Mobile type realtime high-temperature steam sterilizer

A high-temperature steam, mobile technology, applied in heating and other directions, can solve problems such as affecting consumers' recognition of restaurant services, inability to achieve real-time on-site disinfection, high water consumption and power consumption, etc., to achieve strong practical value and Market promotion value, remarkable effect of disinfection and sterilization, and the effect of strong mobility and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

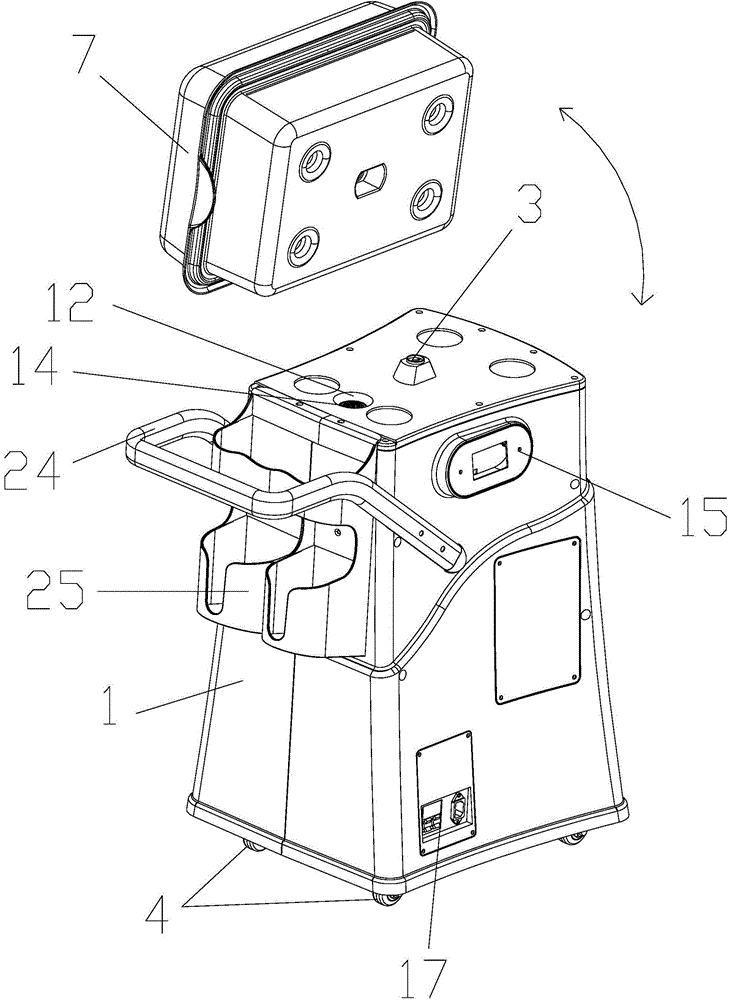

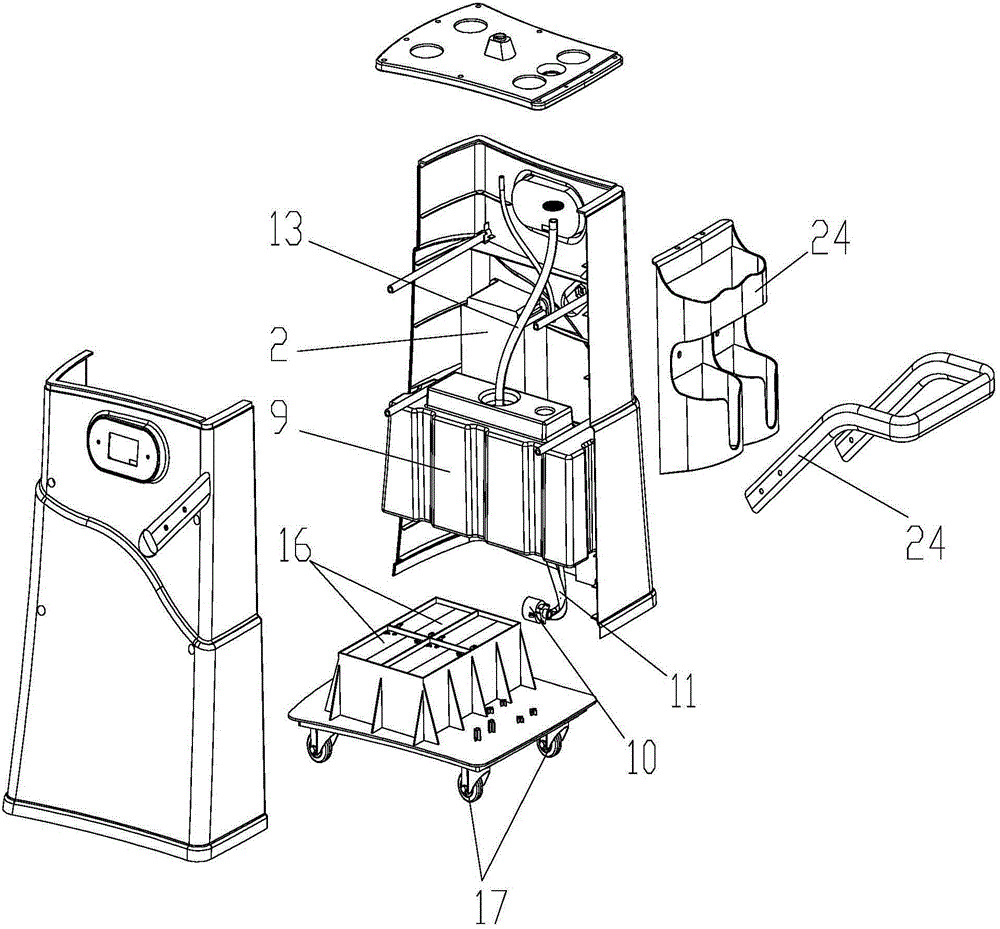

[0034] Such as Figure 1 to Figure 6 As shown, the mobile real-time high-temperature steam sterilizer of the present embodiment includes:

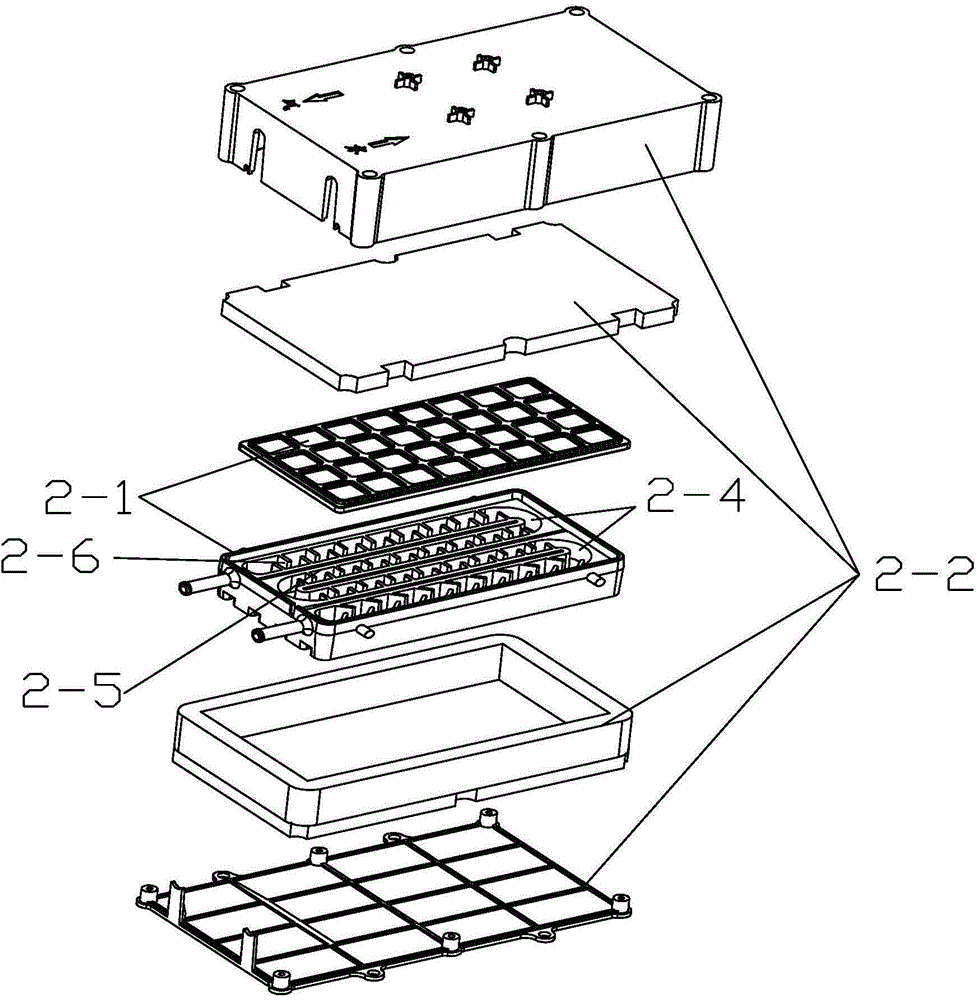

[0035] A main chassis 1, in which a water storage tank assembly for storing normal temperature water, a steam generator 2 for converting the normal temperature water delivered by the water storage tank assembly into high-temperature steam and an electrical control function are installed in the main chassis 1 The power supply control assembly is equipped with a steam nozzle 3 protruding from the top surface of the main chassis 1 on the top surface of the main chassis 1. The steam nozzle 3 is connected to the steam outlet of the steam generator 2 through a pipe, and the steam generator 2 The water inlet is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com