Patents

Literature

193 results about "Steam sterilizers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

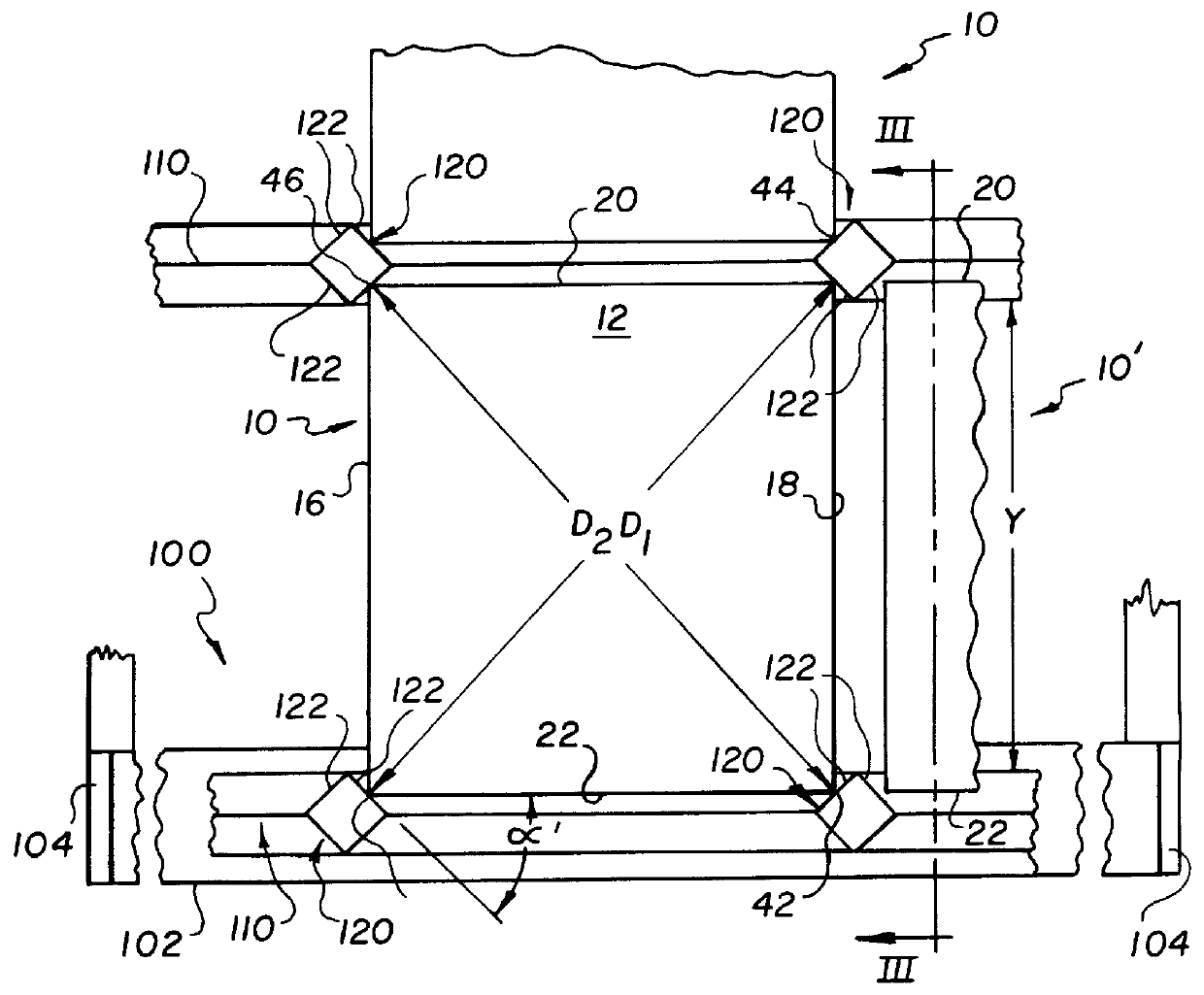

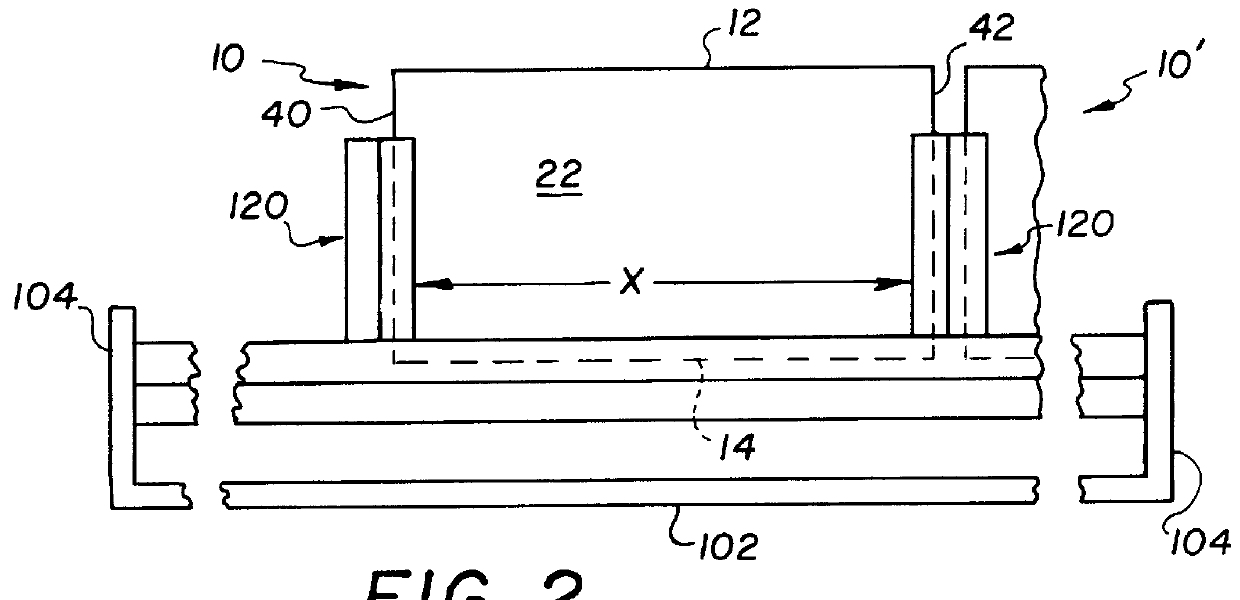

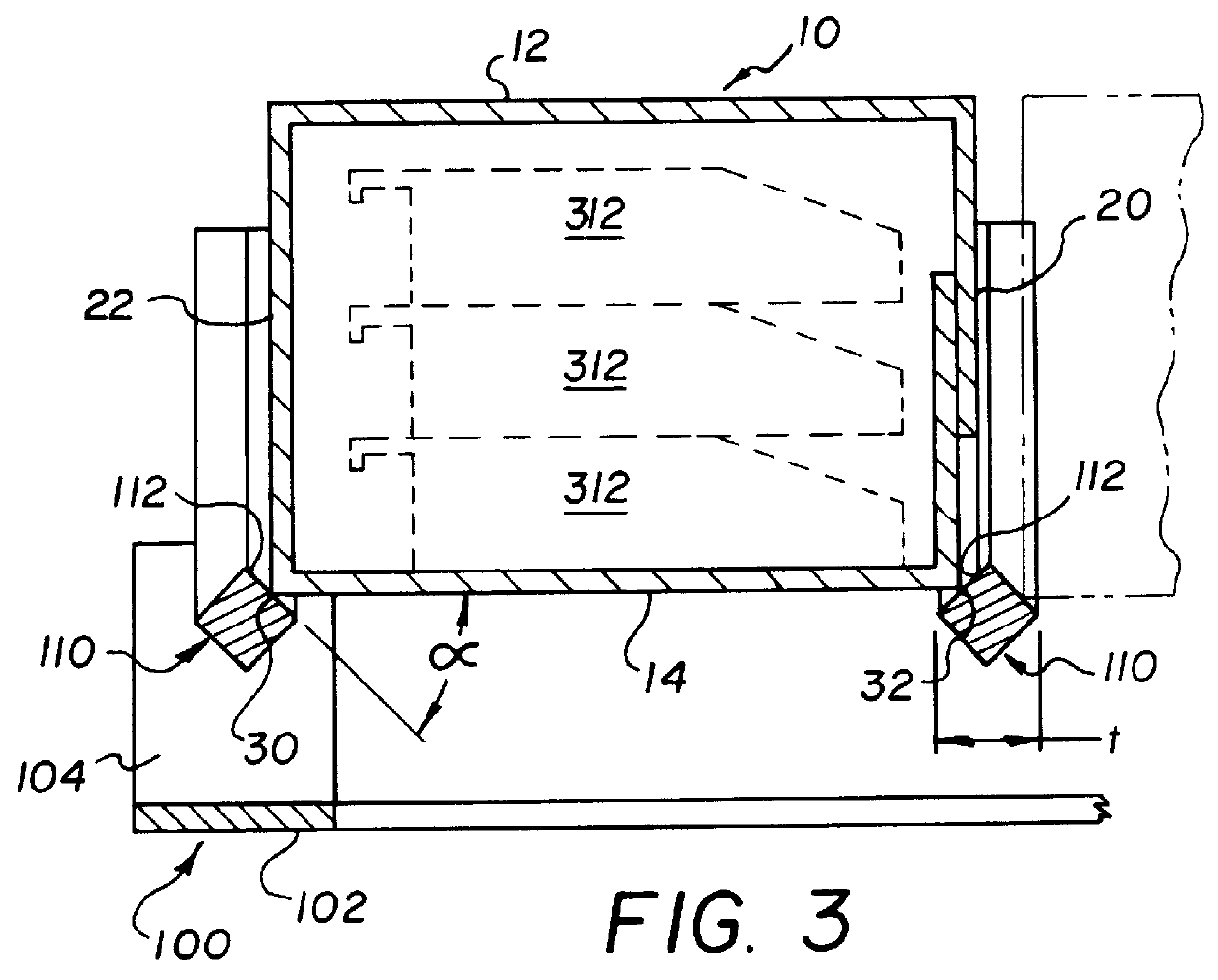

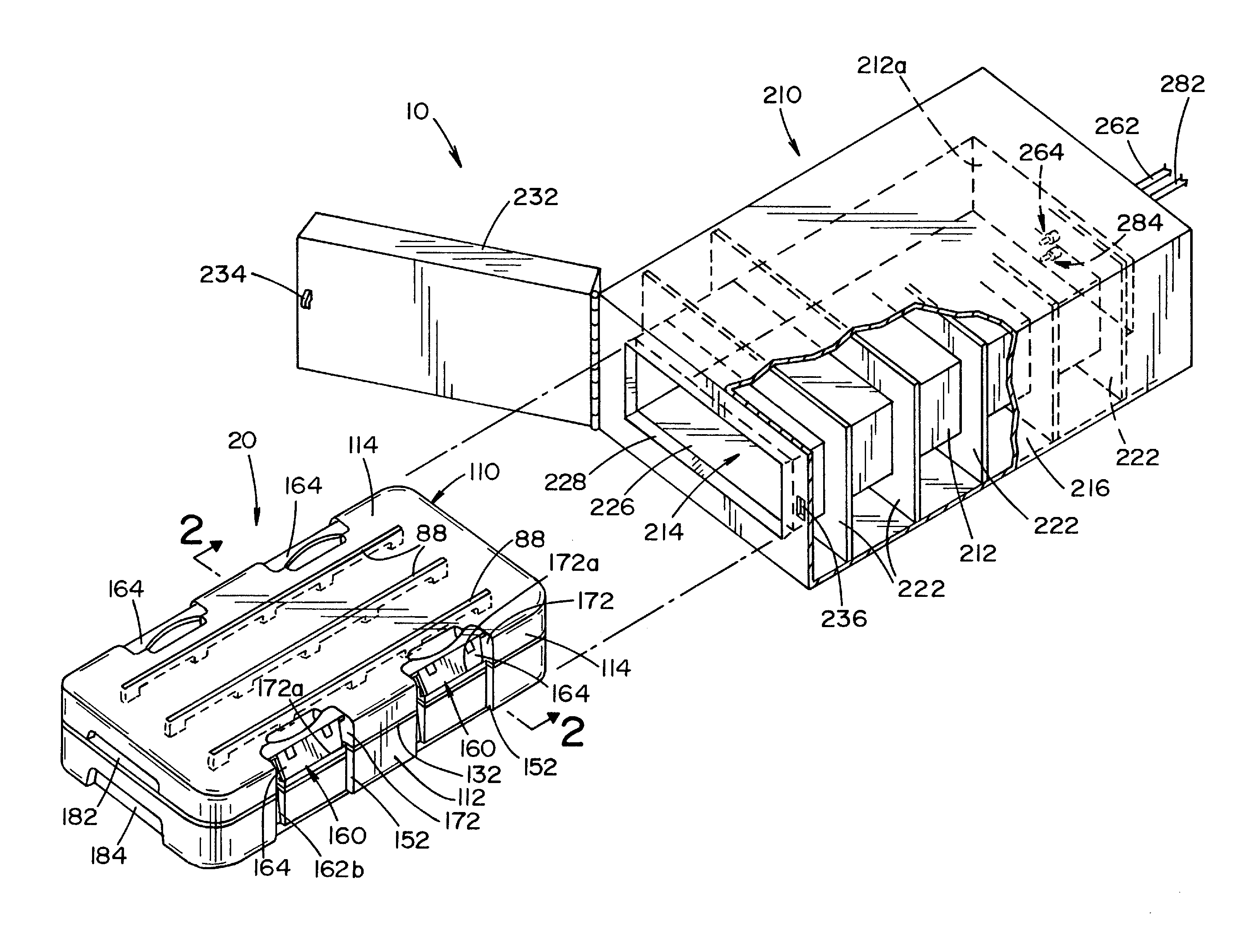

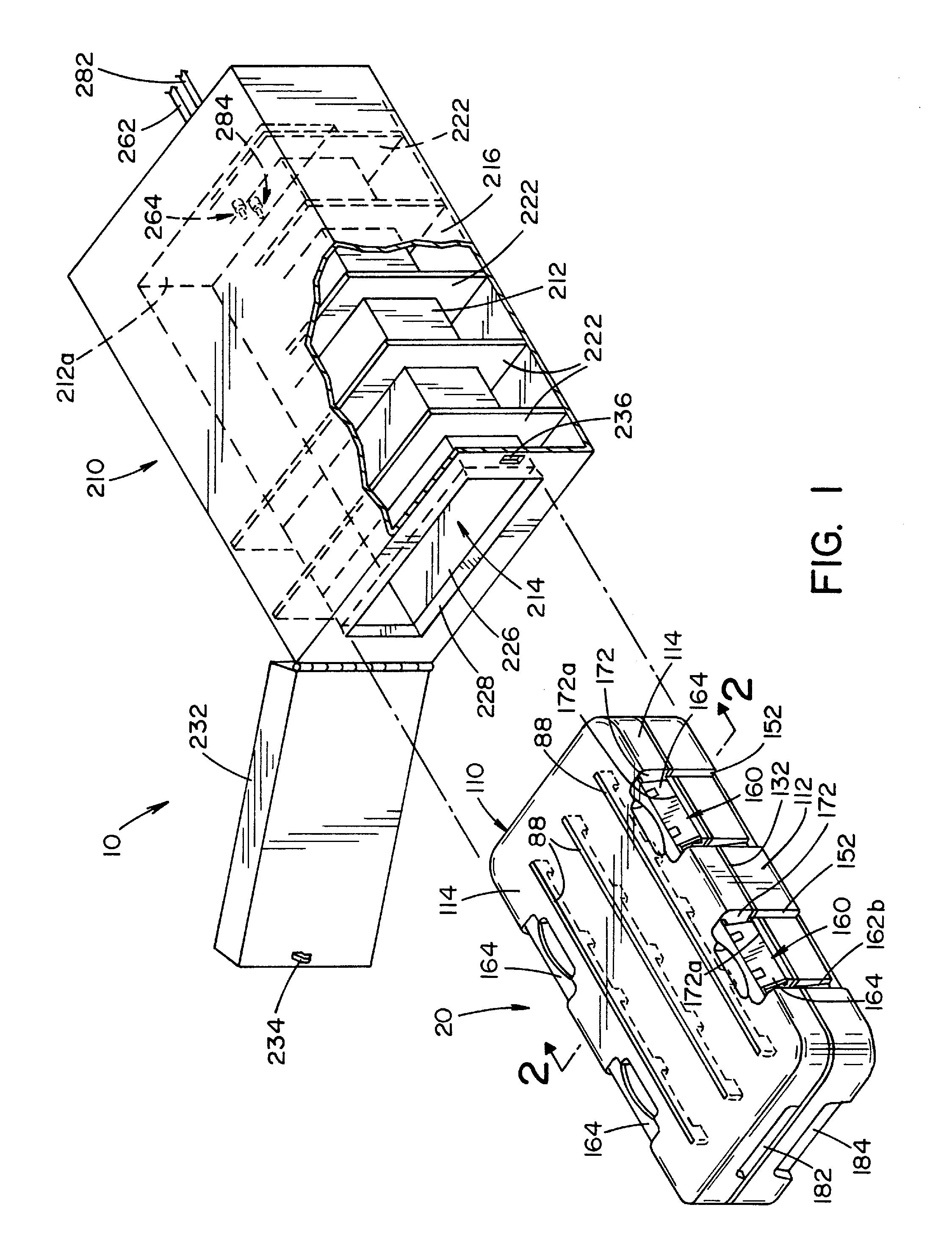

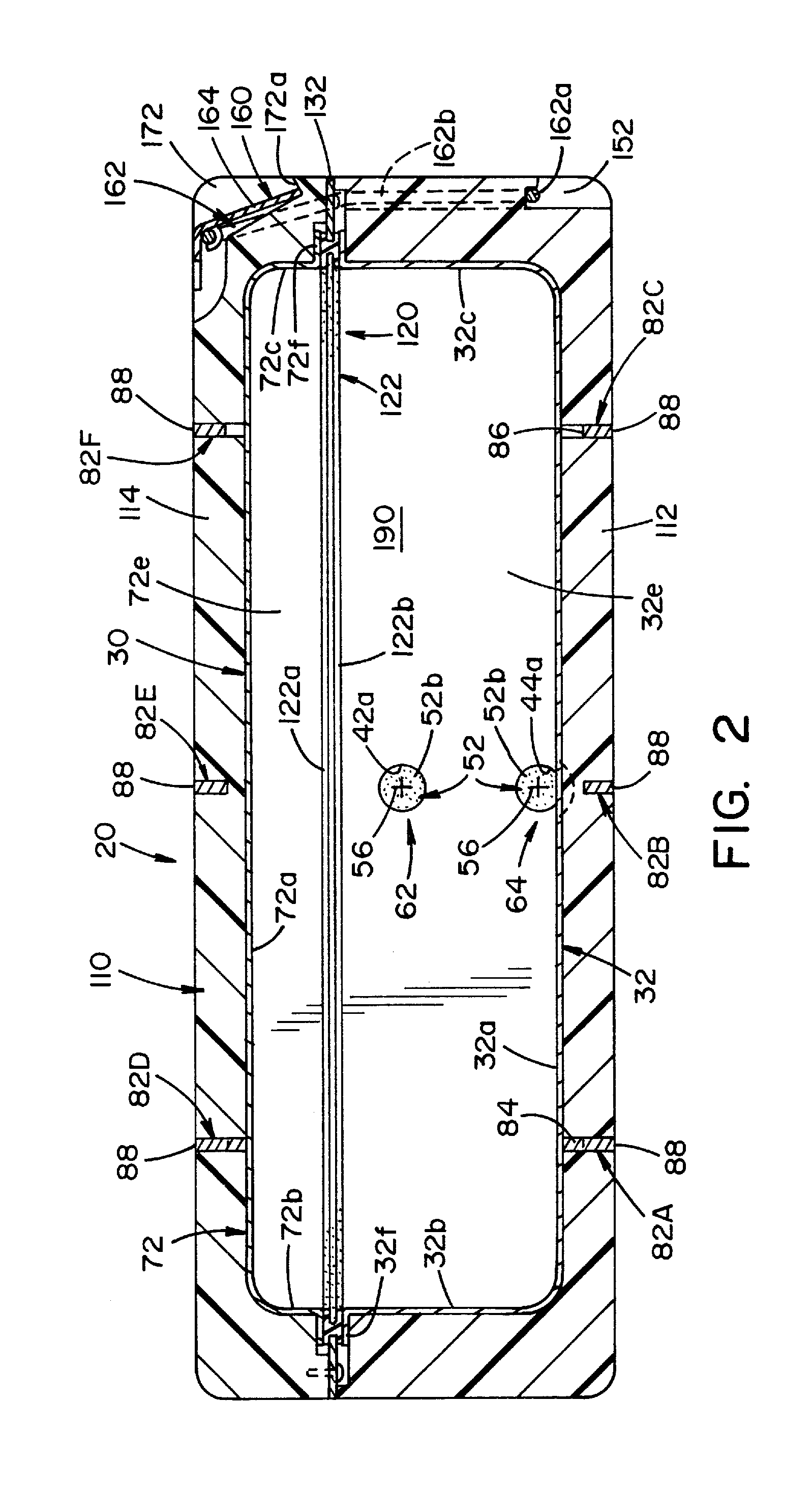

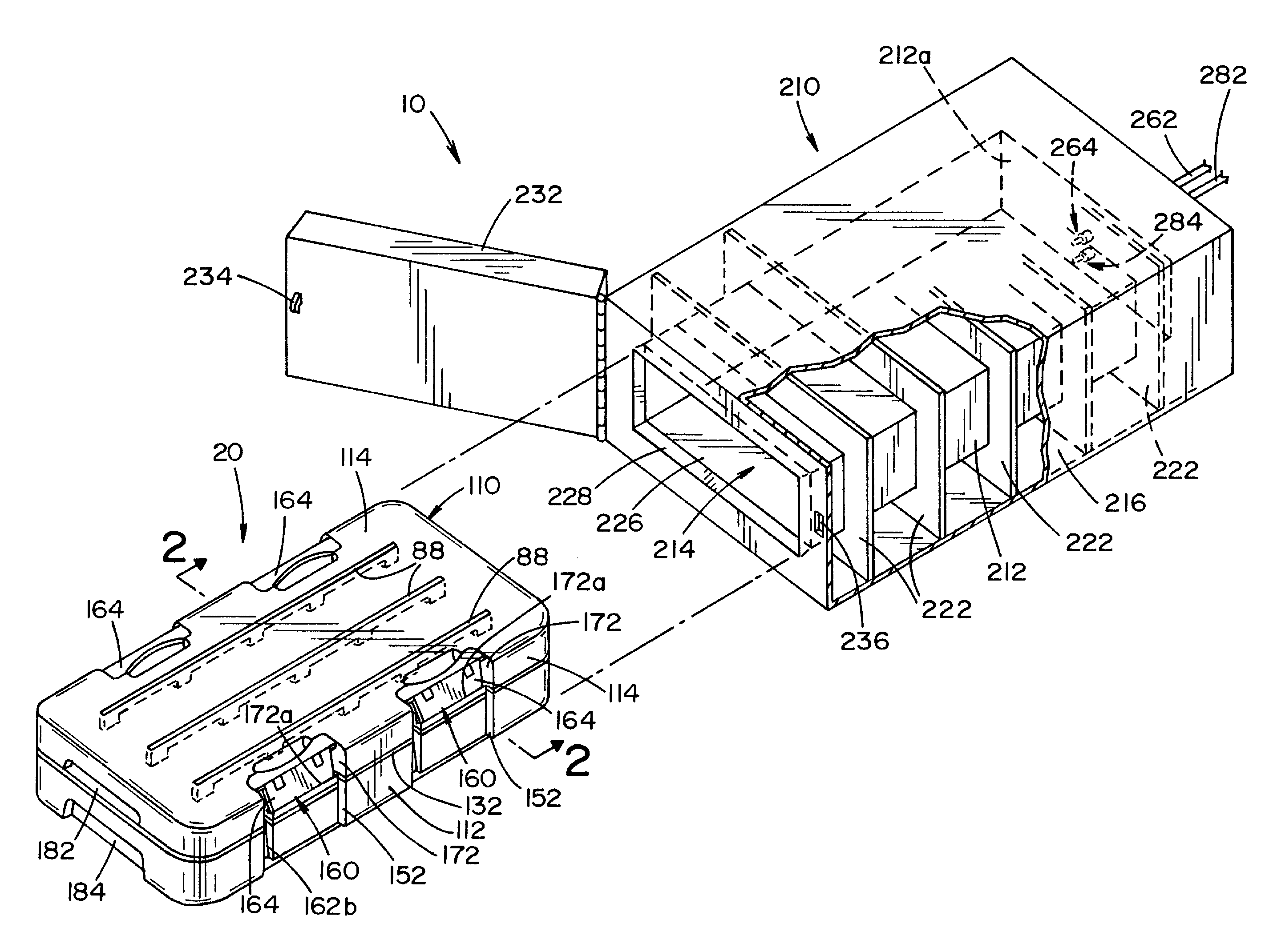

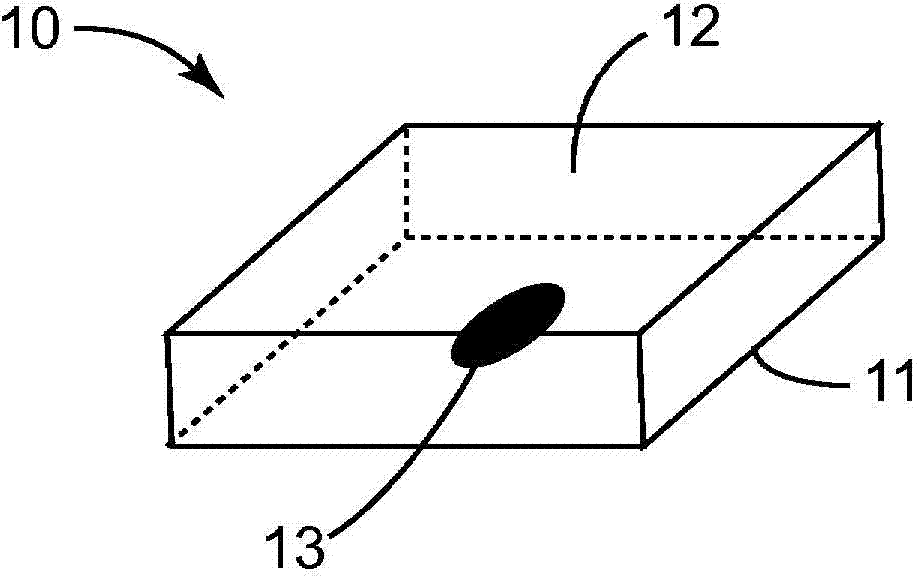

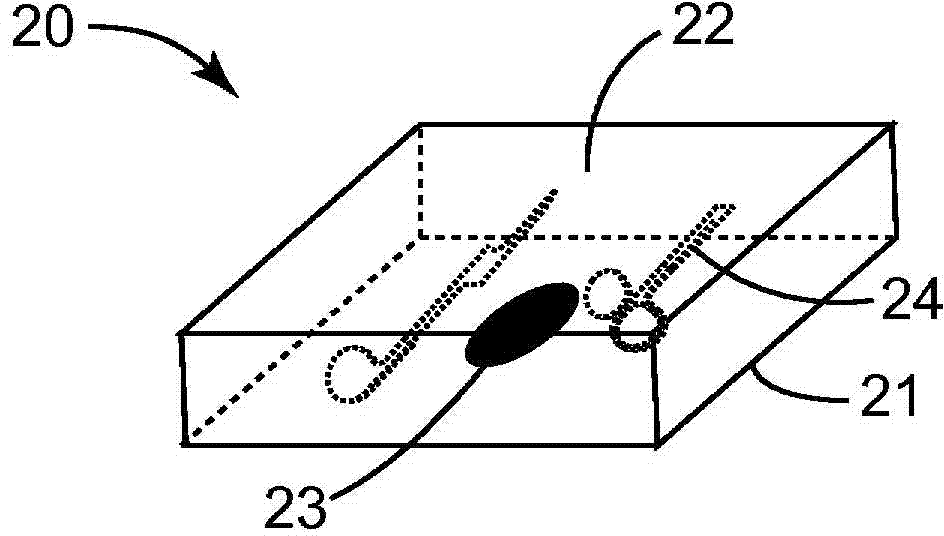

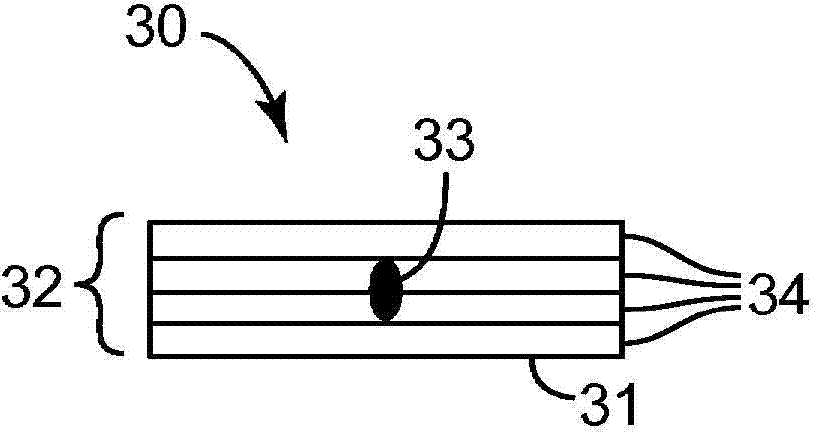

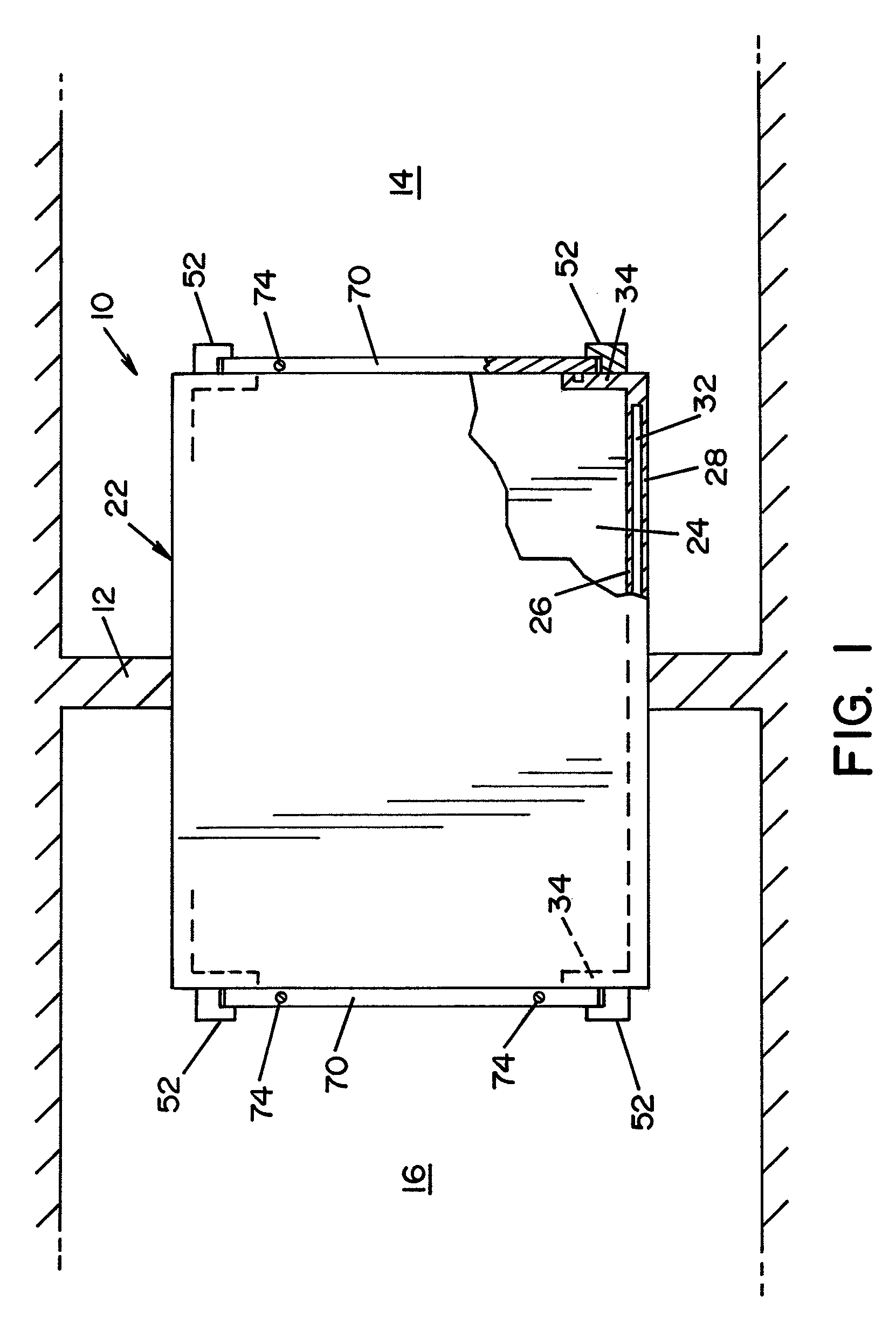

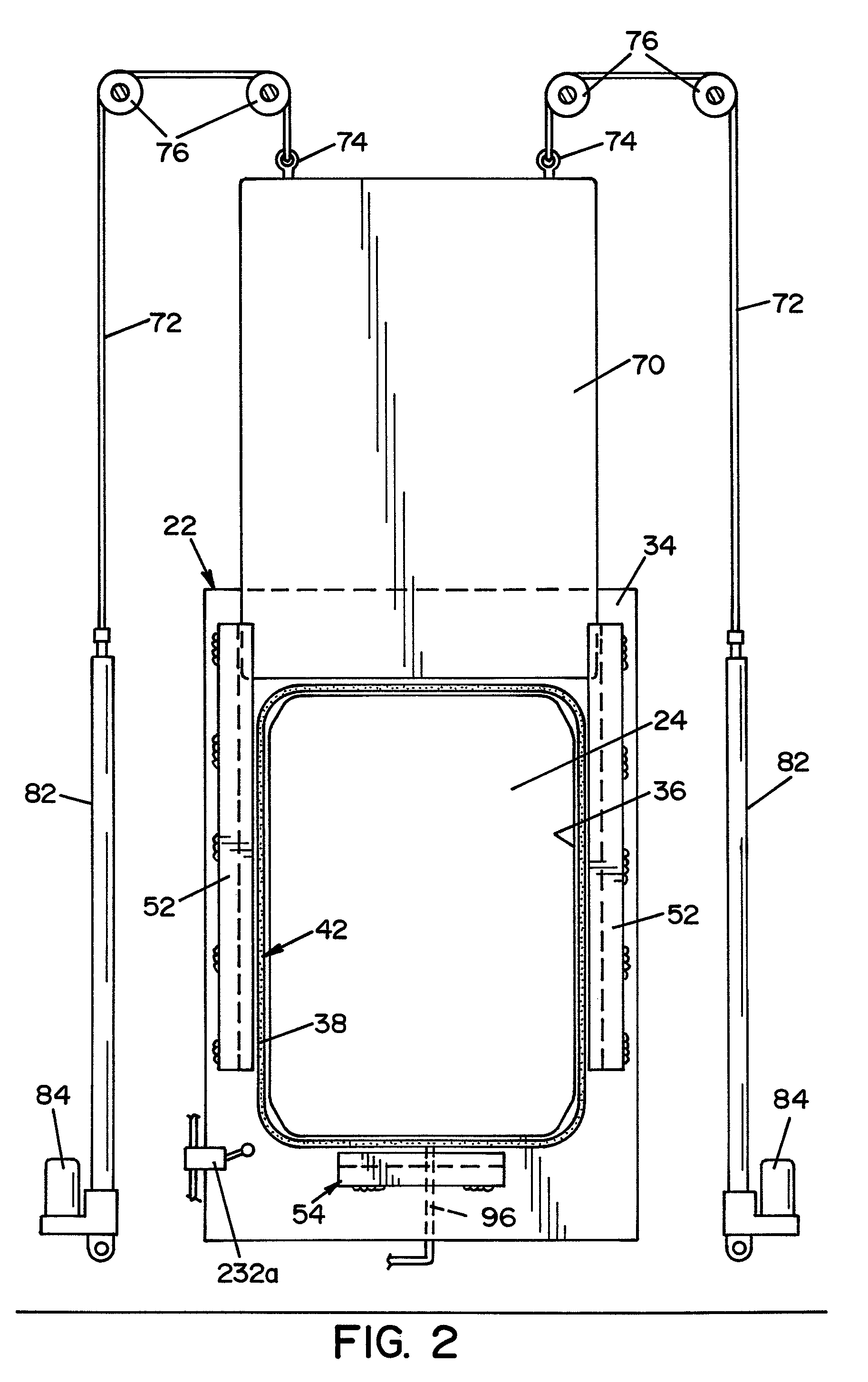

Method and support for supporting packages only at their edges during steam sterilization

InactiveUS6018931AUniform exposurePreventing uneven discolorationShow cabinetsPackage sterilisationEngineeringMechanical engineering

A method and a support for supporting a package in a steam sterilizer, featuring support members configured and positioned to support only at least a portion of at least two opposed side edges, but not a side face, of the package. A diamond shape is particularly preferred for the support members as, when rotated at an angle, its facets provide line contact with appropriate side edges of the package.

Owner:JOHNSON & JOHNSON INC (US)

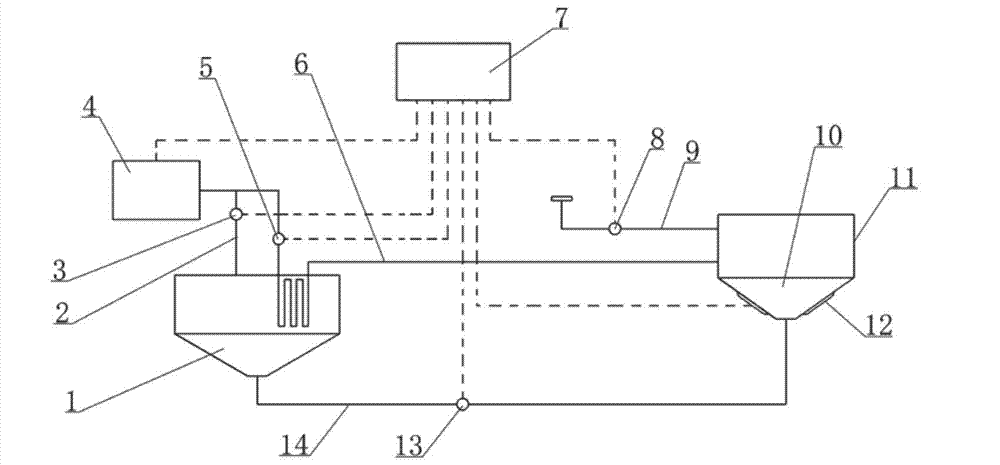

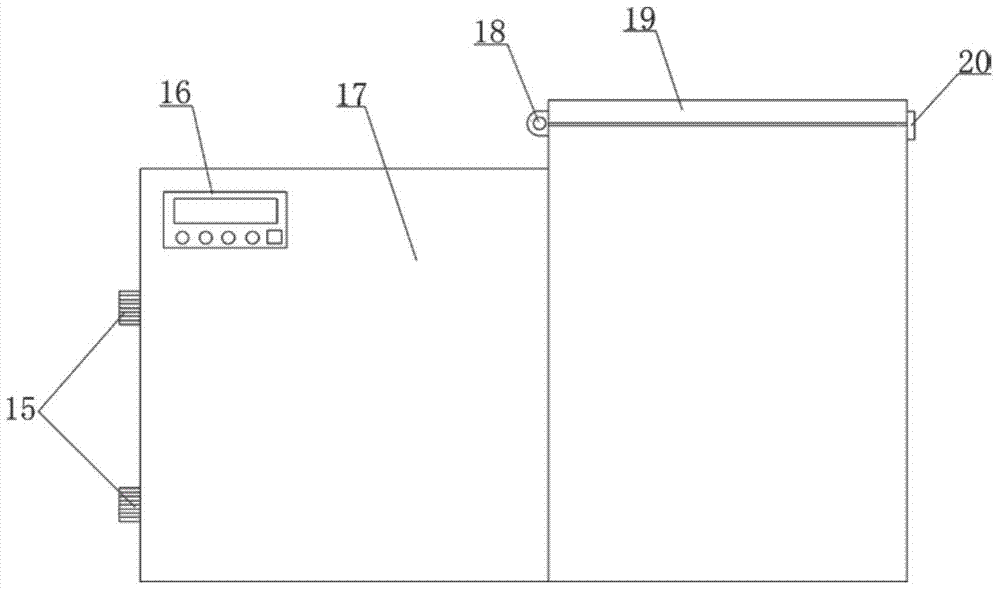

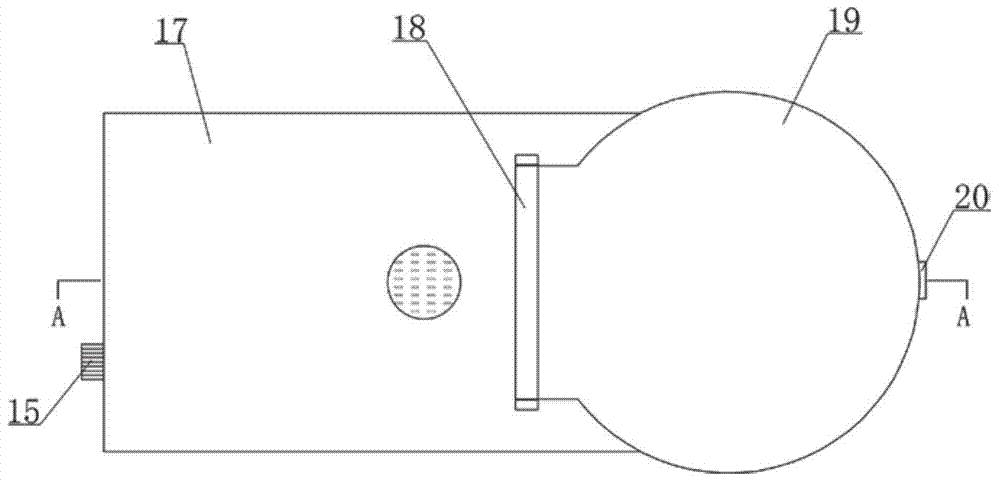

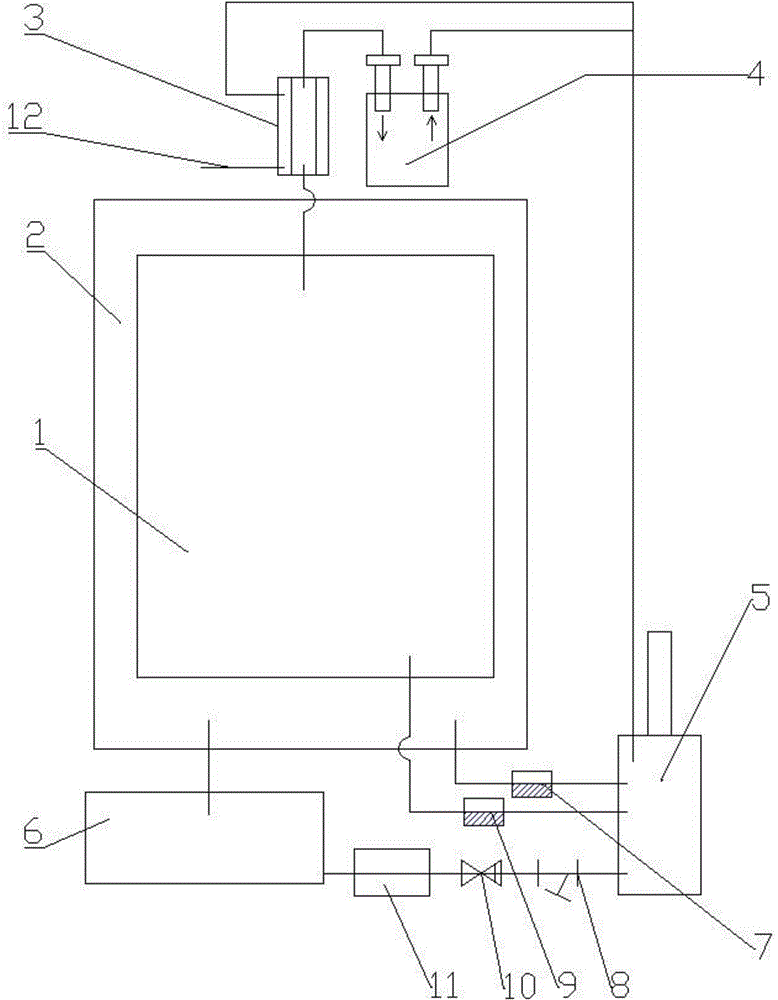

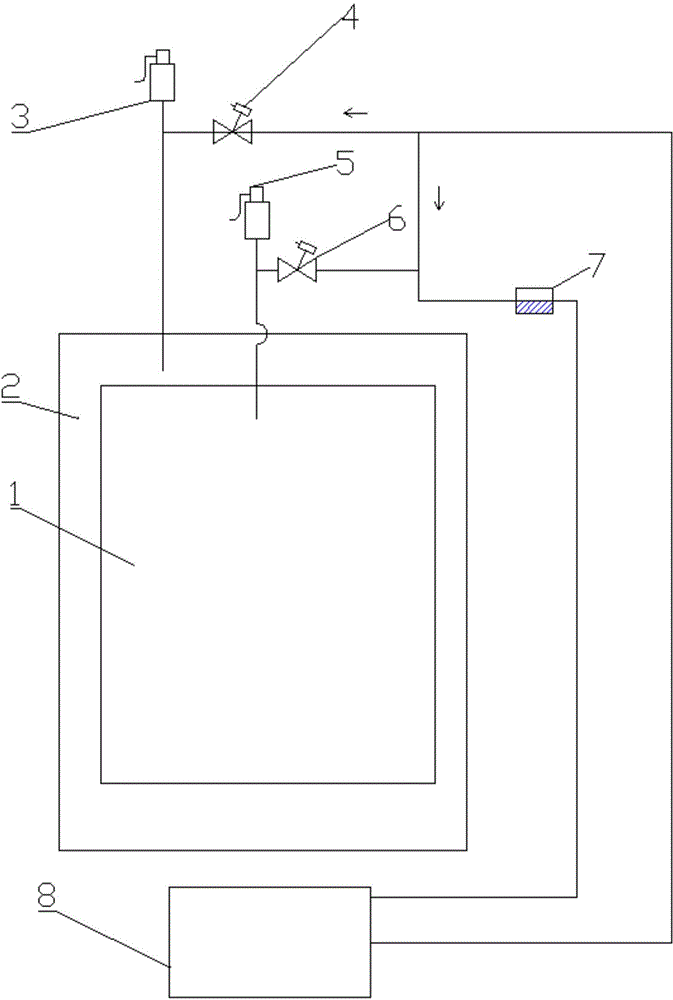

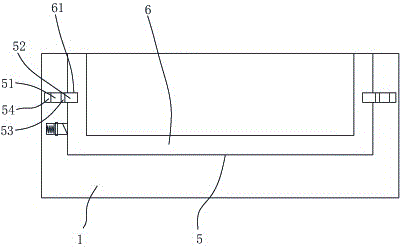

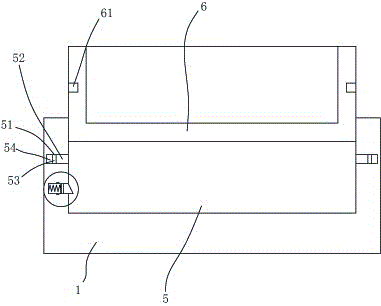

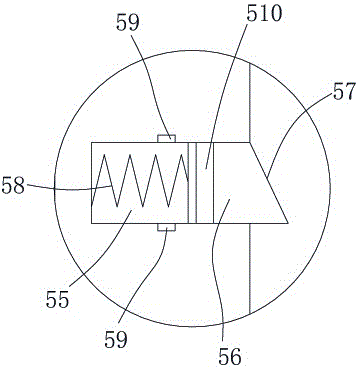

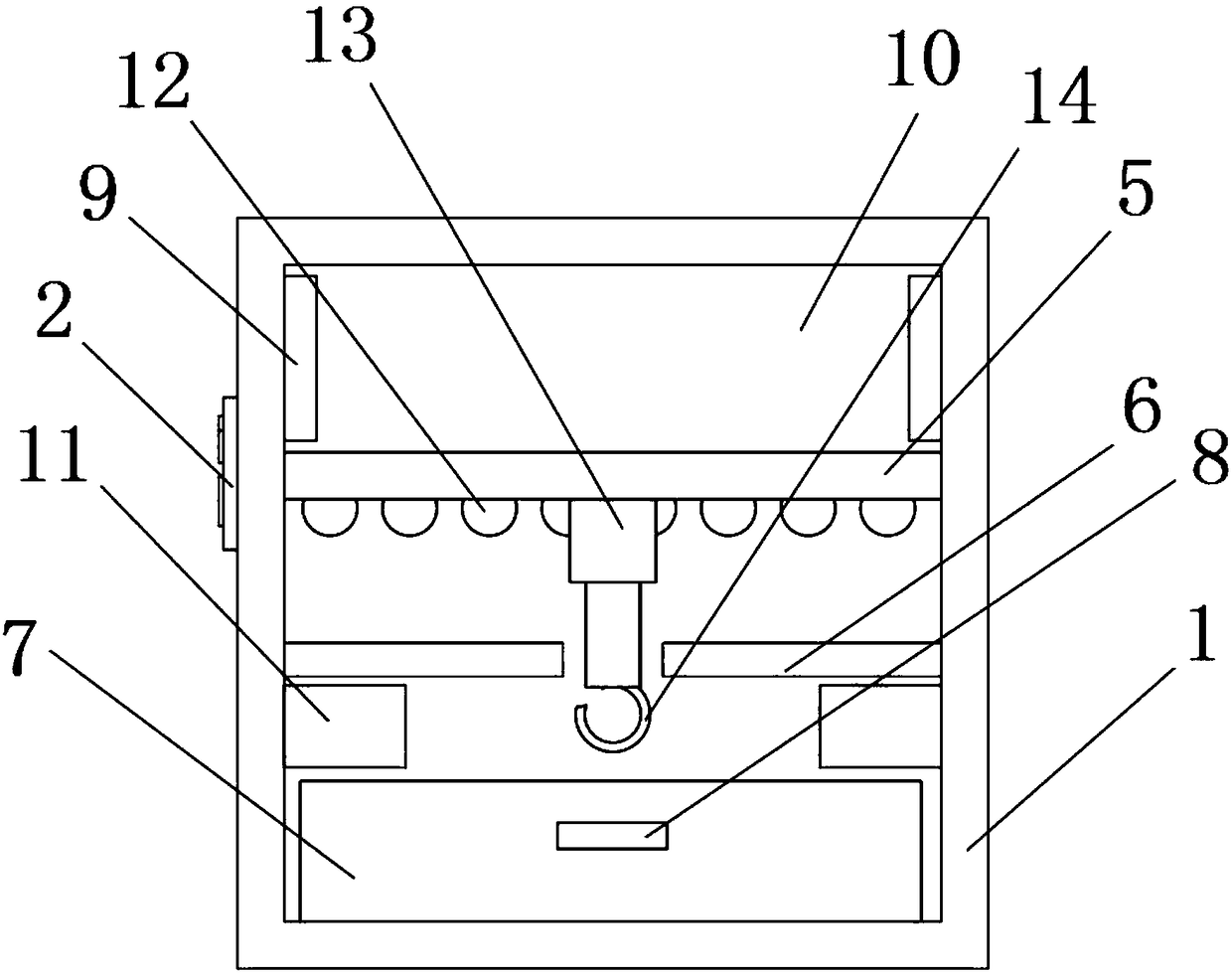

Steam sterilizer

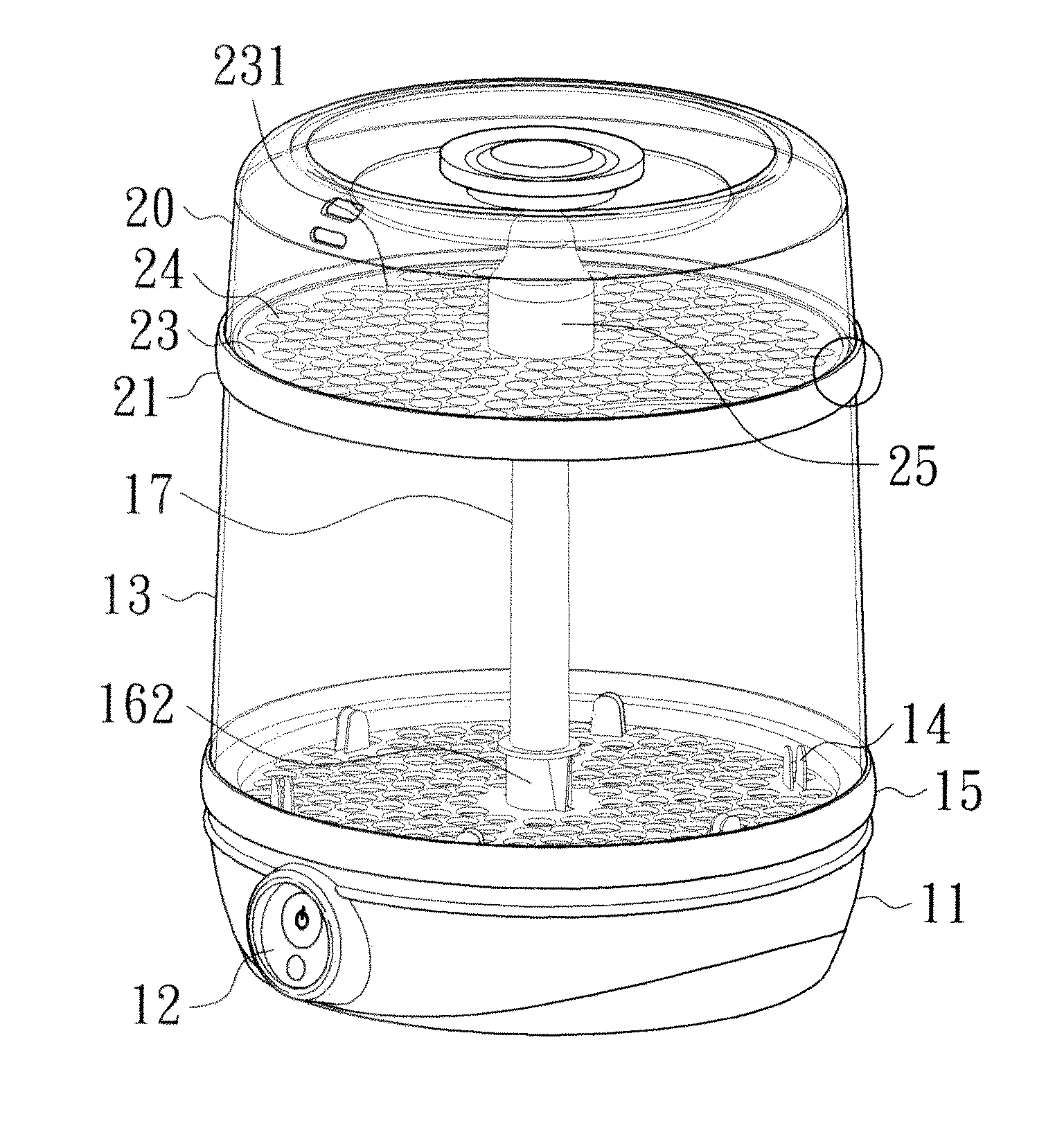

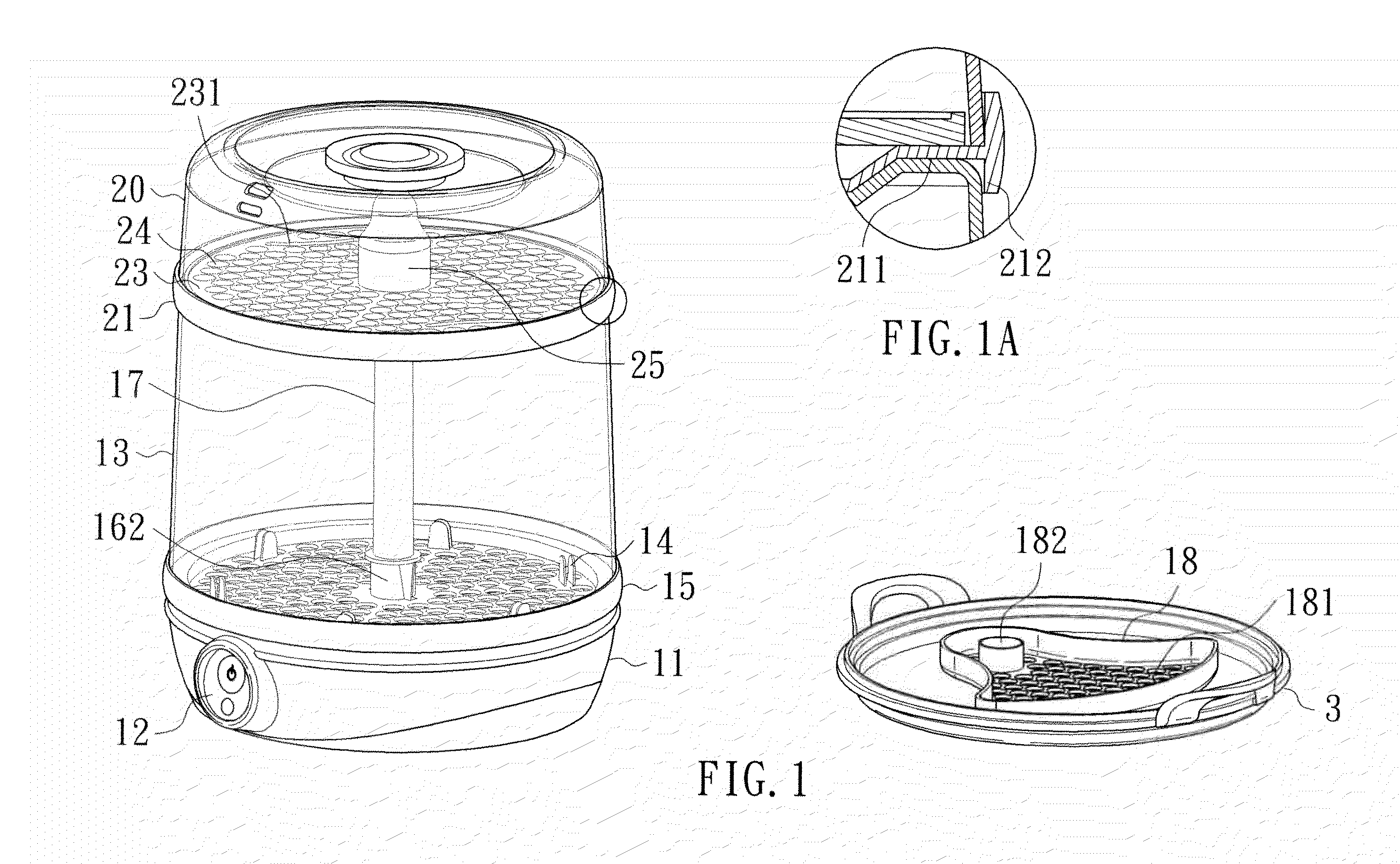

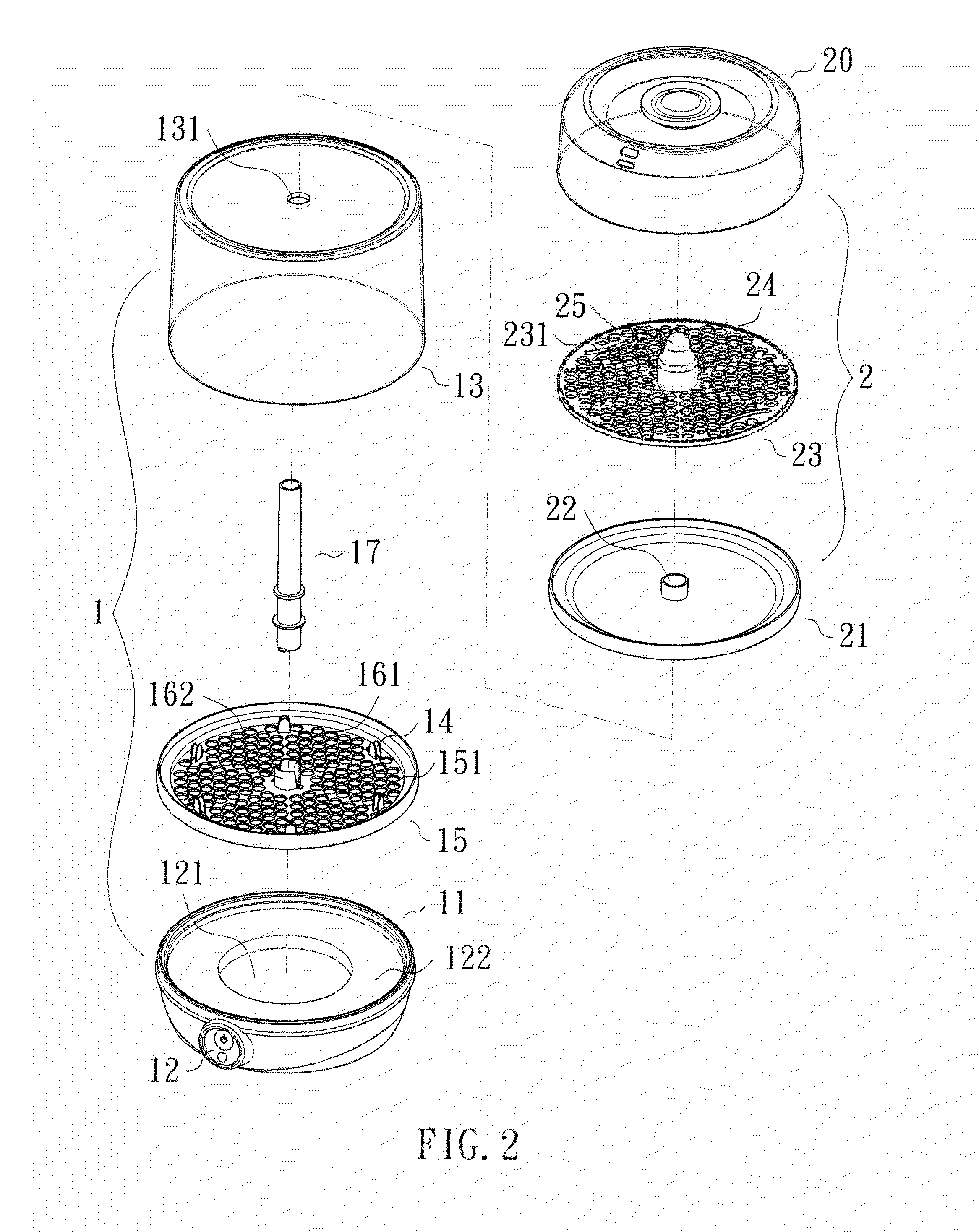

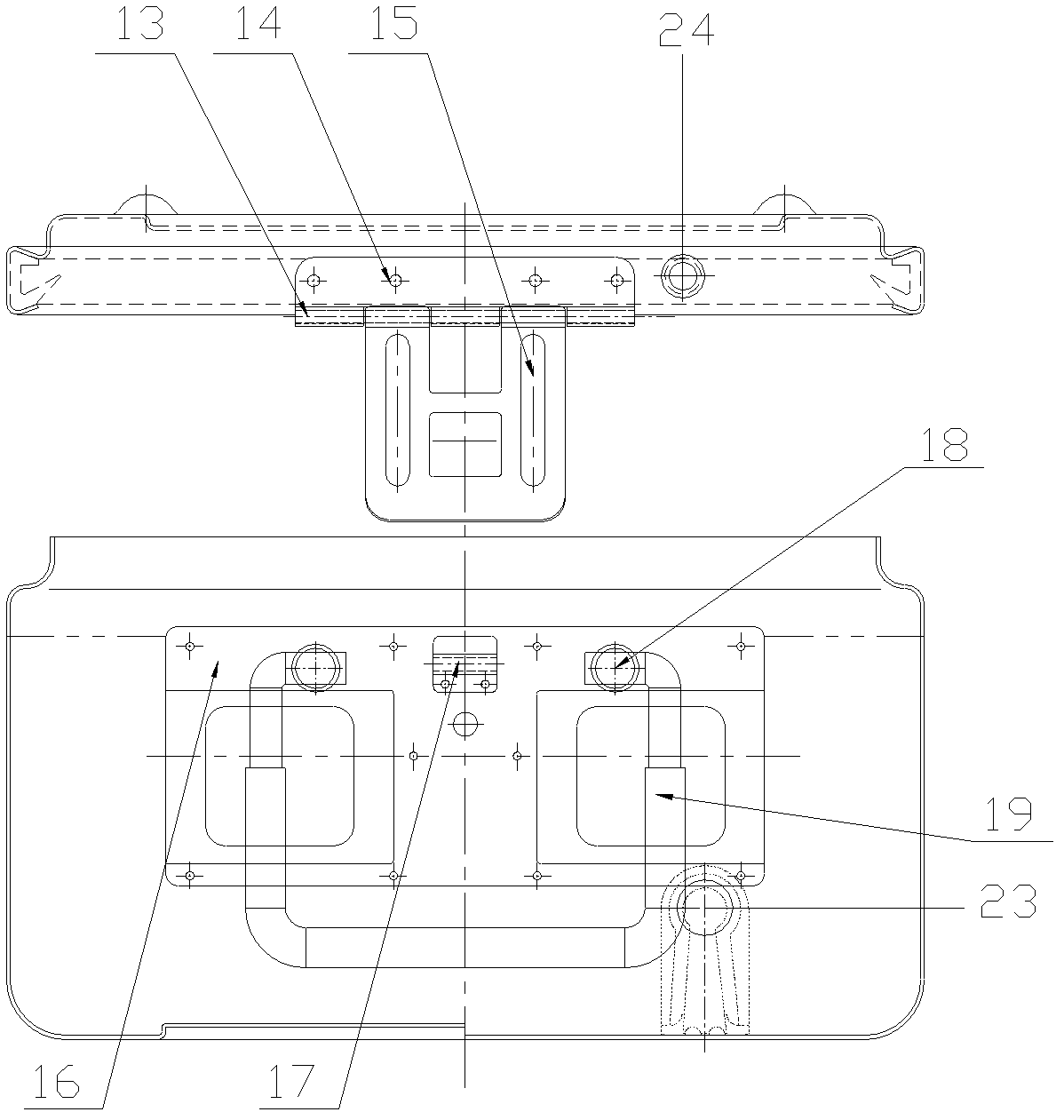

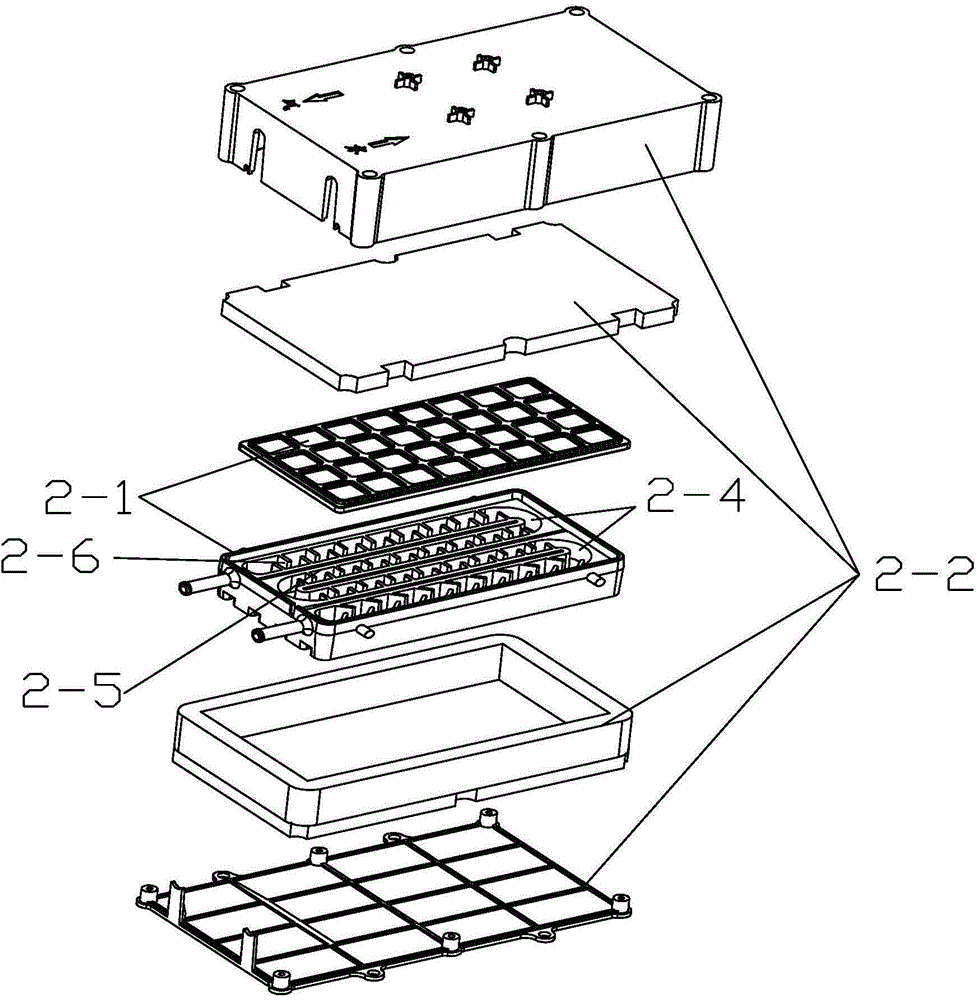

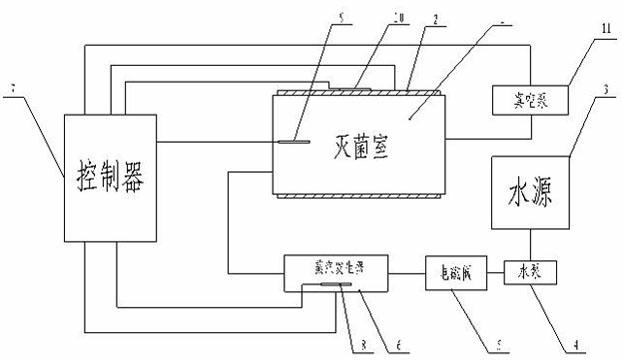

InactiveCN104288798AReduce the chance of secondary pollutionIncrease profitTableware washing/rinsing machine detailsCleaning using liquidsElectricityWater volume

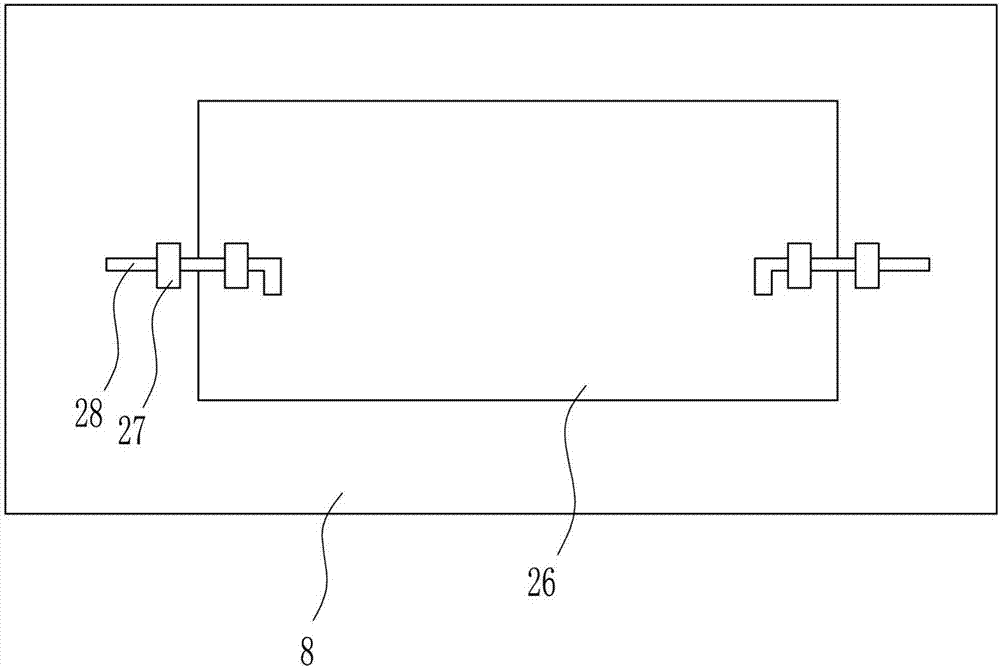

The invention discloses a steam sterilizer, which comprises an evaporating pan assembly having a disinfection chamber, wherein a heating element is arranged at bottom of the disinfection chamber, an exhaust pipe is arranged on the upper part of the disinfection chamber, an exhaust control valve is arranged on the exhaust pipe; a pressure water case, wherein, the bottom of the pressure water case is connected to the bottom of the disinfection chamber through a feed pipe, a water volume control valve is arranged on the feed pipe; a bidirectional air pump connected to the pressure water case through a pressure regulating pipeline and communicated to the disinfection chamber through a hot air pipeline, wherein a pressure regulating valve is arranged on the pressure regulating pipeline, a hot air control valve is arranged on the hot air pipeline; a circuit board assembly connected to the bidirectional air pump, the heating element, the exhaust control valve, the water volume control valve, the pressure regulating control valve and the hot air control valve; and a casing arranged at external part of the above parts for supporting and protecting the above parts. The steam sterilizer has functions of cleaning, disinfection and drying which are carried out in the disinfection chamber, artificial transfer of the disinfection articles is not required, usage is more convenient and faster, disinfection processing efficiency is increased, and secondary pollution probability during a transfer process of the disinfection articles can be reduced. An ingenious design is employed, so that structure is simpler, more compact, smaller and more flexible, comprehensive utilization rate of the parts is high, and manufacture cost and use cost can be better controlled.

Owner:张荣广

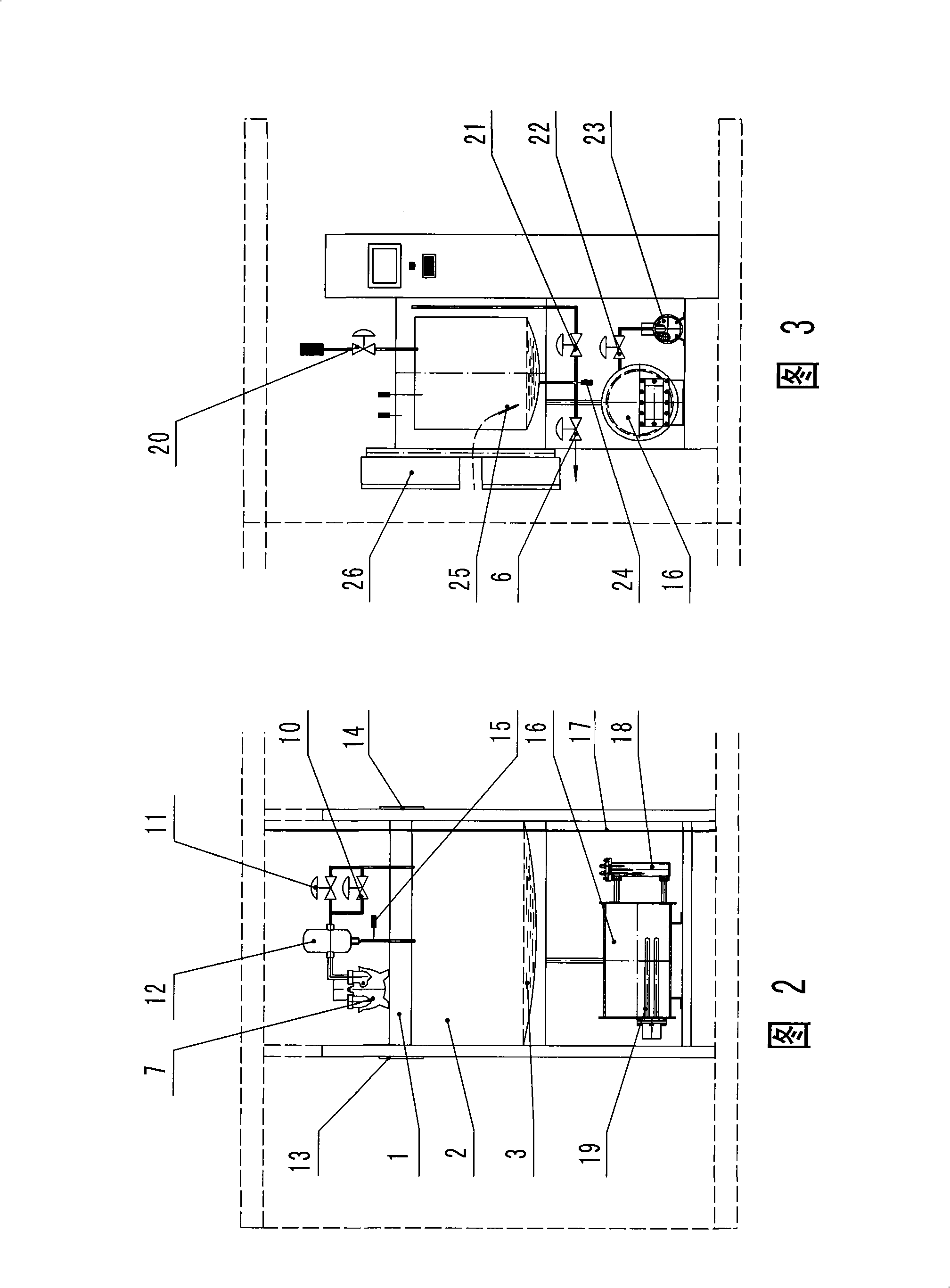

Steam sterilization process and steam sterilization apparatus employed the same

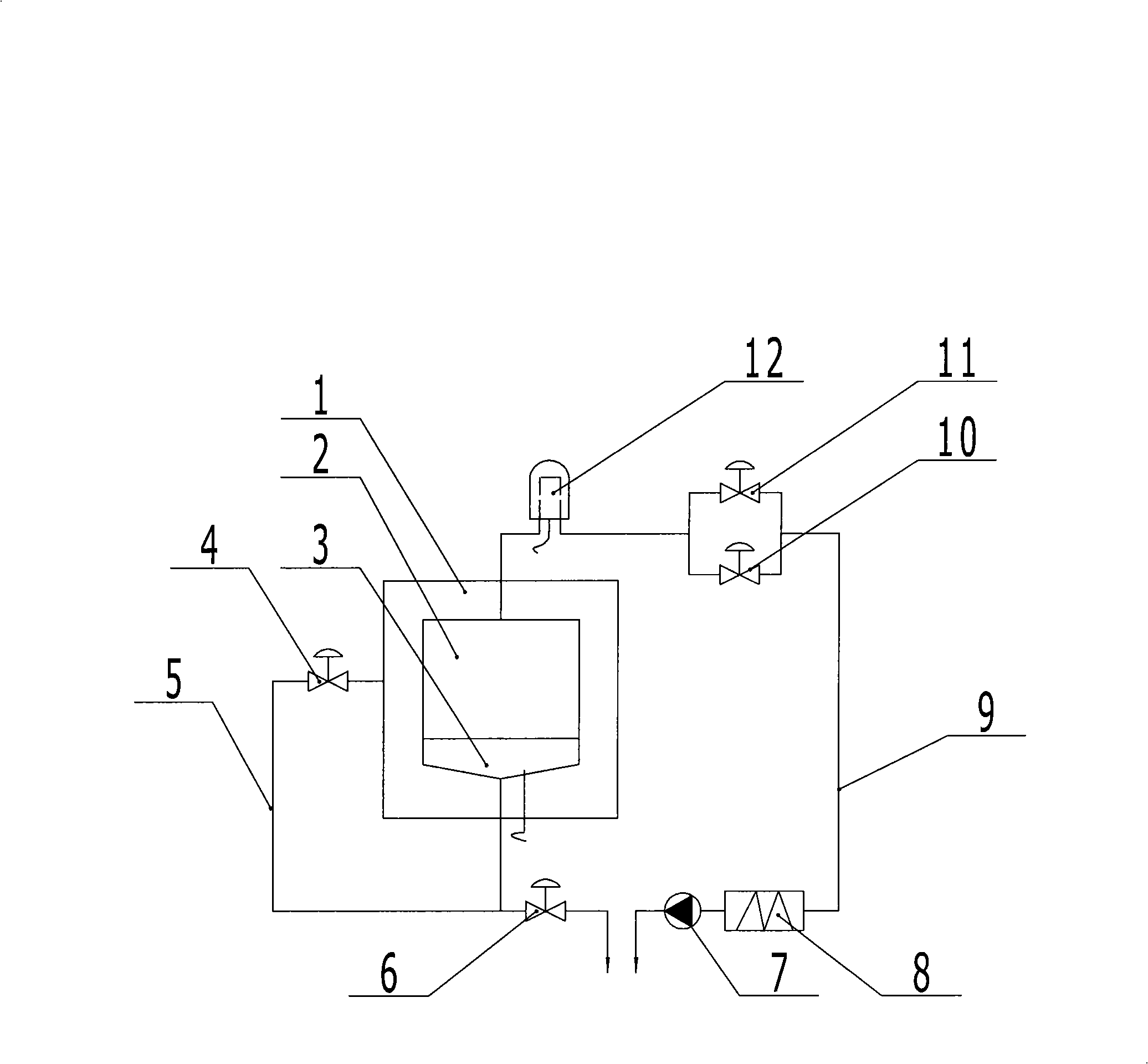

The invention relates to a steam sterilizing process for the disinfection of medical appliances in hospital, and the steam sterilizer employing the steam sterilizing process, which comprises the steps of vacuumizing, preheating, sterilizing and cooling down. The steam sterilizer comprises a steam sterilizing box, a valve group, an air filter, a steam generator, a vacuum pump and an automatic control system.

Owner:何德贤

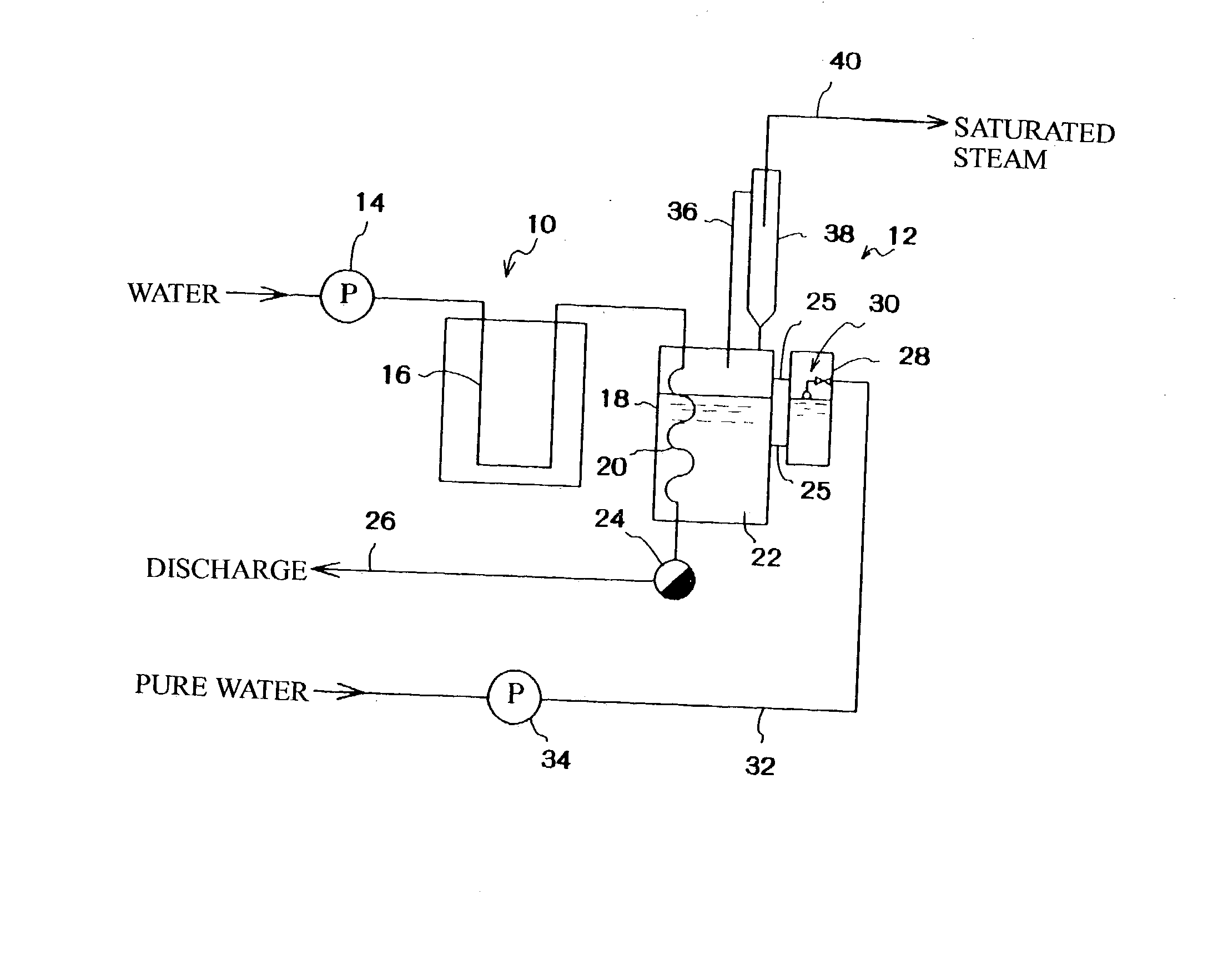

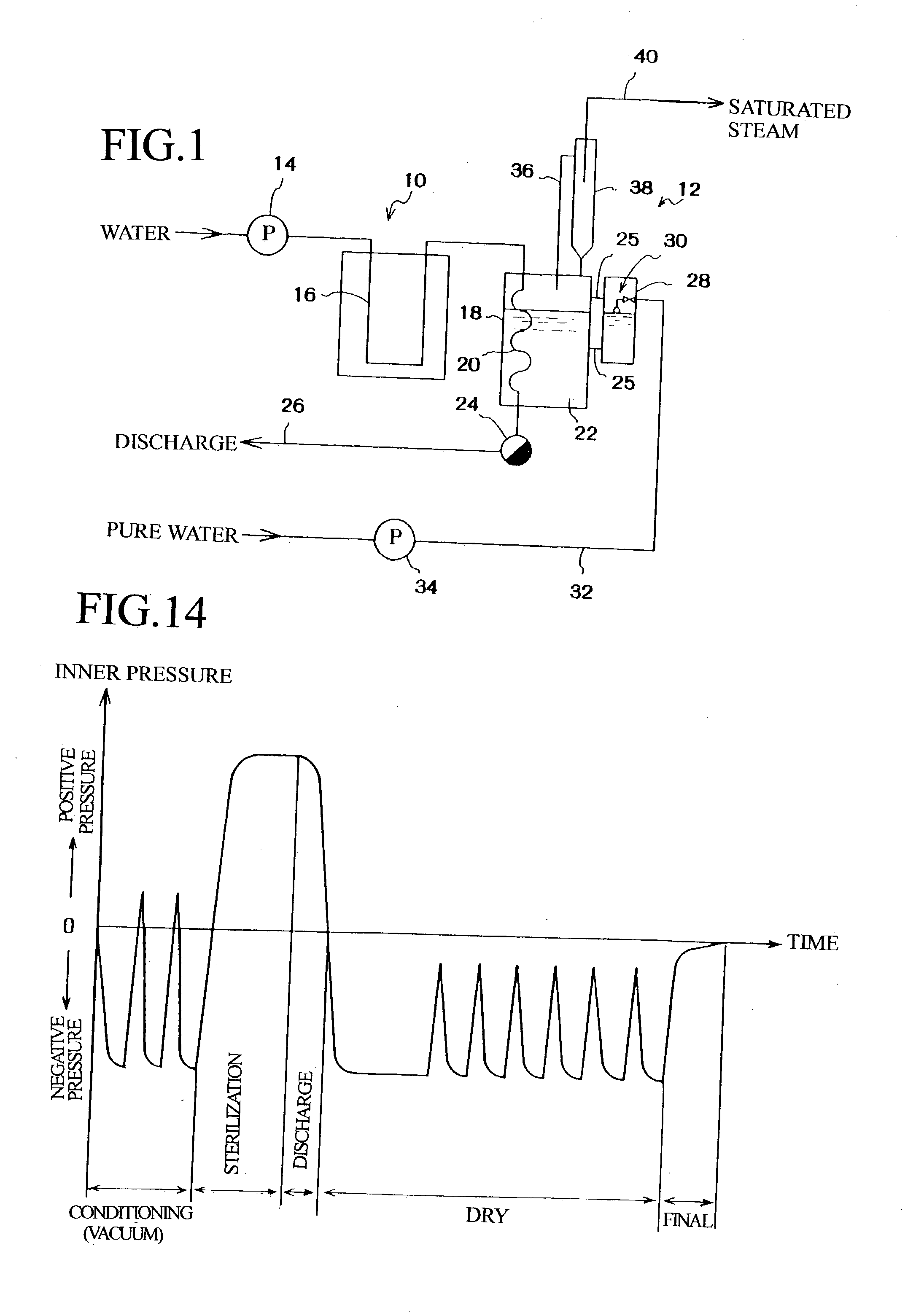

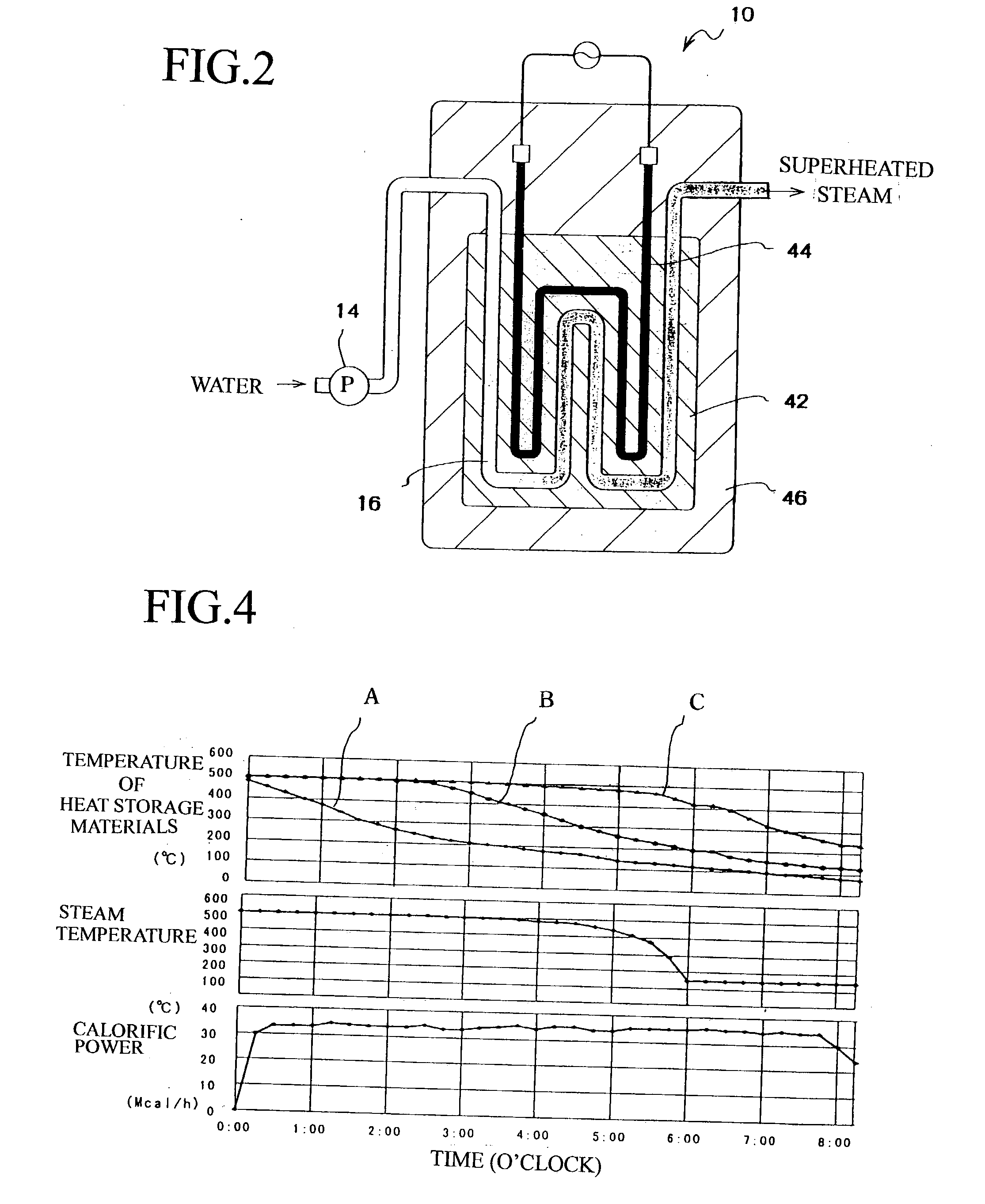

Saturated steam generator, steam sterilizer, and steam sterilization method

InactiveUS20030145806A1Liquid surface applicatorsSteam/vapor condensersHeat transmissionHeat storage material

A saturated steam generator which is provided with a heat source for heating water to generate saturated steam and which can be small-sized. A saturated steam generator for generating saturated steam by heating water with superheated steam resulting from being superheated in a heat transmission tube (16) inserted into a heat storage tank (10), characterized by the provision of a saturated steam generator tank (12), wherein in the heat storage tank (10), disposed in a heat storage section composed by having a solid heat storage material and a liquid heat storage material filled therein are a heat transmission tube (16) and a heater (44), which heats the solid heat storage material and the liquid heat storage material, it being arranged that superheated steam resulting from passing through the heat transmission tube (16) is used as a heat source to heat stored water (22) so as to generate saturated steam.

Owner:SAKURA SEIKI

Steam sterilizer and sterilization process

The invention relates to a steam sterilizer and a sterilization process, and in particular relates to a negative-pressure and low-temperature steam sterilizer and the sterilization process. The steam sterilizer comprises a sandwich layer and an internal chamber, wherein the internal chamber consists of a space enclosed by a front door, a back door and the sandwich layer; a steam channel is formed in the sandwich layer; the sandwich layer is connected with a sandwich layer steam inlet system through a pipeline; the internal chamber is connected with an internal chamber emptying system through a pipeline; the sandwich layer is communicated with the internal chamber through a pipeline, and a first pneumatic control valve is arranged on the pipeline; the internal chamber is connected with an internal chamber vacuumizing drainage system through a pipeline; and the sandwich layer is connected with a sandwich layer vacuumizing drainage system through a pipeline. The steam sterilization process comprises: (1) vacuumizing; (2) sandwich layer steam inlet; (3) heating; (4) sterilization. The low-temperature steam sterilization of a thermolabile article is realized; by virtue of the internal chamber vacuumizing drainage system, condensed water formed in the sterilization process can be effectively drained, and the steam quality and temperature uniformity of the internal chamber are ensured.

Owner:SHINVA MEDICAL INSTR CO LTD

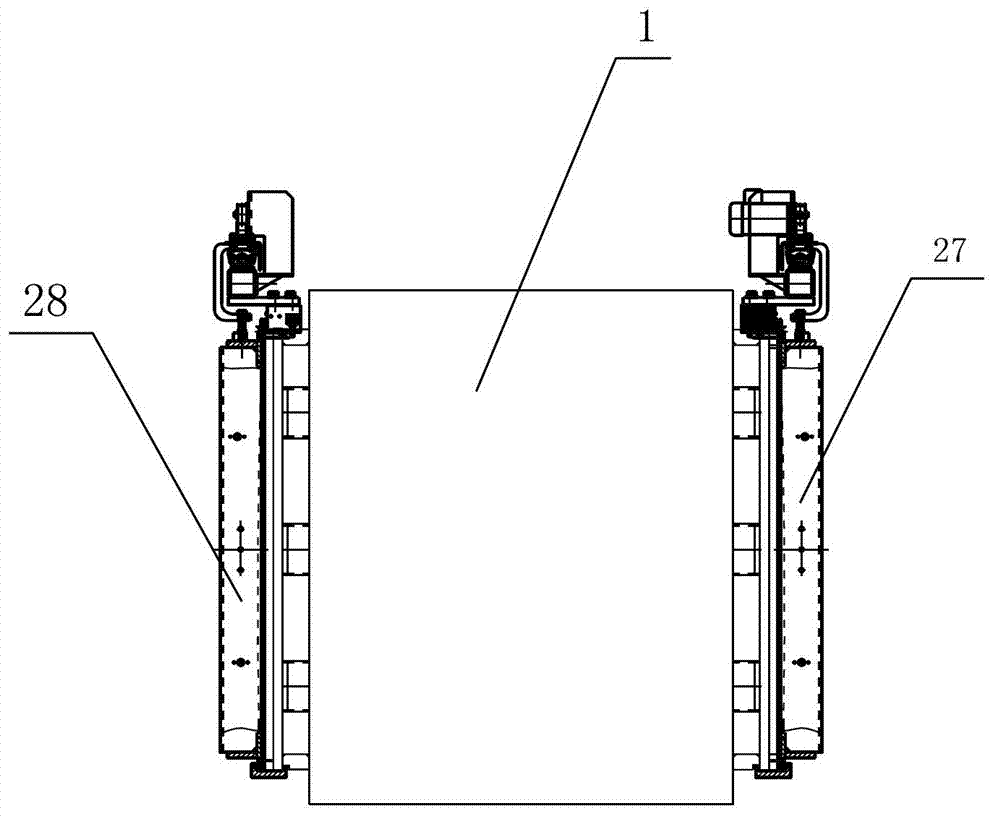

Steam sterilizer

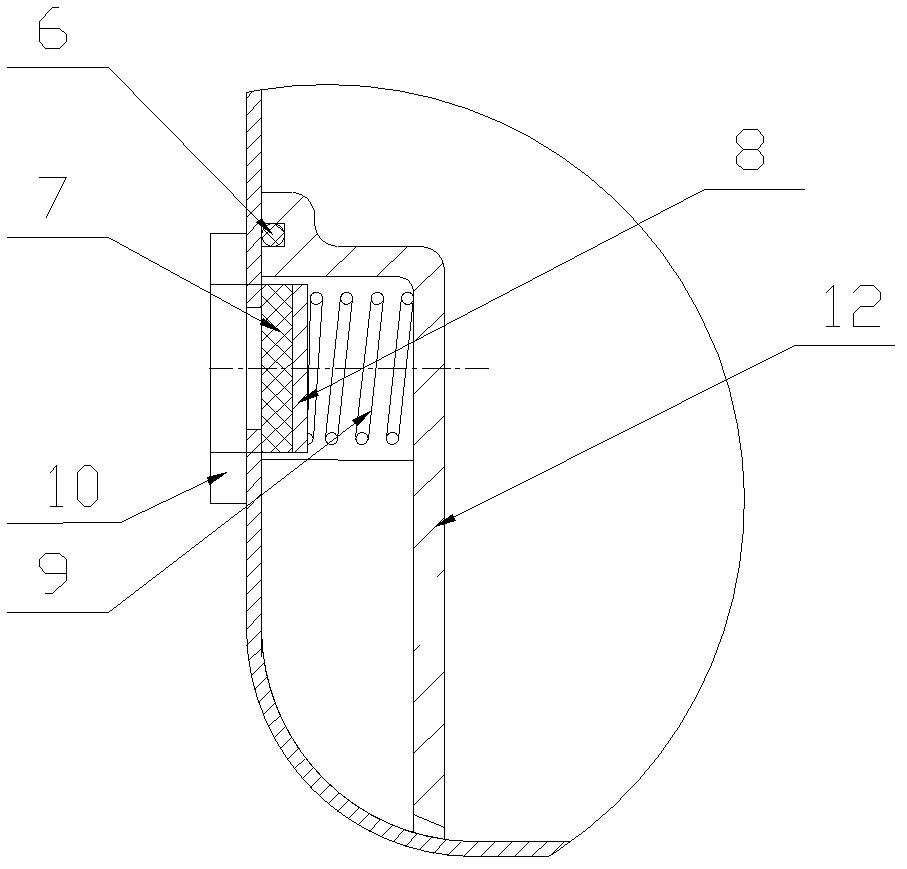

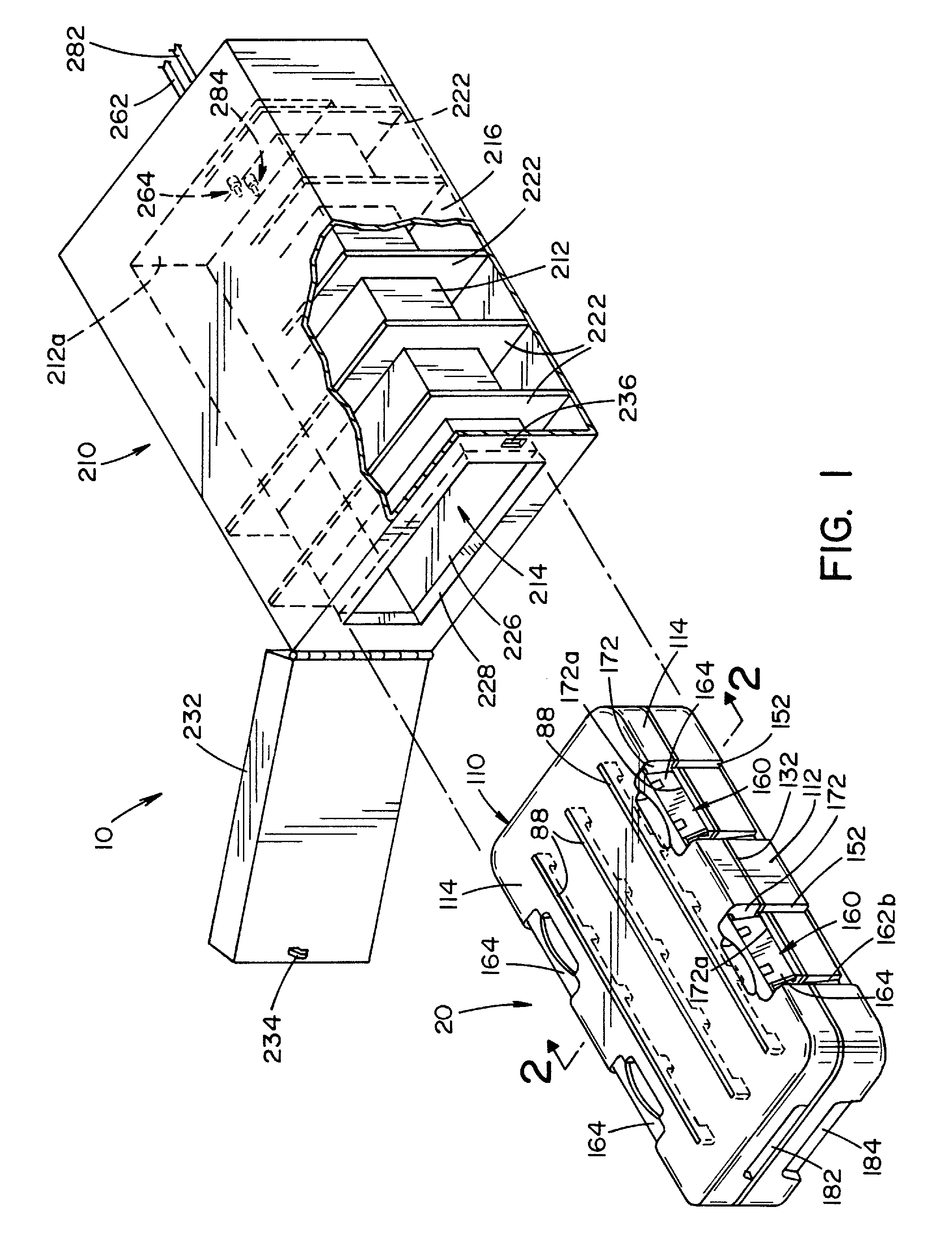

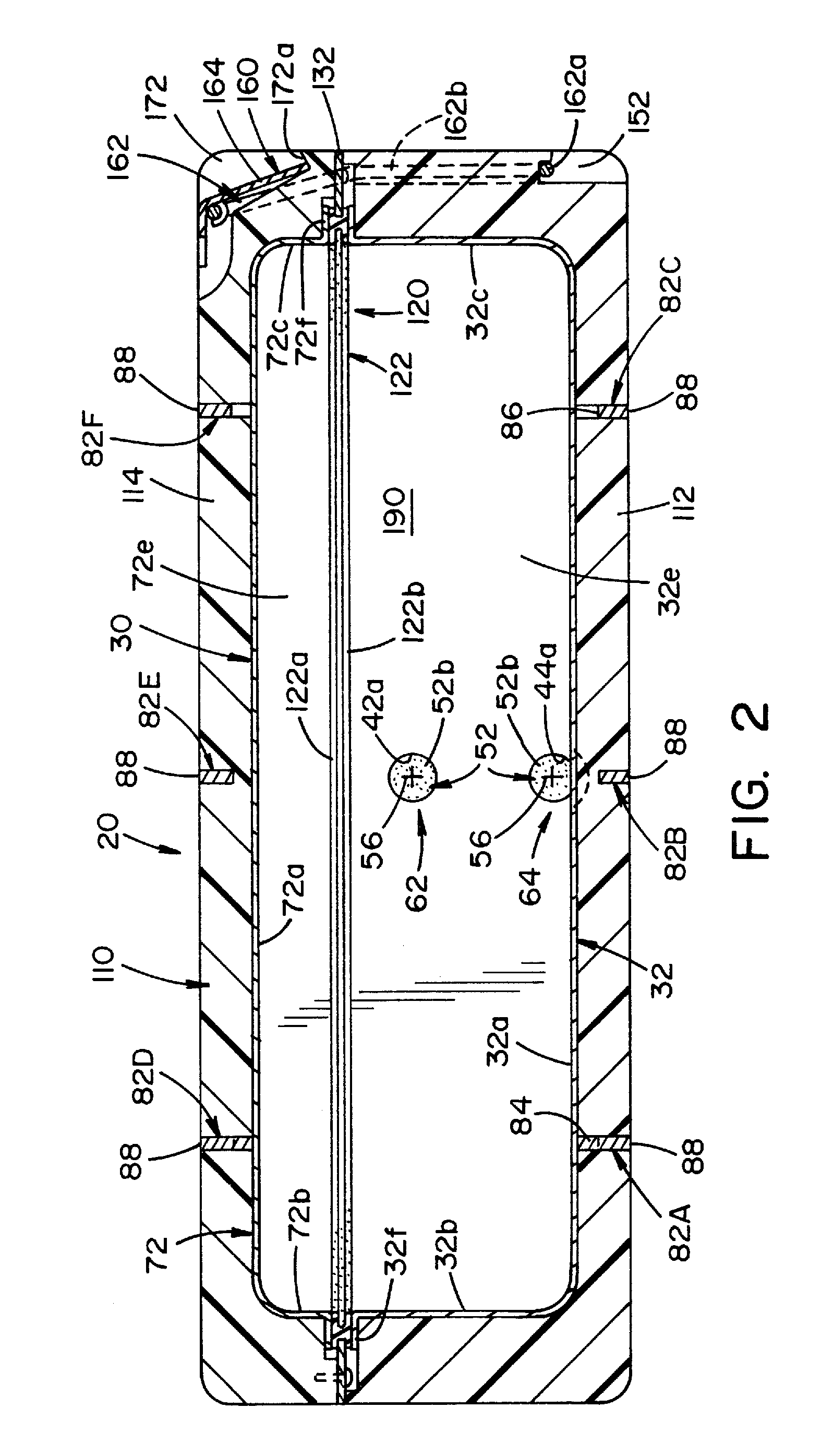

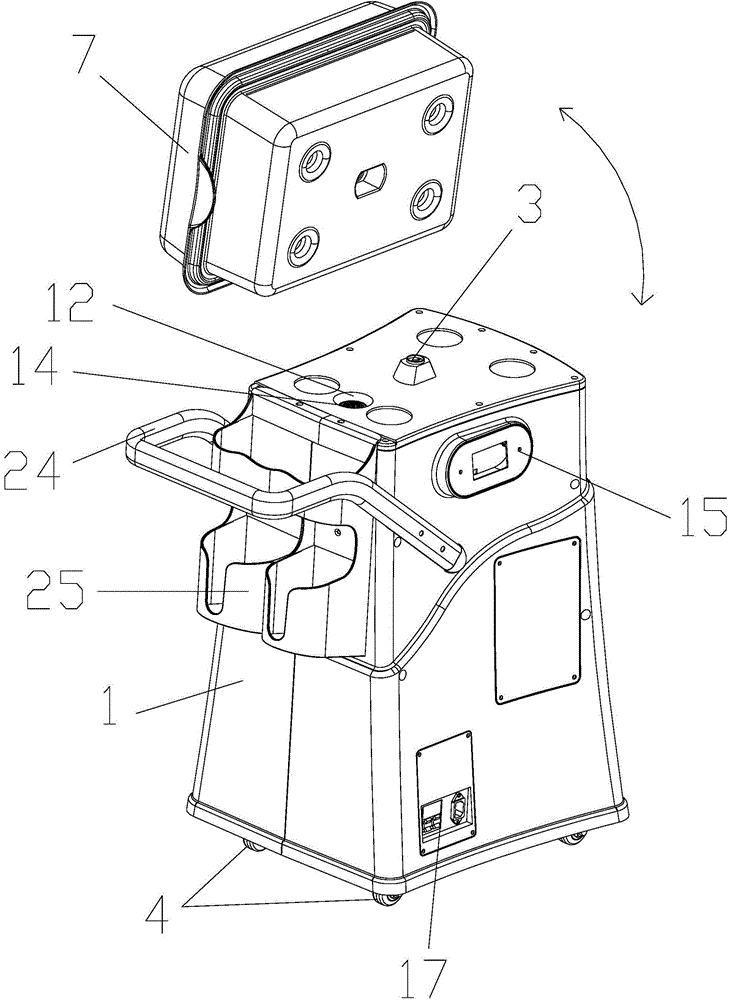

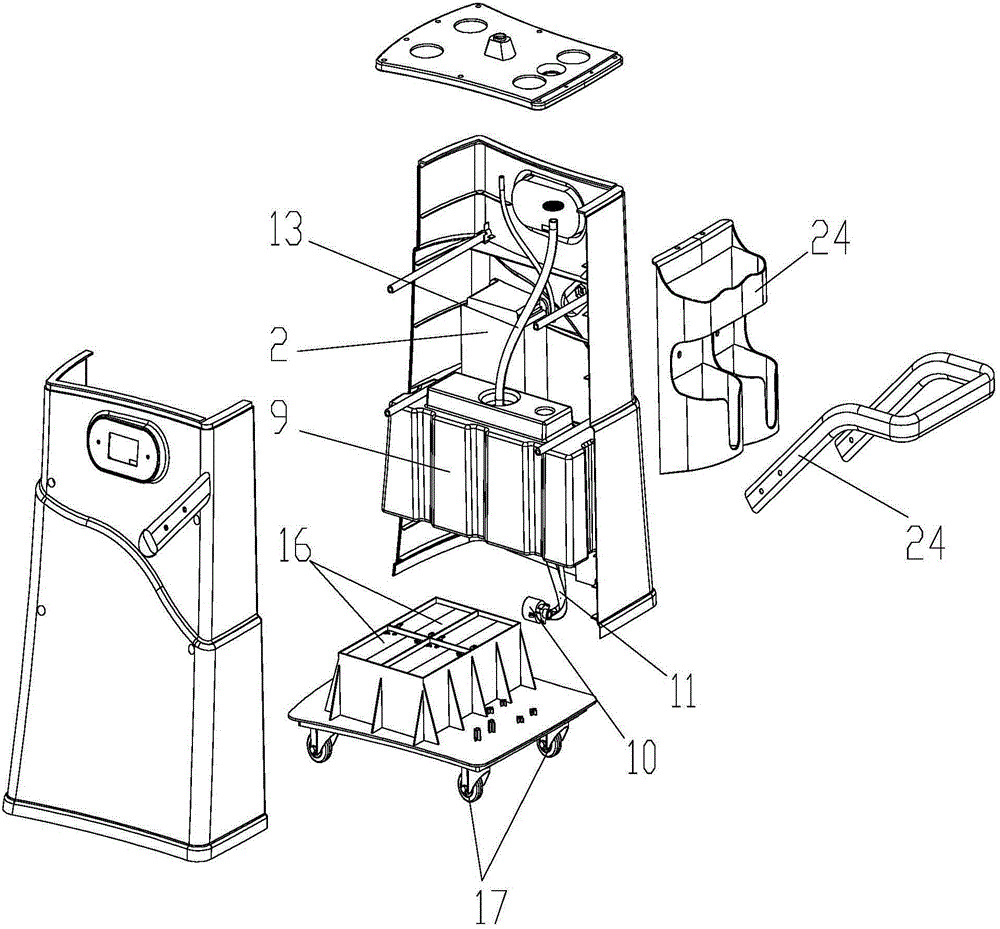

ActiveUS20140050634A1Domestic cooling apparatusLighting and heating apparatusEngineeringMedical device

A sterilizer having a cassette for holding metal instruments or medical devices. The cassette includes a metallic container that defines a sterilization chamber. The container has at least one outer surface. A plurality of spaced-apart, elongated rails extend along the at least one outer surface of the container. Each of the rails includes a free, longitudinal edge wherein the edges of the rails lie in a first plane. An insulating shell encases the metallic container and the plurality of rails. An outer surface of the insulating shell lies in the first plane. A receiving unit includes a housing having an outer surface and an inner surface. The inner surface engages the edges of the rails and the outer surface of the insulating shell when the cassette is disposed within the inner housing. A plurality of spaced-apart elongated ribs extends along the outer surface of the housing.

Owner:AMERICAN STERILIZER CO

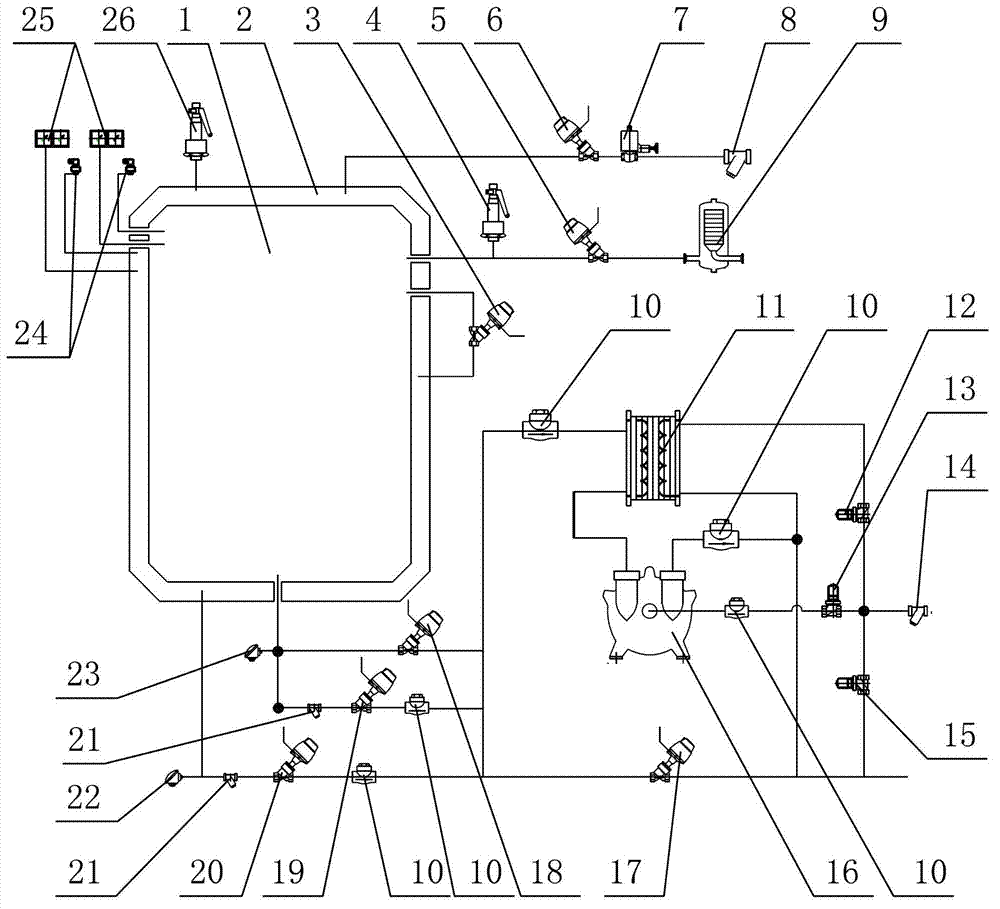

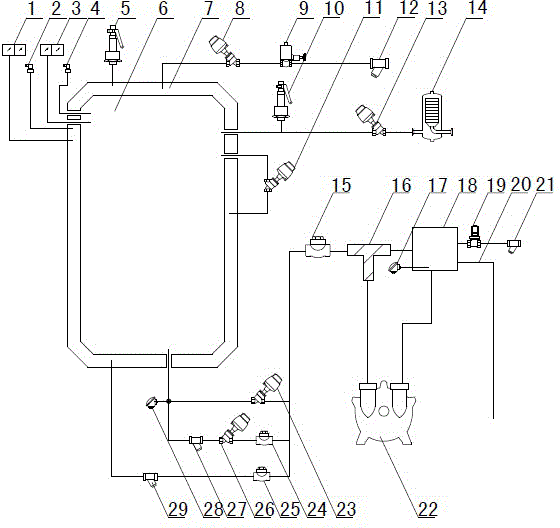

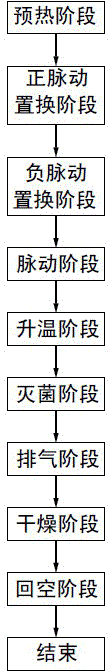

Sterilization method of steam sterilizer and steam sterilizer

The invention discloses a sterilization method of a steam sterilizer and the steam sterilizer. The steam sterilizer comprises a sterilization cavity (6), an interlayer (7), and an injector vacuumizing unit, and is characterized by also comprising a sterilization cavity interlayer air inlet unit, a sterilization cavity air return unit, a sterilization cavity drainage unit, a sterilization cavity vacuumizing unit, an interlayer steam inlet unit and an interlayer drainage unit. The sterilization method comprises the specific sterilization steps: 1, preheating; 2, performing positive pulse replacement; 3, performing negative pulse replacement; 4, pulsing; 5, raising the temperature; 6, sterilizing; 7, exhausting; 8, drying; 9, returning air; and 10, ending. According to the sterilization method disclosed by the invention, rapid and high-efficiency sterilization can be realized through the steam sterilizer with a water injector.

Owner:SHINVA MEDICAL INSTR CO LTD

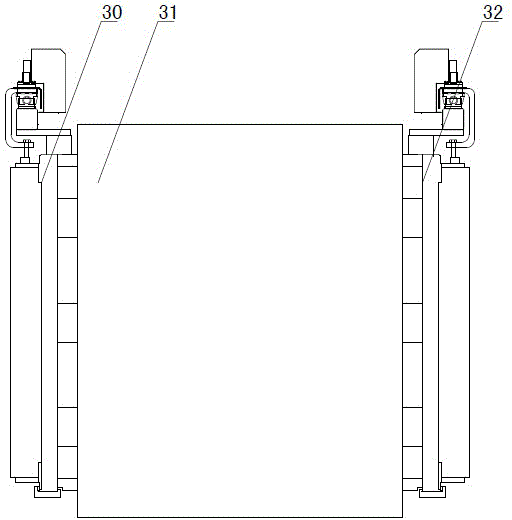

Energy-saving type pulsation vacuum pressure steam sterilizer

The invention discloses an energy-saving type pulsation vacuum pressure steam sterilizer which comprises an inner chamber, a jacket, a heat exchanger, a vacuum pump, a steam generator as well as a multifunctional water tank, wherein the sucking end of the vacuum pump is connected with the inner chamber through the heat exchanger; the air outlet end of the vacuum pump is connected with the water inlet of the multifunctional water tank; the water outlet of the heat exchanger is connected with the water inlet of the multifunctional water tank; the water inlet of the heat exchanger is connected with a tap water pipe; the inner chamber and the jacket are respectively connected with the water inlet of the multifunctional water tank through drain valves; the gas outlet of the steam generator is connected with the gas inlet of the jacket, and the gas inlet of the steam generator is connected with the water outlet of the multifunctional water tank; the steam is accommodated into the multifunctional water tank by the air outlet end of the vacuum pump; operating water accommodated in the heat exchanger is accommodated into the multifunctional water tank by the water outlet of the heat exchanger; condensed water inside the inner chamber and the jacket is also accommodated into the multifunctional water tank; steam and operating water accommodated by the multifunctional water tank are repeatedly conveyed to the steam generator to generate steam for sterilization. Repeated use of water and energy is achieved.

Owner:LAOKEN MEDICAL TECH

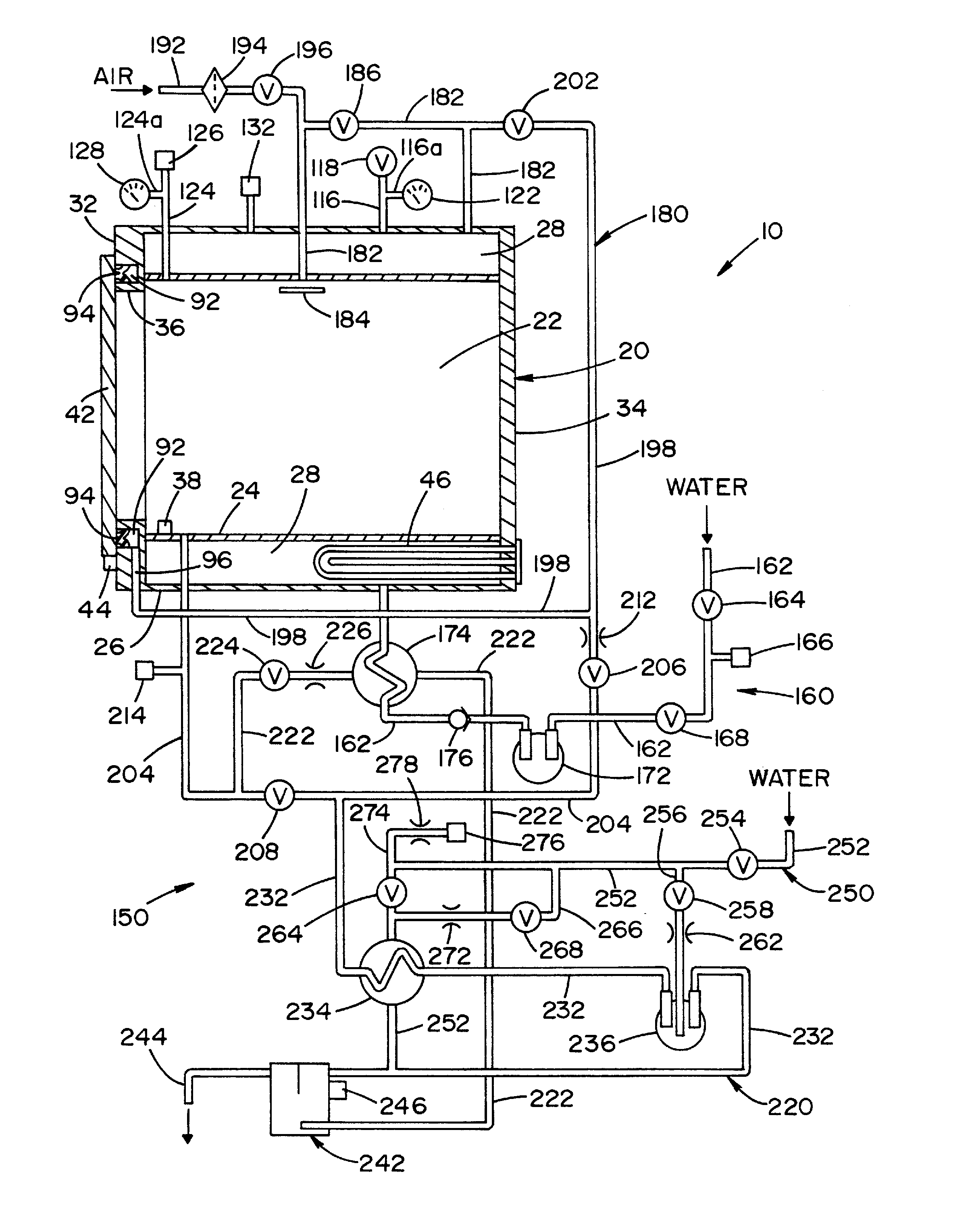

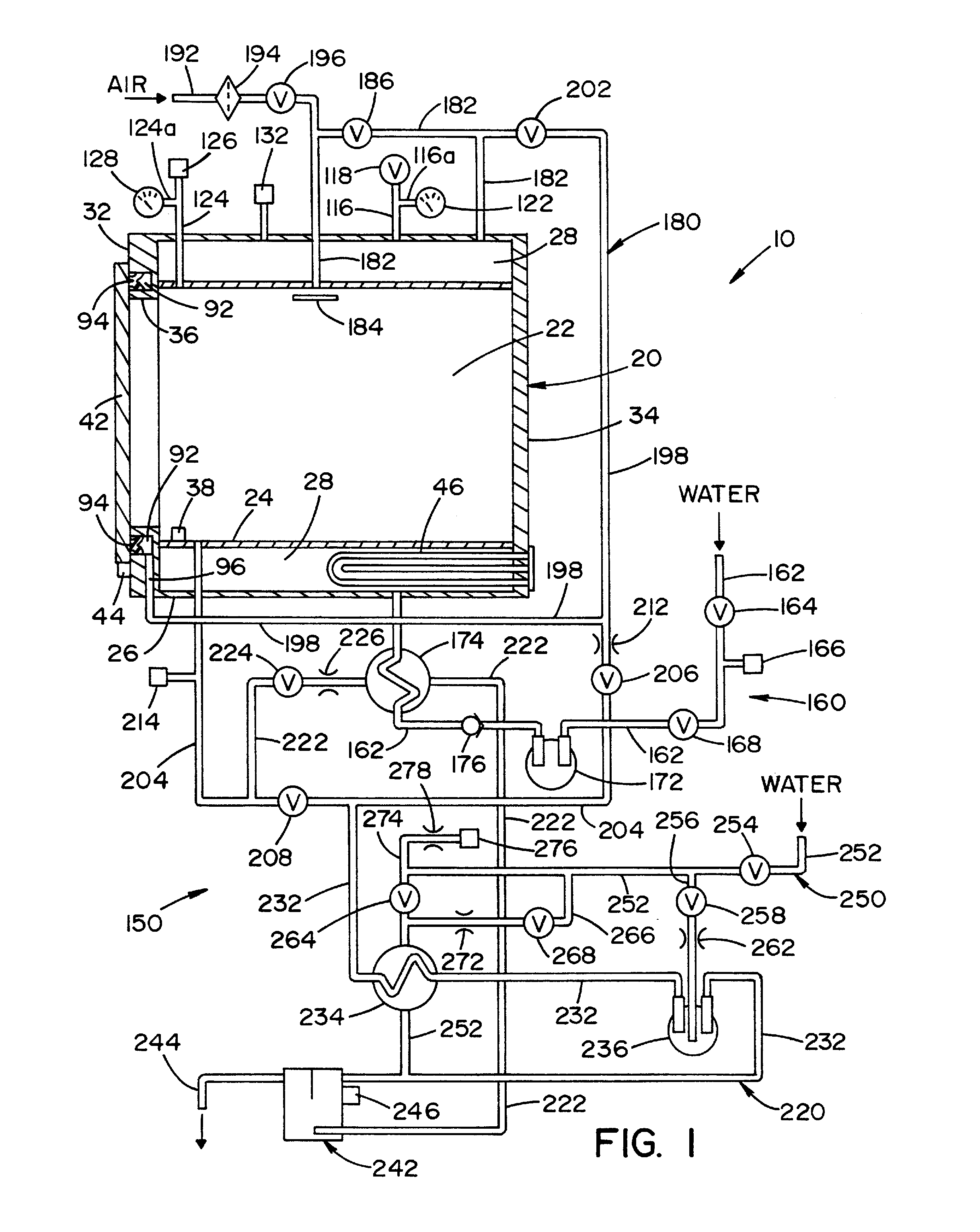

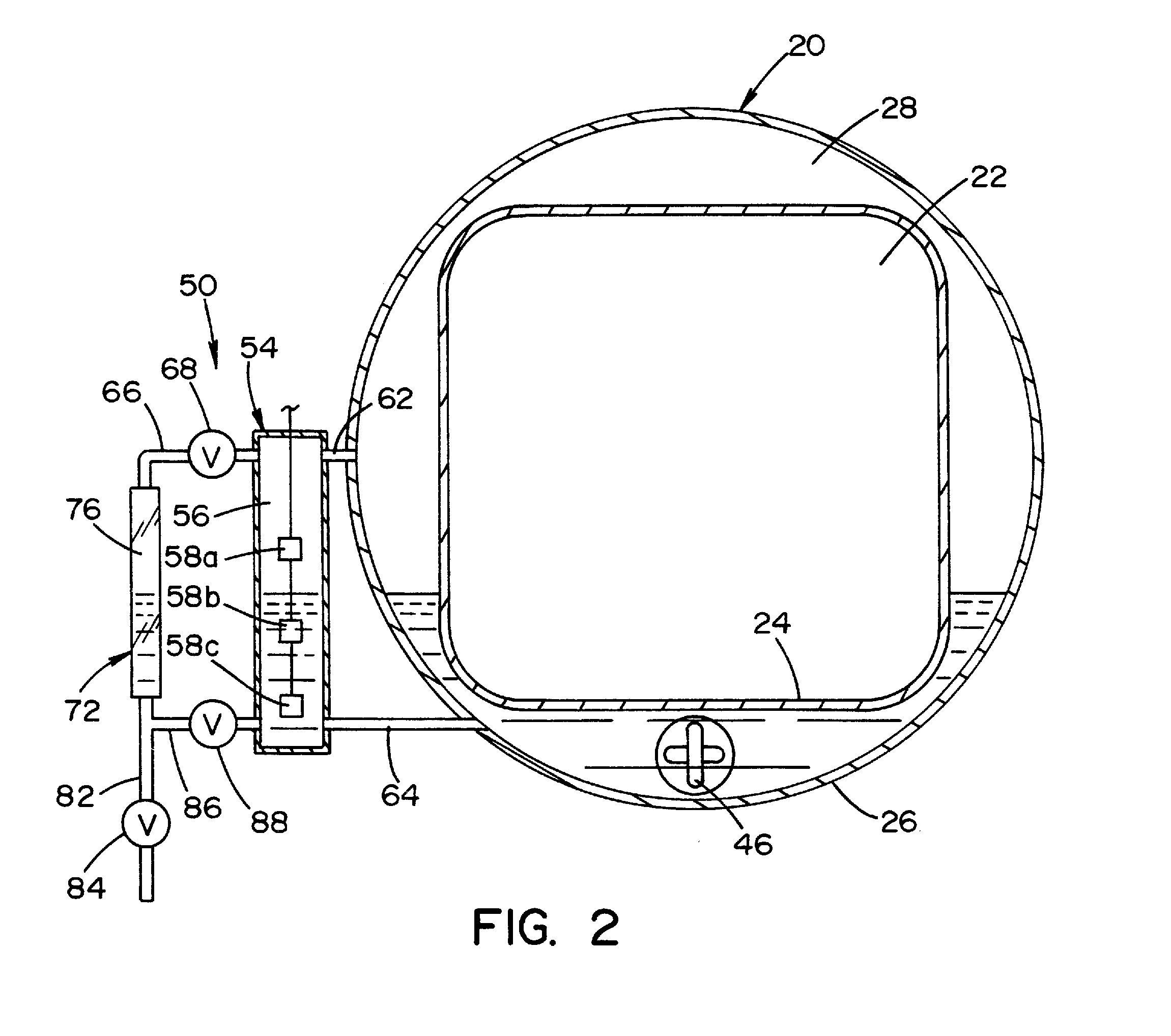

Steam sterilizer

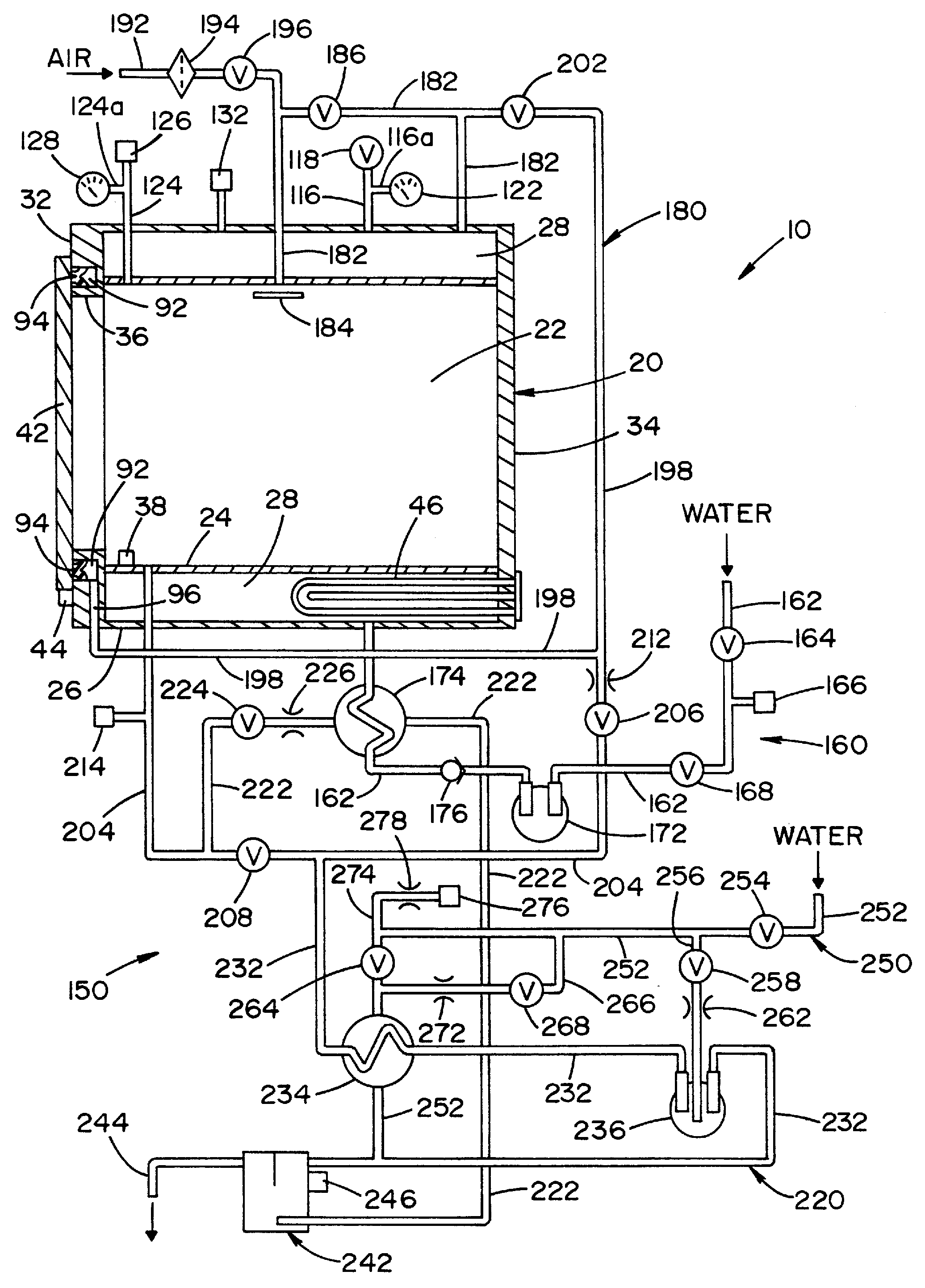

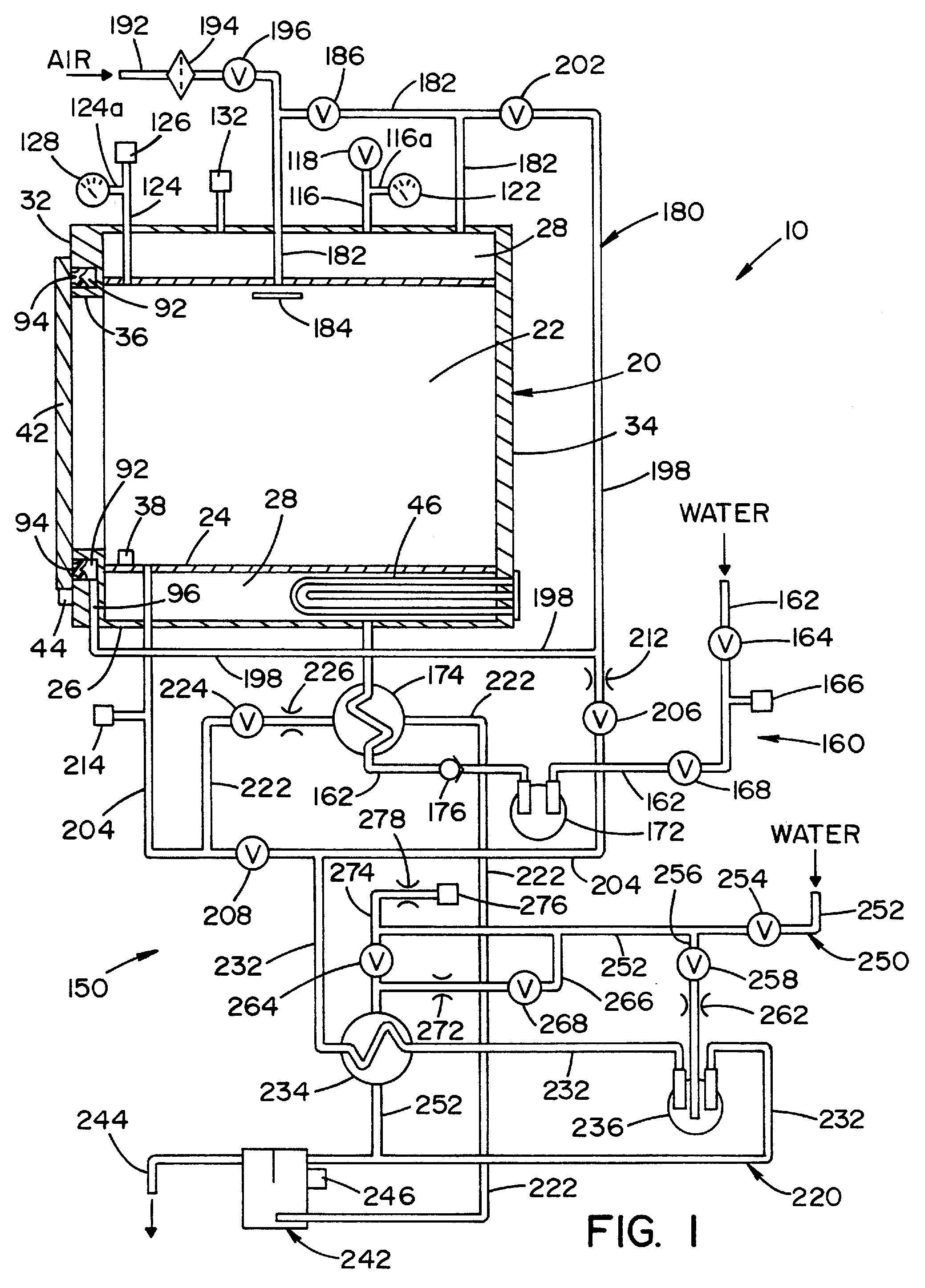

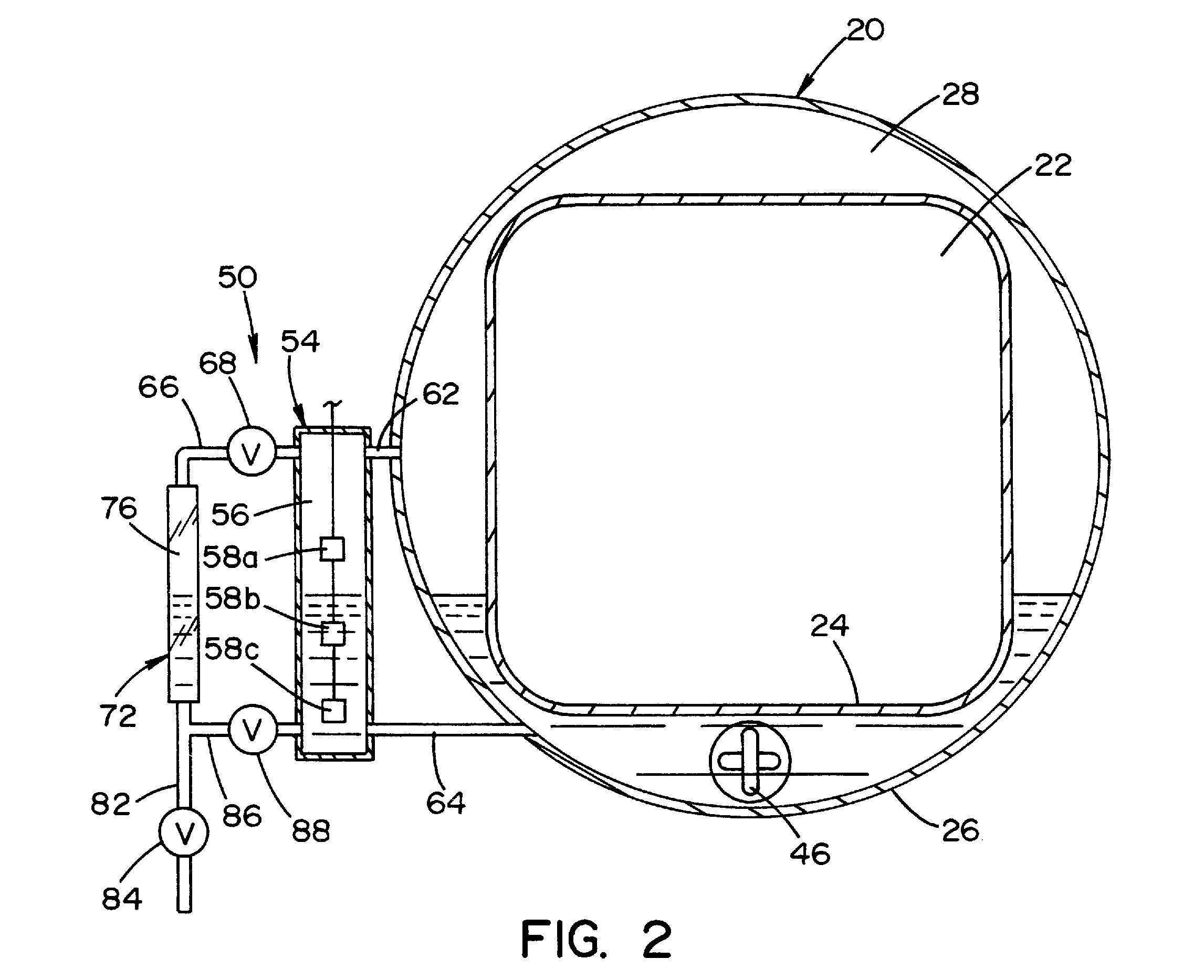

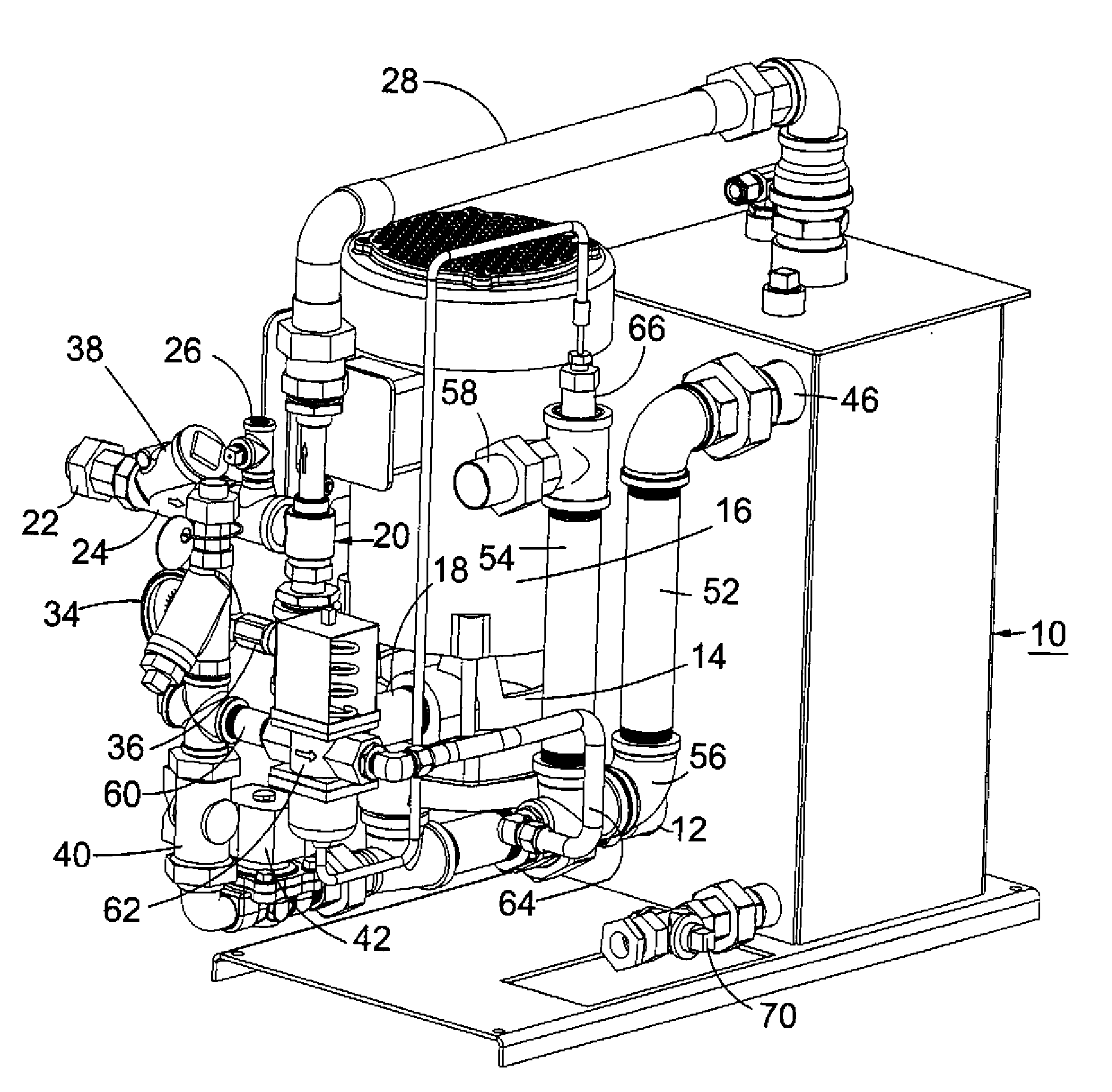

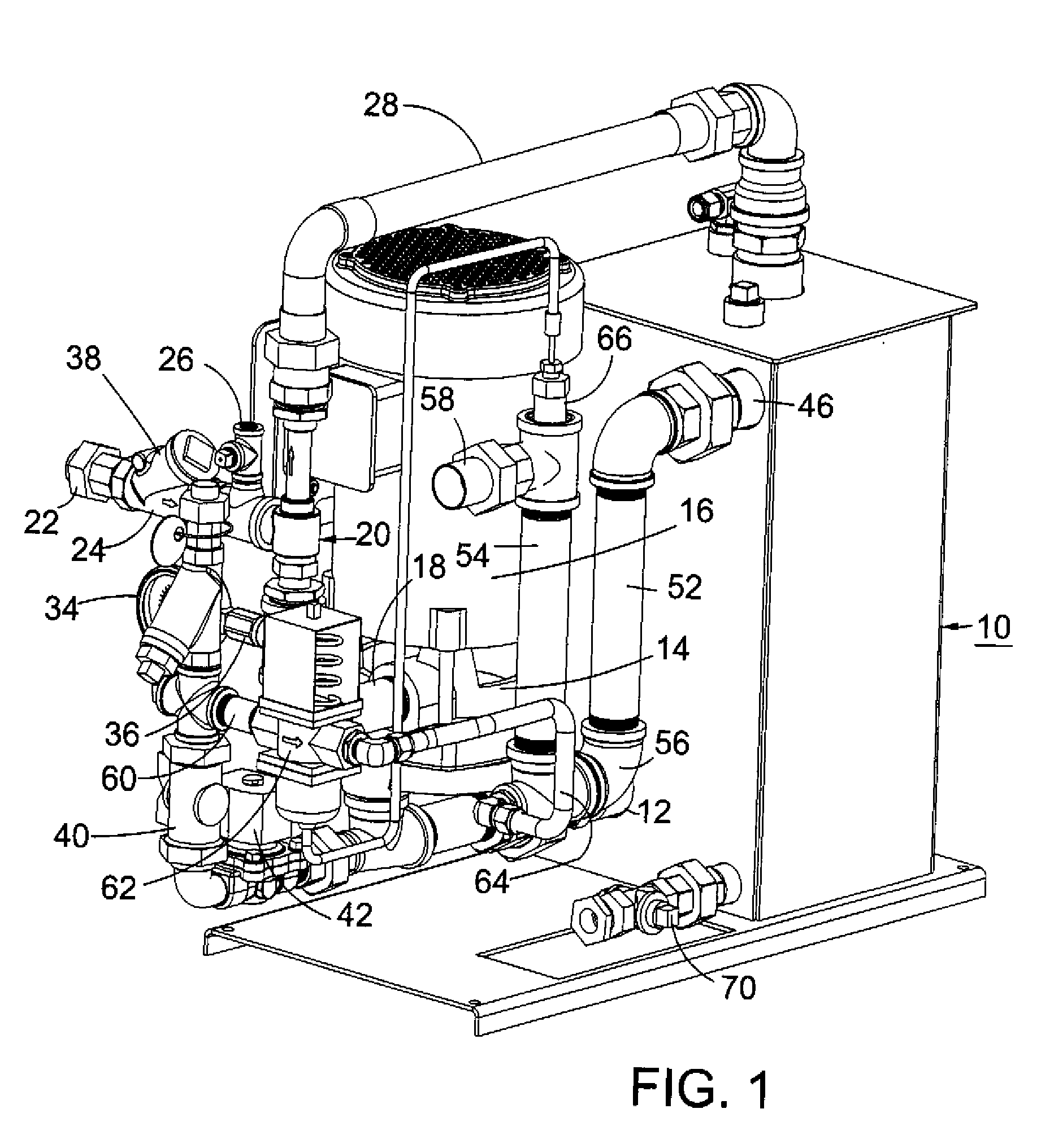

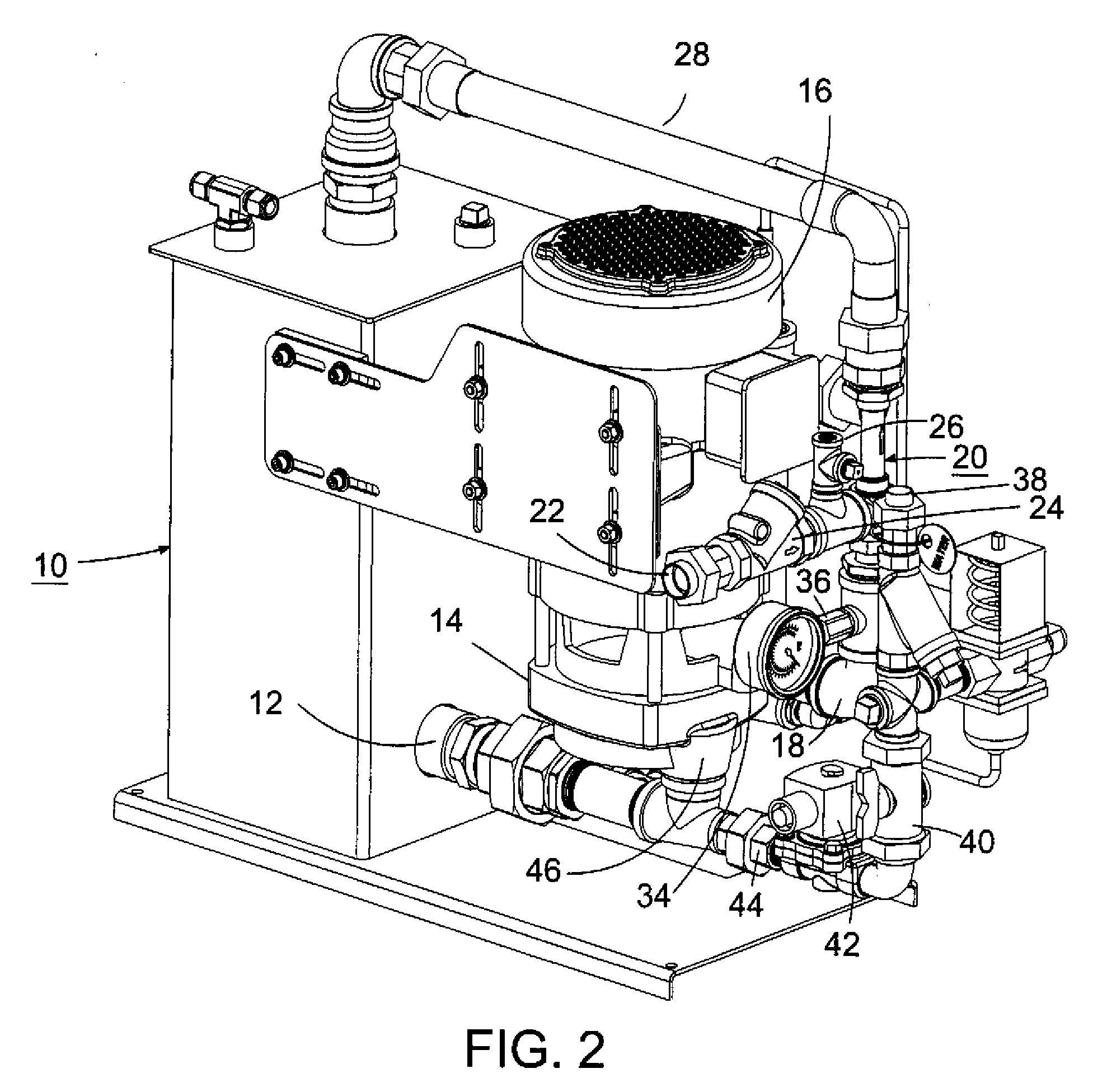

A sterilizer for sterilizing instruments and devices disposed therein. The sterilizer includes a vessel that has an inner wall and an outer wall. The inner wall defines a sterilization chamber. The outer wall is spaced from the inner wall to define a cavity surrounding the sterilization chamber. A heating element for vaporizing a fluid is disposed in a lower portion of the cavity. A fluid circuit is fluidly connected to the vessel to convey fluid to the cavity, to convey steam from the cavity to the sterilization chamber and to exhaust steam from the sterilization chamber. The fluid circuit includes a conduit that fluidly connects the sterilization chamber to the cavity. A valve is disposed in the conduit for controlling the flow of steam from the cavity to the sterilization chamber. A boiler pump is provided for conveying fluid to the cavity of the vessel.

Owner:AMERICAN STERILIZER CO

Steam sterilizer

Owner:LEE IN OK

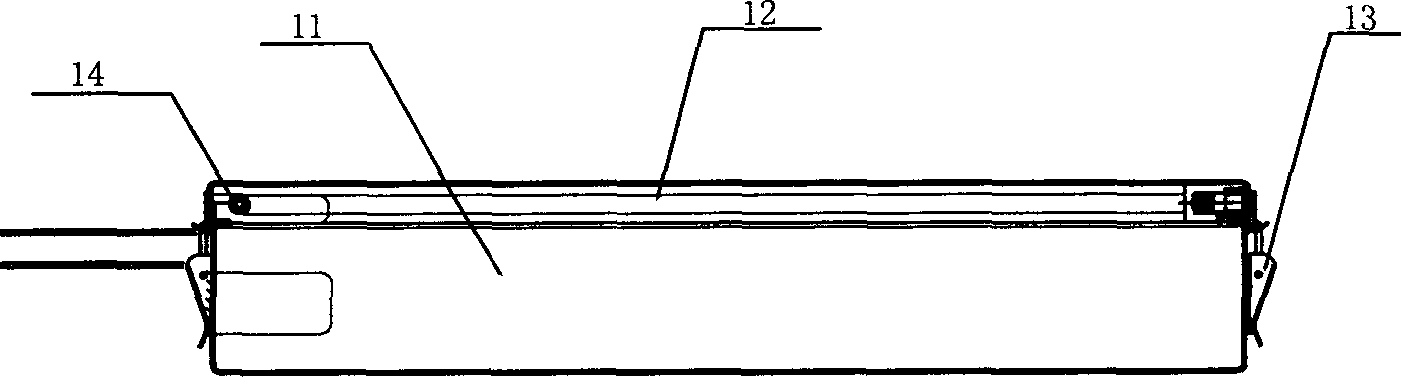

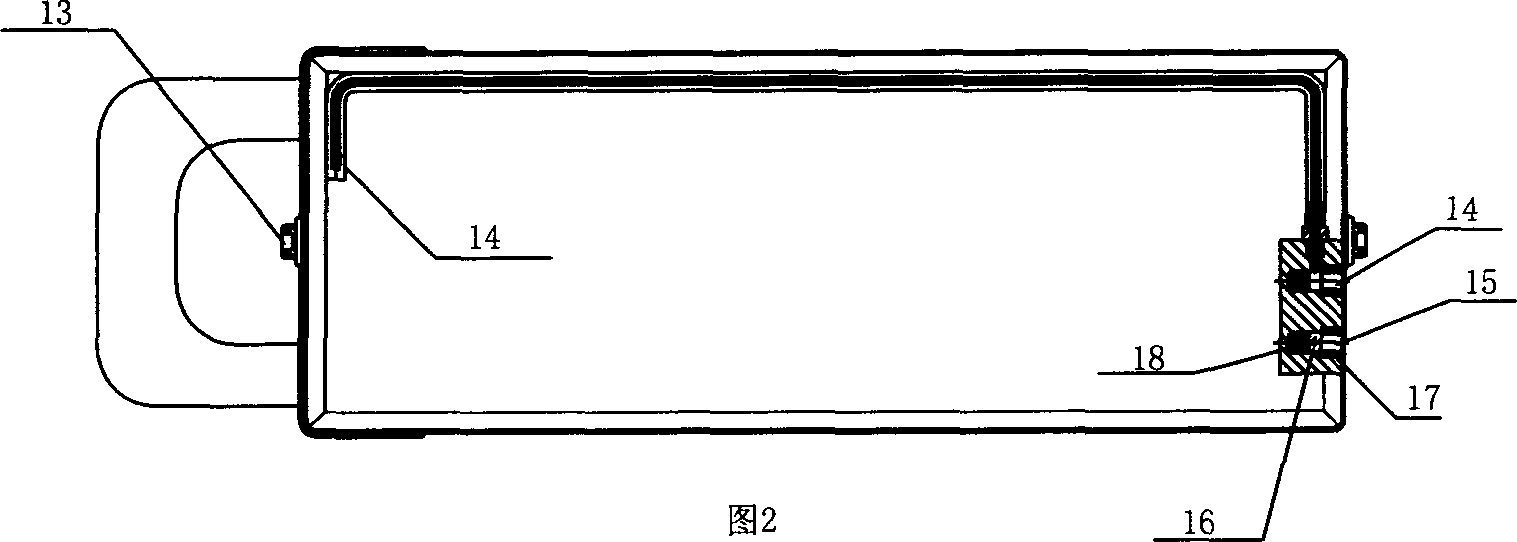

Pulsed steam sterilization process and steam sterilizer thereof

ActiveCN102423495AEvenly distributedShorten heating timeLavatory sanitoryHeatAutomatic controlMedical equipment

The invention discloses a pulsed steam sterilization process suitable for sterilizing medical equipment and a steam sterilizer for the steam sterilization process. The sterilization process comprises the following steps of vacuumizing, preheating, sterilizing, performing vacuum drying and the like. The steam sterilizer comprises a steam sterilization box, a valve bank, an air filter, a steam generator, a vacuum pump and an automatic control system. Compared with the prior art, the invention has the advantages that: by the pulsed steam sterilization process and the steam sterilizer thereof, a sterilization apparatus can be transported without packaging, the temperature raising and reduction time of the sterilization is shortened, the sterilization time of the apparatus is shortened, the labor intensity of medical care personnel is reduced, and the disinfection and sterilization are more complete and have a better effect.

Owner:何德贤

Lovamin and its prepn process

InactiveCN1370524AGuaranteed quality of lifeImprove securityPeptide/protein ingredientsMetabolism disorderAcetic acidSide effect

The present invention belongs to one mixed amino acid injection containing 18 kinds of amino acids and is named Lovamin. Its main components includes 18 kinds of amino acids in 8.5 wt% or 11.4 wt%, sulfite in 0.001-0.003 wt% and glacial acetic acid in small amount other than injection water. Its preparation process includes the steps of compounding of injection, filling and disinfecting in a steam sterilizer. Compared with similar product, the present invention has less side effect.

Owner:费森尤斯卡比华瑞制药有限公司

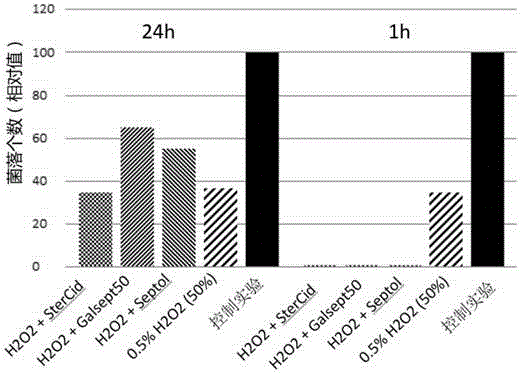

Multi-stage treatment method and equipment for biomedical wastes

PendingCN106729920AGood disinfection and sterilization effectImprove the bactericidal effectSolid waste disposalCement productionHigh concentrationDisinfectant

The invention belongs to the field of biological / medical waste treatment, and discloses a multi-stage treatment method and equipment for biomedical wastes. The method comprises the following steps of (1) smashing the biomedical wastes, and meanwhile, adopting a peroxide disinfectant with the mass concentration being 0.1 to 0.5 percent for carrying out first-stage disinfection treatment on the biomedical wastes; (2) carrying out second-stage disinfection treatment on the treated wastes with the remained peroxide disinfectant and subjected to first-stage disinfection treatment, wherein the second-stage disinfection treatment is characterized by adopting steam sterilizing heat treatment or adopting a high-concentration peroxide disinfectant with the mass concentration being 5 percent to 20 percent for disinfecting. The equipment for implementing the method comprises the following devices: a reaction bin (including a dosage dispenser, a smasher and a disinfection reaction tank) for receiving the wastes, and an enhanced disinfector (including a high-pressure steam sterilizer or a mixed reactor); the multi-stage treatment method and the equipment for the biomedical wastes provided by the invention have the advantages of good sterilization effect, short time and better environmental protection effect.

Owner:GEWA TECH CO LTD +1

Steam sterilizer

A sterilizer for sterilizing instruments and devices disposed therein. The sterilizer includes a vessel that has an inner wall and an outer wall. The inner wall defines a sterilization chamber. The outer wall is spaced from the inner wall to define a cavity surrounding the sterilization chamber. A heating element for vaporizing a fluid is disposed in a lower portion of the cavity. A fluid circuit is fluidly connected to the vessel to convey fluid to the cavity, to convey steam from the cavity to the sterilization chamber and to exhaust steam from the sterilization chamber. The fluid circuit includes a conduit that fluidly connects the sterilization chamber to the cavity. A valve is disposed in the conduit for controlling the flow of steam from the cavity to the sterilization chamber. A boiler pump is provided for conveying fluid to the cavity of the vessel.

Owner:AMERICAN STERILIZER CO

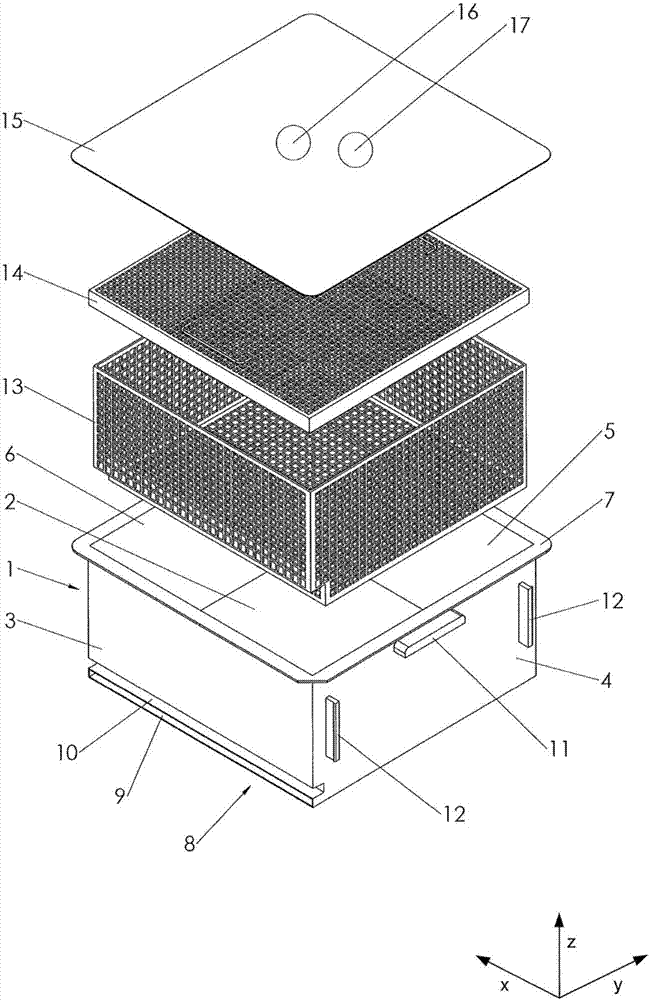

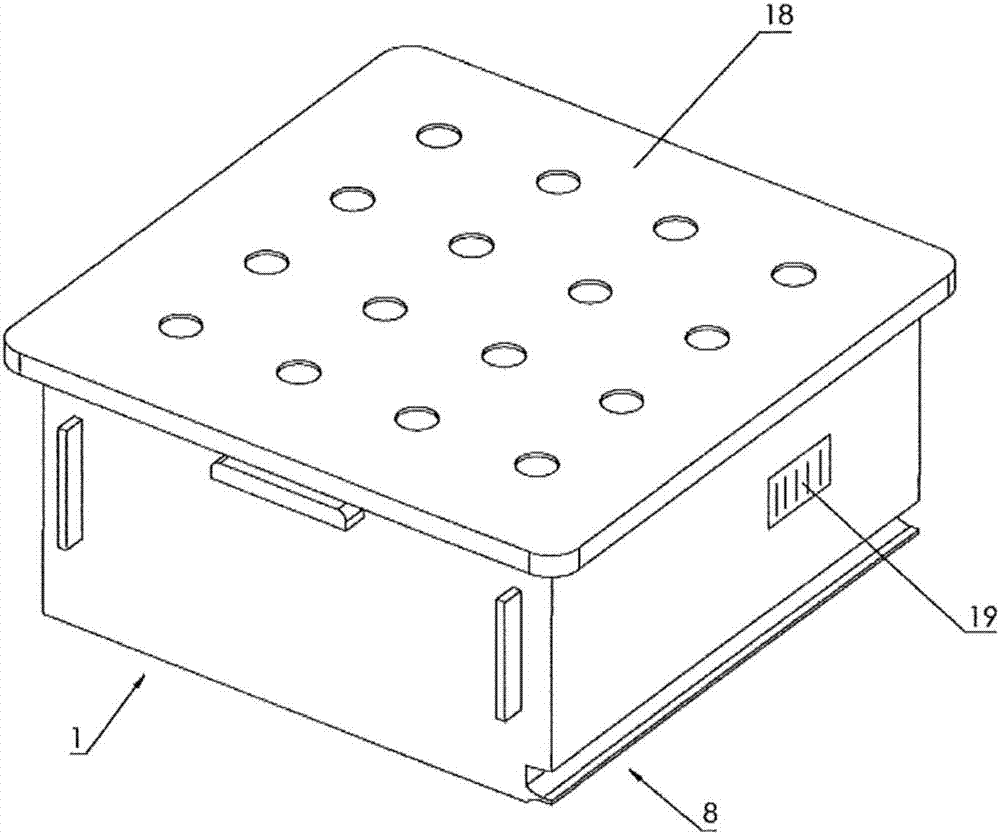

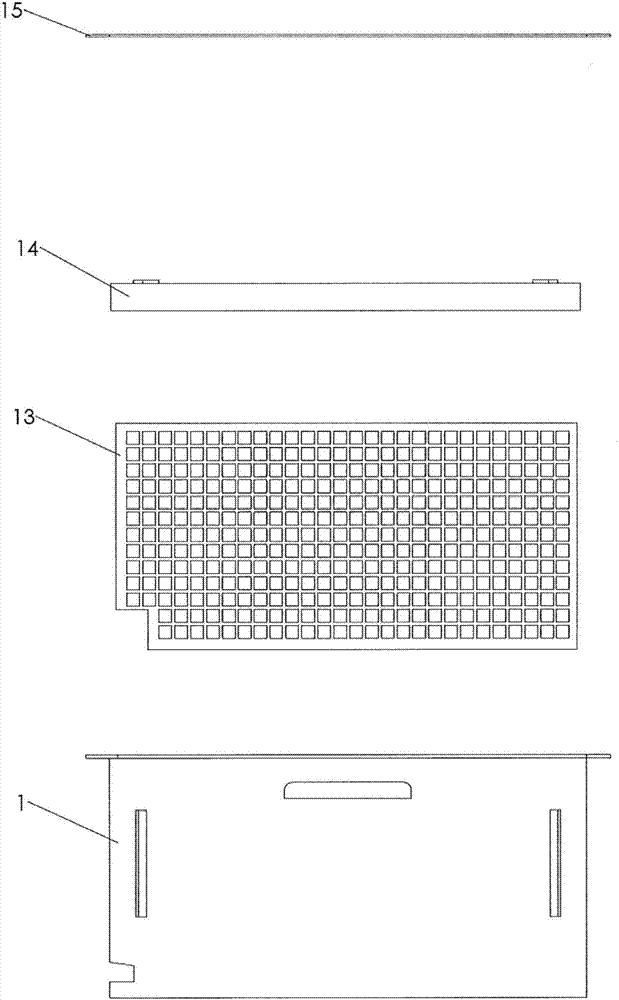

Pulsating vacuum pressure steam sterilizer

The invention relates to a pulsating vacuum pressure steam sterilizer, which comprises an inner chamber, a jacket, a steam generating device and a steam inlet mechanism, wherein the steam inlet mechanism comprises a filter, a jacket safety valve, a jacket air control angle seat valve, an inner chamber safety valve, an inner chamber air control angle seat valve and a drain valve, and the jacket air control angle seat valve is arranged between the jacket and the steam generating device; the inner chamber air control angle seat valve is arranged between the inner chamber and the steam generating device, and the inner chamber and the jacket are provided with the inner chamber safety valve and the jacket safety valve; the drain valve is arranged at the lower end of the steam inlet mechanism so as to drain condensate water in the steam inlet mechanism. Steam is supplied to the jacket and the inner chamber by the steam generating device respectively, so that steam can quickly flow into the inner chamber, and thus the work time of the sterilizer is shortened; meanwhile, the pressure of the jacket is always in a steady state, so that the corresponding steam temperature keeps steady, and thus the preheating and heat insulation effects of the jacket on the inner chamber are ensured.

Owner:LAOKEN MEDICAL TECH

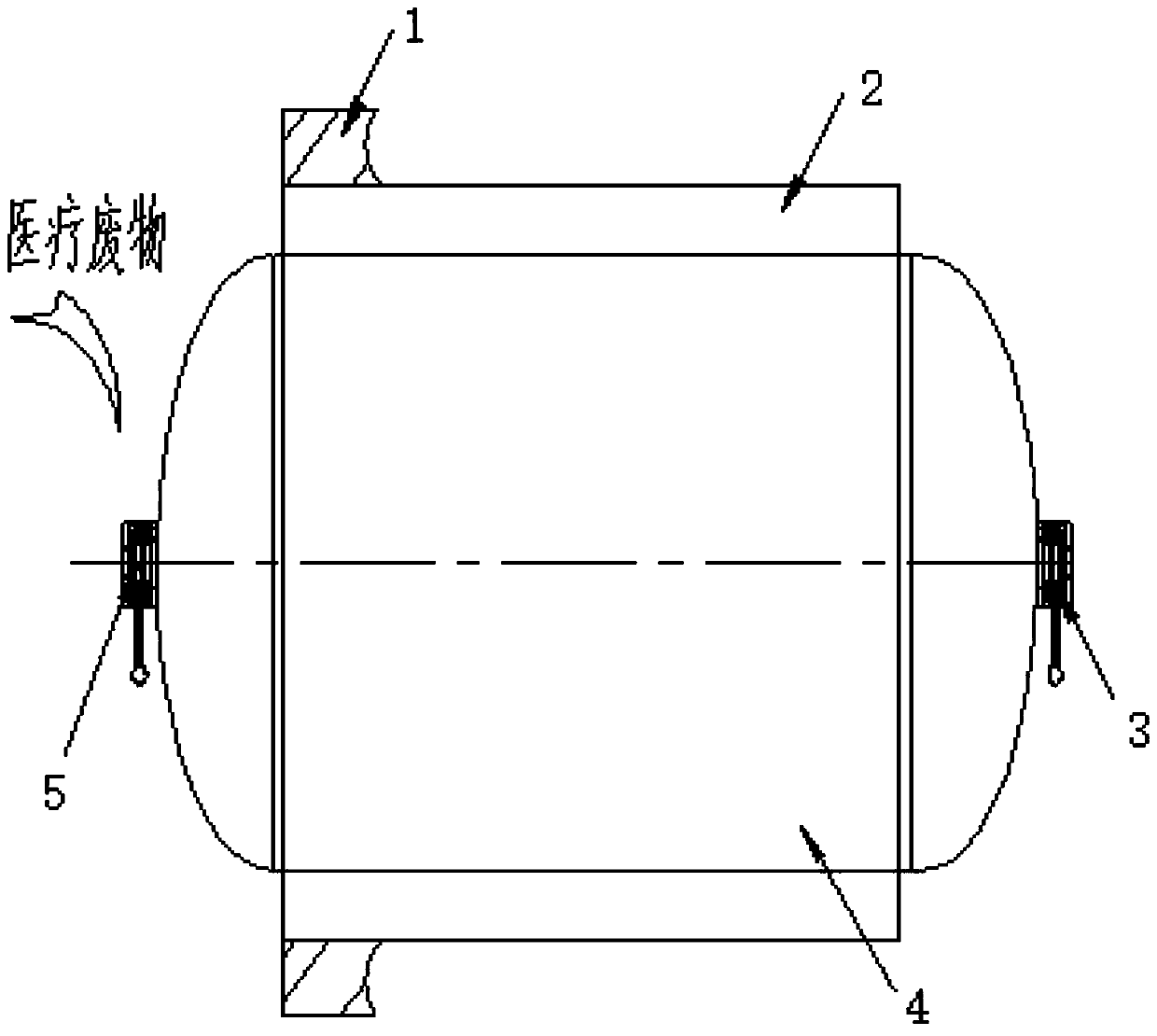

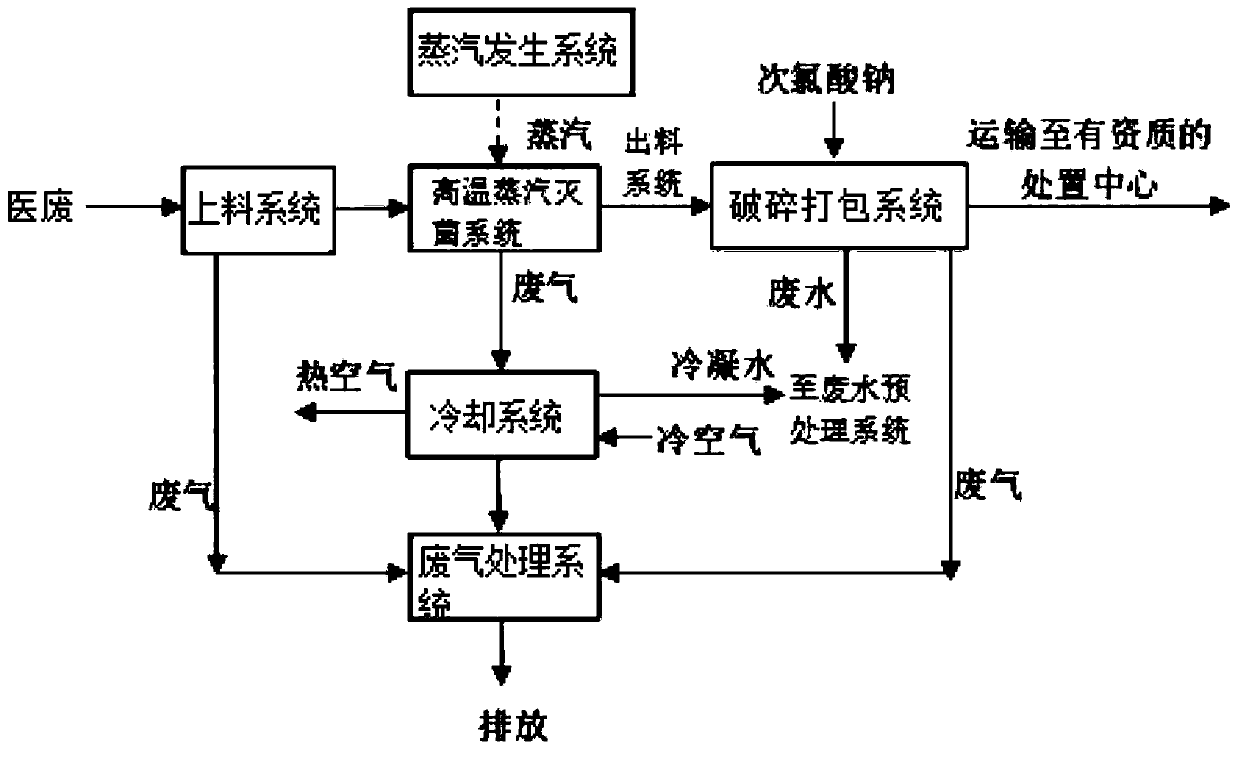

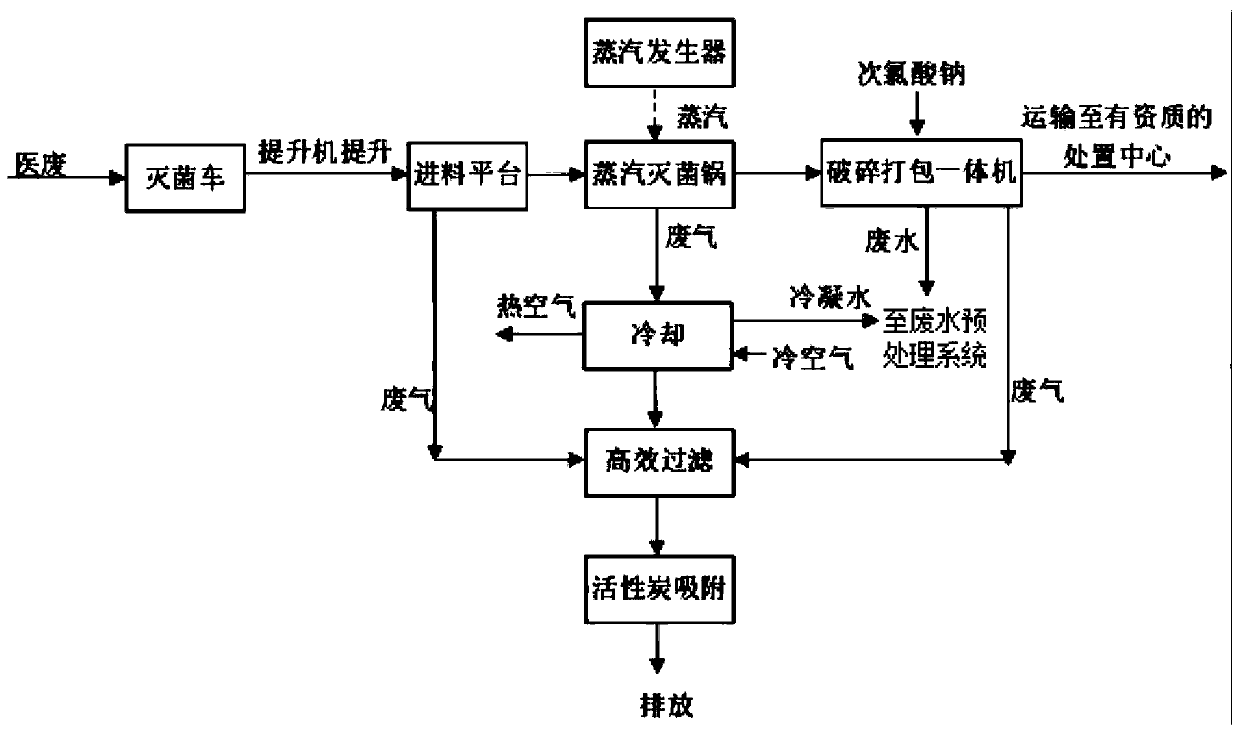

Double-layer steam sterilization pot and moveable medical waste emergent disposal system and application

PendingCN111298148AGuaranteed sterilization effectStable temperatureGas treatmentSolid waste disposalThermodynamicsMedical waste

The invention relates to a double-layer steam sterilization pot and a moveable medical waste emergent disposal system. The sterilization pot comprises a pulse vacuum steam sterilizer pot body, a middle jacket layer and a heat preservation layer, wherein the middle jacket layer is arranged on the outer surface of the pulse vacuum steam sterilizer pot body, a middle jacket layer in a tightly connected manner; a middle interlayer is arranged on the outer surface of the pulse vacuum steam sterilizer pot body, a middle jacket layer and the inner surface of the middle jacket layer; the middle interlayer is capable of containing and introducing steam; the heat preservation layer is arranged on the outer surface of the middle jacket layer in a tightly connected manner; and the system comprises a feeding system, a discharge system, a high-temperature steam sterilization system, a steam generation system, a cooling system, a crushing packaging system, a waste gas treatment system, a wastewater pretreatment system and an auxiliary sterilization system. The system can be applied to emergent disposal on medical wastes involved in an epidemic situation and / or medical wastes of sudden disasters and / or daily medical wastes.

Owner:北京航天环境工程有限公司

Steam sterilizer

A sterilizer having a cassette for holding metal instruments or medical devices. The cassette includes a metallic container that defines a sterilization chamber. The container has at least one outer surface. A plurality of spaced-apart, elongated rails extend along the at least one outer surface of the container. Each of the rails includes a free, longitudinal edge wherein the edges of the rails lie in a first plane. An insulating shell encases the metallic container and the plurality of rails. An outer surface of the insulating shell lies in the first plane. A receiving unit includes a housing having an outer surface and an inner surface. The inner surface engages the edges of the rails and the outer surface of the insulating shell when the cassette is disposed within the inner housing. A plurality of spaced-apart elongated ribs extends along the outer surface of the housing.

Owner:AMERICAN STERILIZER CO

Post-steam sterilization moisture-indicating methods and articles

InactiveCN104781652AMaterial analysis by observing effect on chemical indicatorScattering properties measurementsMoistureSteam sterilizers

Methods for detecting moisture are described. The methods include sequential steps: (a) subjecting an article comprising a reversible moisture-indicating medium to steam sterilization in a steam sterilizer to produce a sterilized article; (b) subjecting the sterilized article to drying to reduce moisture in the sterilized article; (c) removing the sterilized article from the steam sterilizer; and (d) determining the level of moisture in the sterilized article after step (c) based on at least one property of the moisture-indicating medium. Packages comprising reversible steam-sterilization-compatible moisture-indicating media, including post-steam sterilization wet pack indicators, are also described

Owner:3M INNOVATIVE PROPERTIES CO

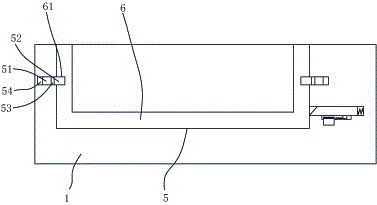

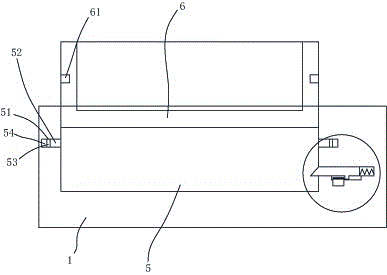

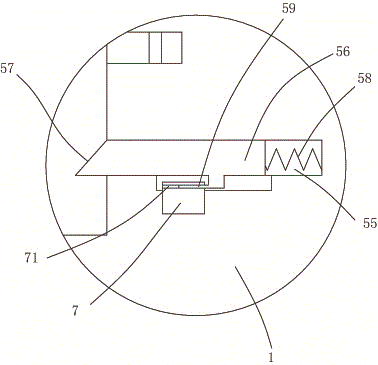

Steam sterilizer

The invention discloses a steam sterilizer, comprising a machine body, a pot body is arranged in the body, a water tank groove is arranged on the body, a water tank is arranged in the water tank groove, a card groove is arranged on the side of the water tank, and a first slideway is arranged on the side of the water tank groove. A block is arranged in the first slideway, a magnet is arranged on the block, an electromagnet is arranged at the end of the first slideway, and the electromagnet is connected to the main circuit of the sterilizer. The side wall of the water tank is also provided with a second slideway. A sliding rod is arranged in the slideway, one end of the sliding rod is provided with a slope matching with the water tank, and the other end is connected with a spring, the spring is fixed in the second slideway, a switch is arranged on the body, a socket is arranged on the switch, and a plug hole is arranged in the middle of the sliding rod. pole. When the steam pressure sterilizer is powered on, the water tank cannot be disassembled from the sterilizer, so as to prevent the steam pressure sterilizer from being damaged, and at the same time ensure the life safety of the user, and at the same time prevent the sterilizer from being opened by mistake after the water tank is removed.

Owner:六安聚首信息科技有限公司

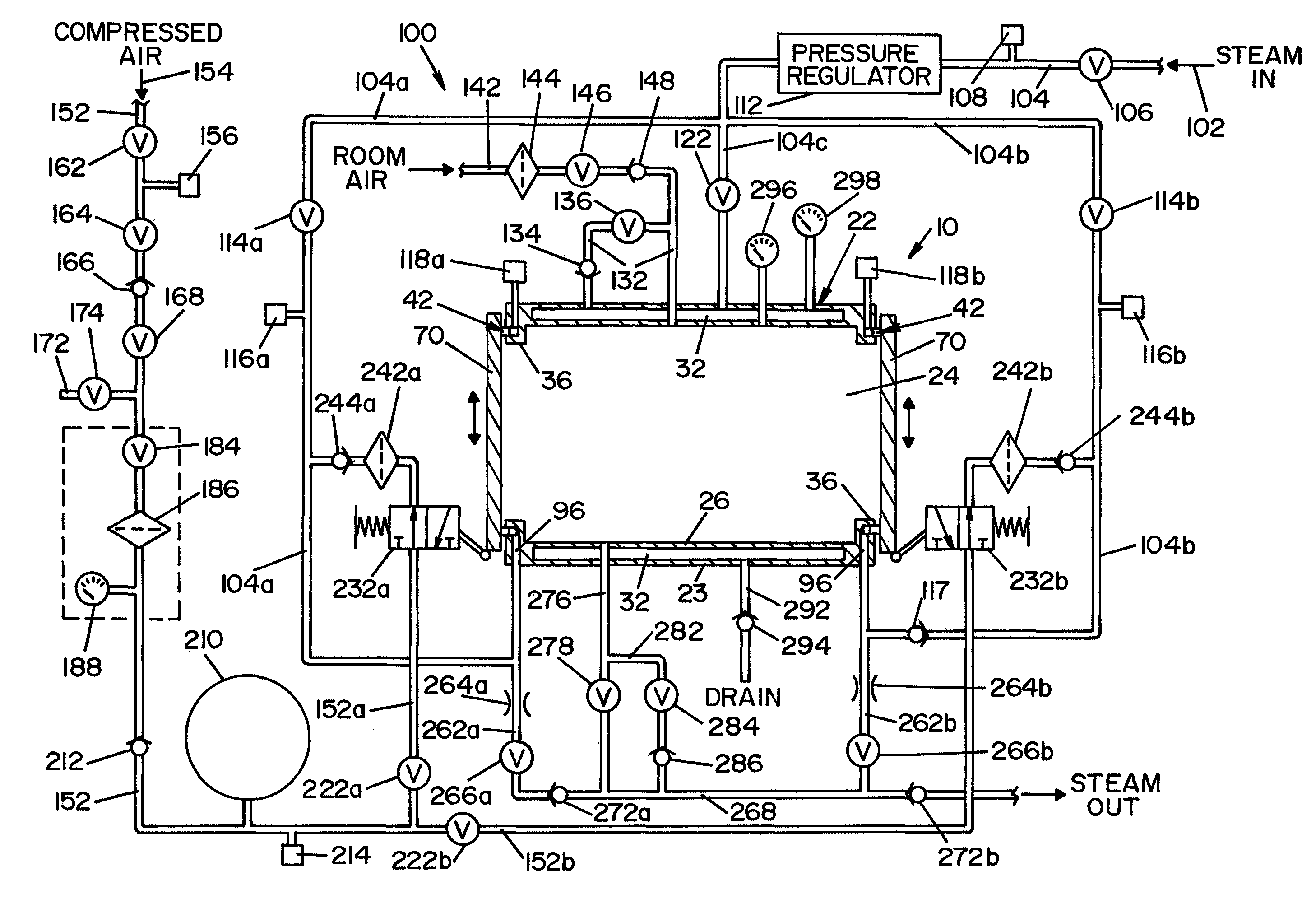

Vacuum unit for steam sterilizer

ActiveUS20090288721A1Improve the level ofReduce probabilityPressure pumpsPipeline systemsWater cyclingEngineering

In a vacuum unit for use in drawing a vacuum on a steam sterilizer, a pump circulates water through an ejector and a reservoir. Fresh water is injected at the pump inlet to maintain a low temperature in the ejector so that it can operate efficiently. Excess water is taken from a location adjacent the bottom of the reservoir through an internal dip tube, and passed through a U-shaped conduit that serves as a condensate trap. To maintain the water discharge temperature below a predetermined level, fresh water is injected into the U-shaped conduit through a valve controlled by a temperature sensor downstream from the water injection point.

Owner:R V INDS

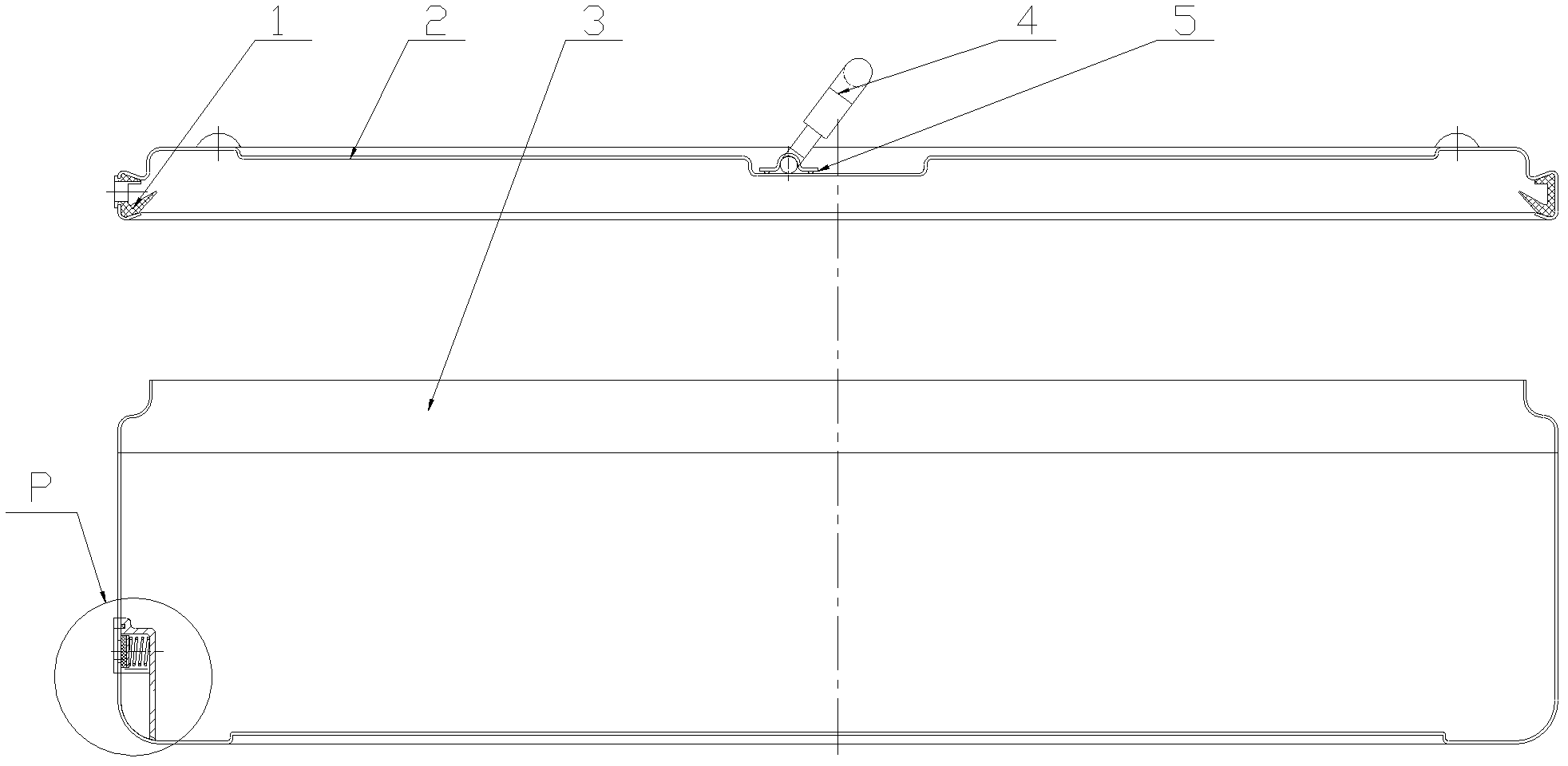

Door seal system for steam sterilizer

Owner:AMERICAN STERILIZER CO

Mobile type realtime high-temperature steam sterilizer

Owner:深圳智太实业有限公司

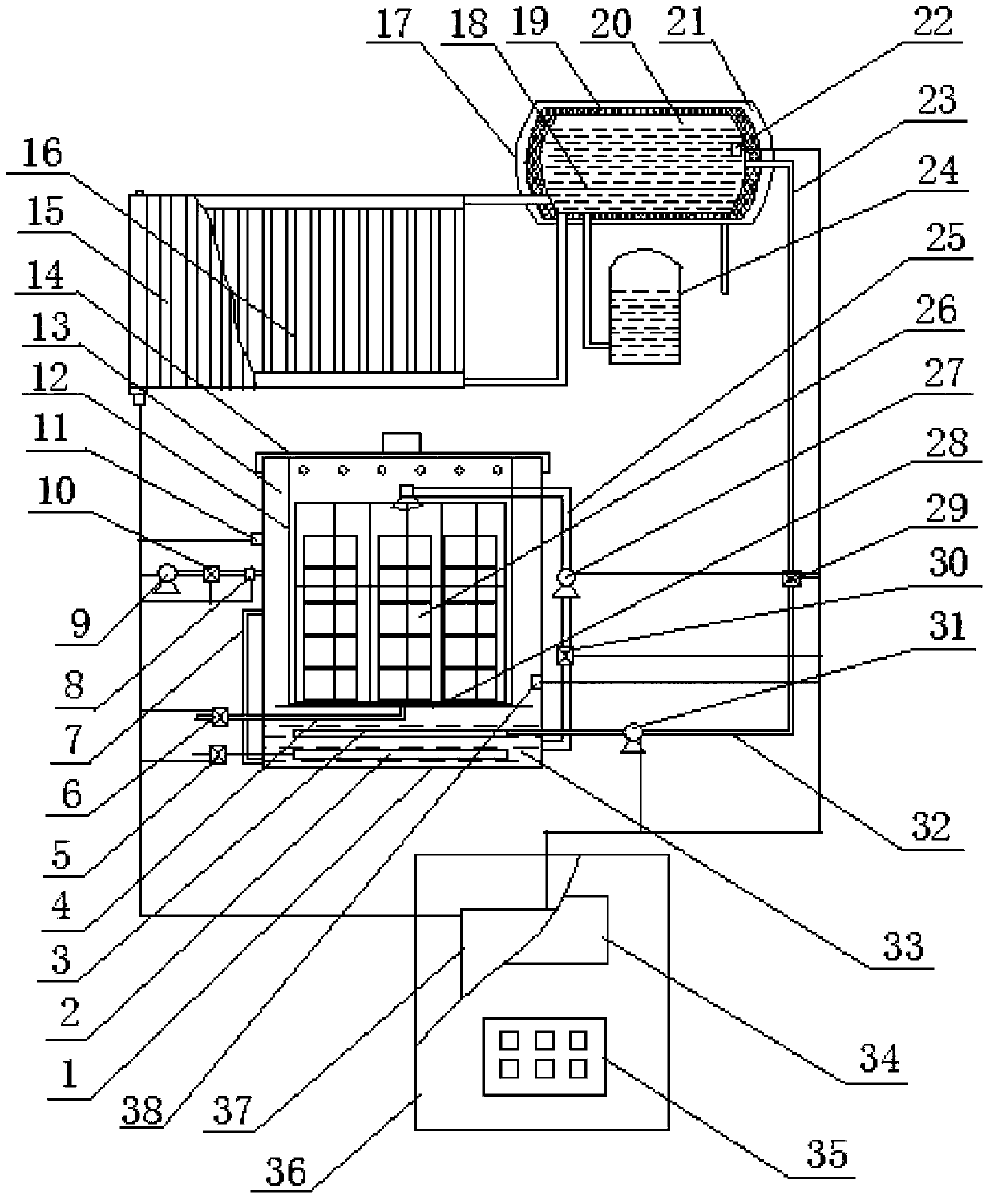

Solar sterilization device

InactiveCN103394103ARealize automatic controlReduce labor intensityFood processingFood preservationAutomatic controlEngineering

The invention discloses a solar sterilization device which comprises a solar heat collector and a steam sterilizer, wherein the solar heat collector is communicated with a heat exchange pipe arranged in the steam sterilizer through a liquid conveying pipeline. The solar sterilization device realizes the sterilization work based on regenerative energy, is suitable for steam sterilization work on medical instruments, packaged food, beverage and the like and can realize the automatic control in the whole sterilization process; the labor intensity is greatly reduced, and the production efficiency is improved; the solar sterilization device is extremely high in quality stability and use safety and reliability, and very easy to operate.

Owner:NANYANG NORMAL UNIV

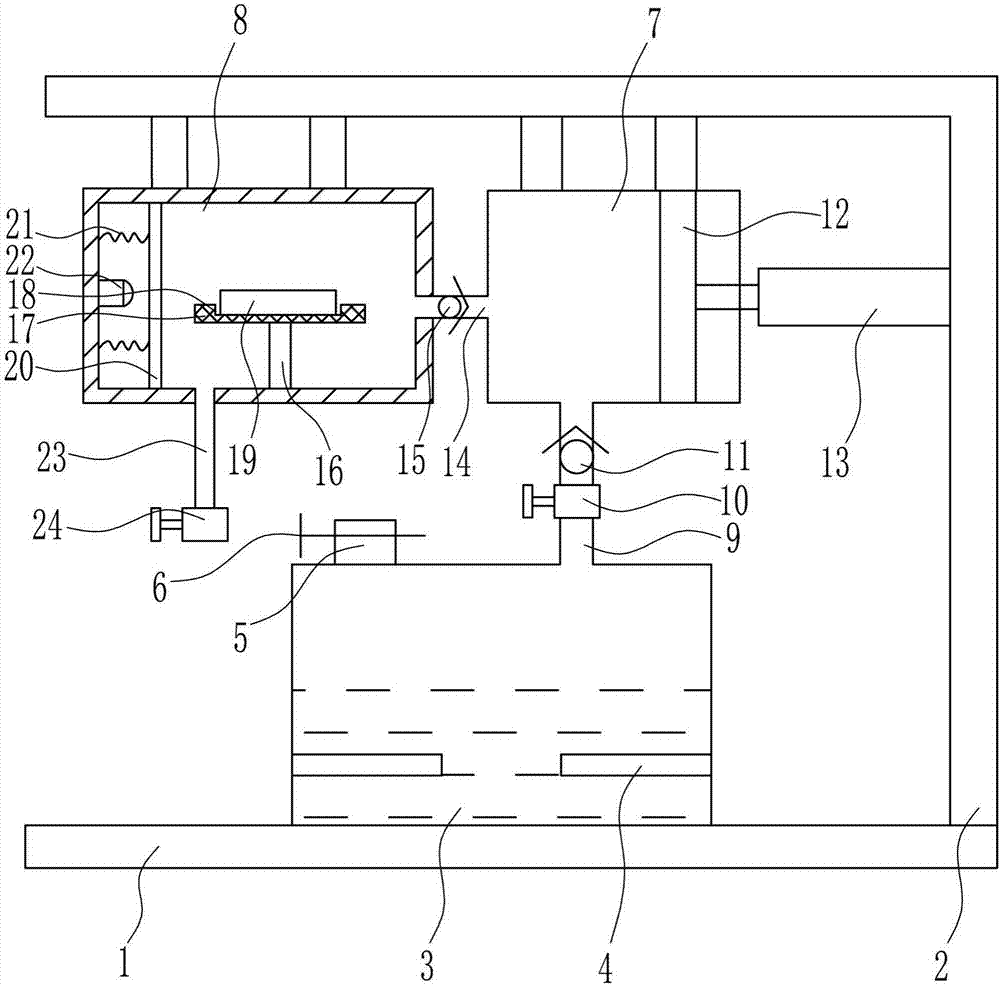

High-pressure steam sterilizer for culture dishes for gene engineering

InactiveCN107261162AImprove work efficiencyImprove the bactericidal effectHeatHigh pressureGene engineering

The invention belongs to the technical field of gene engineering, and particularly relates to a high-pressure steam sterilizer for culture dishes for gene engineering. The technical problem to be solved by the invention is to provide a high-pressure steam sterilizer for culture dishes for gene engineering which has the advantages of good sterilizing effect, simplicity in operation and high working efficiency. In order to solve the technical problem, the invention provides such a high-pressure steam sterilizer for culture dishes for gene engineering, which comprises a bottom plate, a 7-shaped support, a heating tank, heating rods, a valve, a compressing cylinder, a high-pressure steam tank, an intake pipe, a relief valve, a first check valve, a piston, a pneumatic cylinder and the like; the heating tank is welded at the middle of the top of the bottom plate, the 7-shaped support is welded to the rightmost side of the top of the bottom plate, and the heating rod are symmetrically arranged in the lower part of the heating tank. The high-pressure steam sterilizer for culture dishes for gene engineering provided by the invention utilizes hot steam to sterilize culture dishes under high pressure, and thereby the effects of good sterilizing effect, simplicity in operation and high working efficiency are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Food steam sterilizer

InactiveCN101904538AIncrease job securityAvoid harmFood preservationFood materialProcess engineering

The invention discloses a food steam sterilizer which comprises a sterilizing chamber, a steam pipeline and a vacuumizing pipeline, wherein the steam pipeline and the vacuumizing pipeline are respectively communicated with the sterilizing chamber; a vacuum pump is arranged on the vacuumizing pipeline; and the sterilizing chamber is provided with a condensate water drainage pipeline. The food steam sterilizer not only can sterilize food raw materials, but also can maintain the color, the nutrition and the taste of a product.

Owner:XINGHUA DINGNENG FOODS

Electrical heating biosafety steam sterilizer

InactiveCN101284140AEnsure safe dischargeImprove sterilization efficiencyLavatory sanitoryHeatEngineeringHigh pressure

The invention relates to an electrical heating biosafety steam sterilizer, which is a sterilizing device for medical use. The sterilizer comprises a sterilizer main body, a sterilizing chamber, a steam pipeline, an evacuation pipeline, and touch screen control devices. The steam pipeline and the evacuation pipe respectively communicate with the sterilizing chamber having a concave water collecting trough-shaped bottom. The high pressure steam pipeline communicates with an electrical heating steam generator and the sterilizing chamber bottom. The waste generated during sterilizing can be inactivated secondarily to maintain sterile discharge and protect environment. The electrical heating steam generator is directly employed for providing steam, with compact structure, low investment, no coal fired pollution, stable performance, convenient control, and ensured sterilizing quality. Furthermore, a sealing plate is employed for effective sealing and isolating to maintain sterile condition, with good safety and reliability. Two sets of touch screen control devices maximally satisfy the man machine interaction, and are convenient for observation and control.

Owner:SHINVA MEDICAL INSTR CO LTD

Steam sterilizer

The invention discloses a steam sterilizer. The steam sterilizer comprises a body, wherein a pot body is arranged in the body; a water tank groove is formed in the body, and a water tank is arranged in the water tank groove; a trough is formed in the side face of the water tank; a first sliding chute is formed in the side face of the water tank groove, a fixture block is arranged in the first sliding chute, a magnet is arranged on the fixture block, an electromagnet is arranged at the end part of the first sliding chute, and the electromagnet is connected with the main circuit of the sterilizer; a second sliding chute is formed in the side wall of the water tank groove, a slide rod is arranged in the second sliding chute, one end of the slide rod is provided with a slope matched with the water tank, and the other end of the slide rod is connected with a spring; the spring is fixed in the second sliding chute; wafers are arranged on two sides of the second sliding chute; a conductive block is arranged on the slide rod; and the wafers are connected with the main circuit of the sterilizer. According to the steam pressure sterilizer, the water tank cannot be detached from the sterilizer when the sterilizer is electrified, so that the steam pressure sterilizer is protected from damage, the life safety of users can be guaranteed, and the sterilizer is prevented from being opened by mistake after the water tank is detached.

Owner:六安聚首信息科技有限公司

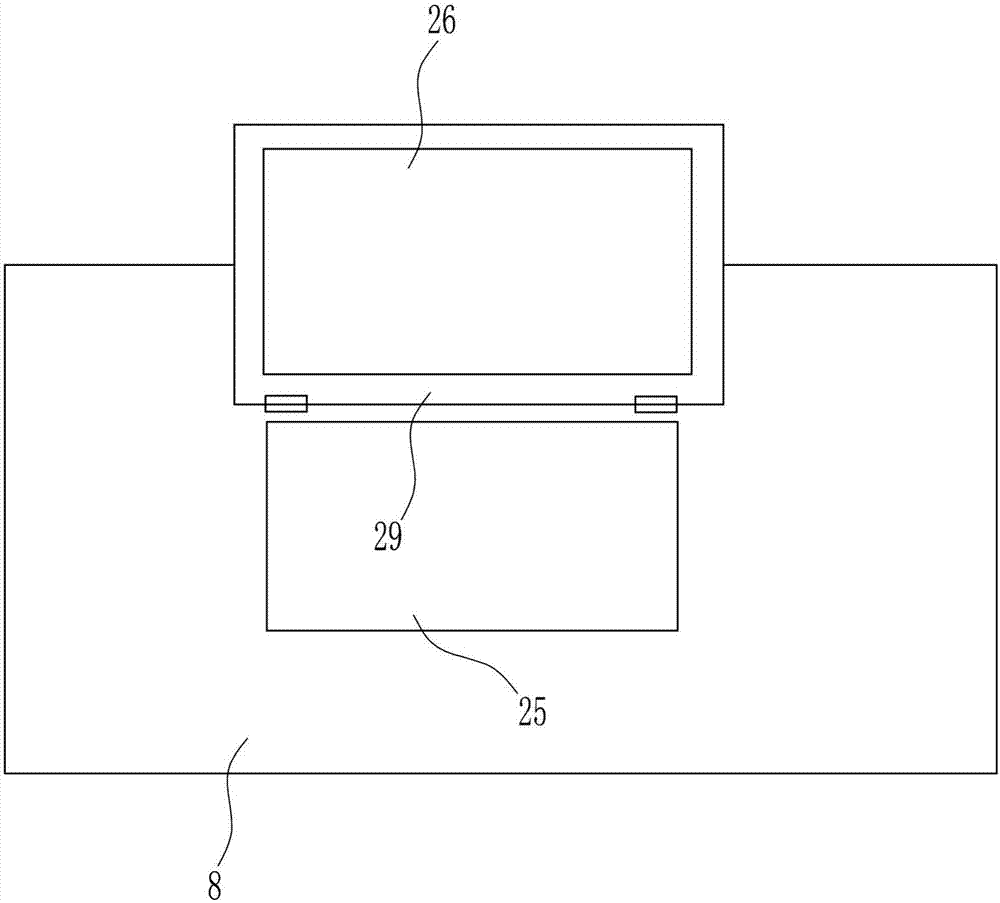

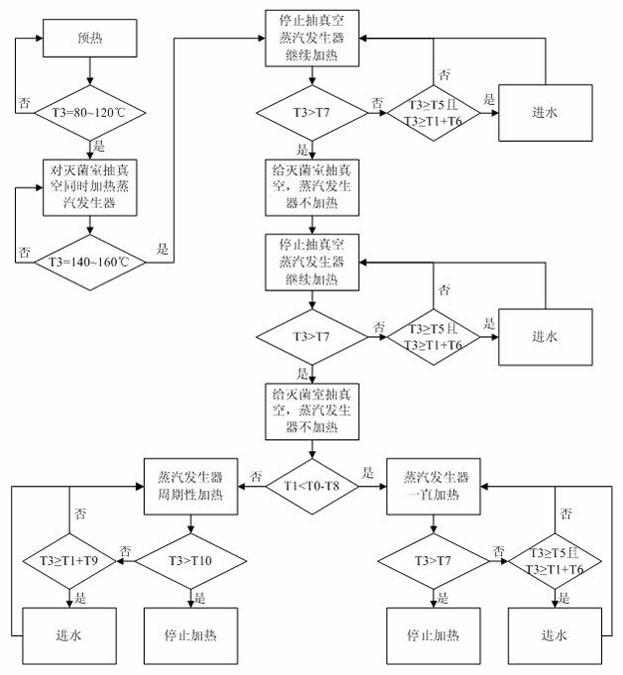

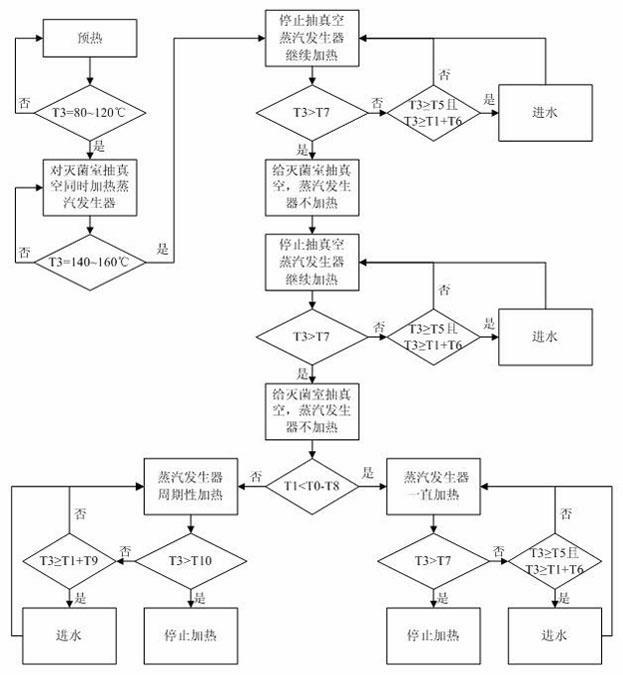

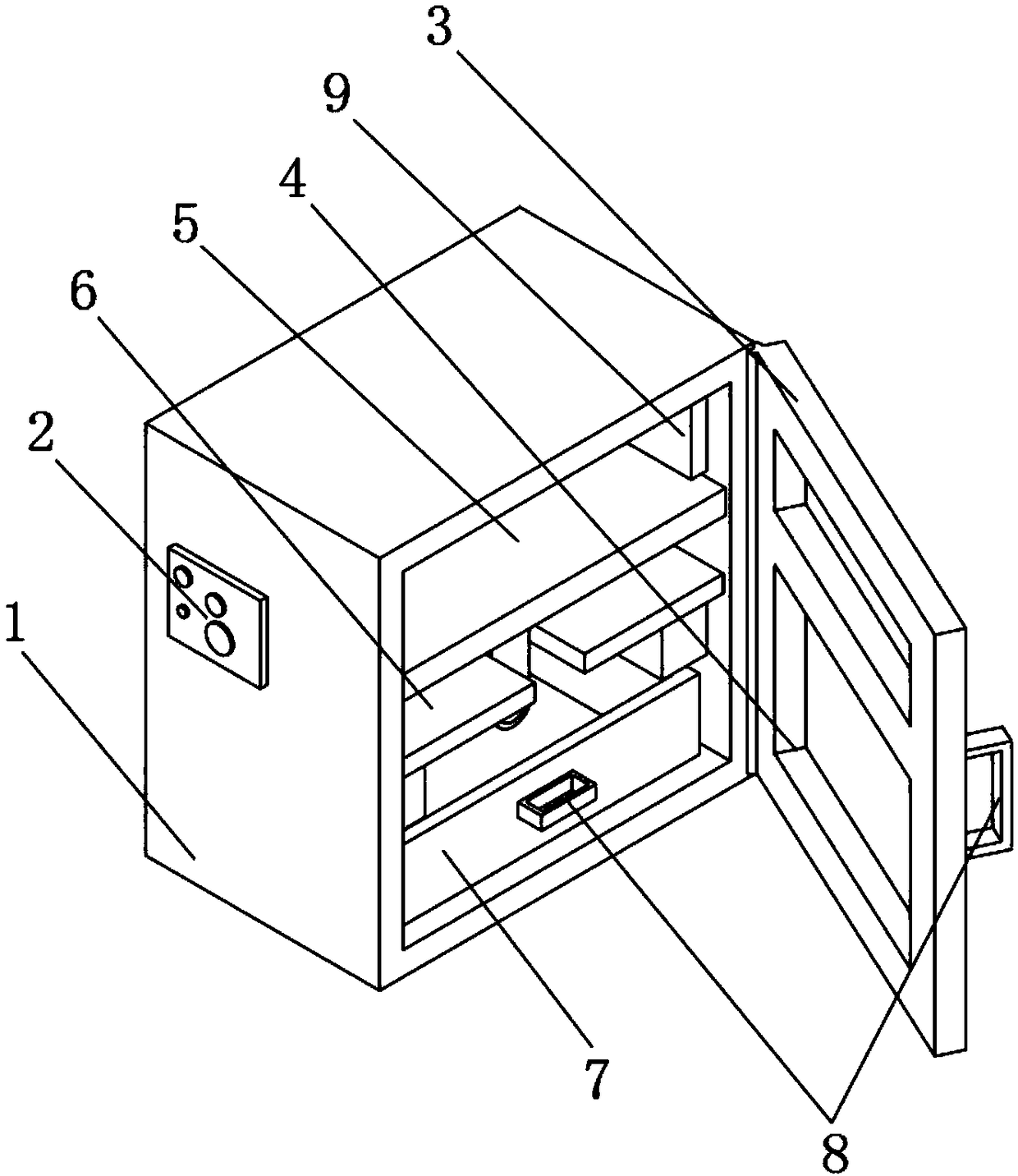

Heating control method for pressure steam sterilizer

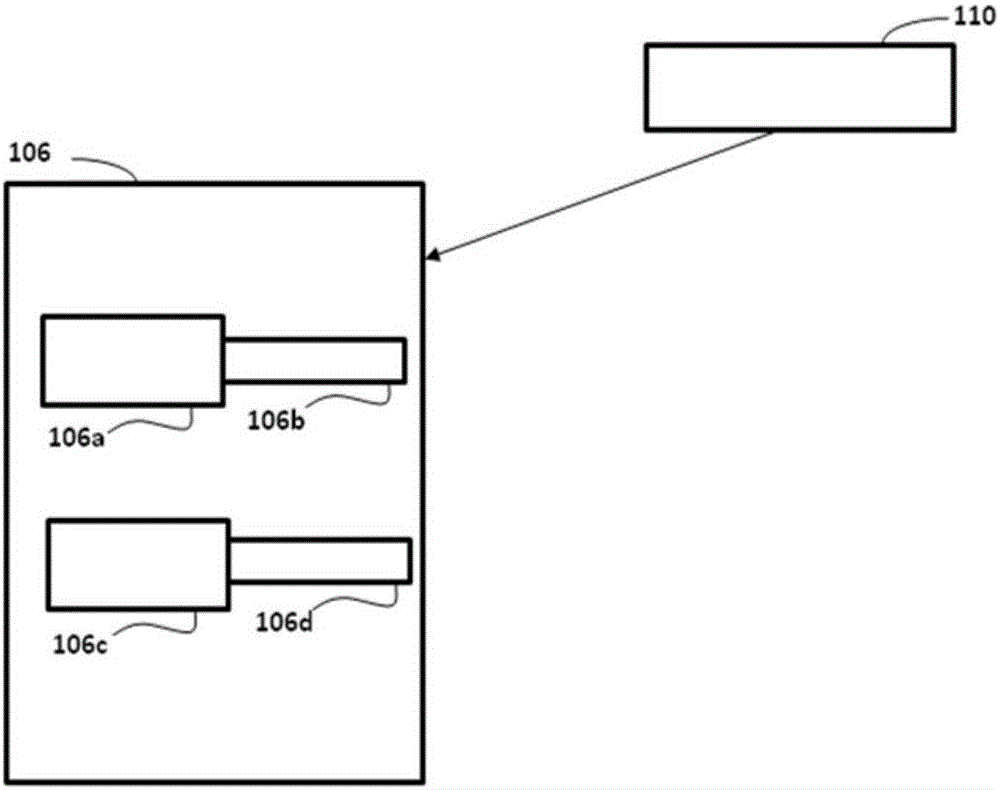

ActiveCN102306032AAvoid not producingSmall temperature fluctuationsAuxillary controllers with auxillary heating devicesWorking temperatureHeat control

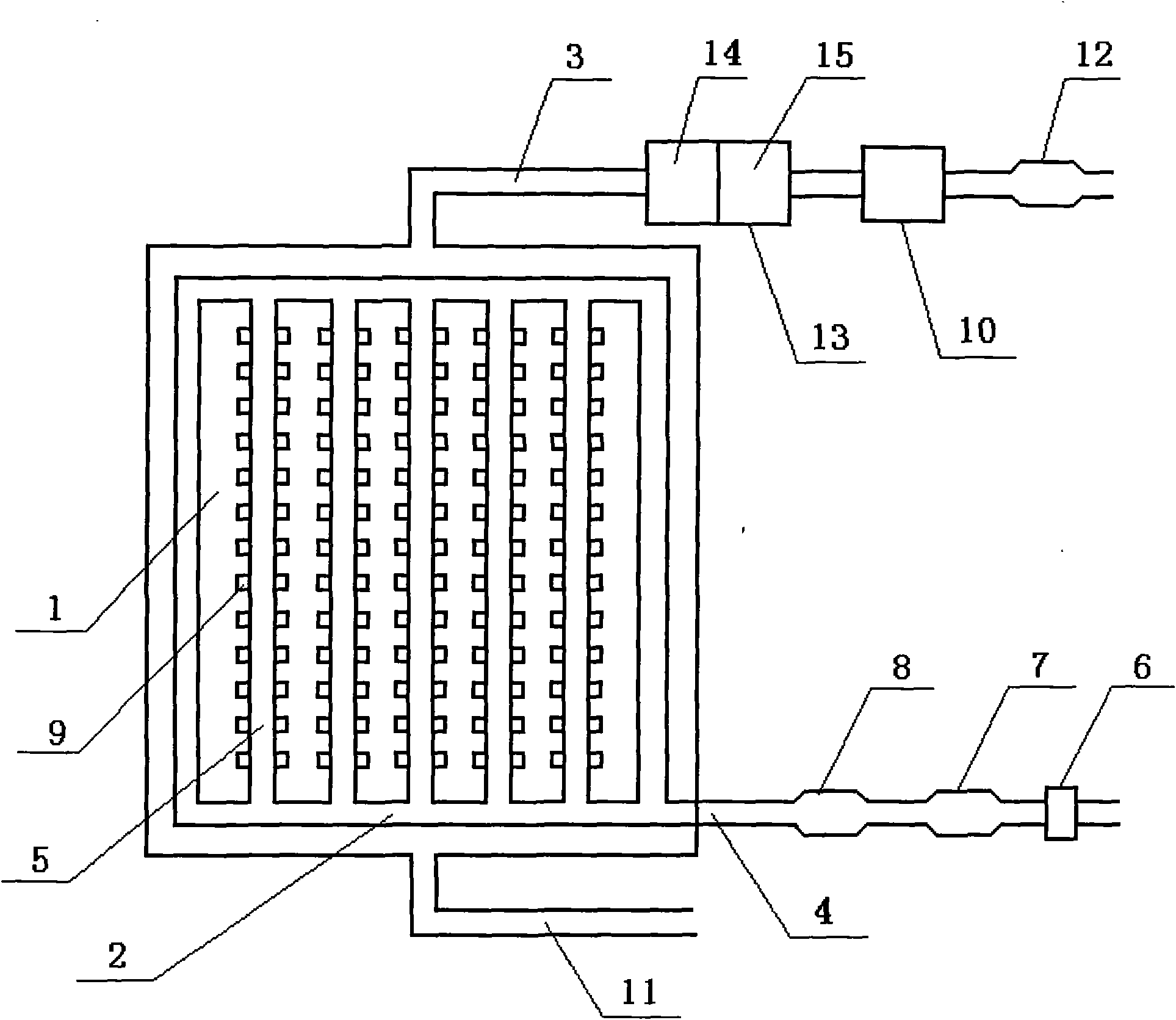

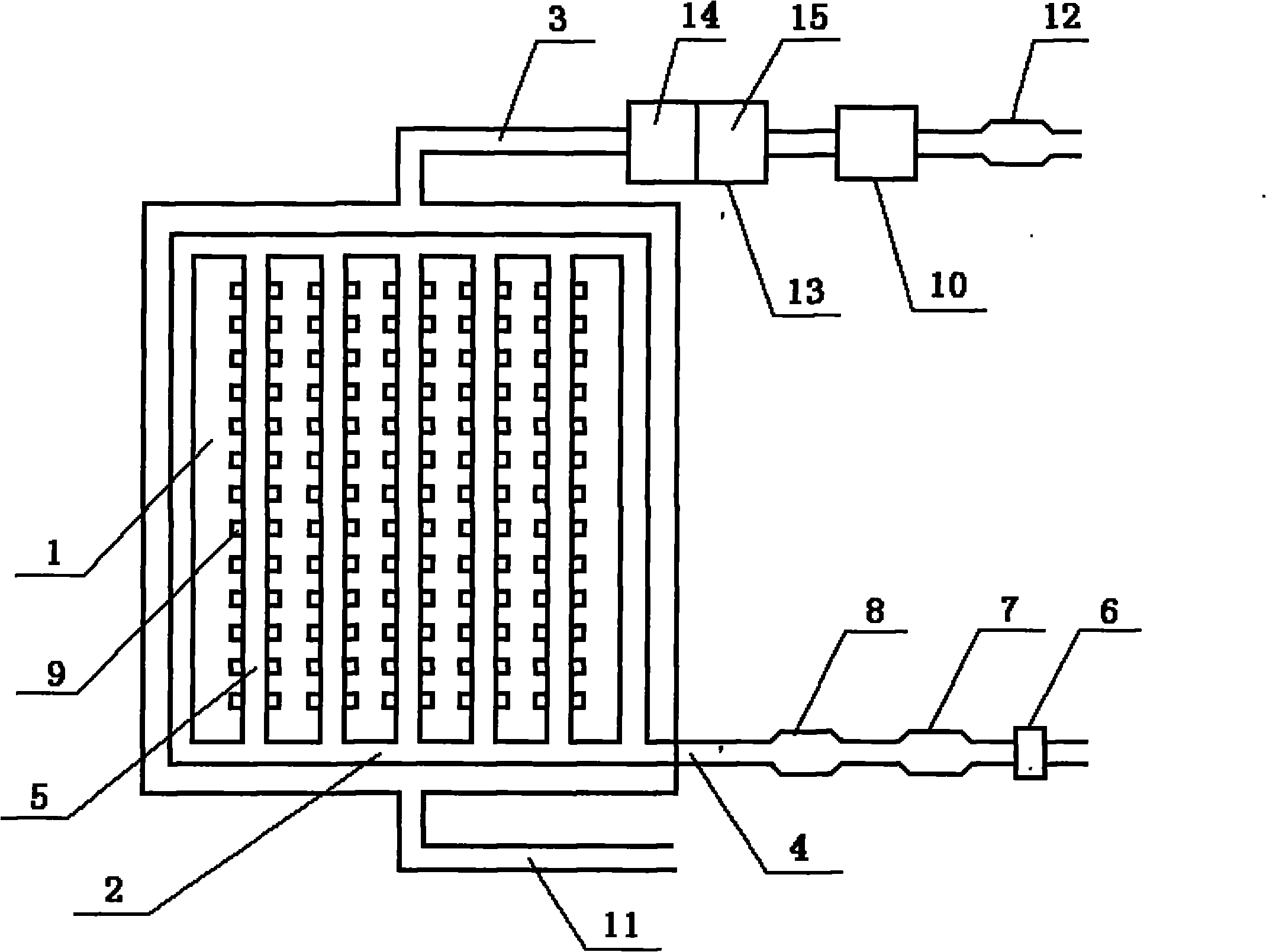

The invention discloses a heating control method for a pressure steam sterilizer. Working temperature T0 set by the sterilizer is 105-134 DEG C; temperature in a sterilizing chamber (1), which is detected by a temperature sensor (9), is T1; the temperature of the outer wall of the sterilizing chamber (1), which is detected by a temperature sensor (10) is T2; temperature in a steam generator (6), which is detected by a temperature sensor (8), is T3; temperature T4 is set as 0-10 DEG C, T5 is set as 100-120 DEG C, T6 is set as 6-20 DEG C, T7 is set as 155-180 DEG C, T8 is set as 5-10 DEG C, T9 is set as 5-10 DEG C, and T10 is set as 150-160 DEG C. The heating control method comprises the following steps: (1) controlling to heat a heating element (2) on the outer wall of the sterilizing chamber; and (2) controlling to heat the steam generator (6). Compared with the prior art, the heating control method disclosed by the invention has the advantages that: a steam generation device generates saturated steam for sure, and supersaturated steam can be prevented, the phenomenon that the steam is not generated for a long time can be avoided, a heating process smoothly enters a sterilizing process, and temperature fluctuation is little in the sterilizing process.

Owner:NINGBO YESON MEDICAL EQUIP

Medical apparatus disinfecting box

The invention discloses a medical apparatus disinfecting box which comprises a body. A control switch is arranged on the outer side surface of the body. An input end of the control switch is electrically connected with an output end of an external power supply. A box door is hinged to the side surface of the body. A partition plate is arranged on the inner side surface of the body. A high-pressuresteam sterilizing cavity is formed between the partition plate and an inner top plate of the body. A high-pressure steam sterilizer is arranged on the inner side surface of the high-pressure steam sterilizing cavity. A disinfecting liquid box is placed on the inner upper surface of the body. Shelves are arranged on the two side surfaces in the body respectively. Ultraviolet lamps are evenly arranged on the lower surface of the partition plate. The medical apparatus disinfecting box is simple in structure; different apparatuses are disinfected in a targeted mode through various disinfecting modes, the disinfecting effect is improved, and use is convenient; high-pressure steam sterilizing can be conducted through the high-pressure steam sterilizer, ordinary bacteria, fungi and other microorganisms can be killed through high-temperature and high-pressure sterilizing, and a killing effect on germs and spores is also achieved.

Owner:韩金星

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com