Steam sterilizer

A sterilizer and steam technology, applied in chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of high cost, low utilization rate, secondary pollution, etc., and achieve the cost of manufacturing and use. Control, manufacturing cost and use cost are good, and the effect of reducing the probability of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

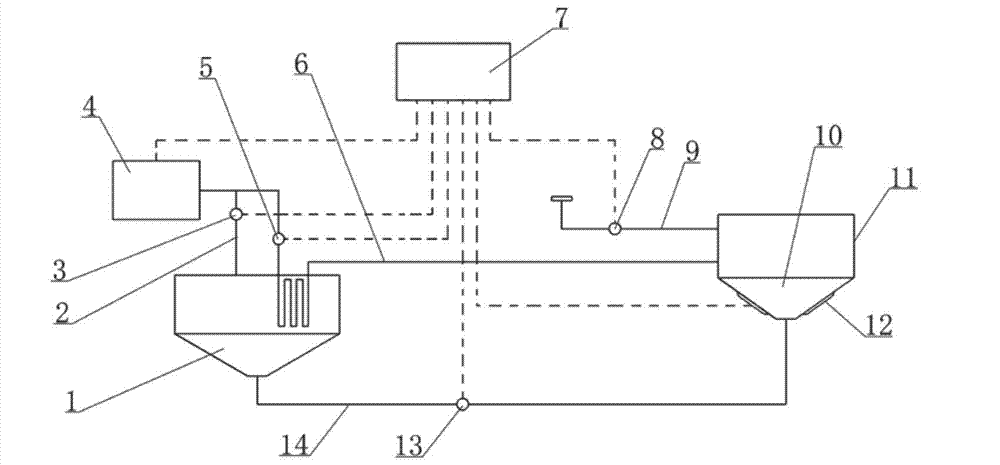

[0031] see figure 1 As shown, a steam sterilizer disclosed by the present invention is mainly composed of a cooking pot assembly 11, a pressure water tank 1, a two-way air pump 4, a circuit board assembly 7 and a casing; wherein, the cooking pot assembly 11 has a sealable The sterilization chamber 10, the sterilization chamber 10 is used to accommodate the articles to be sterilized, water and steam, the bottom of the sterilization chamber 10 is provided with an electric heating element 12, and the electric heating element 12 is used to heat the water in the sterilization chamber 10, sterilize The top of the bacteria chamber 10 is provided with an exhaust pipe 9, and the exhaust pipe 9 is provided with an exhaust control valve 8, which can control the communication state between the sterilization chamber 10 and the outside world through the exhaust control valve 8; The airtight chamber for storing water, the bottom of the pressure water tank 1 and the bottom of the sterilizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com