Electrical heating biosafety steam sterilizer

A biosafety and steam sterilization technology, which is applied in the direction of heating, sanitary equipment for toilets, water supply equipment, etc., can solve the problem of not being able to effectively separate the sterile area from the sterile area, the boiler steam pressure is unstable, and the aseptic condition cannot be solved. To achieve the effect of compact structure, convenient control and improved sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

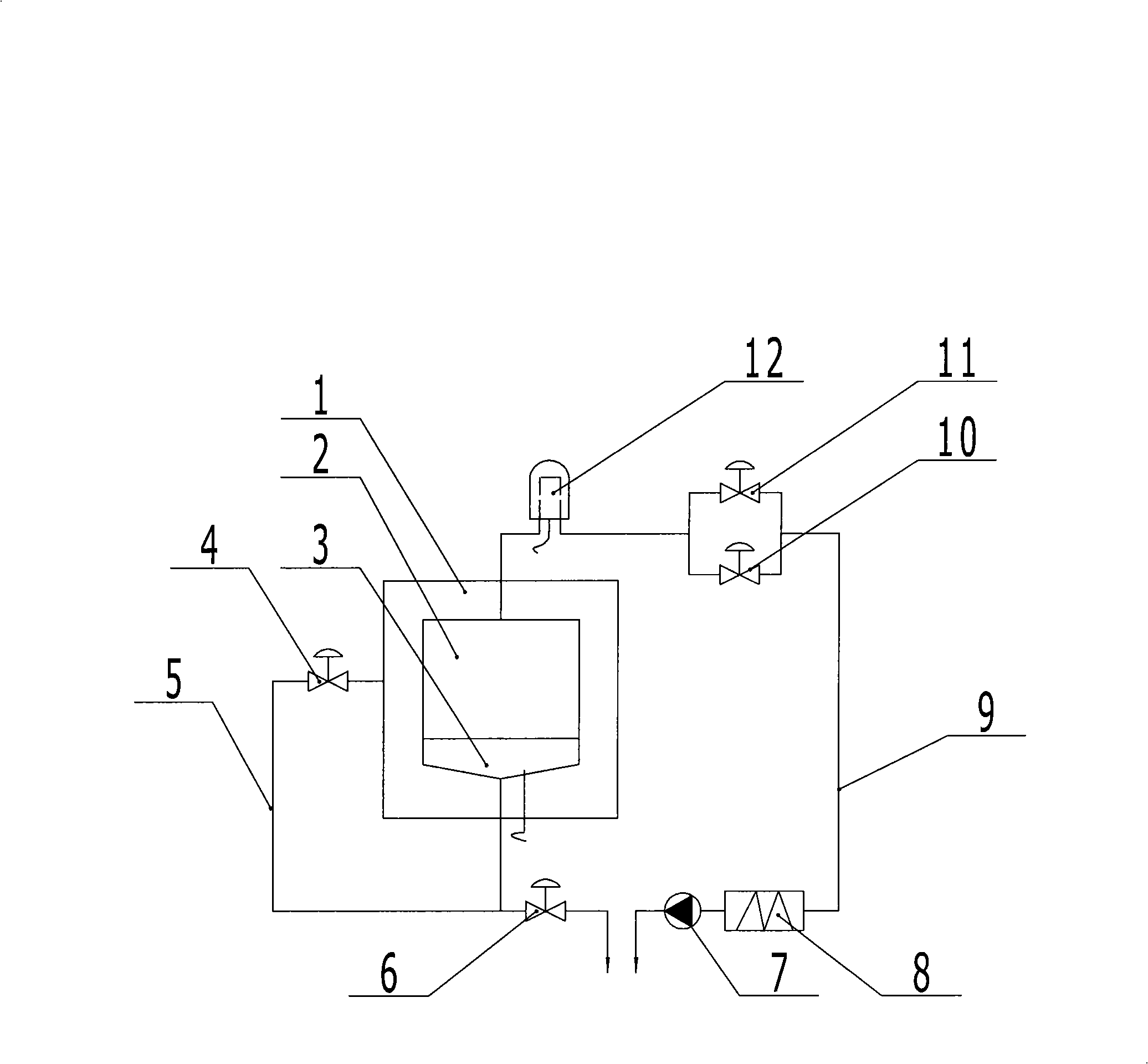

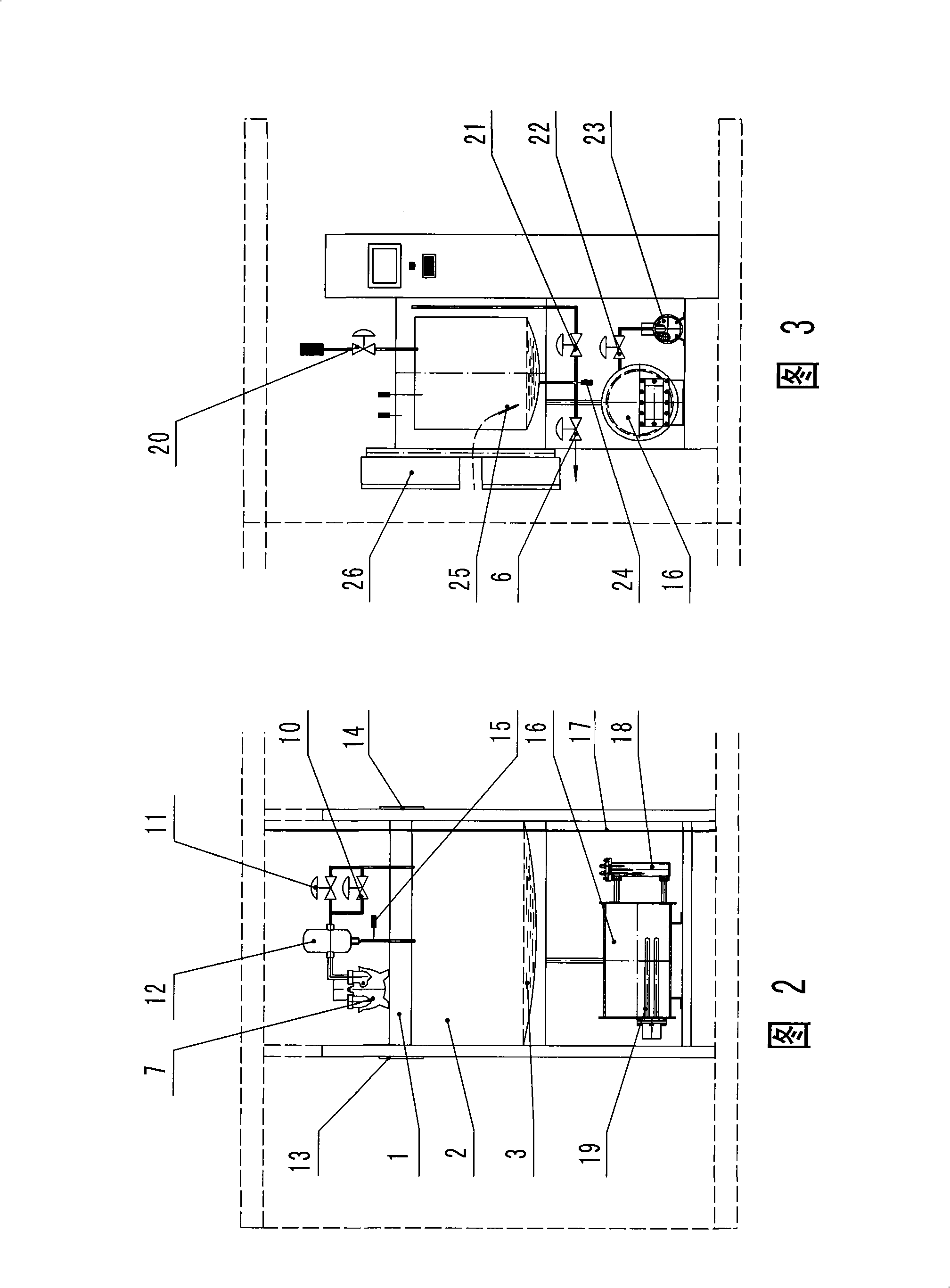

[0024] like figure 1 , shown in Fig. 2 and Fig. 3, electric heating biosafety steam sterilizer of the present invention comprises sterilizer main body, sterilization chamber 2, steam pipeline 5 and vacuumizing pipeline 9, sterilization chamber 2 cavities The wall is a sandwich structure, the interlayer 1 is connected to the steam pipeline 5, the steam pipeline 5 and the vacuum pipeline 9 are respectively connected to the sterilization chamber 2, and the bottom of the sterilization chamber 2 is in the shape of a sunken sump, which can be curved. The electric heating steam generator is communicated with the bottom of the sterilization chamber 2. The electric heating steam generator is an airtight container 16, and an electric heating tube 19 is installed in the airtight container 16. The airtight container 16 is also connected with a water pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com