Stable peroxyacetic acid disinfectant

A peracetic acid disinfectant, peracetic acid technology, applied in directions such as disinfectants, biocides, animal repellents, etc., can solve the problems that safety and stability cannot meet production and use requirements, complex production processes, and high manufacturing costs , to achieve the effect of good disinfection and sterilization, simple production process and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0029] 1. Weigh 25g of sodium tungstate, 25g of ethylenediaminetetramethylphosphoric acid, and 50g of 1,3,5-mellitic acid, mix and fully stir to obtain 100g of compound stabilizer.

[0030] 2. Weigh 100g of the compound stabilizer prepared above, 100g of isomeric decanol polyoxyethylene ether surfactant, 3400g of hydrogen peroxide, 3000g of acetic acid and 3400g of water respectively.

[0031] 3. First pump water into the enamel jacketed reaction kettle, then add compound stabilizer and surfactant and stir to dissolve, then pump in hydrogen peroxide and acetic acid in sequence, and stir for 30 minutes to obtain stable peracetic acid disinfection agent.

preparation Embodiment 2

[0033] 1. Weigh 25g of potassium tungstate, 25g of hydroxycresylidene diphosphate, and 50g of 1,2,3-diphenylenetricarboxylic acid, mix and fully stir to obtain 100g of compound stabilizer.

[0034] 2. Weigh 100g of the compound stabilizer prepared above, 100g of isomeric undecyl alcohol polyoxyethylene ether surfactant, 3400g of hydrogen peroxide, 3000g of acetic acid and 3400g of water.

[0035] 3. First pump water into the enamel jacketed reaction kettle, then add compound stabilizer and surfactant and stir to dissolve, then pump in hydrogen peroxide and acetic acid in sequence, and stir for 30 minutes to obtain stable peracetic acid disinfection agent.

proportion Embodiment 1

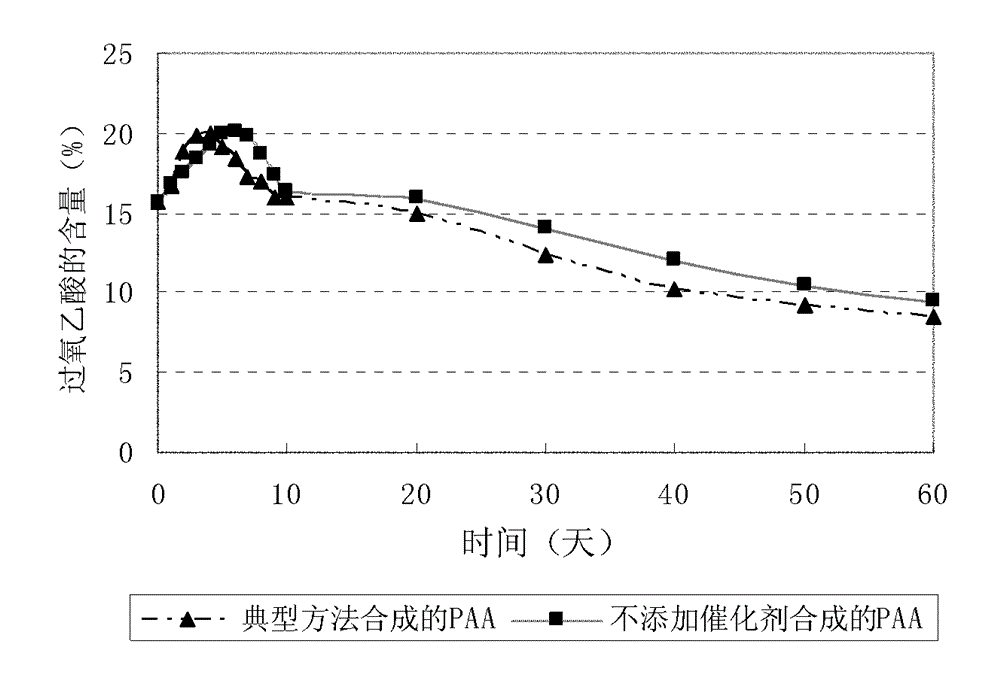

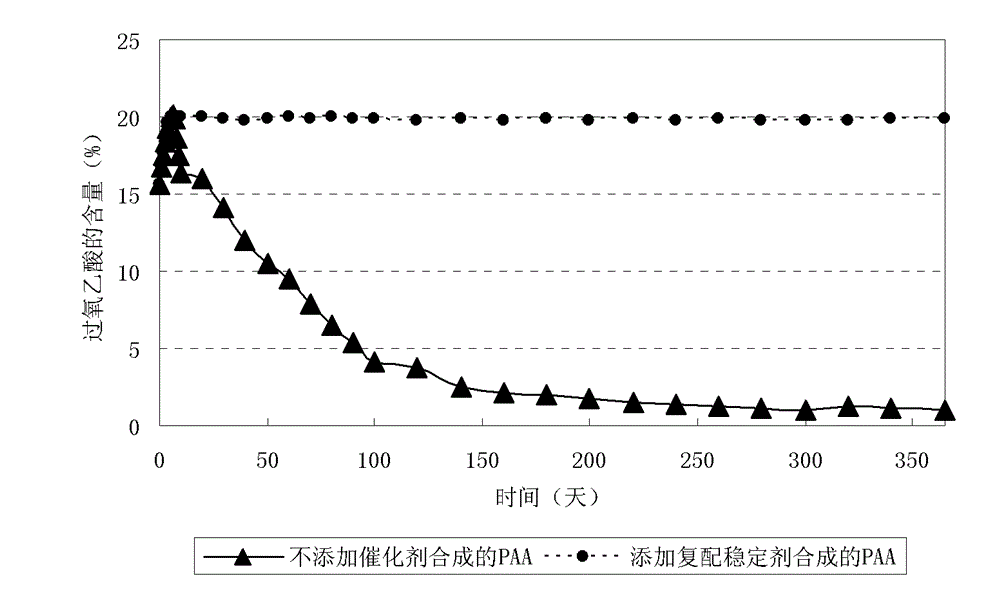

[0036]Proportional embodiment one: the comparison of the stability of the synthetic peracetic acid of typical method and the synthetic peracetic acid of not adding catalyzer (sulfuric acid):

[0037] 1. Typical method synthesis: hydrogen peroxide reacts with acetic acid in the presence of sulfuric acid catalyst

[0038] 2. No catalyst synthesis: direct reaction of hydrogen peroxide and acetic acid

[0039] After the two are stored at room temperature and protected from light, after 12 natural months, the appearance is clear and transparent, without color change, precipitation and suspended matter. The comparison of the change of its peracetic acid content is as follows: figure 1 Shown:

[0040] From figure 1 It can be seen that the peracetic acid synthesized by the typical method is due to the catalysis of sulfuric acid, and the synthetic speed of peracetic acid is relatively fast, and its highest concentration can be measured after 48 hours; Slow, its highest concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com