High-pressure steam sterilizer for culture dishes for gene engineering

A high-pressure steam and genetic engineering technology, applied in the field of genetic engineering, can solve problems such as low work efficiency, poor sterilization effect, and complicated operation, and achieve the effects of high work efficiency, good sterilization effect and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

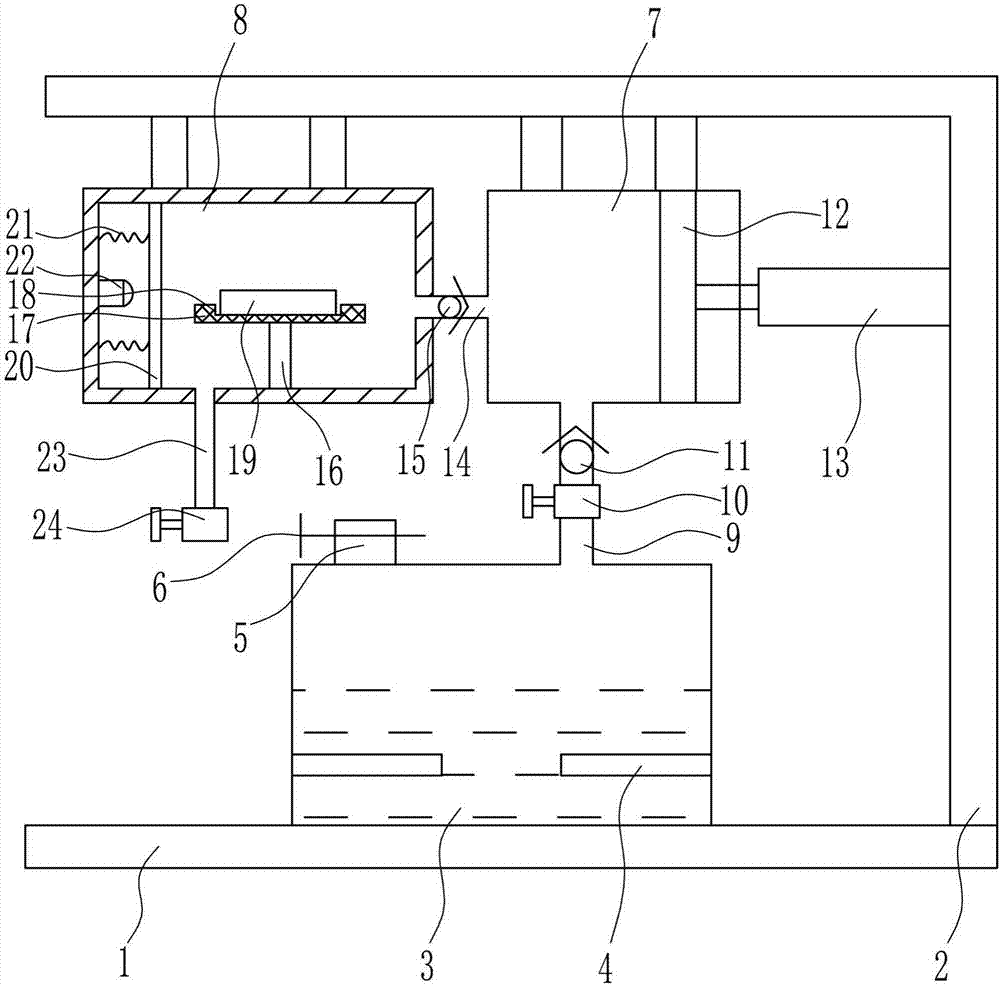

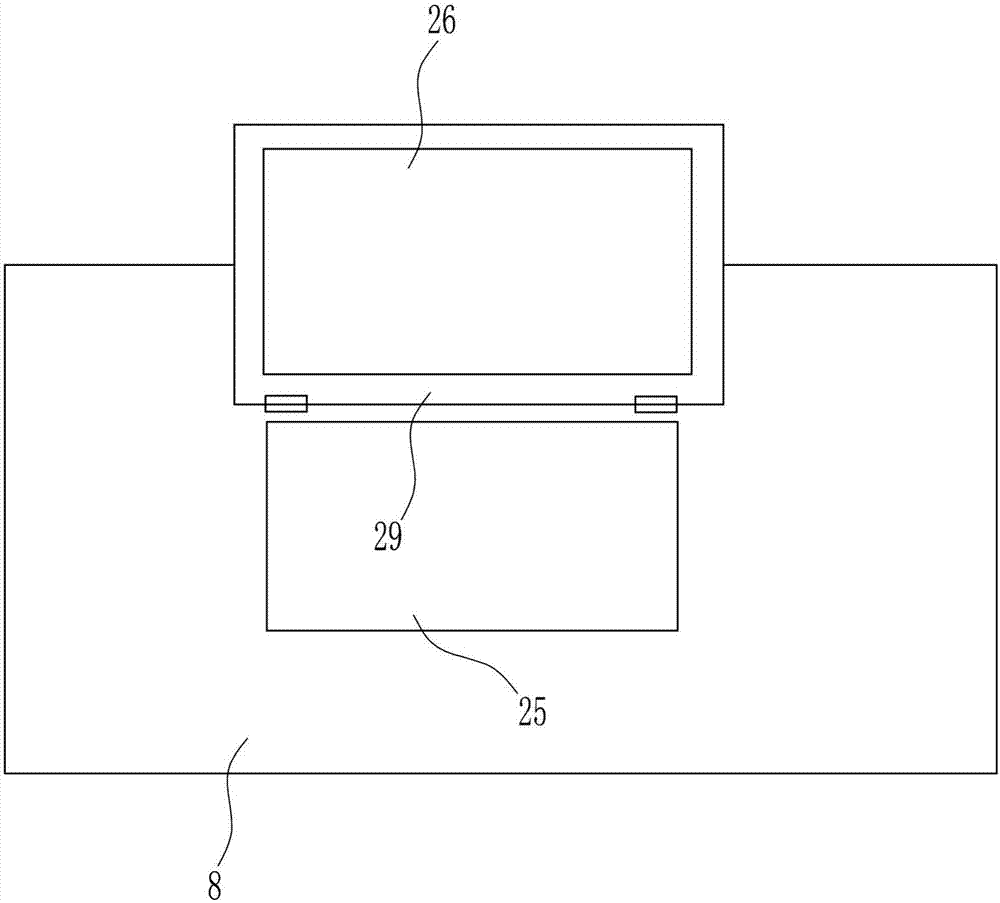

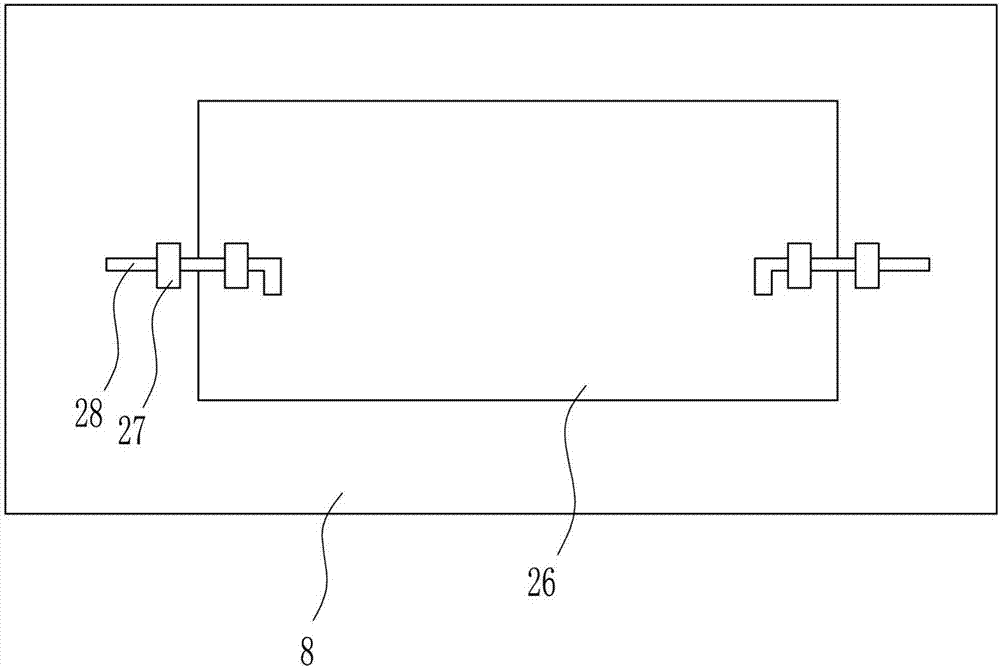

[0029] A high-pressure steam sterilization device for a petri dish for genetic engineering, such as Figure 1-5 As shown, it includes a bottom plate 1, a 7-type bracket 2, a heating box 3, a heating rod 4, a valve 6, a compression cylinder 7, a high-pressure steam box 8, an air intake pipe 9, a safety valve 10, a first one-way valve 11, and a piston 12 , cylinder 13, air outlet pipe 14, second one-way valve 15, pole 16, place plate 17, pressing plate 20, spring 21, button 22, exhaust pipe 23, exhaust valve 24, hinge 30, box cover 26, Rubber ring 29, ferrule 27 and plug 28, heating box 3 is welded in the middle of the top of bottom plate 1, type 7 bracket 2 is welded on the far right of the top of bottom plate 1, heating rod 4 is symmetrically arranged in the lower part of heating box 3, heating box 3 There is a water inlet 5 on the left side of the top, and a valve 6 is arranged on the water inlet 5. A compression cylinder 7 and a high-pressure steam box 8 are welded on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com