Food steam sterilizer

A steam sterilization, food technology, applied in food preservation, food science, application, etc., can solve the problems of human hazards, indeterminate hazards, lower quality, etc., achieve high safety performance, overcome the hazards of residual chlorine to the human body, maintain color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

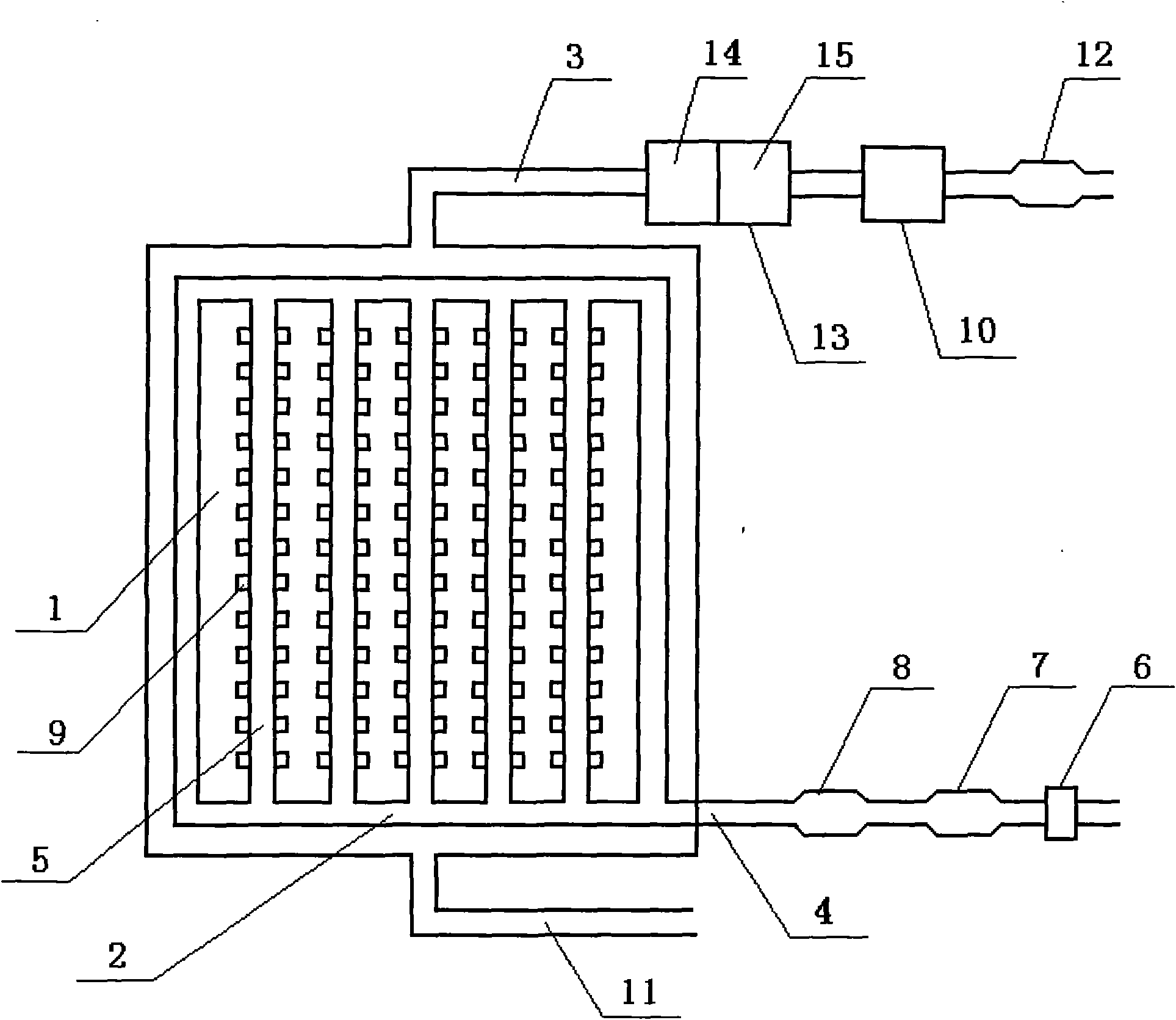

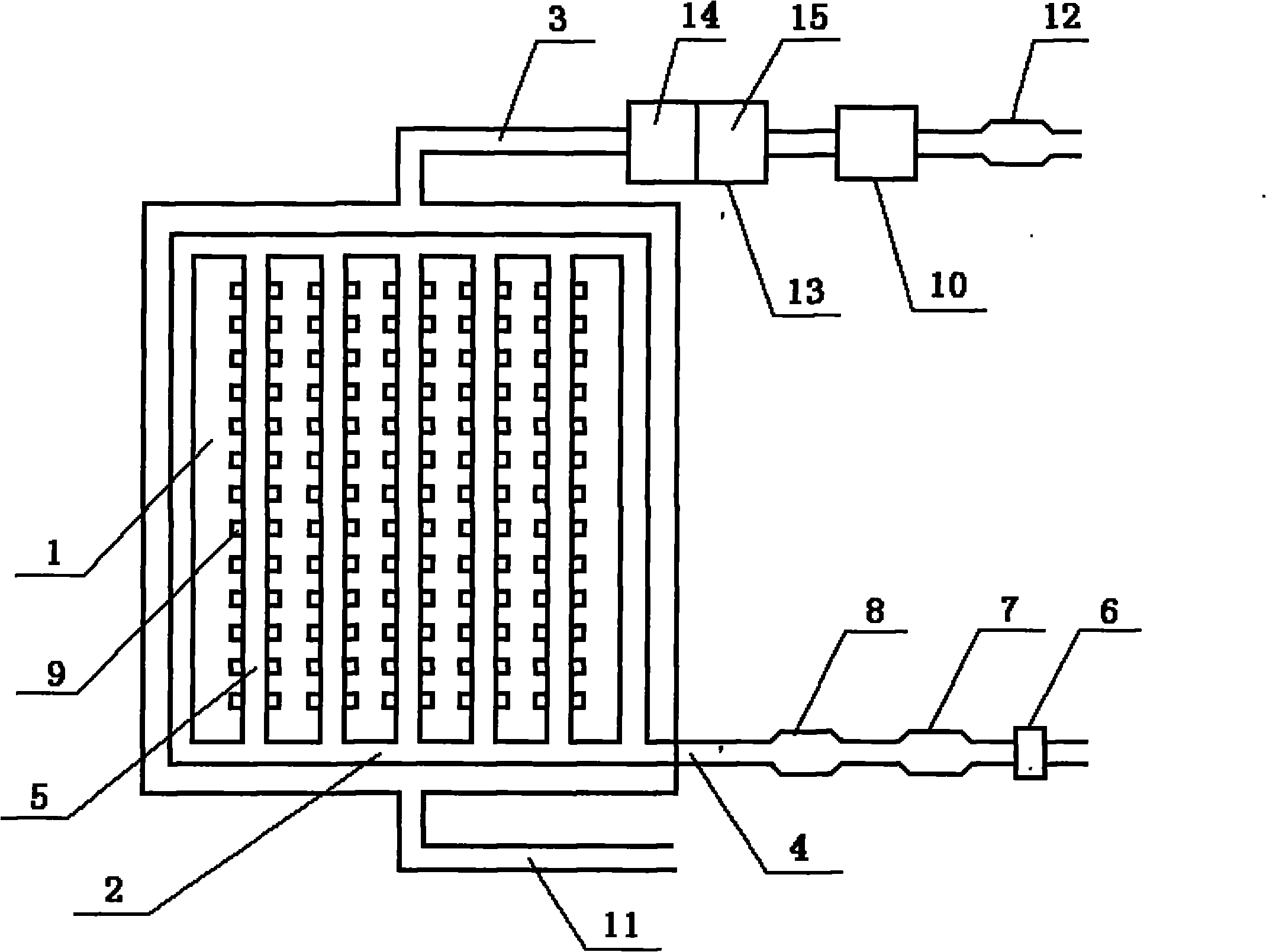

[0013] Embodiment: a food steam sterilizer, including a sterilization chamber 1, a steam pipeline 2 and a vacuum pipeline 3, the steam pipeline 2 and the vacuum pipeline 3 are respectively connected to the sterilization chamber 1; the steam pipeline 2 It includes a steam inlet pipeline 4 and a steam injection pipeline 5 arranged in the sterilization chamber 1. The steam inlet pipeline 4 is provided with a steam inlet valve 6, a pressure reducing valve 7 and an electric control valve 8. The described The steam injection pipeline 5 is distributed on the inner wall of the sterilization chamber 1, and the steam injection pipeline 5 is provided with a nozzle 9; the vacuum pumping pipeline 3 is connected with a waste gas and waste liquid disinfection treatment device 13, so that The waste gas and waste liquid disinfection treatment device 13 includes a waste liquid disinfection container 14 and a filter 15 for removing bacteria. The exhaust gas and waste liquid output pipeline of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com