Sterilization method of steam sterilizer and steam sterilizer

A technology of steam sterilization and sterilization method, which is applied in heating and other directions, can solve problems such as the influence of workers, loud working noise, and potential safety hazards, and achieve the effect of ensuring uniformity, penetration, and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

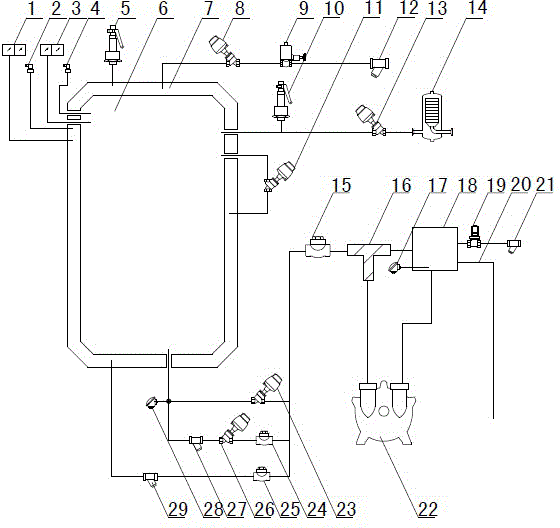

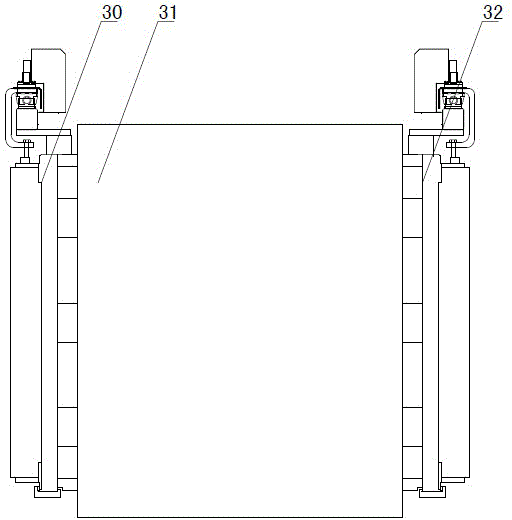

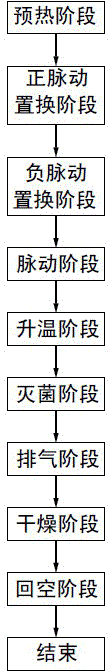

[0049] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0050] Such as Figure 1~2As shown, a steam sterilizer with a water ejector includes a casing 31, a front door 30 and a rear door 32 fixed at both ends of the casing 31. The inside of the shell 31 is provided with a sterilization chamber 6 surrounded by the front door 30, the rear door 32 and the wall of the sterilization chamber, and an interlayer 7 is arranged outside the sterilization chamber 6, and only the sterilization chamber 6 and the interlayer 7 are passed through The cavity interlayer air intake unit is connected. The interlayer thermometer 1, the interlayer manometer 2 and the interlayer safety valve 5 that respectively monitor and display the temperature and pressure in the interlayer 7 are provided at the interlayer 7; The temperature and pressure are monitored and displayed by the sterilizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com