Integral submersible direct-driven screw pump

A screw pump and direct drive technology, applied in the direction of pumps, mining fluids, rotary piston pumps, etc., can solve the problems of difficulty in ensuring concentricity, complex mechanical structure, and long overall length, so as to improve the adaptability of the well type and simplify the machinery. The effect of enhanced structure and operational capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

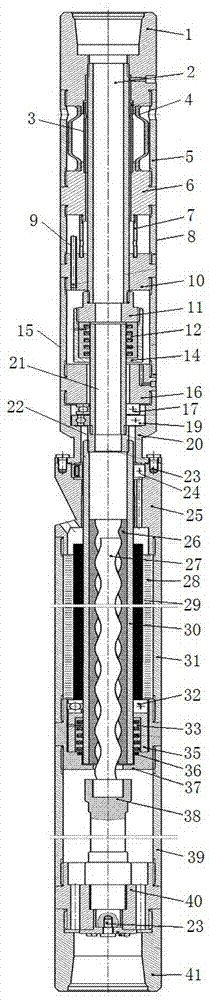

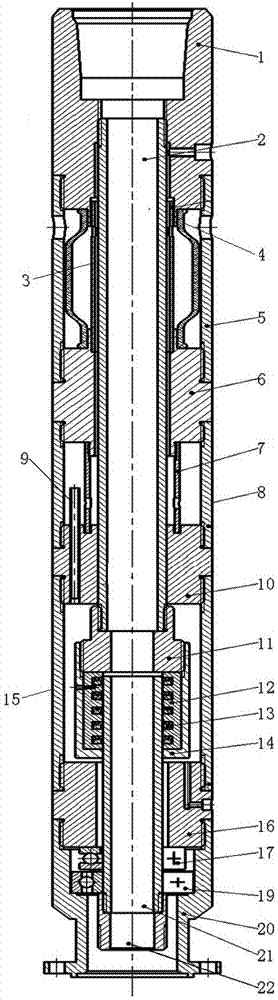

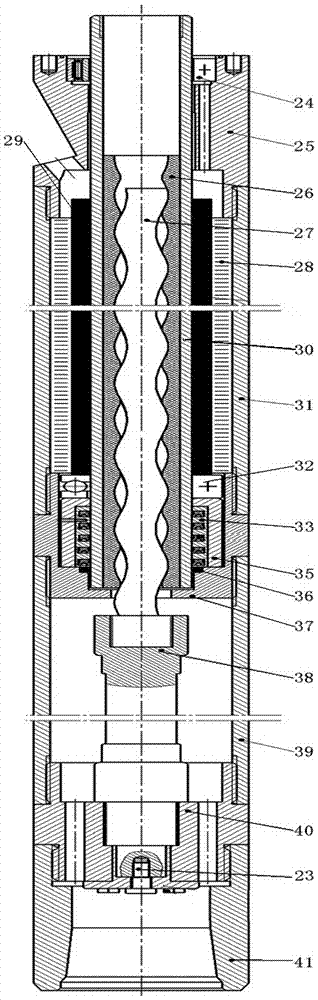

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] combine figure 1 , figure 2 , image 3 As shown, this integrated submersible direct drive screw pump includes a protector, a submersible motor, and a screw pump. There are oil delivery casing I2 and oil delivery casing II21 in the protector, oil delivery casing I2 and oil delivery casing Ⅱ21 is connected, the upper end of the oil delivery casing I2 is connected to the upper coupling 1 of the oil pipe, the protector base 20 is fixedly connected to the motor upper joint 25 of the submersible motor, and the oil delivery casing II21 of the protector is connected to the submersible motor through the casing joint 22 The motor rotor 30 is connected; the motor rotor 30 is a hollow tube, the permanent magnet suit is fixed outside the motor rotor 30, the motor stator 28 is arranged on the outer layer of the permanent magnet 29, and the second permanent magnet 29 bottom end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com