Device for introducing filling material into capsules

a filling machine and capsule technology, applied in capsule delivery, medical preparations, packaging, etc., can solve the problem of restricting the production capacity of the filling machine, and achieve the effect of preventing the influence of product properties and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

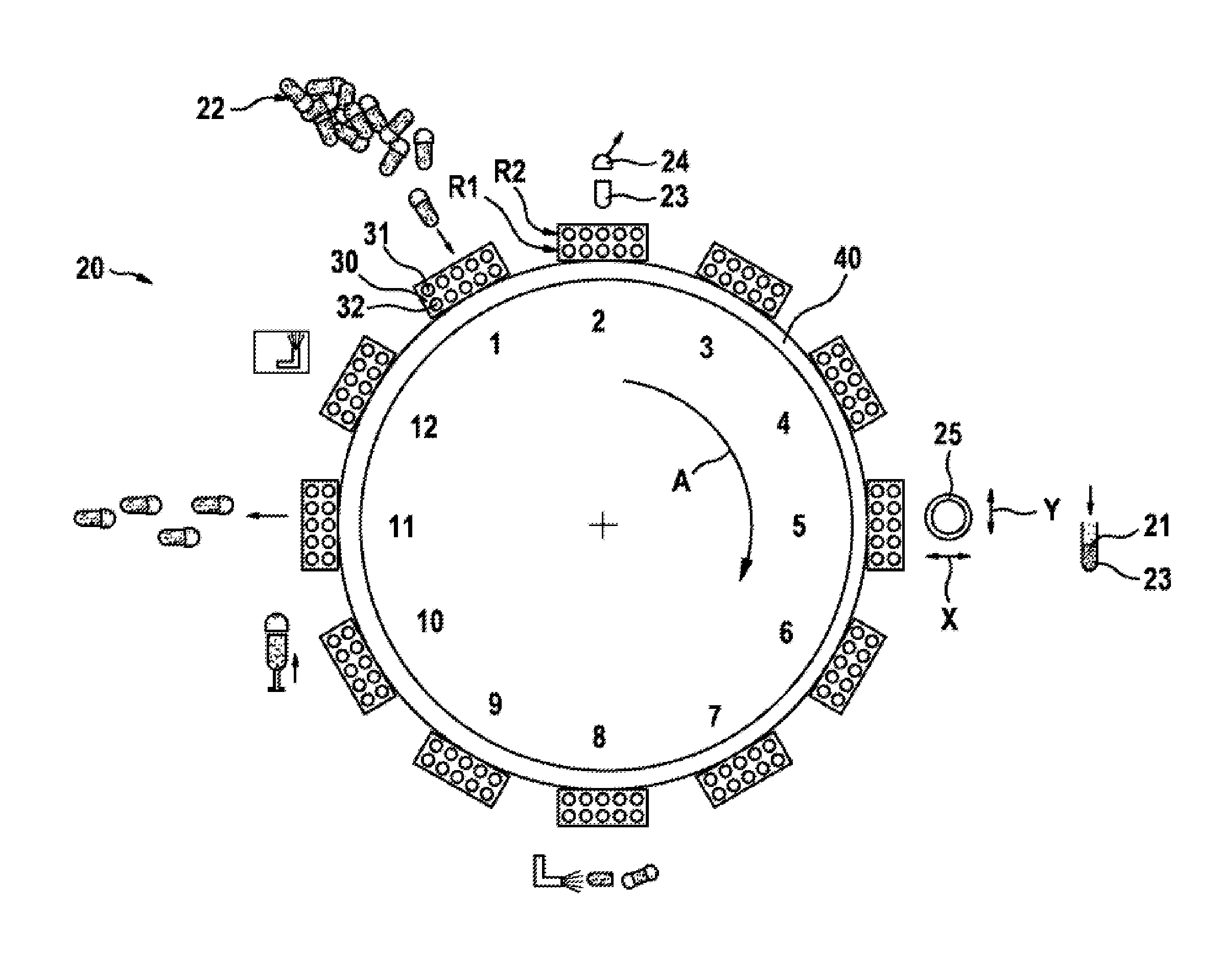

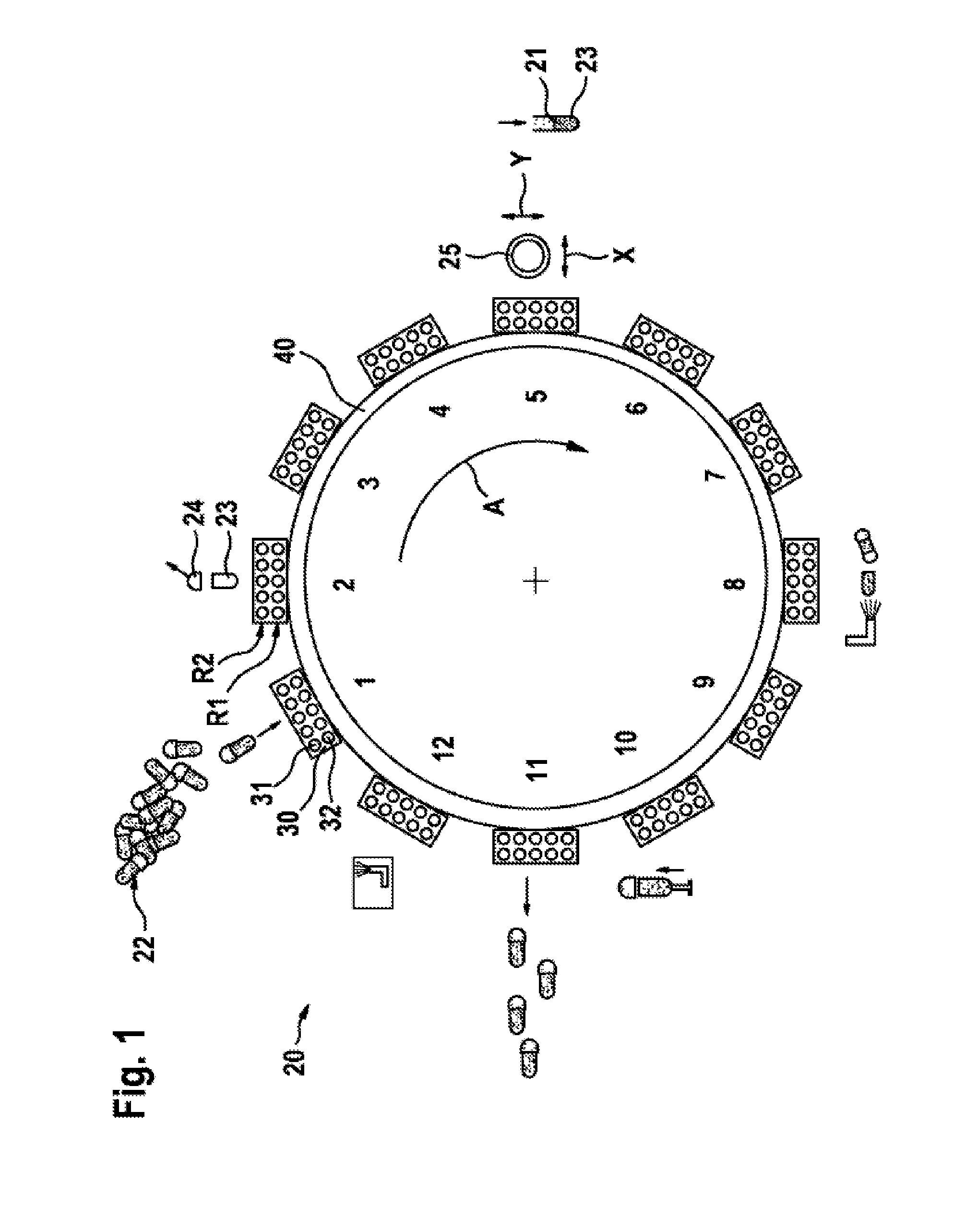

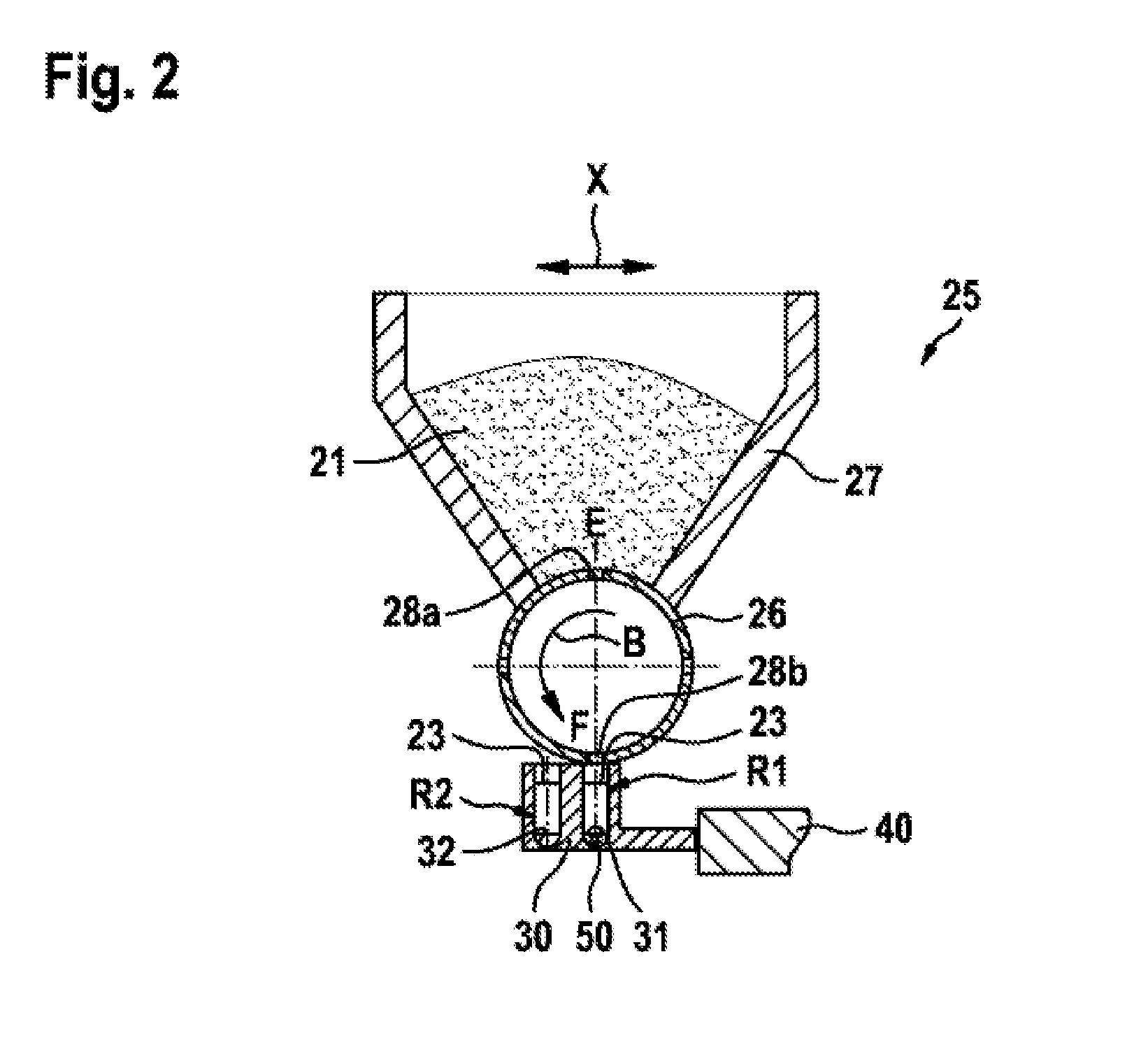

[0029]A device 20 for introducing powdery filling material 21 according to a first preferred exemplary embodiment is described in detail below with reference to FIGS. 1 to 5.

[0030]FIG. 1 shows an overall view of the device 20 which includes a station wheel 40 having a total of twelve stations 1 to 12. A total of twelve capsule holders 30 are arranged along the circumference of the station wheel 40, each capsule holder 30 having a plurality of accommodating means 31, 32 for accommodating capsules 22. The accommodating means 31, 32, in this case, are arranged in two rows, namely a first row R1 and a second row R2, parallel to each other in each capsule holder 30. A direction of rotation of the station wheel 40 is marked by the arrow A.

[0031]The stations of the station wheel 40, in this case, are as follows. Empty, closed capsules, which include a capsule bottom part 23 and a capsule top part 24, are supplied from a hopper to the station 1. The capsules, in this case, are inserted indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com