Magnetic ring for micromotor rotor

A micro-motor and magnetic ring technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of increasing motor vibration and noise, difficult processing, affecting motor performance, etc., to ensure uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

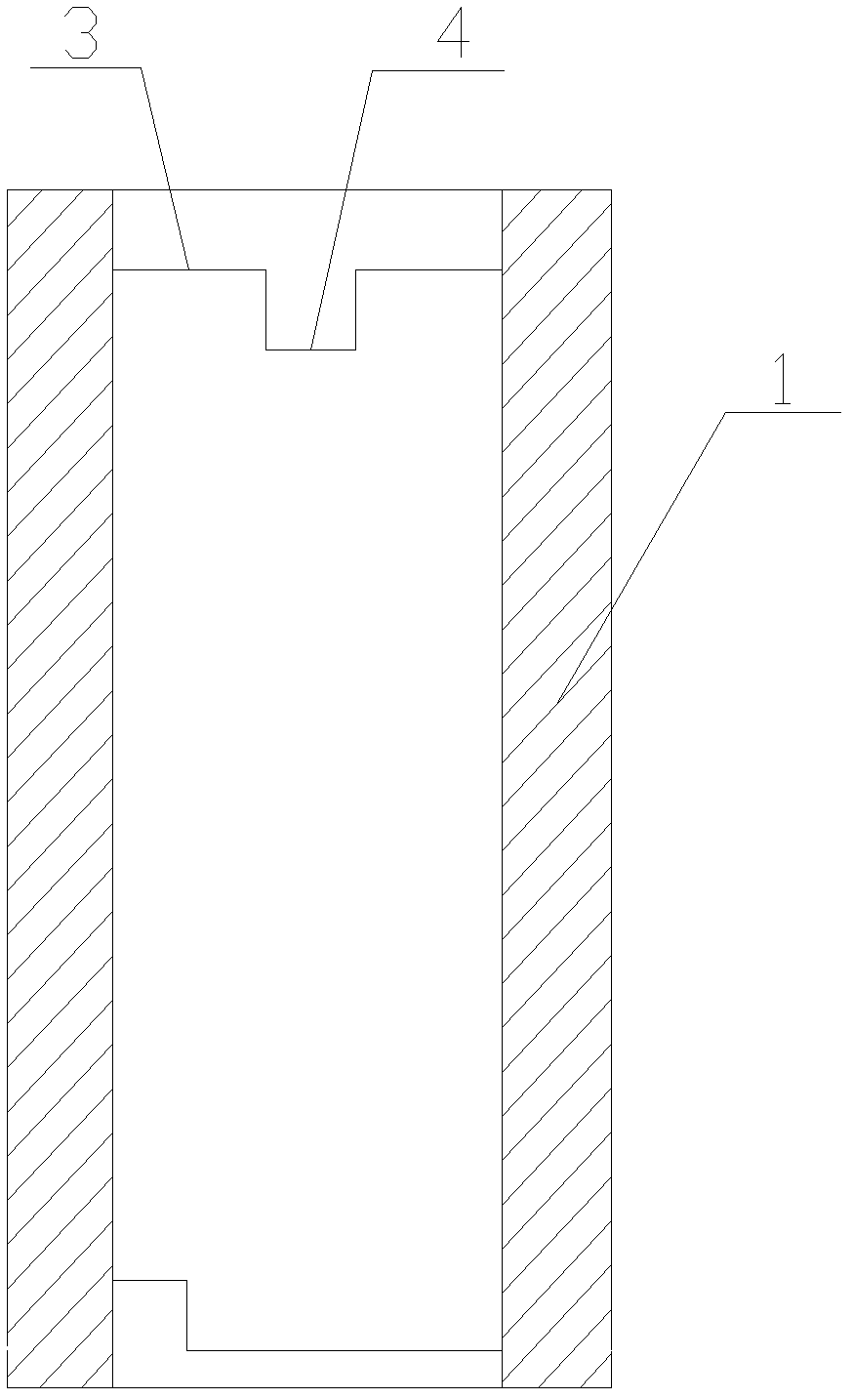

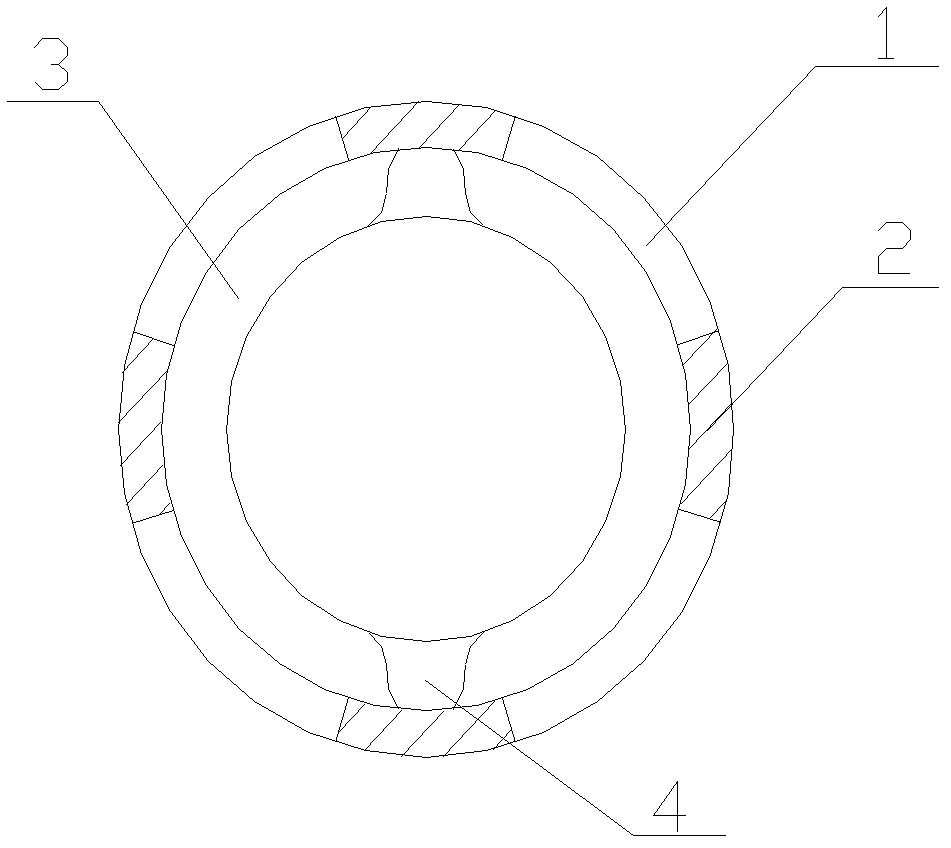

[0014] Such as Figure 1~2 The magnetic ring for the micro-motor rotor shown includes a magnetic ring body 1 and at least two pairs of arc-shaped magnetic segments 2. The magnetic ring body 1 is an integral structure formed by injection molding of magnetic materials, and the magnetic segment 2 is embedded in the magnetic ring body 1. , the magnetic segments 2 are evenly arranged in the magnetic ring body 1 according to the mutually reversed polarity, the upper surface of the magnetic ring body 1 is connected with an end face 3 facing the inner wall of the magnetic ring body 1, and two equally divided circles are arranged on the end face 3 groove 4.

[0015] The magnetic segments 2 are four pairs.

[0016] The magnetic ring body 1 is a cylindrical structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com