Distributed energy resource comprehensive utilization system and method used for natural gas station

A distributed energy and natural gas technology, applied in the pipeline system, gas/liquid distribution and storage, and other non-combustion heat generation, can solve the problems of low outlet water temperature, waste of heat energy, and large cooling water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

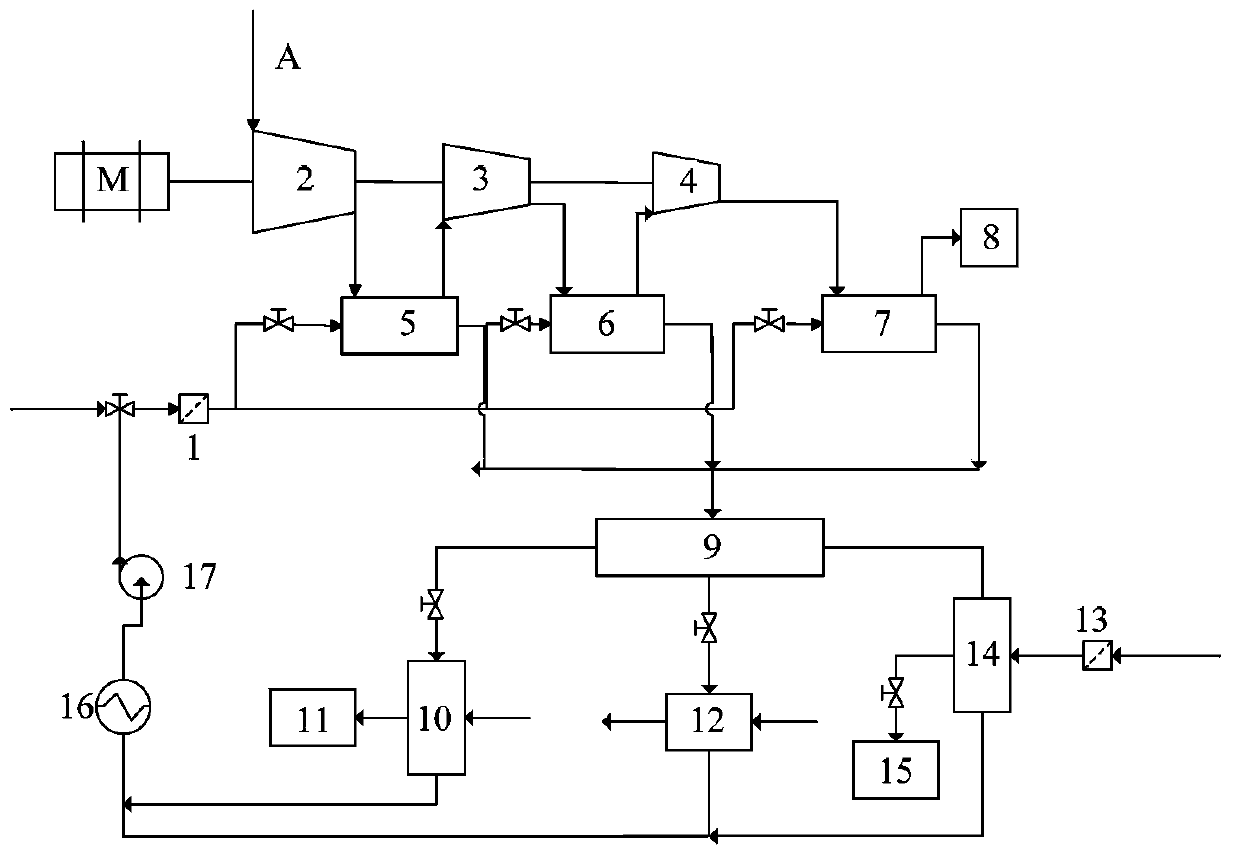

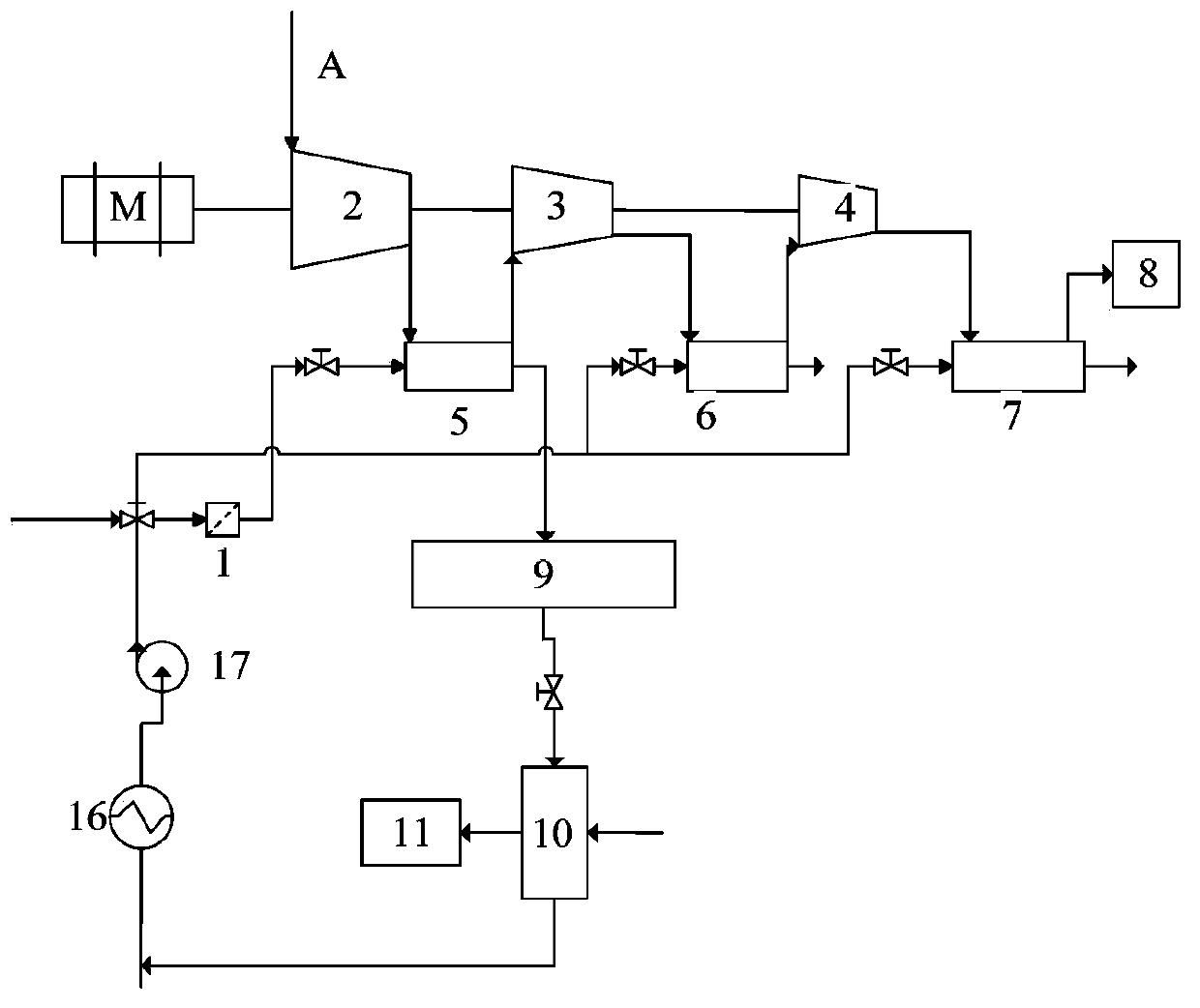

[0027] figure 1 It is Embodiment 1 of the waste heat distributed energy system device of the natural gas filling station of the present invention. The system device mainly includes a compressor unit (2, 3, 4 represent the low-pressure stage, medium-pressure stage, and high-pressure stage of the compressor), high-efficiency heat exchangers 5, 6, and 7, and secondary heat exchangers 10, 12, and 14 , Gas storage device 8, hot water storage tank 9, water processor 1,13, heat users 11,15, water inlet cooler 16, and interconnected pipelines and valves thereof.

[0028] The composition and working process of the device are as follows: the compressor unit is driven by the driving motor M, and the imported natural gas or air and other medium A are compressed through multi-stage intercooling compression, and finally enter the gas storage devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com