Energy-saving type pulsation vacuum pressure steam sterilizer

A technology of pulsating vacuum and pressure steam, applied in the field of medical equipment, can solve the problems of failing to meet national discharge standards, wasting water resources, wasting energy, etc., and achieve the effects of ensuring purity and sterilization, saving water sources, and preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

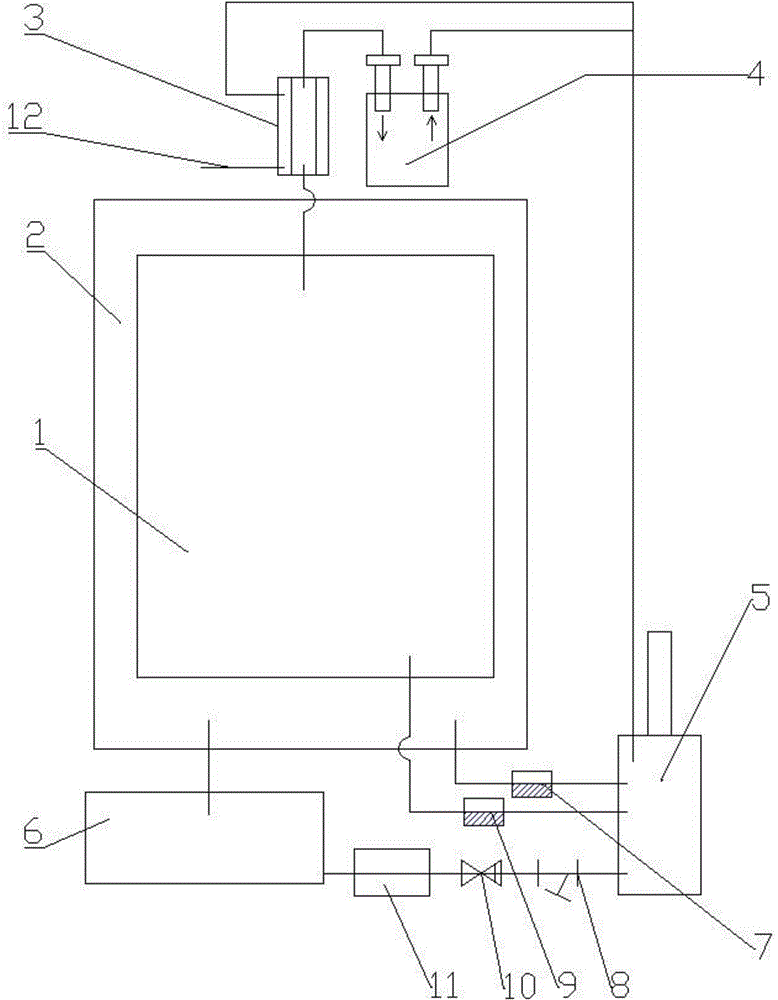

[0025] As shown in the accompanying drawings, the energy-saving pulsating vacuum sterilizer has three inner layers and an outer layer of the heat exchanger. The suction end of the vacuum pump 4 is connected to the outlet end of the inner layer of the heat exchanger 3. The air end is connected to the inner chamber 1, the air outlet of the vacuum pump 4 is connected to the multifunctional water tank 5; ; The inner chamber 1 is connected with the multifunctional water tank 5 through the inner chamber trap 9, and the jacket 2 is connected with the multifunctional water tank 5 through the jacket steam trap 7; The outlet of the steam generator 6 is connected with the jacket 2, and the steam generator 6 The water inlet is connected with the multifunctional water tank 5 through the filter 8, the one-way valve 10 and the high-pressure water pump 11; PLC control system (not shown in the figure).

[0026] The steam in the inner chamber 1 is sucked by the vacuum pump 4 and passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com