Multi-stage treatment method and equipment for biomedical wastes

A biomedical and treatment method technology, applied in the field of biological/medical waste treatment, can solve the problems of high cost of disinfectant, no mention of medical waste disinfection, affecting the stability of disinfectant, etc., to achieve good disinfection effect and good sterilization Disinfection effect, good effect of disinfection and sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0075] Specific examples are shown in the associated drawings. The size and function of the components shown in the figure are only for the accuracy and convenience of description, and are not actual scale.

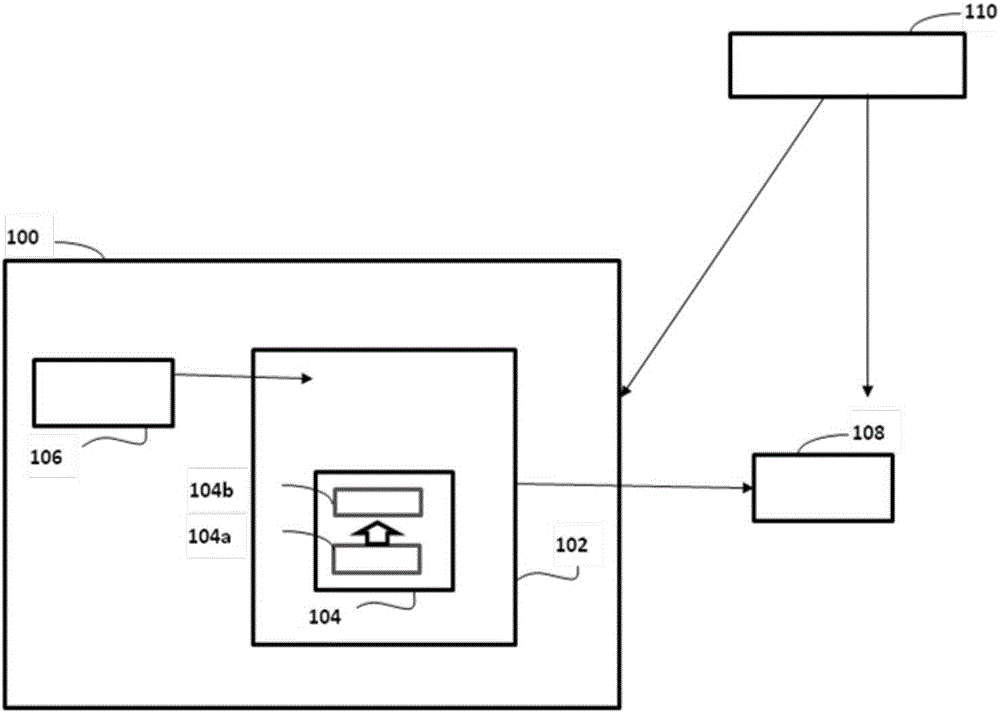

[0076] Figure 1A It is a schematic structural diagram of the device of the present invention, including a reaction chamber 100 , a controller 110 and an enhanced sterilizer 108 . The reaction chamber 100 is used to treat waste to make it suitable for subsequent enhanced disinfection (steam sterilization heat treatment using an autoclave or high concentration peroxide disinfection solution disinfection with a hybrid reactor). The reaction chamber 100 is equipped with a drug dispenser 106, a shredder 104 and a reaction pool 102 for receiving biomedical waste or biol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com