Novel proportion electromagnet

A proportional electromagnet and a new type of technology, applied in the field of electromagnets, can solve problems such as the inability to ensure the stability and control accuracy of the electromagnet, the difficulty of ensuring the concentricity of the two bearings, and the increase of the scrap rate of the casing, so as to reduce the scrap rate of the casing. , good concentricity, and the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following are specific embodiments of the present invention in conjunction with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

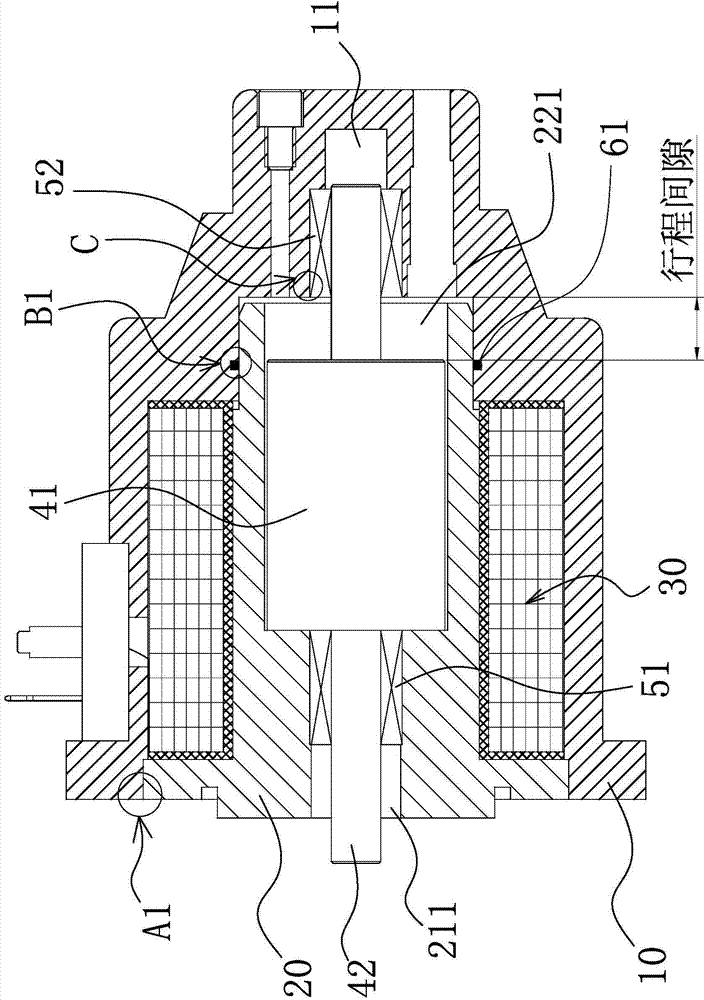

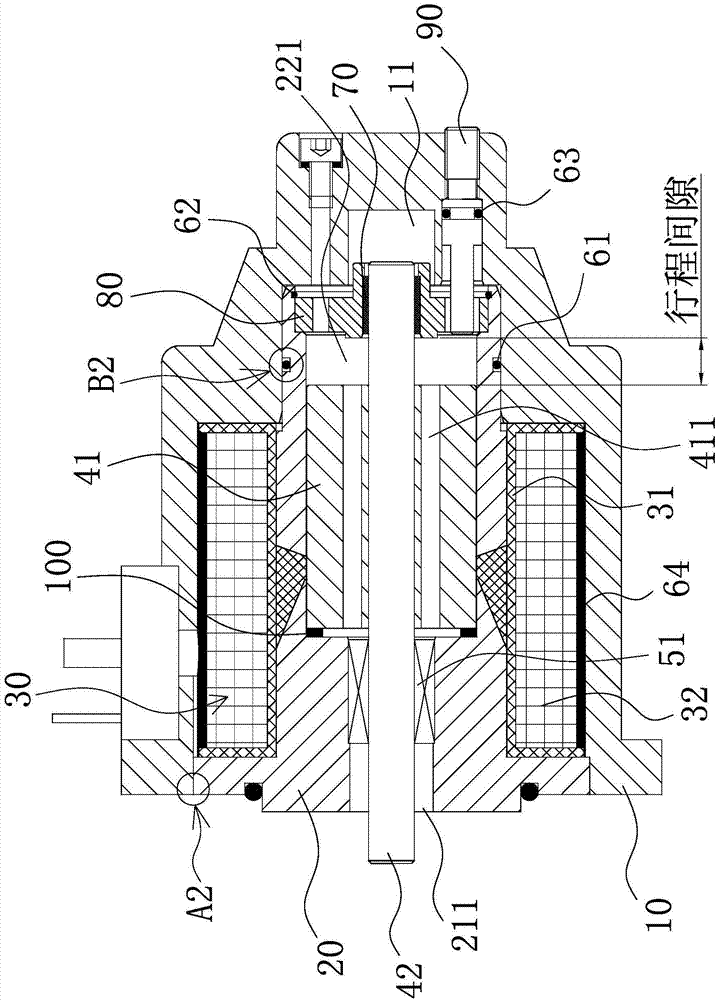

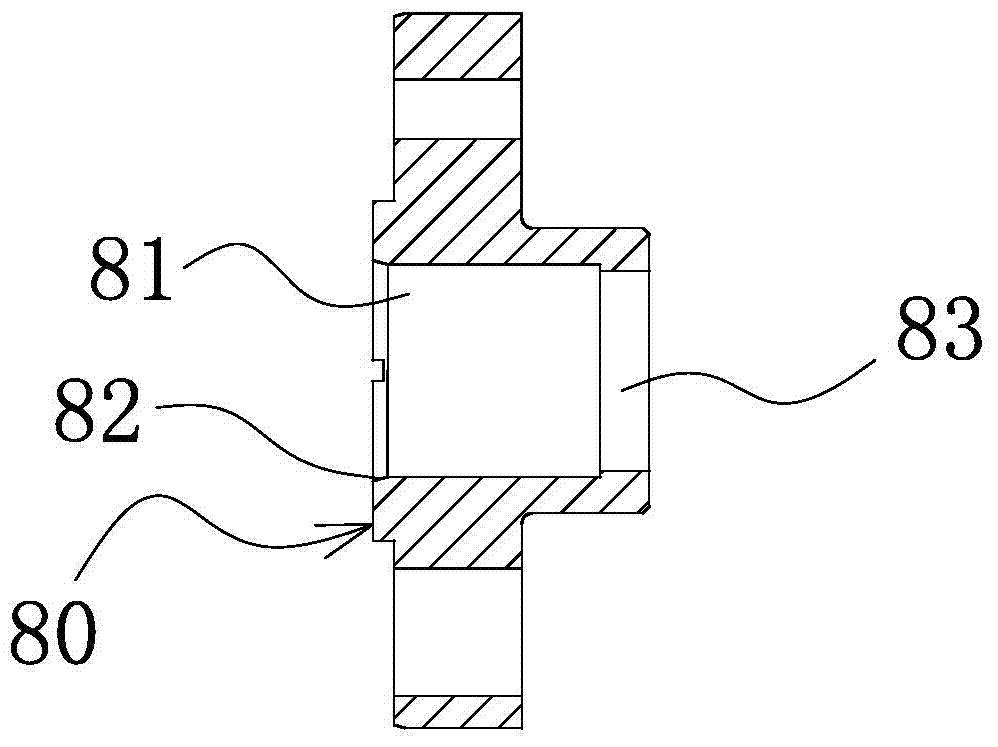

[0025] Such as figure 2 As shown, the proportional electromagnet of the present invention includes a housing 10 having a first cavity and a second cavity 11, and the first cavity is communicated with the second cavity 11, and the magnetic core tube 20 and the surrounding The coil assembly 30 arranged outside the magnetic core tube 20, the housing 10, the magnetic core tube 20 and the coil assembly 30 are hermetically connected. The central part of the magnetic core tube 20 is provided with an output through hole 211 and is connected to the output through hole 211 and the second The accommodating cavity 221 communicating with the inner cavity 11 is installed in the accommodating cavity 221 with an armature assembly composed of an arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com