient to use.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

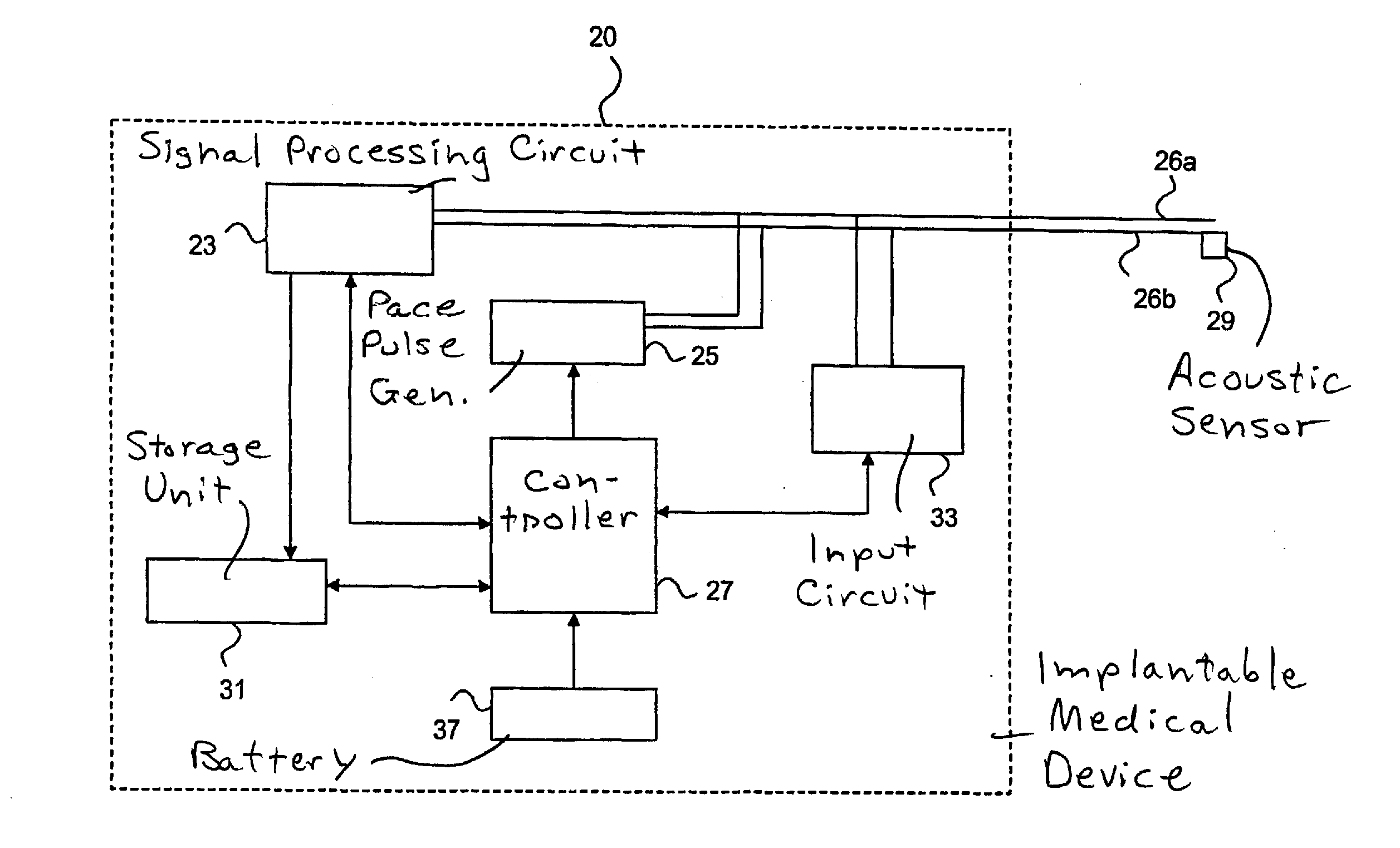

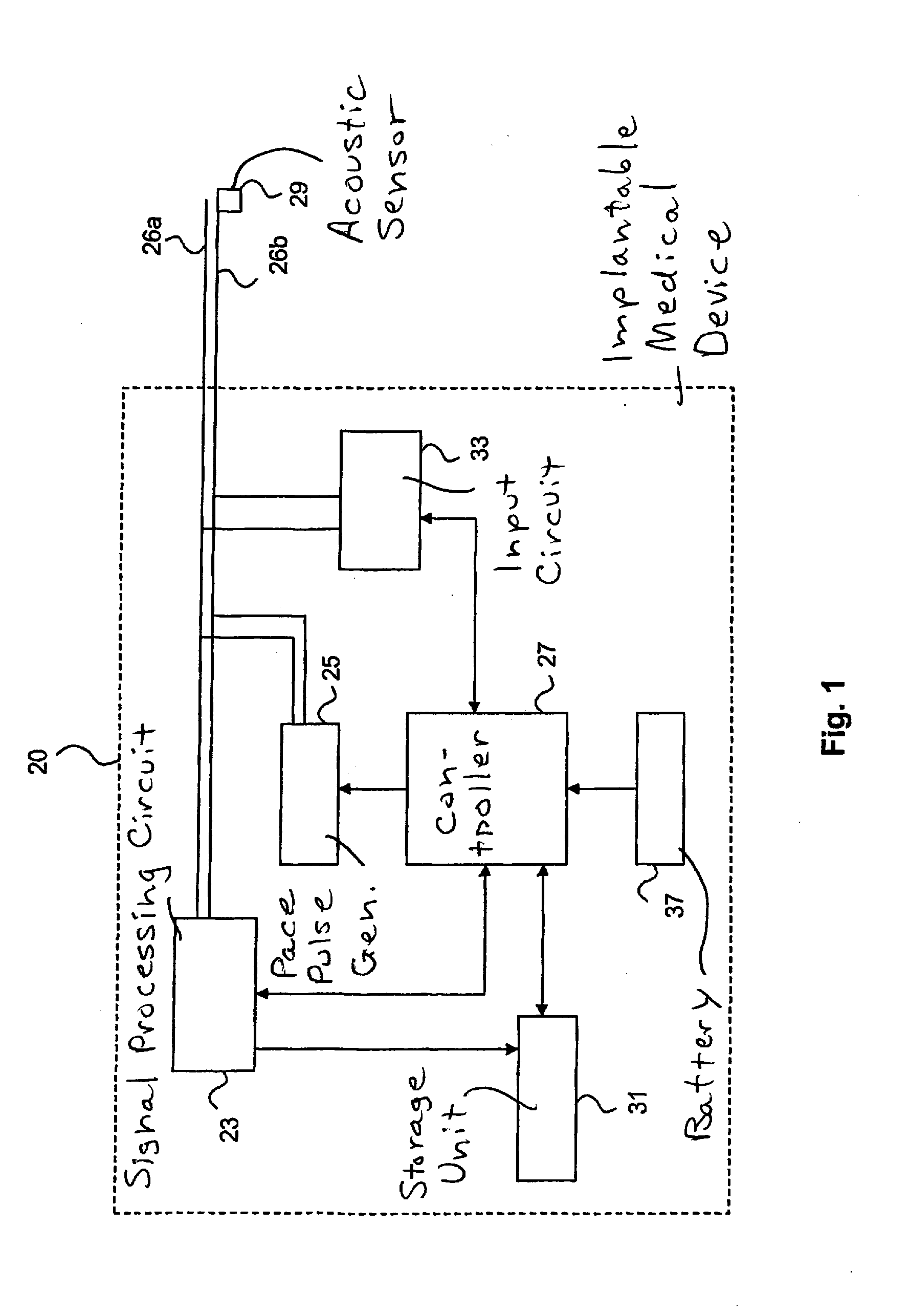

Implantable medical device with optimization procedure

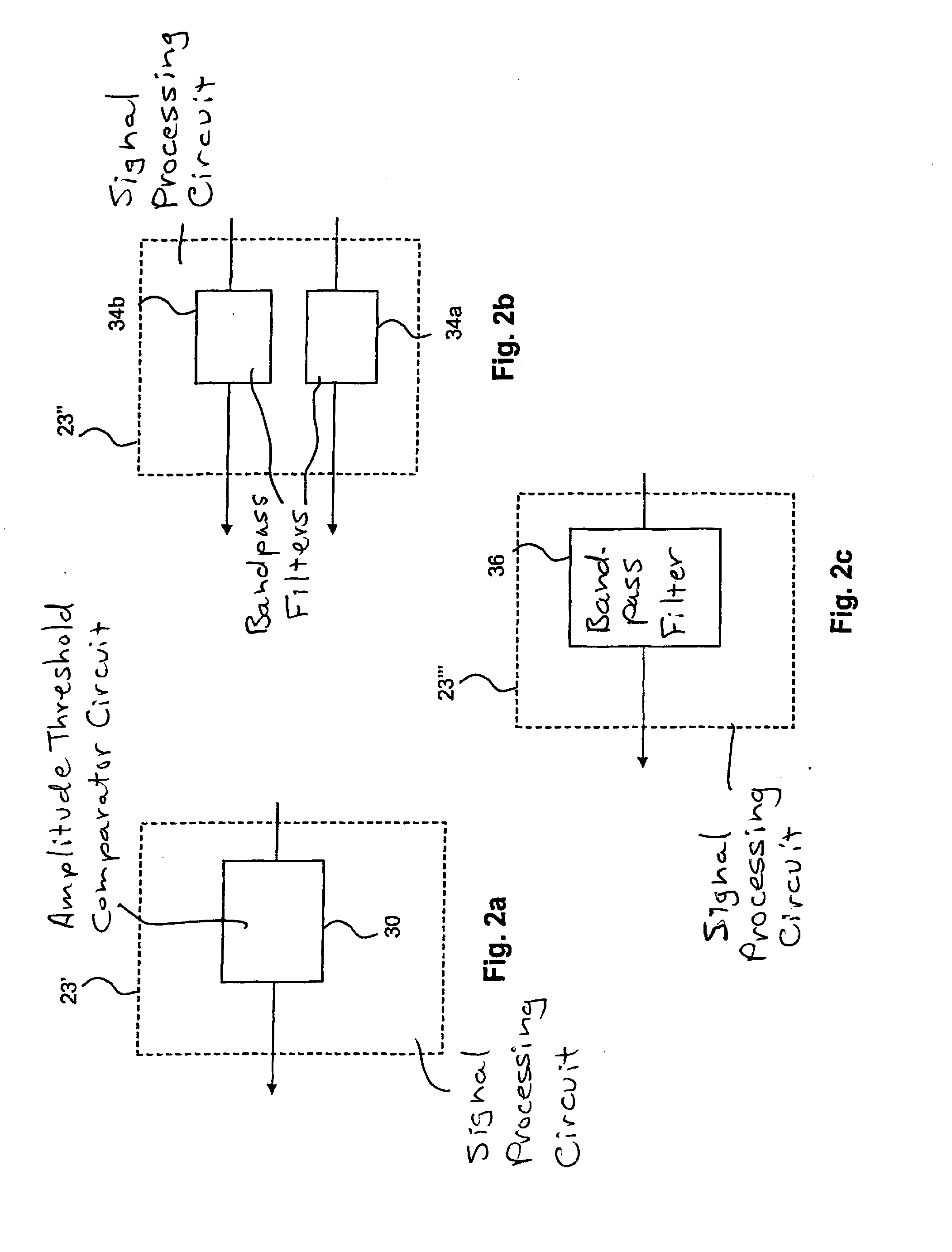

InactiveUS20090254139A1More time to relaxFaster filling timeStethoscopeHeart stimulatorsAcoustic energyCardiac cycle

In an implantable medical device and a method for the operation thereof, acoustic energy is sensed in a subject in whom the device is implanted, and signals indicative of heart sounds of the heart of the patient are produced over predetermined periods of a cardiac cycle, during successive cardiac cycles. A signal corresponding to the second heart sound (S2) is extracted from the sensed signal, and the respective durations of successive second heart sound signals are determined. An optimization procedure is implemented that includes controlling delivery of pacing pulses based on the determined durations of successive second heart sounds, to determined a combination of stimulation intervals, including at least the AV interval and the VV interval, that causes a substantially synchronized closure of the aortic and pulmonary valves.

Owner:ST JUDE MEDICAL

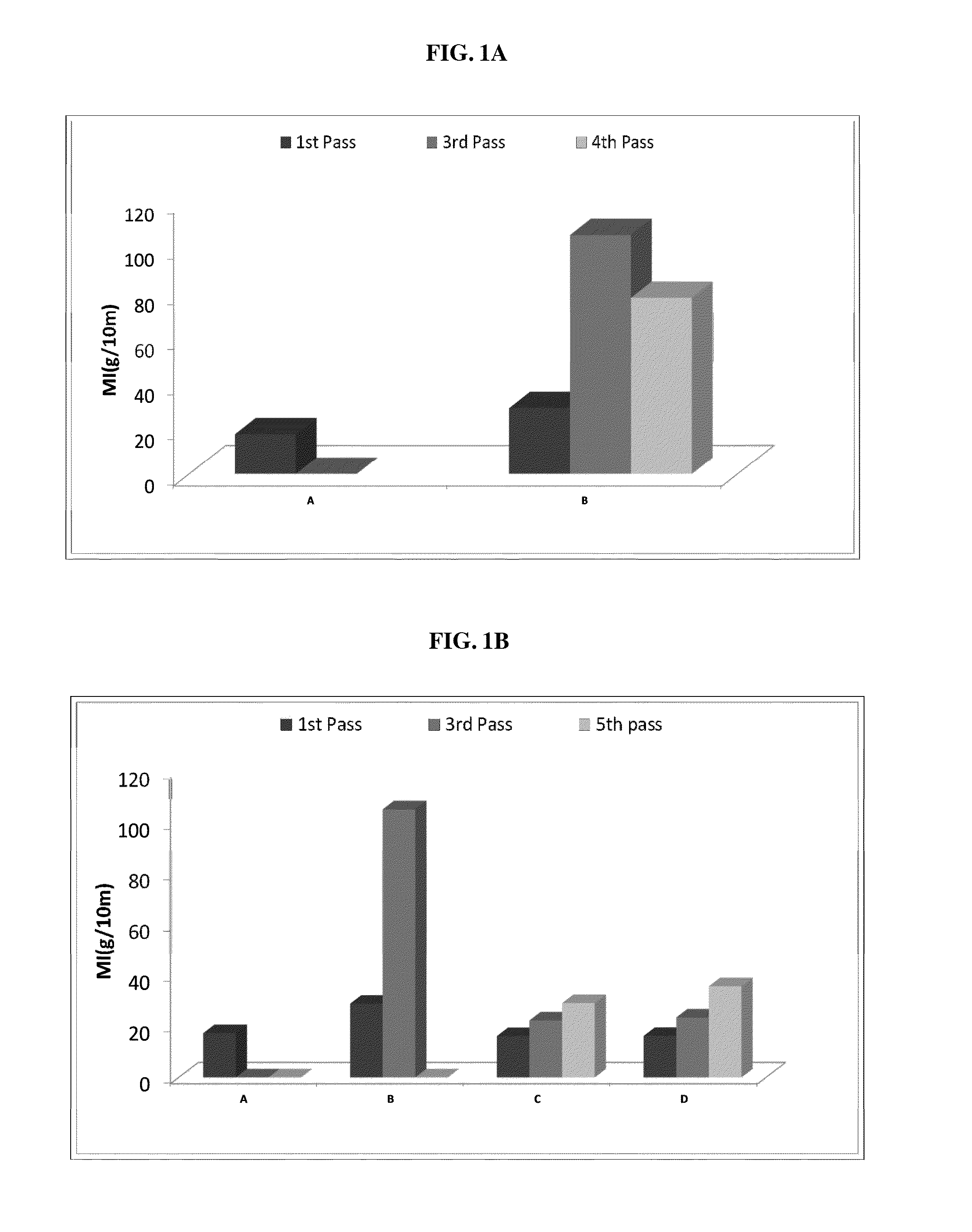

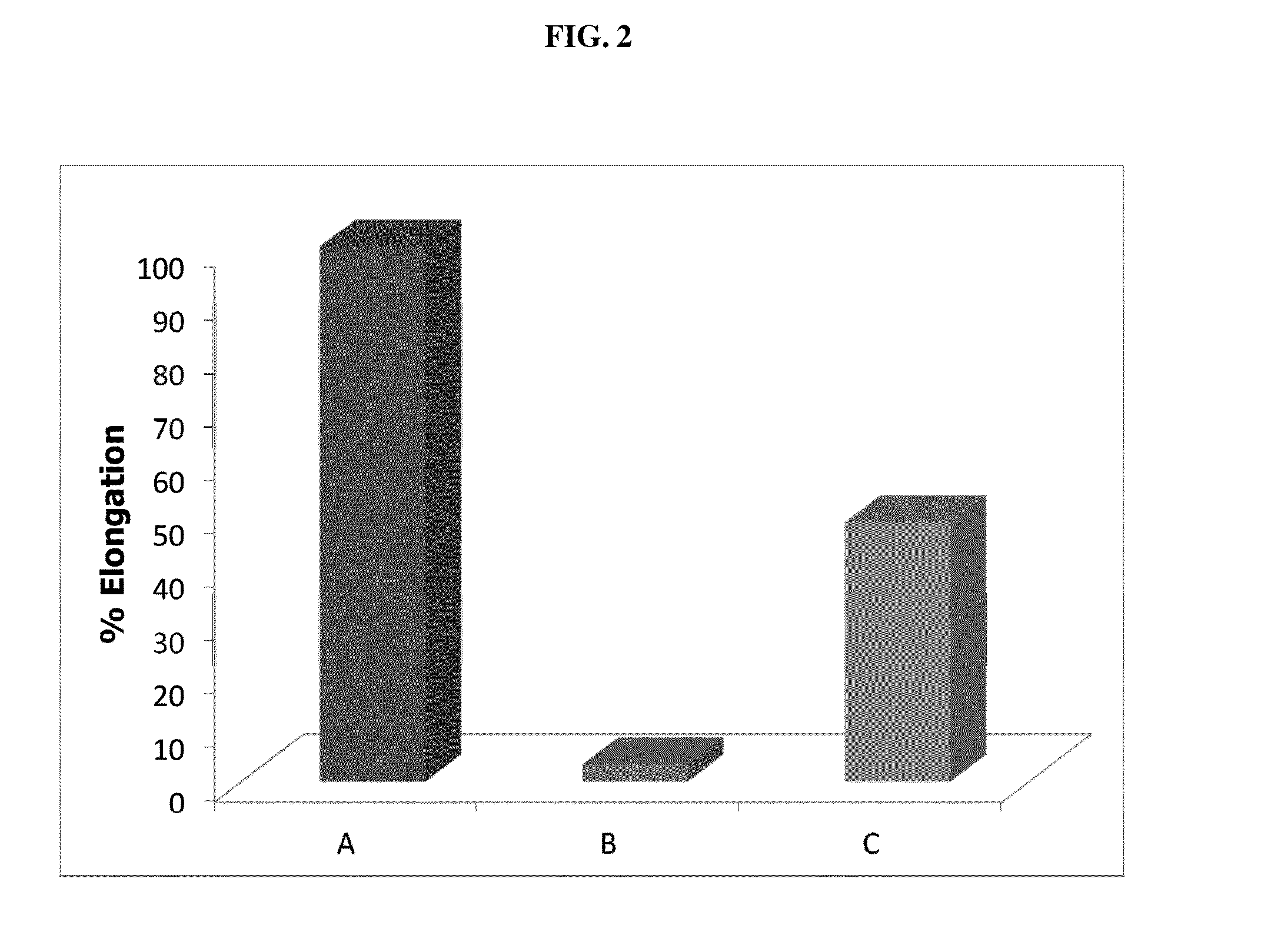

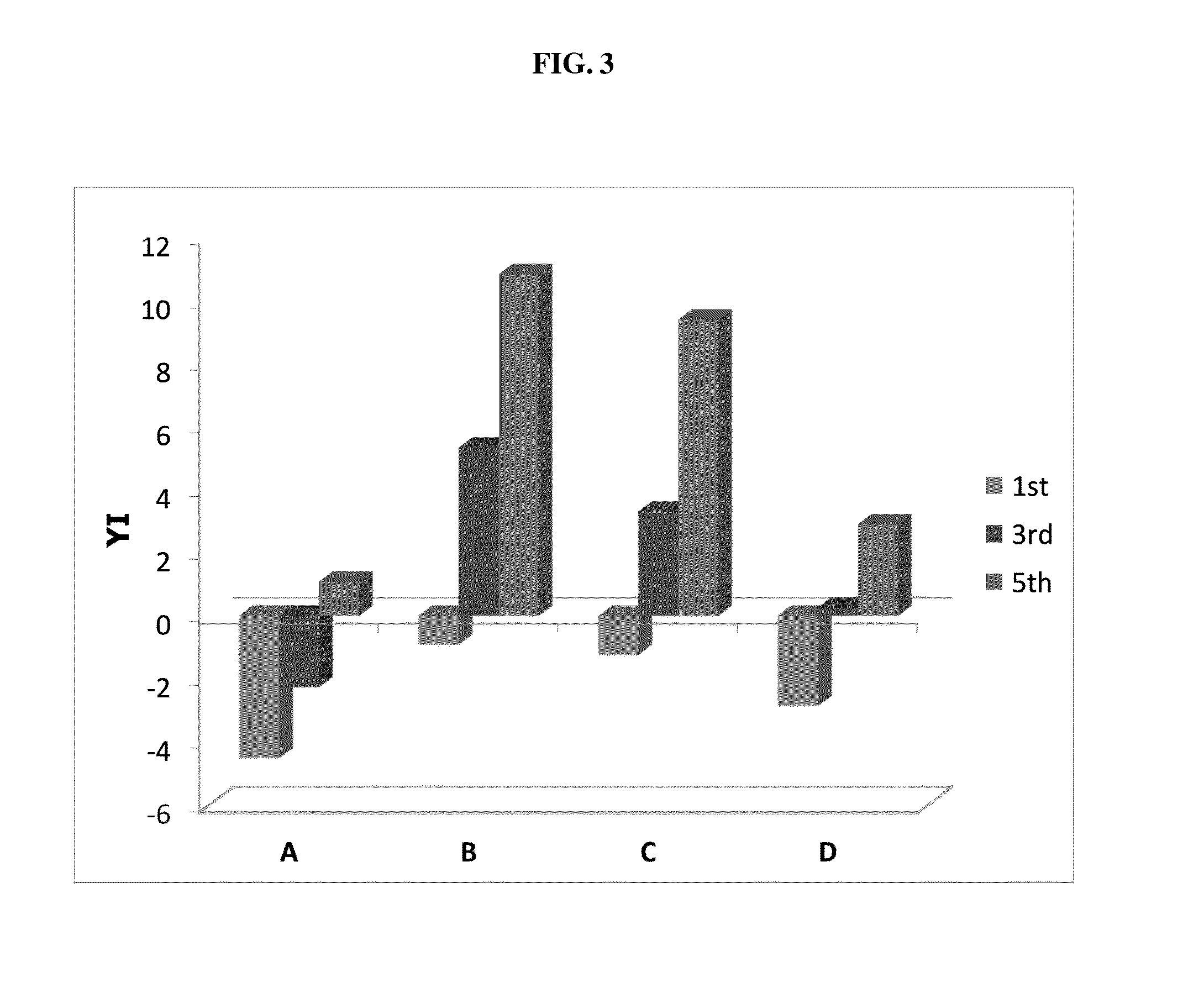

Stabilizer Compositions Containing Substituted Chroman Compounds and Methods of Use

ActiveUS20130145962A1Excellent characteristicsImprove performanceOrganic chemistryWater-repelling agents additionBenzeneOxygen

Stabilizer compositions having a chroman-based compound according to Formula (V):and their use in processes for stabilizing organic materials subject to degradation and / or discoloration due to the effects from light, oxygen and heat, and in processes for producing articles from organic materials blended therewith, are provided herein.

Owner:CYTEC TECH CORP

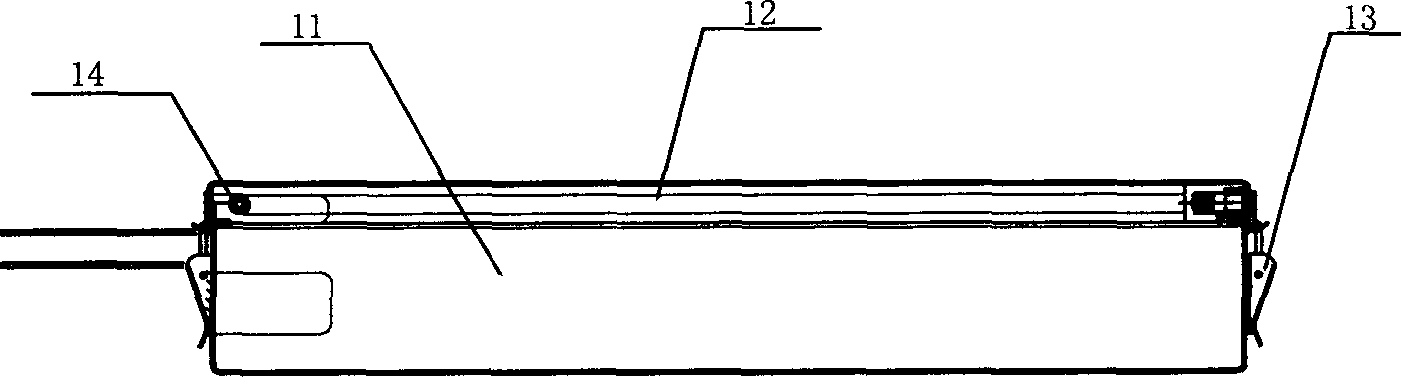

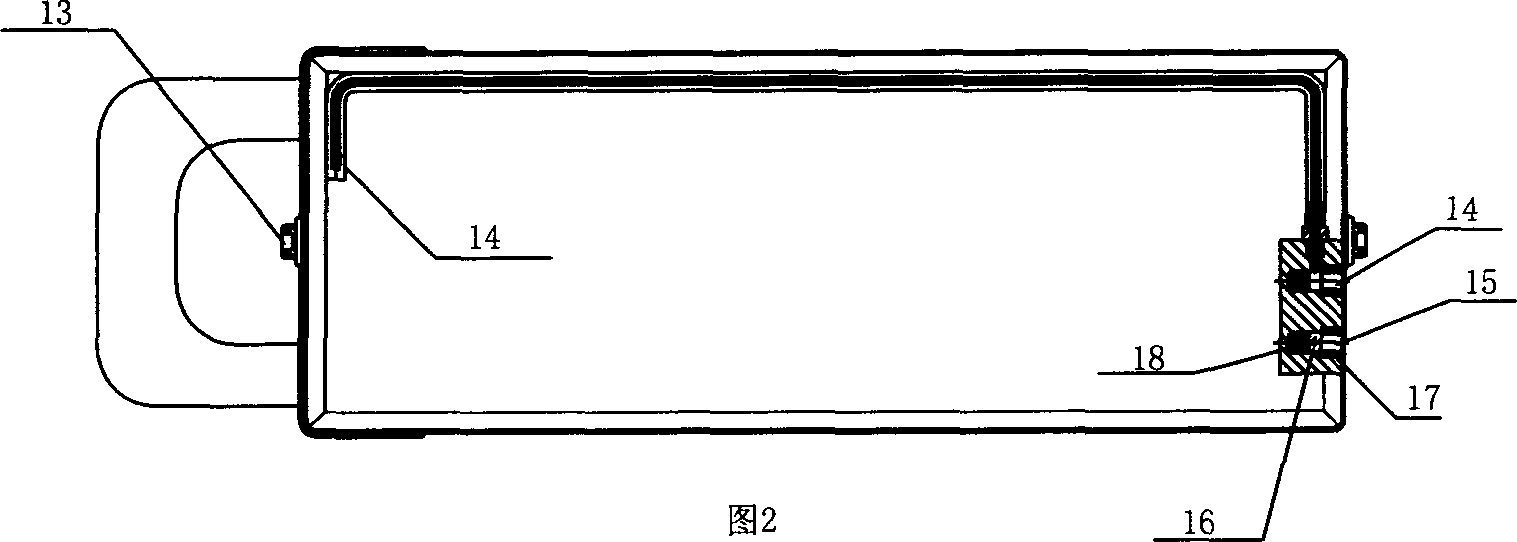

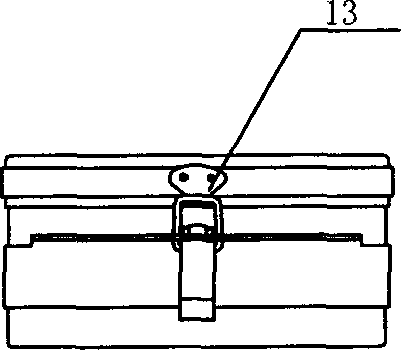

Steam sterilization process and steam sterilization apparatus employed the same

The invention relates to a steam sterilizing process for the disinfection of medical appliances in hospital, and the steam sterilizer employing the steam sterilizing process, which comprises the steps of vacuumizing, preheating, sterilizing and cooling down. The steam sterilizer comprises a steam sterilizing box, a valve group, an air filter, a steam generator, a vacuum pump and an automatic control system.

Owner:何德贤

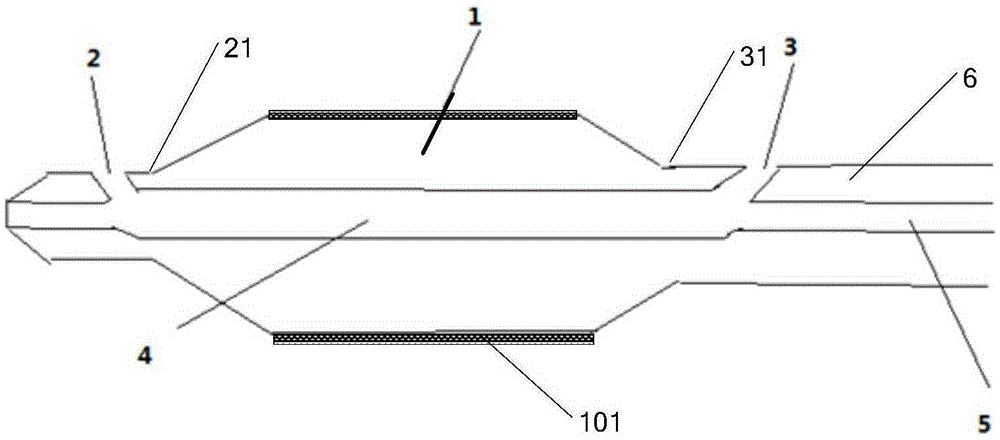

Drug eluting balloon system

InactiveCN105288823APromote absorptionFaster filling timeBalloon catheterCoatingsCurative effectTherapeutic effect

The invention discloses a drug eluting balloon system which comprises a balloon catheter and a drug eluting balloon, wherein the balloon catheter is provided with a wire guide cavity arranged along the axial direction; the drug eluting balloon is arranged along the partial length of the balloon catheter and is expanded by virtue of a pressure medium provided by the balloon catheter; the external surface of the balloon body of the drug eluting balloon is provided with a drug coating; the drug coating comprises an inner layer and an outer layer, wherein the inner layer is a taxol and hirudin mixed drug coating, and the outer layer is a hirudin drug coating; a flow channel is also arranged in the wire guide cavity, and the flow channel is arranged at the partial length position of the balloon catheter; and the flow channel is provided with two openings which are respectively formed in two ends of the drug eluting balloon. When the drug eluting balloon system releases drugs, blood flow can not be blocked and drug release can be prolonged to any time, so that the action time of the drugs is increased and the curative effect is improved.

Owner:王显

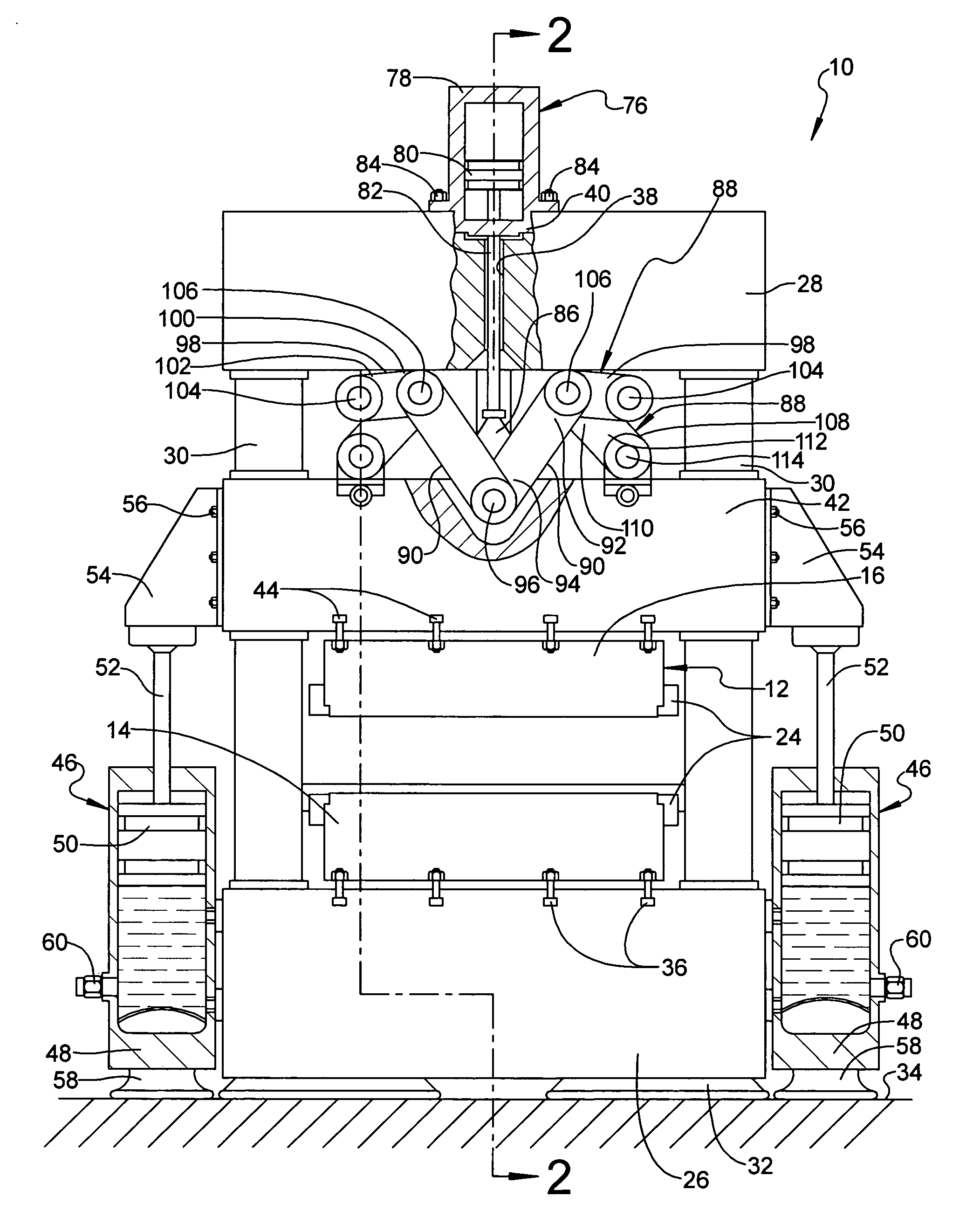

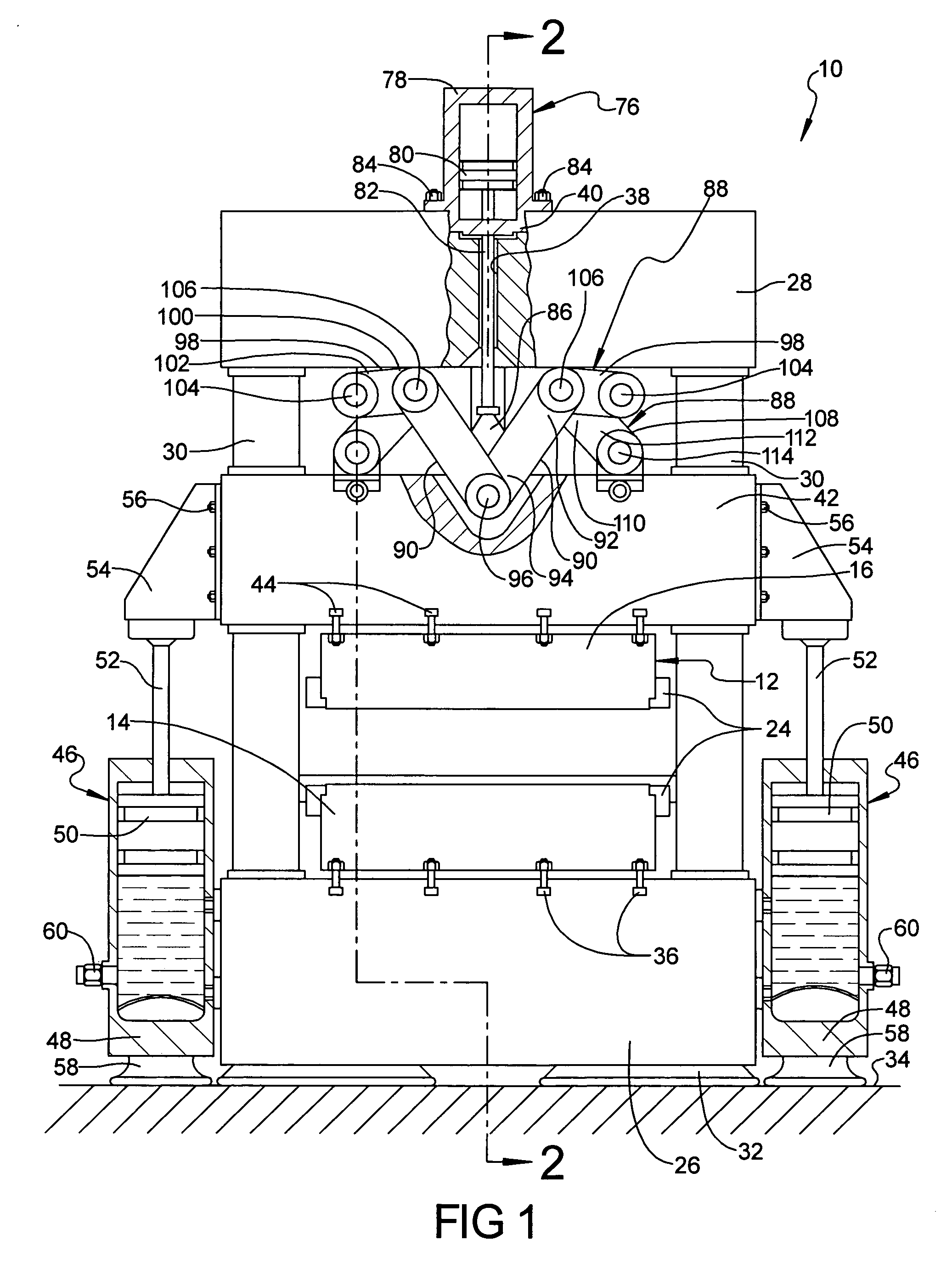

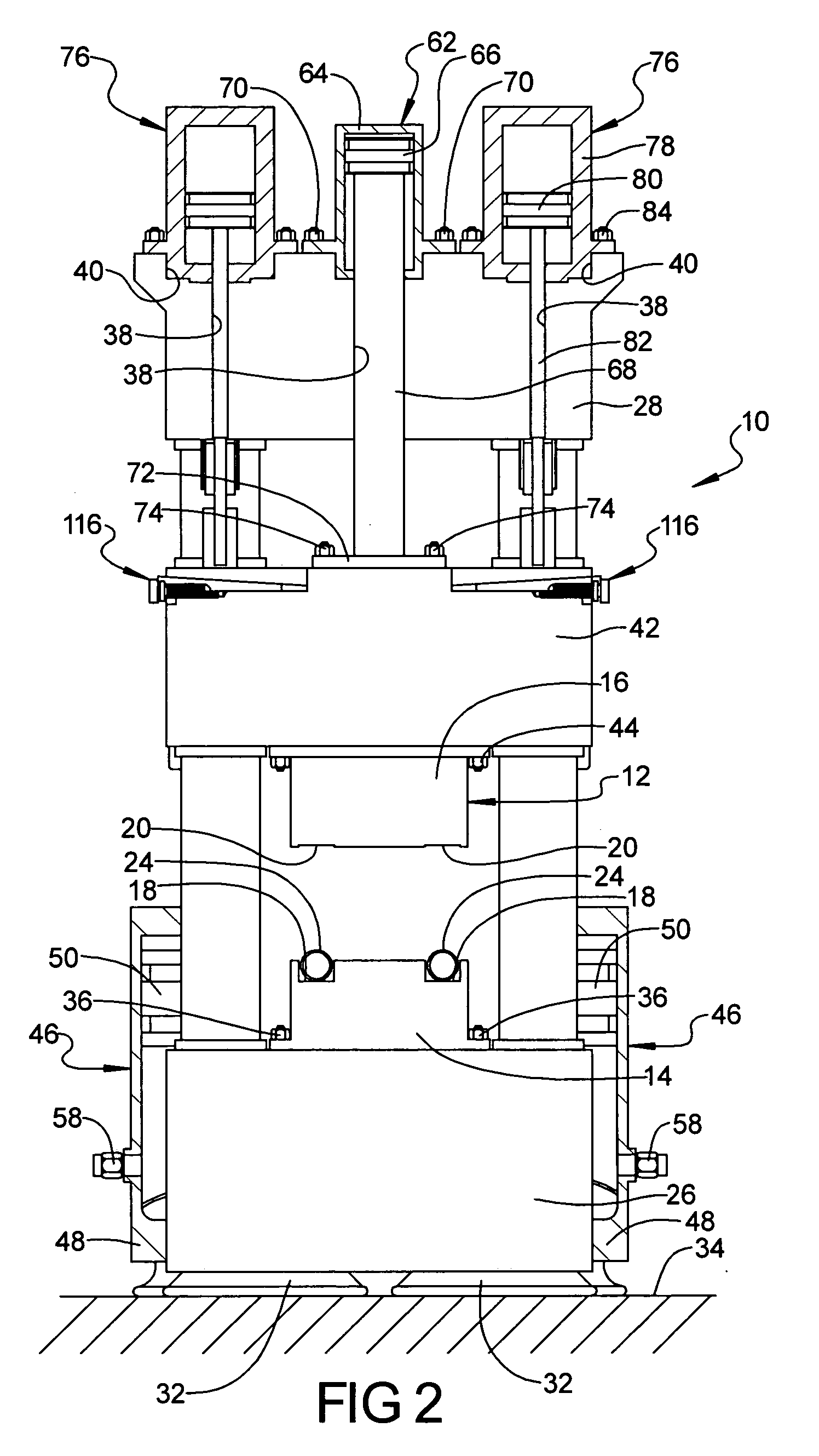

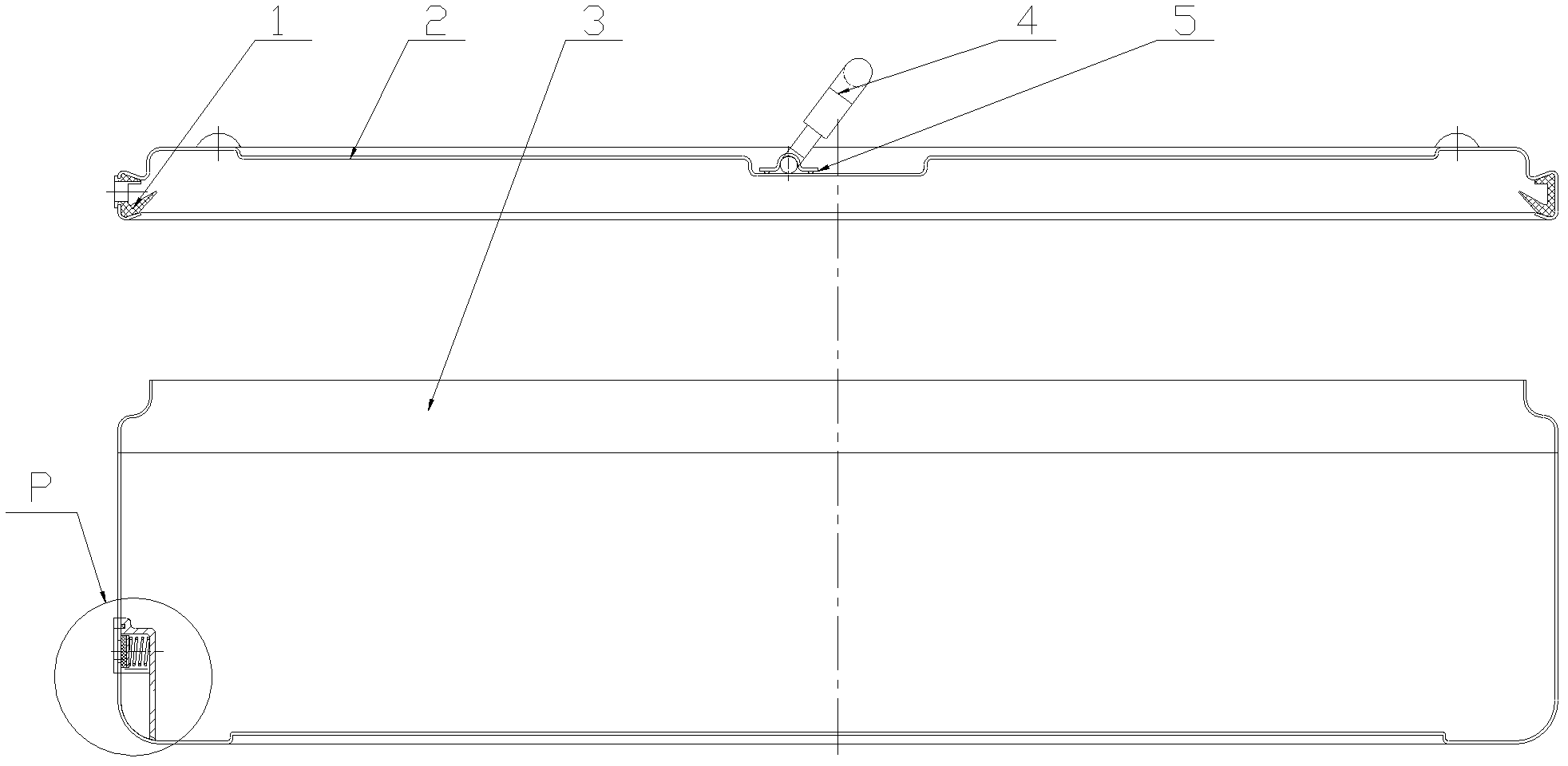

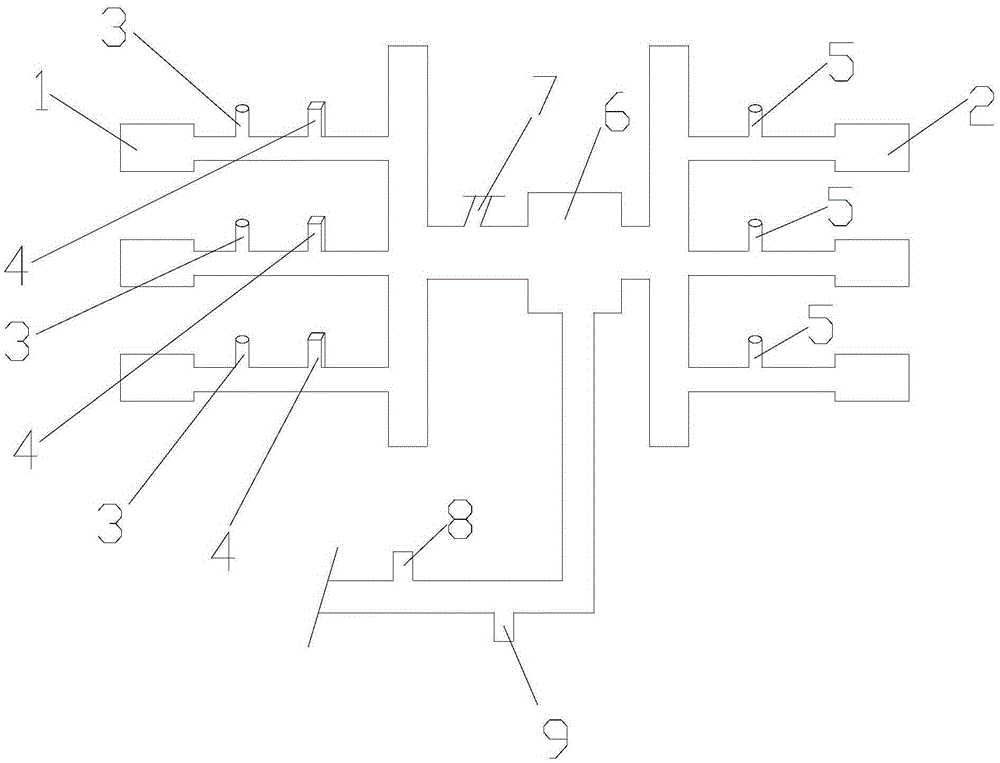

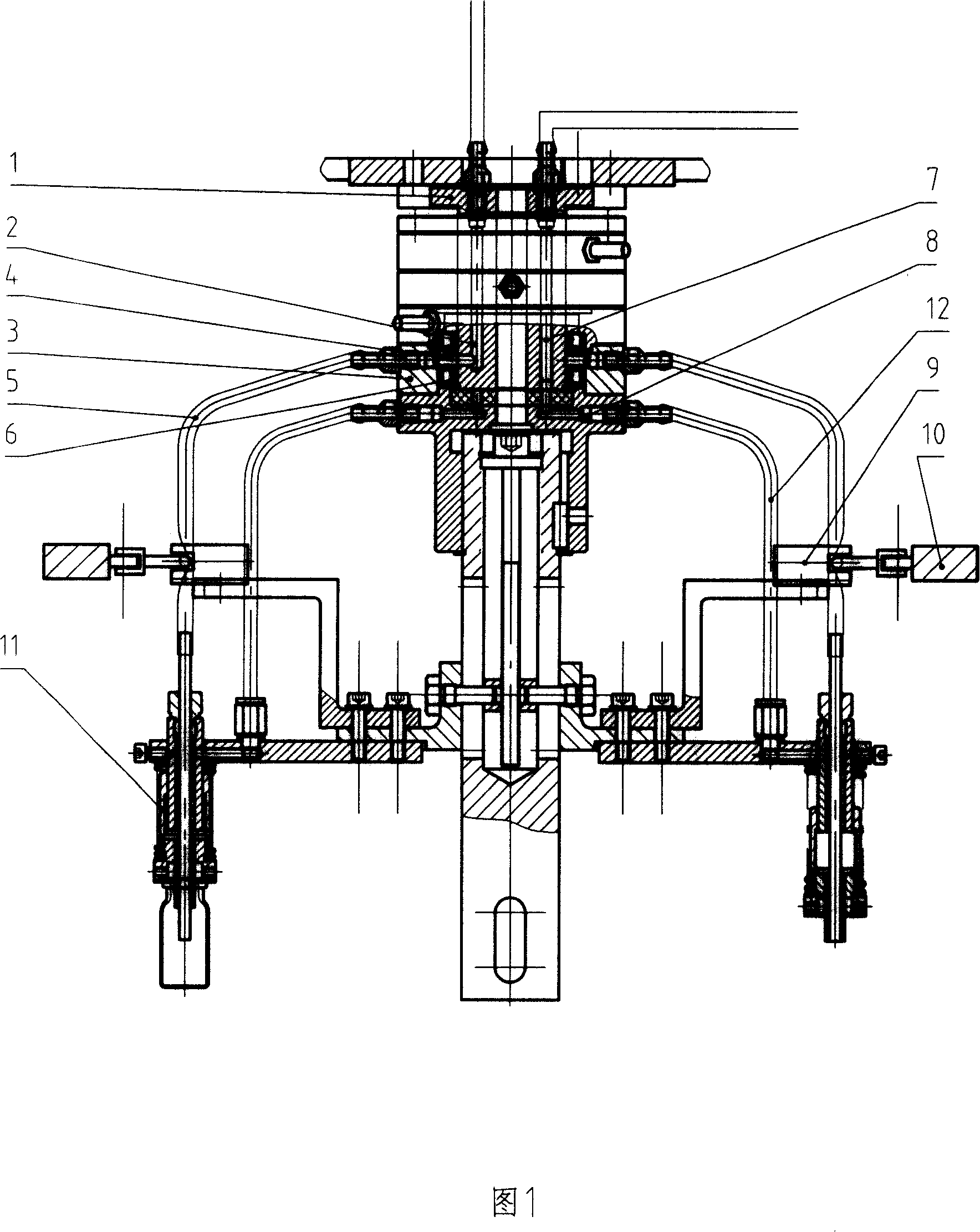

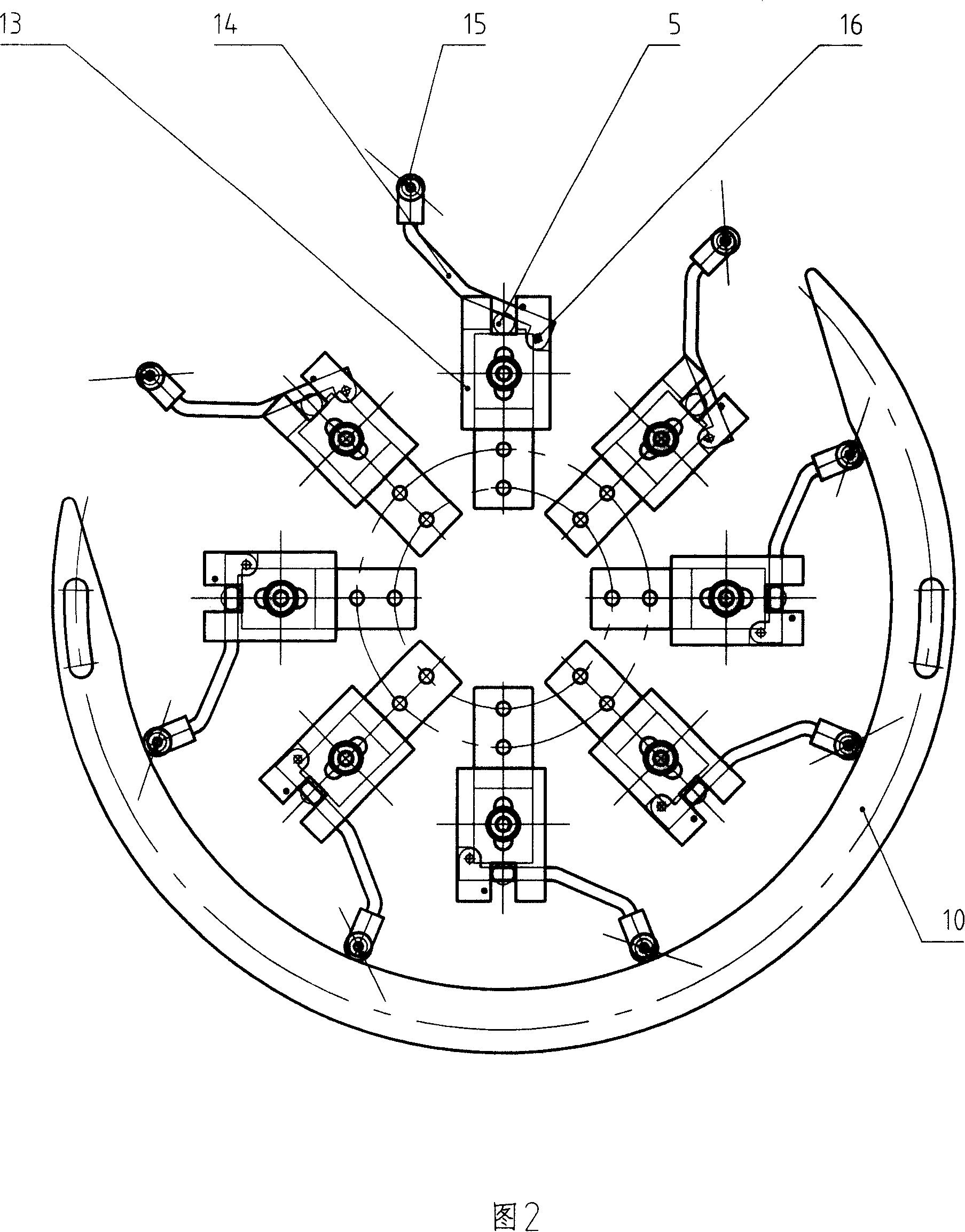

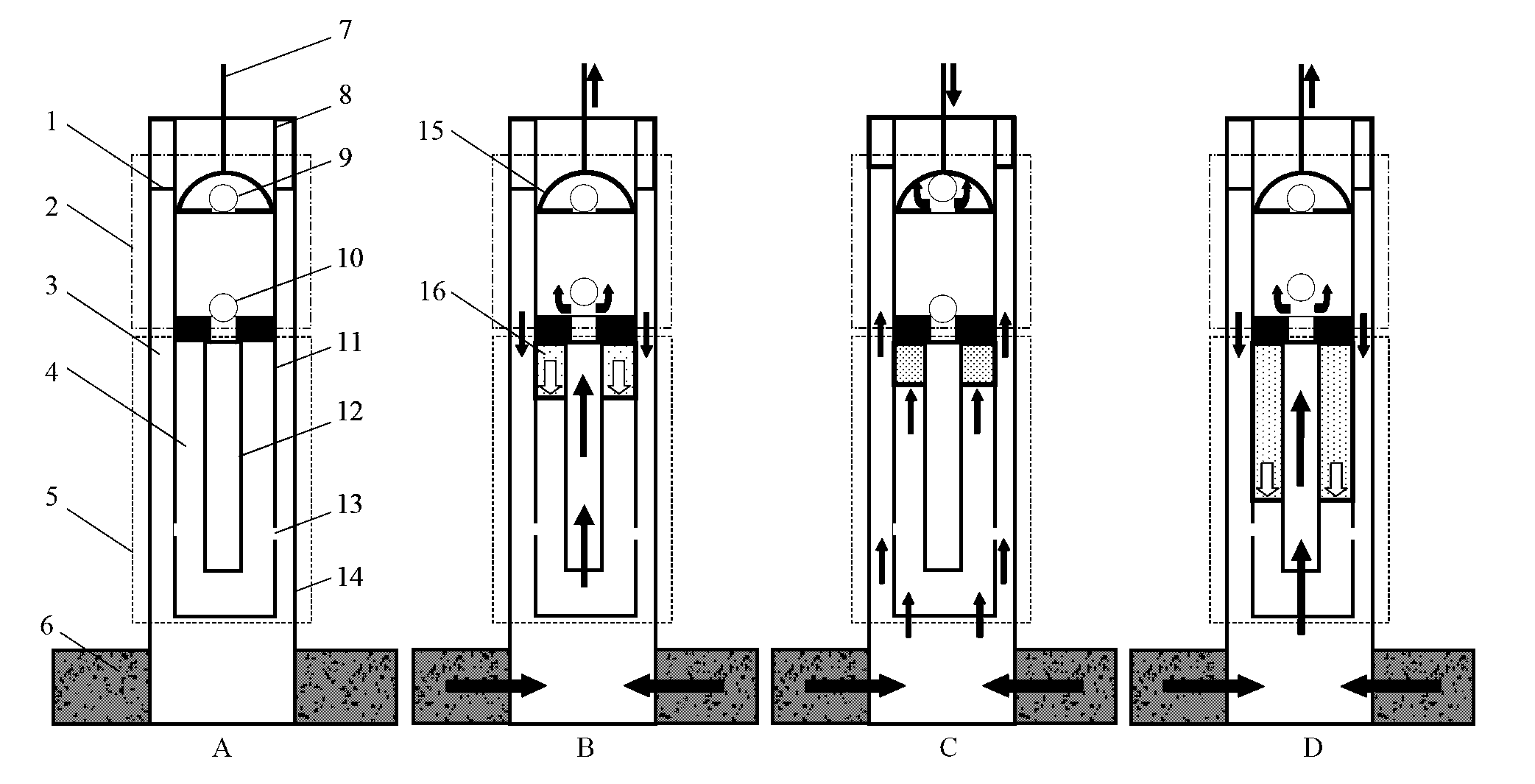

Clamp assembly for hydroforming die

InactiveUS7124618B1Withstand extremely high forceReduce operating costsForging press detailsForging press drivesHydroforming

A clamp assembly for a hydroforming die includes a stationary lower bed to support a lower die half of the hydroforming die, a stationary upper bed spaced above the lower bed, at least one guide post extending between the lower bed and the upper bed, a movable slide disposed between the upper bed and the lower bed and movable along the at least one guide post to support an upper die half of the hydroforming die, a lifting cylinder operatively connected to the movable slide to move the movable slide and upper die half toward and away relative to the lower die half, at least one link mechanism connected to the upper bed and the movable slide to equalize a force on the hydroforming die, and at least one linkage cylinder operatively connected to the at least one link mechanism to activate the at least one link mechanism to prevent the movable slide and upper die half from moving away from the lower die half to keep the hydroforming die closed during a hydroforming process.

Owner:GM GLOBAL TECH OPERATIONS LLC

Pulsed steam sterilization process and steam sterilizer thereof

ActiveCN102423495AEvenly distributedShorten heating timeLavatory sanitoryHeatAutomatic controlMedical equipment

The invention discloses a pulsed steam sterilization process suitable for sterilizing medical equipment and a steam sterilizer for the steam sterilization process. The sterilization process comprises the following steps of vacuumizing, preheating, sterilizing, performing vacuum drying and the like. The steam sterilizer comprises a steam sterilization box, a valve bank, an air filter, a steam generator, a vacuum pump and an automatic control system. Compared with the prior art, the invention has the advantages that: by the pulsed steam sterilization process and the steam sterilizer thereof, a sterilization apparatus can be transported without packaging, the temperature raising and reduction time of the sterilization is shortened, the sterilization time of the apparatus is shortened, the labor intensity of medical care personnel is reduced, and the disinfection and sterilization are more complete and have a better effect.

Owner:何德贤

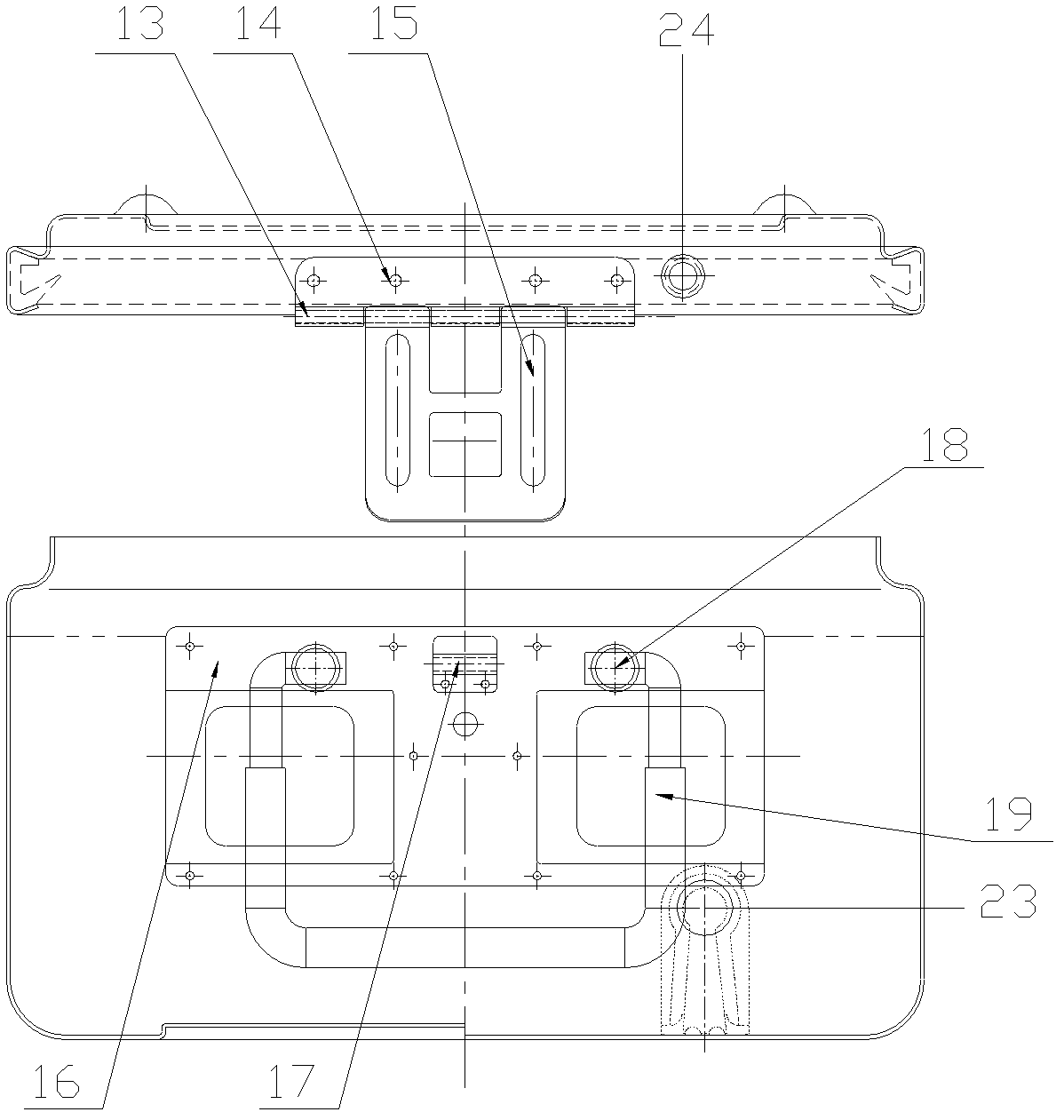

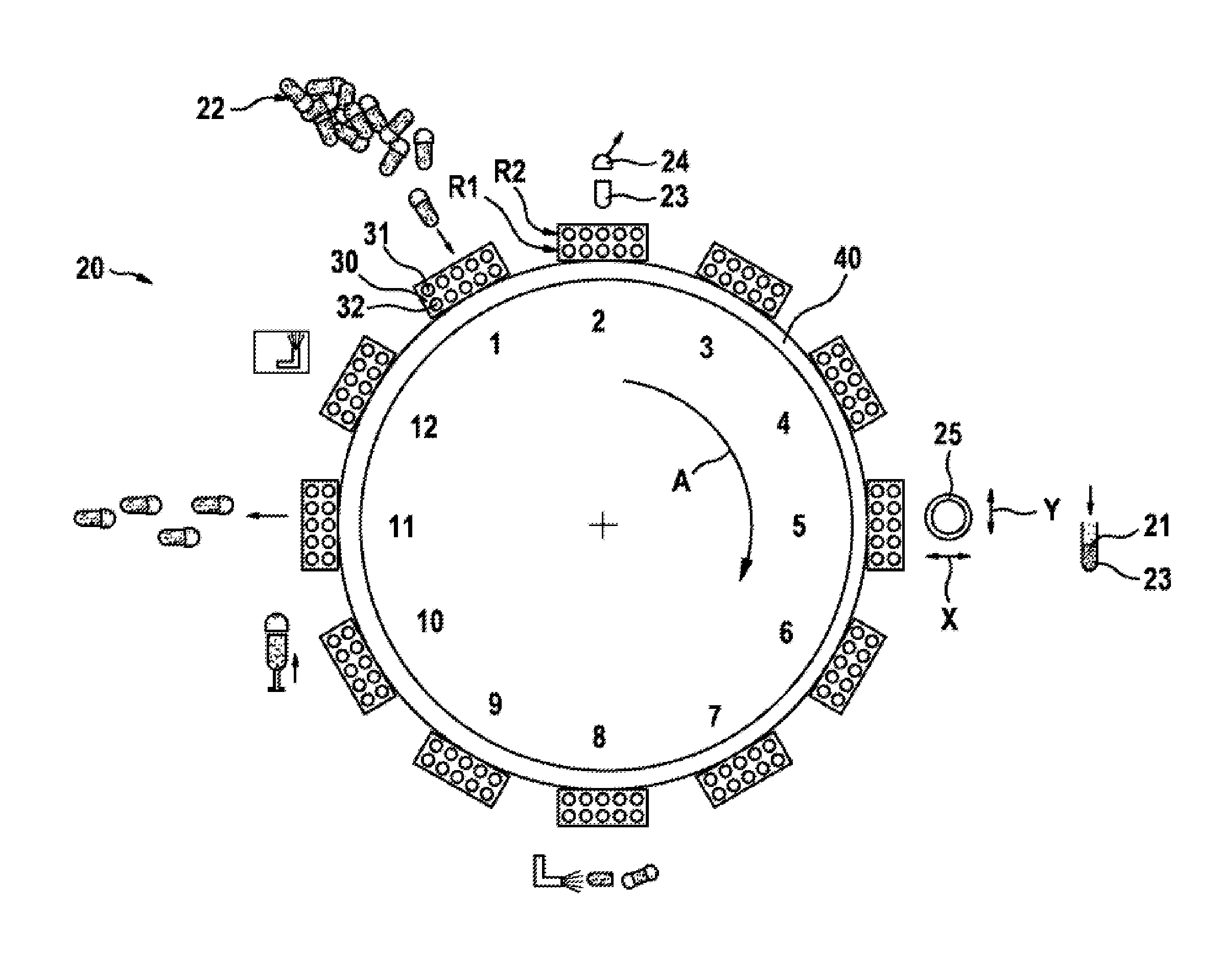

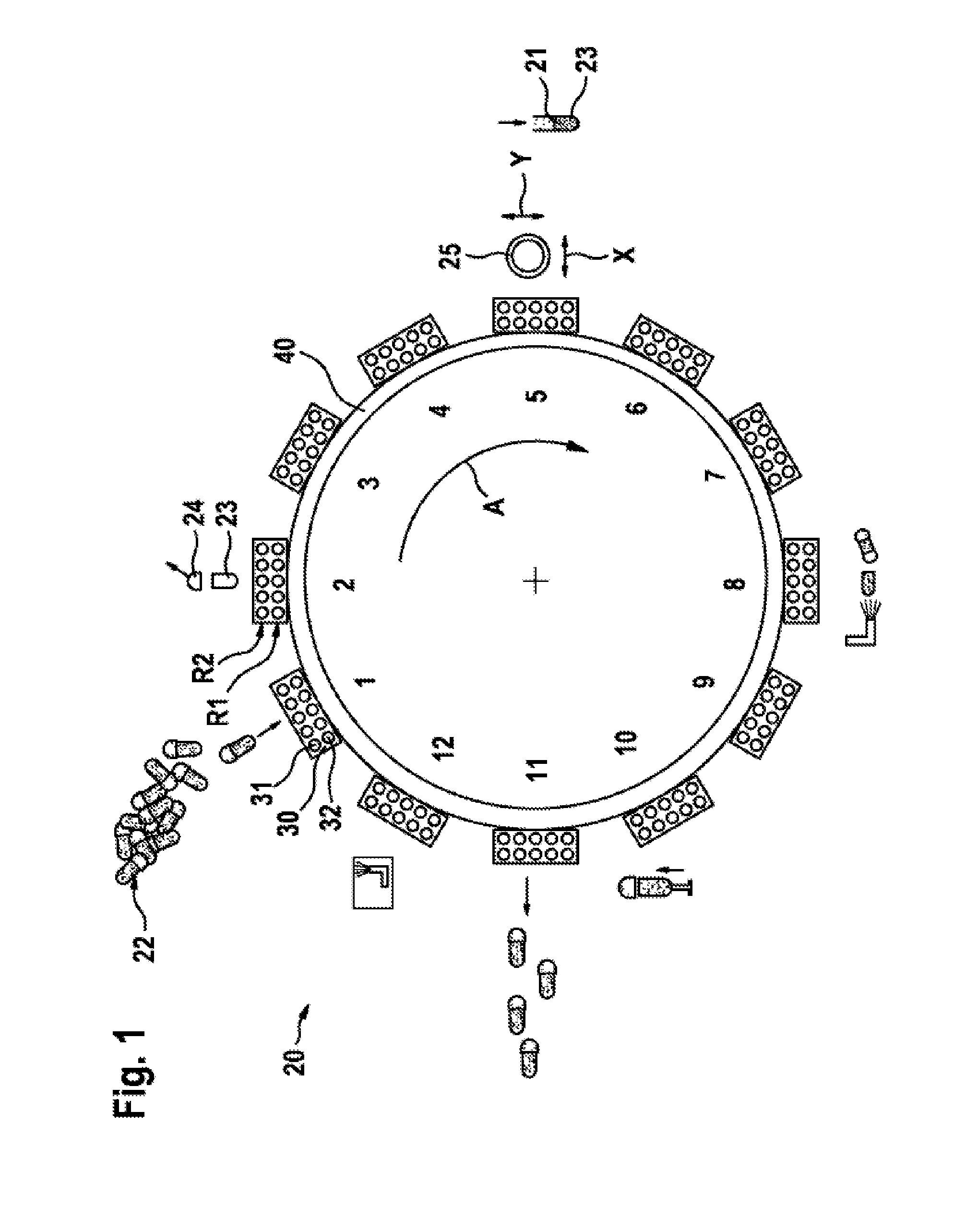

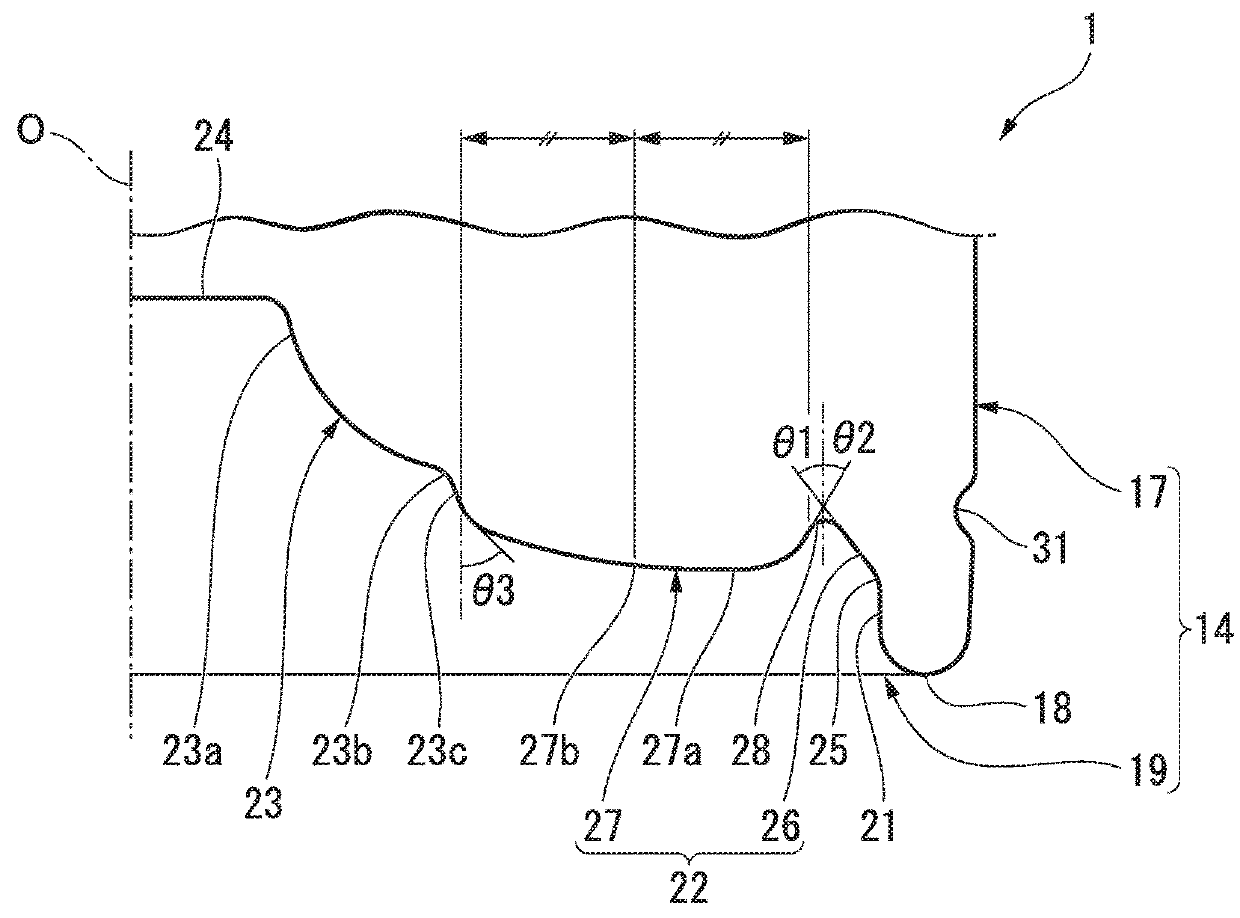

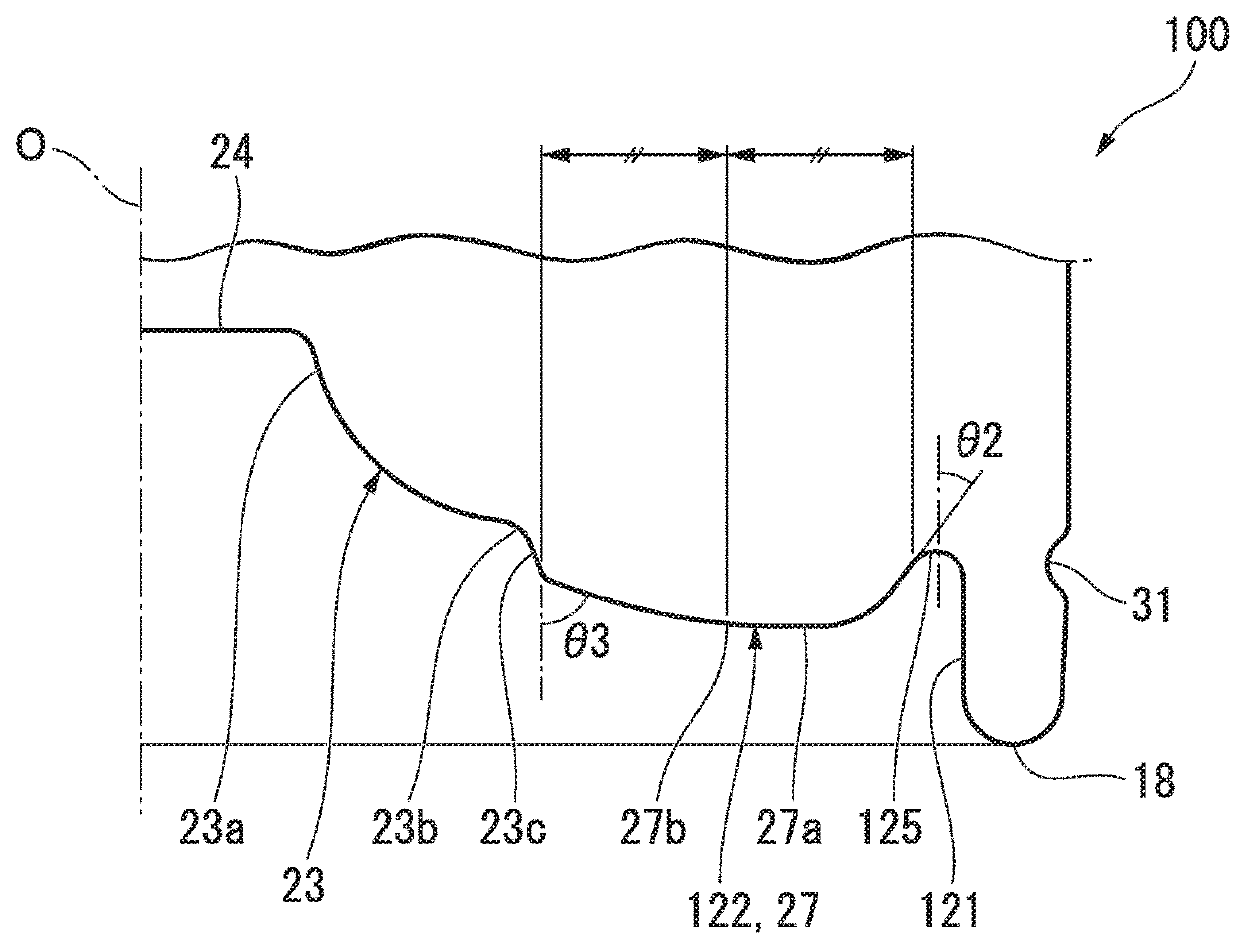

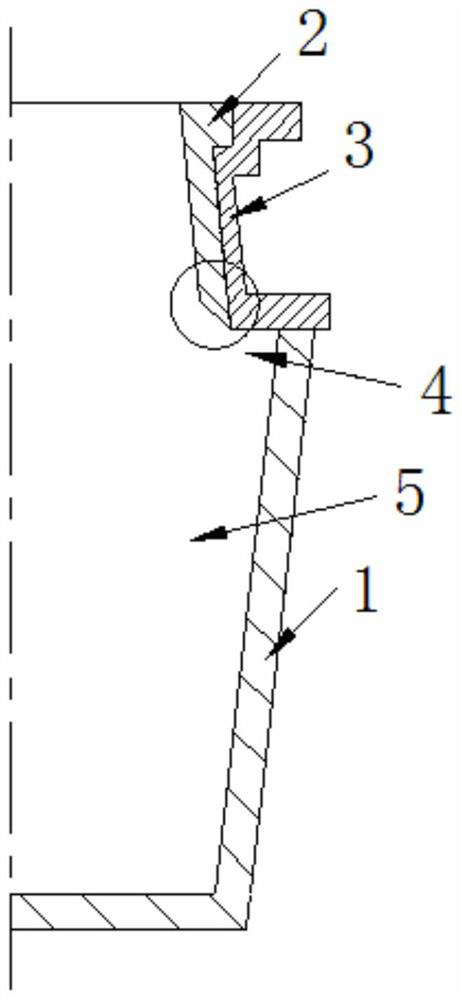

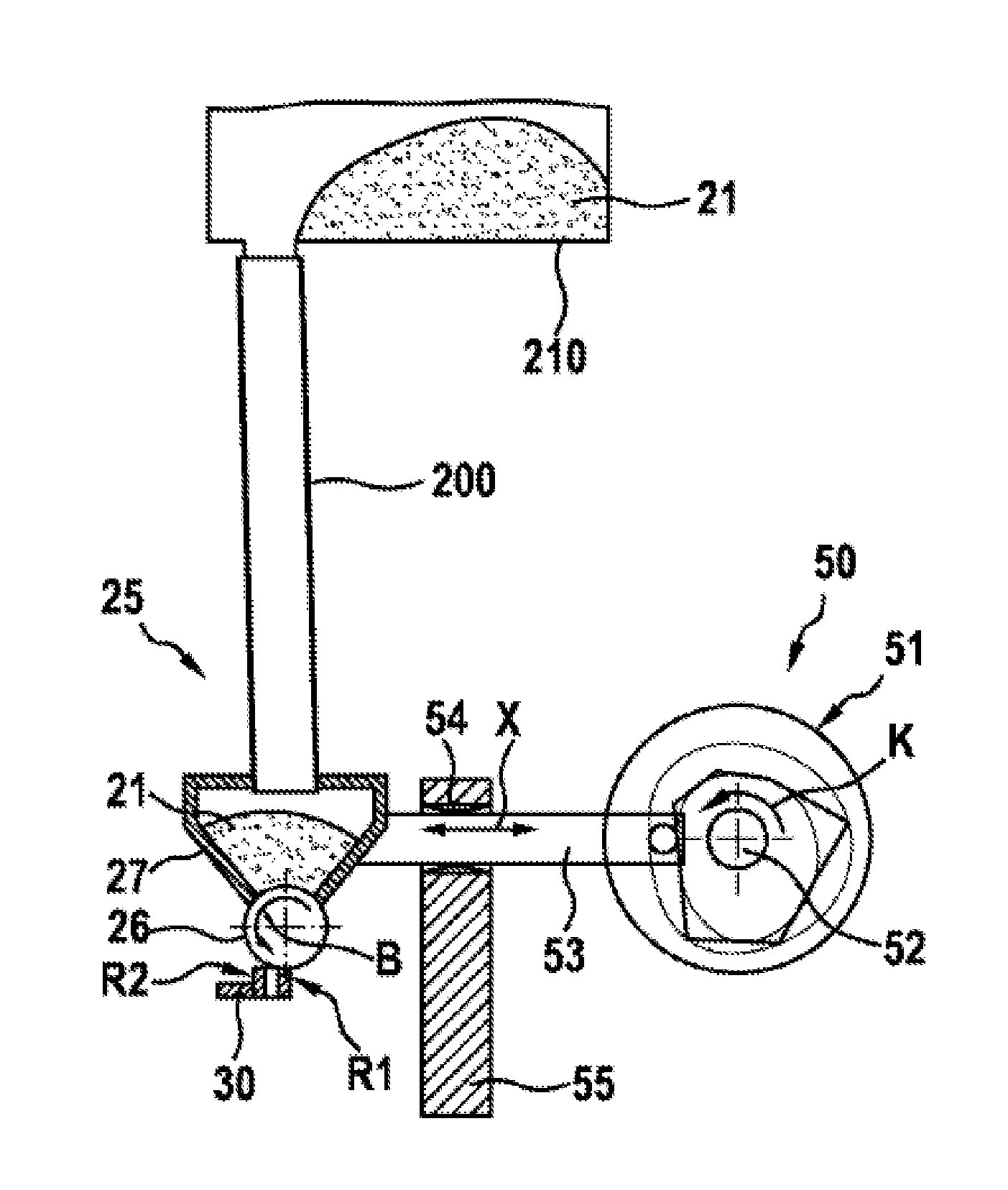

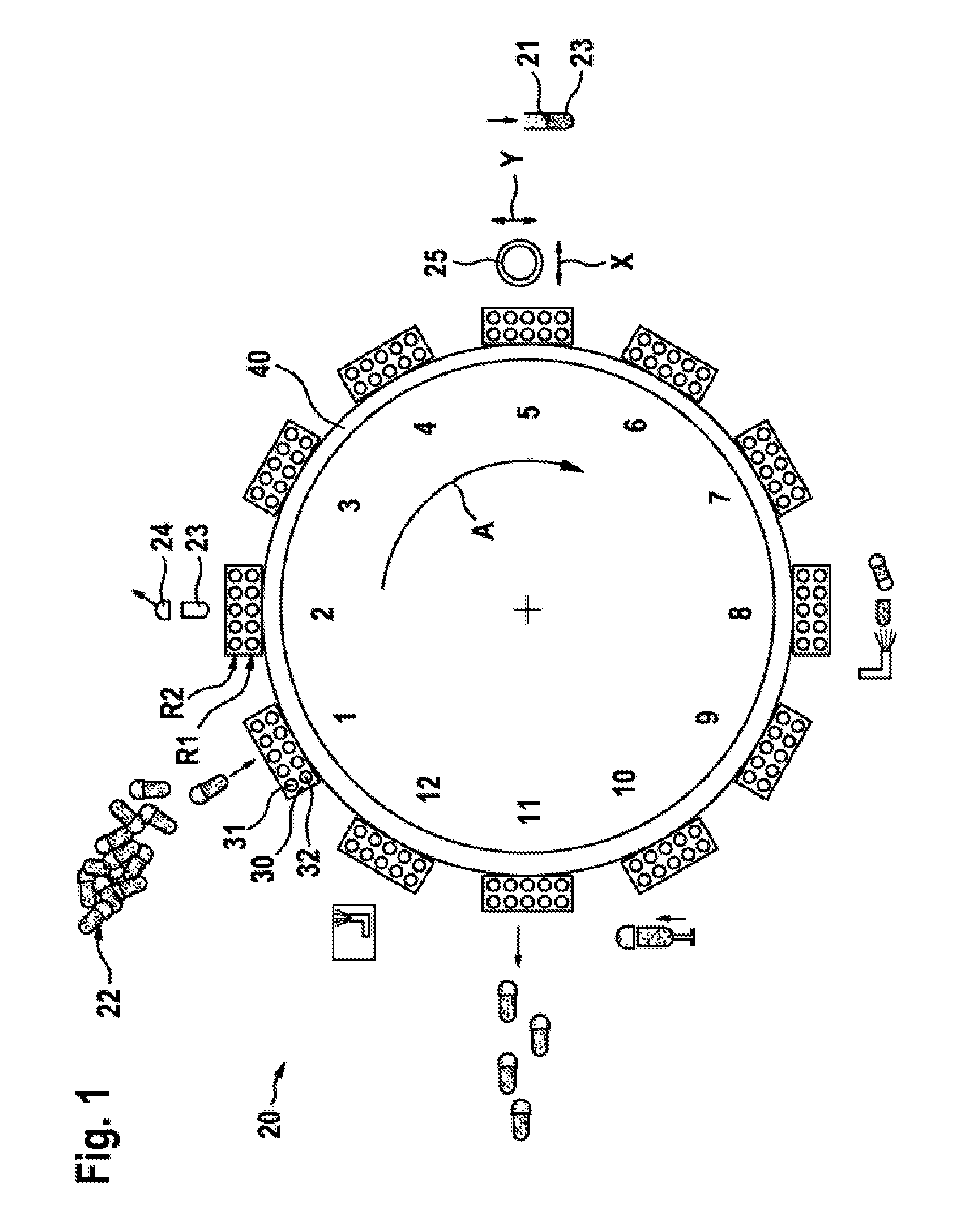

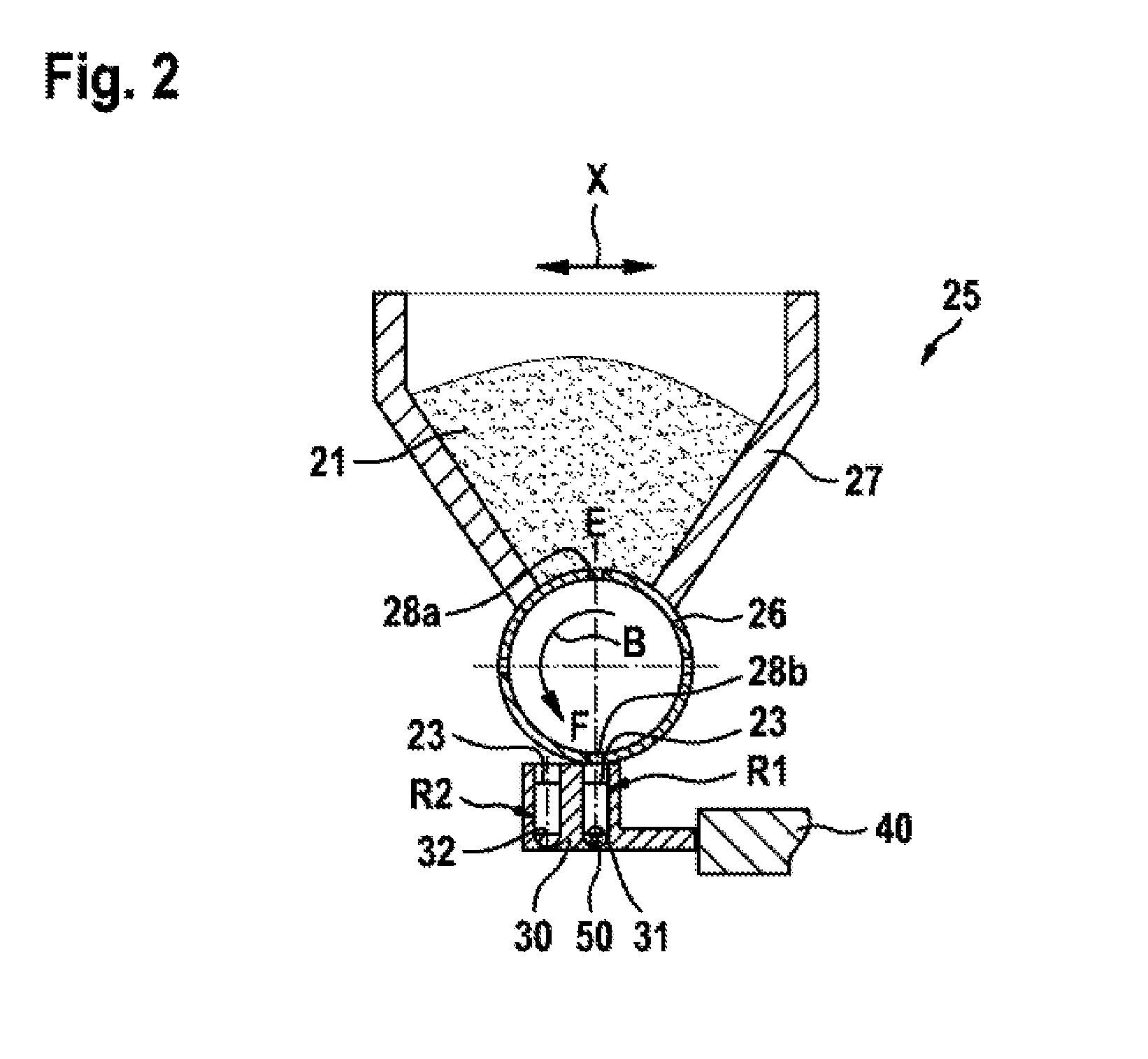

Device for introducing filling material into capsules

ActiveUS20130255833A1Easy to cleanPrevent influence propertyCapsule deliveryLiquid bottlingRelative motionSurgery

The present invention relates to a device for introducing filling material (21) into capsules (22), comprising a filling device (25) for feeding filling material (21) to the capsules (22), a capsule holder (30) with at least one row of seats (31) in which the capsules (22) that are to be filled are arranged, a station arrangement with several stations arranged one after another, wherein the station arrangement comprises at least one filling station (5) and a synchronously operating drive, and a movement device which, at the capsule-filling station (5), executes a relative movement between the filling device (25) and the capsule holder (30), wherein the filling device (25) adopts, relative to the capsule holder (30), at least a first filling position for filling a first capsule and a second filling position for filling a second capsule.

Owner:SYNTEGON TECHNOLOGY GMBH

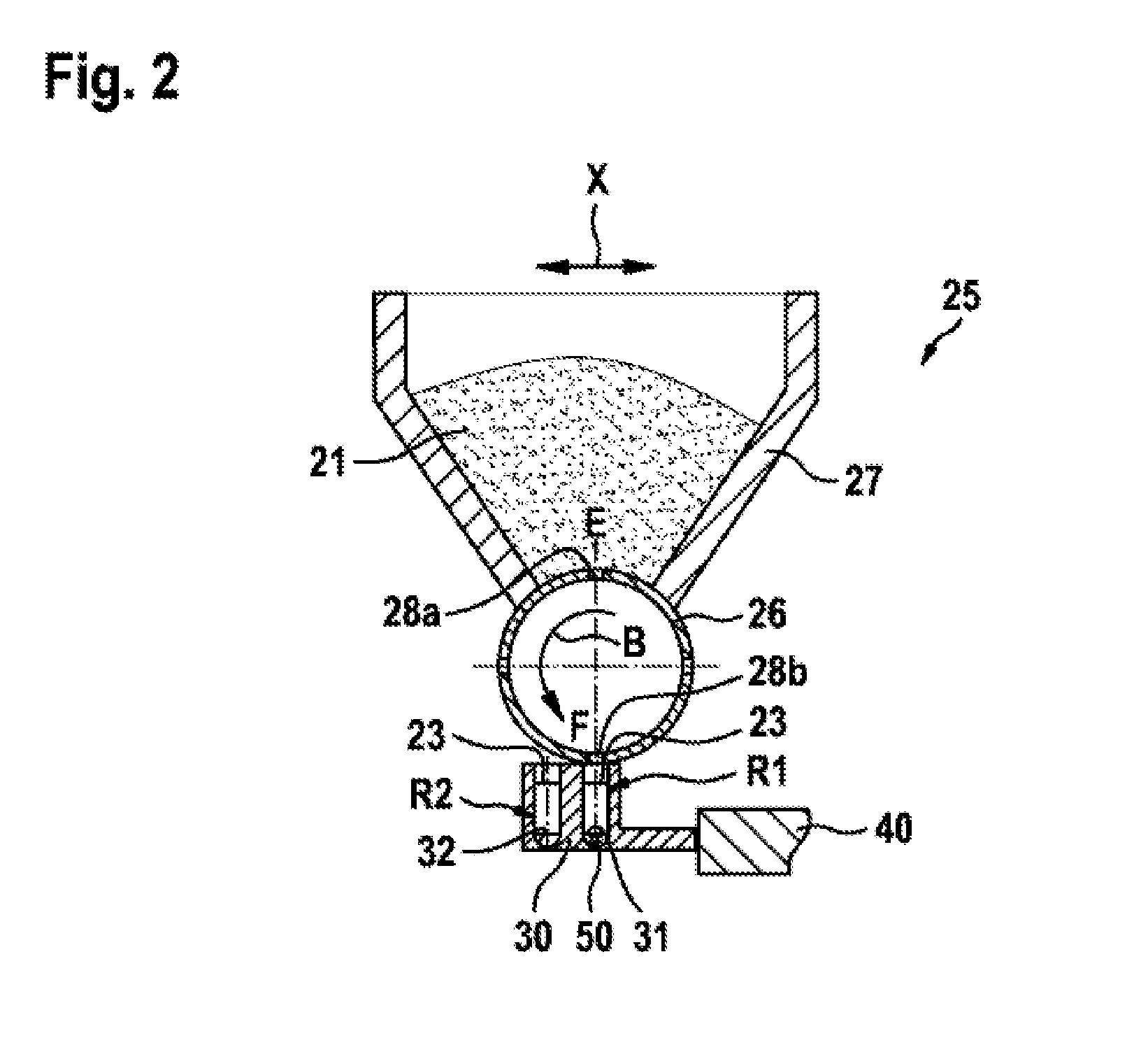

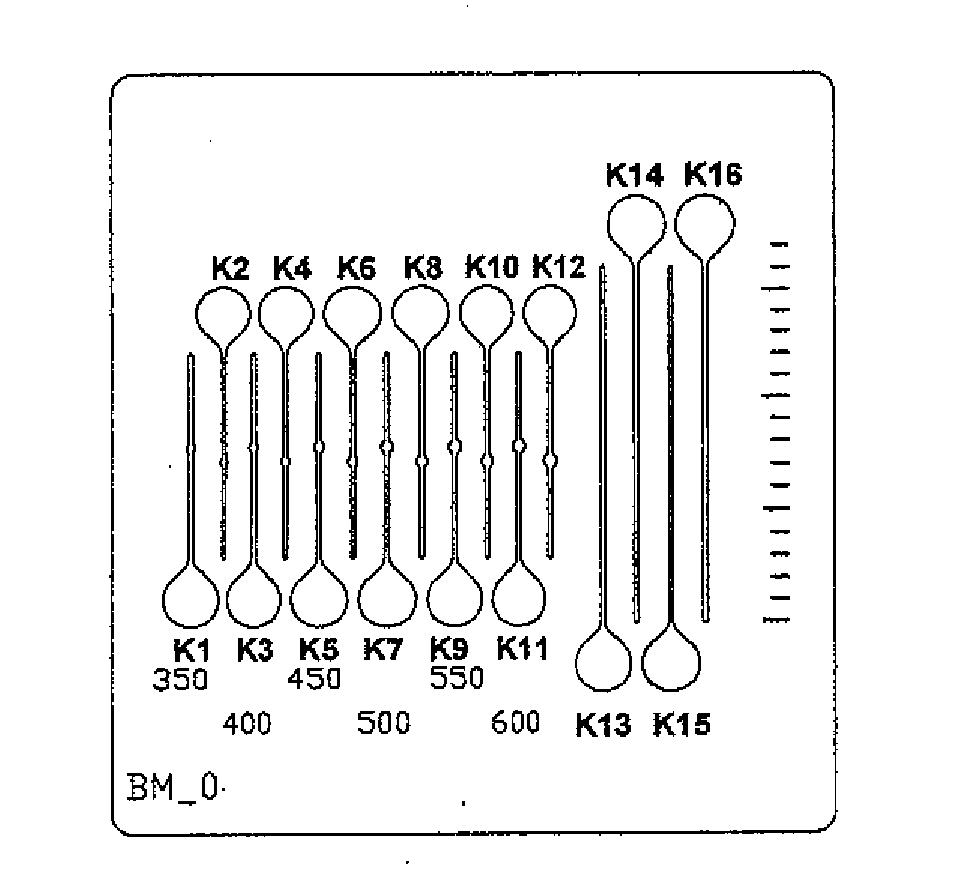

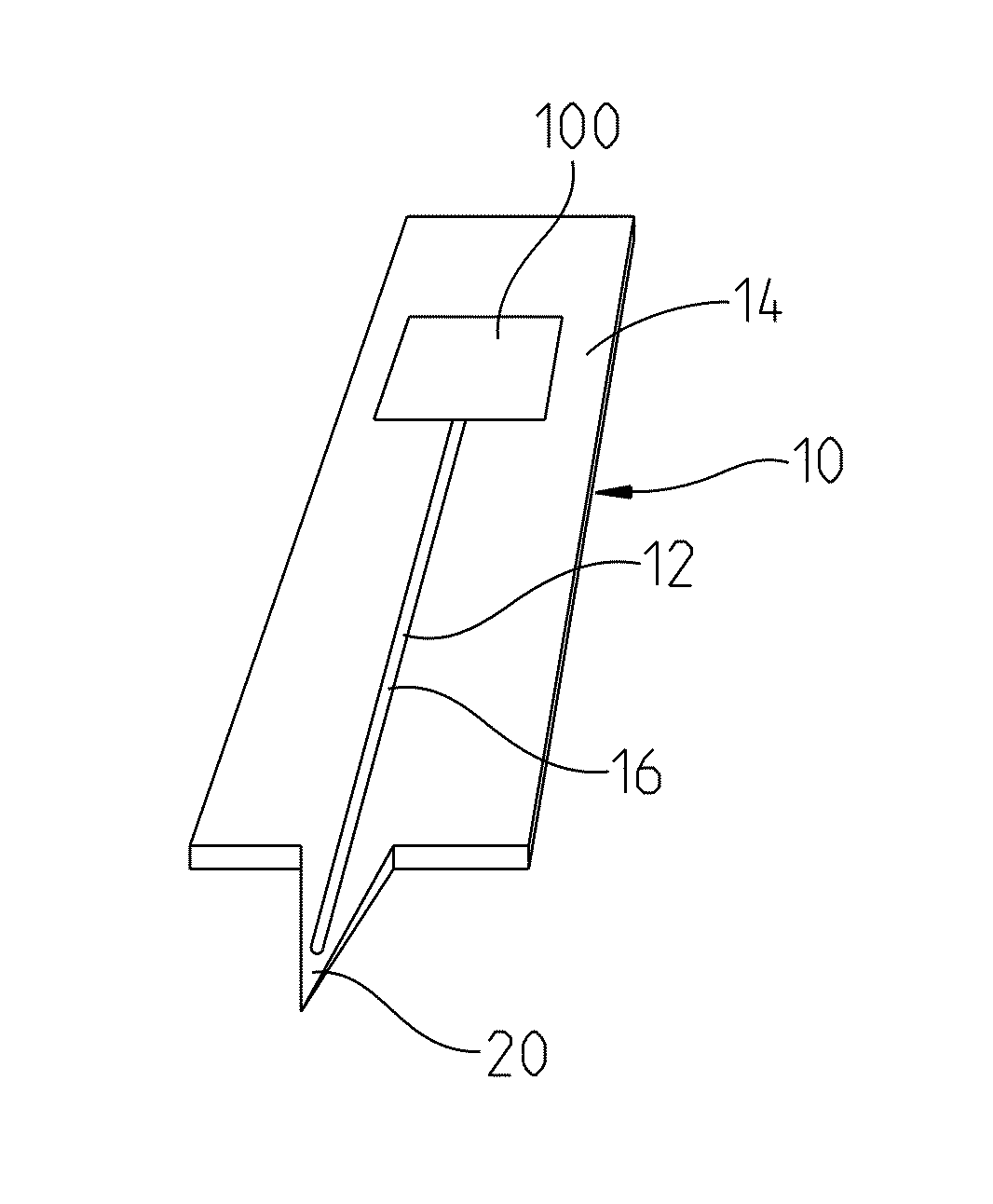

Microfluidic system and coating method therefor

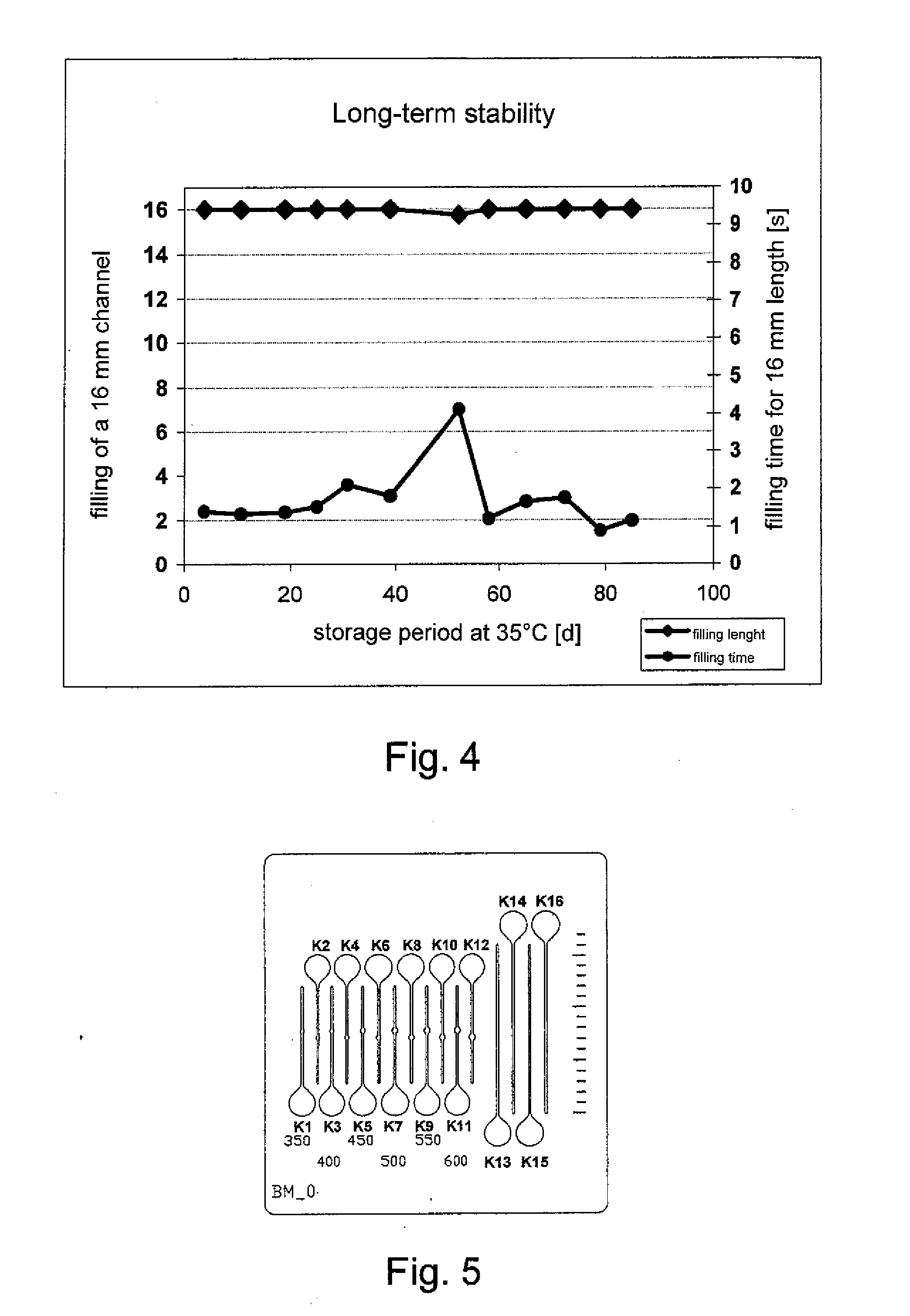

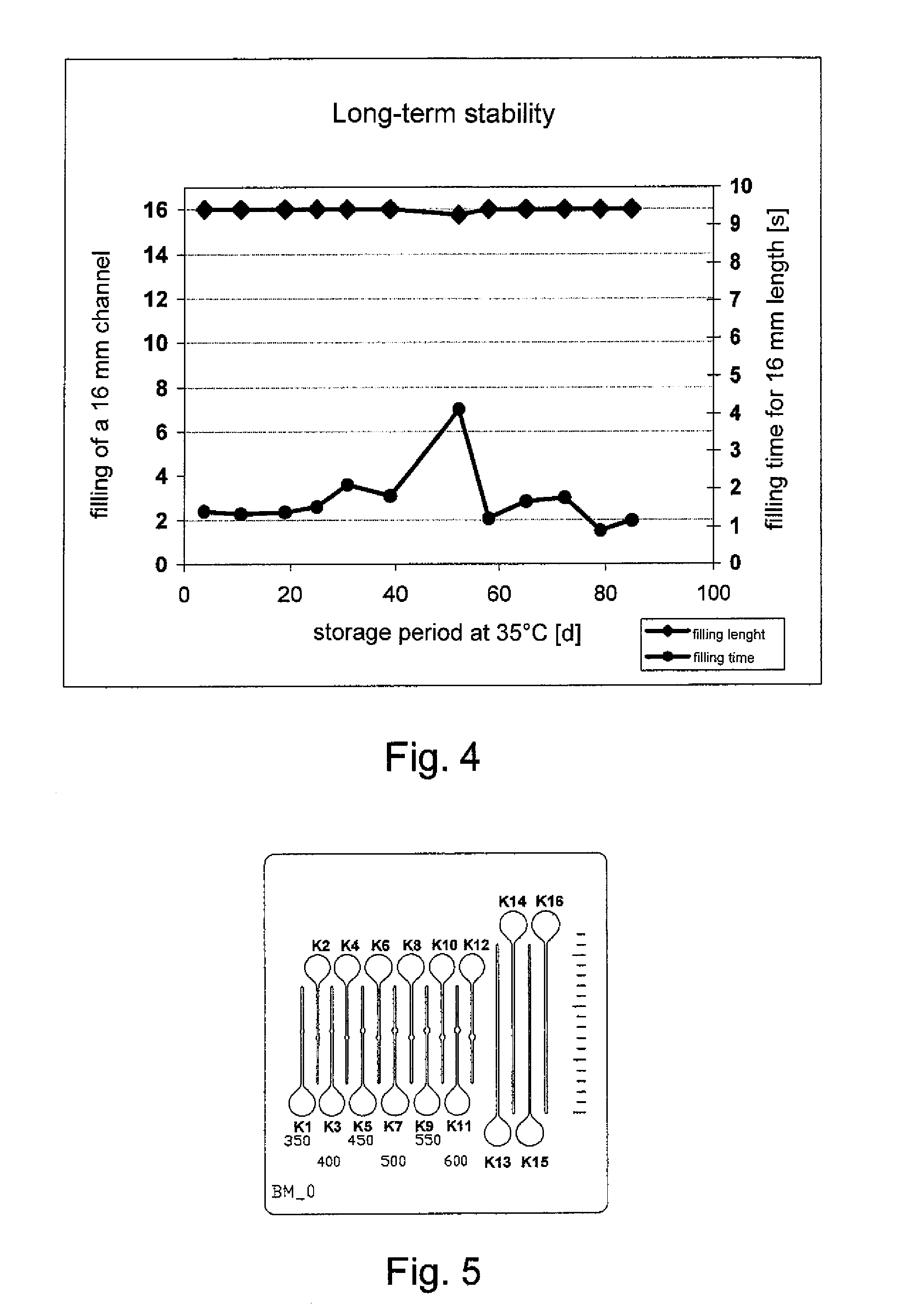

InactiveUS20080056947A1Faster filling timeResists contaminationVacuum evaporation coatingPretreated surfacesALLYL SUCROSEPolyacrylic acid

A microfluidic system having a microchannel for the capillary transport of a liquid, in particular a body fluid for analytical purposes. The microchannel is provided with a surface coating comprising at least one hydrophilic substance selected from the group consisting of polyacrylic acid, polyacrylate, dextran sulfate and chondroitin sulfate. The invention also concerns a coating method that is suitable for this.

Owner:ROCHE DIABETES CARE INC

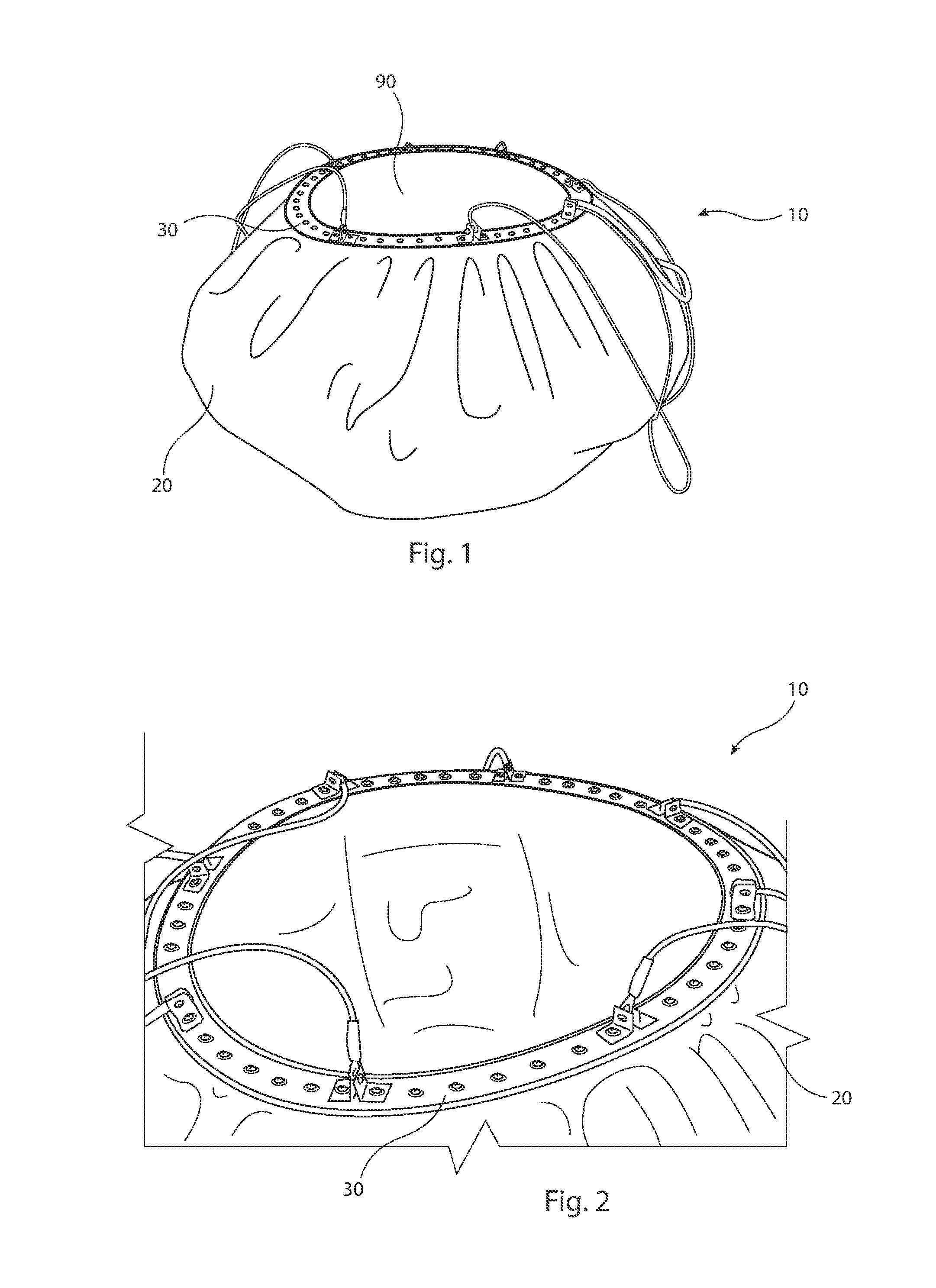

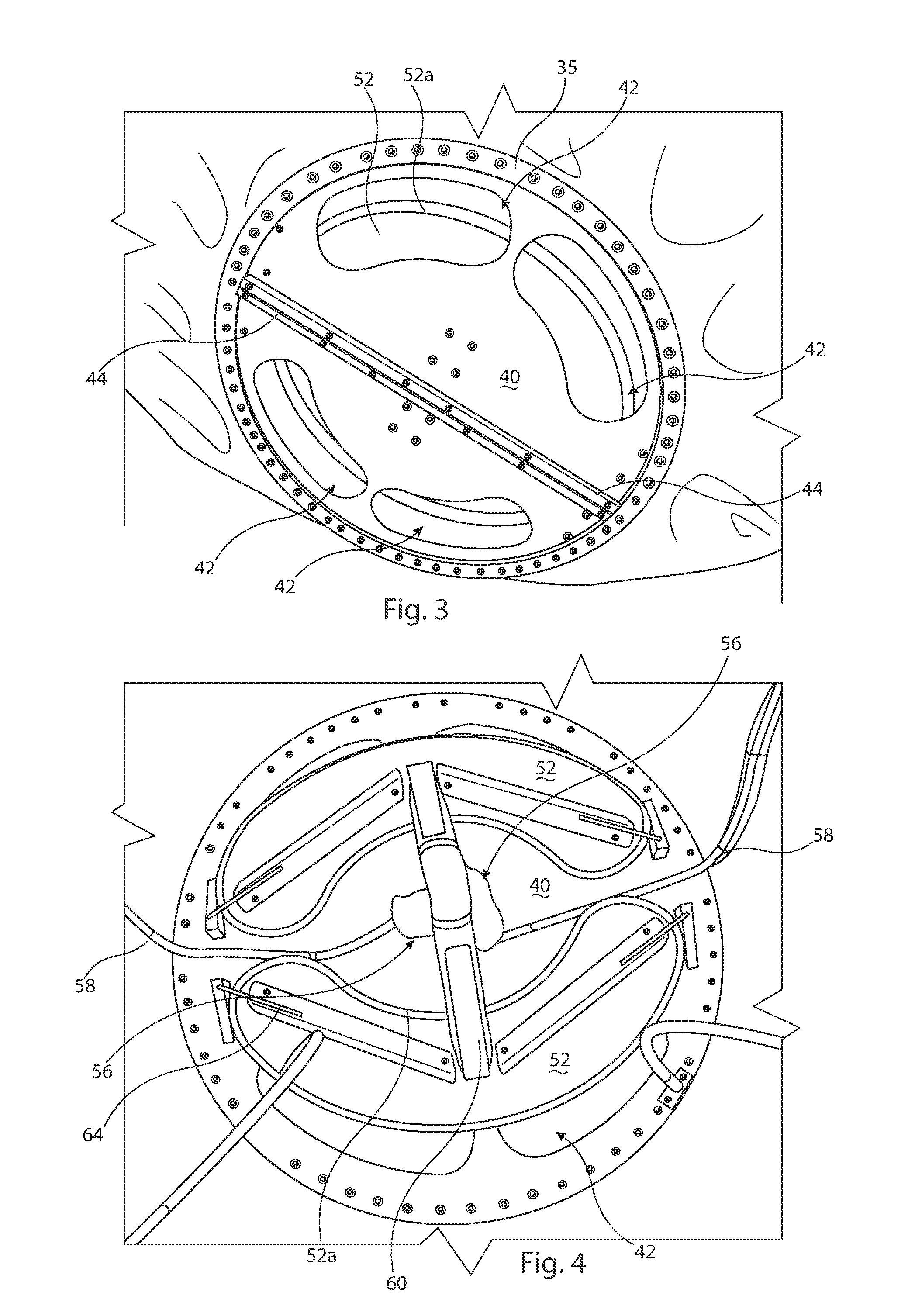

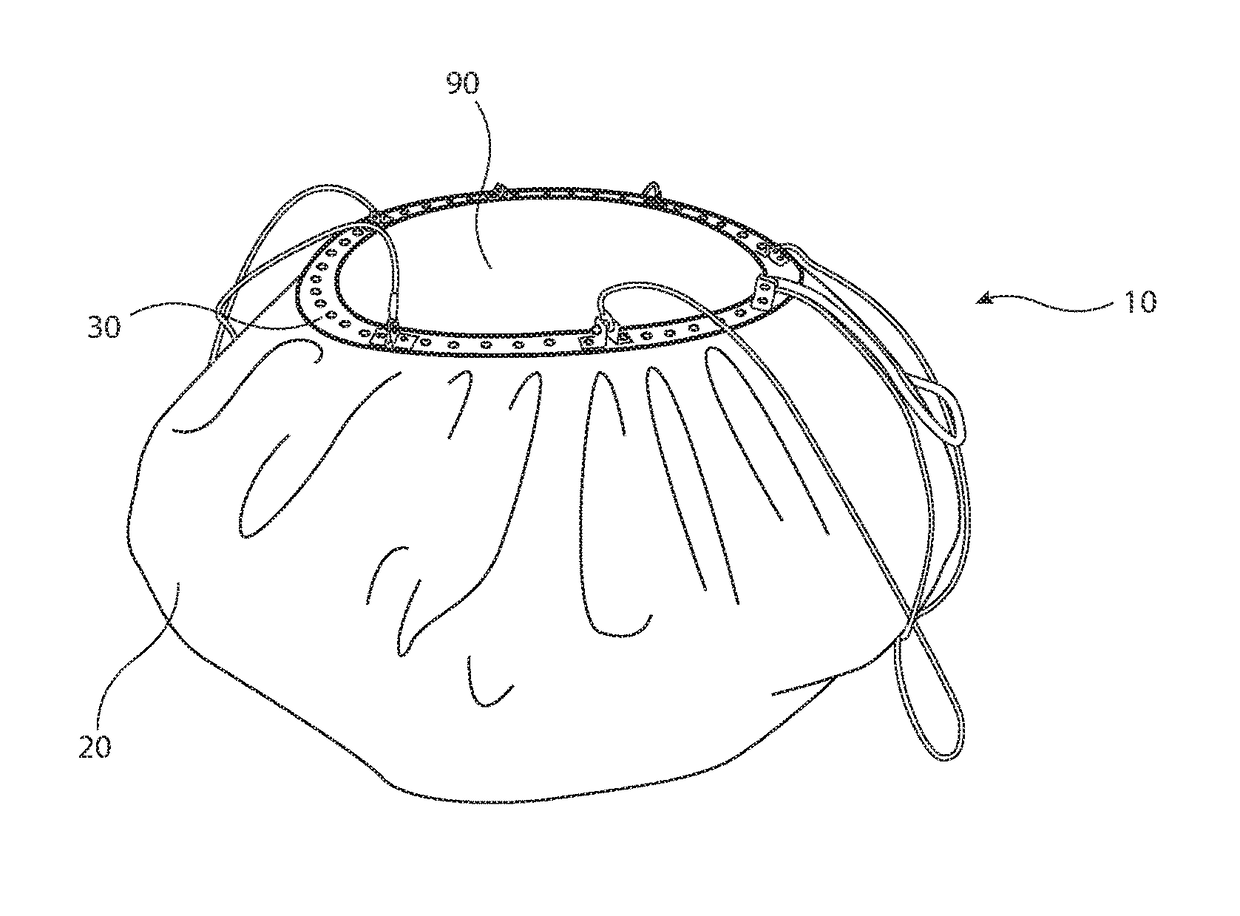

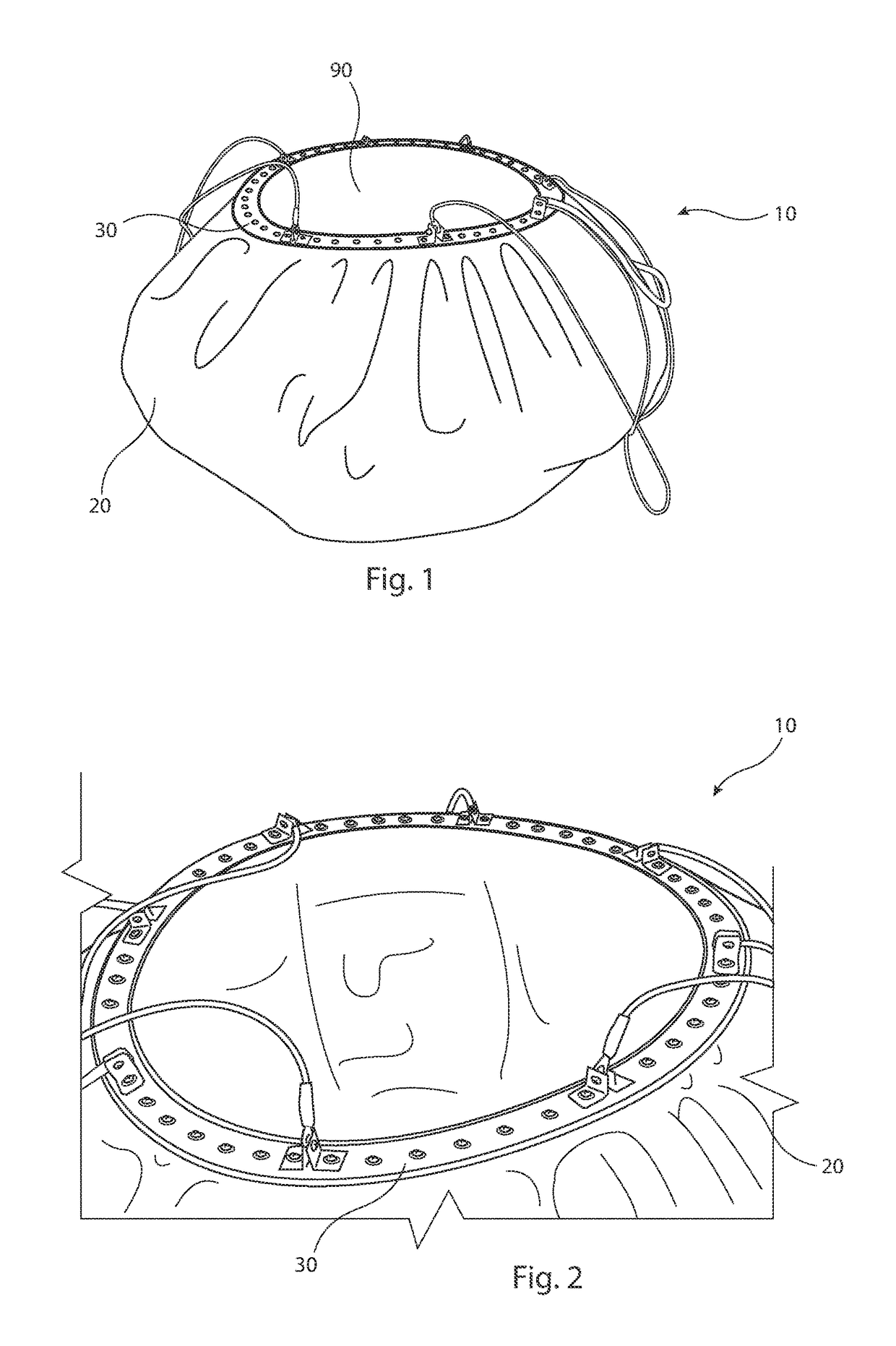

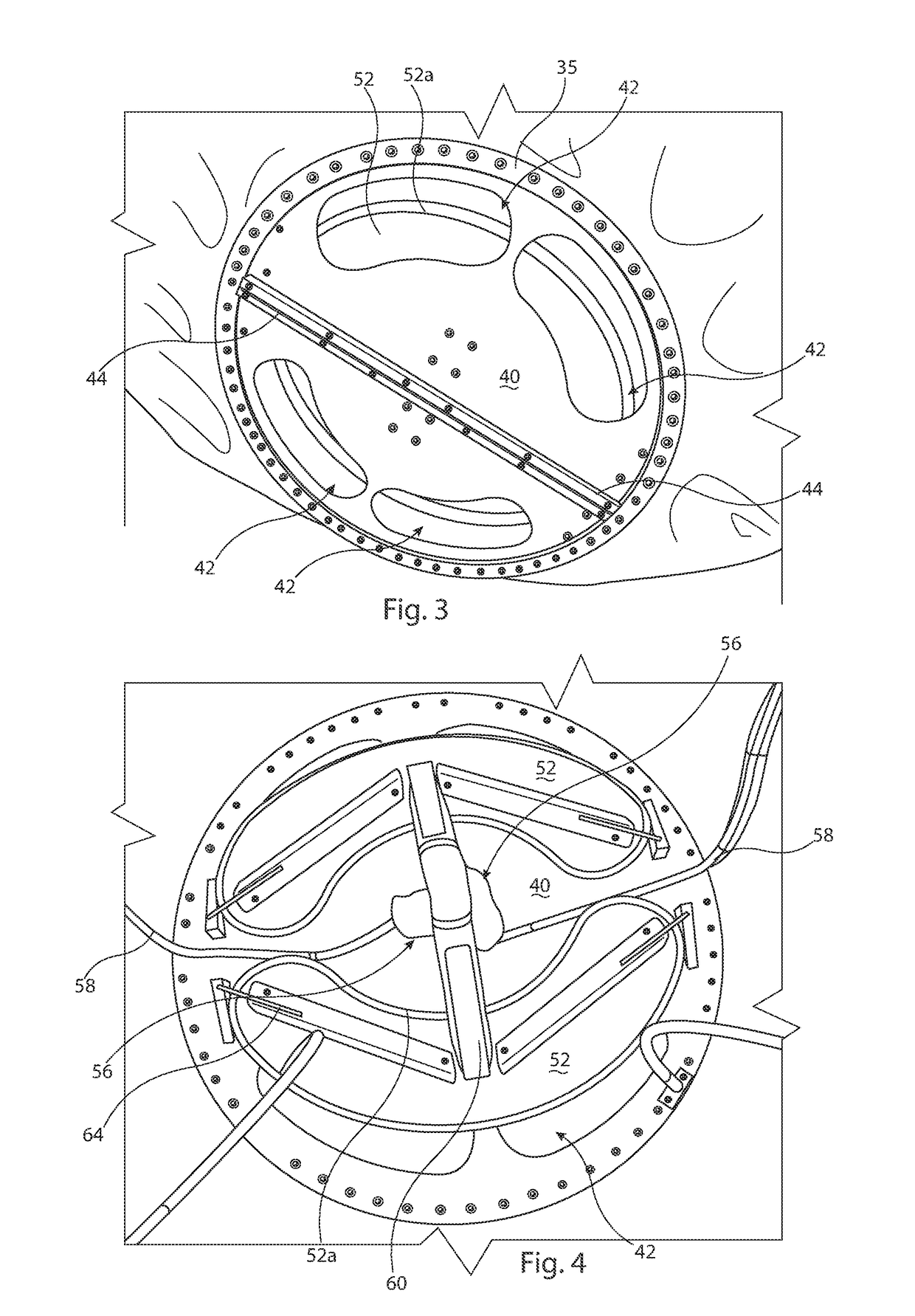

Aerial fire-fighting bucket

InactiveUS20160166863A1Shorten the timePromote rapid developmentOperating means/releasing devices for valvesFire rescueEngineeringLinear actuator

The present invention relates to an aerial fire-fighting bucket. The bucket includes a base plate and a valve arrangement including at least one valve and a liner actuator. The base plate includes at least one aperture and the valve is arranged to block the aperture in a closed position and to allow fluid to pass from within the bucket through the aperture when in an open position. The valve is arranged to be moved by the linear actuator generally transversely across an upper face of the base plate between the closed position and the open position of the valve to progressively reveal the aperture.

Owner:AERIAL FIRE CONTROL INT PTY LTD

Exosome freeze-drying powder, preparation method of exosome freeze-drying powder and preparation comprising exosome freeze-drying powder

ActiveCN110279893ALong lastingGood filling effectPharmaceutical delivery mechanismProsthesisMedicineCentrifugation

The invention discloses exosome freeze-drying powder, a preparation method of the exosome freeze-drying powder and a preparation comprising the exosome freeze-drying powder. The preparation method of the exosome freeze-drying powder comprises the following steps of: preparing platelet factor-rich plasma: collecting autologous blood for centrifugation, preparing exosome: collecting autologous fat to prepare fat mesenchymal stem cells, and culturing the mesenchymal stem cells, preparing a freeze-drying liquid: mixing the platelet factor-rich plasma and the exosome and adding trehalose for mixing, and performing freeze-drying: performing freeze-drying on the freeze-drying solution. The preparation comprises the exosome freeze-drying powder, hyaluronic acid and saline. The preparation can effectively solve the problems that the existing cosmetic preparation has a poor filling effect, short maintenance time and high immunological rejection response.

Owner:CHENGDU QINGKE BIOTECH

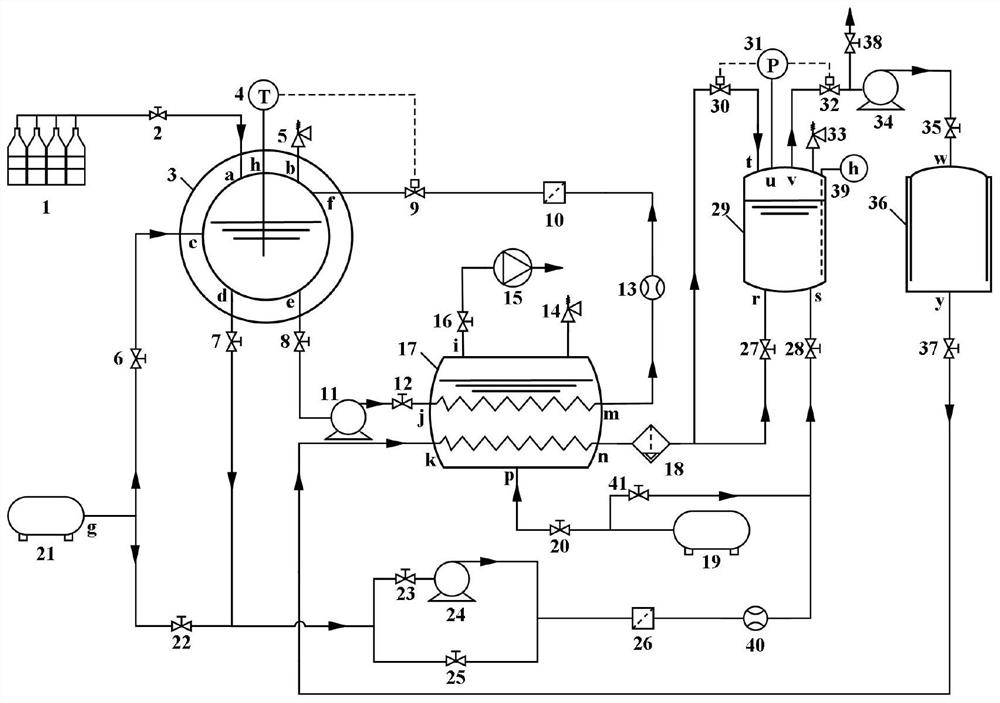

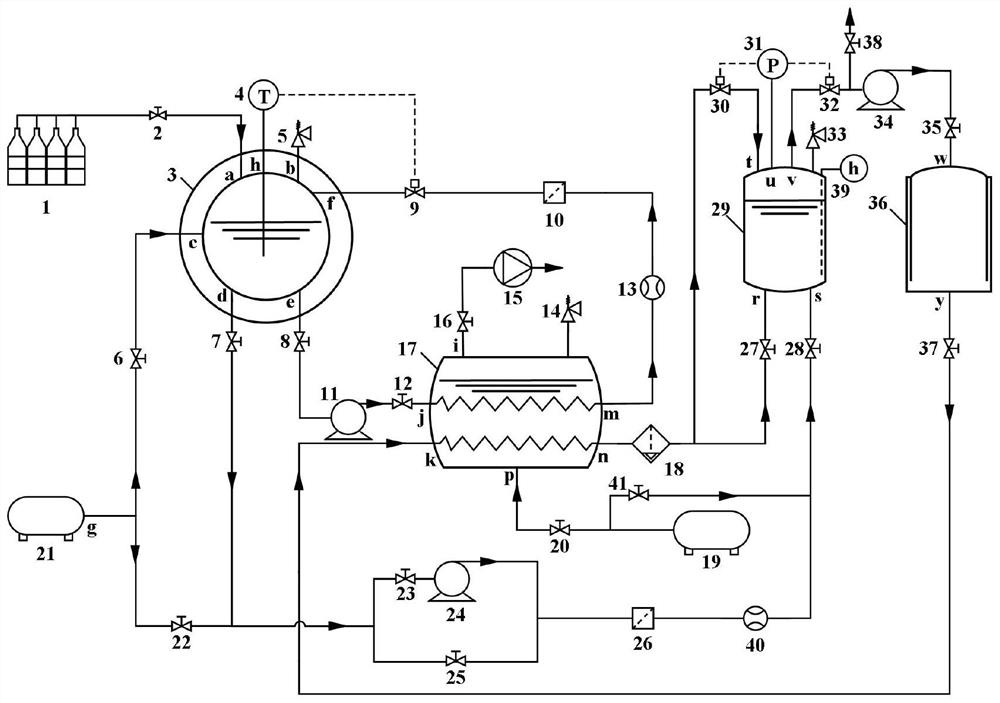

Deep supercooled liquid oxygen filling and control system in low-temperature rocket launching site and method

ActiveCN112228765AQuality improvementNo need to consider load matchingVessel wallsPipeline systemsPositive pressureRocket launch

The invention discloses a deep supercooled liquid oxygen filling and control system in a low-temperature rocket launching site and a method. The system comprises a ground circulating liquid oxygen storage tank, a negative-pressure liquid nitrogen bath type heat exchanger and an on-rocket liquid oxygen storage tank. Before launching, saturated liquid nitrogen and low-temperature helium are combinedto precool the on-rocket storage tank in sequence, after the precooling requirement is met, a large-flow filling mode is adopted for filling, and the purpose of rapid filling is achieved; and a coldhelium technology is adopted to dynamically adjust the pressure of a rocket storage tank and maintain large supercooling of liquid oxygen temperature, and meanwhile, a cold helium recycling technologyis considered based on a cryogenic liquefaction separation method. According to the system and the method, the functions of deep supercooled acquisition and high-flow rapid filling of liquid oxygen,advanced falling of a filling system, micro-positive pressure adjustment and large supercooling degree maintenance of the deep supercooled liquid oxygen of the on-rocket storage tank, helium cyclic utilization and the like are realized, and effective reference can be provided for deep supercooling and filling processes and a control mode of the liquid oxygen in the low-temperature rocket launchingsite.

Owner:XI AN JIAOTONG UNIV

Gas filling system

ActiveCN105351743AReduce the temperatureGuaranteed pressureFluid handledContainer discharging methodsGas cylinderProcess engineering

The invention discloses a gas filling system. The gas filling system comprises a gas supplying module, a gas pressurizing module and a to-be-filled module which are sequentially communicated, wherein a high-pressure cooler is further arranged in the gas pressurizing module to lower the temperature of gas in the gas pressurizing module; a pipeline switch is further arranged between the gas supplying module and the gas pressurizing module; the gas supplying module comprises at least one gas supplying bottle, and an output stop valve is further arranged at the output end of each gas supplying bottle; the to-be-filled module comprises at least one bottle to be filled with gas, and an input stop valve is further arranged between each bottle to be filled with gas and the gas pressurizing module. The gas filling system can improve the gas filling efficiency and is good in operation flexibility.

Owner:WUHU HONGQIANG SHIP EQUIP

Microfluidic system and coating method therefor

InactiveUS8961901B2Faster filling timeResists contaminationVacuum evaporation coatingPretreated surfacesALLYL SUCROSEBody fluid

A microfluidic system having a microchannel for the capillary transport of a liquid, in particular a body fluid for analytical purposes. The microchannel is provided with a surface coating comprising at least one hydrophilic substance selected from the group consisting of polyacrylic acid, polyacrylate, dextran sulfate and chondroitin sulfate. The invention also concerns a coating method that is suitable for this.

Owner:ROCHE DIABETES CARE INC

Digital control continuous liquid filling machine

A digital control continuous liquid filler comprises the digital control device, power and drive device, bottle supply device, filling device, nitrogen filling and plugging device, a stationer at the filling device with a liquid through cavity, which connects with the worm pump liquid supply pipe, rotor matching with the stator, with ring liquid through cavity connected to the stator of the rotor, ring liquid through cavity connected to the liquid through pipe of the can filler, with sealing ring between the stator and the rotor. It can reach synchronic movement of the rotor and the drug bottle together with the filling head, extending filling time with greatly improved working efficiency.

Owner:张正杰

Preparation method of Balsa wood core material of wind driven generator blade web

ActiveCN111958711AMass does not increaseLow moisture absorptionFinal product manufactureWood veneer joiningWind drivenEngineering

The invention relates to the technical field of wind driven generator blades, and particularly relates to a preparation method of a Balsa wood core material of a wind driven generator blade web. The preparation method comprises the steps of slicing, accurate grinding, dehumidification, double-end sawing treatment and gluing, and after pretreatment, shallow groove forming, punching, cloth pasting,deep groove forming, finished product inspection, template manufacturing, line drawing, edge cutting, mark writing, chamfering, IPQC process inspection, plate separation, dehumidification, laying inspection and packaging and warehousing are sequentially conducted. According to shallow groove forming, a plurality of shallow grooves are formed in at least one surface of the core material and are staggered on the surface of the core material to be arranged in a rectangular grid shape, and through holes penetrating through the upper surface and the lower surface of the core material are punched inthe intersection points of the multiple shallow grooves. According to the preparation method, three times of humidity detection are set, the moisture absorption possibility of the core material in the preparation process is further reduced, the risk of corrosion of bacteria and the like sealed in the core material in the operation process is reduced, and therefore the defects of the Balsa wood core material are effectively overcome.

Owner:常州兆庚新材料有限公司

Semiconductor device and semiconductor module employing thereof

ActiveUS7768133B2Faster filling timeLower resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringSilicon

A semiconductor device is provided with a silicon substrate and a structure filled in a through hole that has a rectangular cross section and extends through the silicon substrate. The structure comprises a pipe-shaped through electrode, stripe-shaped through electrodes, silicons, a first insulating film, a second insulating film and a third insulating film. The pipe-shaped through electrode is utilized as a pipe-shaped electric conductor that extends through the silicon substrate. In addition, the stripe-shaped through electrodes are provided in the interior of the pipe-shaped through electrode so that the stripe-shaped through electrodes extend through the silicon substrate and is spaced away from the pipe-shaped through electrode. A plurality of through electrodes are provided in substantially parallel within the inner region of the pipe-shaped through electrode.

Owner:TESSERA ADVANCED TECH

Anti-attrition oil saving agent for structural porcelain

InactiveCN101665739AReduce coefficient of frictionReduce wearAdditivesMachine partsMechanical equipment

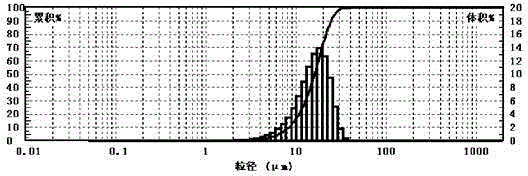

The invention relates to an anti-attrition oil saving agent for structural porcelain, comprising lubricating oil or lubricating grease used as a carrier. Natural ore powder with fineness specificationof 500 nanometers-2 micrometer is uniformly added in the lubricating oil or the lubricating grease, the content of the natural ore powder in the lubricating oil or the lubricating grease is 0.01-1%,the natural ore powder comprises the following elements in percentage by weight: 5-20% of silicon, 5-20% of aluminum, 5-20% of calcium, 5-20% magnesium, 1-10% of ferrum and 1-10% of natrium, and the natural ore powder is selected and added in the lubricating oil or the lubricating grease according to a certain proportion, and after emulsification and diffusion treatment, the anti-attrition oil saving agent is prepared. A appropriate amount of the anti-attrition oil saving agent is added in engine oil so as to synthesize a smooth and hard structural porcelain protection layer with machine bodyelements on a negative friction surface in virtue of heat energy generated by high-temperature fuel gas of the engine and friction during the operation of mechanical equipment, thereby reducing the friction coefficients of machine parts and the abrasion and achieving the purpose of saving oil.

Owner:关景瀛

A kind of poly-L-lactic acid filler for injection and preparation method thereof

ActiveCN105879124BFast dissolutionGood dispersionPharmaceutical delivery mechanismProsthesisAlcoholFiller Excipient

The invention discloses an L-polylactide filler for injection and a preparation method thereof. Active ingredients of the filler are L-polylactide particles, honeycomb HA and a synergist, the honeycomb HA is obtained by alcohol precipitation and drying of a water solution formed by mixing sodium hyaluronate high in molecular weight and sodium hyaluronate low in molecular weight in an alkaline condition, and the synergist is mannitol or a mixture of mannitol and aloe polysaccharide with a mass ratio of 1:0.05-0.12. The filler is simple to prepare, shorter in re-suspension time, long in validity period and more convenient to use.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

Aerial fire-fighting bucket

InactiveUS9914000B2Easy to controlReduces insipient dragOperating means/releasing devices for valvesFire rescueEngineeringLinear actuator

Owner:AERIAL FIRE CONTROL INT PTY LTD

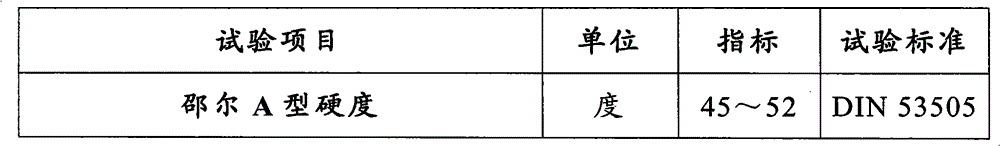

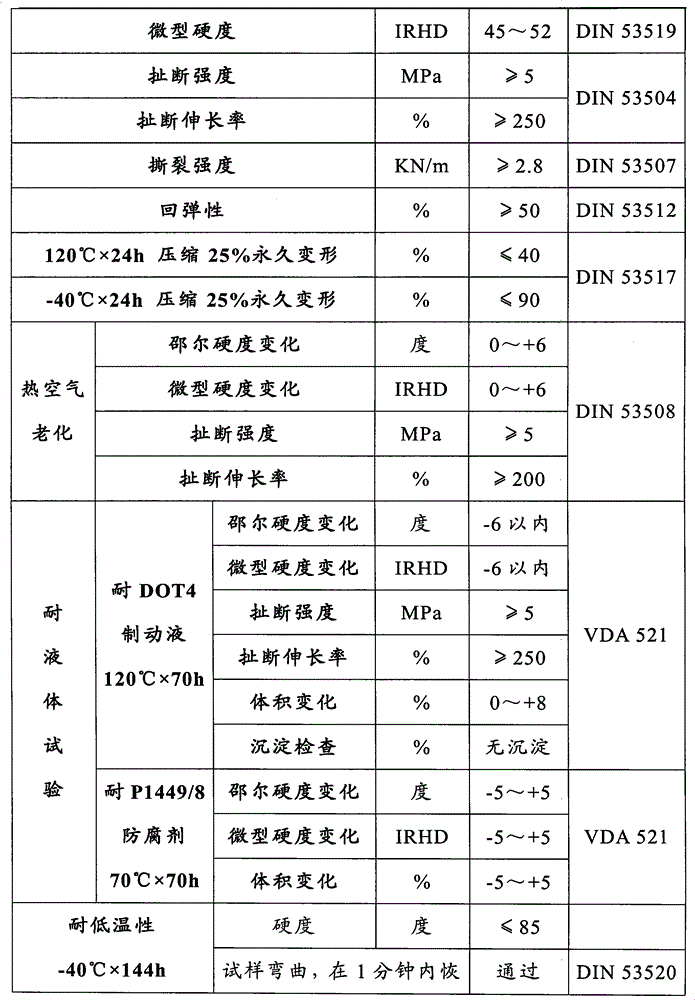

Oil inlet sealing ring material for vehicle brake master cylinder and process thereof for manufacturing sealing ring

The invention discloses an oil inlet sealing ring material for a vehicle brake master cylinder and a process thereof for manufacturing a sealing ring. The material is prepared from the following components in part by weight: 80 to 120 parts of ethylene propylene rubber, 4 to 6 parts of active agent, 1 to 3 parts of lubricant, 2 to 4 parts of acid-base balance agent, 1 to 3 parts of age resistor, 2 to 4 parts of sulfurizing agent and 25 to 35 parts of inorganic filler; then the components are subjected to the processes, namely mixing and molding, primary sulfurizing, punching and edge removingand secondary sulfurizing to obtain the oil inlet sealing ring material product with high strength, low compression deformation, tear resistance, resistance to braking fluid corrosion, resistance to low and high temperatures and excellent performance for the vehicle brake master cylinder; and the production efficiency and the product percent of pass are high, and the product can completely substitute similar imported products.

Owner:DATWYLER SEALING TECH ANHUI

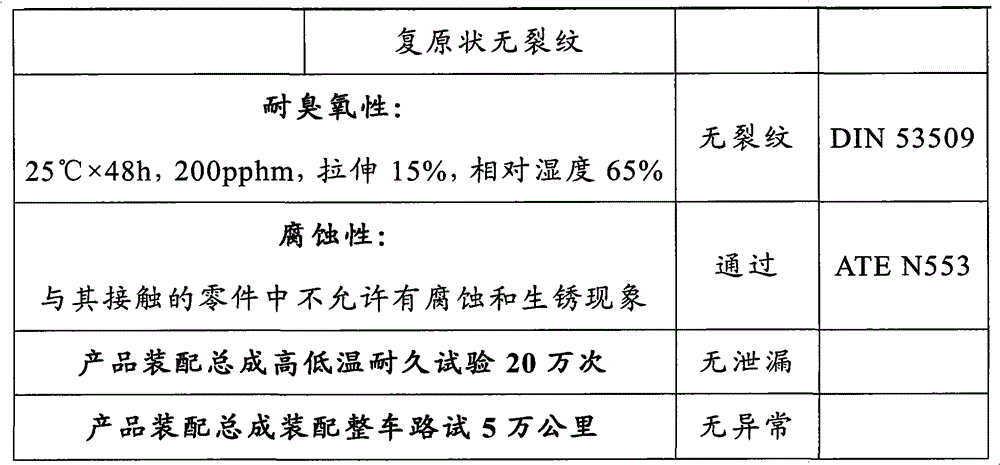

Oil-well pump energy-storage enhancing device capable of compressing natural gas automatically

InactiveCN103161433AReduce turn-on timeFast pumping speedPositive displacement pump componentsFluid removalCompressed natural gasEngineering

The invention discloses an oil-well pump energy-storage enhancing device capable of compressing natural gas automatically. The oil-well pump energy-storage enhancing device capable of compressing the natural gas automatically comprises an upper connector, an inner pipe, an outer pipe and a lower connector, wherein the upper connector is connected with an oil-well pump, and the lower connector is connected with a tail pipe. The oil-well pump energy-storage enhancing device capable of compressing the natural gas automatically is characterized in that the inner pipe and the outer pipe which are coaxial form an annular space with the sealed upper portion and the communicated lower portion, the annular space serves as a storage space of the natural gas separated from crude oil and an energy-storage and energy-release space for compression and expansion of the natural gas, and gas pressure-limitation holes with certain quantity and inner diameter are formed at the lower portion of the outer pipe and serve as a discharging passageway for residual gas in annular spaces of the inner pipe and the outer pipe. The oil-well pump energy-storage enhancing device capable of compressing the natural gas automatically is simple in structure, free of any moving component, stable, reliable, convenient to construct on site, and environment-friendly, and does not pollute the environment and an oil layer. The natural gas is compressed automatically as an energy-storage method, additional power is not needed, the problem of the service life in the energy-storage process of a compression spring is resolved at the same time, and the practicality is strong. The oil-well pump energy-storage enhancing device has a function as a gas anchor, is capable of preventing separated gas from entering the pump, and reduces the influence on pump efficiency when the gas enters the pump.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Deep subcooled liquid oxygen filling and control system and method in cryogenic rocket launch site

ActiveCN112228765BQuality improvementNo need to consider load matchingVessel wallsPipeline systemsRocket launchControl system

A deep supercooled liquid oxygen filling and control system and method in a low-temperature rocket launch site, including a ground circulation liquid oxygen storage tank, a negative pressure liquid nitrogen bath heat exchanger and an arrow liquid oxygen storage tank; The combination of liquid nitrogen and low-temperature helium pre-cools the storage tanks on the arrow successively. After the pre-cooling requirements are met, the high-flow filling method is used for filling to achieve the goal of rapid filling; the pressure of the rocket storage tanks is controlled by cold helium technology. Carry out dynamic adjustment and maintenance of large supercooling of liquid oxygen temperature. At the same time, based on the low-temperature liquefaction separation method, cold helium gas recovery and reuse technology is considered; the invention realizes deep supercooling acquisition of liquid oxygen, rapid filling of large flow rate, and filling system The functions of falling off in advance, micro-positive pressure adjustment of deep supercooled liquid oxygen in storage tanks on arrows, maintenance of large supercooling degree, and recycling of helium can provide effective support for deep supercooling of liquid oxygen, filling process and control methods of cryogenic rocket launch sites. refer to.

Owner:XI AN JIAOTONG UNIV

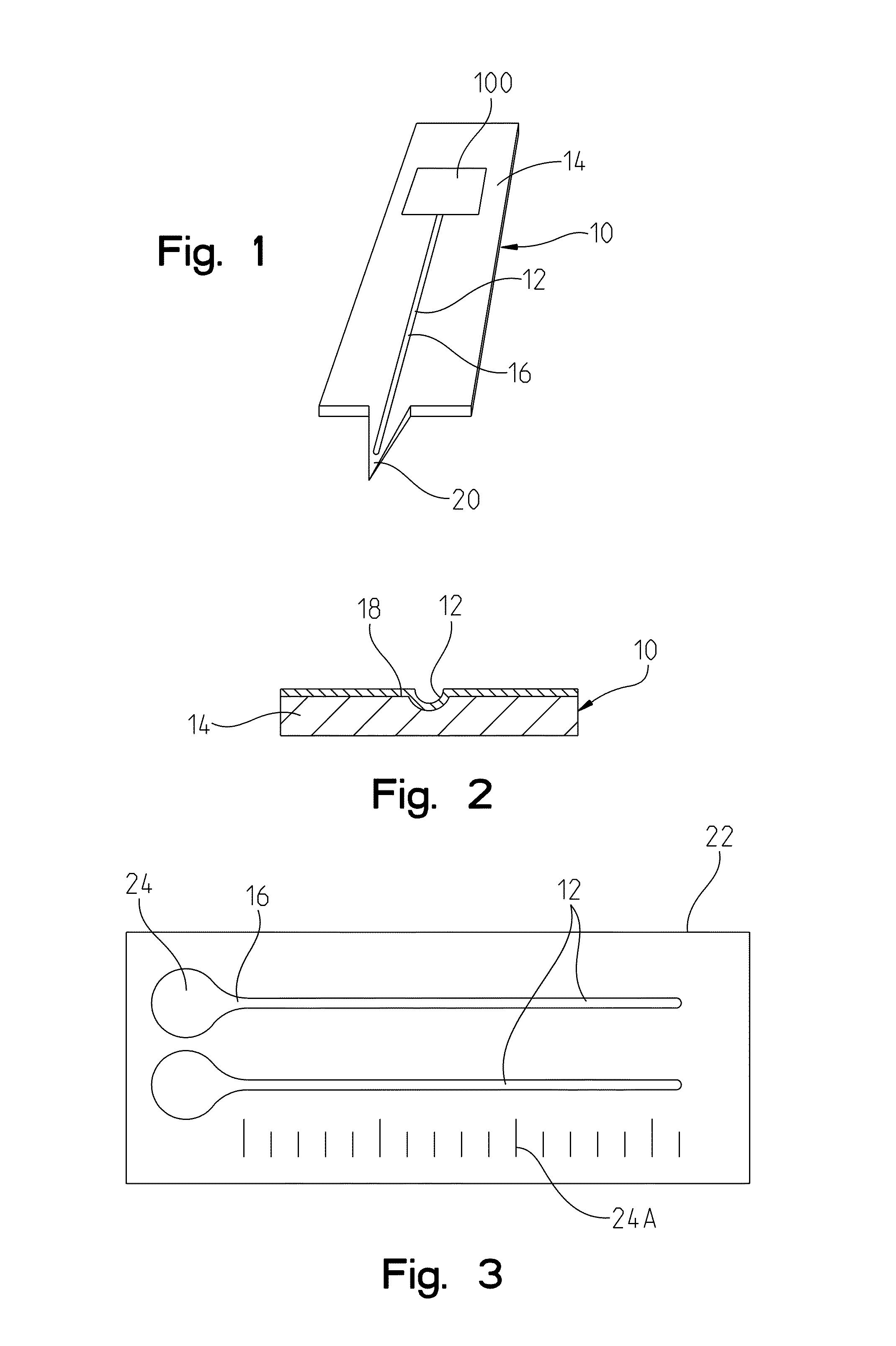

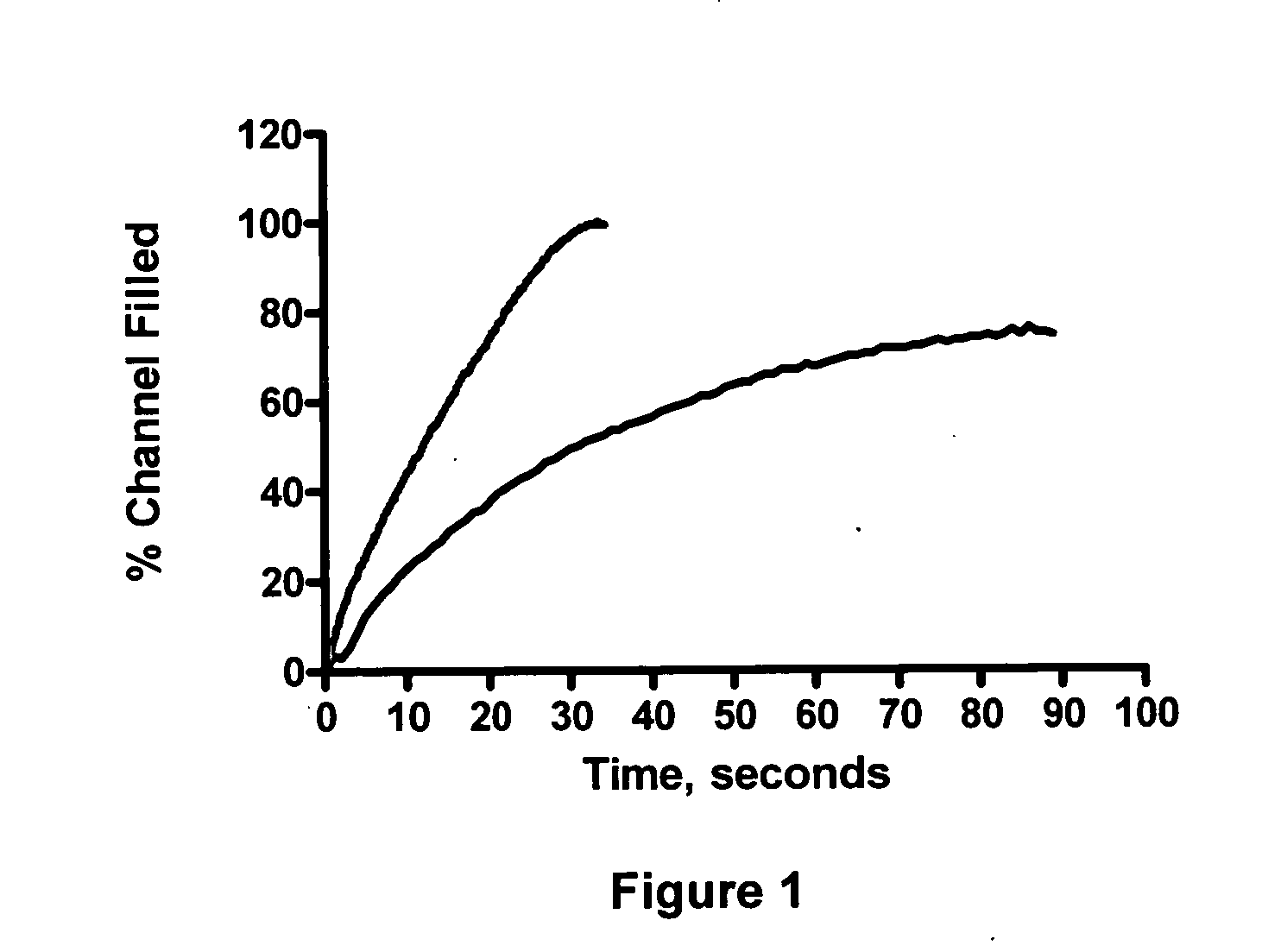

Rough channel microfluidic devices

InactiveUS20070140913A1Less susceptibleMore predictableAnalysis using chemical indicatorsFluid dynamicsEngineeringMicrofluidic channel

There is provided a rough microfluidic channel for use, for example, in a lateral flow assay device. The rough microfluidic channel has a roughness greater than a similar channel that is smooth, as measured by a Reynolds number for flow under otherwise identical conditions, which is at least 50 percent greater than the Reynolds number for the smooth channel. Alternatively, the roughness may be greater than a similar channel that is smooth, as measured by the fill time which is at least 25 percent lower for said rough channel than said smooth channel.

Owner:KIMBERLY-CLARK WORLDWIDE INC

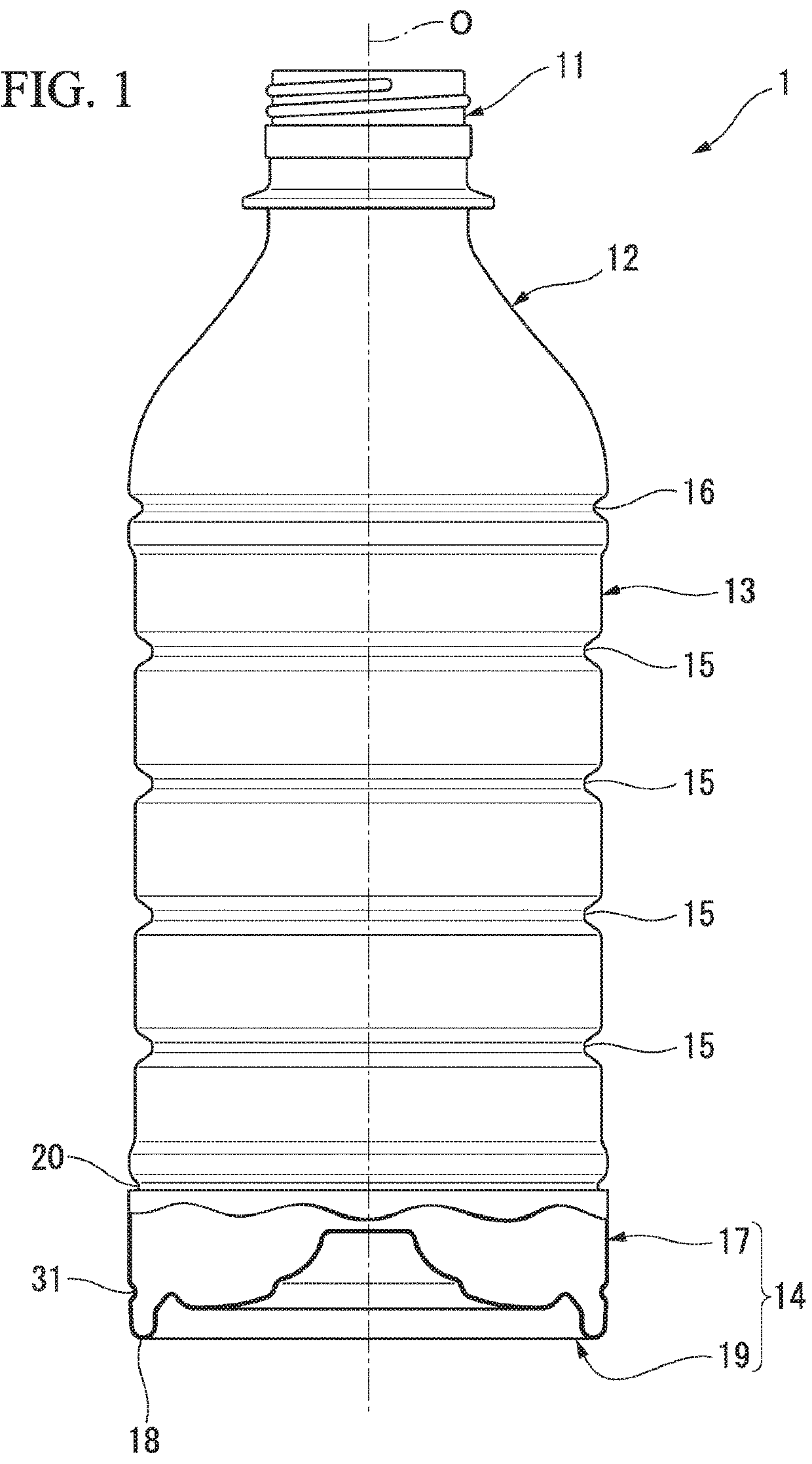

Pressure reduction-absorbing bottle

The present invention is a pressure reduction-absorbing bottle having a cylindrical shape with a bottom made of a synthetic resin material in which a bottom wall portion of a bottom portion of the bottle includes a grounding portion, a rising circumferential wall portion, a movable wall portion, and a central wall portion, the movable wall portion includes a curved portion having a curved surface shape protruding downward, the curved portion is connected to an outer end portion of the central wall portion in a bottle radial direction, and a lowest portion of the curved portion positioned at a lowest position thereof is located at a portion of the curved portion further outward in the bottle radial direction than a central position of the curved portion in the bottle radial direction.

Owner:YOSHINO KOGYOSHO CO LTD

A kind of exosome freeze-dried powder and its preparation method and preparation comprising the exosome freeze-dried powder

ActiveCN110279893BLong lastingGood filling effectPharmaceutical delivery mechanismSkeletal/connective tissue cellsFreeze-dryingBlood plasma

The invention discloses a freeze-dried exosome powder, a preparation method thereof, and a preparation containing the freeze-dried exosome powder. The preparation method of the freeze-dried exosome powder includes the following steps: preparation of platelet-rich factor plasma: taking Autologous blood, prepared by centrifugation, prepared by exosomes; obtained from autologous fat, prepared adipose-derived mesenchymal stem cells, and cultured the mesenchymal stem cells; prepared by lyophilization: platelet-rich factor plasma, and exosomes The body is mixed, and trehalose is added therein, and mixed to obtain the preparation; freeze-drying: the freeze-dried liquid is subjected to freeze-drying to obtain the preparation. The preparation includes freeze-dried exosome powder, hyaluronic acid and physiological saline, which can effectively solve the problems of poor filling effect, short maintenance time and large immune rejection in existing cosmetic preparations.

Owner:CHENGDU QINGKE BIOTECH

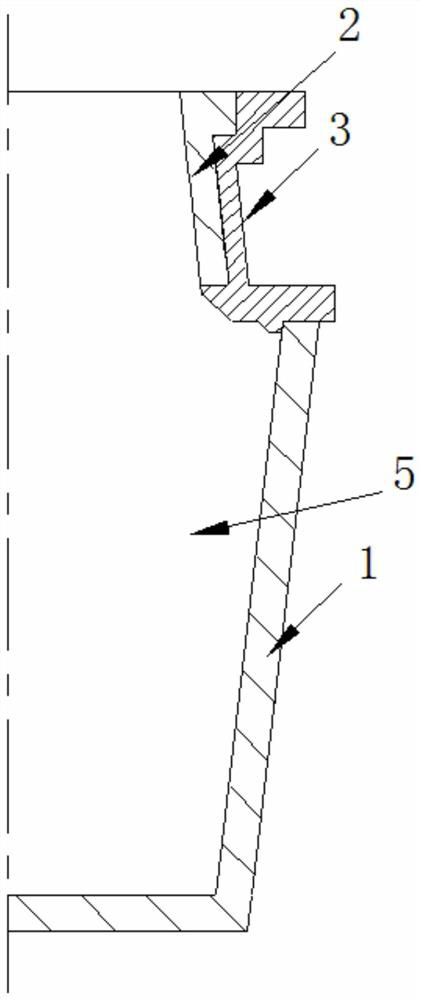

Mounting structure of die-cast cap mouth shell and method of die-casting pouring

The invention relates to an installation structure of a die-cast cap mouth shell and a die-cast pouring method, which belong to the technical field of metal casting. In the present invention, one or two inwardly protruding structures are arranged on the lower part of the inner cavity of the split-type cap mouth shell. It has a trapezoidal cross-section and fits with the inner surface of the metal mold; the above-mentioned raised structure can play a transitional role in the pouring process, and the lower end surface of the heat-insulating plate is flat, and the lower end of the heat-insulating plate is no longer provided with a chamfer structure, so as to avoid The previous problem of easy damage to the refractory material caused by the thinning of the chamfer at the lower part of the heat insulation board and the defect of the ingot is solved, and the yield of the final ingot can be increased by 2% to 5%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Structure ceramic metal abrasion reduction material

The invention relates to a structure ceramic metal abrasion reduction material which comprises lubricating oil or lubricating grease used as a carrier; natural ore powder with the fineness specification of 100 to 500 nanometers is uniformly added into the lubricating oil or the lubricating grease; the content of the ore powder in the lubricating oil or the lubricating grease is 0.1% to 1%; the core powder comprises elementary components: 5% to 20% of silicon, 5% to 20% of aluminium, 5% to 10% of calcium, 5% to 20% of magnesium, 5% to 10% of carbon, 1% to 10% of iron, 1 to 10% of sodium and 0.01% to 1% of scandium; the structure ceramic metal abrasion is prepared by the steps of: selecting the ore powder, adding the ore powder into the lubricating oil or the lubricating grease according toa certain proportion and carrying out emulsification and diffusion treatment; a right amount of reduction material is added into machine oil of an engine; in the running process of mechanical equipment, the reduction material is combined with engine body elements on the frictional negative surface by virtue of the heat energy generated by the high temperature gas and the friction of the engine toform a smooth and hard structure ceramic protective layer, thereby achieving the purpose that frictional factors of the machine elements are decreased, the abrasion is reduced, the service life of the machine elements is prolonged and the oil is saved.

Owner:中科宝鹿新材料(辽宁)有限公司

Device for introducing filling material into capsules

ActiveUS9549876B2Low structural expenditureImprove performanceCapsule deliveryLiquid bottlingFilling materialsBiomedical engineering

The present invention relates to a device for introducing filling material (21) into capsules (22), comprising a filling device (25) for feeding filling material (21) to the capsules (22), a capsule holder (30) with at least one row of seats (31) in which the capsules (22) that are to be filled are arranged, a station arrangement with several stations arranged one after another, wherein the station arrangement comprises at least one filling station (5) and a synchronously operating drive, and a movement device which, at the capsule-filling station (5), executes a relative movement between the filling device (25) and the capsule holder (30), wherein the filling device (25) adopts, relative to the capsule holder (30), at least a first filling position for filling a first capsule and a second filling position for filling a second capsule.

Owner:SYNTEGON TECHNOLOGY GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com