Soybean milk machine with inner smashing cup

An inner crushing cup and soymilk machine technology, which is applied to milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of rough bean dregs, inability to make thick pulp, inability to adjust, etc., so as to achieve a fast and simple pulping process and improve homogeneity. Emulsifying effect, the effect of realizing automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

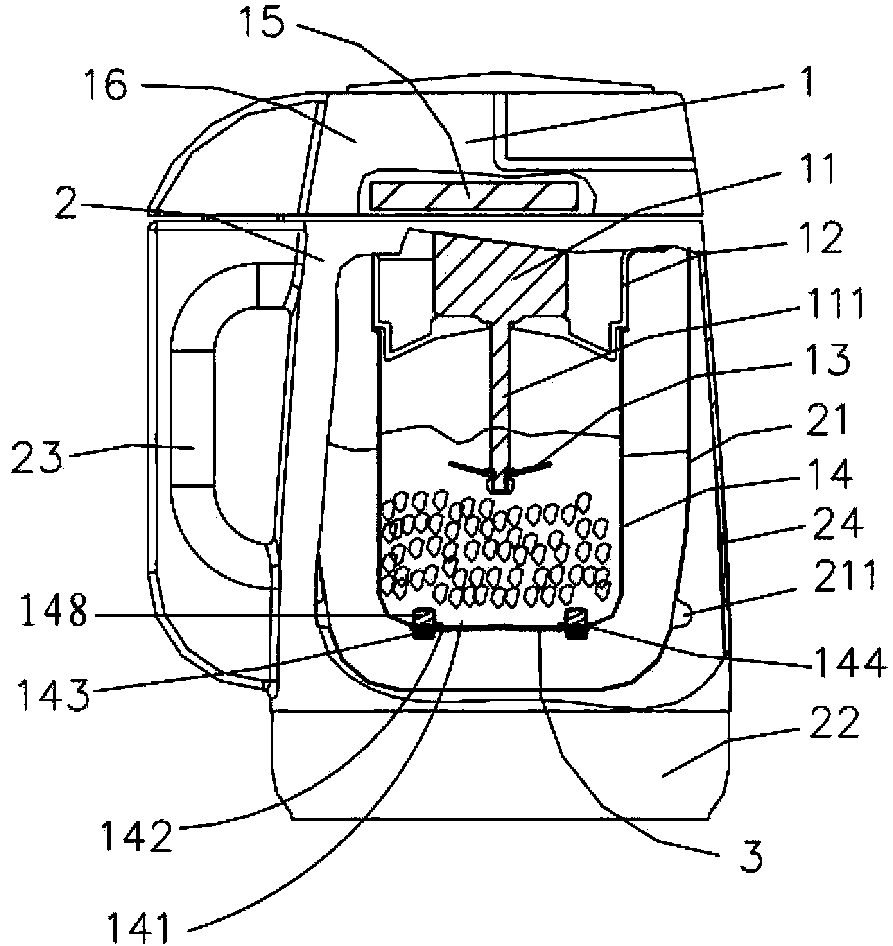

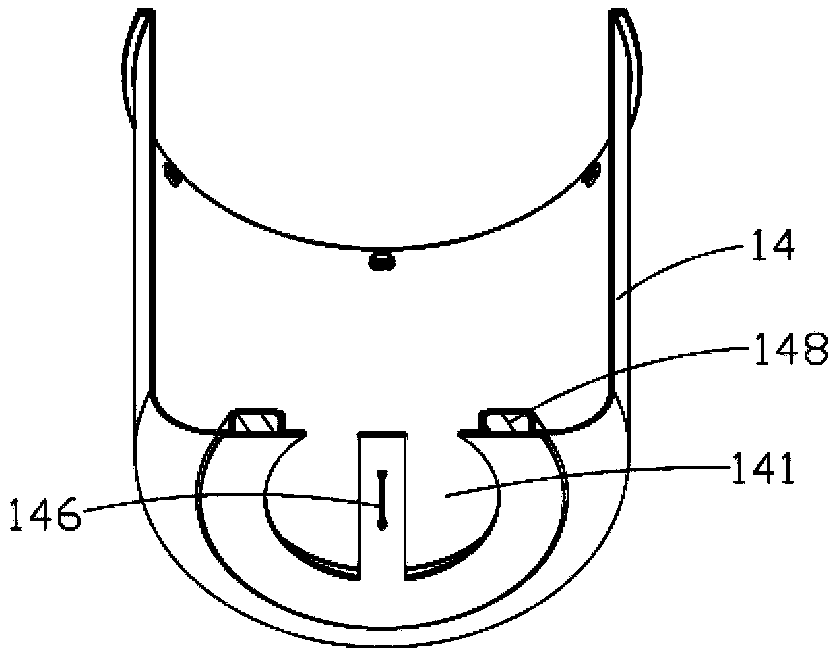

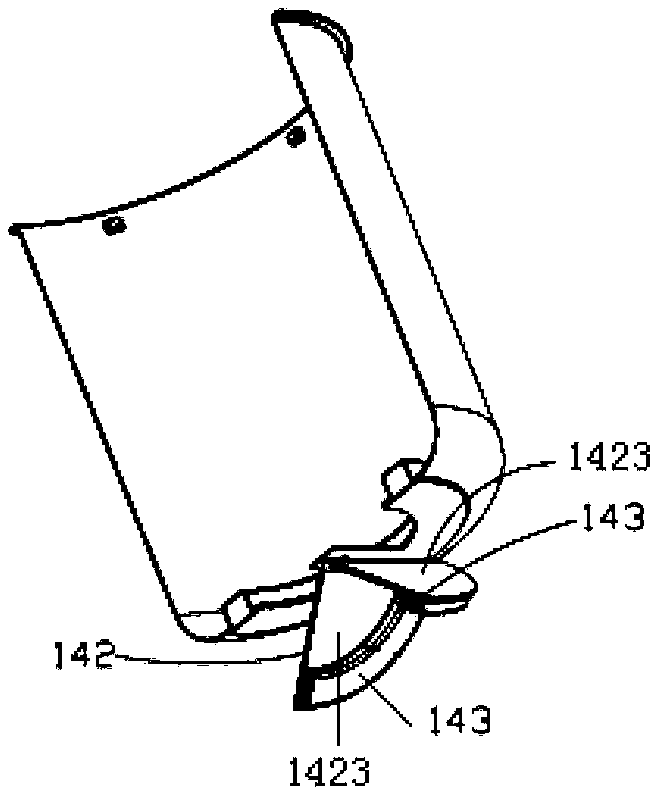

[0035] As the first embodiment of the soymilk maker of the present invention and the inner crushing cup provided thereon, as Figure 1 to Figure 3 As shown, the soybean milk machine includes a machine head 1, a circuit control board 15, a motor 11 arranged in the machine head 1, an inner crushing cup 14, a crushing cutter 13, a cup body 2 and a heating device 211, and the machine head 1 is buckled on the On the cup body 2, the machine head 1 includes a machine head upper cover 16 and a machine head lower cover 12, the motor 11 and the heating device 211 are respectively electrically connected to the circuit control board, and the inner crushing cup 14 is located in the cup body 2, and Installed on the machine head lower cover 12, the inner crushing cup 14 is a cylindrical body with an upper end opening, the slurry outlet 141 is arranged at the bottom of the inner crushing cup 14, and the slurry outlet 141 and the cover 142 are provided There is a sealing ring 144, the inner cr...

Embodiment 2

[0052] Embodiment 2 of the soymilk machine of the present invention and the inner crushing cup provided thereon, such as Figure 5 and Figure 6As shown, the difference from the inner crushing cup in Embodiment 1 is that one end of the cover 142 is fixed on the inner crushing cup 14 through a pivot pin 146, and the other end is fastened to the slurry outlet 141 through a buckle structure 145. superior. In this embodiment, the buckle structure 145 includes a hook 1451 provided on the inner crushing cup 14 and a lug 1421 provided on the cover 142 to engage with the hook 1451. The temperature control structure It is a hook 1451 made of a bimetal sheet. Under normal temperature, the hook 1451 made of a bimetal sheet hooks the lug 1421 on the cover 142 so that the material is stored in the crushing cup 14 . When the water temperature in the cup reaches T 1 , the hook 1451 made of the bimetal sheet is deformed, and the hook 1451 made of the bimetal sheet is disengaged from the lu...

Embodiment 3

[0055] As the third embodiment of the soybean milk machine provided with the inner crushing cup according to the present invention, as Figure 8 , Figure 9 and Figure 10 As shown, the difference from Embodiment 1 is that the heating device 211 is arranged at the bottom of the inner layer 21 of the cup, the inner crushing cup 14 is installed on the cup body through a screw-in structure, and the inner crushing cup 14 is the upper end Open cylindrical body, the upper opening of the inner crushing cup 14 is also provided with a sealing ring 144, the sealing ring 144 is an annular body made of silica gel material, the upper opening of the inner crushing cup 14 is in contact with the machine head lower cover 12 conflict, so that the inner crushing cup 14 and the lower cover 12 of the machine head form an airtight small crushing space. In this embodiment, the bottom of the inner cup body 21 of the cup body 2 is provided with a connecting ring 212, the connecting ring 212 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com