Steam sterilizer and sterilization process

A technology of sterilizer and steam, which is applied in the field of negative pressure low-temperature steam sterilizer and disinfection process, steam sterilizer and disinfection process, can solve the problems that negative pressure low-temperature disinfection cannot be realized, achieve good disinfection effect, ensure uniformity, temperature Controlling the effect of stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

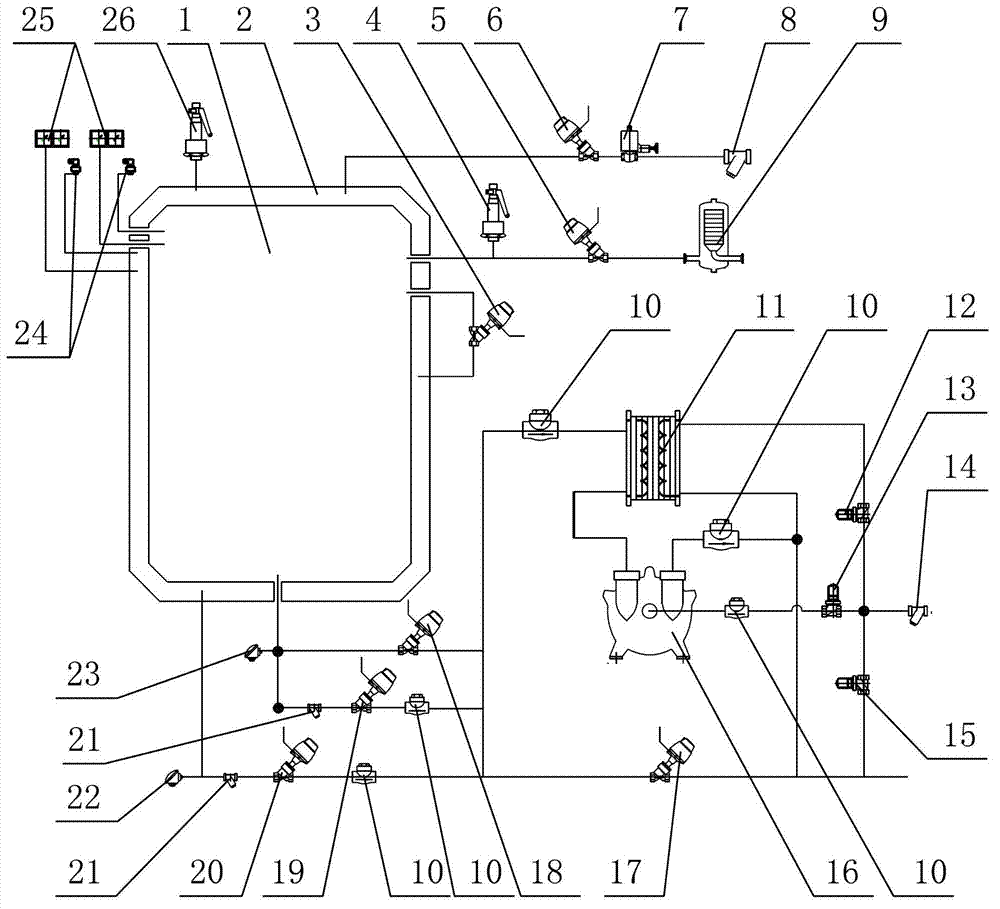

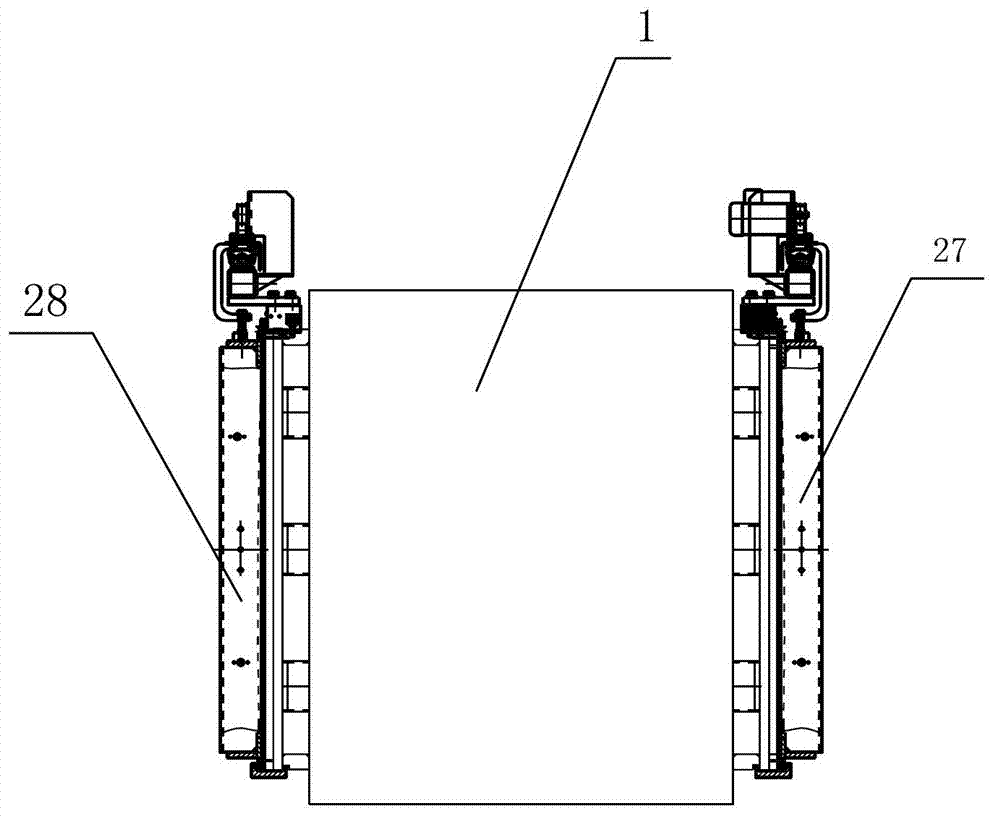

[0034] Such as figure 1 , figure 2 As shown, the sterilization chamber of the present invention includes a front door 27, a rear door 28, and an interlayer 2. The space surrounded by the three forms an inner chamber 1. A steam channel is provided in the interlayer 2. The interlayer 2 is respectively connected to the interlayer steam inlet system and the interlayer extraction system through pipelines. Vacuum drainage system, the inner chamber 1 is respectively connected to the inner chamber return system and the inner chamber vacuum drainage system through pipelines, the interlayer 2 is provided with an interlayer safety valve 26, and the interlayer 2 and inner chamber 1 are respectively installed with a pressure sensor 24 and a vacuum pressure gauge 25, to detect the pressure in the interlayer 2 and the inner chamber 1.

[0035] The inner chamber air intake system includes a first pneumatic control valve 3, which is respectively connected to the interlayer 2 and the inner ch...

Embodiment 275

[0051] Embodiment 275 ℃ disinfection procedure:

[0052] In the steam inlet stage of the working process b, the interlayer pressure reaches the predetermined pressure -55KPa;

[0053] In the pulsating emptying stage of the working process d, the inner chamber 1 is filled with saturated steam from the interlayer 2 to a relative pressure of -65KPa in the inner chamber 1, and the number of cycles is 3 times;

[0054] Working process f disinfection stage, steam relative pressure is-65KPa~-60KPa, temperature is 75 ℃~77 ℃, maintains 90min, all the other are the same as embodiment 1.

Embodiment 385

[0055] Example 385°C disinfection program:

[0056] In the steam inlet stage of the working process b, the interlayer pressure reaches the predetermined pressure -33KPa;

[0057] In the pulsating emptying stage of the working process d, the inner chamber 1 is filled with saturated steam from the interlayer 2 to the relative pressure of the inner chamber 1 -43KPa, and the number of cycles is 5 times;

[0058] Working process f disinfection stage, steam relative pressure is -43KPa~-38KPa, temperature is 85 ℃~87 ℃, maintains 30min, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com