Patents

Literature

234 results about "Basaltic rock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Since the iron content in basaltic rocks they are typically darker and denser then granitic rocks. One type of basaltic rock is basalt it is mainly composed of olivine, pyroxene and plagioclase feldspar. There are two types of basaltic rock one is intrusive which means it is course-grained.

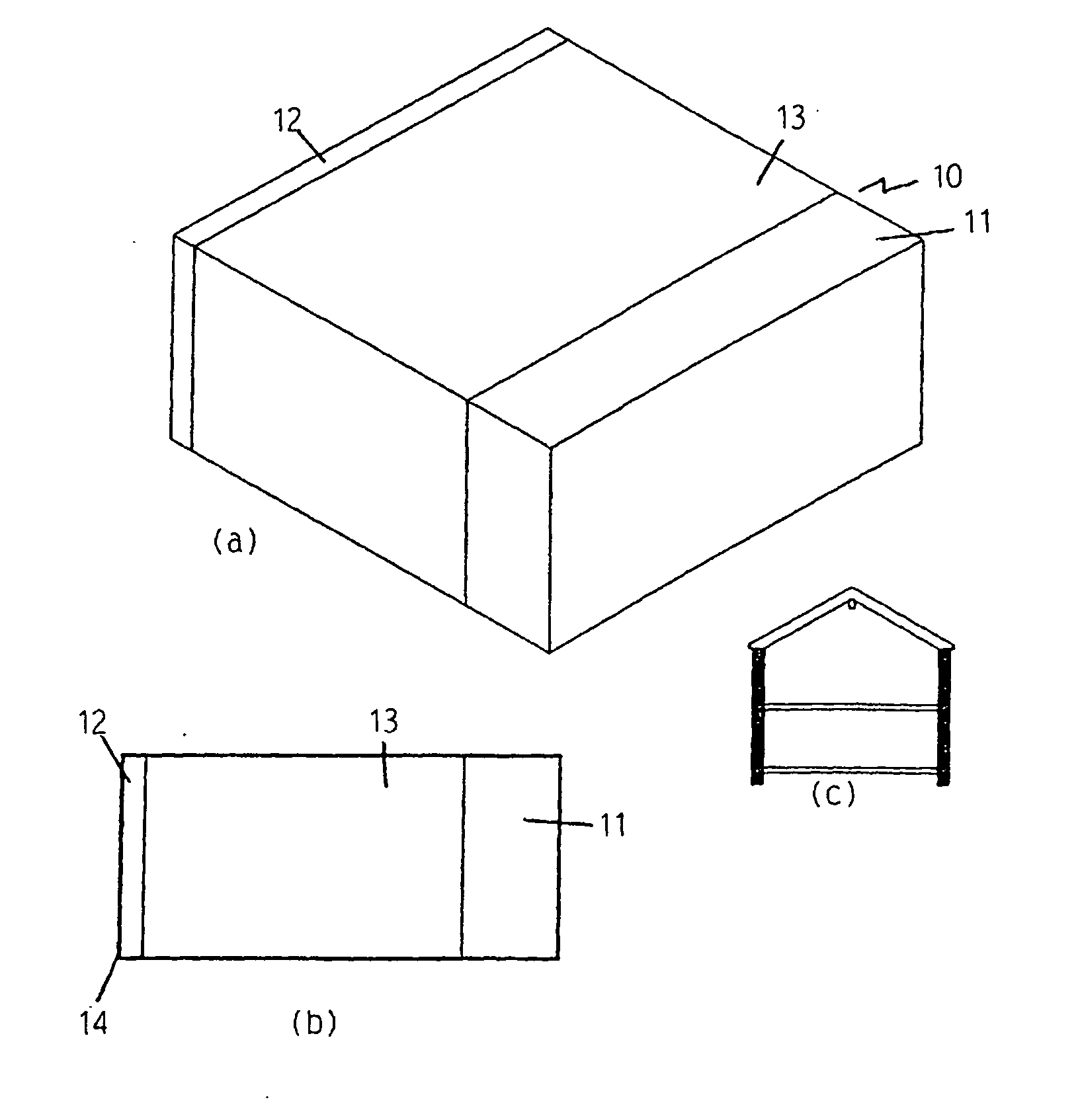

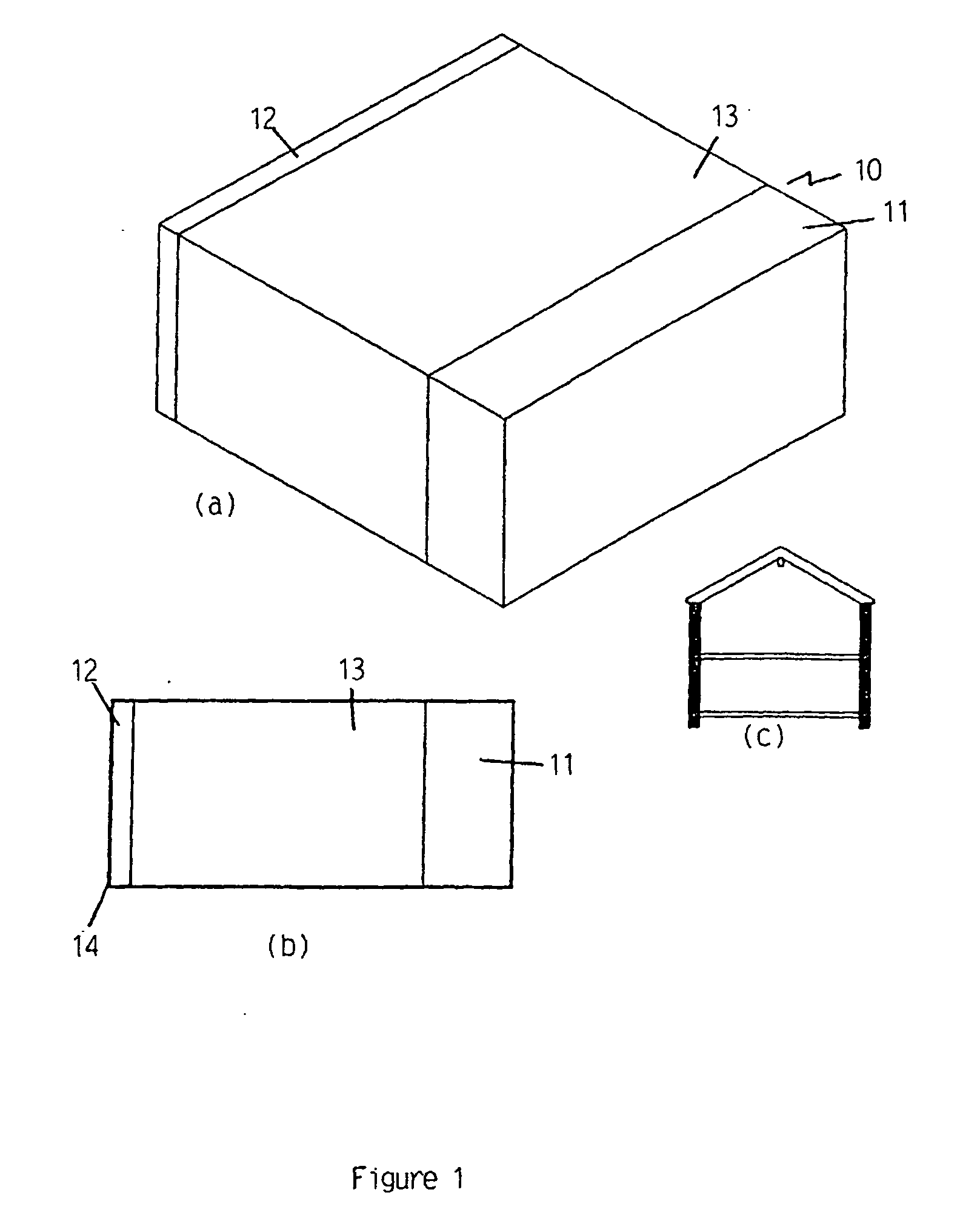

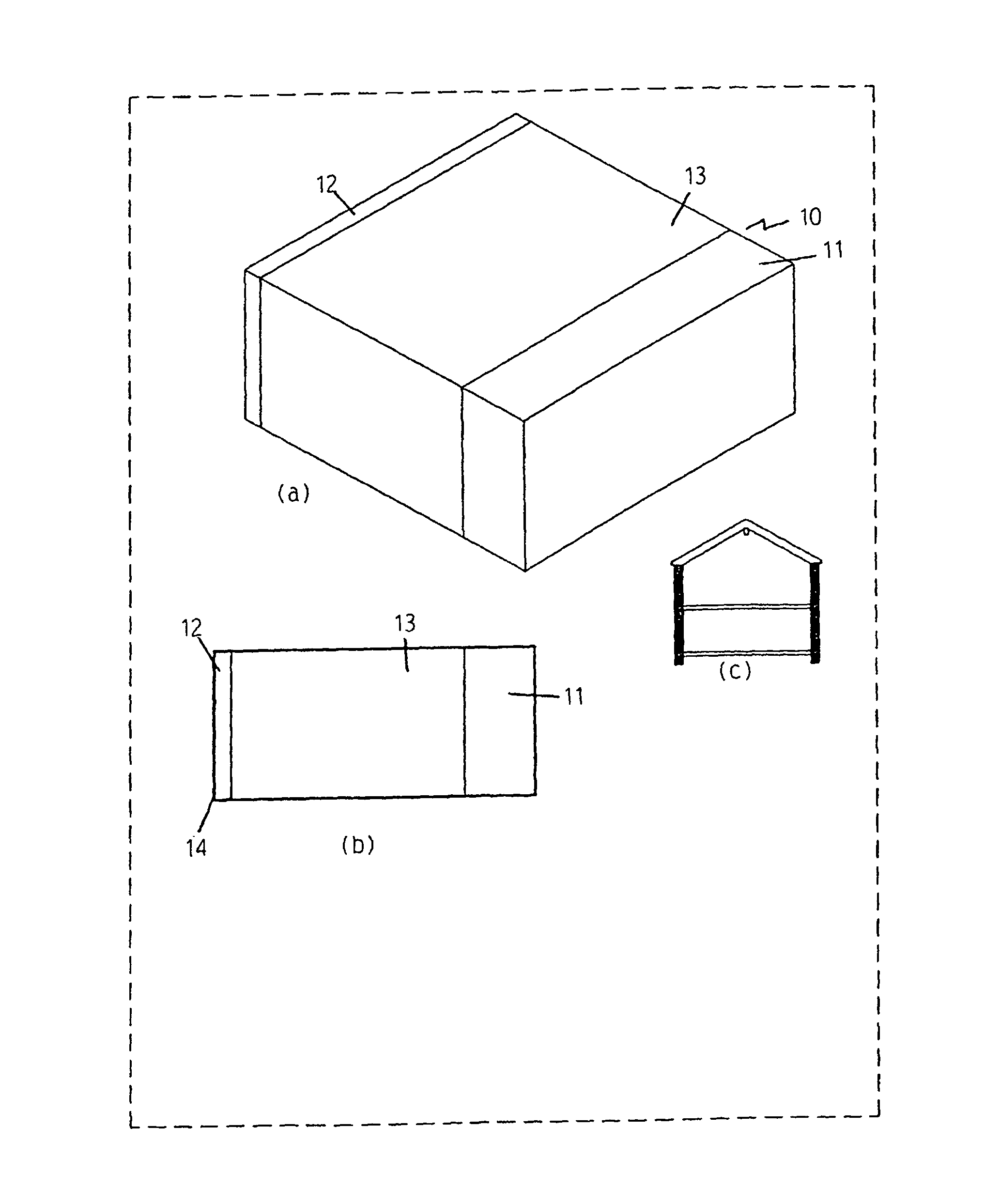

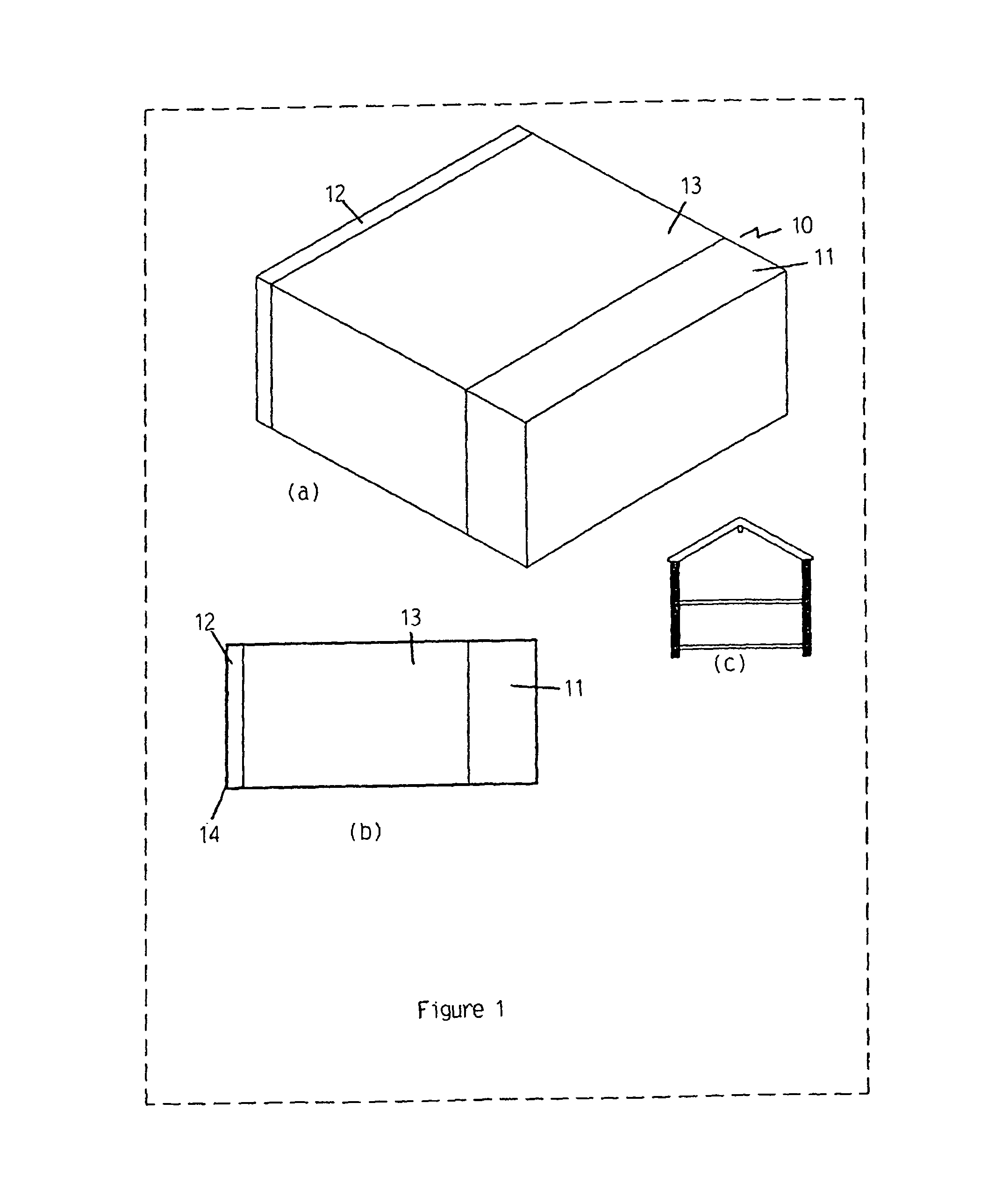

Geopolymeric structural building units and methods of manufacture thereof

ActiveUS20120260594A1Improve thermal efficiencyImprove thermal performanceSolid waste managementCement productionGeopolymer cementBuilding unit

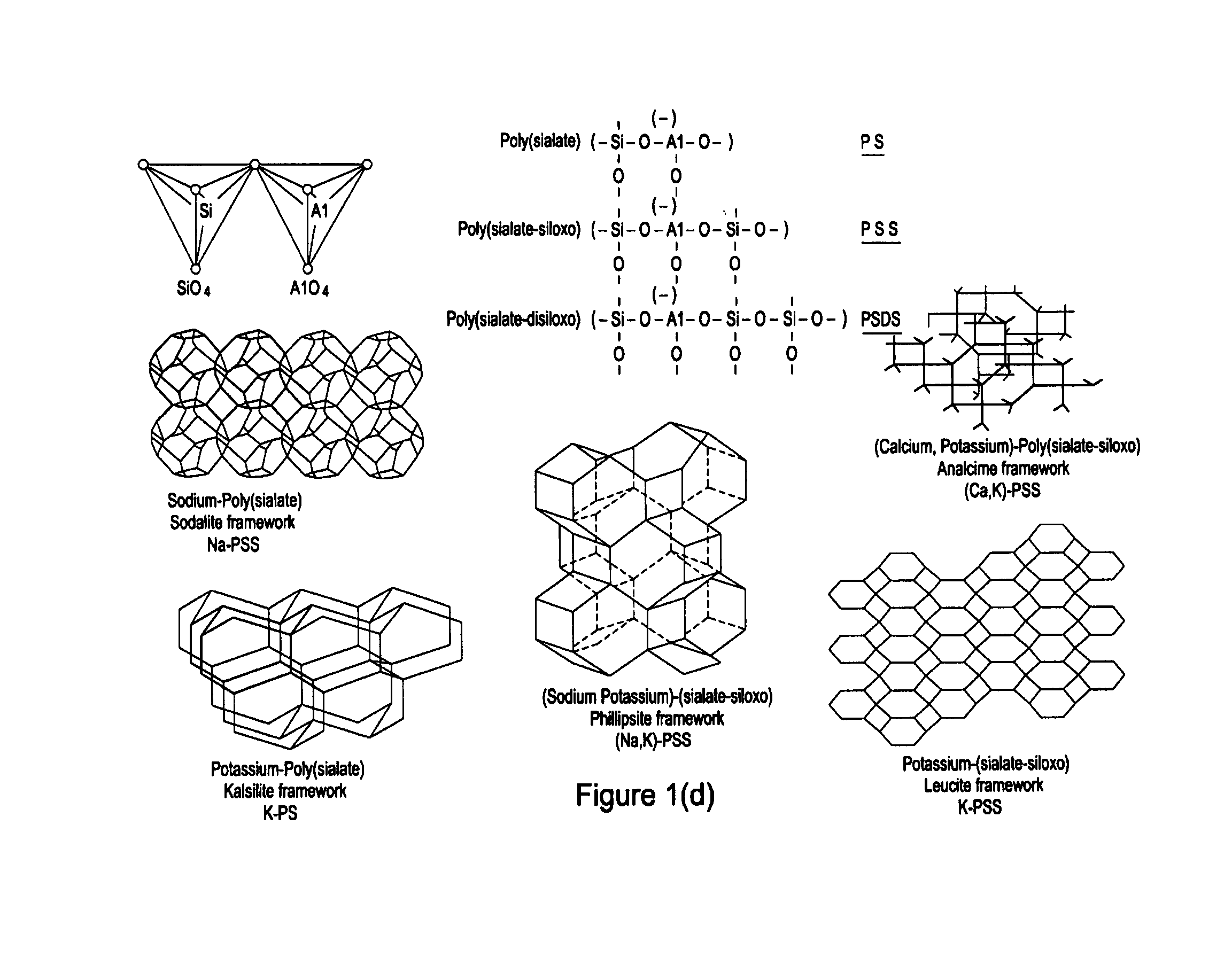

The present invention provides a geopolymeric cement formed from a precursor having a relatively high alumina content (Si:Al atomic ratio of less than or equal to 1.3:1) to form an alkaline multiphase alumino-silicate material.The precursor comprises basaltic rock in which kaolinization is at an advanced stage, preferably Interbasaltic material found in Northern Ireland.The present invention also provides structural units for constructing a building, the structural units being manufactured using the geopolymeric cement of the invention.The invention also provides a process for producing a geopolymeric cement comprising a precursor having a relatively high alumina content (Si:Al atomic ratio of less than or equal to 1.3:1) to form an alkaline alumino-silicate geopolymer material for manufacturing geopolymeric structural building units having compressive strengths of greater than 3 N / mm2 and preferably having compressive strengths in the range of 12-25 N / mm2.

Owner:RANDOM TECH

Light environment-friendly rock glaze imitated ceramic and preparation process

The invention relates to the technical field of ceramics, in particular to a light environment-friendly rock glaze imitated ceramic and a preparation process.The light environment-friendly rock glaze imitated ceramic comprises a ceramic body, ground glaze and cover glaze.The ground glaze is prepared from feldspar, dolomite, kaolin, talc, ferric oxide, pelelith, heavy calcium carbonate powder and sepiolite.The cover glaze is prepared from feldspar, quartz, calcium carbonate powder, zinc oxide, dolomite, limonite, medical stone, zirconium silicate and ferric oxide.The light environment-friendly rock glaze imitated ceramic is similar to common basalt and limestone, the glaze surface touch sense is rough, and rough and plain visual perception is given to people.The ceramic body of the light environment-friendly rock glaze imitated ceramic is low in mass, the ceramic body is combined with the appearance of rock glaze, a distinct conflict is formed, and a special effect is achieved.The rock glaze imitated ceramic is high in strength and good in toughness, and is fired at a time, energy saving and environment friendliness are achieved, and the production cost is reduced.

Owner:FUJIAN PROVINCE DEHUA COUNTY LUXURIES CERAMICS CO LTD

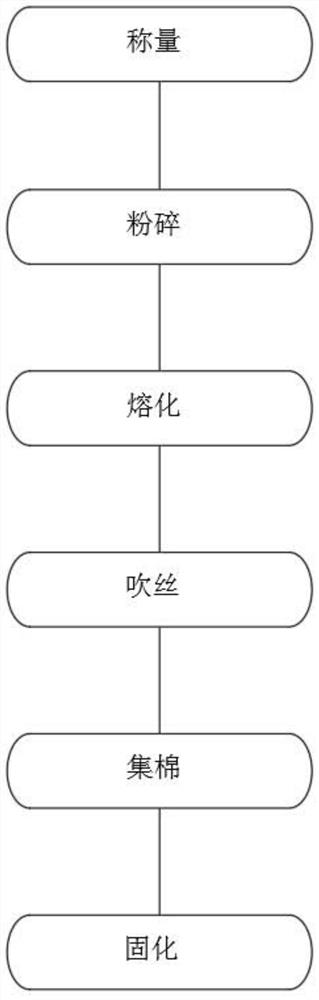

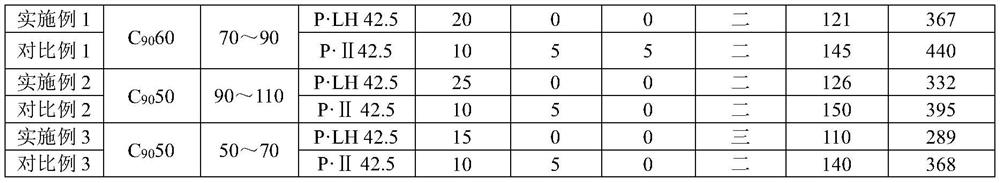

Method for preparing concrete by using basalt micropowder-slag micropowder-limestone powder as blending material

The invention discloses a method for preparing concrete by using basalt micropowder-slag micropowder-limestone powder as a blending material. The method is characterized in that (1), raw materials consist of a gelatinizing material, an exciting agent, aggregate, additives and water, wherein the gelatinizing material is formed by compounding cement, basalt micropowder, slag micropowder and limestone powder; and the additives comprise an alkaline exciting agent and a high-efficiency water-reducing agent; (2), the specific surface area of the basalt micropowder, the slag micropowder and the limestone powder is controlled to be 400 to 600 m<2> / kg, 500 to 800 m<2> / kg and 600 to 900 m<2> / kg respectively; (3), small-size continuous grading coarse aggregate is adopted; and (4), the exciting agentis dissolved into water in advance and is mixed with the mixing water. By the method, the process is simple; concrete of C20-C60 grade can be prepared; the adding amount of industrial residues in theconcrete can be increased obviously; the concrete has high work performing; and durability such as shrinkage resistance, freezing resistance, seawater erosion resistance and the like is improved obviously.

Owner:南宁兴典混凝土有限责任公司

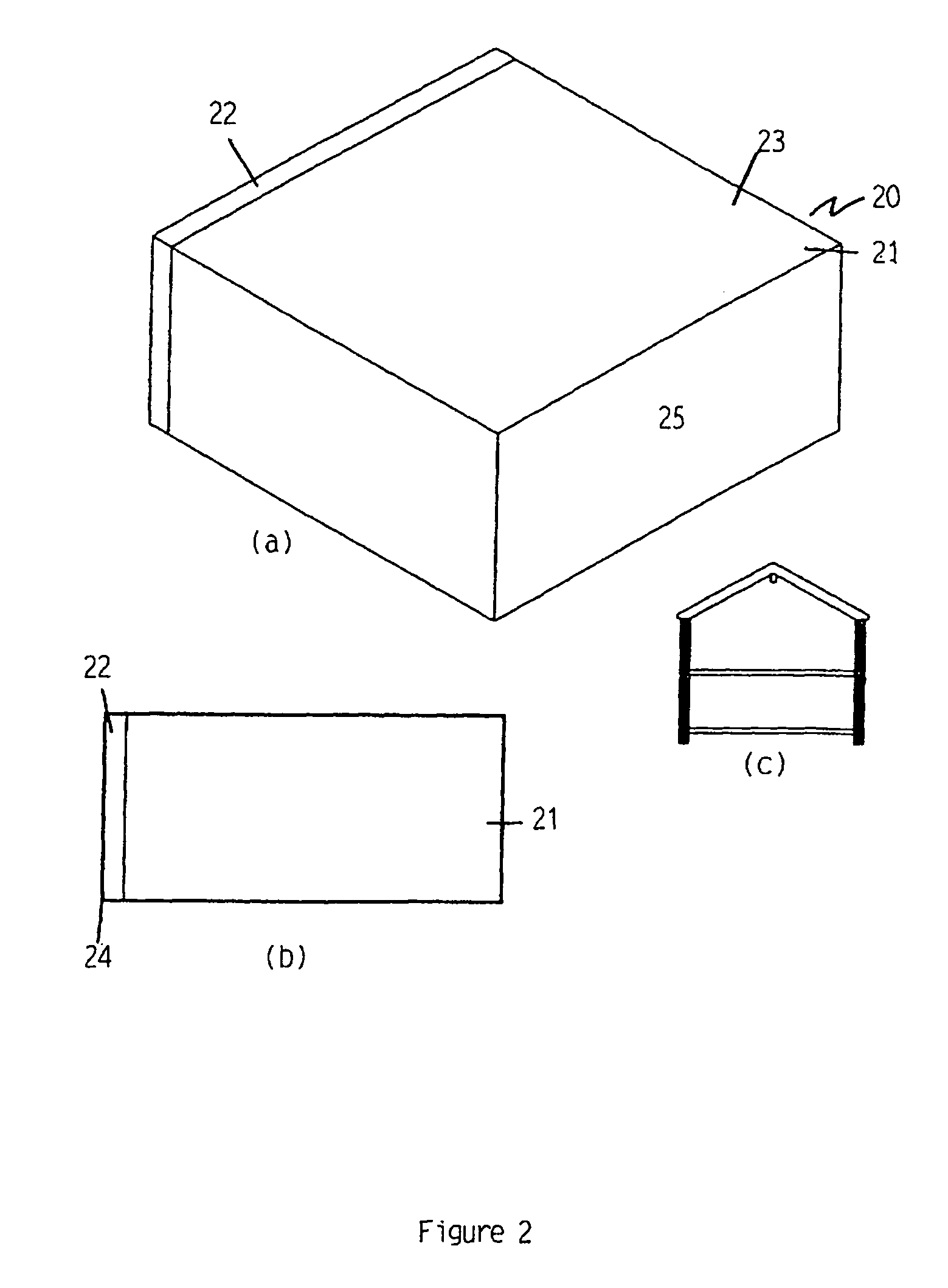

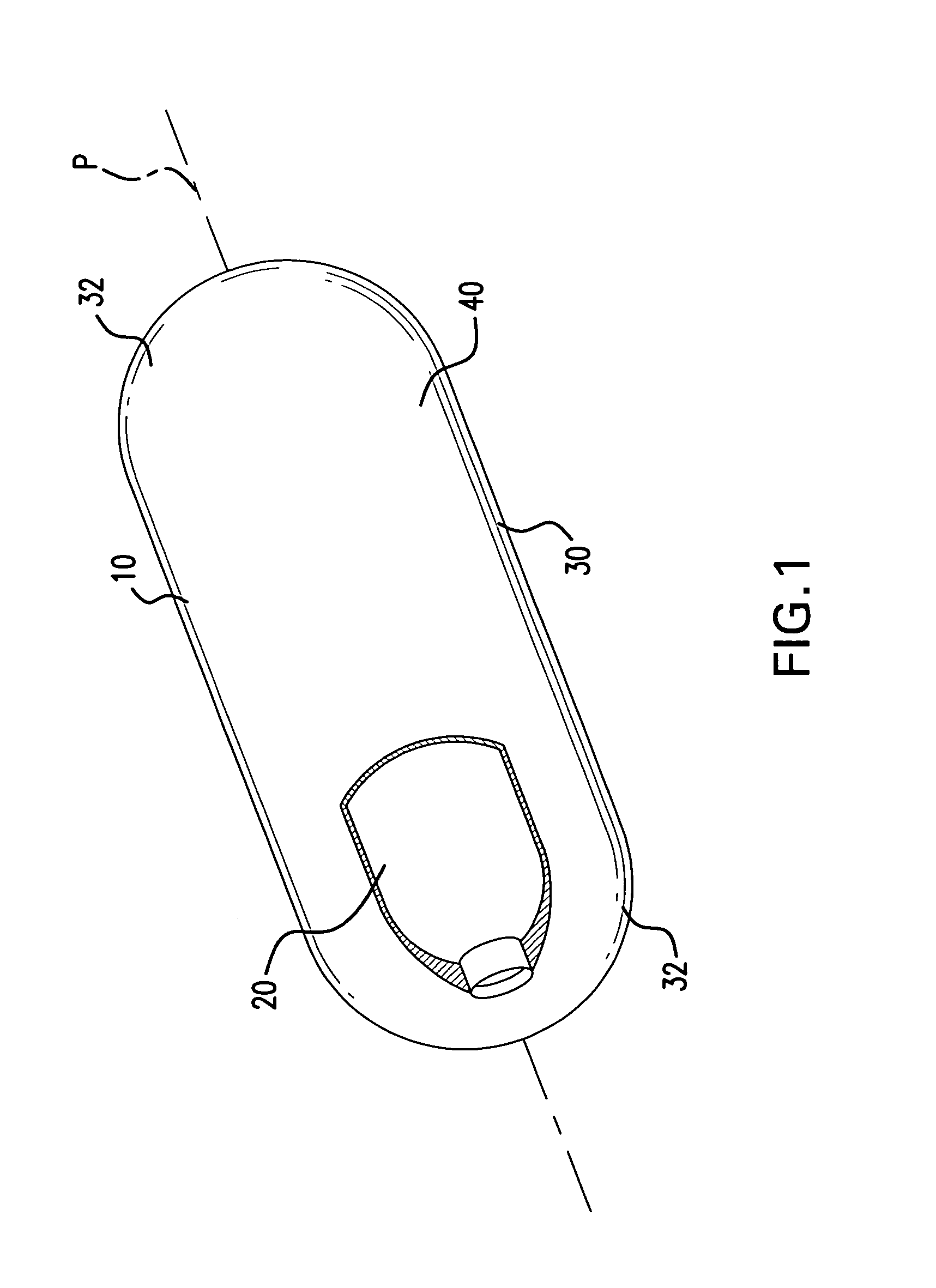

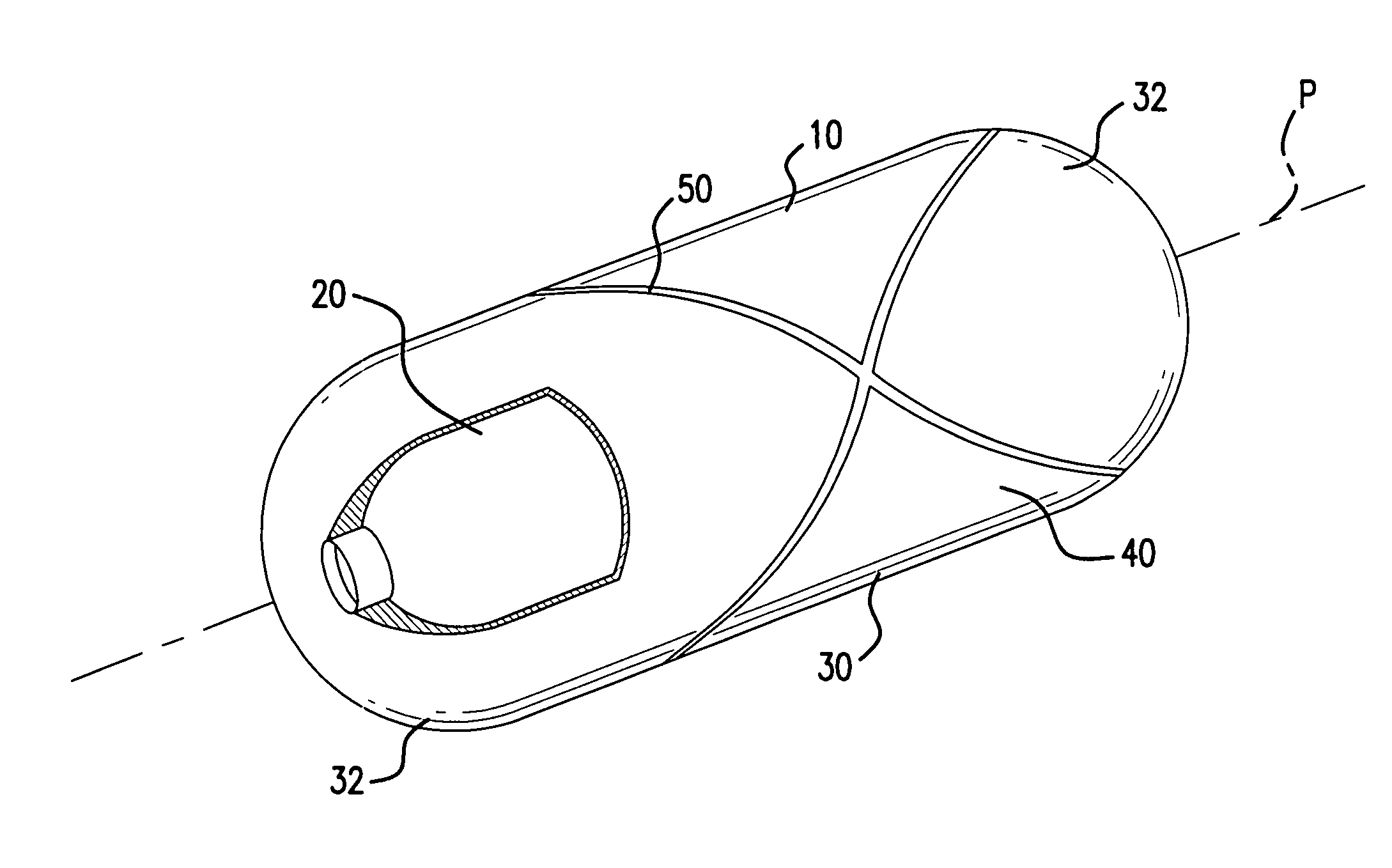

Concentric Shells for Compressed Gas Storage

ActiveUS20140166670A1Reduce intensityHigh strengthVessel manufacturingVessel geometry/arrangement/sizeAramidesFiber-reinforced composite

Gas containment vessels are provided that are comprised of an inner corrosion resistant shell made of lower strength steel alloy or aluminum alloy or thermoplastic polymer, and an outer concentric shell constructed of high strength, albeit lower corrosion resistant, metal or fiber-reinforced composite. The fiber can comprise filaments derived from basaltic rocks, the filaments having been immersed in a thermosetting or thermoplastic polymer matrix, and comingled with carbon, glass or aramid fibers such that there is load sharing between the basaltic fibers and carbon, glass or aramid fibers.

Owner:QUANTUM FUEL SYSTEMS LLC

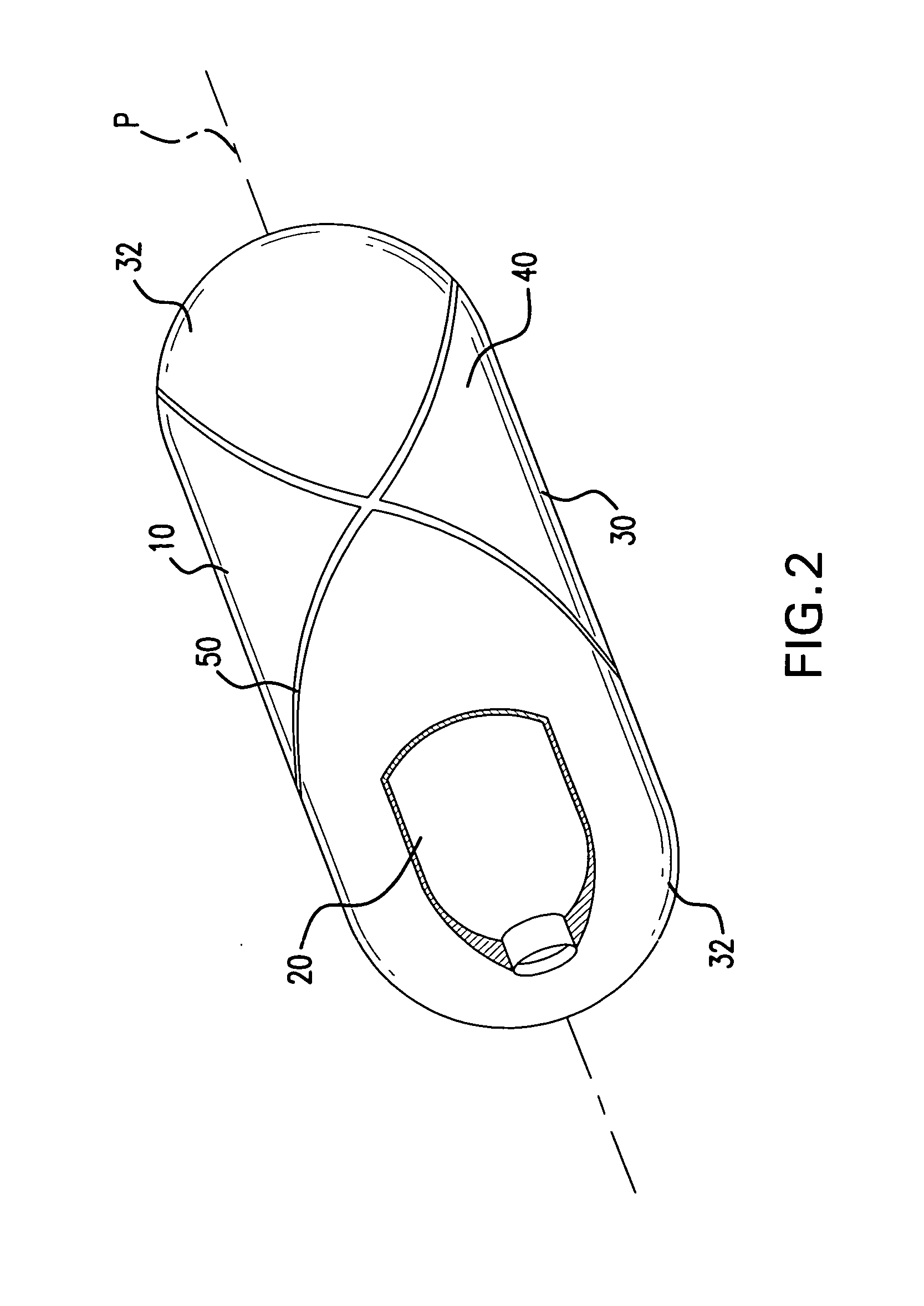

Rock wool and method for producing and manufacturing rock wool

InactiveCN111847891ASimilar melting rateImprove melting efficiencyGlass furnace apparatusNon-woven fabricsFiberSlag

The invention discloses rock wool. The rock wool is prepared from the following raw materials in parts by weight: 390 parts of basalt, 60 parts of slag, 70 parts of dolomite, 0.7 part of a water repellent and auxiliary materials. According to the rock wool and the method for producing and manufacturing the rock wool in the invention, the basalt, the dolomite and the slag in the raw materials are crushed to particle size ranges of 80-120 mm, 40-60 mm and 60-100 mm, respectively, so the melting speeds of the basalt, the dolomite and the slag in a cupola furnace are guaranteed to be similar, andthe melting efficiency of the basalt, the dolomite and the slag and mixing effect after melting are improved to the maximum extent; and molten liquid passes through an adjustable launder to form a stable stream, the stable stream is conveyed to a wire roller centrifugal machine for thread throwing to prepare fibers, and the quality of the made fibers is improved.

Owner:湖南恒盛新材料有限公司

Basalt-long-fiber-enhanced polypropylene composite material and application thereof

InactiveCN106750899AEasy to prepareExcellent overall performanceCell component detailsHigh intensityFibre reinforcement

The invention discloses a basalt-long-fiber-enhanced polypropylene composite material and an application thereof. The basalt-long-fiber-enhanced polypropylene composite material is prepared from raw materials such as modified basalt fiber, high-melt-index polypropylene PP, a compatilizer, an elastomer and high-mesh-number talcum powder, and is used for preparing an automobile battery box. The basalt-long-fiber-enhanced polypropylene composite material and the application disclosed by the invention have the advantages that the preparation method is simple and the comprehensive performance is excellent; the prepared battery box has the advantages of high strength, excellent impact resistance, creep resistance, high size stability, excellent heat resistance, fatigue resistance and chemical resistance and light weight; the basalt-long-fiber-enhanced polypropylene composite material can be combined with for producing high-strength products with more complex structures; and the production period is short, the production cost is low, and the basalt-long-fiber-enhanced polypropylene product can be recycled, so that the environment-friendly effect is good.

Owner:扬州市邗江扬子汽车内饰件有限公司

High-strength ceramic rock plate and preparation method thereof

ActiveCN112028607AHigh hardnessLow water absorptionCeramic materials productionClaywaresGlazeMontmorillonite

The invention belongs to the technical field of ceramic materials, and particularly relates to a high-strength ceramic rock plate and a preparation method thereof. The ceramic rock plate comprises a rock plate blank, ground glaze and surface glaze, wherein the rock plate blank is composed of the following raw materials in parts by weight: 8-15 parts of calcined kaolin, 30-35 parts of diatomite, 3-5 parts of feldspar, 5-10 parts of basalt and 20-25 parts of montmorillonite. The high-strength ceramic rock plate disclosed by the invention is low in water absorption rate, high in hardness and scratch-resistant, and has certain stain resistance and antibacterial property. The preparation method of the high-strength ceramic rock plate is reasonable in parameter design and easy to implement, andindustrial production is easy to realize.

Owner:淄博峰霞陶瓷有限公司

High-strength high-crack-resistance anti-impact-wear concrete adopting basalt excavated materials as aggregates and preparation method of same

ActiveCN112250381AHigh economic and environmental benefitsRealize the utilization of local materialsCrack resistanceMining engineering

The invention discloses high-strength, high-crack-resistance and abrasion-resistance concrete adopting basalt excavated materials as aggregates. The concrete comprises the following components in parts by weight: 246-294 parts of low-heat Portland cement, 43-83 parts by weight of I-grade fly ash; 629-694 parts by weight of artificial sand produced from a basalt excavation material; 1346-1469 partsby weight of broken stone produced from a basalt excavation material; 110-126 parts by weight of water; 2.026-2.936 parts by weight of a retarding type polycarboxylic acid high-performance water reducing agent; and 0.023-0.033 part by weight of an air entraining agent. According to the high-strength, high-crack-resistance and anti-impact-wear concrete adopting the basalt excavation material as the aggregate and the preparation method thereof, the problems that the construction site is occupied and rock mineral resources are wasted due to stacking of the excavation material of a water-power engineering cavern are solved; and the contradiction between high strength and high crack resistance of the hydraulic anti-abrasion concrete is economically and effectively solved from the aspect of mixproportion design.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

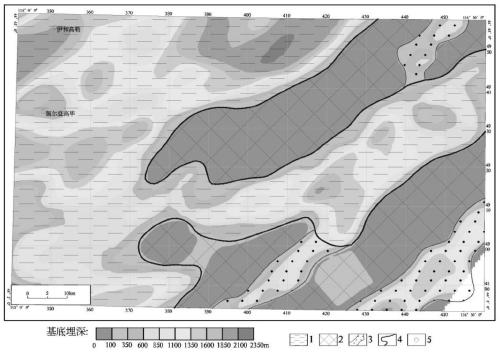

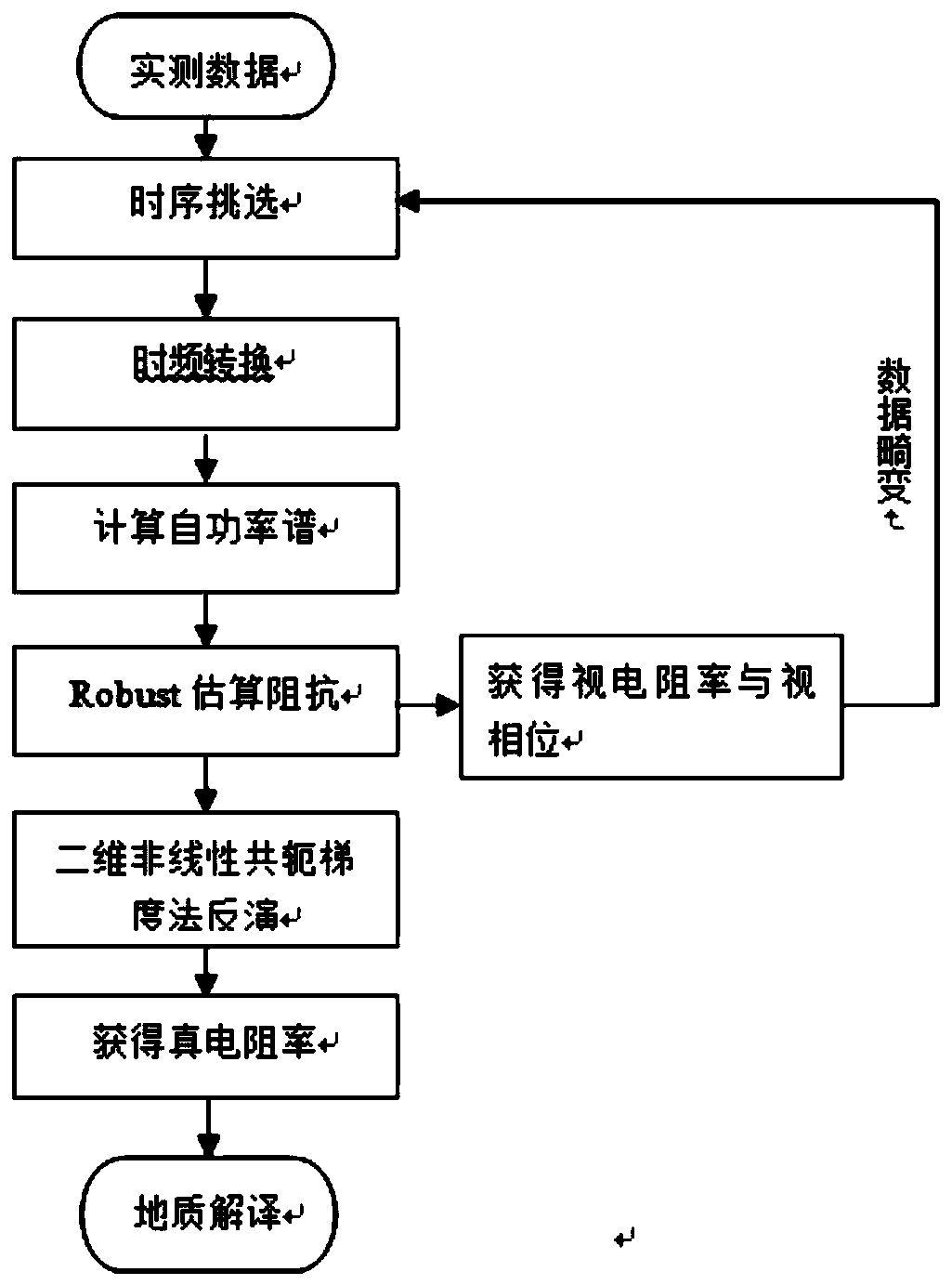

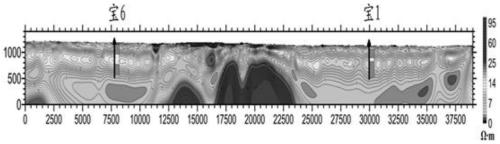

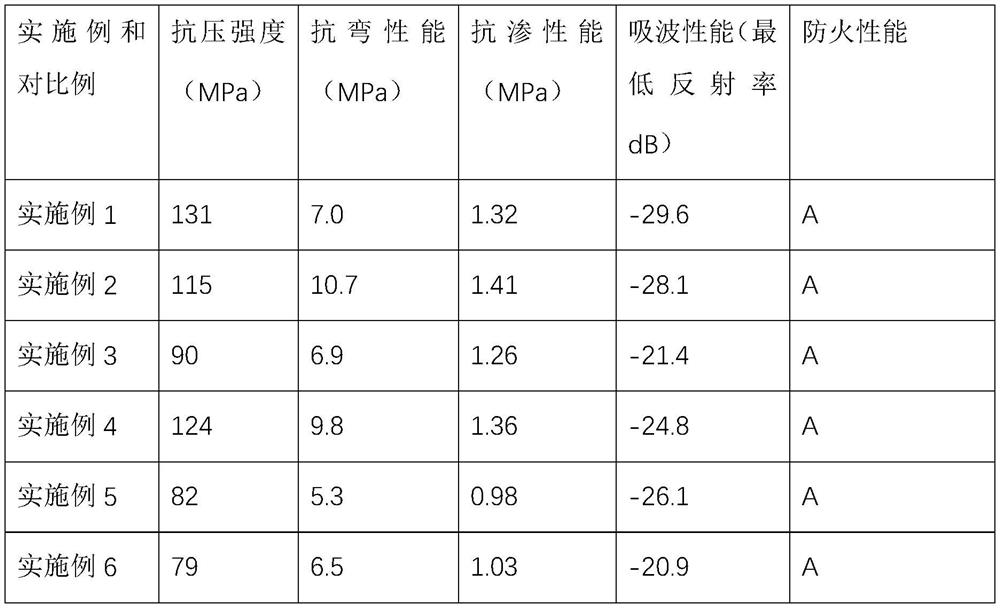

Method for identifying and positioning favorable sand body for ore-forming of sandstone-type uranium ore in basalt coverage area

ActiveCN111045114AReduce exploration investment riskShorten the evaluation periodElectric/magnetic detectionAcoustic wave reradiationLithologyUranium mineralization

The invention belongs to the technical field of uranium mineralization prediction, and particularly relates to a method for identifying and positioning a favorable sand body for ore-forming of a sandstone-type uranium ore in a basalt coverage area. The method comprises the steps of 1, finding out the range of a basalt coverage area on the ground surface; 2, calculating the basement burial depth ofthe basalt coverage area; 3, finding out the basement lithology of the basalt coverage area and determining a favorable sandstone-type uranium ore-forming section, wherein the step includes the sub-steps of 3.1, interpreting the basement lithology according to aeromagnetic data, and 3.2, determining a favorable sandstone-type uranium ore-forming section; 4, finding out characteristics of the sandbody in the sedimentary stratum under the basalt coverage, wherein the step includes the sub-steps of 4.1, carrying out broadband magnetotelluric profile measurement, and 4.2, finding out characteristics of the sand body in the sedimentary stratum under the of basalt coverage; 5, identifying and positioning a favorable sandstone-type uranium ore ore-forming sand body, wherein the step includes the sub-steps of 5.1, identifying and positioning a favorable ore-forming sand body in a basin area, and 5.2, identifying and positioning a favorable ore-forming sand body in a favorable riverway development area of an upheaval area; and 6, verifying the favorable ore-forming sand body through drilling.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

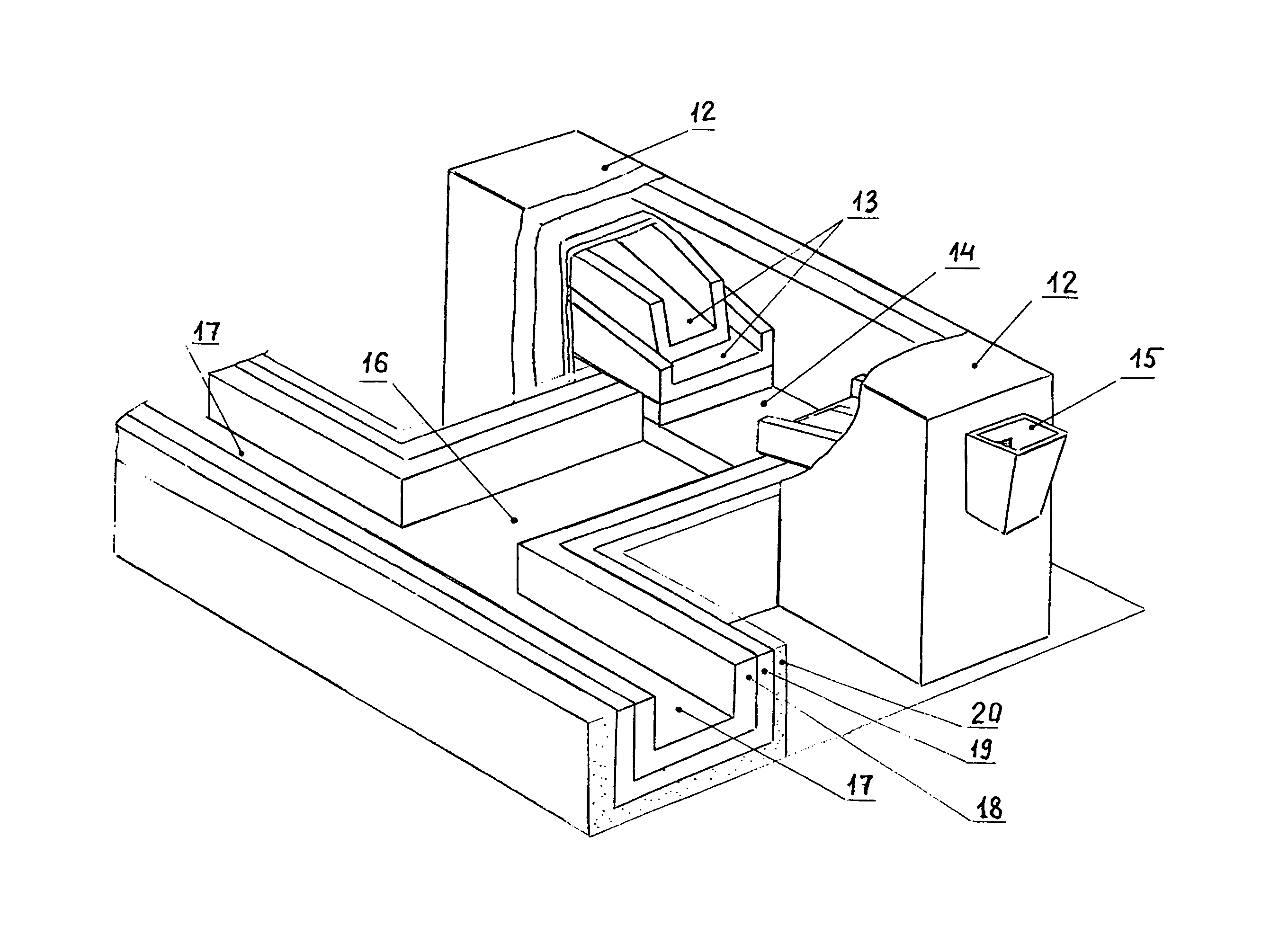

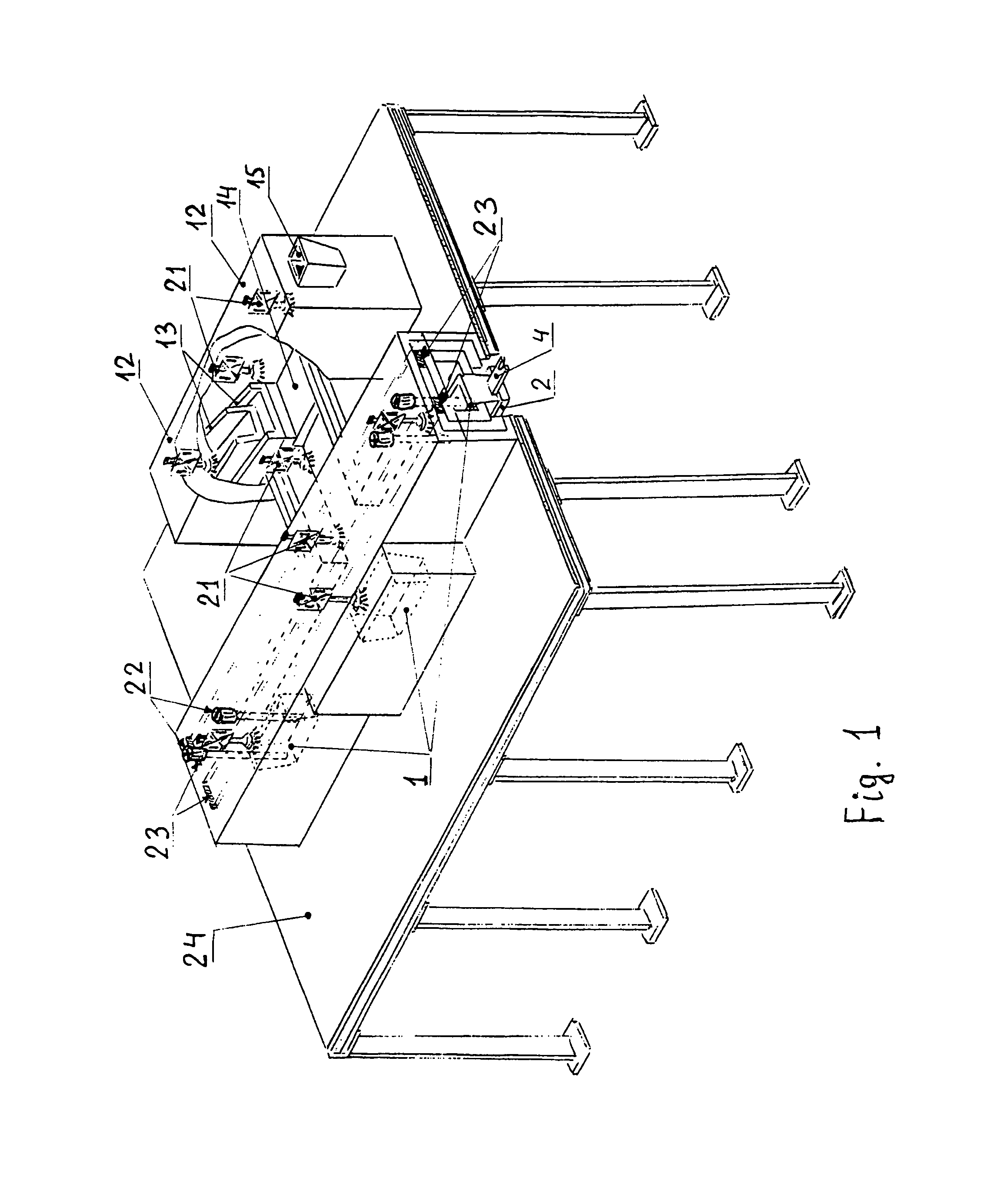

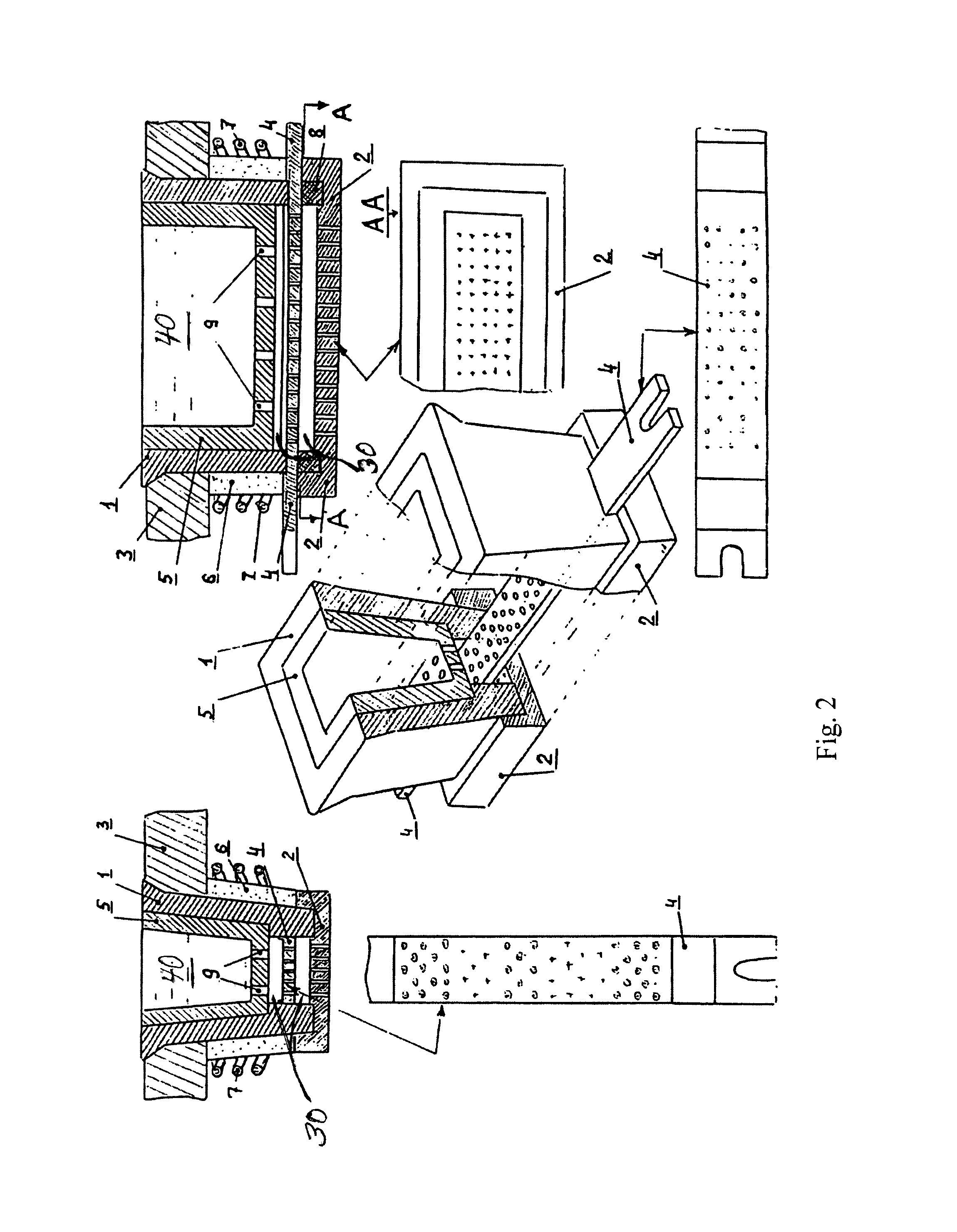

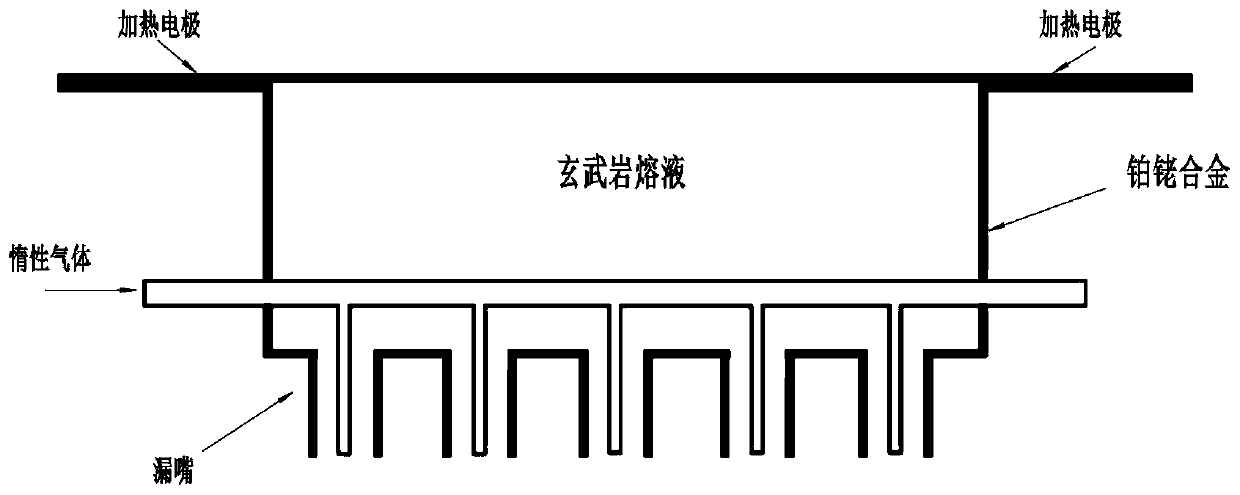

Ceramic bushing/s consisting local heating/s integrated in apparatus for manufacturing mineral/basalt fibers

ActiveUS8806900B2Accelerated corrosionEnhanced mechanical stability and thermal shock and corrosion resistanceGlass furnace apparatusRotary drum furnacesRebarBasalt fiber

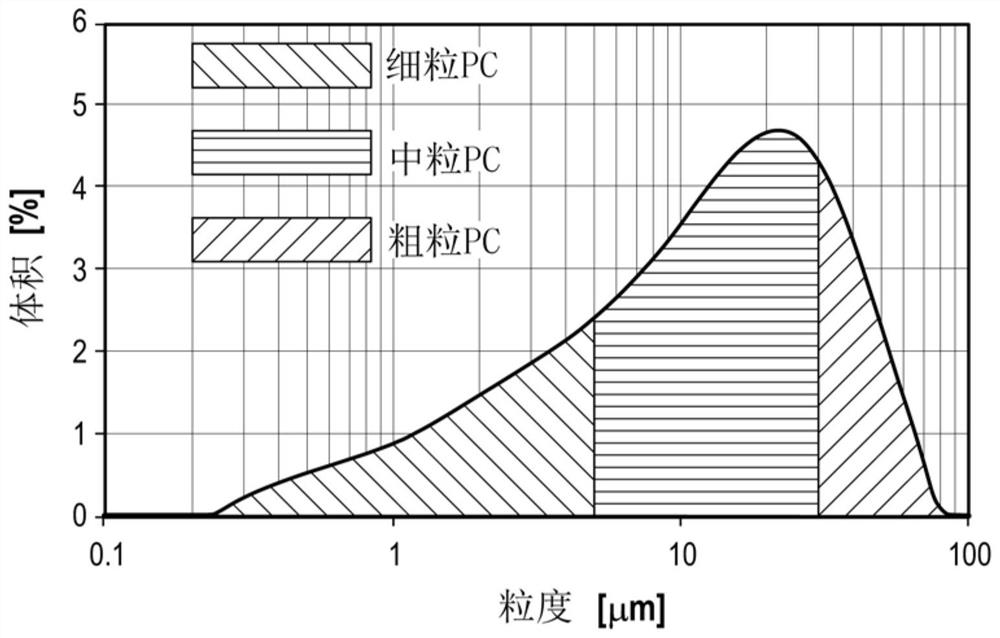

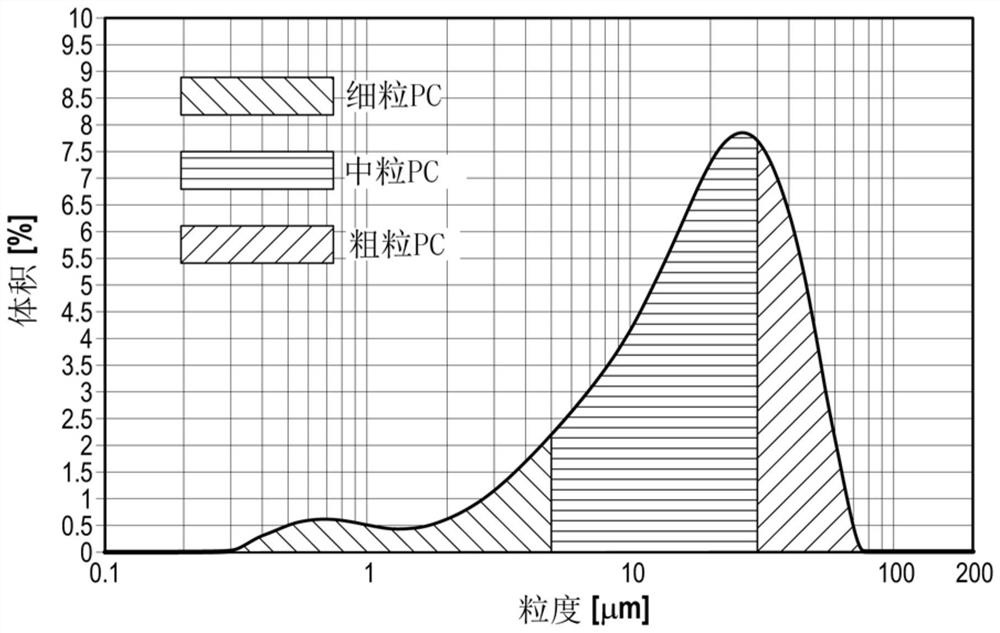

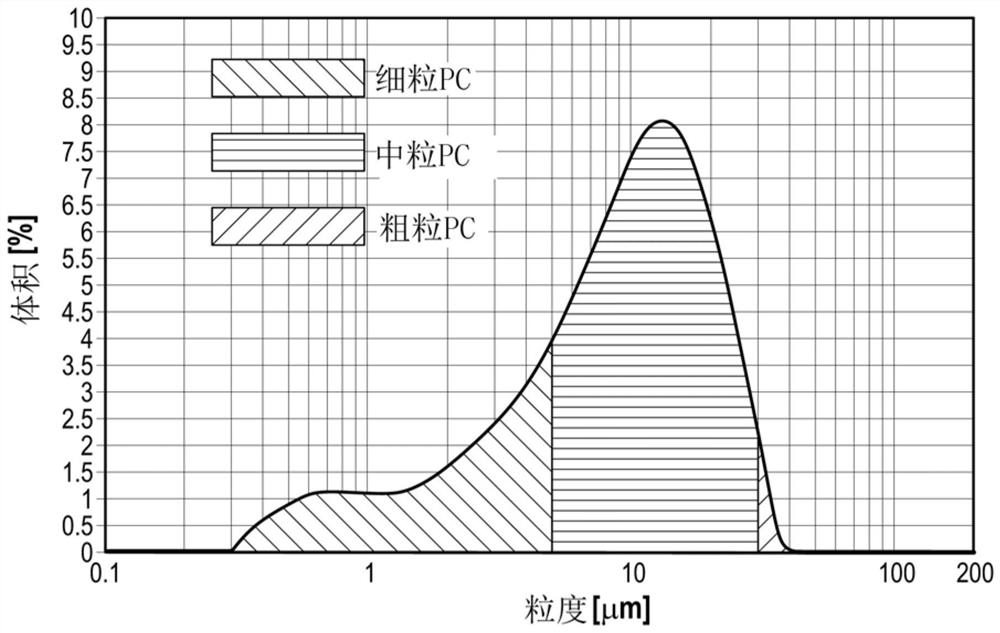

Several versions of ceramic bushing / s consisting local heating element / s integrated in apparatus for manufacturing mineral / basalt fibers from natural basalt rocks have been designed based on alternatives to Pt / Pt-Rd bushings approach. The ceramic bushing / s having local heating element / s concept promotes minimization or complete replacement of platinum group metals from the process of continuous basalt fiber manufacturing. More specifically, the invention discloses ceramic bushing / s comprising in combination apparatus are designed for manufacturing continuous mineral (basalt) fibers from 7 to 20 micrometers (μm), and also the coarse fibers from 20 μm to 100 micrometers (μm) in amorphous structural state which exhibit flexible / ductile properties. The minimization or complete replacement of the precious Pt, Rd metals allows reduce the cost of basalt fiber therefore increase its compatibility in reinforced concrete / composite applications including Three Dimension Fiber Reinforced Concrete—3D FRC and many other applications. The currently available Pt-Rd orificed bushings are applied for basalt fiber industry greatly limit both the initial raw materials composition, and the efficiency of continuous basalt fiber production increasing their cost. The ceramic bushing / s consisting local heating elements are integrated in apparatus all together capable provide operations from natural basalt rock melting, homogenous basalt glass body preparation, basalt glass body supply to the bushings positioned beneath the bottom platform of the feeder's forehead.

Owner:BLACKBULL IND INC +1

Formula of high-durability rock wool

InactiveCN111533459AQuality improvementIncreased durabilityGlass making apparatusAdhesivePhysical chemistry

The invention discloses a formula of high-durability rock wool, and relates to the technical field of rock wool. The rock wool comprises the following raw materials: 35-50 parts of basalt, 25-30 partsof quartz sand, 20-25 parts of slag, 15-20 parts of perlite, 12-15 parts of limestone, 8-10 parts of phenolic resin, 6-8 parts of a water repellent, and 2-3 parts of an adhesive. The formula processing of the high-durability rock wool comprises the following specific steps of (1) raw material processing, (2) raw material melting reaction, (3) rock wool fiber forming, (4) wool collecting and pressing and (5) curing finishing. According to the formula of rock wool, the slag is used as the raw material, waste can be recycled, environmental pollution can be reduced, and environmental benefits canbe improved; the basalt can improve the performance of the rock wool, the quartz sand is a nonmetal mineral substance and is a silicate mineral substance which is hard, wear-resistant and stable in chemical performance, and the quartz sand is added so that the strength of the rock wool is improved, the service life of the rock wool is prolonged, and the durability of the rock wool is better.

Owner:NANJING TONTECH ROCKWOOL CO LTD

Concentric is shells for compressed gas storage

ActiveUS9234625B2Vessel manufacturingVessel geometry/arrangement/sizeAramidesFiber-reinforced composite

Owner:QUANTUM FUEL SYSTEMS LLC

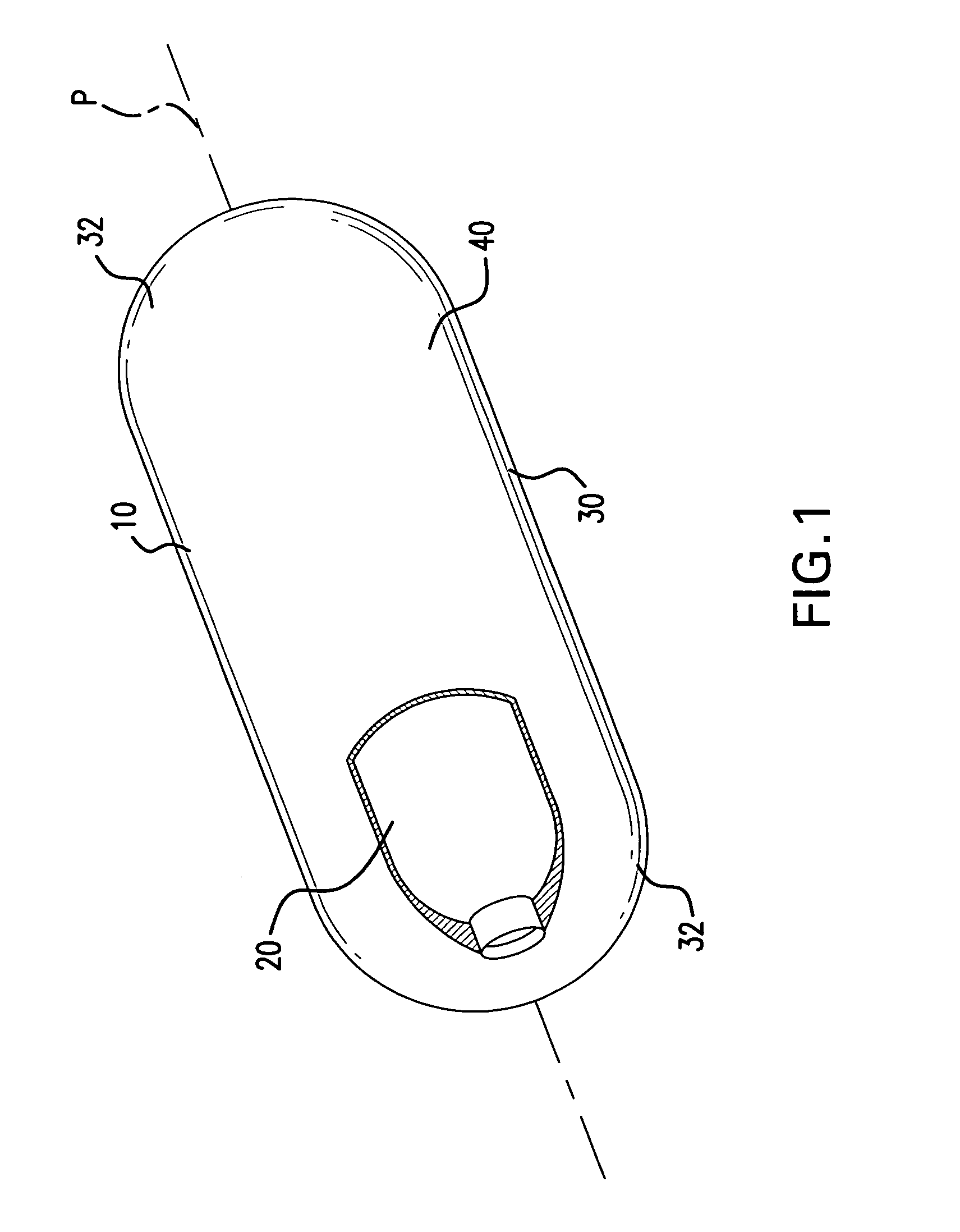

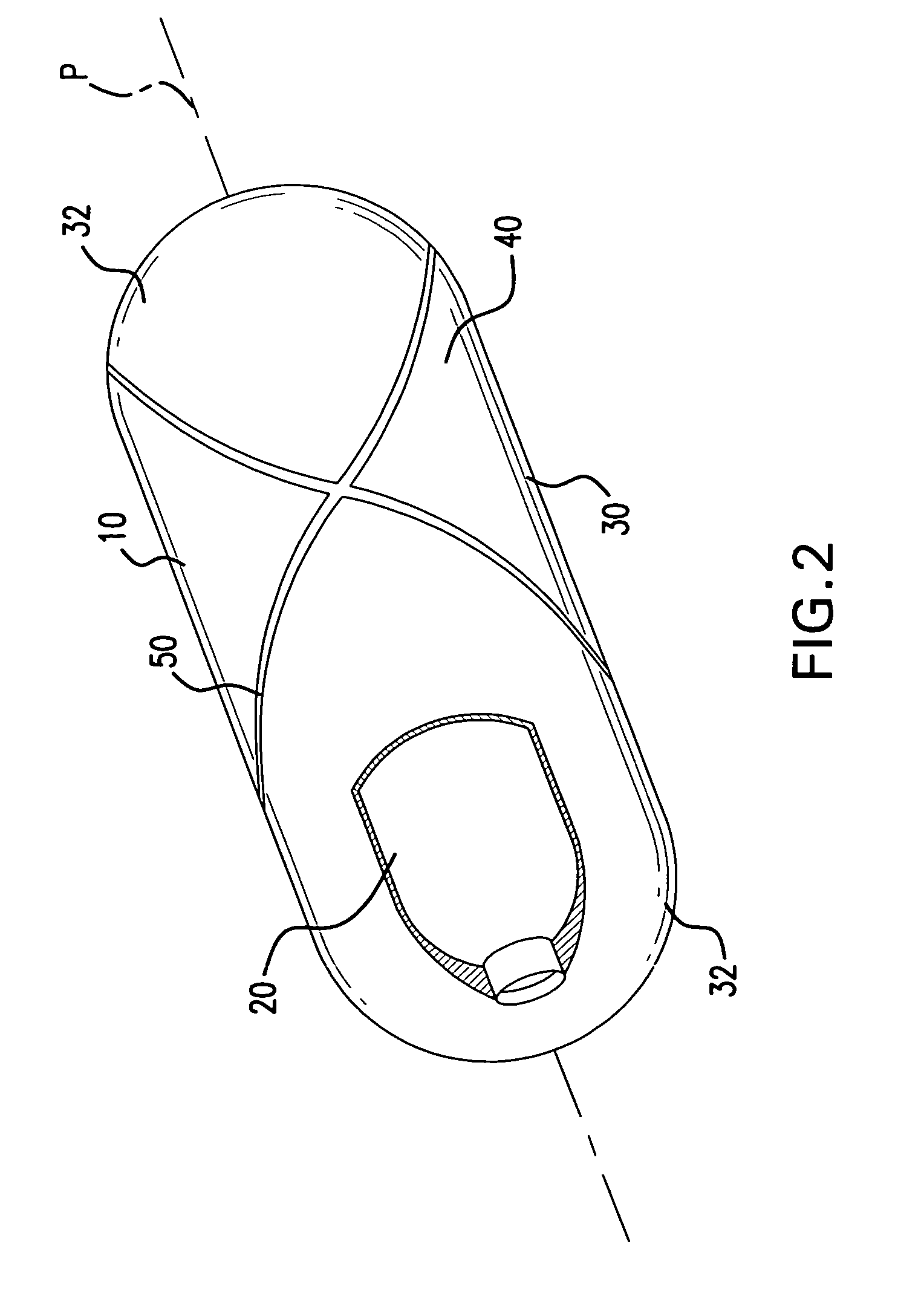

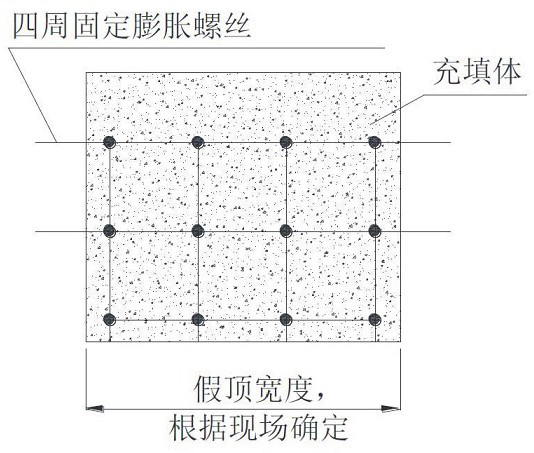

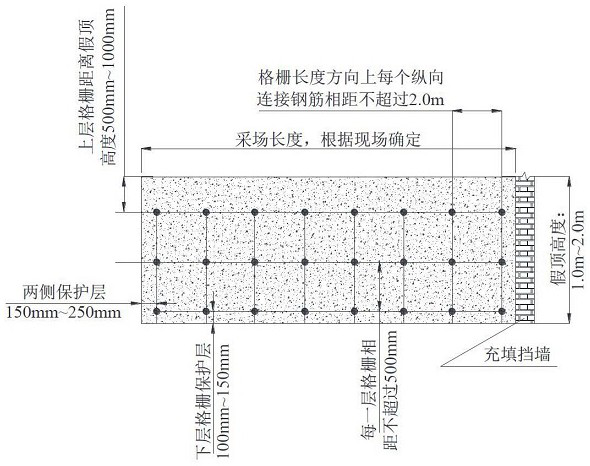

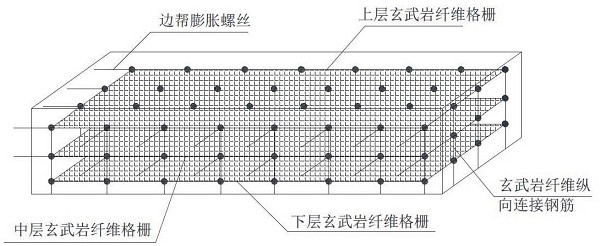

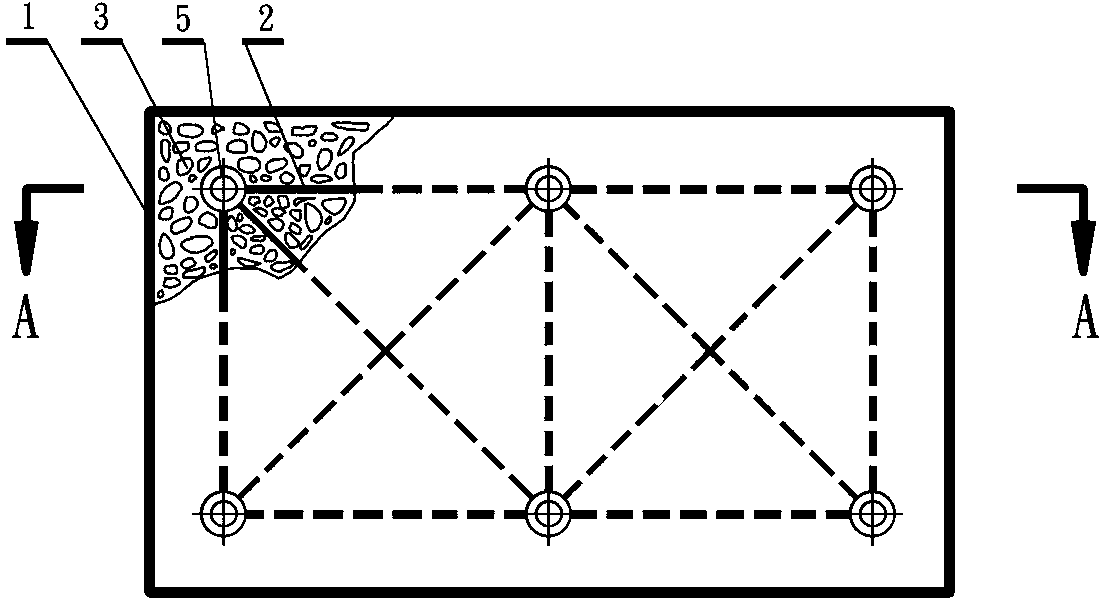

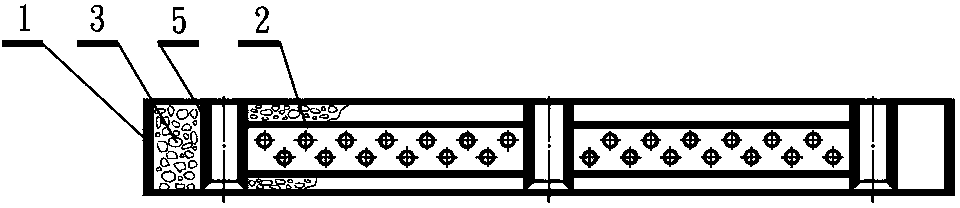

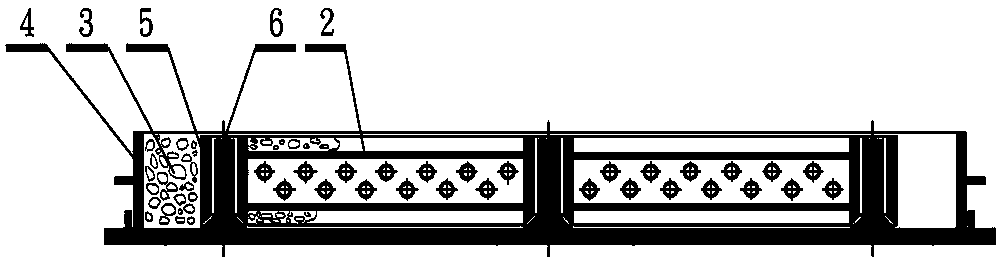

Artificial false roof construction method of built-in basalt fiber geogrid reinforced structure

ActiveCN113250745AReduce weightReduce labor intensityMaterial fill-upArchitectural engineeringStructural engineering

The invention provides an artificial false roof construction method of a built-in basalt fiber geogrid reinforced structure, and belongs to the technical field of mining filling false roof manufacturing. The method comprises the steps that after mining is finished, a site is leveled, large waste stones existing in an access road are removed, and pumice stones protruding out of the two sides are treated; basalt fiber grids are cut according to the size of a stope, the basalt fiber grids are a whole in the span and length direction of the stope, and the three basalt fiber grids are cut to be arranged in a filling body in an upper layer, a middle layer and a lower layer; and then two layers of expansion screws are arranged along the side of the stope, finally, the expansion screws are arranged in the stope from inside to outside, and the three basalt fiber grids are arranged into three layers from top to bottom. According to the method, the false roof filling process is simple, integrity is high, safety is high, and cost is low.

Owner:UNIV OF SCI & TECH BEIJING

Impact-resistant basalt fiber reinforced concrete and preparation method thereof

The invention relates to impact-resistant basalt fiber reinforced concrete and a preparation method thereof. The impact-resistant basalt fiber reinforced concrete comprises the following components inparts by weight: 400-800 parts of cement, 80-170 parts of a mineral admixture; 500-1200 parts of fine aggregate; 90-1800 parts of coarse aggregate; 2-4 parts of basalt fiber; and 200-400 parts of water. According to the impact-resistant basalt fiber reinforced concrete, the basalt fiber has excellent impact resistance, and the impact failure load is higher than that of common concrete. The relative dynamic elastic modulus and the mass loss rate are obviously controlled under the condition of multiple freezing and thawing, the anti-freezing performance is outstanding, and the concrete has important significance in the fields of port deep wharfs, cross-sea bridges and the like.

Owner:SHENYANG LIGONG UNIV

Environment-friendly basalt acoustic board

ActiveCN103556734AStrong foaming abilityHigh foaming ratioNoise reduction constructionSound proofingFoaming agentEngineering

The invention discloses an environment-friendly basalt acoustic board. According to the technical scheme, a built-in frame is horizontally placed on a mold; after short steel tubes in the built-in frame are inserted in vertical columns, composite basalt foaming agents are poured on the periphery of the built-in frame, and the built-in frame is completely inlaid in the composite foaming agents; and after the composite foaming agents are solidified in a standing manner, roasted and cooled, the built-in frame which is completely inlaid in the composite foaming agents is packaged to obtain the finished product of the environment-friendly basalt acoustic board. The composite basalt foaming agents consist of raw materials such as vesicular basalt powder, attapulgite clay powder and hydrogen peroxide; after the composite basalt foaming agents are solidified, the composite basalt foaming agents and the built-in frame form an integrated body, and the integral strength, the bending resistance and the actual using effect of the environment-friendly basalt acoustic board are improved; and the environment-friendly basalt acoustic board not only has an effect of strengthening sound absorption and controlling noise pollution, but also has functions of preserving heat, absorbing sound and purifying air. In addition, the environment-friendly basalt acoustic board is applicable to facilities such as an expressway, a viaduct, an urban light rail, a metro, a factory and a public place.

Owner:BEIJING MUNICIPAL INST OF LABOUR PROTECTION +4

Geopolymeric structural building units and methods of manufacture thereof

InactiveUS9126865B2Improve performanceSolid waste managementCement productionGeopolymer cementBuilding unit

The present invention provides a geopolymeric cement formed from a precursor having a relatively high alumina content (Si:Al atomic ratio of less than or equal to 1.3:1) to form an alkaline multiphase alumino-silicate material.The precursor comprises basaltic rock in which kaolinization is at an advanced stage, preferably Interbasaltic material found in Northern Ireland.The present invention also provides structural units for constructing a building, the structural units being manufactured using the geopolymeric cement of the invention.The invention also provides a process for producing a geopolymeric cement comprising a precursor having a relatively high alumina content (Si:Al atomic ratio of less than or equal to 1.3:1) to form an alkaline alumino-silicate geopolymer material for manufacturing geopolymeric structural building units having compressive strengths of greater than 3 N / mm2 and preferably having compressive strengths in the range of 12-25 N / mm2.

Owner:RANDOM TECH

Process for manufacturing basalt capillary tube by using stretching method

PendingCN111470779AHigh strengthCorrosion resistantGlass furnace apparatusCapillary TubingEngineering

The invention discloses a process for manufacturing a basalt capillary tube by using a stretching method, and relates to the technical field of manufacturing of hydrogen storage capillary tubes. The method comprises the following steps: S1, selecting a proper basalt ore raw material, adding the basalt ore raw material into a crusher for crushing, screening the crushed basalt through a screening machine with a 200-300-mesh screen, removing large-particle basalt, and storing the basalt raw material cleaned by deionized water in a stock bin for later use; and S2, conveying the basalt stored in the step S1 to a quantitative feeder through a lifting conveyor, and feeding the basalt into a unit melting furnace. The hollow basalt microtube prepared by the method has the characteristics of high strength, corrosion resistance, acid and alkali resistance and the like; the basalt capillary tube is very suitable for being used as a high-pressure hydrogen storage material, the viscosity of basalt molten liquid is reasonably adjusted, the preparation quality is improved, the preparation uniformity of the capillary tube is guaranteed, and the phenomenon that the inner diameter of a local pipelineis large or small in the wire drawing process due to insufficient viscosity is avoided.

Owner:深圳中科氢能科技有限公司

Gold glaze material and glazing method thereof

ActiveCN111792844AUnique colorWith health functionCeramic shaping apparatusPhysical chemistryBasaltic rock

The invention provides a gold glaze material, which comprises the following components: 80-120 parts of the potassium feldspar, 40-60 g of the calcite, 5-20 g of the aluminum ore, 5-20 parts of iron ore, 40-60 parts of limestone, 5-15 parts of fluorite, 40-60 parts of dark jade, 90-120 g of the Lushan jade, 25-35 g of plant ash and 15-25 g of basalt. According to the invention, the gold glaze material with golden color is prepared, is unique in color, stable and durable, has a certain health-care function, and has the effects of clearing and activating the channels and collaterals, prolonginglife, purifying water, activating blood, expelling toxin, improving eyesight, moistening lung and reducing blood pressure; and the glazing method suitable for the gold glaze material is designed, wherein glazing is completed through mechanical operation, and the obtained finished product is uniform in color and luster and rich in layering sense.

Owner:鲁山花瓷股份有限公司

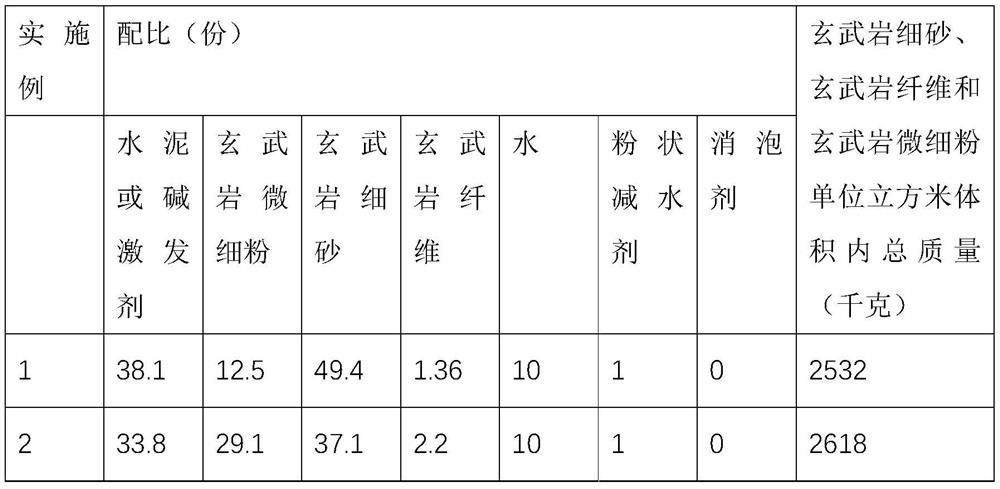

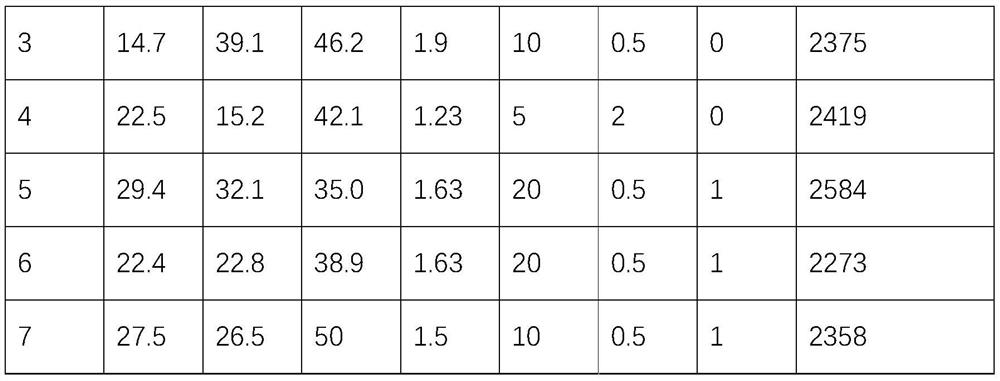

Multifunctional environment-friendly mortar modified by optimizing basalt admixture system and preparation method of multifunctional environment-friendly mortar

ActiveCN113045264AEfficient use ofReduce preparation energy consumptionSolid waste managementBasaltic rockCement mortar

Owner:浙江汇安工程质量检测有限公司

Preparation method of formaldehyde-free rock wool

InactiveCN111331995AUse safety and environmental protectionGlass making apparatusLamination ancillary operationsFiberSlag

The invention relates to the technical field of rock wool preparation, and discloses a formaldehyde-free rock wool preparation method, which comprises: S1, material preparing: weighing a certain amount of basalt, dolomite, slag and coke according to a ratio of 60-65:15-20:20:17; S2, high-temperature melting: mixing the basalt, the dolomite, the slag and the coke, putting the mixture into a meltingfurnace, blowing hot air at 450-550 DEG C for supporting combustion, controlling the melting temperature of the melting furnace to be greater than 1450 DEG C, and melting the mixture into a melt forlater fiber forming. According to the preparation method of the formaldehyde-free rock wool, the prepared rock wool does not release formaldehyde, so that the rock wool is environment-friendly and safe to use.

Owner:NANJING TONTECH ROCKWOOL CO LTD

Method for identifying and positioning ancient riverway under basalt coverage

ActiveCN111045091AQuick identificationIdentify and locate the economyWater resource assessmentElectric/magnetic detectionMetallogenyRiver routing

The invention belongs to the technical field of uranium mineralization prediction, and particularly relates to a method for identifying and positioning an ancient riverway under basalt coverage. The method comprises the steps of 1, finding out spatial and temporal distribution characteristics of basalt on the ground surface and determining a possible distribution direction of the ancient riverway,wherein the step includes the sub-steps of 1.1, finding out spatial and temporal distribution characteristics of basalt on the ground surface, and 1.2, determining the possible distribution directionof the ancient riverway under basalt coverage; 2, determining an ancient riverway distribution pre-selection area, wherein the step includes the sub-steps of 2.1, finding out a structure, a vegetation zone and a water system zone of a basalt coverage area, and 2.2, determining an ancient riverway distribution pre-selection area; 3, identifying and positioning the ancient riverway covered by basalt, wherein the step includes the sub-steps of 3.1, collecting aviation transient electromagnetic data, 3.2, identifying and positioning the ancient riverway covered by basalt, 3.3, determining the horizon in which the ancient riverway is developed, and 3.4, finding out the scale of the ancient riverway; and 4, drilling to verify the ancient riverway.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

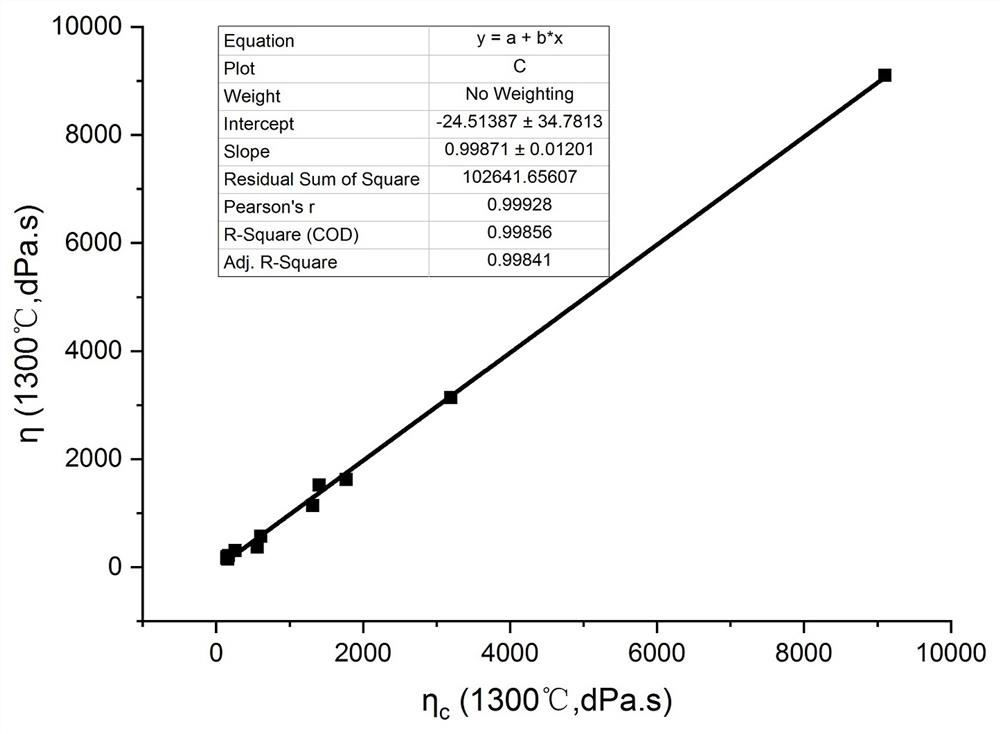

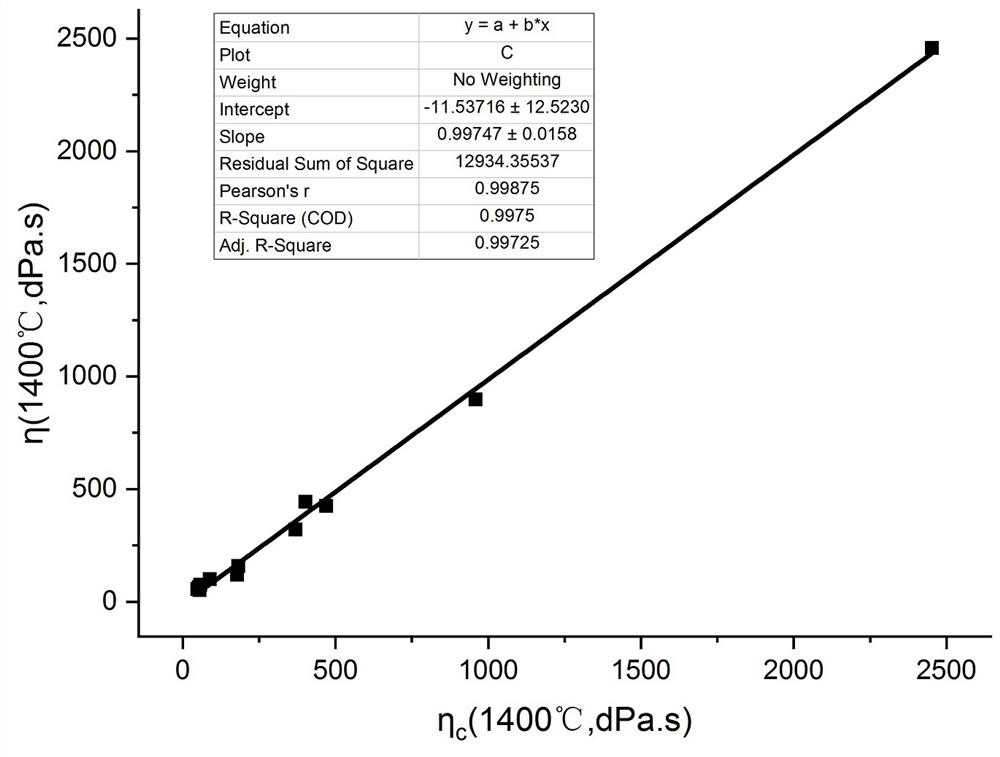

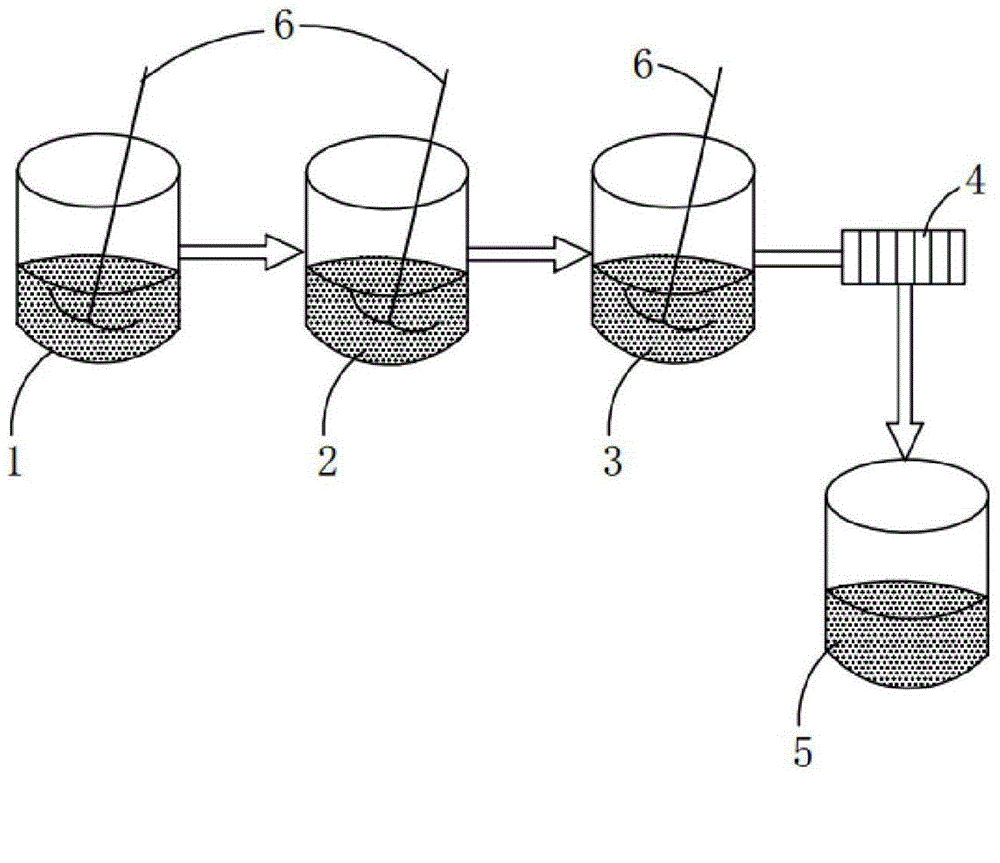

Method for predicting high-temperature viscosity and wire drawing temperature of basalt melt through viscosity modulus

ActiveCN111613278AAssurance controlGuaranteed stabilityChemical property predictionMolecular entity identificationEngineeringBasaltic rock

The invention discloses a method for predicting high-temperature viscosity and wire drawing temperature of basalt melt through viscosity modulus. The method comprises the following steps: determiningthe viscosity modulus of each component in a basalt raw material according to the mole percentage of the component; predicting the viscosity of the basalt melt at each high-temperature point accordingto the viscosity modulus; further obtaining a prediction formula of the viscosity of the basalt melt at any temperature point within the range of 1250-1550 DEG C; and defining the wire drawing temperature as the temperature at which the melt viscosity is 318 dPa.s, so that the wire drawing temperature can be solved. According to the method, the accurate prediction of the high-temperature viscosity of the basalt ore and the wiredrawing temperature can be simply, conveniently and quickly predicted, and compounding of basalt raw materials can be quickly realized; basalt ore which is originally not suitable for producing continuous basalt fibers can be continuously used after viscosity optimization, and the problems that in the prior art, high-temperature viscosity testing of basalt consumestime and labor, the wire drawing temperature is manually set according to experience, and product quality improvement and stability control are not facilitated are solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Mineral compound material and its use in sewage treatment

InactiveCN105984925ALow costReduced activityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationClay mineralsSewage

The invention discloses a mineral composite material and its application in sewage treatment. The mineral composite material is composed of granite, basalt, peridotite, clay minerals, water and inorganic acid. The parts by weight of each component are: 10-20 parts of granite, 8-18 parts of basalt, 8-18 parts of peridotite, 10-20 parts of clay mineral, 5-15 parts of water and 0.5-8 parts of inorganic acid. The components are pulverized and mixed; adding concentrated hydrochloric acid or concentrated sulfuric acid to dissolve the components; adding water and stirring to fully dissolve; standing still and filtering to remove residues to obtain the mineral composite material. The mineral composite material of the invention can be used to remove fluorine element, hexavalent chromium element and lead element in sewage, and can also reduce TOC and BOD content in sewage.

Owner:吴书文

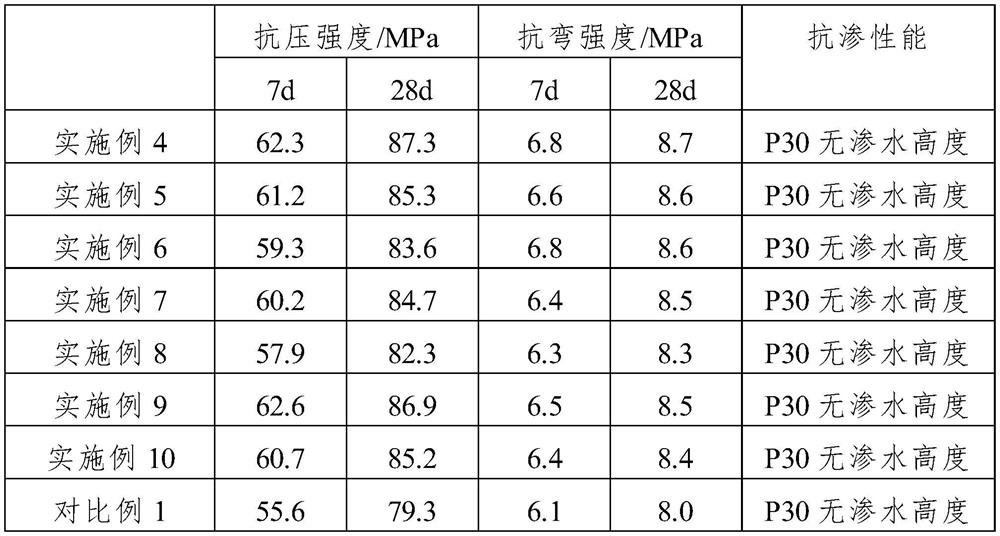

Preparation method of high-strength self-compacting concrete

The invention provides a preparation method of high-strength self-compacting concrete. The preparation method comprises the following steps: (1), weighing the following raw materials, by weight: 290-320 parts of cement, 70-85 parts of fly ash, 65-75 parts of silica fume, 650-750 parts of quartz sand, 700-800 parts of gravels, 25-35 parts of glass beads, 12-15 parts of a nano titanium dioxide / basalt stone powder composite material, 1.5-2 parts of redispersible polymer rubber powder, 1-1.2 parts of an epoxy silane coupling agent and 10-15 parts of an additive; and (2), uniformly mixing glass beads, redispersible polymer rubber powder and an epoxy silane coupling agent to obtain a pre-mixture; pouring cement, fly ash, silica fume and the nano titanium dioxide / basalt stone powder composite material into a stirrer, uniformly performing stirring, adding the pre-mixture, water and quartz sand, performing stirring for 120-150 seconds, then adding crushed stone and the additive, continuously performing stirring for 120-150 seconds, and uniformly performing stirring, so as to obtain the self-compacting concrete. The concrete prepared in the invention has the advantages of high strength, goodworking performances and excellent durability.

Owner:江苏昆腾新材料科技有限公司

Ceramic material, digital glaze spraying ceramic rock plate as well as preparation method and application of digital glaze spraying ceramic rock plate

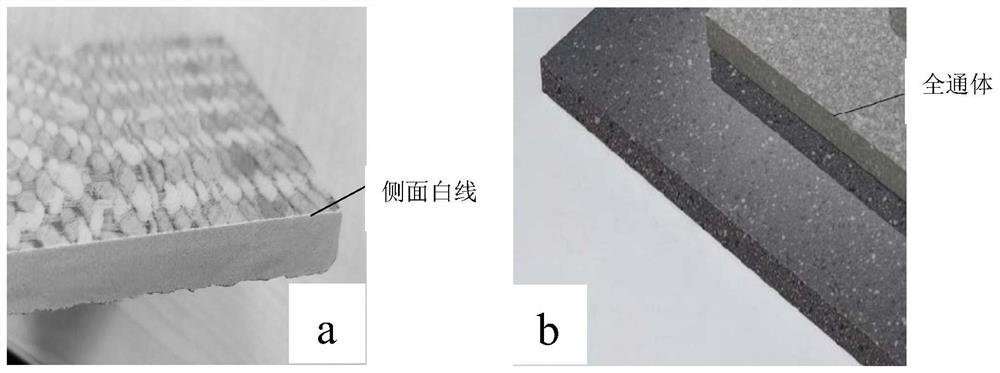

ActiveCN112500144AImprove high temperature resistanceGood chemical resistanceCeramic materials productionGlazeBasaltic rock

The invention belongs to the technical field of building ceramics, and discloses a ceramic material, a digital glaze spraying ceramic rock plate and a preparation method and application thereof, the ceramic material is mainly prepared from quartz, basalt and a flexural strength functional additive, the basalt is beneficial to improving the compactness and the like of the rock plate, sodium humatein the flexural strength functional additive can improve the drying flexural strength of a green body and shorten the drying time of the green body. The invention also provides a digital glaze spraying ceramic rock plate and a preparation method thereof, the main raw material of the rock plate is the ceramic material, and in the preparation method, digital glaze spraying is adopted for surface glaze application, so that the problems that the glaze surface of the ceramic rock plate produced by a traditional glaze spraying mode is too thick, and a relatively obvious white line isolation layer exists from the side view are avoided; and the full-body effect is achieved after the green body is subjected to polishing treatment. The obtained digital glaze spraying ceramic rock plate is more compact, more resistant to fire, high temperature, pollution and corrosion, free of permeation, high in hardness and extremely excellent in scratch resistance and wear resistance, and can be applied to thefields of buildings, decoration and the like.

Owner:FOSHAN OCEANO CERAMICS

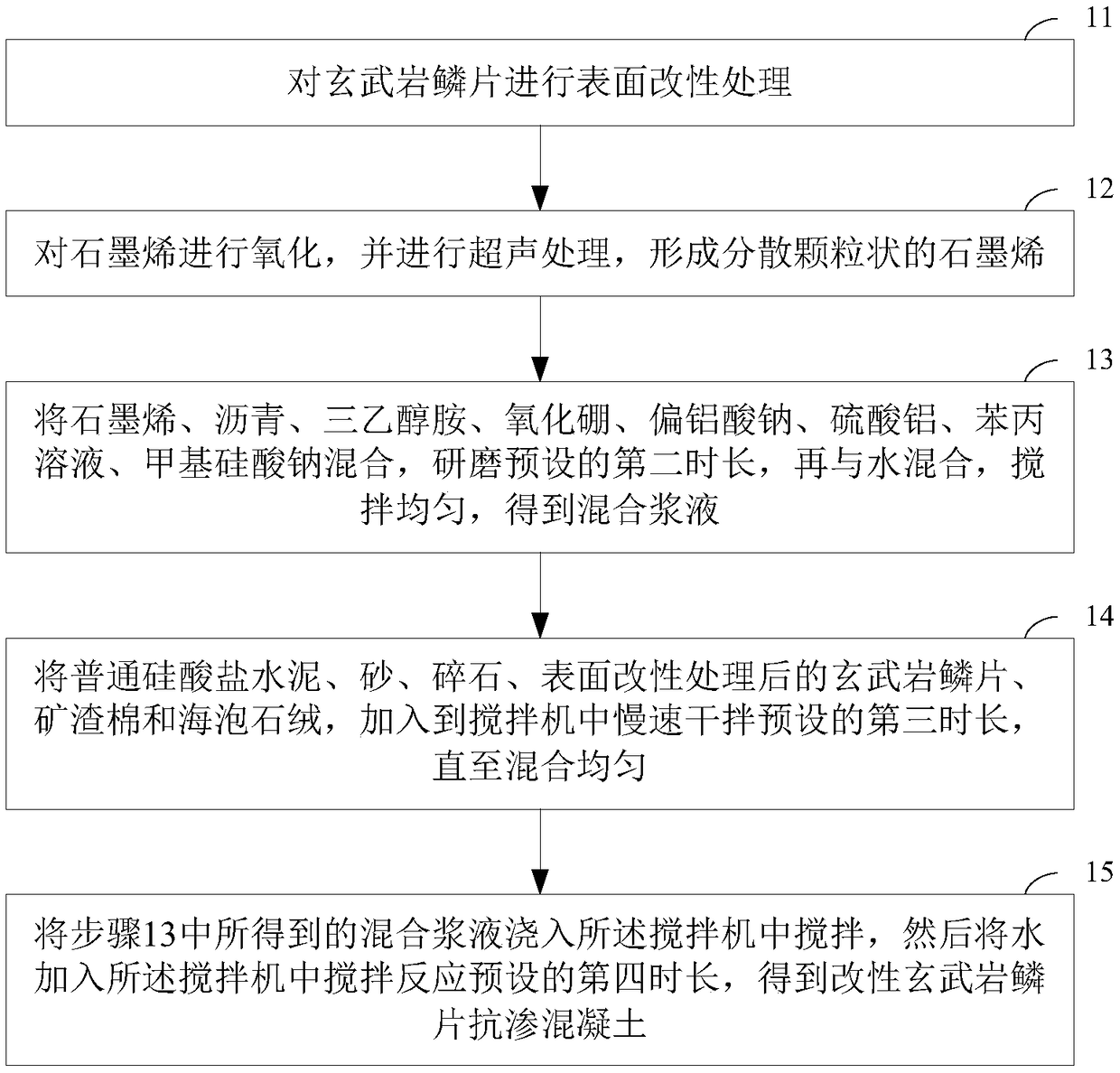

Modified basalt-flake impermeable concrete and preparation method thereof

The invention provides modified basalt-flake impermeable concrete and a preparation method thereof. The modified basalt-flake impermeable concrete is prepared from the following components in parts bymass: 170-200 parts of ordinary Portland cement, 10-50 parts of coal ash, 400-600 parts of rubble, 300-400 parts of sand, 50-70 parts of basalt flakes, 0.4-0.6 part of graphene, 1-3 parts of water reducer, 1-2 parts of silicone coupling agent, 10-15 parts of mineral cotton and sepiolite velvet, 30-40 parts of pitch, 1-2 parts of triethanolamine, 6-8 parts of boron oxide, 7-10 parts of sodium metaaluminate, 1-4 parts of aluminum sulfate, 20-30 parts of styrene-acrylic solution, 1-5 parts of methanesiliconic acid sodium salt and 60-100 parts of water. By applying the method, the impermeabilityof the prepared concrete can be improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

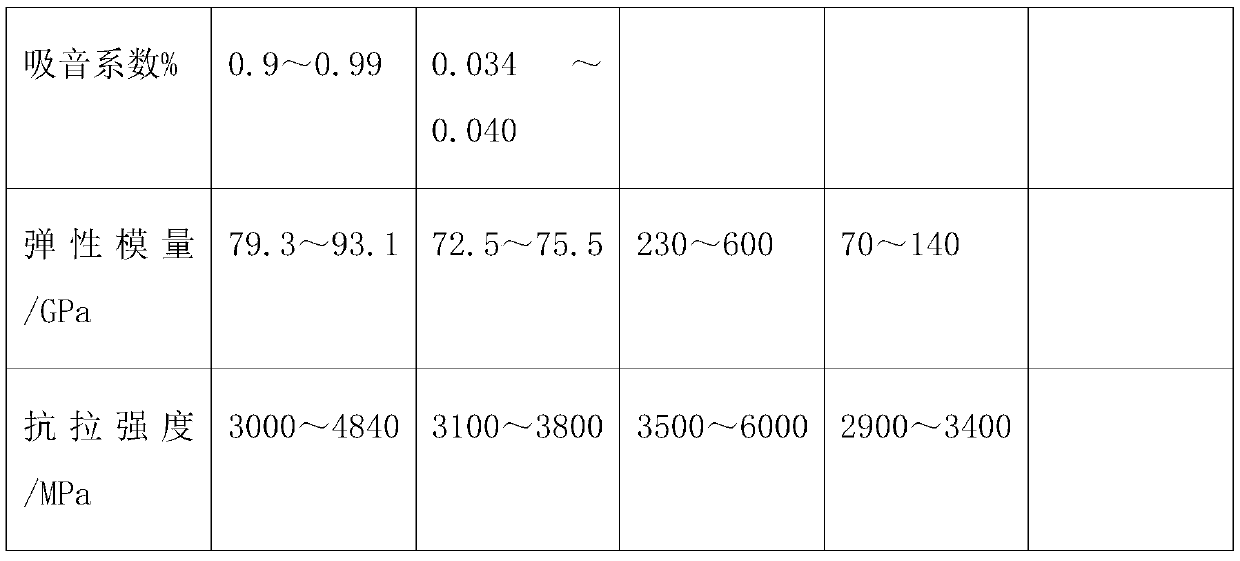

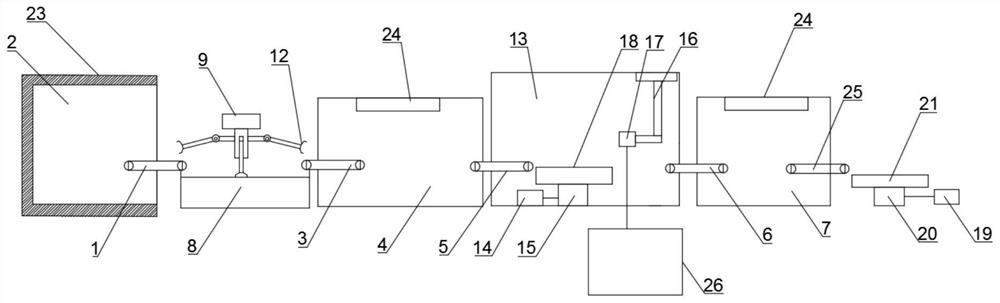

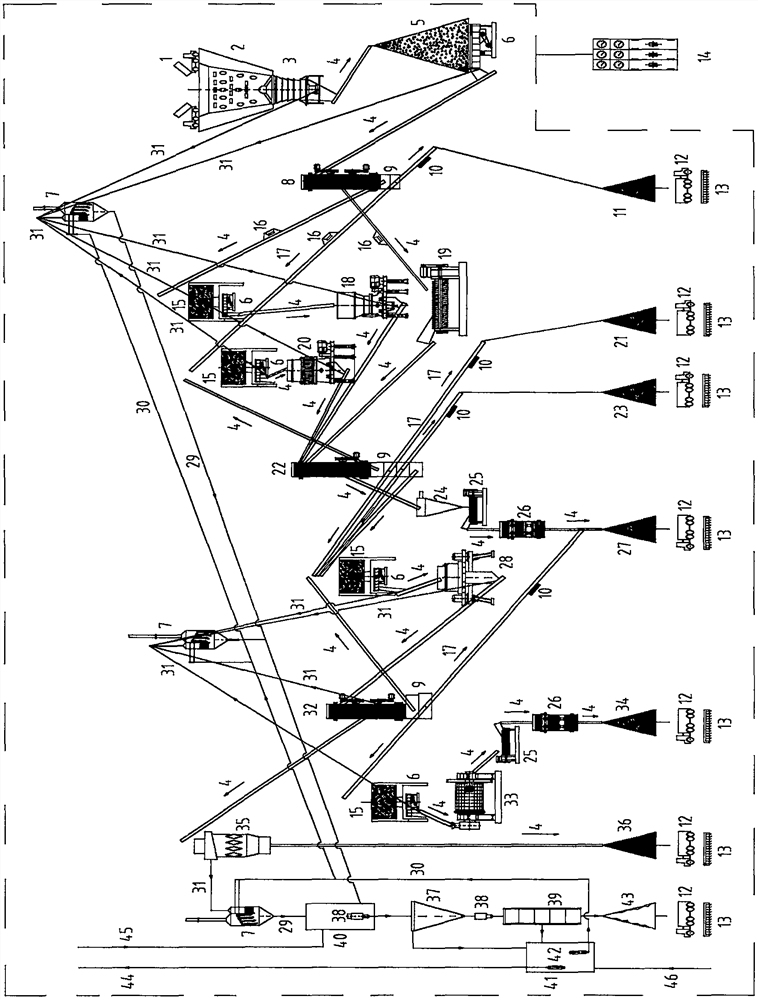

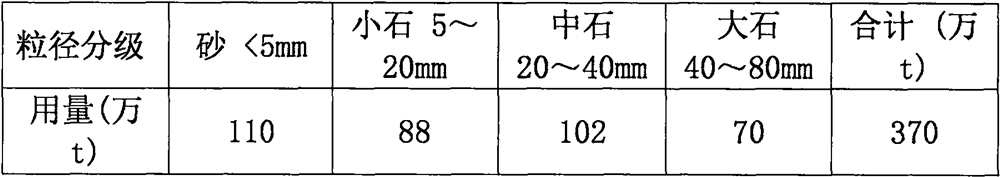

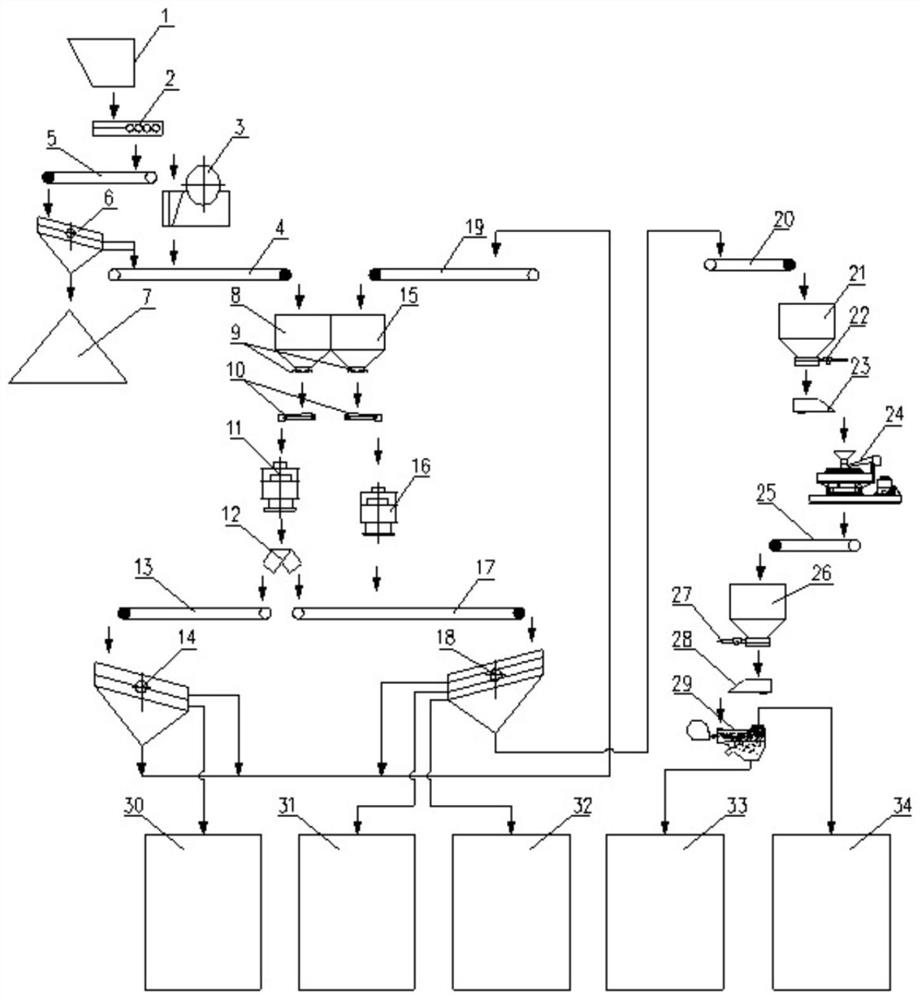

High-quality basalt machine-made sandstone aggregate production line and technological process thereof

PendingCN112452502AReasonable fineness modulusAppropriate fineness modulusSievingScreeningIntelligent environmentProcess engineering

The invention belongs to the field of manufacturing of machine-made sandstone equipment, and provides a dry-wet combined intelligent environment-friendly high-quality basalt machine-made sandstone aggregate production line. A technological process is designed into three-section crushing, wet method and dry method combined production, wherein coarse crushing is carried out by a hydraulic gyratory crusher in an open circuit manner; the intermediate crushing is formed into closed-loop production through a cone crusher and graded screening; and fine crushing is formed into dry-method closed-loop production through vertical shaft sand crushing and checking and screening, and is also supplemented with open-loop production of a rod mill. According to the dry-wet combined intelligent environment-friendly high-quality basalt machine-made sandstone aggregate production line, by comprehensively utilizing technical means such as a computer network, wireless communication, space positioning and geographic information, controllability of the whole production process of the sandstone aggregate is achieved. By adopting the dry-wet combined intelligent environment-friendly high-quality basalt machine-made sandstone aggregate production line, firstly, the high quality of the aggregate can be ensured; secondly, green and environment-friendly production is realized; and thirdly, intellectualization and controllability of process control can be realized.

Owner:青岛方特远矿山机械有限公司

Activation of natural pozzolan and use thereof

An activated pozzolan composition includes a fine interground particulate blend of an initially unactivated natural pozzolan and a supplementary cementitious material (SCM) different than the initially unactivated natural pozzolan. The initially unactivated natural pozzolan may include volcanic ash or other natural pozzolanic deposit having a moisture content of at least 3%, and the activated pozzolan composition can have a moisture content less than 0.5%. The initially unactivated natural pozzolan may have a particle size less than 1 mm before intergrinding with the SCM. The SCM used to activate the initially unactivated natural pozzolan can be initially coarse or granular with a size greater than 1-3 micrometers and may include granulated blast furnace slag, steel slag, other metallurgical slag, pumice, limestone, fine aggregate, shale, tuff, trass, geologic material, waste glass, glass shards, basalt, sinters, ceramics, recycled bricks, recycled concrete, refractory materials, other waste industrial products, sand, or natural mineral.

Owner:ROMAN CEMENT

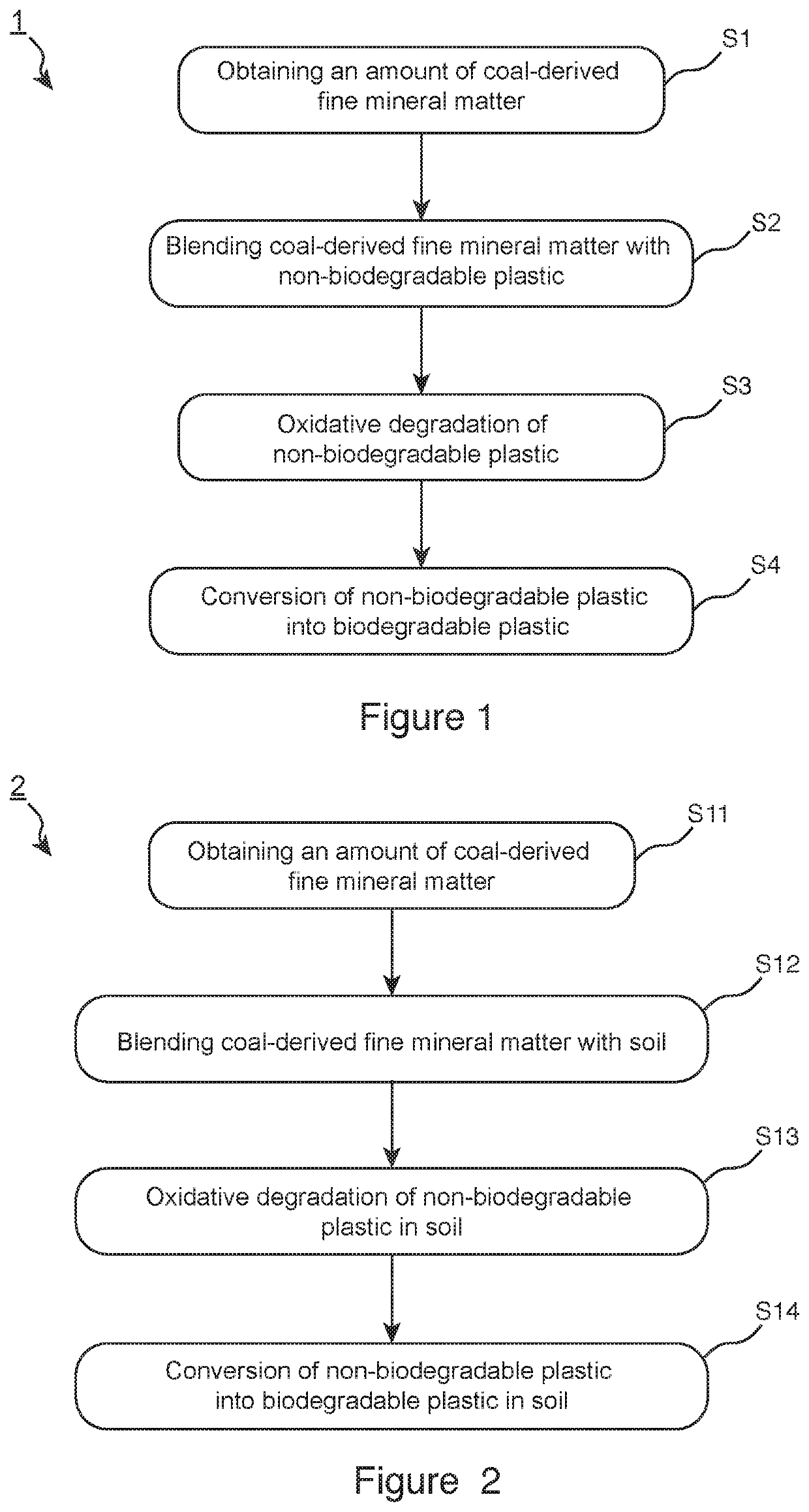

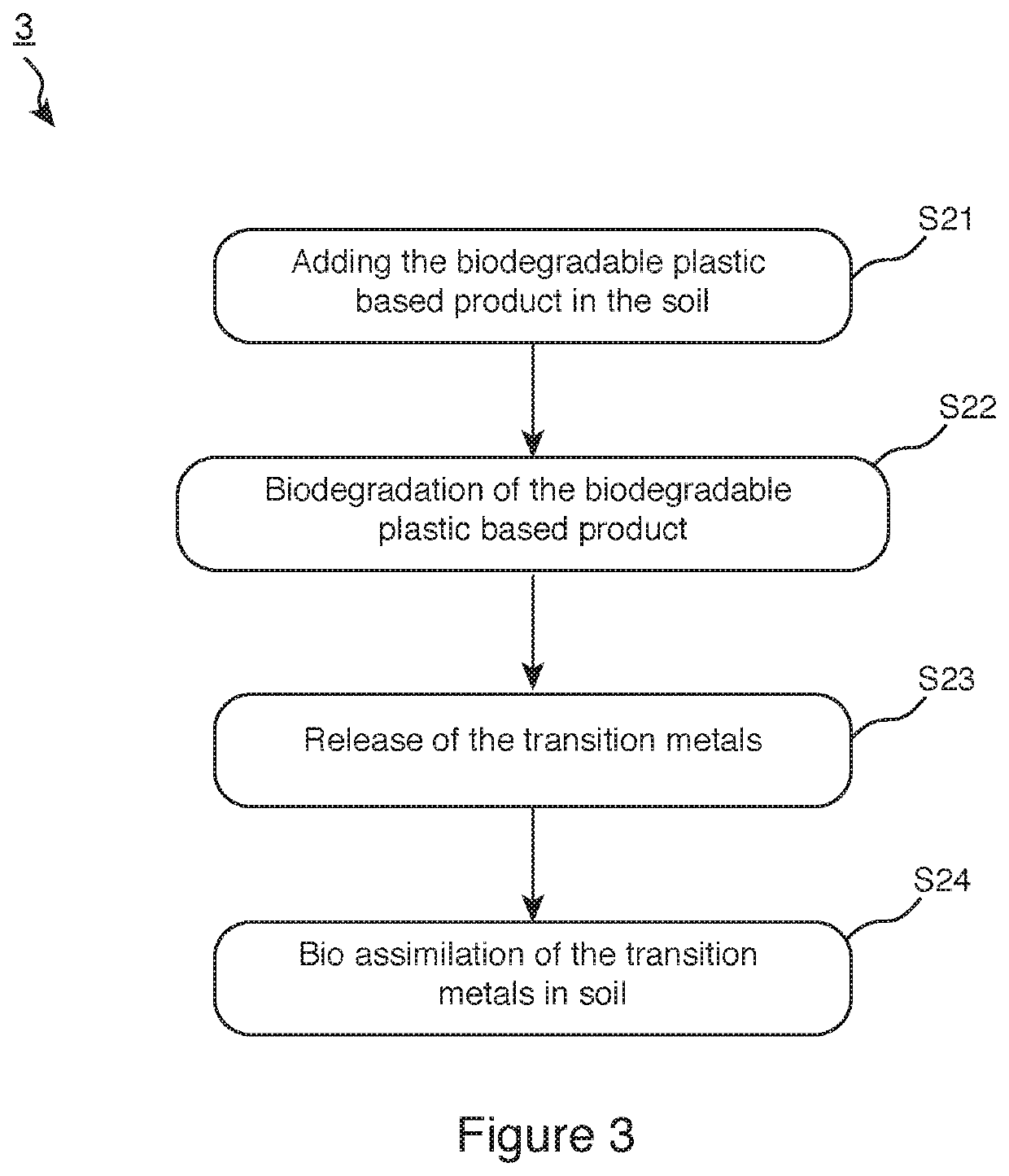

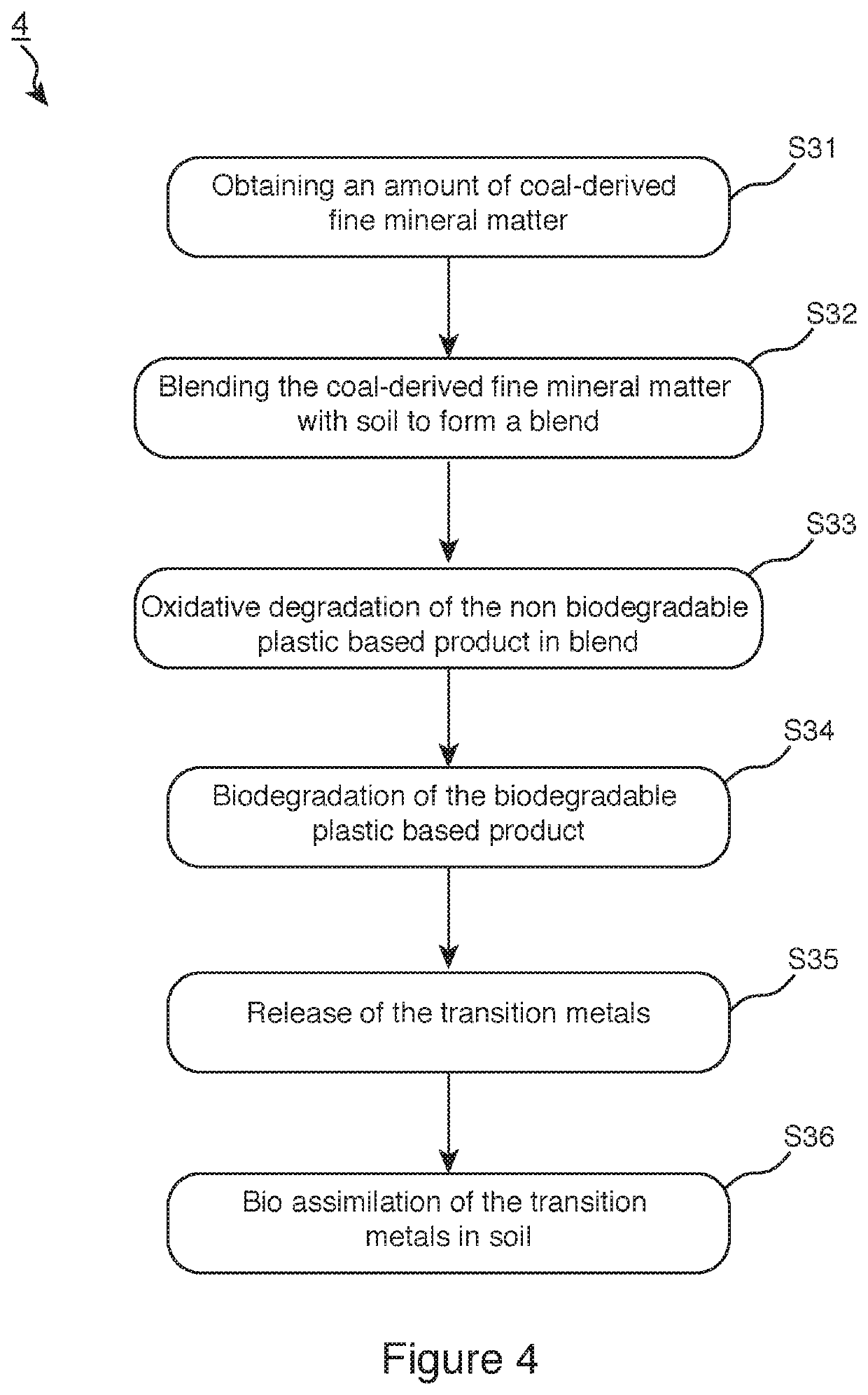

Utilization of Fine Mineral Matter in the Conversion of Non-Biodegradable Plastic and in Remediation of Soils Polluted with Non-Biodegradable Plastic

ActiveUS20200009762A1Improve soil qualityLow costContaminated soil reclamationSolid fuelsSilicic acidPotassium silicate

The disclosed invention describes a novel approach to the utilization of the fine mineral matter derived from coal and / or coal refuse (a by-product of coal refining) to convert a non-biodegradable plastic into a biodegradable plastic. The fine mineral matter could also be based on volcanic basalt, glacial rock dust deposits, iron potassium silicate and other sea shore mined deposits. The conversion of the non-biodegradable plastic into biodegradable plastic in soil further increases nutrients availability in soil with the transition metals released as a result of biodegradation of the biodegradable plastic.

Owner:RADICAL PLASTICS INC

Integrated basalt utilization system and process

The invention discloses an integrated basalt utilization system and process. The integrated basalt utilization system comprises a primary bin, a rod vibrating feeder and a soil removal screen, whereinthe rod vibrating feeder is installed on the lower side of the primary bin, a material which cannot pass through gaps between rods of the rod vibrating feeder enters a jaw crusher for coarse crushing, and the material discharged from the jaw crusher enters a first belt conveyor; a material which passes through the gaps between the rods enters the soil removal screen through a second belt conveyor; and the soil removal screen is a double-layer circular vibrating screen, the materials screened and intercepted by a first layer and a second layer enter a secondary crushing surge bin through the first belt conveyor, the secondary crushing surge bin is connected with a first cone crusher through a conveying device, and a discharging chute of the first cone crusher is provided with an electric-hydraulic three-way distributor. The integrated basalt utilization process and device are provided, railway ballast and road surface rubble aggregates can be produced at the same time, and in the production process, the device can be adjusted according to an order at any time to determine whether to produce the railway ballast.

Owner:SHAANXI METALLURGICAL DESIGN & RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com