L-polylactide filler for injection and preparation method thereof

A technology of L-polylactic acid and fillers, which is applied in the fields of pharmaceutical formula, medical science, prosthesis, etc., can solve the problems of inconvenient application, accumulation of D-lactic acid, biocompatibility without hyaluronic acid, etc., and reduce hydration The effect of mixing time, improving skin quality, and reducing subcutaneous nodules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The filler formula is (wt%, the same as in the following examples): L-polylactic acid 41%, honeycomb HA 11%, mannitol 48%. The molecular weight of poly-L-lactic acid is 50000 Da.

[0055] The preparation method of filler is as follows:

[0056] 1. Preparation of L-polylactic acid microparticles: Under the condition that the working pressure is 0.6 MPa and the feed rate of L-polylactic acid is 60g / min, it is pulverized with a jet mill to prepare L-polylactic acid particles with an average particle size of 30 μm and a molecular weight of 50000 Da. Lactic acid microparticles, the obtained microparticles were soaked and washed twice with a hydrochloric acid solution of pH 6.0, and dried in vacuum to obtain L-polylactic acid microparticles.

[0057] 2. Preparation of Honeycomb HA: Dissolve 3 g of high molecular weight sodium hyaluronate with a molecular weight of 2000 kDa and 7 g of low molecular weight sodium hyaluronate with a molecular weight of 300 kDa in 400 g of water...

Embodiment 2

[0060] Filler formula: with embodiment 1.

[0061] The preparation method of filler is as follows:

[0062] 1. Preparation of L-polylactic acid microparticles: Under the condition that the working pressure is 0.6 MPa and the feed rate of L-polylactic acid is 60g / min, it is pulverized with a jet mill to prepare L-polylactic acid particles with an average particle size of 30 μm and a molecular weight of 50000 Da. Lactic acid microparticles, the obtained microparticles were infiltrated and washed twice with a hydrochloric acid solution of pH 6.0, and then the L-polylactic acid microparticles were transferred to a 10 μm microporous filter and soaked in a volume fraction of 15%-20% with hydrochloric acid adjusted to a pH of 6.0. (v / v) ethanol solution, sieve out some tiny particles by dead-end filtration under stirring, and dry in vacuum to obtain L-polylactic acid particles.

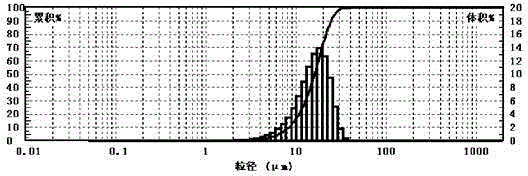

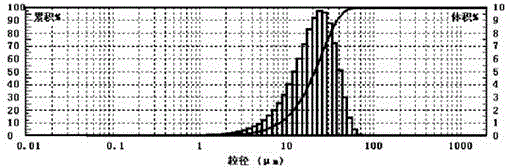

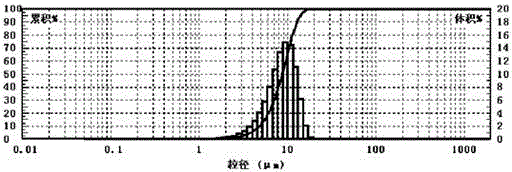

[0063] Figure 1-3 It is the particle size distribution of the particles tested by the Winner2308A lase...

Embodiment 3

[0068] Filler formula (wt%): L-polylactic acid 41%, honeycomb HA 11%, mannitol 48%. The molecular weight of poly-L-lactic acid is 50000 Da.

[0069] The preparation method of filler is as follows:

[0070] 1. Preparation of L-polylactic acid microspheres: Dissolve L-lactic acid in dichloromethane to make a solution with a mass concentration of 3.0%, take 40ml of the solution, and slowly inject 640mL of 0.15% (w / v) in a polyvinyl alcohol (PVA) aqueous solution, stirring and emulsifying at room temperature for 5 min; after the emulsification is completed, stirring and volatilizing under normal pressure or reduced pressure to remove methylene chloride, filtering the remaining reaction solution, and washing the filter cake 3 times to obtain L-polylactic acid microspheres, particle size 30μm, molecular weight of L-lactic acid 50000Da.

[0071]2. Preparation of Honeycomb HA: Dissolve 3 g of high molecular weight sodium hyaluronate with a molecular weight of 2000 kDa and 7 g of lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com