Straight-flow steam generator

A technology of steam generator and evaporation chamber, which is applied in the direction of steam generation, steam generation method using heat carrier, forced flow steam boiler, etc., which can solve the problems of inability to realize reverse flow of media on both sides, poor heat transfer effect, and difficulty in manufacturing Large and other problems, to achieve the effect of effective thermal expansion difference, reduce thermal stress, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

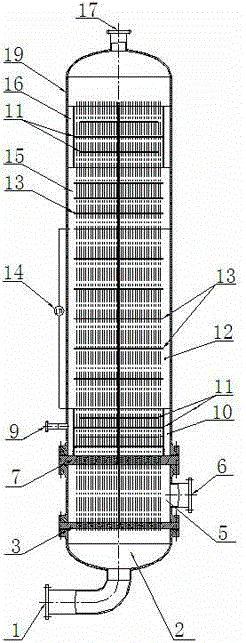

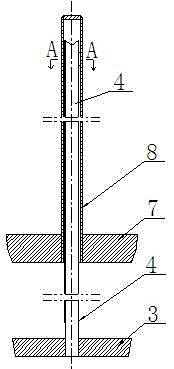

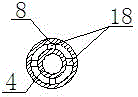

[0031] see Figure 1 to Figure 6 : The present invention includes a housing 19 and heat exchange tubes.

[0032] Wherein, the housing 19 is sequentially divided into an oil inlet chamber 2 , an oil outlet chamber 5 , a preheating chamber 10 , an evaporation chamber 12 , a dehumidification chamber 15 and an overheating chamber 16 from bottom to top. The oil inlet chamber 2 is provided with a heat transfer oil inlet 1, and an inner tube plate 3 is arranged between the oil inlet chamber 2 and the oil outlet chamber 5. A heat transfer oil outlet 6 is arranged on the oil outlet chamber 5 , and an outer tube plate 7 is arranged between the oil outlet chamber 5 and the preheating chamber 10 . A feed water inlet 9 is provided on the preheating chamber 10 , and the feed water liquid enters the casing 19 . The evaporation chamber 12 is provided with a liquid level measuring instrument 14 through which the liquid level in the housing 19 can be monitored locally. The top of the superhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com