Patents

Literature

38results about How to "Guaranteed quality uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

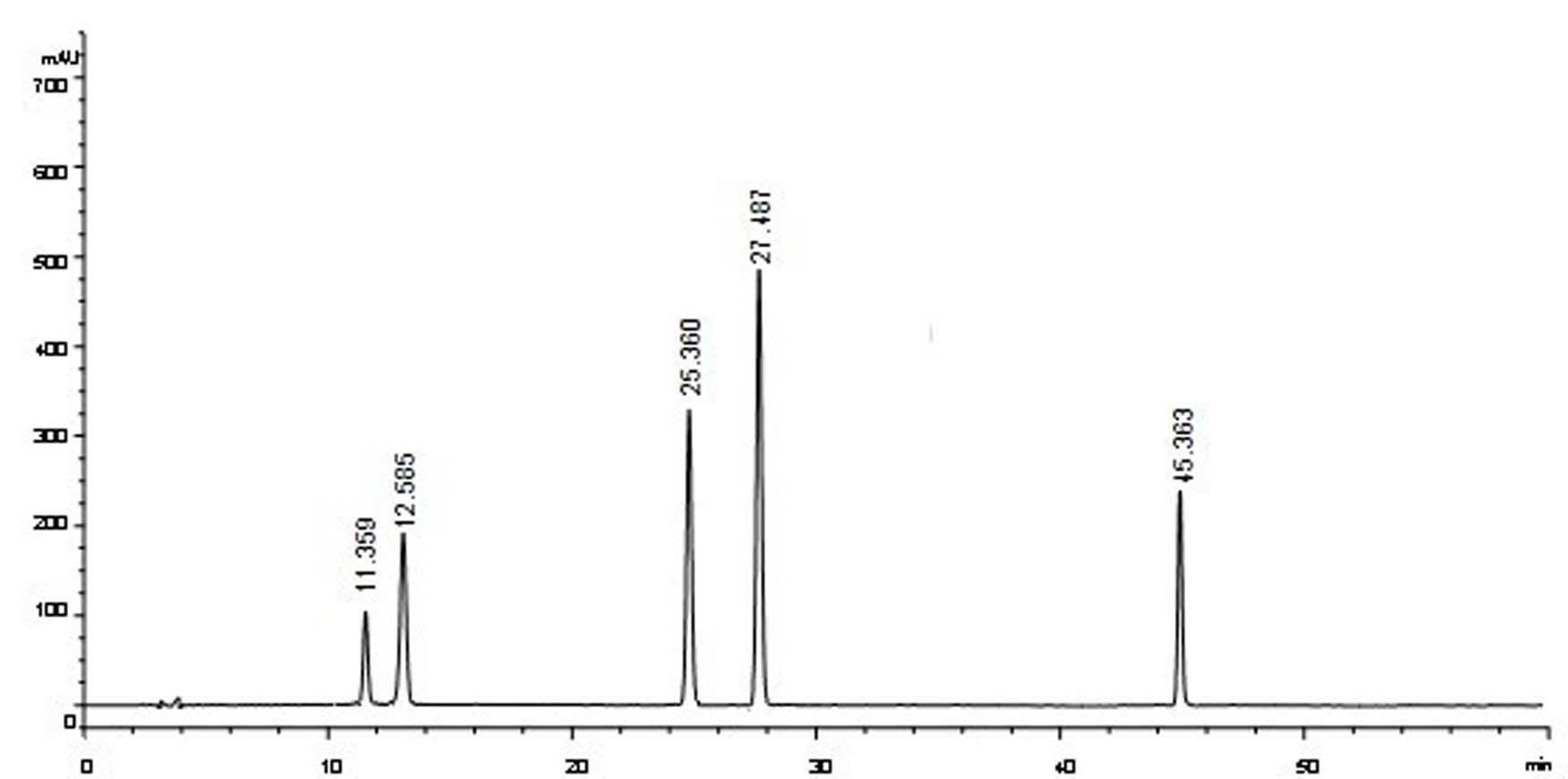

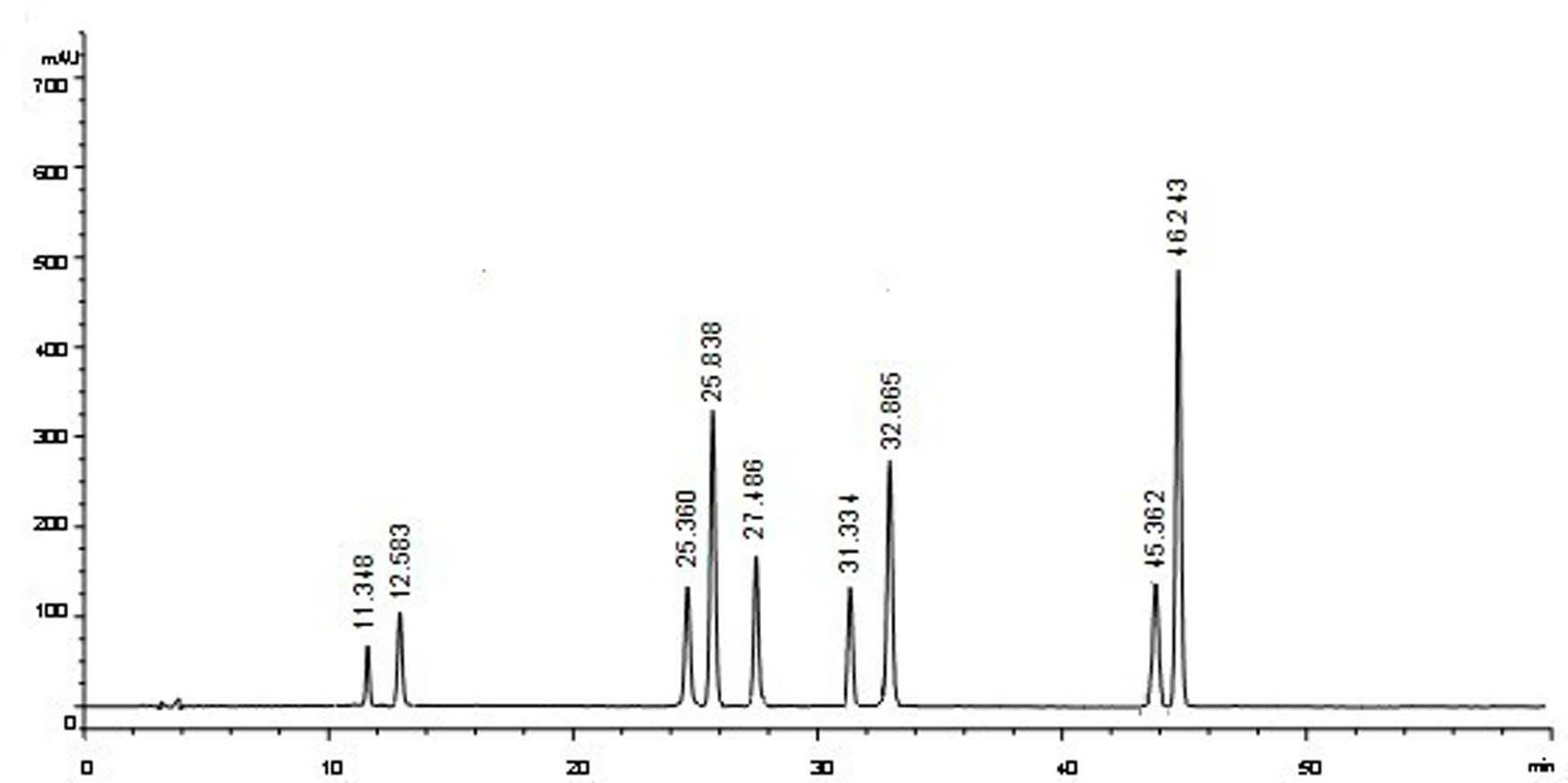

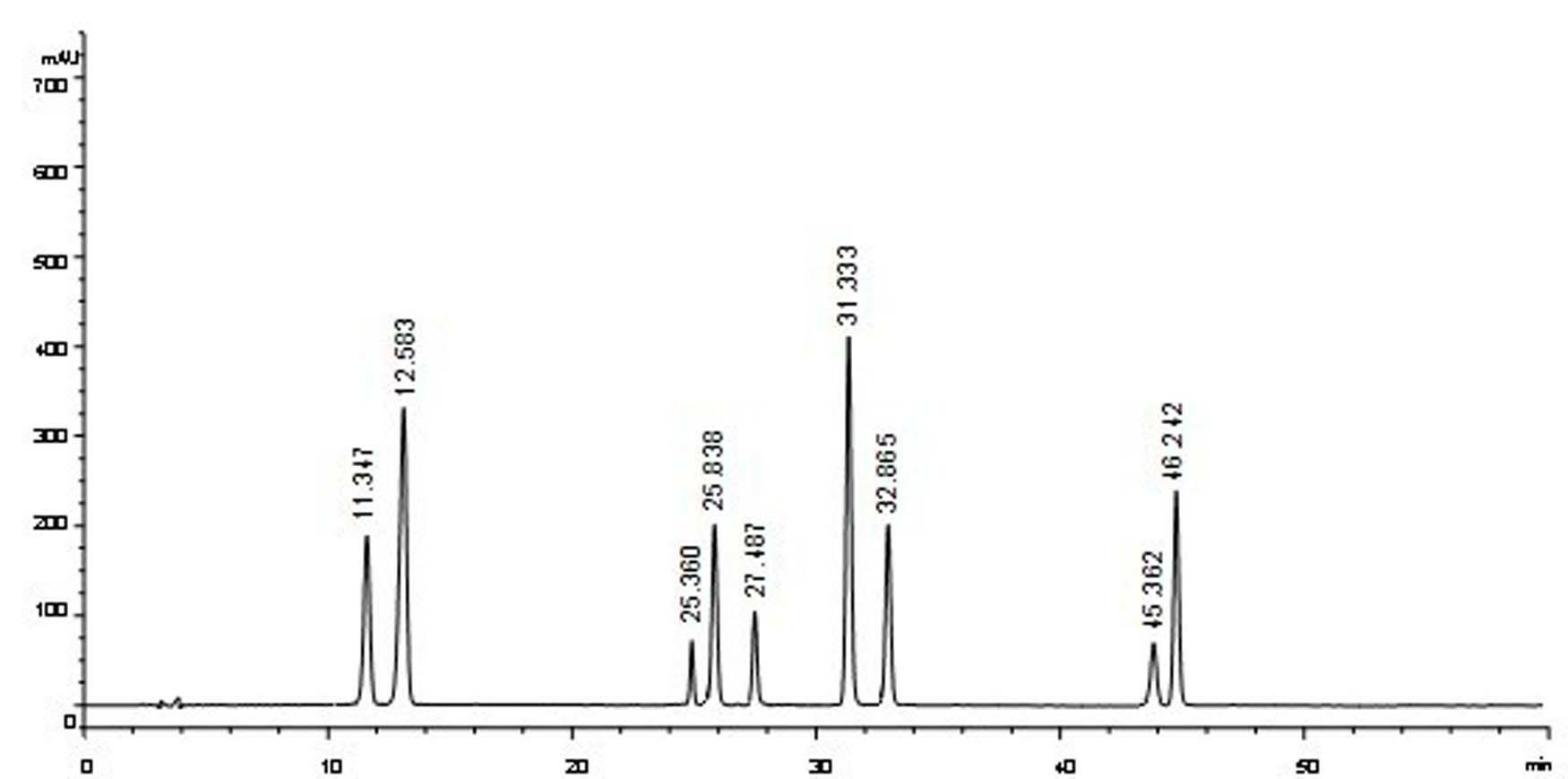

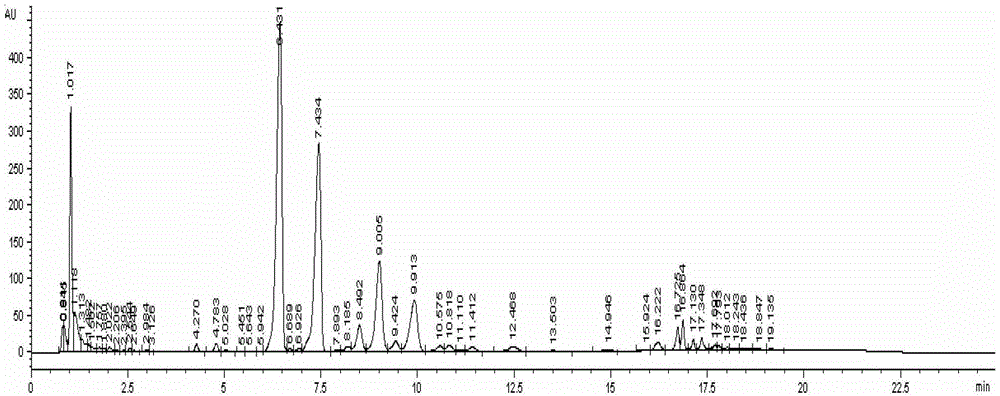

Fingerprint building method and quality control method of Shenxiong glucose injection raw material, Shenxiong glucose injection midbody and Shenxiong glucose injection preparation

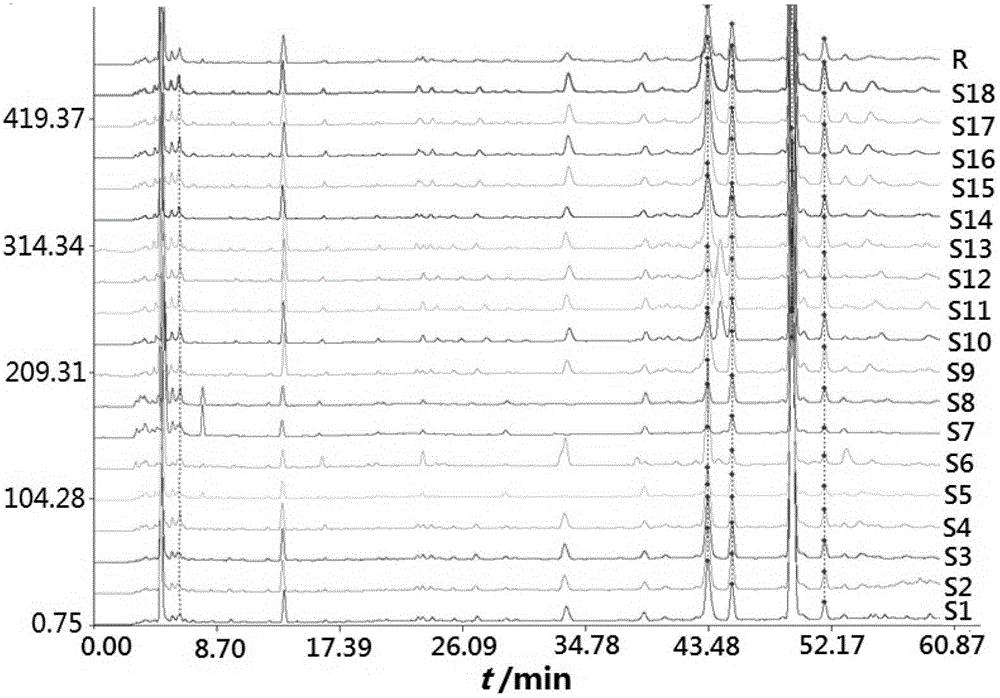

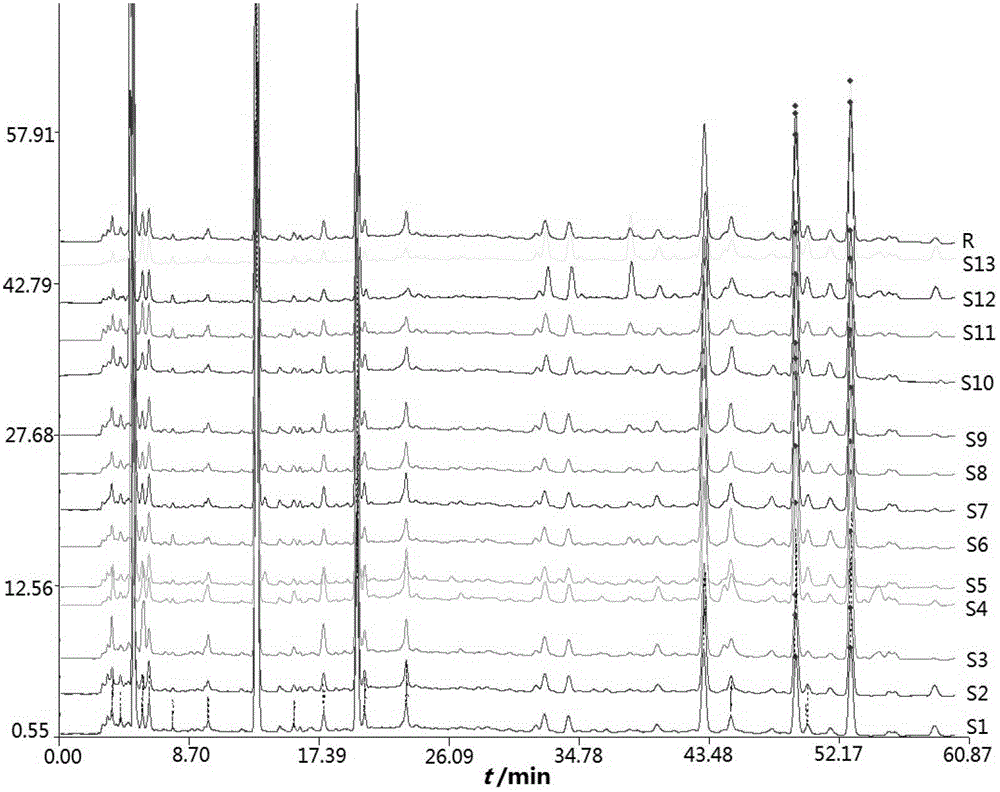

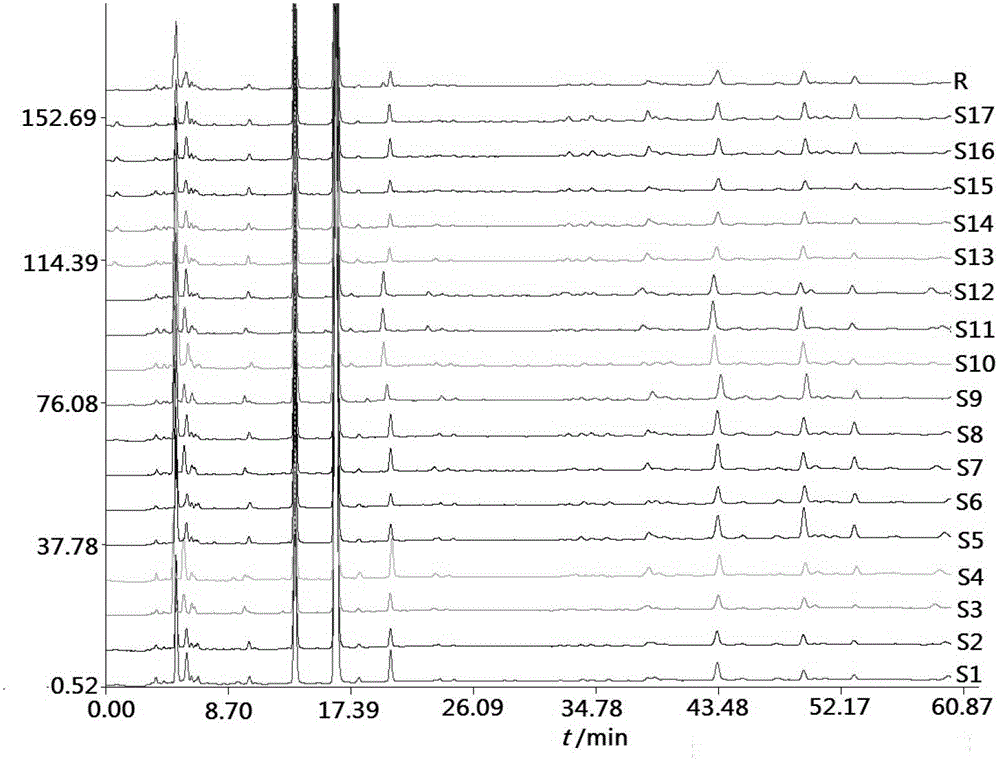

ActiveCN103149310AGood repeatabilityImprove quality controlComponent separationPhosphoric acidGradient elution

The invention discloses a fingerprint building method and a quality control method of Shenxiong glucose injection raw material, a Shenxiong glucose injection midbody and Shenxiong glucose injection preparation. Fingerprint detection is conducted on the raw material, the midbody and the preparation of the raw material and the midbody under the condition of the same chromatograph. Octadecylsilane chemically bonded silica is used as chromatographic column filling agent, acetonitrile-phosphate aqueous solution is used as mobile phase, gradient elution is conducted, a test sample fingerprint and a contrasted fingerprint have good relevance, similarity is larger than 0.90, a fingerprint of the Shenxiong glucose injection raw material, a fingerprint of the Shenxiong glucose injection midbody and a fingerprint of the Shenxiong glucose injection preparation have good relevance, and each characteristic peak in the preparation fingerprint can be tracked in the raw material and the midbody. The fingerprint building method and the quality control method of the Shenxiong glucose injection raw material, the Shenxiong glucose injection midbody and the Shenxiong glucose injection preparation can be used for controlling conditions and quality of the preparation technology of Shenxiong glucose injection products and ensure stability of the preparation technology and the quality of the products. A fingerprint detecting method has the advantages of being simple and convenient to operate, accurate, reliable, and suitable for controlling the quality of Shenxiong glucose injection.

Owner:GUIZHOU JINGFENG INJECTION

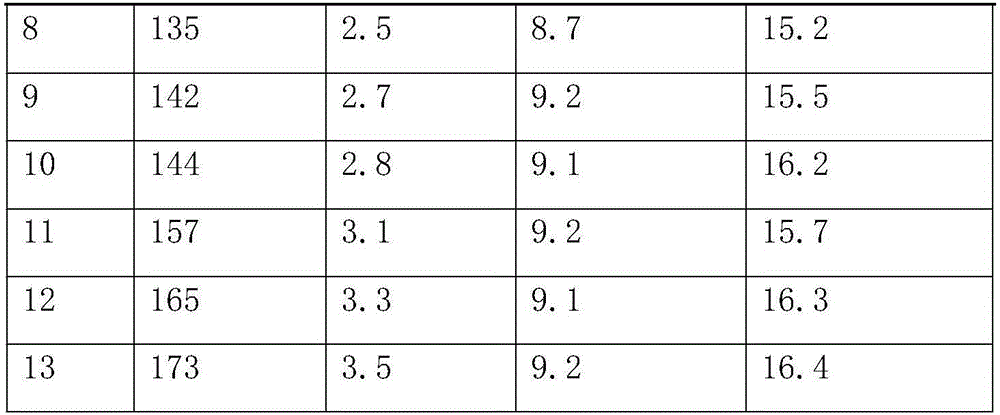

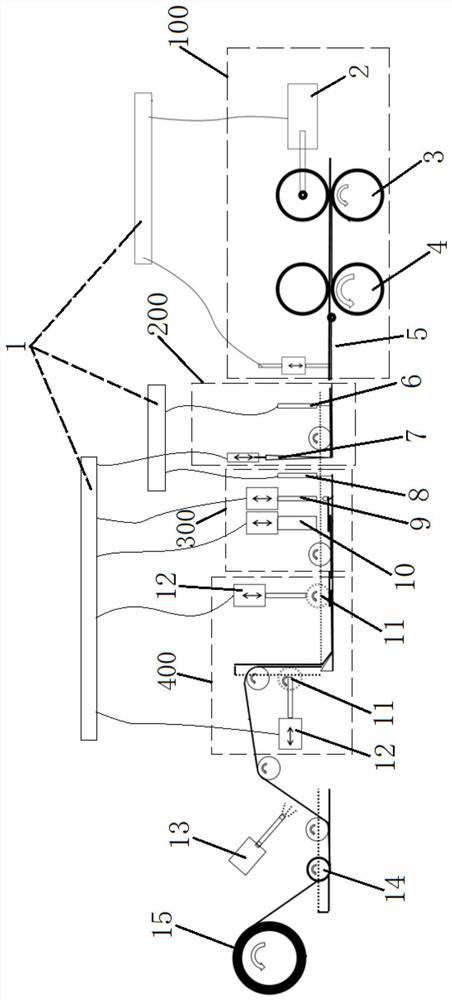

Microwave and low-pressure superheated steam combined drying test apparatus and drying method

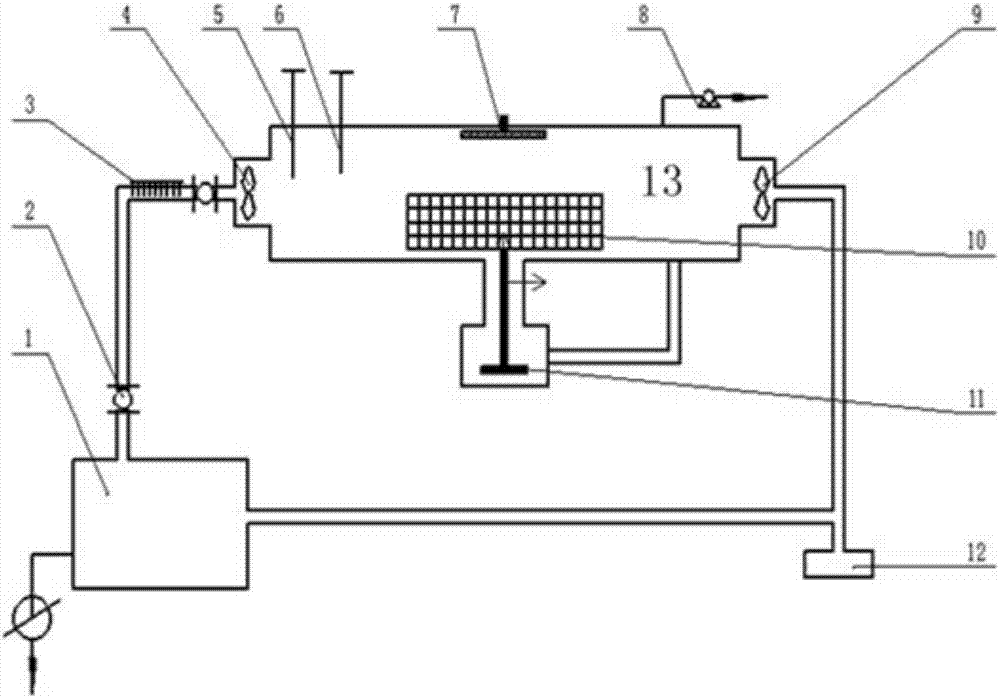

InactiveCN106979669ADry fastReduce thermal stress cracksDrying using combination processesDrying solid materials with heatThermal energyAtmospheric air

The present invention belongs to the technical field of material drying, and discloses a microwave and low-pressure superheated steam combined drying test apparatus and a drying method. The combined drying test apparatus is composed of a steam generator, steam opening valves, a heater, an inlet fan, an air velocity transducer, a temperature sensor, a microwave generator, a vacuum pump, an outlet fan, a net-shaped material tray, a weighing sensor, a running water valve and a drying box. The drying method comprises that low-pressure superheated steam is used as a drying medium of a closed drying system, and materials are dried by the superheated steam and microwave together. The interiors of agricultural products are heated, inside moisture transfer speed of the agricultural products is raised, drying of the agricultural products is accelerated, temperature difference between the inside and the surface is reduced, generation of thermal stress cracks is reduced, and the drying quality and the drying uniformity of the agricultural products are ensured. No dust or volatile substances are discharged into the air in the drying process, the exhaust gas is saturated steam and can be recycled, the heat utilization rate is raised and total energy consumption of drying is lowered.

Owner:CHINA AGRI UNIV

High-temperature bolt steel BG25Cr2MoVA and preparation method thereof

InactiveCN108531815ARealize continuous casting productionReduce the cost per ton of steelProcess efficiency improvementElectric furnaceMechanical propertyImpurity

The invention discloses high-temperature bolt steel BG25Cr2MoVA and a preparation method thereof. The high-temperature bolt steel BG25Cr2MoVA comprises the following components of, by weight, 0.23-0.27% of C, 0.20-0.35% of Si, 0.54-0.62% of Mn, 0-0.015% of P, 0-0.012% of S, 1.64-1.72% of Cr, 0.28-0.32% of Mo, 0.20-0.24% of V, 0-0.15% of Ni, 0-0.15% of Cu, 0.020-0.040% of Alt, and the balance Fe and inevitable impurities. The high-temperature bolt steel BG25Cr2MoVA is high in steel purity degree, resistant to high temperature and fatigue, and stable in mechanical property. The preparation method is simple and practical, and the technology is stable.

Owner:BENGANG STEEL PLATES

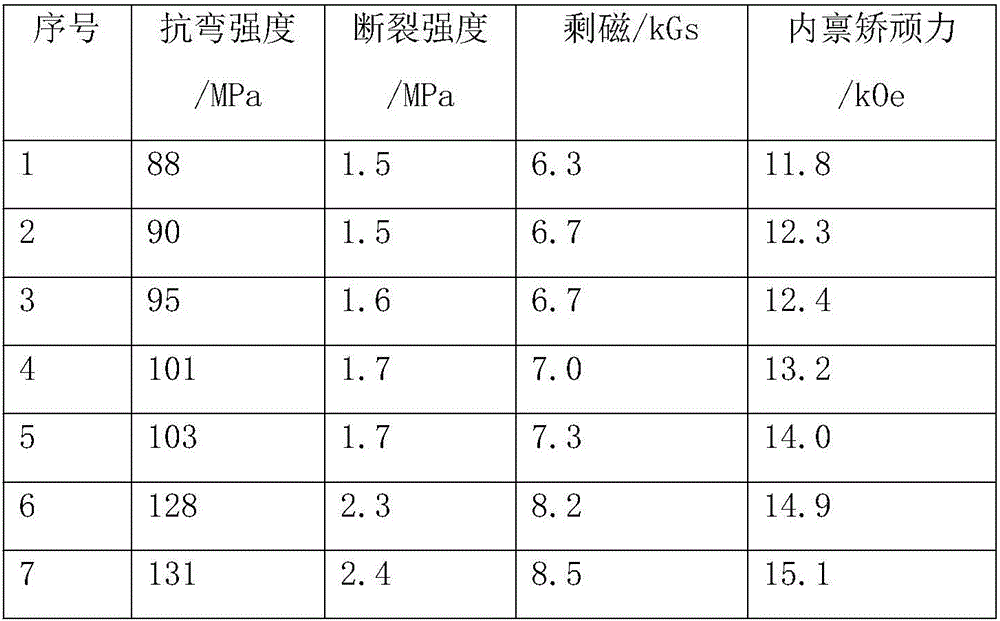

Preparation method of high-performance samarium-cobalt permanent magnetic material

ActiveCN106328366AReduce participationReduce distractionsInductances/transformers/magnets manufactureMagnetic materialsSolution treatmentSolid solution

The invention discloses a preparation method of a high-performance samarium-cobalt permanent magnetic material. The method at least comprises one of the following steps: raw material preparation, smelting, pulverization, orienting compression, sintering and aging treatment; sintering is that degassing dedusting, pre-sintering, vacuum sintering, protective atmosphere sintering and solution treatment are sequentially carried out on a blank which is obtained by orienting compression; and pre-sintering is pre-sintering at 1050-1180 DEG C for 20-30 minutes. A high-temperature sintering zone is formed by selecting and controlling different vacuum degrees and temperatures in the sintering process of a sintering method in the scheme, a high-vacuum, high-heat and constant-temperature sintering process is formed and a single-phase uniform solid solution samarium-cobalt permanent magnet blank is obtained, so that the quality of a permanent magnet product is improved, the production benefits of a sintering furnace are improved and the yield of the product is improved by 30%.

Owner:NINGBO NINGGANG PERMANENT MAGNETIC MATERIALS

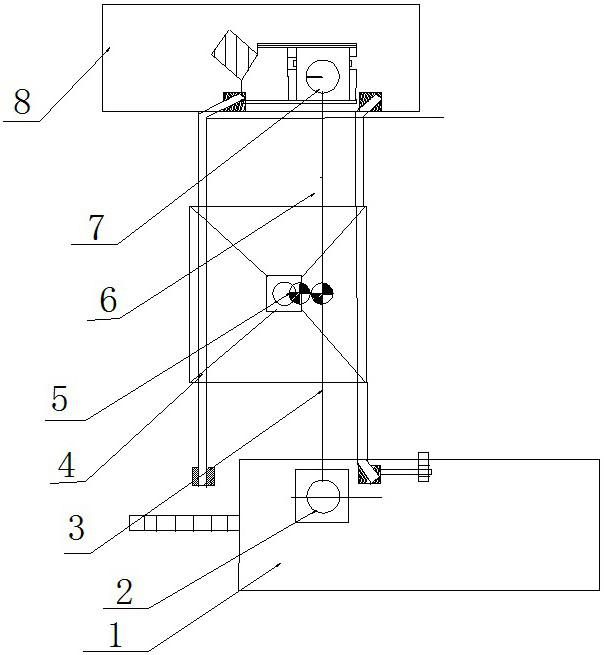

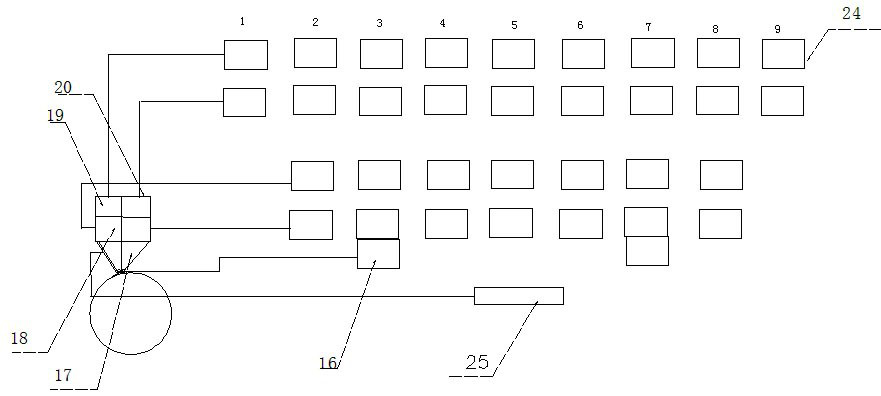

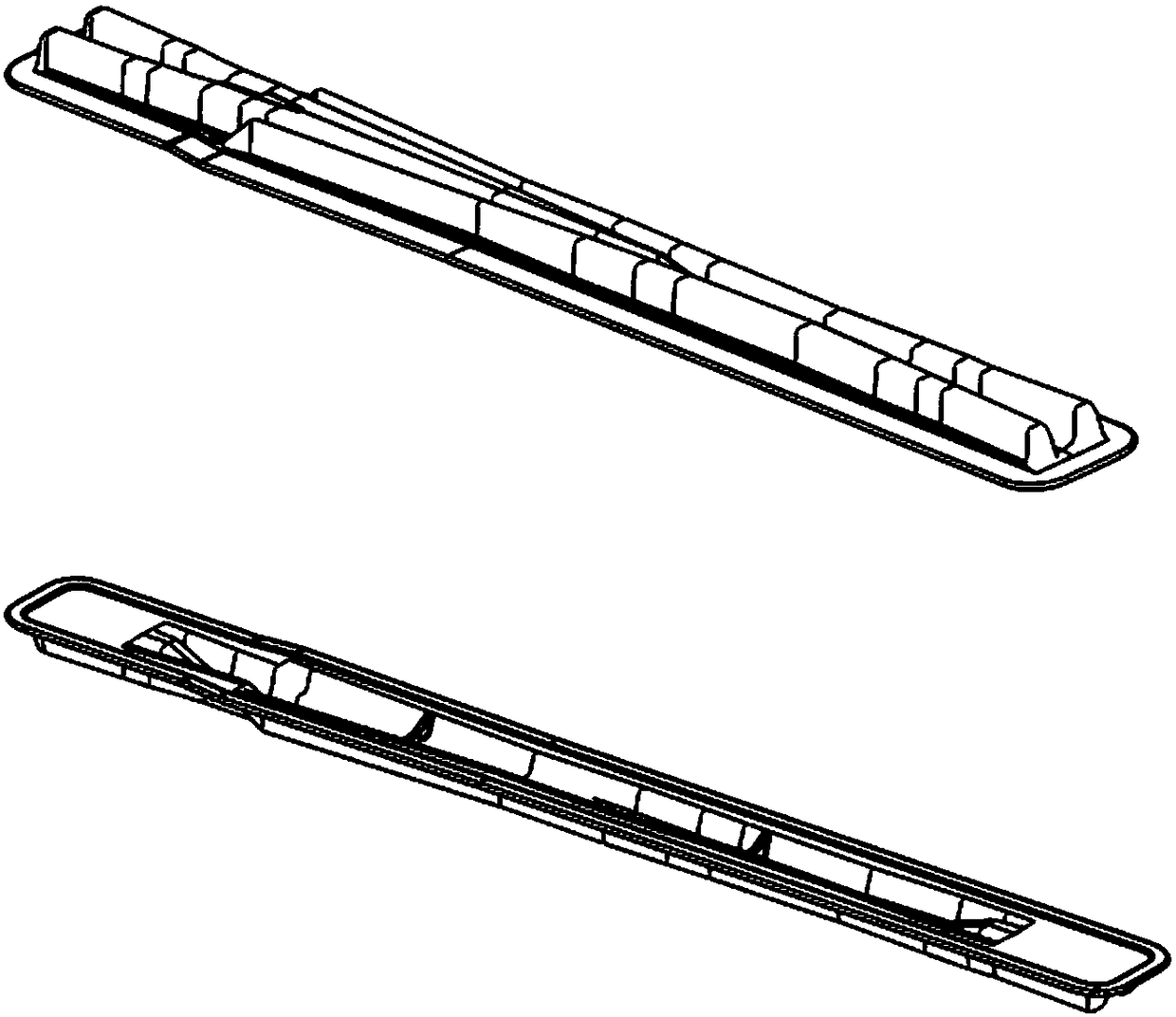

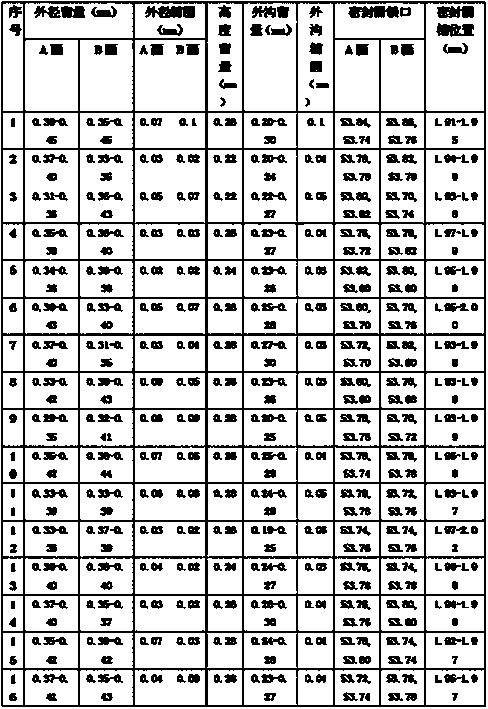

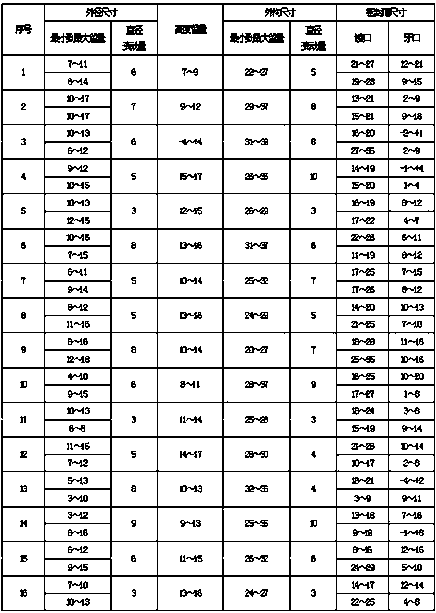

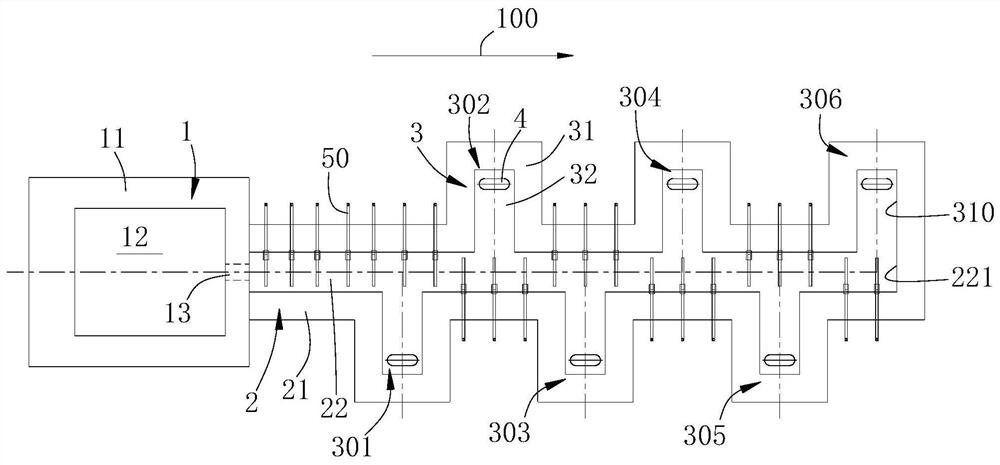

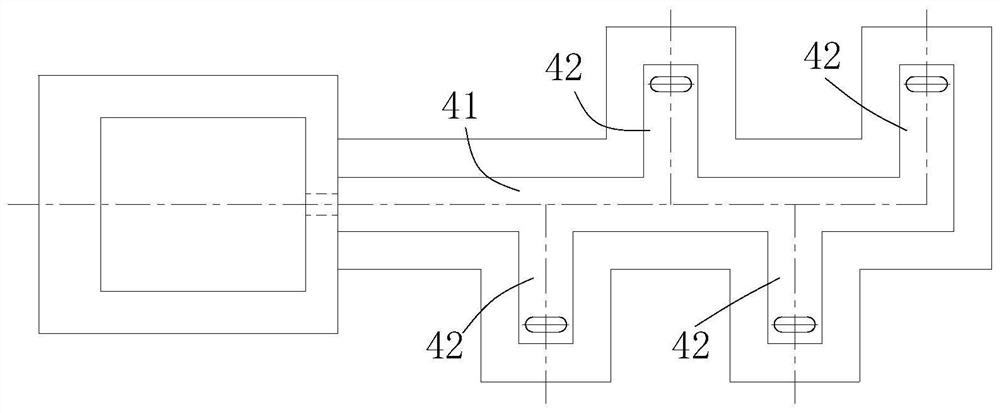

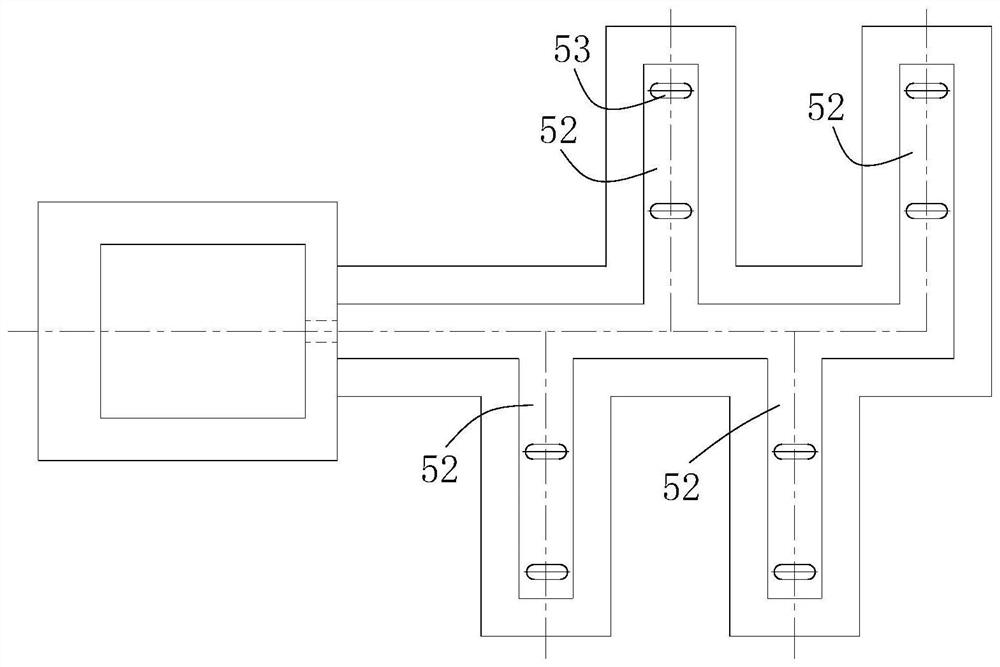

Casting sheet mold head automatic control system for polyester optical film

The invention belongs to the technical field of polyester optical film production, particularly relates to a casting sheet mold head automatic control system for a polyester optical film, and aims to solve the problems that in the prior art, automatic dust removal cannot be implemented in a mold head casting sheet, the product quality of a film in the next process cannot be guaranteed, and the production efficiency is low. The system comprises a main machine system and an auxiliary machine system; the main machine system comprises a main machine filter, a first main machine pipeline, a mold head exhaust hood, a mold lip positioning point, a mold head, a mold lip, a cold drum, a hot wire pipe, a front mold lip heater and a mold head temperature assembly; the auxiliary machine system comprises a first auxiliary machine pipeline, an auxiliary machine filter, an auxiliary machine system, a numerical control system, a dust cover, an adapter and a second auxiliary machine pipeline; and the first main machine pipeline is connected with the first auxiliary machine pipeline. By utilizing the principle of electrostatic adsorption and humidification dust falling, dust particles can be automatically removed in the mold head casting piece, so that the product of the film in the next process is ensured to be free of defects, and the production efficiency is improved.

Owner:SHANDONG SNTON OPTICAL MATERIALS TECH CO LTD

Control method for simultaneously detecting content of nine components through five wavelength merging method for licorice medicinal materials

InactiveCN102539576AEffective evaluationEffective controlComponent separationInformatizationQuality control

The invention discloses a control method for simultaneously detecting content of nine components through a five wavelength merging method for licorice medicinal materials, which combines a modern analysis detecting method and a computer information merging method, accords with a principle of largest informatization, and effectively merges spectrum information and chromatograph information of index components so as to adopt a microscopic and comprehensive quantitative method to reflect the inner quantity of Chinese medicine materials. The quality control method is simple to operate, stable, reliable and good in reappearance, can be used in evaluation and control of the quality of the Chinese medicine materials and development and research of novel medicines, and especially can serve as one of the indexes for quality control and authenticity identification of the licorice medicinal materials.

Owner:LIAONING UNIV OF TRADITIONAL CHINESE MEDICINE

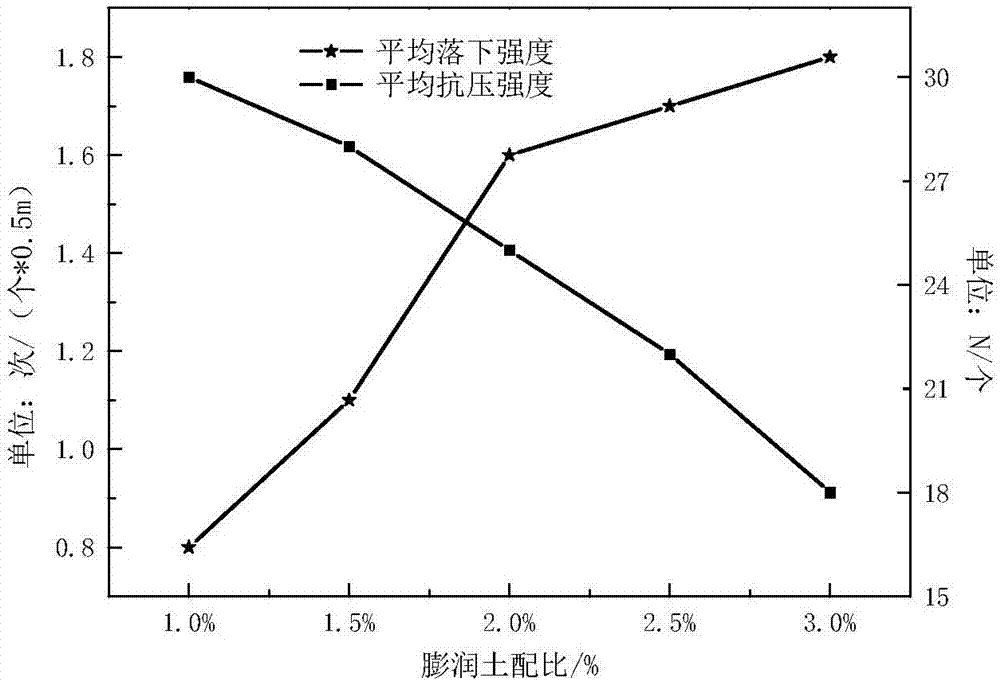

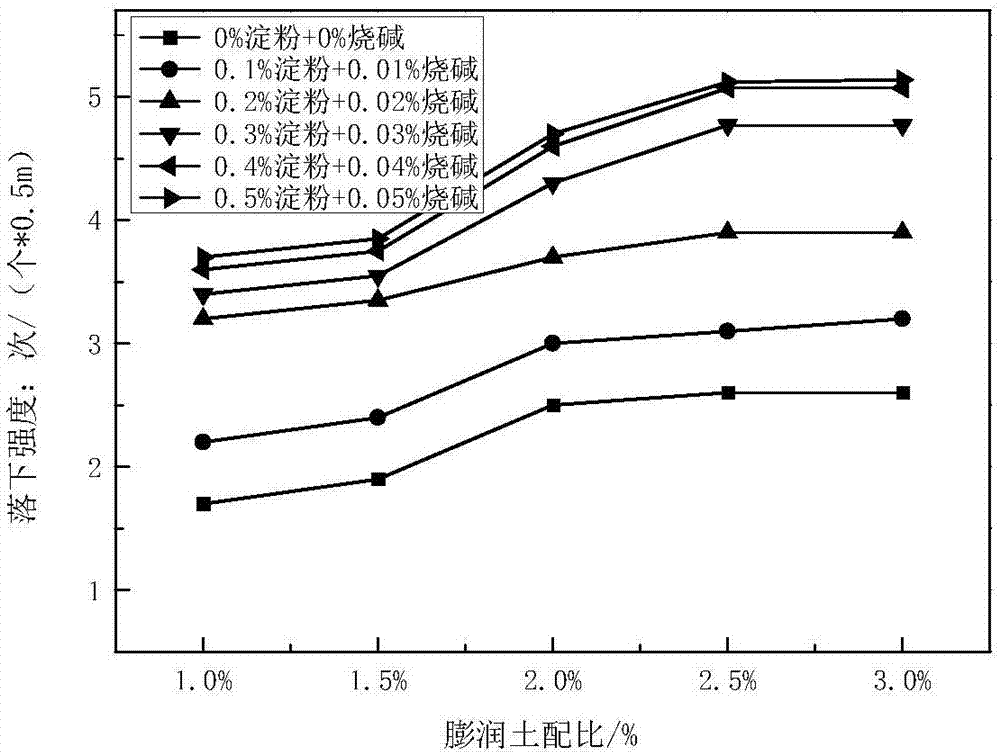

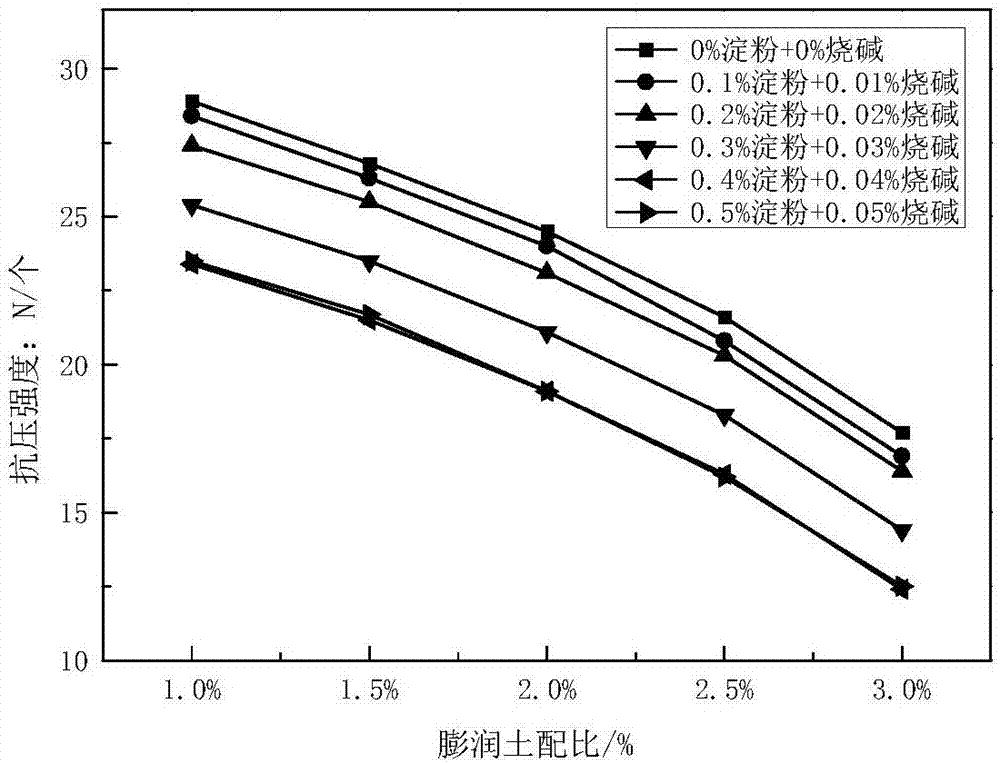

Binder for producing carbon-containing pellets, carbon-containing pellets and preparation method thereof

The invention discloses a binder for producing carbon-containing pellets, the carbon-containing pellets and a preparation method thereof. The binder comprises, by weight, 1.5-2.5 parts of bentonite, 0.3-0.5 part of starch, and 0.03-0.05 part of caustic soda. The carbon-containing pellets containing the binder comprise, by weight, 100 parts of laterite nickel ore, 25-28 parts of reduced coal, 12-15parts of limestone, 1.5-2.5 parts of bentonite, 0.3-0.5 part of starch and 0.03-0.05 part of caustic soda. The preparation method for the carbon-containing pellets comprises the steps that the laterite nickel ore, the reduced coal, the limestone and the bentonite are compounded according to the mass ratio to obtain a first ingredient group, and the starch, the caustic soda and water are mixed according to the mass ratio to be dissolved and stirred to obtain a second mixture; and then the first ingredient group and the second mixture are mixed together to obtain a third mixture, the third mixture is fed into a ball press machine to produce wet carbon-containing pellets, and the wet carbon-containing pellets are dried. The binder for producing the carbon-containing pellets has less additionamount and can be evenly mixed with laterite nickel ore, the formability of the produced carbon-containing pellets is good, and the drop strength, the compressive strength and the like are significantly improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

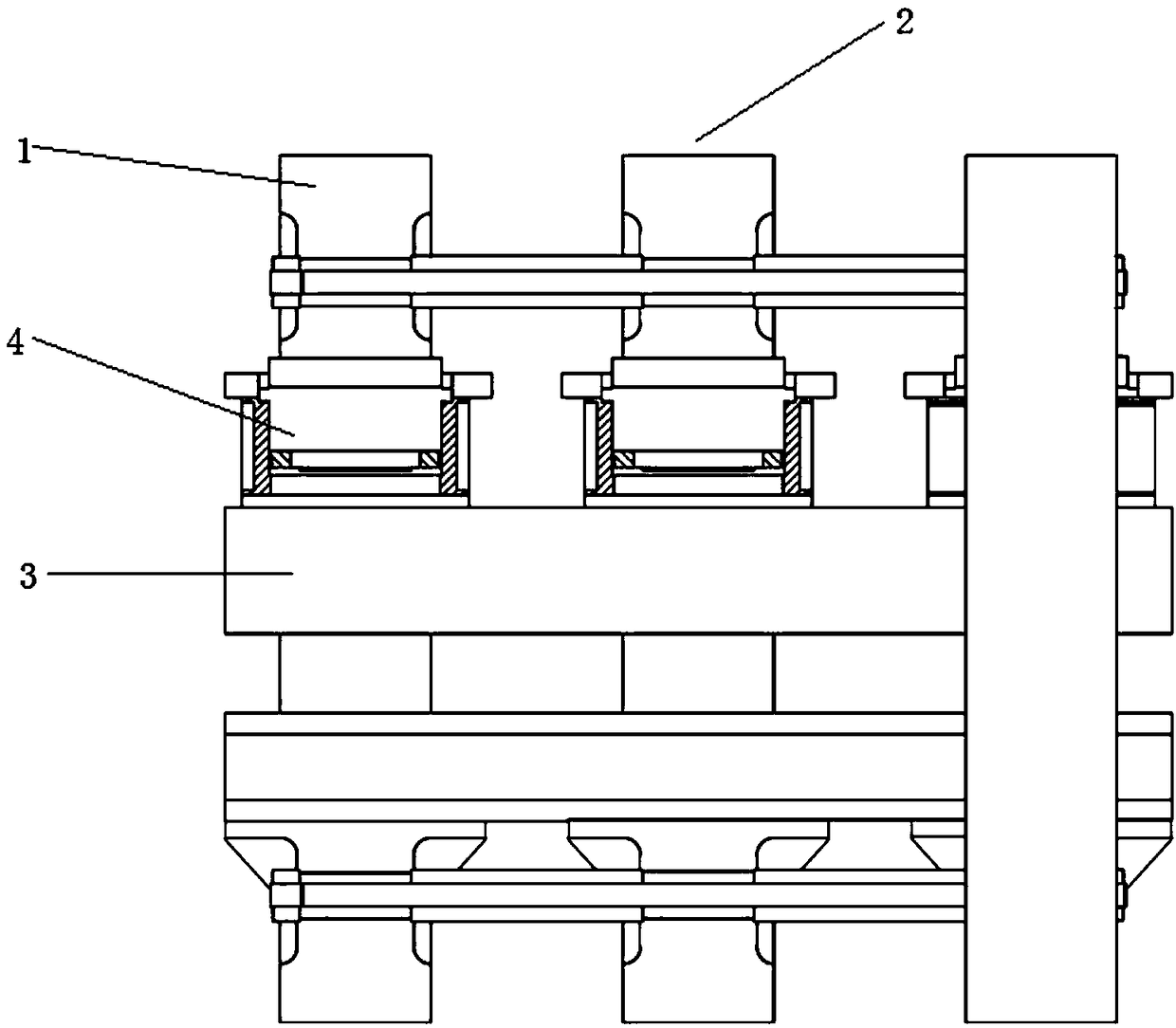

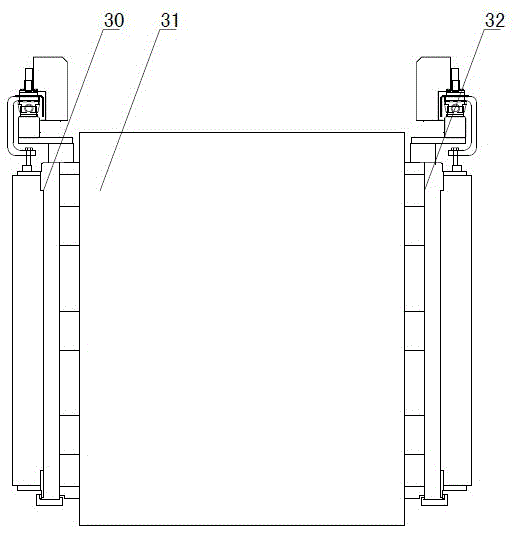

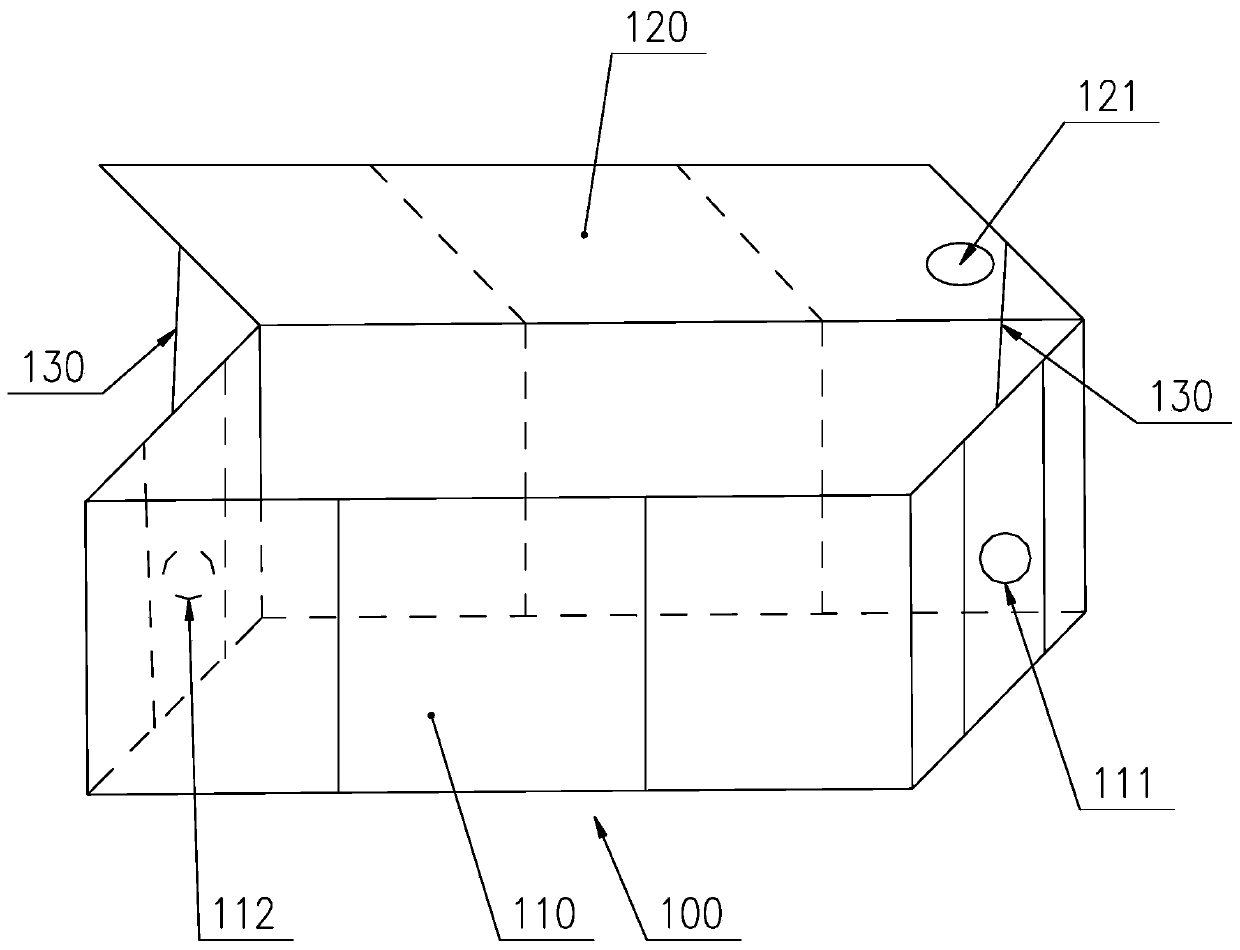

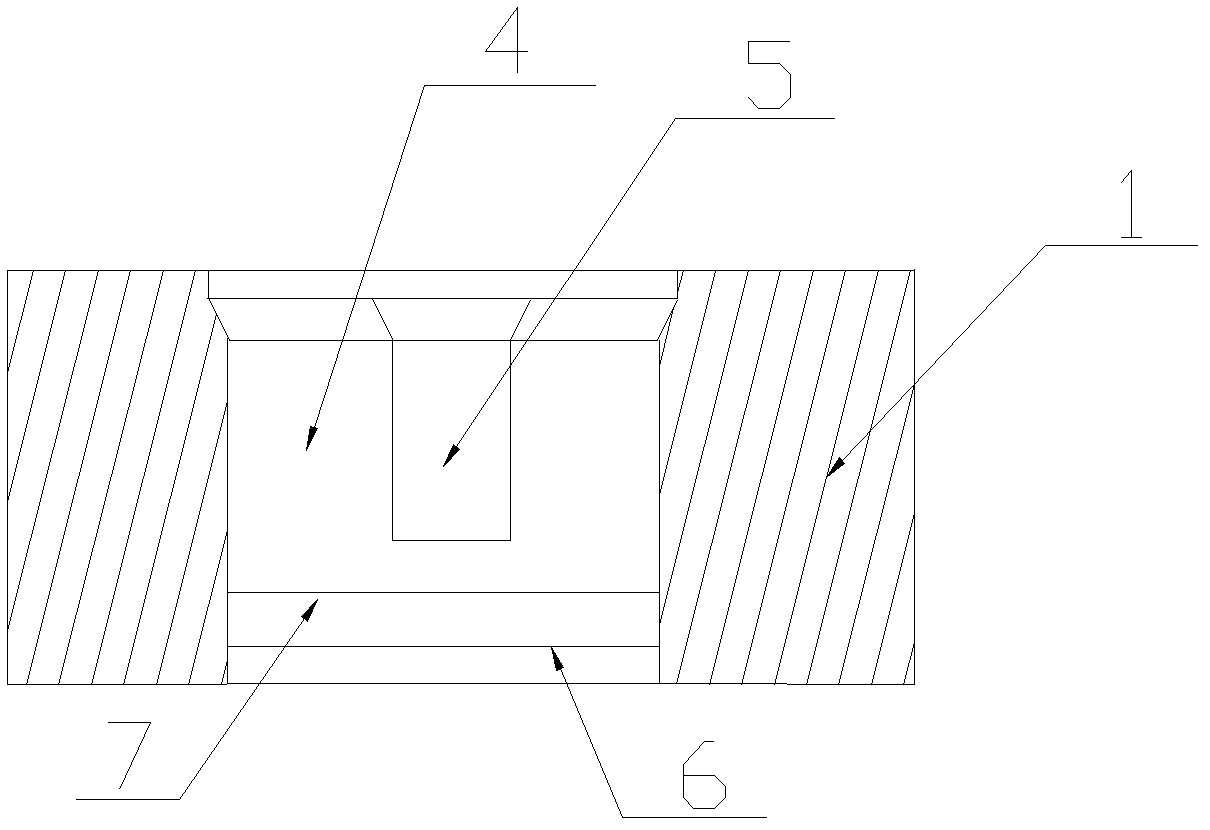

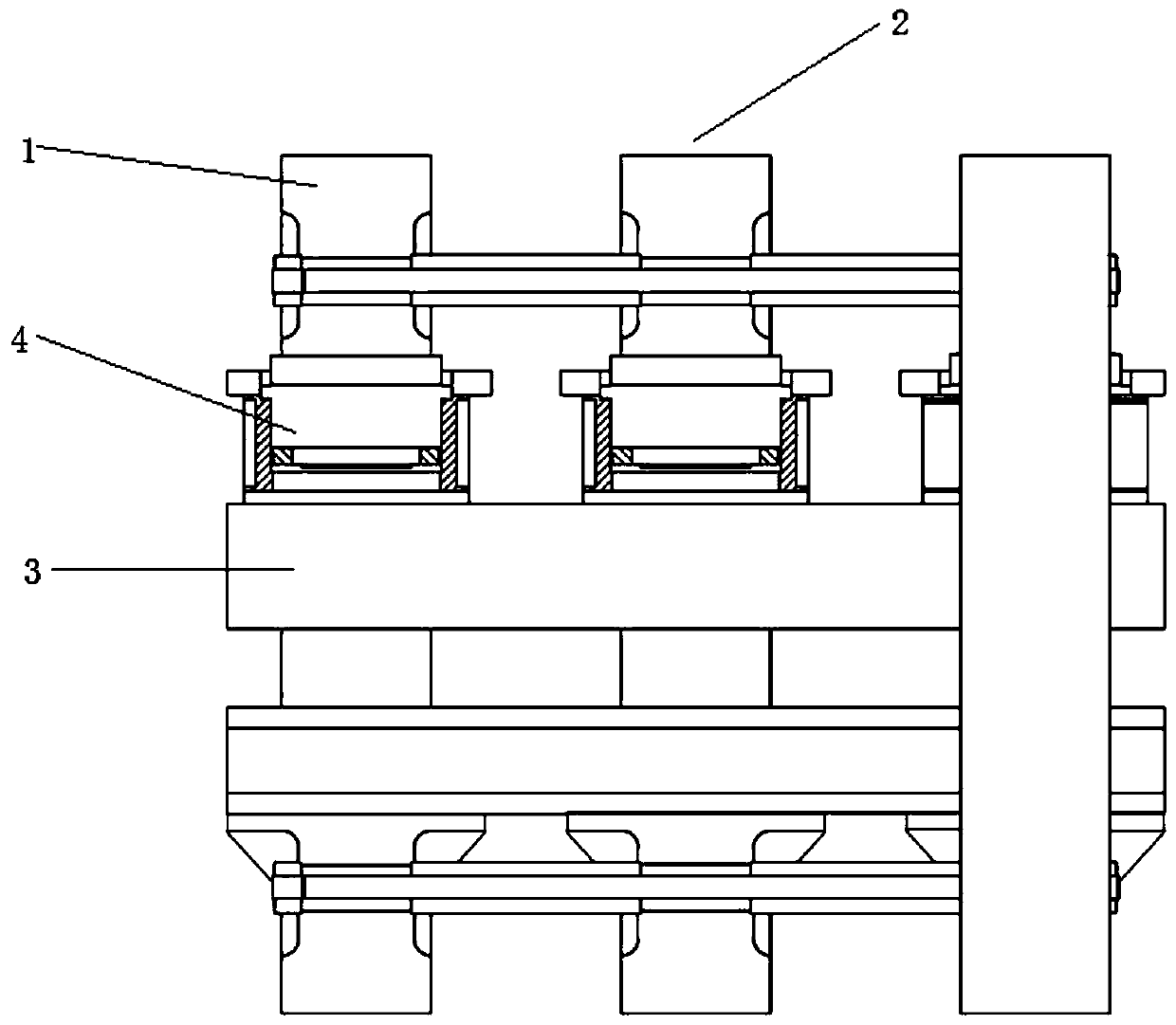

Die forging press

ActiveCN108160892AReduce weightEnsure balanceForging press detailsForging press drivesLoad resistanceMaster cylinder

The embodiment of the invention provides a die forging press. The die forging press includes a rack and an integrally formed movable girder, wherein multiple housings are parallelly arranged and fixedly connected with one another to form the rack, each housing includes a main cylinder, a column piston of each main cylinder is fixedly connected to the corresponding housing, the cylinder bottom of each main cylinder is connected to the upper surface of the movable girder, and all main cylinders are movable oil cylinders and are linearly distributed. By means of the integrally formed movable girder and the rack formed by parallelly arranging and fixedly connecting the housings, the demanded length of the movable girder for production of long-shaft type components is achieved, and since each main cylinder is the movable oil cylinder, a great guiding effect is ensured, so that the unbalance loading resistance of the die fording press is improved, and the service life is prolonged. Additionally, instead of being distributed in a two-dimensional mode in the traditional sense, the main cylinders are distributed linearly, and therefore the position of each main cylinder can be quickly adjusted to ensure the balance of the movable girder. Thus, inclination of the movable girder and other phenomena caused by unbalanced stress during machining is avoided, and the quality uniformity of forging pieces is guaranteed.

Owner:TSINGHUA UNIV

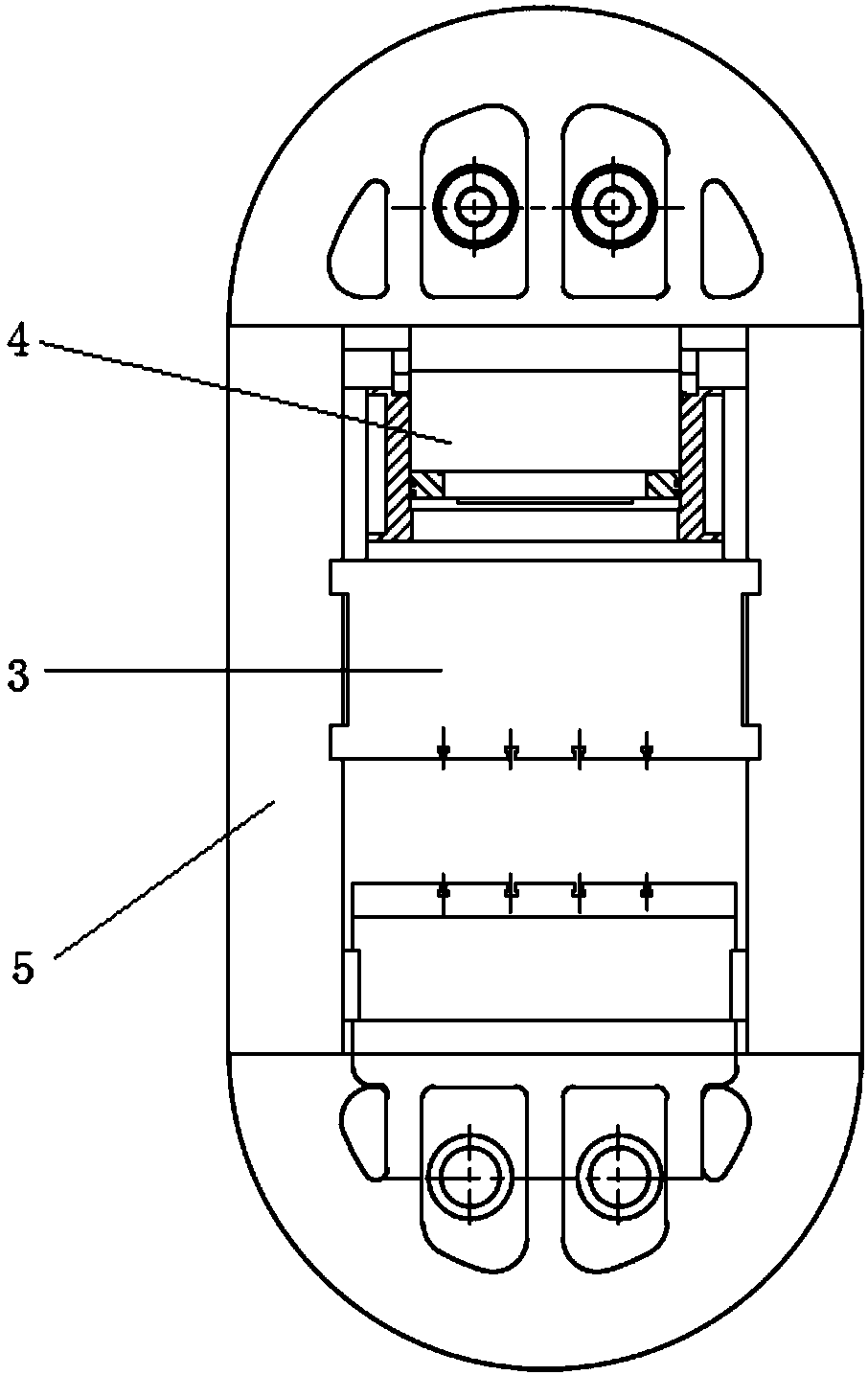

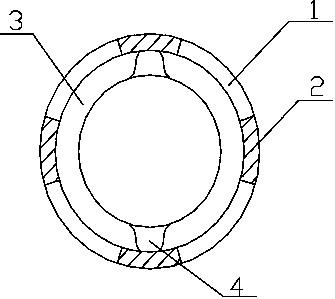

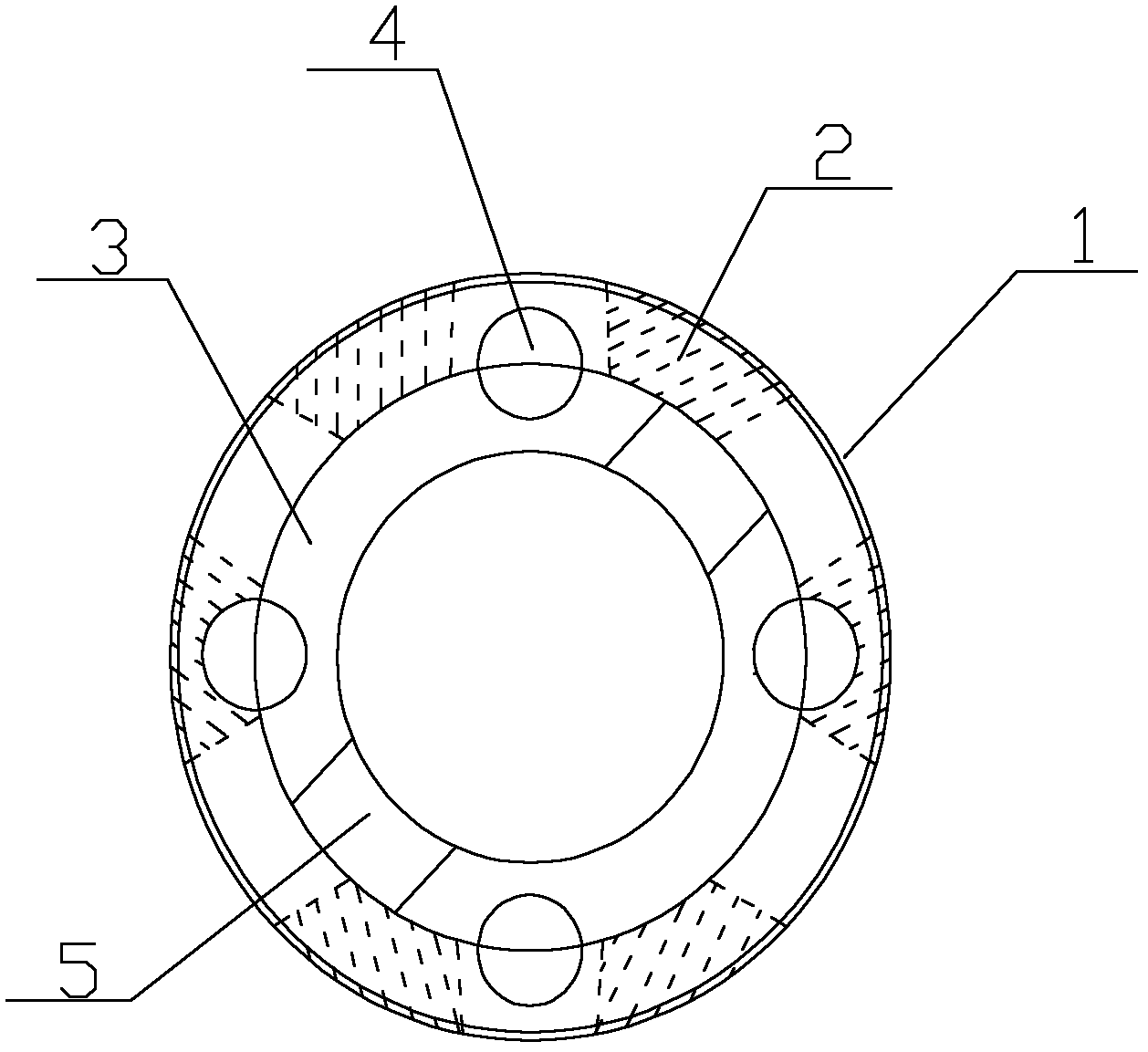

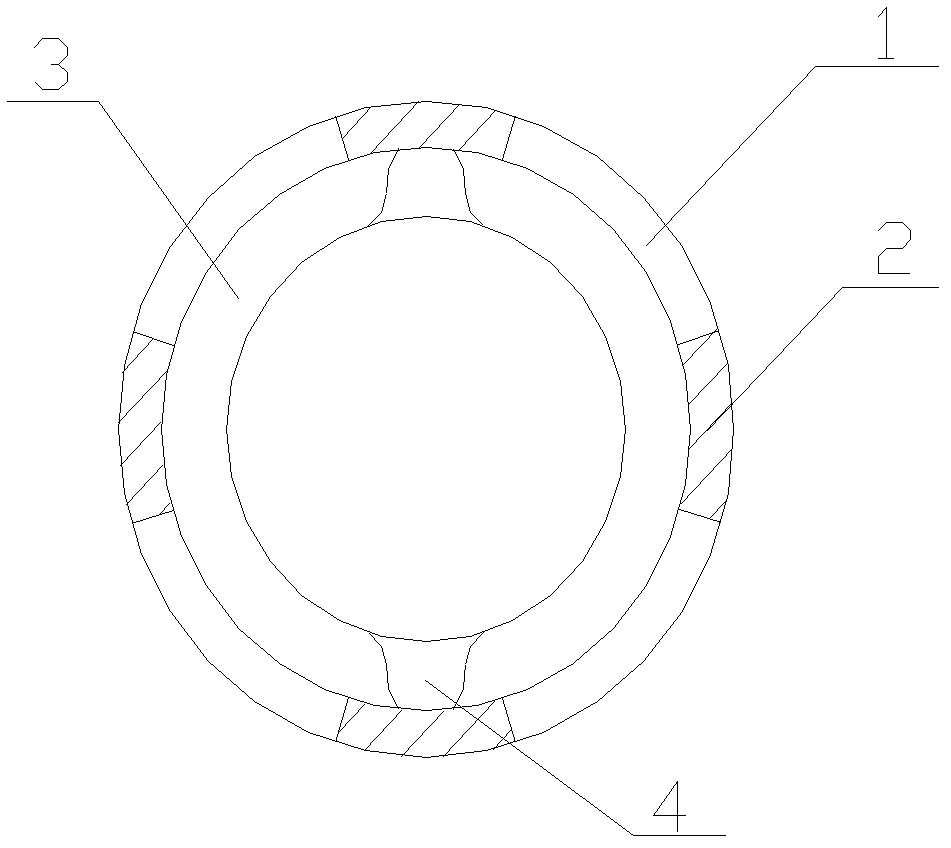

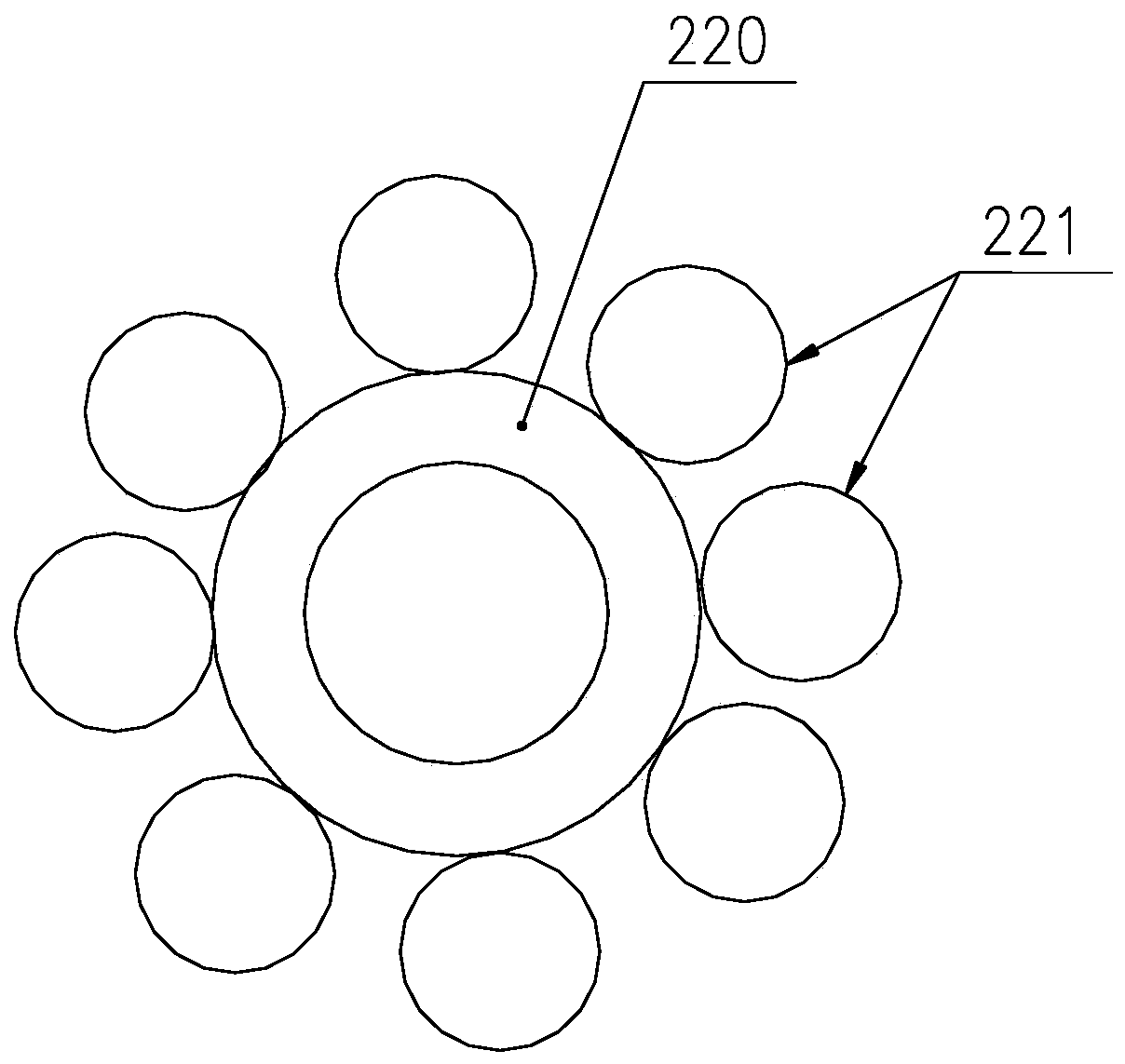

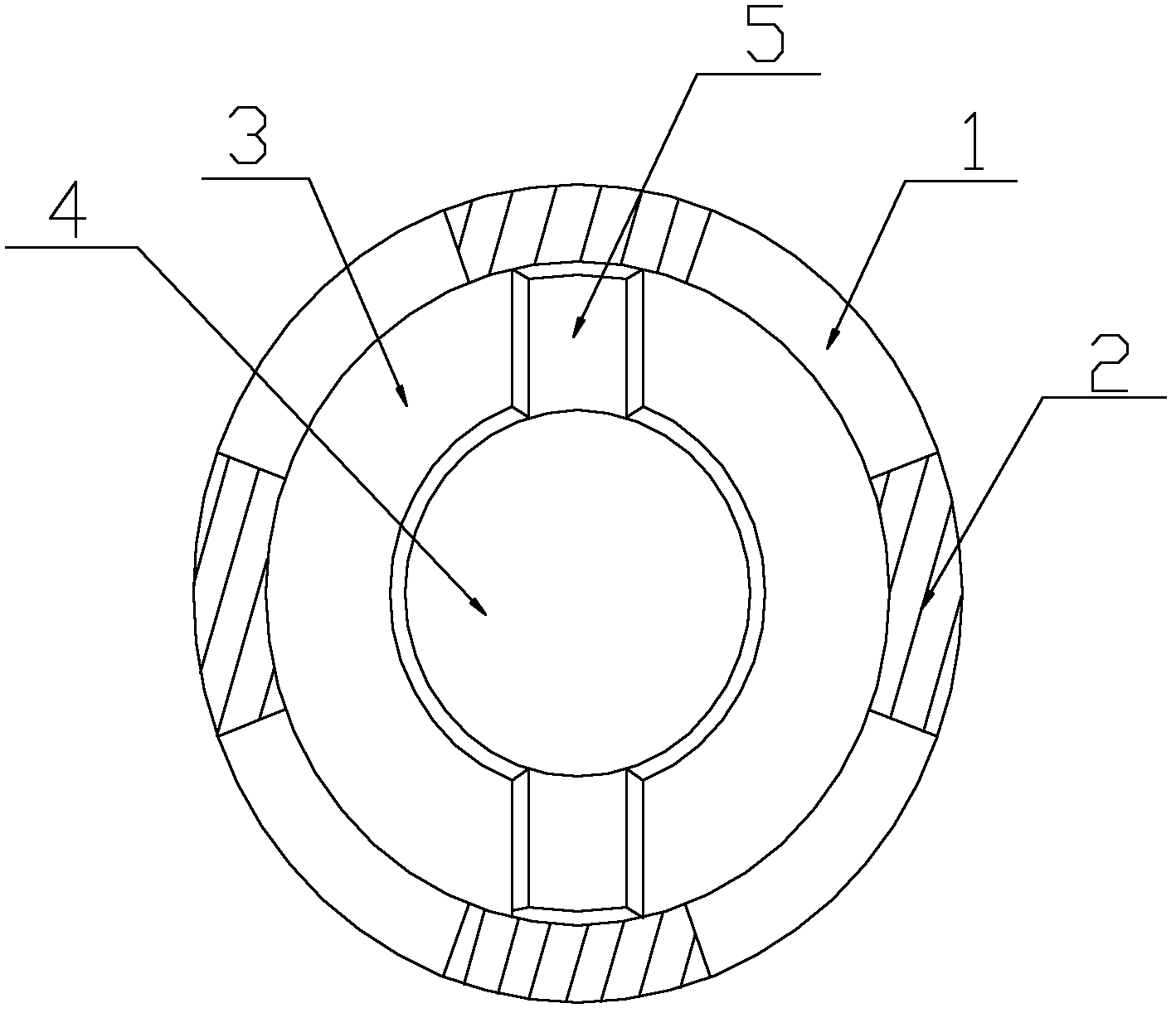

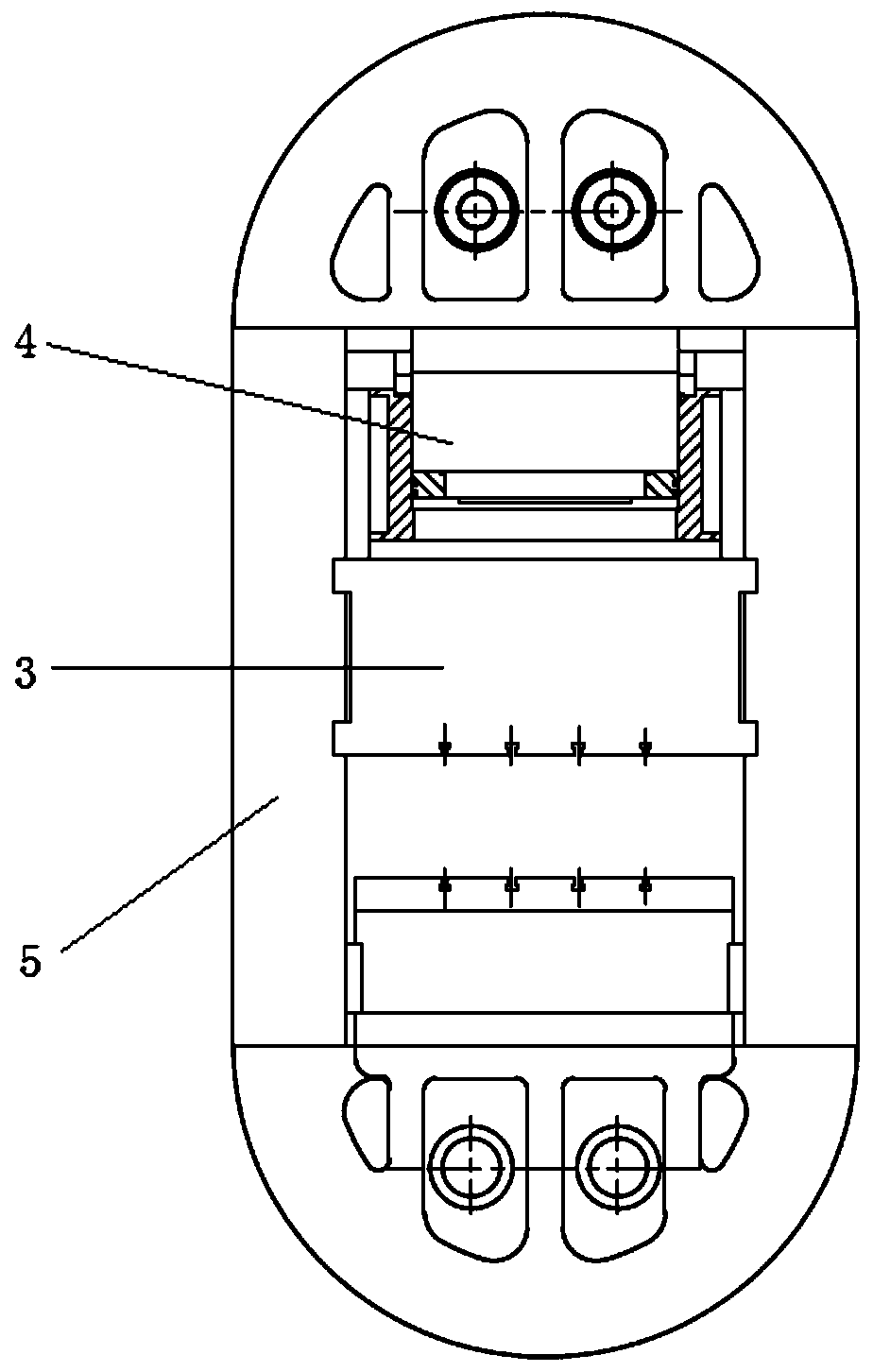

Magnet ring based on micro motor rotor

InactiveCN108808908AGuaranteed concentricityGuaranteed quality uniformityMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsNylon 6Electrical polarity

The invention discloses a magnet ring based on a micro motor rotor; the magnet ring comprises a magnet ring body and at least two pairs of arc-shaped magnet sections; the magnet ring body is an integrated structure formed by a magnetic material via injection moulding; the magnet sections are embedded in the magnet ring body, and evenly arranged in the magnet ring body with their polarities mutually inverted; the top surface, facing the inner wall of the magnet ring body, of the magnet ring body is connected with an end face, and two grooves are peripherally divided on the end face; the magnetring body is the integrated structure formed by a ferrite magnetic powder, a poly1, 9-subnonyl terephthalamide, a Polylaurolactam, a nylon 6 / clay nanocomposite and an oleic acid via injection moulding. The one time moulding multi-pole magnet ring can ensure the magnet ring concentricity and mass uniformity, and can simultaneously minimize the whole machine weight, so the motor can be higher in work efficiency, lower in noises, higher in an operation frequency, and large in a pull-out torque, thus fundamentally greatly improving the motor quality, and obtaining great technical progress.

Owner:XUZHOU XINLONG ELECTRONIC TECH CO LTD

Multipole magnetic ring

InactiveCN103138415AGuaranteed concentricityGuaranteed quality uniformityMagnetic circuit shape/form/constructionElectrical polarityMicromotor

The invention relates to the technical field of micromotors, in particular to a multipole magnetic ring. The multipole magnetic ring comprises a magnetic ring body and at least two pairs of circular arc-shaped magnetic sections, wherein the magnetic ring body has an integral structure which is made of magnetic materials by injection molding, the magnetic sections are embedded inside the magnetic ring body, and the magnetic sections are arranged evenly inside the magnetic ring body according to mutually-reversed polarities. A first step is arranged on one side, facing towards the inner wall of the magnetic ring body, of the upper surface of the magnetic ring body, four circular holes are formed in a whole surface where the upper surface of the magnetic ring body and the surface of the first step are connected, wherein a circumference where the four circular holes are located is evenly divided by the four circular holes, and centers of the circular holes are located on a common boundary where the upper surface and the surface of the first step are connected. Two first grooves arranged oppositely are formed in the surface of the first step, a second step is arranged on one side, facing towards the inner wall of the magnetic ring body, of the bottom surface of the magnetic ring body, and second grooves are formed in the second step. The magnetic ring is made of the magnetic materials by once-forming, so that concentricity and mass uniformity of the magnetic ring are guaranteed, and meanwhile, at least two magnetic sections are embedded when the magnetic ring is formed, so that the formed magnetic ring is enabled to have multipole magnetic fields.

Owner:陈朝辉

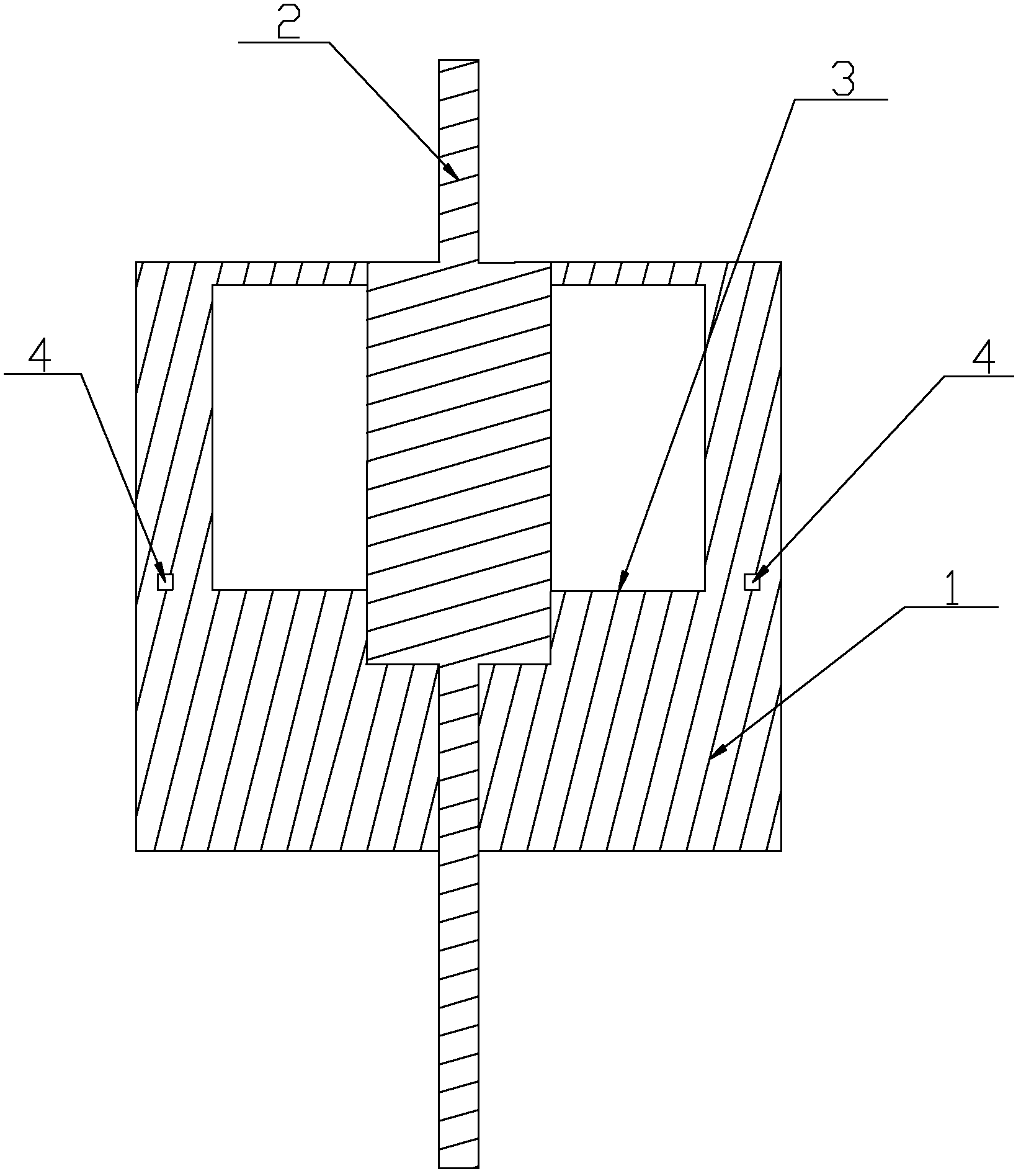

Micromotor rotor

InactiveCN103138443AGuaranteed concentricityGuaranteed quality uniformityMagnetic circuit rotating partsMagnetic polesElectrical polarity

The invention relates to the technical field of motors and particularly relates to a micromotor rotor. The micromotor rotor comprises a plastic magnet ring and a rotating shaft, wherein the plastic magnet ring is subjected to integrated injection molding, the rotating shaft is embedded inside the magnet ring, the magnet ring is an integrated structure formed by injection molding of magnetic materials, a plurality of magnetic poles are injected on the surface of the magnetic ring, magnetic poles are uniformly arranged inside the body of the magnet ring in the sequence of reversed polarities, an end face is connected inside the magnet ring, two round holes which are arranged oppositely are arranged on the end face, and a reinforcing rib is arranged from the position of the rotating shaft on the upper portion of the end face to the position of the inner wall of the magnet ring. The rotor is formed once with magnetic materials, the rotating shaft serves as an insert during once molding, the concentricity of the rotor and the uniformity of the quality can be guaranteed, and simultaneously, the plurality of magnetic poles are injected at the same time of molding, so that the produced magnet rotor is provided with a multipole magnetic field.

Owner:陈朝辉

Magnetic ring for micromotor rotor

InactiveCN103138432AGuaranteed concentricityGuaranteed quality uniformityMagnetic circuit rotating partsElectrical polarityMicromotor

The invention relates to a motor industry, in particular to a magnetic ring for a micromotor rotor. The magnetic ring for the micromotor rotor comprises a magnetic ring body and at least two pairs of circular arc-shaped magnetic sections. The magnetic ring body with an integrated structure is formed by magnetic materials in an injection molding mode. The magnetic sections are embedded inside the magnetic ring body, and are evenly arrayed inside the magnetic ring body according in a mutually reversed polarity mode. One end surface is connected with one side, facing towards an inner wall of the magnetic ring body, of an upper surface of the magnetic ring body, two grooves with equant circumferences are arranged on the end surface. Due to the fact that the magnetic ring for the micromotor rotor is a multiple-electrode magnetic ring molded by magnetic materials once, concentricity of the magnetic ring and homogeneity of quality are guaranteed, and when the magnetic ring is molded, at least two pairs of magnetic sections are embedded inside the magnetic ring body so that the magnetic ring has a multiple-electrode magnetic field.

Owner:陈朝辉

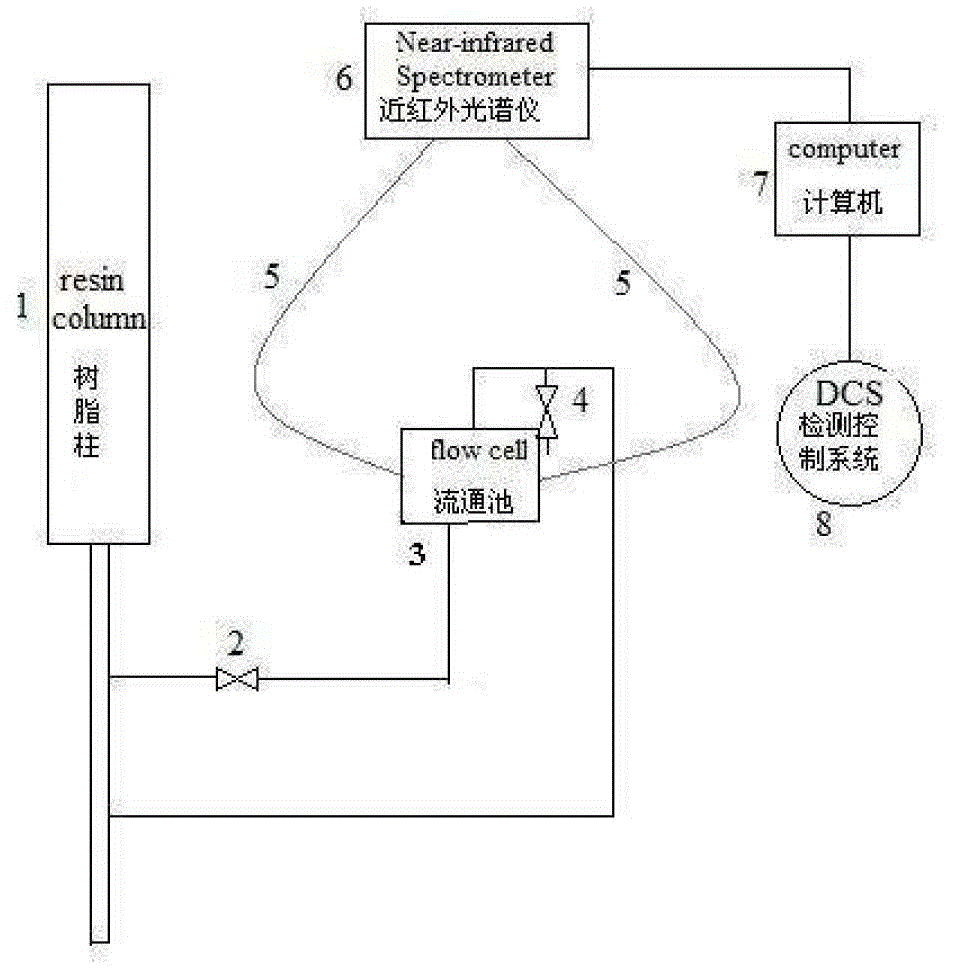

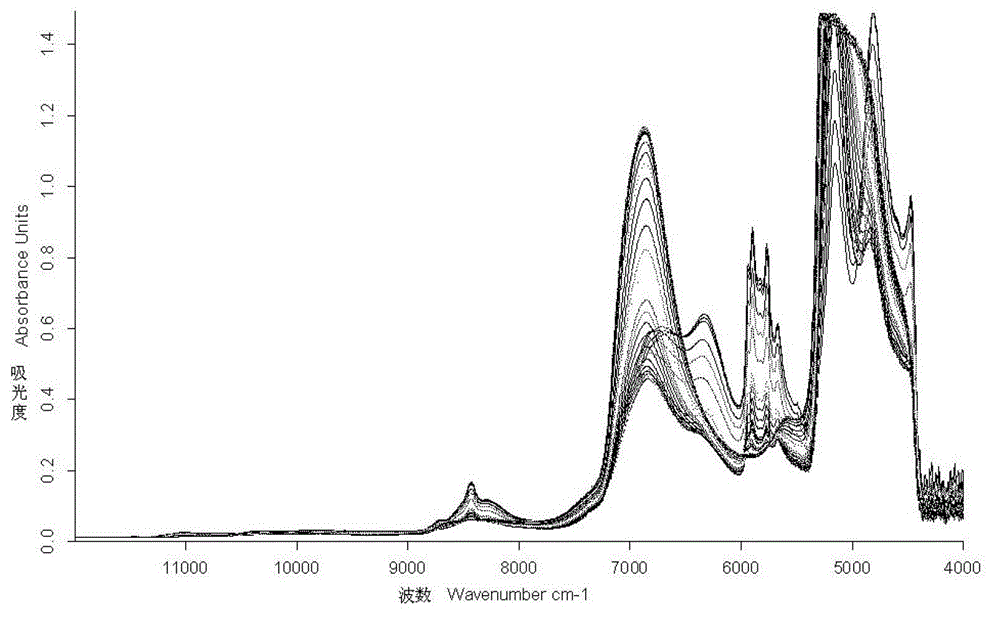

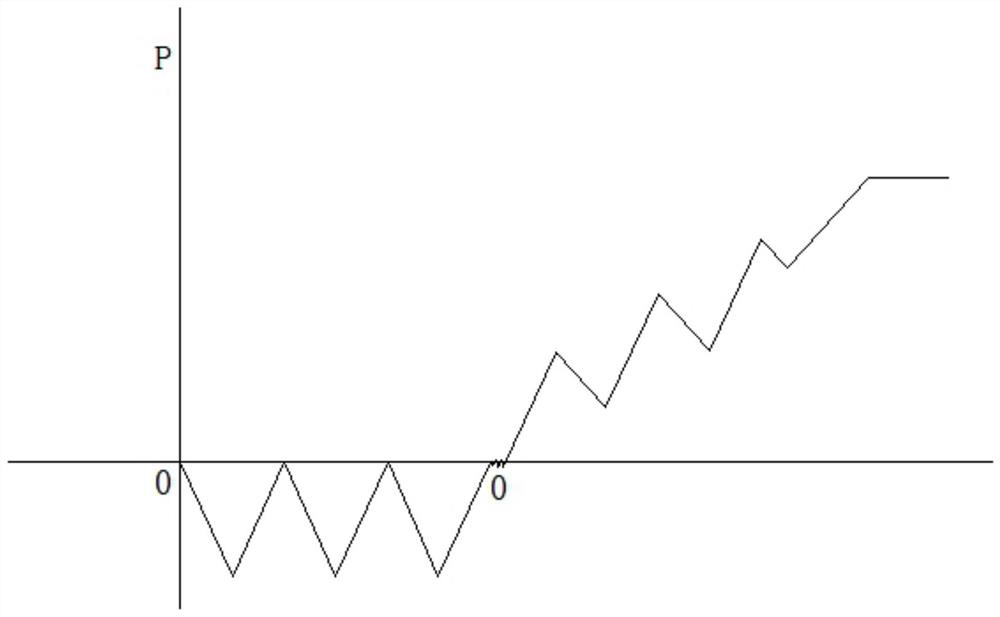

Automatic judgment and control for eluant receiving of buckeye extract

ActiveCN103203123BGuaranteed quality uniformityEnsure quality stabilitySolid sorbent liquid separationColor/spectral properties measurementsAutomatic controlEngineering

The invention provides an automatic detection and control method of elusion start points and end points during macroporous resin purification of buckeye extract. An aescin macroporous resin purification near-infrared calibration model is built by using total content of aescin as evaluation index, the calibration model is used in online detection of buckeye extract macroporous resin elusion, and accordingly automatic judgment of elusion start points and end points during macroporous resin purification of buckeye extract is achieved, and automatic control of eluant receiving and receiving stopping is achieved. The method is fast, accurate, high in automation level and the like, manual errors are reduced, the problem that products of different batches are poor in quality uniformity is solved, effective component loss and waste can be avoided effectively, and a new technique is provided for automatic control and process quality control during macroporous resin purification of buckeye extract.

Owner:SHANDONG LUYE PHARMA CO LTD

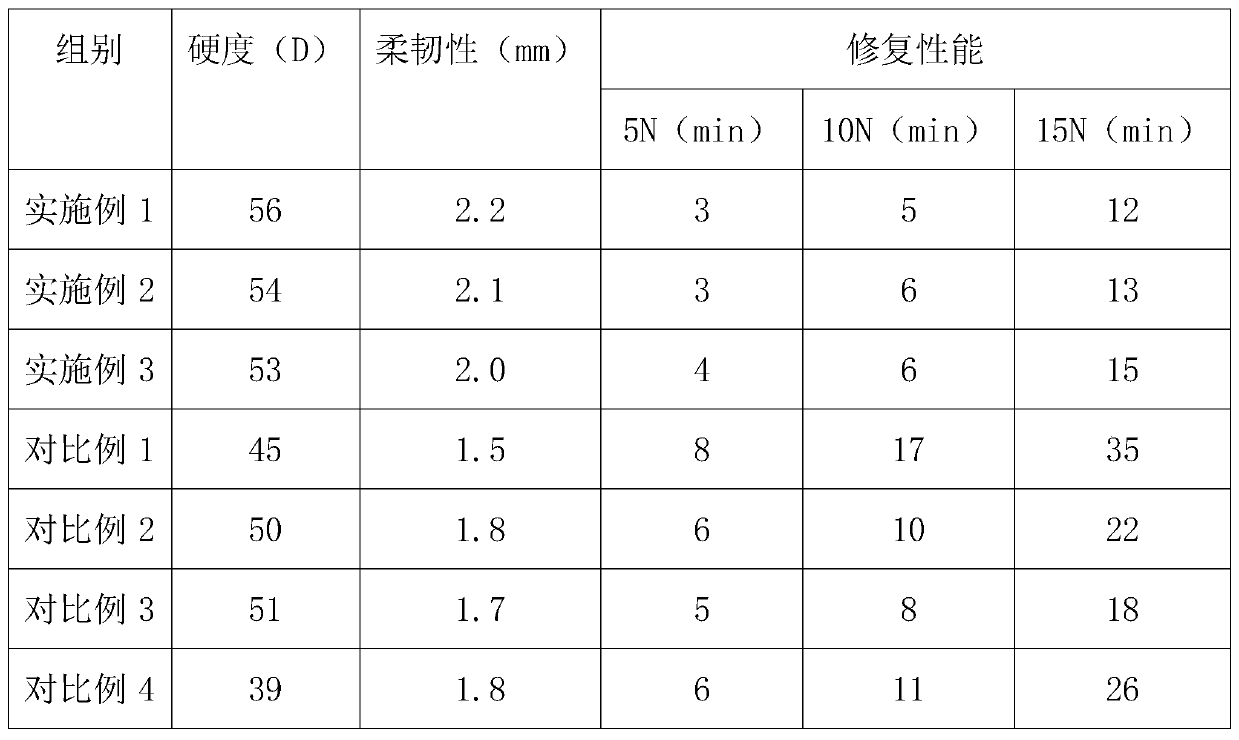

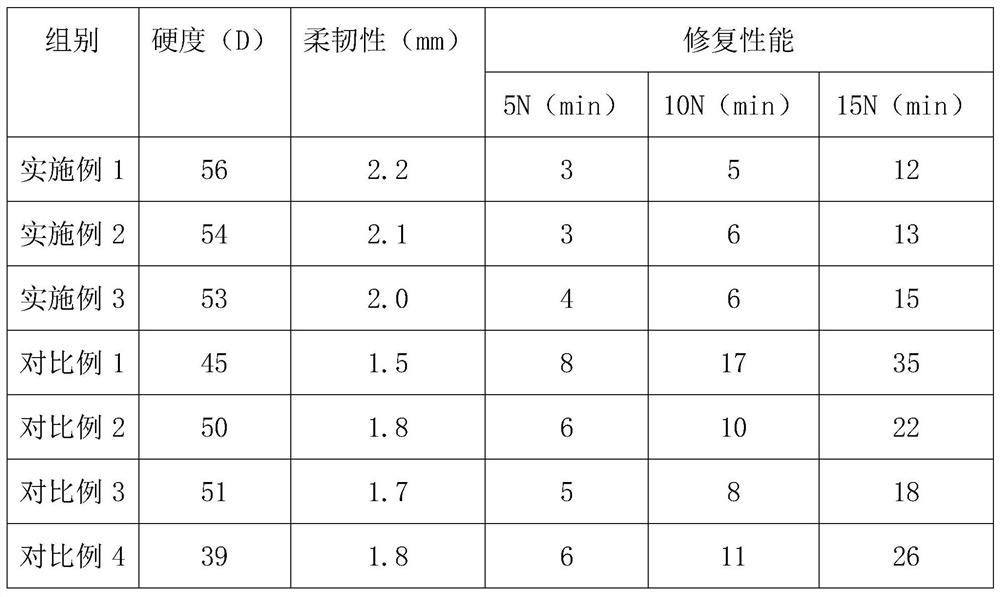

Automobile paint cleaning and repair agent and preparation method thereof

ActiveCN110106032ASave repair cost and construction costGuaranteed quality uniformityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsDimethyl formamideWax removal

The invention discloses an automobile paint cleaning and repair agent and a preparation method thereof. The cleaning and repair agent is prepared from fatty alcohol-polyoxyethylene ether as a non-ionic surface active agent, diglycolamide oleate borate as a corrosion-inhibition repair agent, sodium alga acid as an excipient, xylene as a wax removal agent, dimethyl formamide as a purifying agent, simethicone as a defoaming agent, a diluent composed of multiple organic solvents and independently developed self-repair filler through mixing, stirring, vacuum defoamation and stirring. After the cleaning and repair agent is sprayed on scratches of an automobile, automobile paint is not damaged, the cleaning and repair agent is compatible with automobile surface varnish, after scratch pits are automatically filled with the automobile paint cleaning and repair agent and the automobile paint cleaning and repair agent is leveled to form a film, obvious stains and scratches cannot be seen by the eyes, the automobile paint is not damaged, one-time cleaning and repair of the automobile paint are completed, and the automobile scratch repair cost and the construction cost are saved.

Owner:陈丽瑜

A kind of preparation method of high performance samarium cobalt permanent magnet material

ActiveCN106328366BReduce participationReduce distractionsInductances/transformers/magnets manufactureMagnetic materialsSolution treatmentSolid solution

The invention discloses a preparation method of a high-performance samarium-cobalt permanent magnetic material. The method at least comprises one of the following steps: raw material preparation, smelting, pulverization, orienting compression, sintering and aging treatment; sintering is that degassing dedusting, pre-sintering, vacuum sintering, protective atmosphere sintering and solution treatment are sequentially carried out on a blank which is obtained by orienting compression; and pre-sintering is pre-sintering at 1050-1180 DEG C for 20-30 minutes. A high-temperature sintering zone is formed by selecting and controlling different vacuum degrees and temperatures in the sintering process of a sintering method in the scheme, a high-vacuum, high-heat and constant-temperature sintering process is formed and a single-phase uniform solid solution samarium-cobalt permanent magnet blank is obtained, so that the quality of a permanent magnet product is improved, the production benefits of a sintering furnace are improved and the yield of the product is improved by 30%.

Owner:NINGBO NINGGANG PERMANENT MAGNETIC MATERIALS

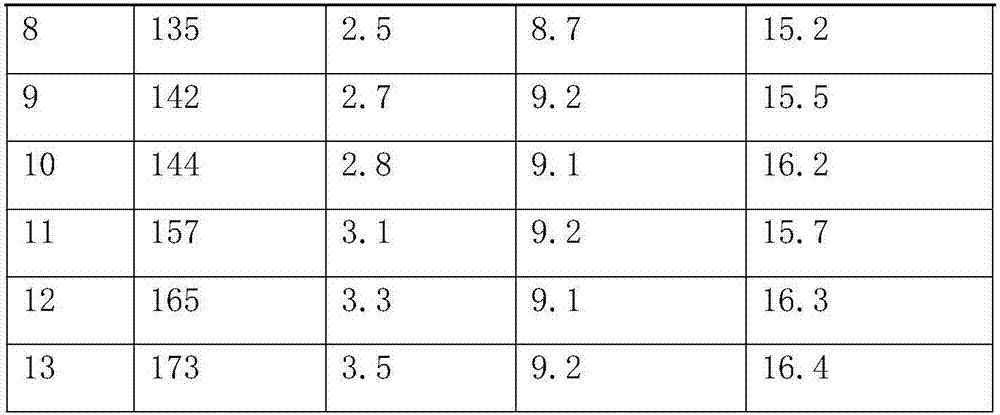

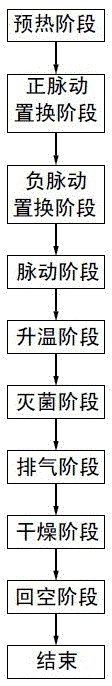

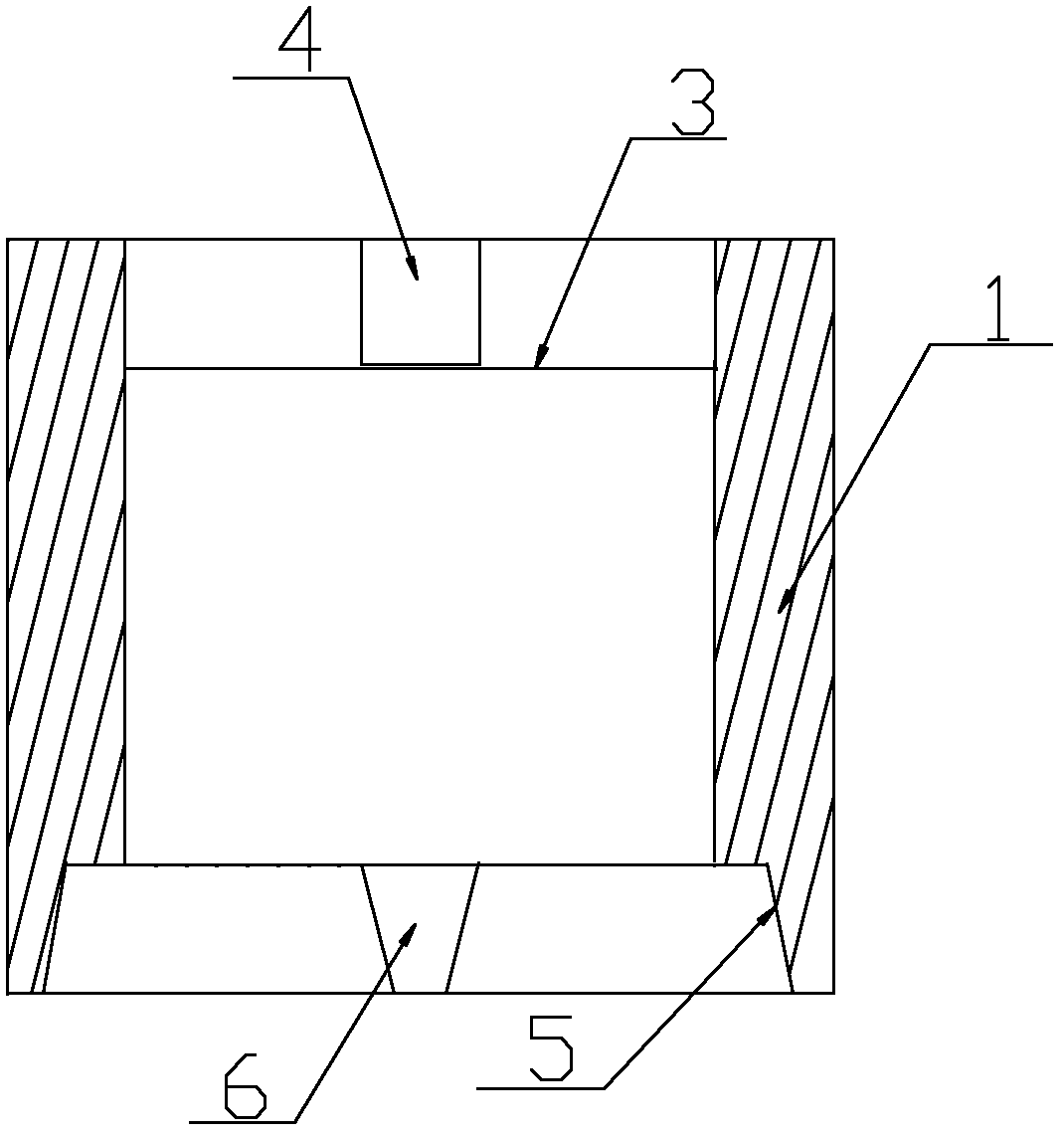

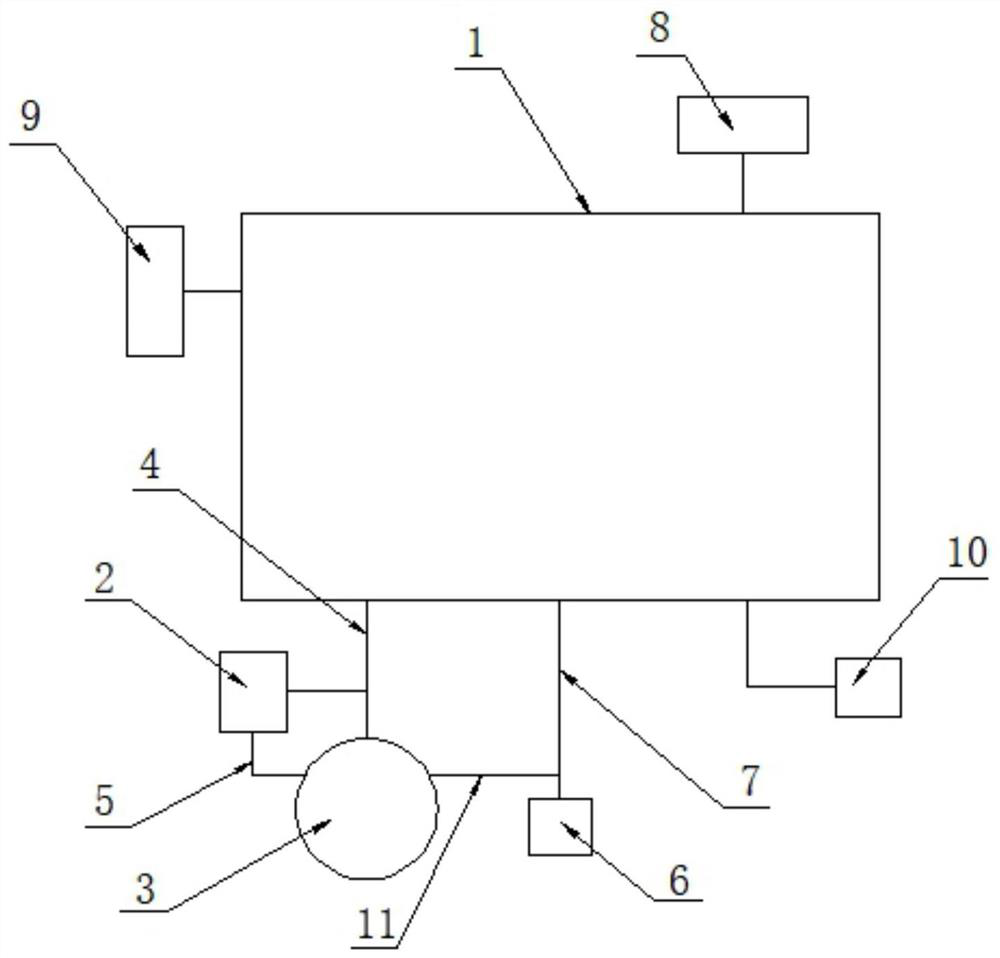

A kind of sterilization method of steam sterilizer and steam sterilizer

ActiveCN104083781BEfficient sterilizationRapid sterilizationHeatProcess engineeringSteam sterilizers

The invention discloses a sterilization method of a steam sterilizer and the steam sterilizer. The steam sterilizer comprises a sterilization cavity (6), an interlayer (7), and an injector vacuumizing unit, and is characterized by also comprising a sterilization cavity interlayer air inlet unit, a sterilization cavity air return unit, a sterilization cavity drainage unit, a sterilization cavity vacuumizing unit, an interlayer steam inlet unit and an interlayer drainage unit. The sterilization method comprises the specific sterilization steps: 1, preheating; 2, performing positive pulse replacement; 3, performing negative pulse replacement; 4, pulsing; 5, raising the temperature; 6, sterilizing; 7, exhausting; 8, drying; 9, returning air; and 10, ending. According to the sterilization method disclosed by the invention, rapid and high-efficiency sterilization can be realized through the steam sterilizer with a water injector.

Owner:SHINVA MEDICAL INSTR CO LTD

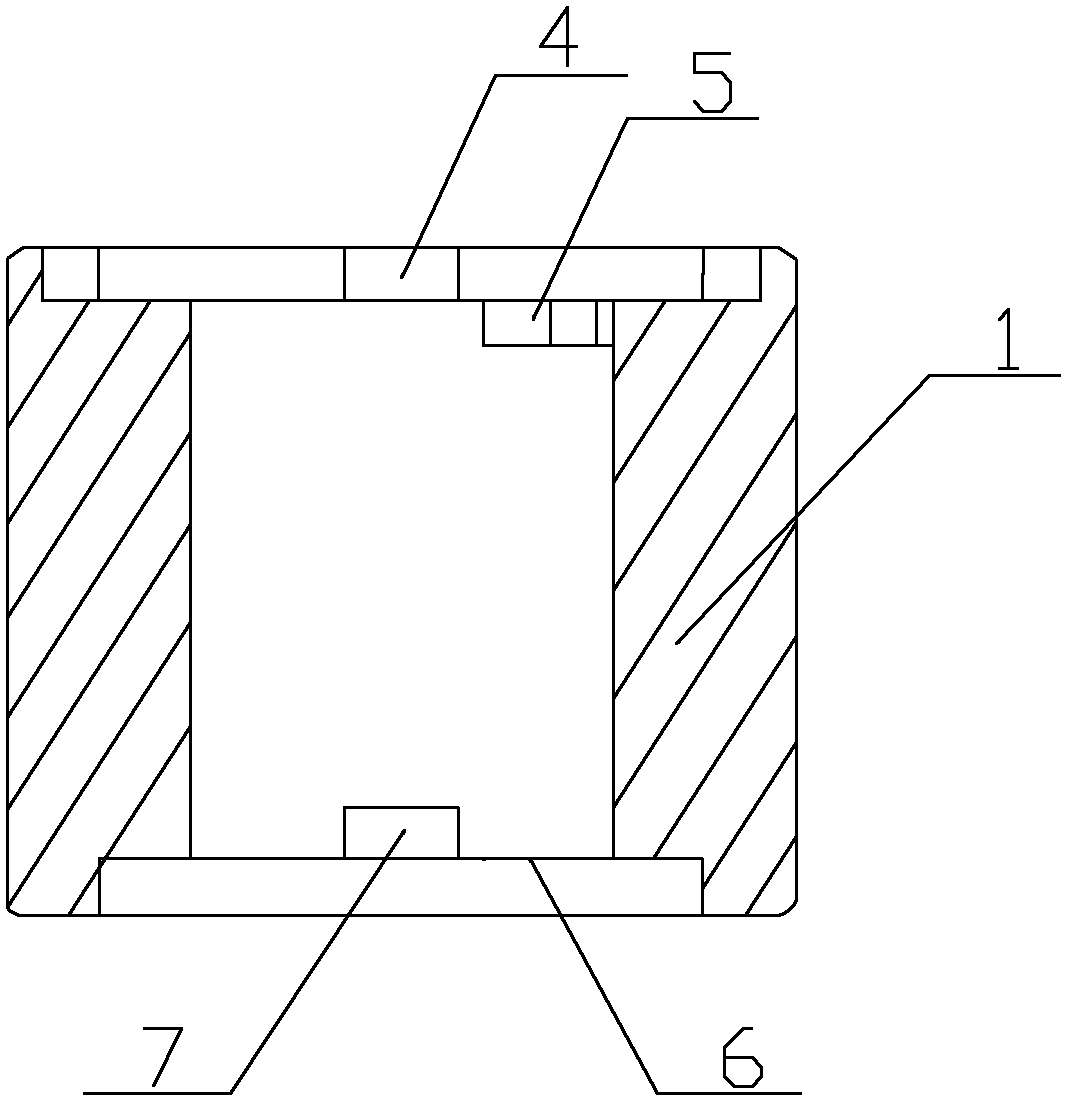

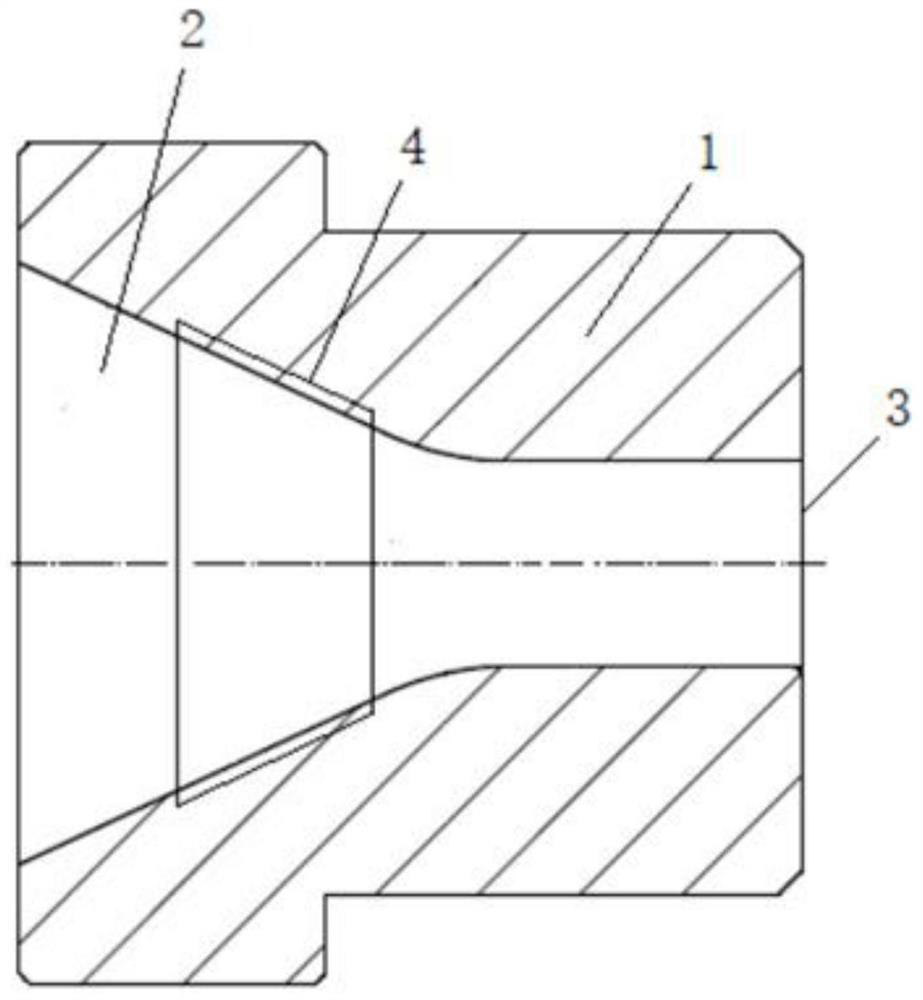

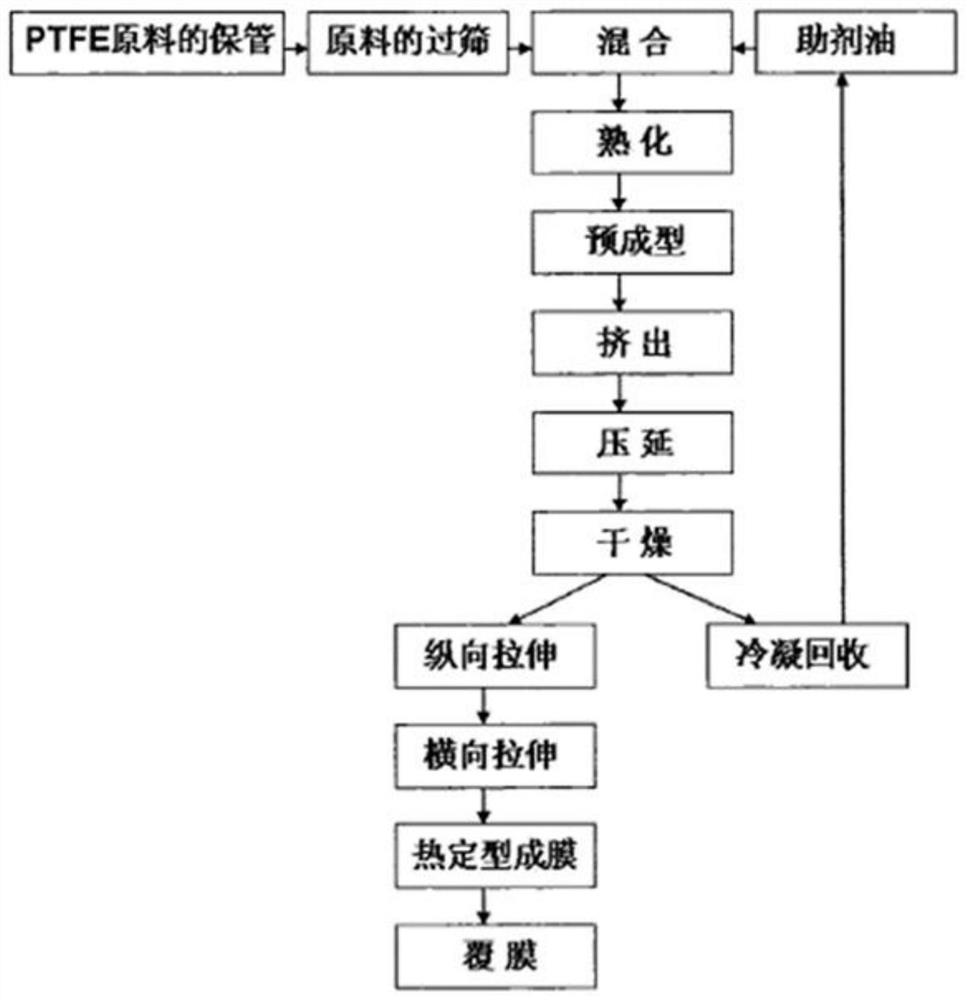

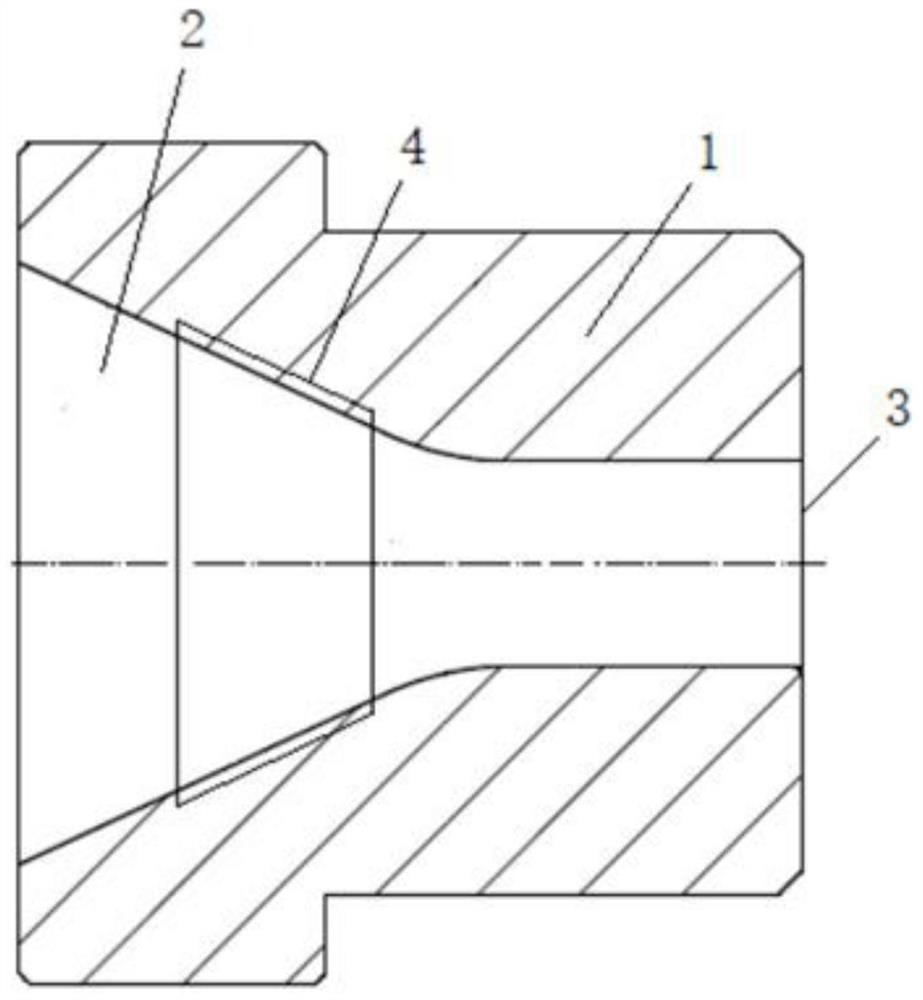

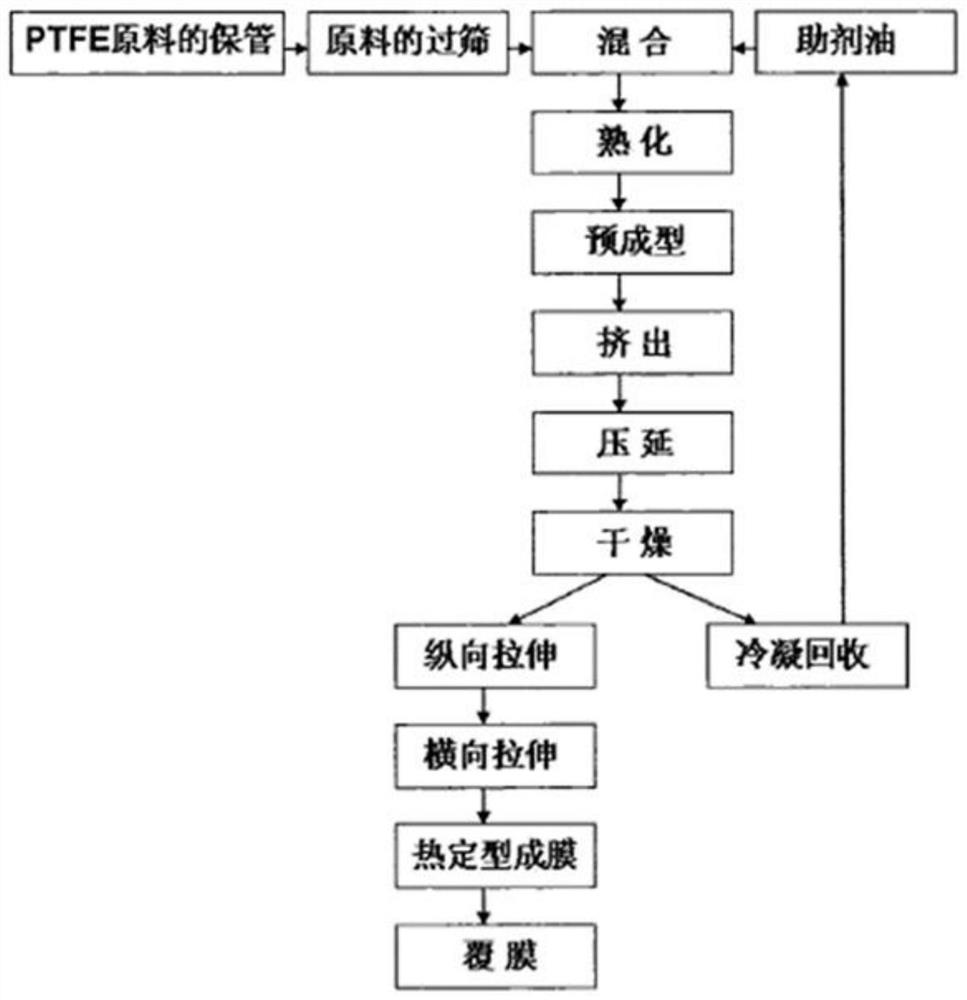

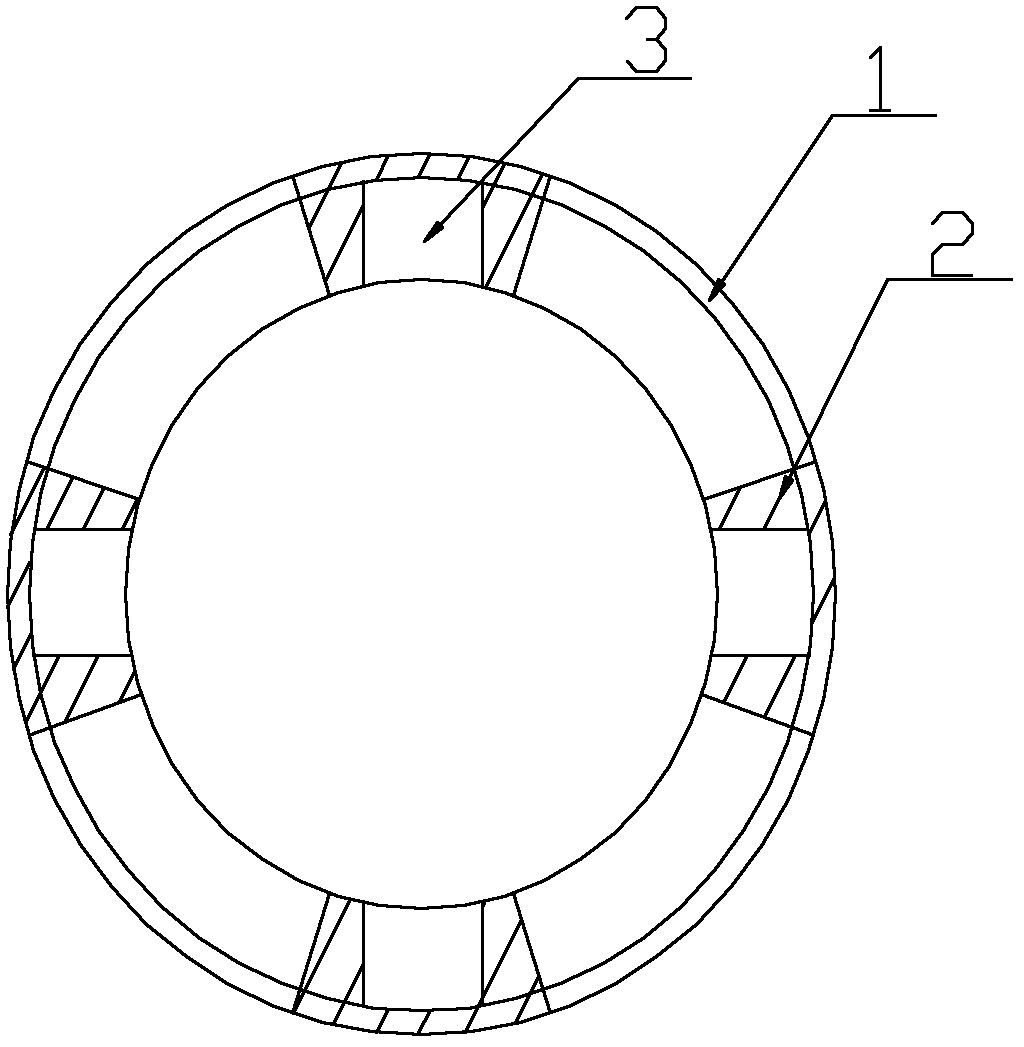

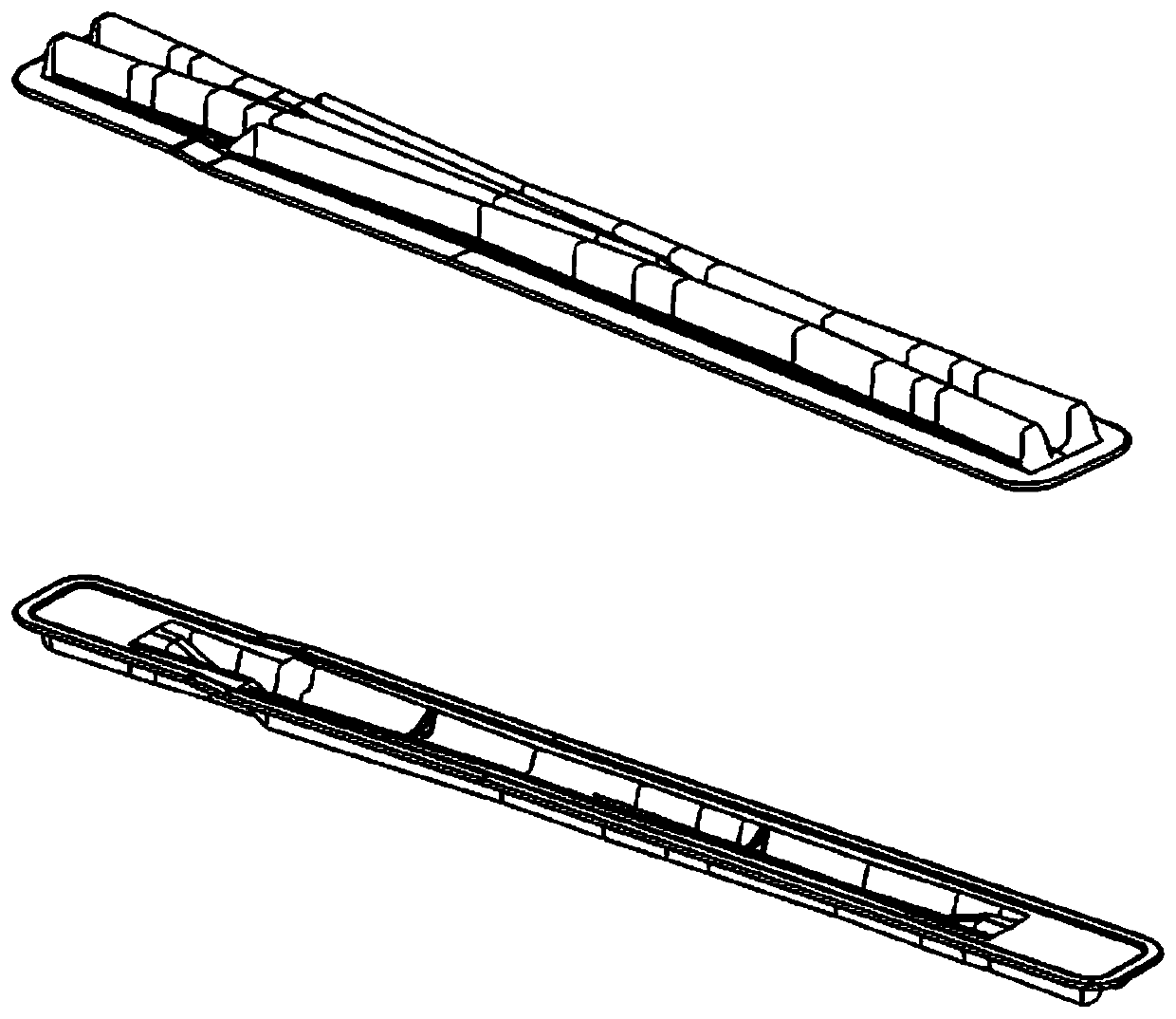

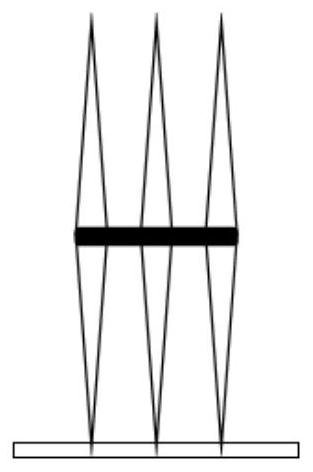

Extrusion die for screw thread inner wall and method of improving fibrosis degree of thin film charge bar

ActiveCN111805869AIncreased shear frictionHigh degree of fibrosisFlat articlesFiberMechanical stability

The invention provides an extrusion die for screw thread inner walls and a method of improving fibrosis degree of thin film charge bars. The extrusion die comprises a die body, wherein a conical holecavity and an extrusion hole are arranged in the die body. A small diameter end of the conical hole cavity is communicated with the extrusion hole, and screw threads are arranged on the inner wall ofthe conical hole cavity. According to the extrusion die for the screw thread inner walls, the screw threads are arranged on the inner wall of the conical hole cavity, the shear friction between powderparticles and the inner wall of the die can be effectively improved in the process of plunger type extrusion of PTFE, so that the fibrosis degree of the charge bars is significantly improved. And dueto a guiding role of the screw thread, the action direction of the shear force is always parallel to the direction of the screw thread, corresponding generated micro fiber will orient along the direction of the screw thread, and fibrosis direction is more accurate, therefore the quality uniformity and mechanical stability of the final produced PTFE thin film are ensured. The CV value of the thickness uniformity of the PTFE thin film produced by general mold is 30-50%, while the thickness uniformity CV value of the PTFE thin film prepared by the extrusion die for the screw thread inner wallsand the method of improving fibrosis degree of the thin film charge bars can reach less than 10%.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

A threaded inner wall extrusion die and a method for improving the degree of fiberization of film rods

ActiveCN111805869BIncreased shear frictionHigh degree of fibrosisFlat articlesThin membraneMechanical stability

The present invention proposes a threaded inner wall extrusion die and a method for improving the degree of fibrosis of a film material rod. The holes are connected, and the inner wall of the cone cavity is provided with threads. The invention can effectively improve the shear friction between the powder particles and the inner wall of the mold during the plunger pushing process of PTFE by providing threads on the inner wall of the cone cavity, so that the degree of fibrosis of the rod can be significantly improved. And due to the guiding effect of the thread, the direction of the shear force is always parallel to the direction of the thread, and the corresponding microfibers will be oriented along the direction of the thread, and the fiberization direction is more accurate, ensuring that the final produced Quality uniformity and mechanical stability of PTFE film, the polytetrafluoroethylene film of general mold production, the CV value of its thickness uniformity is at 30~50%, and adopt the PTFE film prepared by the present invention, the CV value of its thickness uniformity Can reach within 10%.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

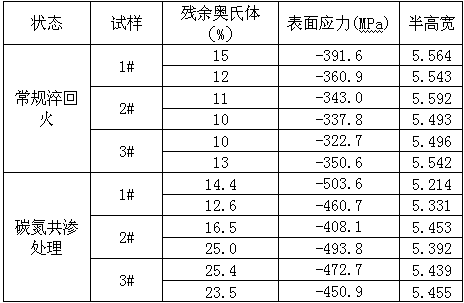

A kind of carbonitriding heat treatment process method

ActiveCN106637060BAdd depthAvoid defectsSolid state diffusion coatingFurnace typesCarbon potentialAlcohol

The invention discloses a carbonitriding heat treatment technique under a new atmosphere. The technique comprises the following steps that (a), a multi-purpose chamber furnace suitable for carburizing treatment is selected; (b), a nitrogen, methyl alcohol, ammonia gas and dimethylmethane carburizing medium is adopted, and an oxygen probe is adopted to control the carbon potential, so that control over the carbon potential of the atmosphere in the furnace is achieved; (c), according to a charging mode, charging layers are chosen according to the heights of workpieces, and gaps are kept between the workpieces of each layer to guarantee the uniformity of infiltration layers; (d), according to technological parameters, the carbonitriding temperature is 815 DEG C-825 DEG C, the carbon potential is 1.20%-1.30%, and strong infiltration is conducted for 3 h-3.5 h; in the diffusion period, the temperature is 815 DEG C-825 DEG C, the carbon potential is 1.10%-1.20%, and diffusion is conducted for 3 h-3.5 h; KR-218 fast bright quenching oil is used for quenching, and cooling is conducted for 8 min-15min; and air cooling is conducted after tempering; and (e), steel foil is used for carbon determination during strong infiltration of each furnace. According to the carbonitriding heat treatment technique under the new atmosphere, a carbonitriding layer with a certain depth can be obtained in a relatively short time, and higher hardness is achieved.

Owner:LUOYANG LYC BEARING

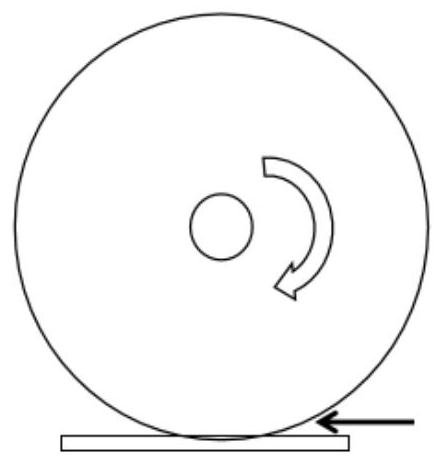

Equipment and method for continuous pickling of titanium and titanium alloy oil pipes

ActiveCN111501054BSimple structureLow costDirt cleaningCleaning using gasesProcess engineeringTitanium

The invention belongs to the field of manufacturing technology, and specifically discloses a device and method for continuous pickling of titanium and titanium alloy oil pipes, which have low safety risks and are beneficial to control the surface quality and size uniformity of oil pipe pickling. The equipment for continuous pickling of titanium and titanium alloy oil pipes includes an equipment box, an actuator, a circulation mechanism and an acid mist collection device. The equipment for continuous pickling of titanium and titanium alloy tubing can fix the tubing on the rotary shaft and drive it to rotate in the equipment box to complete the pickling, neutralization and cleaning steps, which is beneficial to ensure the surface quality and size of the tubing pickling Uniformity; at the same time, the acid liquid, neutralizing liquid and cleaning liquid are pumped separately, which can not only improve the pickling efficiency, but also reduce the labor intensity of workers and reduce the risk of corrosion damage; in addition, during the pickling process, the acid produced The mist can be pumped into the lye tank by the fan through the acid mist discharge hole for neutralization treatment, which avoids the risk of acid mist overflow and meets the environmental protection requirements.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Plant and method used for continuous acid washing of titanium and titanium alloy oil pipe

ActiveCN111501054ASimple structureLow costDirt cleaningCleaning using gasesProcess engineeringTitanium

The invention belongs to the manufacturing technical field and specifically discloses a plant and method used for continuous acid washing of a titanium and titanium alloy oil pipe, and the plant and method are low in safety risk and beneficial to control over the oil pipe acid washing surface quality and size uniformity. The plant used for continuous acid washing of the titanium and titanium alloyoil pipe comprises a plant box, an executive mechanism, a circulating mechanism and an acid mist collecting device. By the adoption of the plant used for continuous acid washing of the titanium and titanium alloy oil pipe, the oil pipe can be fixed to a rotation pipe shaft so as to be driven by a drive device to rotationally finish an acid washing step, a neutralizing step and a washing step in the plant box, and the oil pipe acid washing surface quality and size uniformity can be guaranteed; meanwhile, acid liquid, neutralizing liquid and washing liquid are pumped through pumps, acid washingefficiency can be improved, the labor intensity of workers is reduced, and corrosion harm risks are reduced; and in addition, in the acid washing process, generated acid mist can be exhausted by a draught fan through an acid mist exhausting hole into an alkali liquor barrel to be neutralized, the risk that the acid mist overflows is avoided, and the requirement for environment friendliness is met.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

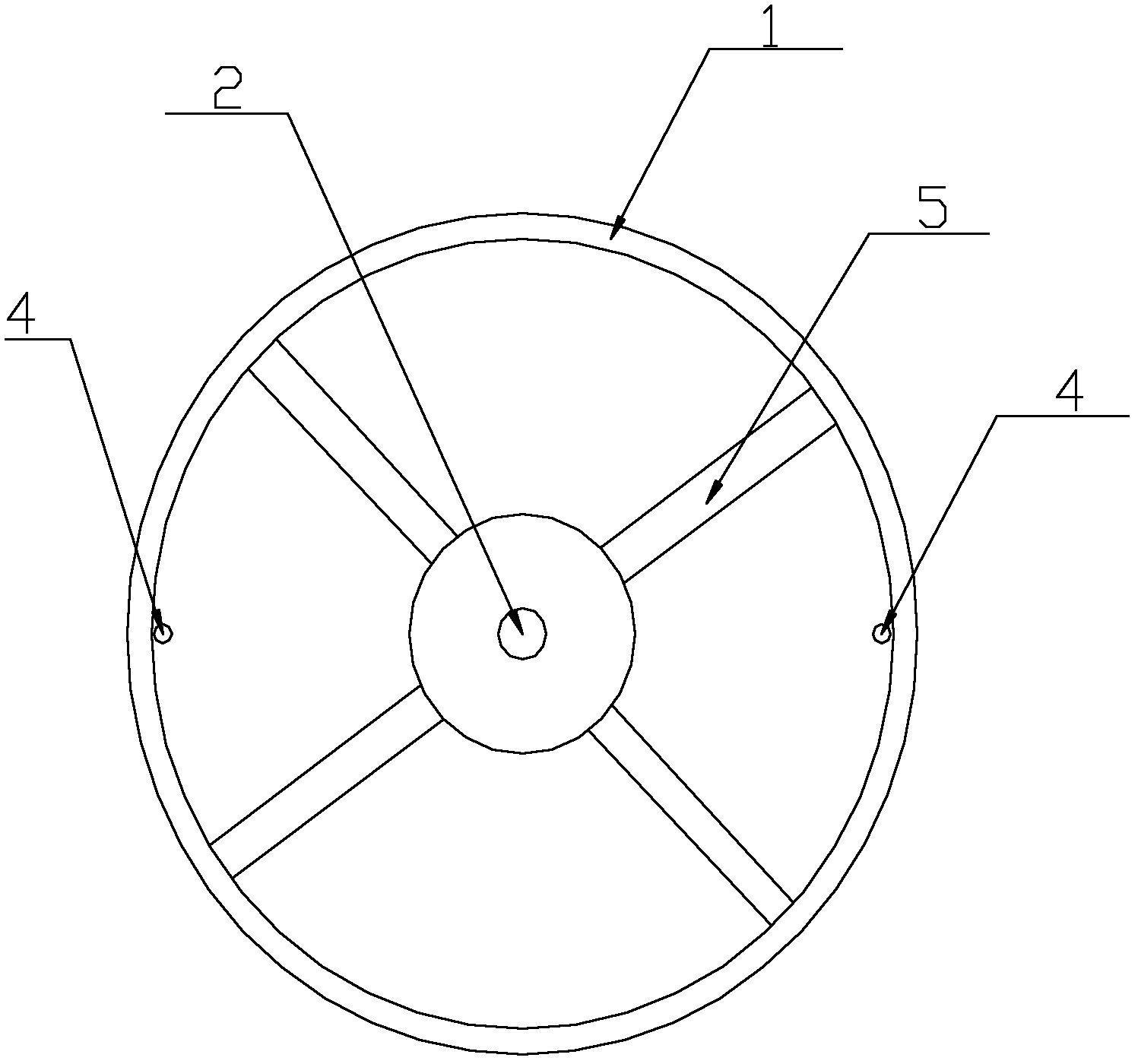

Magnet ring used for micro-motor

InactiveCN103138413AGuaranteed concentricityGuaranteed quality uniformityMagnetic circuit rotating partsPhysicsMicro motor

The invention relates to the technical field of micro-motors, in particular to a magnet ring used for the micro-motor. The magnet ring used for the micro-motor comprises a magnet ring body and at least two pairs of circular arc magnet sections. The magnet ring body is of an integrated structure and made of magnetic materials in an injection molding mode. The magnet sections are inlaid into the magnet ring body, and evenly arranged in the magnet ring body according to mutually reverse polarity. One end face is connected to one side, facing toward the inner wall of the magnet ring body, of the upper surface of the magnet ring body. Four protrusions are arranged on the end face, wherein a circumference is equally divided by the four protrusions. One inclined face is arranged one side, facing toward the inner wall of the magnet ring body, of the bottom face of the magnet ring body. Four circular-arc-shaped grooves are formed in the whole face which is formed by connection of the bottom face and the inclined face, and a circumference is equally divided by the four circular-arc-shaped grooves. The magnet ring is made of the magnetic materials in a once formed mode. Concentricity of the magnet ring and evenness of mass are guaranteed, the magnet ring is formed, and meanwhile the at least two pairs of the magnet sections are inlaid so that the magnet ring has multi-pole magnetic fields.

Owner:陈朝辉

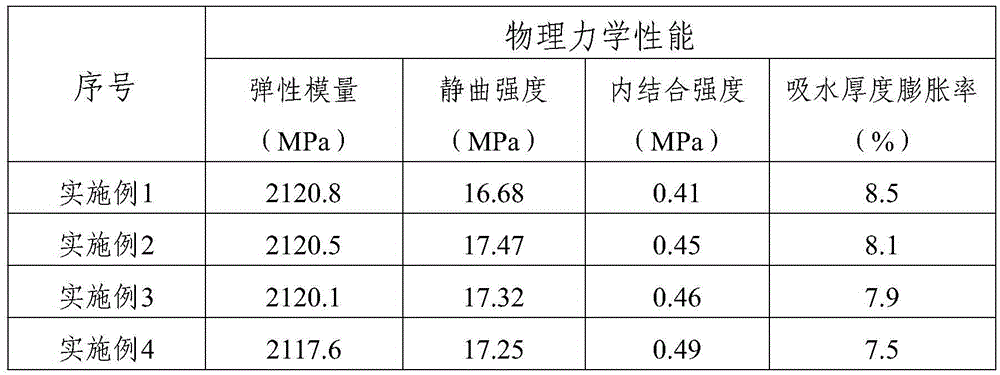

A kind of processing method of sorghum stalk particleboard

InactiveCN104029271BHigh fiber contentImprove physical and mechanical propertiesFlat articlesDomestic articlesEcological environmentMechanical property

The invention discloses a method for processing a sorghum stalk shaving board. The method includes the steps of preparing a raw material, sieving, flaking, drying, storing, stirring the material, entering a mold, hot pressing, checking, being put in storage and the like. The shaving board processed through the processing method has an excellent mechanical property, the static bending intensity is larger than or equal to 16 MPa, the elasticity modulus is larger than or equal to 2117 MPa, the inner bonding strength is larger than or equal to 0.4 MPa, the thickness swelling rate of water absorption is smaller than 8%, and the method has the advantages of being low in cost, simple and convenient to implement in processing technology, capable of not generating pollutants and capable of not damaging the ecological environment; meanwhile, wood shaving is conduced first after the raw material is sliced, the quality evenness of wood shavings can be guaranteed, and therefore the surface flatness and fineness of the finished shaving board can be improved.

Owner:SUIYANG XINGHAN ROULETTE MFG

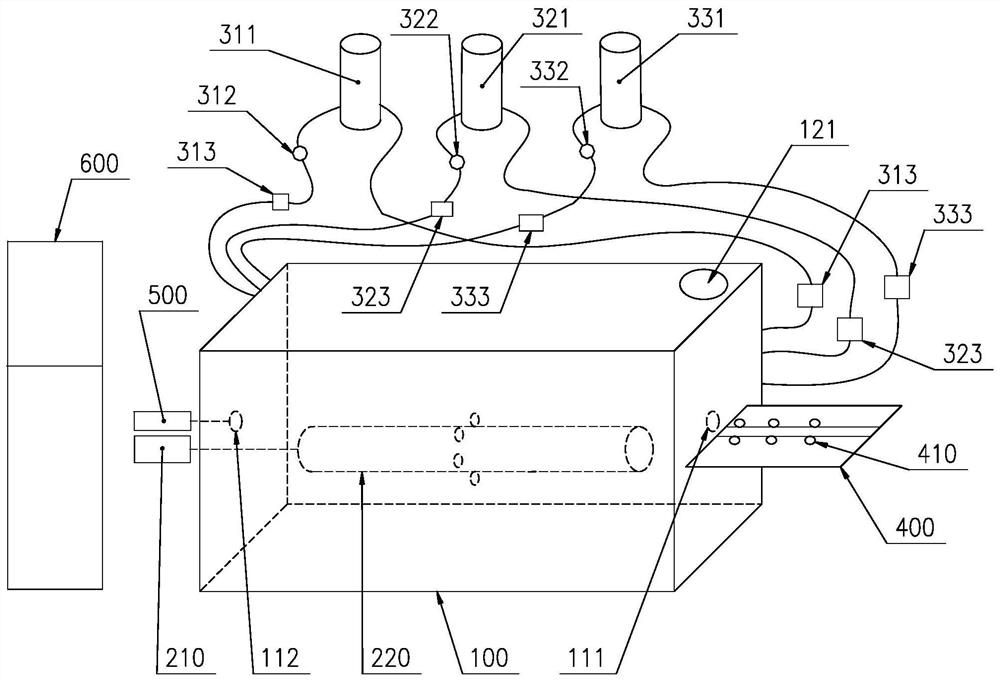

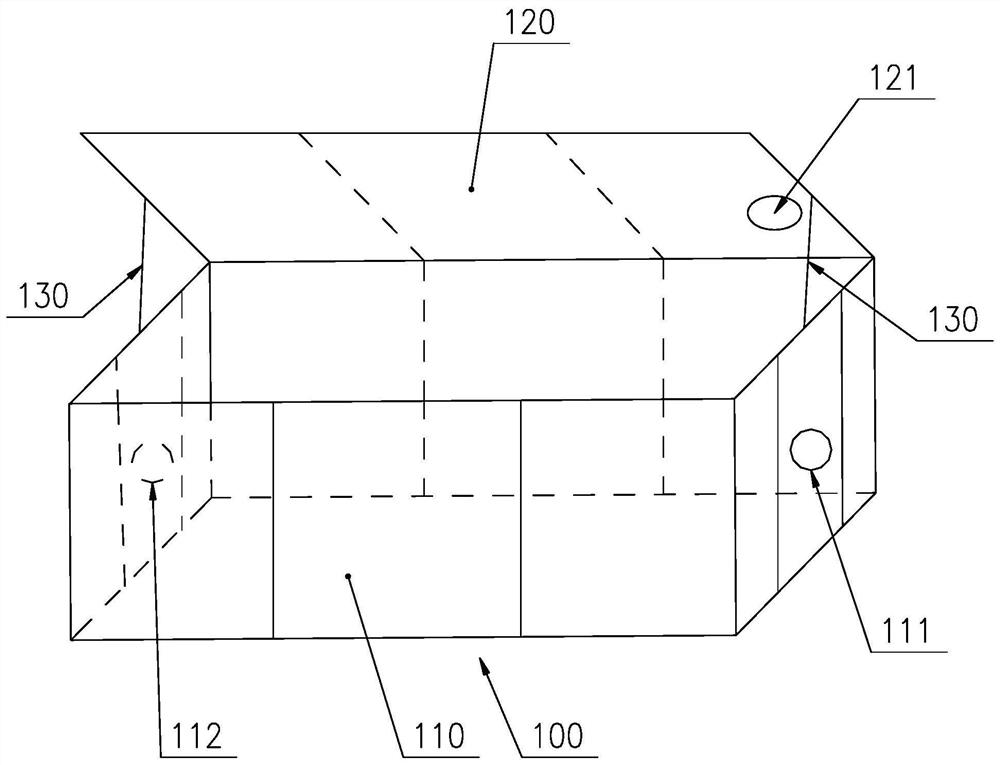

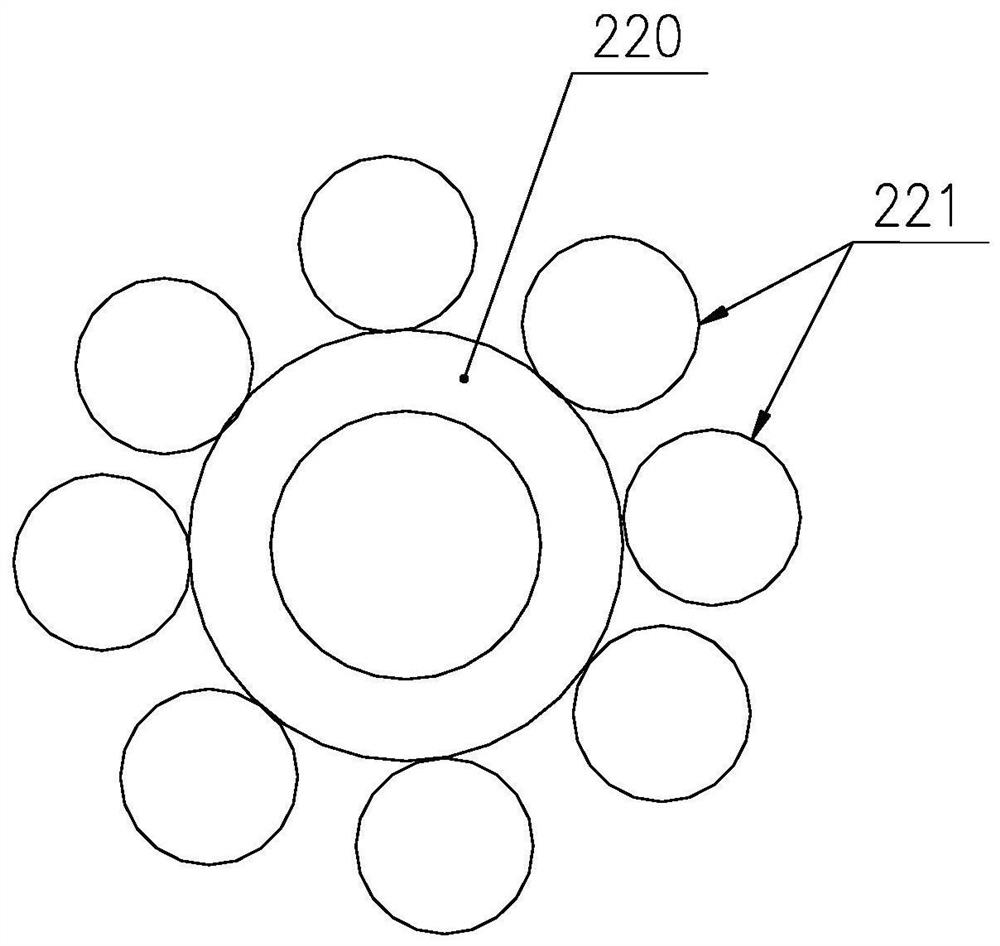

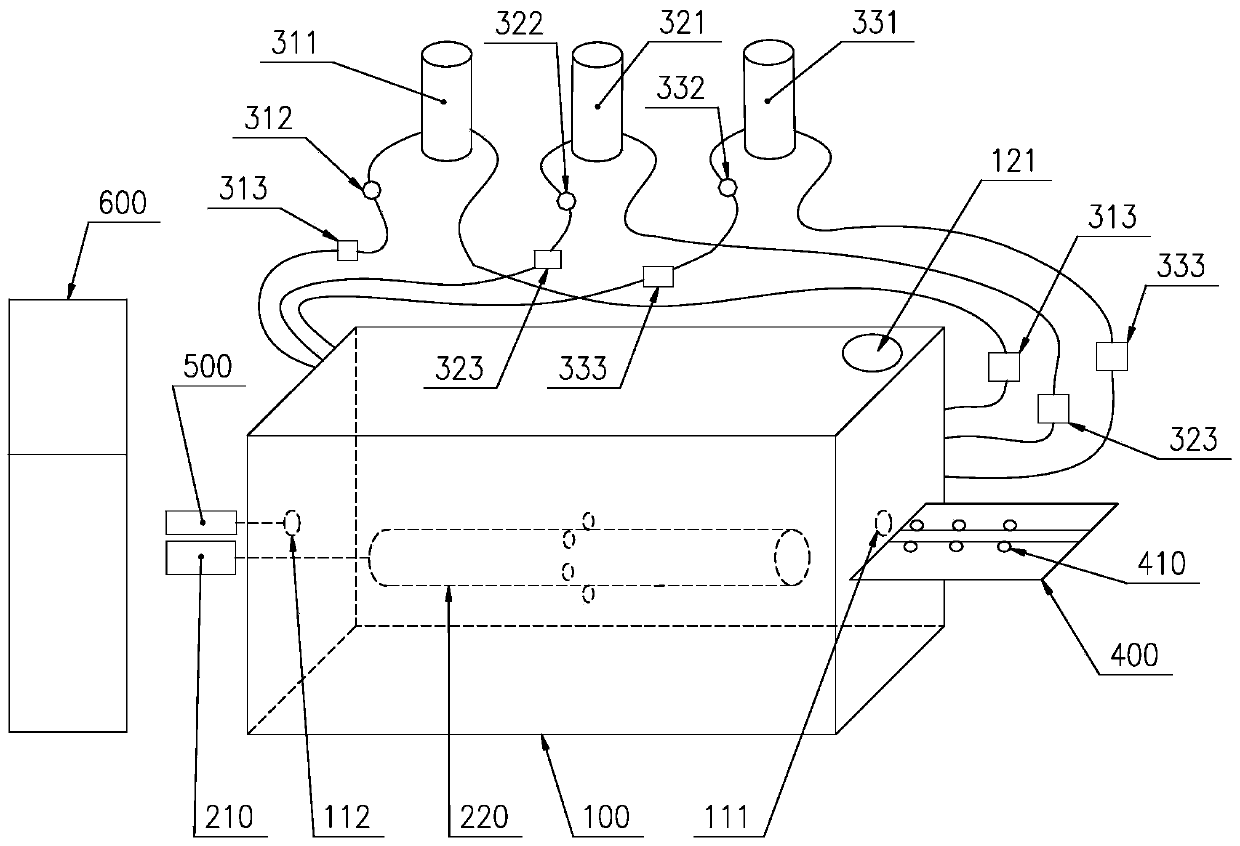

a forehearth structure

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

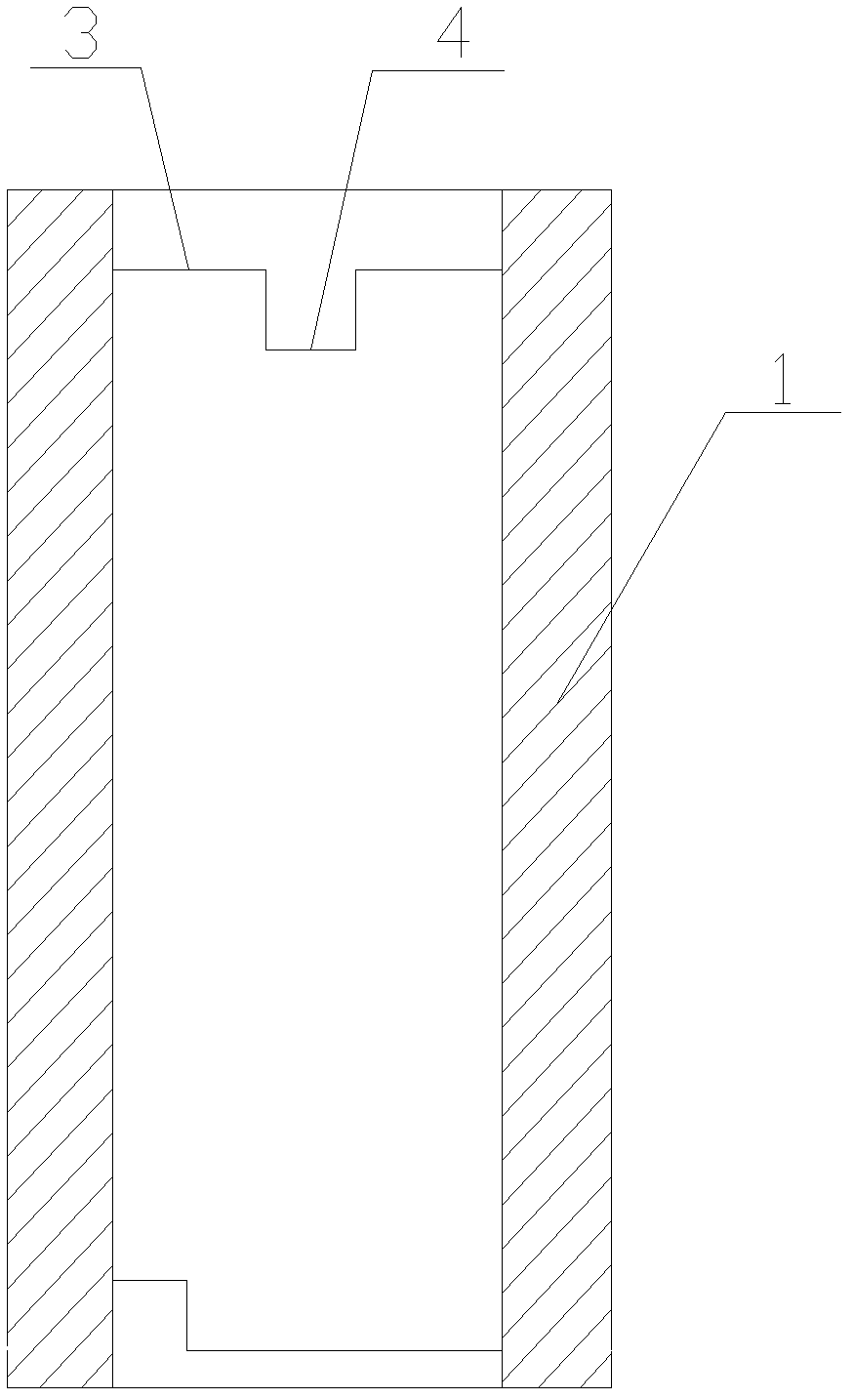

Micromotor magnet ring

InactiveCN103138429AGuaranteed concentricityGuaranteed quality uniformityMagnetic circuit rotating partsElectrical polarityMicromotor

The invention relates to the technical field of micromotors and particularly relates to a micromotor magnet ring. The micromotor magnet ring comprises a magnet ring body and at least two pairs of arc-shaped magnetic sections, wherein the magnet ring body is an integrated structure which is formed by injection molding of magnetic materials, magnetic sections are inlaid inside the magnet ring body and are uniformly arranged inside the magnet ring body in the sequence of reversed polarities, a first end face is connected with one side of the upper surface of the magnet ring body, which faces towards the inner wall of the magnet ring body, a round hole and two grooves which are arranged oppositely are arranged on the first end face, the round hole is connected with grooves, a second end face is arranged on one side of the bottom surface of the magnet ring body, which faces towards the inner wall of the magnet ring body, and the second end face is connected with an inclined face. The micromotor magnet ring is formed once with magnetic materials, the concentricity of the magnet ring and the uniformity of the quality can be guaranteed, and simultaneously, at least two pairs of magnetic sections are inlaid at the same time of molding, so that the produced magnet ring is provided with a multipole magnetic field.

Owner:陈朝辉

A kind of car paint surface cleaning and repairing agent and preparation method thereof

ActiveCN110106032BGuaranteed quality uniformityEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAutomotive paintSurface cleaning

The invention discloses an automobile paint surface cleaning and repairing agent and a preparation method thereof. The selected components of the cleaning and repairing agent include nonionic surfactant fatty alcohol polyoxyethylene ether, corrosion inhibitor oleic acid diethanolamide borate, excipient Forming agent sodium alginate, wax removing agent xylene, purifying agent dimethylformamide, defoaming agent dimethyl silicone oil, diluent composed of various organic solvents and self-repairing filler developed by ourselves, through mixing and stirring, vacuum removal Prepared by stirring. The cleaning and repairing agent of the present invention is sprayed on the scratches of the car, does not damage the car paint, and is compatible with the varnish on the car surface. After it automatically fills up the scratch pits and forms a film, no obvious stains and scratches can be seen with the naked eye. No scratches, no damage to the car paint, one-time cleaning and repair of the car paint surface, saving the cost of repairing car scratches and construction costs.

Owner:翁源县好尔威化工有限公司

A 10,000-ton die forging press used for forging forgings with obvious cross-section changes

ActiveCN108160892BGuaranteed quality uniformityReduce weightForging press detailsForging press drivesLoad resistanceMaster cylinder

The embodiment of the invention provides a die forging press. The die forging press includes a rack and an integrally formed movable girder, wherein multiple housings are parallelly arranged and fixedly connected with one another to form the rack, each housing includes a main cylinder, a column piston of each main cylinder is fixedly connected to the corresponding housing, the cylinder bottom of each main cylinder is connected to the upper surface of the movable girder, and all main cylinders are movable oil cylinders and are linearly distributed. By means of the integrally formed movable girder and the rack formed by parallelly arranging and fixedly connecting the housings, the demanded length of the movable girder for production of long-shaft type components is achieved, and since each main cylinder is the movable oil cylinder, a great guiding effect is ensured, so that the unbalance loading resistance of the die fording press is improved, and the service life is prolonged. Additionally, instead of being distributed in a two-dimensional mode in the traditional sense, the main cylinders are distributed linearly, and therefore the position of each main cylinder can be quickly adjusted to ensure the balance of the movable girder. Thus, inclination of the movable girder and other phenomena caused by unbalanced stress during machining is avoided, and the quality uniformity of forging pieces is guaranteed.

Owner:TSINGHUA UNIV

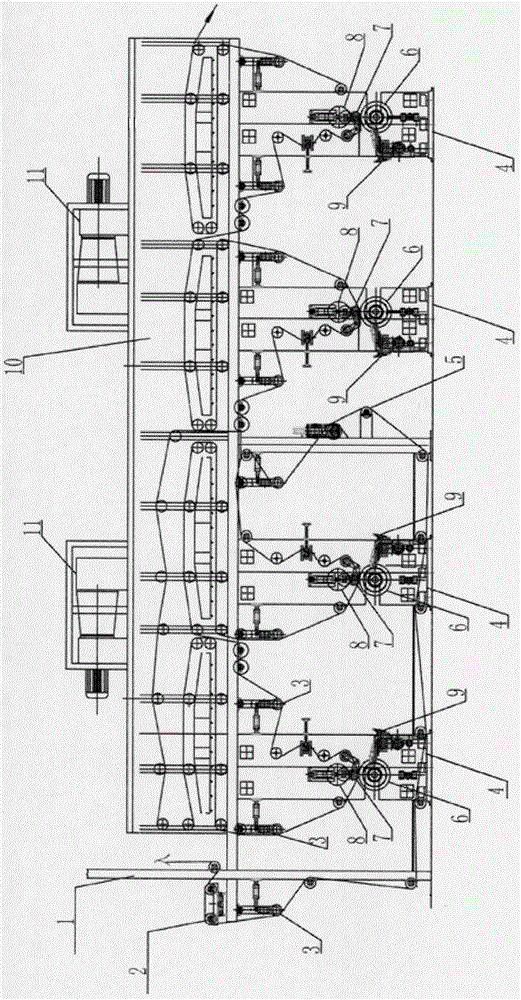

Coating device and production process used in blown film equipment

ActiveCN103706521BImprove or add special featuresGuaranteed continuityPretreated surfacesCoatingsBi layerGreenhouse

The invention relates to a coating device for improving the interior of blown film equipment and a production process. The coating device comprises a rack, a deviation correcting device, a tension control device, guide rollers, a traction device, a first intaglio coating component, a second intaglio coating component, a third intaglio coating component, a fourth intaglio coating component and a horizontal labyrinth dryer. By adopting the coating device, double surfaces of a wide-size agriculture greenhouse film (other functional films) can be quantitatively coated for two or multiple layers, each unit is independently driven, or the thickness and the content of other effective components of each layer of a functional coating liquid are quantitatively controlled according to the specification of each unit net wire, so that special functions of the agriculture greenhouse film (other functional films) are improved or added, and the continuity and the quality uniformity and stability in production are ensured.

Owner:辽宁宝博包装有限公司

A continuous strip bamboo strip preparation system and preparation method

ActiveCN114083629BQuality assuranceGuaranteed quality uniformityBio-packagingCane mechanical workingMechanical engineeringComposite material

Owner:INT CENT FOR BAMBOO & RATTAN

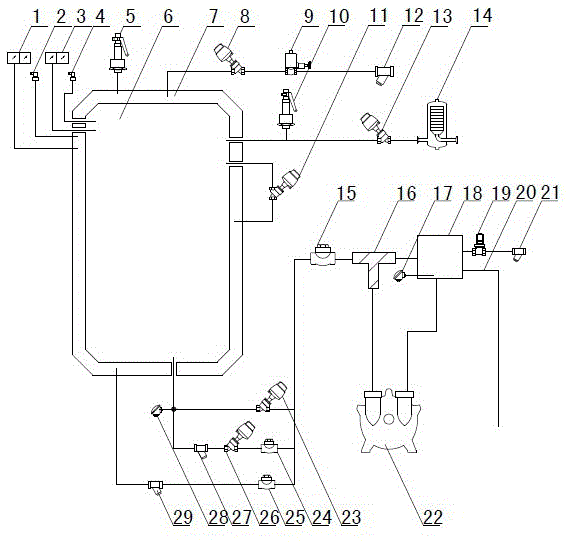

Pulsation control system for pulsation sterilizer and control method thereof

PendingCN111813158AIncreased pressure shockImprove service life and safety performanceFluid pressure control using electric meansHeatEngineeringMechanical engineering

The invention discloses a pulsation control system for a pulsation sterilizer and a control method thereof, and relates to the technical field of pulsation sterilizers. The system comprises a sterilizer body. A vacuumizing pipeline is arranged on one side of the sterilizer body, and a heat exchange pipeline is arranged on one side of the vacuumizing pipeline. In the invention, a novel control method is designed for a pulsation technology; the sterilizer body can be ensured to have operations of negative pressure pulsation, cross pressure pulsation and positive pressure pulsation at the same time; meanwhile, positive and negative pressure pulsation processes can be ensured; pressure is adjustable, the sequential pulsation is increased or decreased progressively; a pressure impact on the sterilizer main body due to great increase of the pressure is avoided; and once cross-pressure pulsation is carried out in the process so that multiple times of cross-pressure pulsation are avoided, theproblem of material fatigue strength caused by an alternating load borne by the sterilizer main body is reduced, a service life of the sterilizer main body can be prolonged, the safety performance ofthe sterilizer main body is improved, sterilization quality and temperature uniformity are guaranteed, and product sterilization performance is improved.

Owner:JIANGYIN BINJIANG MEDICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com