a forehearth structure

A technology of material channel and distribution flow channel, which is applied in the field of processing equipment of inorganic non-metallic materials, can solve problems affecting fiber quality and yield, affecting equipment production efficiency, separate maintenance of bushing plate, etc., to improve production efficiency and ensure quality Uniformity, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

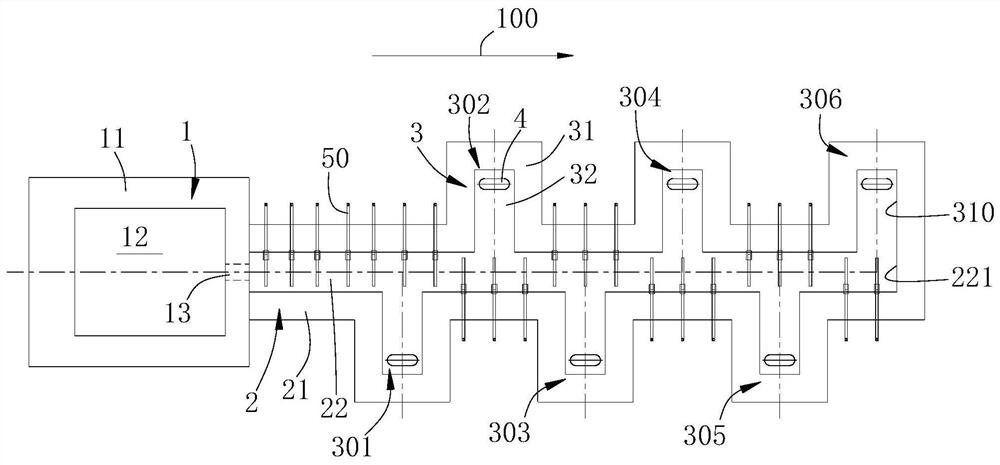

[0020] refer to figure 1 , a feedway structure, which includes a liquid flow distribution area 2 extending along a first direction 100 in a length direction, and the liquid flow distribution area 2 includes a main casing 21 and a distribution channel 22 disposed in the main casing 21; Both sides of the liquid flow distribution area 2 in the width direction are provided with ear pools 3, the ear pools 3 include a pool body 31 and a liquid flow chamber 32 arranged in the pool body 31, the liquid flow chamber 32 communicates with the distribution channel 22, and The bottom of the ear pool 3 is provided with a drain plate 4 communicating with the liquid flow cavity 32 .

[0021] Along the first direction, the ear cisterns 3 located on both sides of the width direction of the liquid flow distribution area are arranged alternately. In this embodiment, six ear pools are provided, two of which are arranged on both sides of the width direction of the liquid flow distribution area 2, a...

Embodiment 2

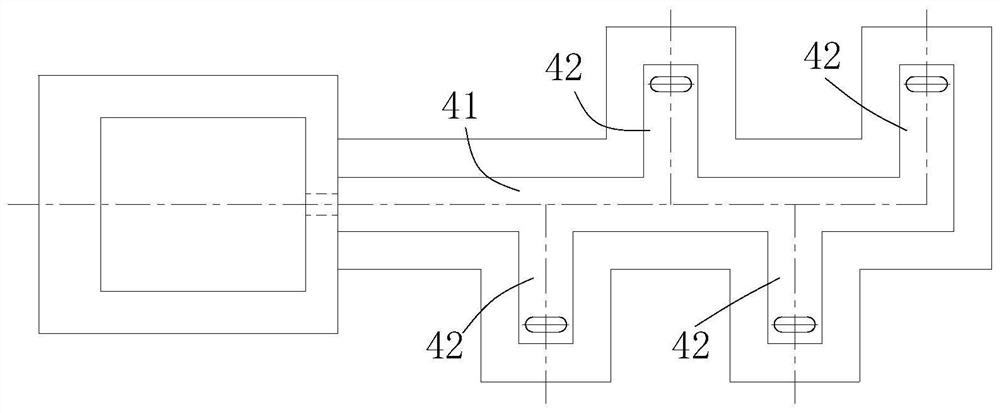

[0030] This embodiment is an improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is only the number of ear pools. Please refer to figure 2 , in this embodiment, two ear pools 42 are provided on both sides of the liquid flow distribution area 41, and the ear pools 42 on one side are spaced apart from the ear pools 42 on the other side. figure 2 In , to simplify the drawing, the heater is not shown.

Embodiment 3

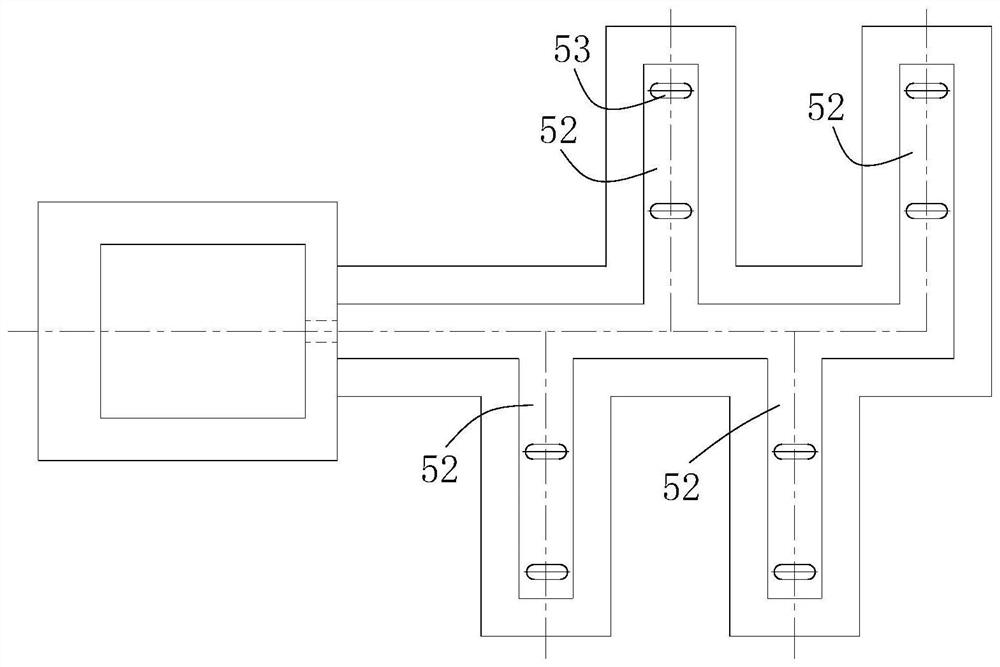

[0032] This embodiment is an improvement on the basis of embodiment 2. The difference between this embodiment and embodiment 1 is the difference in the number of bushings. Please refer to image 3 , in this embodiment, two drain plates 53 are provided in each ear pool 52 . It can be understood that, according to different production scales, the number of floors in each ear pool can be increased, for example, 3, 5 or more. image 3 In , to simplify the drawing, the heater is not shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com