Substrate for heating, heating plate, humidifier and machining methods of substrate and heating plate

A processing method and heating plate technology, applied in the processing of substrates and heating plates, and in the field of humidifiers, can solve the problems of easy aging of heating film materials, low resistance consistency, and damage to heating structures, so as to improve temperature control accuracy and response Excellent speed, good resistance to cold and heat shock, and the effect of reducing temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

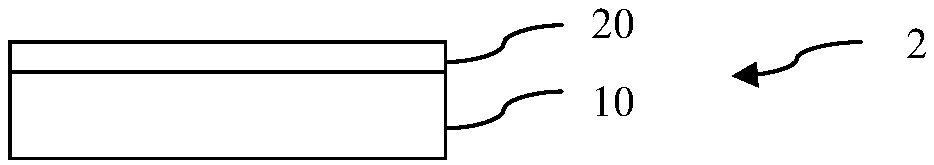

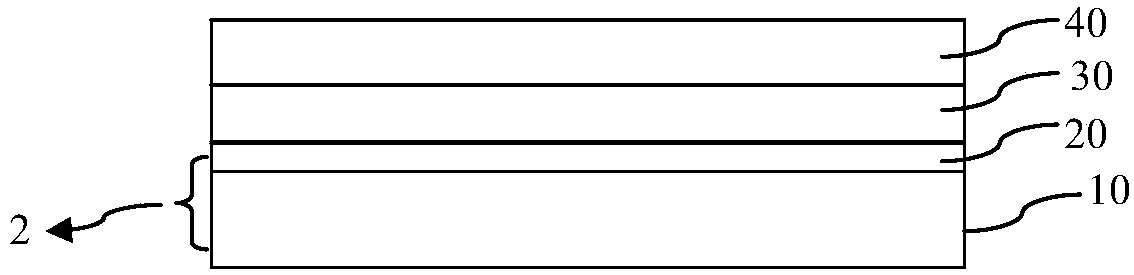

[0083] Substrate body material: 6061 aluminum alloy, polished surface, thickness about 1-2mm;

[0084] Process:

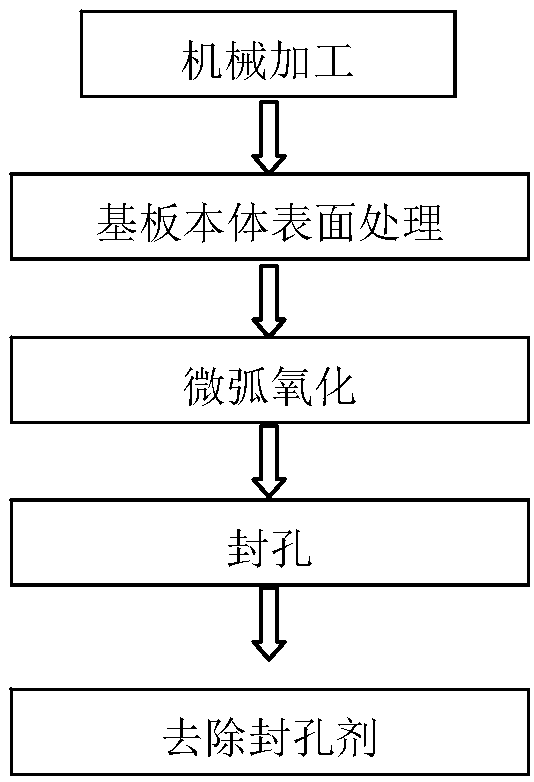

[0085] (1) Mechanical processing: forming the substrate body into the desired shape through punching, chamfering, stamping, etc.;

[0086] (2) Surface treatment of the substrate body: immerse the processed substrate body in an organic solvent such as ethanol, acetone, or NaOH solution, and ultrasonically clean the grease on the surface of the substrate body.

[0087] (3) Micro-arc oxidation: put the surface-treated substrate body into a micro-arc oxidation electrolytic cell for micro-arc oxidation, form an oxide ceramic layer on the substrate body, clean and dry, and obtain a Rockwell hardness of about 600 Oxide ceramic layer at -800HV; in micro-arc oxidation:

[0088] a) Electrolyte: base solution containing sodium silicate 10-15g / L, sodium hexametaphosphate 8-12g / L, ethylene glycol 0.1-1.0g / L and glycerol 0.1-0.6g / L, with KOH Solution Adjust the pH of the base...

Embodiment 2

[0103] Substrate body material: the same as in Embodiment 1;

[0104] processing, such as Figure 11 As shown,:

[0105] (1), mechanical processing: with embodiment one;

[0106] (2) The surface treatment of the substrate body: the same as in the first embodiment.

[0107] (3), micro-arc oxidation: with embodiment one; In micro-arc oxidation:

[0108] a) Electrolyte: containing sodium silicate 10-15g / L, sodium phosphate 8-12g / L, sodium citrate 0.1-0.6g / L, ethylene glycol 0.1-1.0g / L, glycerol 0.1-0.6g / L base solution, adjust the pH value of the base solution to 8-12 with KOH solution.

[0109] b) Micro-arc oxidation parameters:

[0110] Immerse the substrate body to be oxidized as the anode in the electrolyte, the electrolyte temperature: 20°C-30°C, constant temperature stirring

[0111] Current density: 5-15A / dm 2 ,

[0112] Voltage: 500-700V,

[0113] DC pulse frequency: 200-500Hz,

[0114] Duty cycle: 20%-50%,

[0115] Reaction time: 20-40min.

[0116] (4) Seali...

Embodiment 3

[0121] Substrate body material: the same as in Embodiment 1;

[0122] Process:

[0123] (1), mechanical processing: with embodiment one;

[0124] (1) Surface treatment of the substrate body: same as in Embodiment 1.

[0125] (3), micro-arc oxidation: with embodiment one; In micro-arc oxidation:

[0126] a) Electrolyte: containing sodium silicate 10-15g / L, sodium phosphate 8-12g / L, sodium citrate 0.1-0.6g / L, ethylene glycol 0.1-1.0g / L, glycerol 0.1-1.0g / L base liquid, use KOH solution to adjust the pH value of the base liquid to 8-12; then add 0.1-0.5g / L sealing agent nano-alumina powder with a particle size of 10-20nm and 0.1-0.6g / L The dispersant polyoxyethylene alkylphenol ether (APEO) or high-carbon aliphatic alcohol polyoxyethylene ether (AEO) completes the sealing of micropores in the process of forming the oxide ceramic layer.

[0127] b) Micro-arc oxidation parameters:

[0128]Immerse the substrate body to be oxidized as the anode in the electrolyte, the electroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com