Steam sterilization process and steam sterilization apparatus employed the same

A technology of steam sterilization and sterilizer, which is applied in heating and other directions, can solve the problems of long heating and cooling time for sterilization, high requirements for environmental cleanliness, and prolonging the heating time of sterilization, so as to shorten the heating and cooling time and improve Sterilization efficiency, effect of accelerating filling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

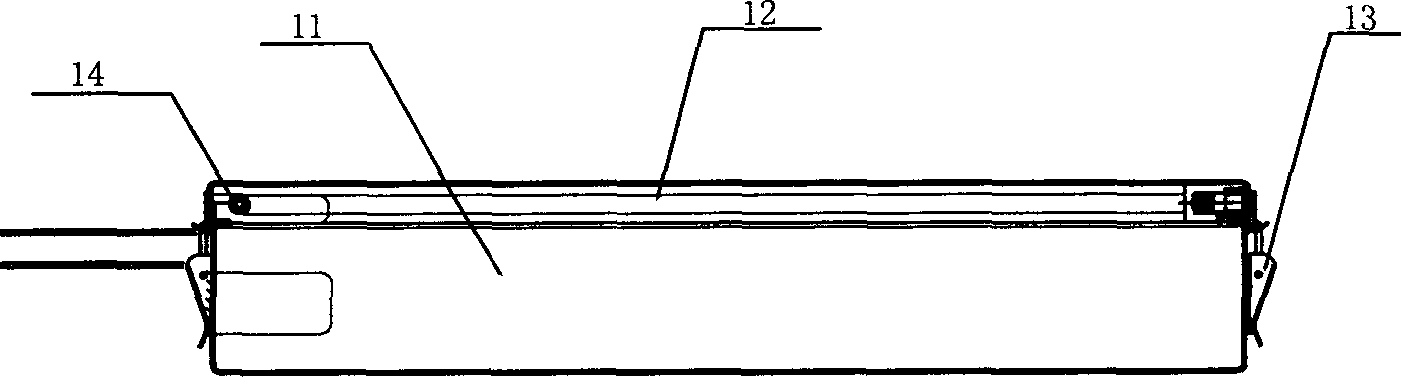

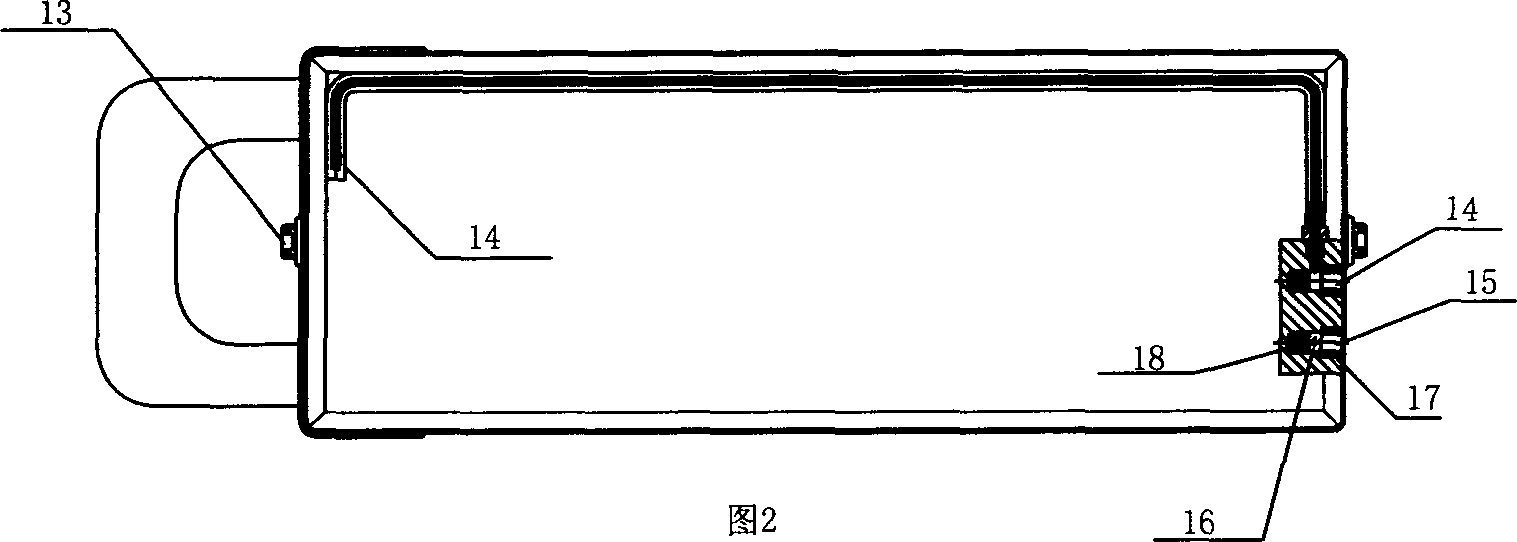

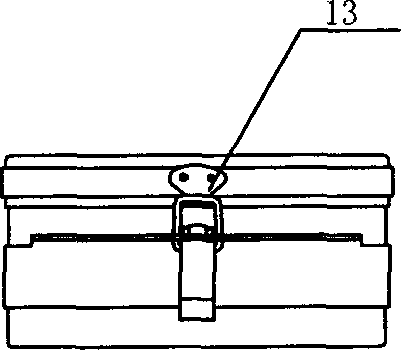

[0027] Such as figure 1 , Figure 2 and image 3 As shown, the steam sterilization box 1 of the steam sterilizer of the present invention includes a box body 11 and a box cover 12, the box cover 12 is fastened to the box body 11, and a seal The structure and locking device are also provided with an air supply hole 14 and an air suction hole 15 on the box cover 12, and a closure is provided on the air supply hole 14 and the air suction hole 15. The input port of the air supply channel 14 is set on one side of the box cover 12 , and the output port of the air extraction channel 15 is set on the other side of the box cover 12 . In Fig. 2, the closure member is composed of a valve core 16, a valve seat 17 and a return spring 18, the valve core 16 is located at one end of the return spring 18 and is closed on the valve hole of the valve seat 17, the side of the valve core 16 The wall of the hole is provided with a passage connected to the inner side of the box cover 12 , and this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com