Preparation method of high-strength self-compacting concrete

A self-compacting concrete, high-strength technology, applied in the field of concrete, can solve the problems that cannot meet the increasingly high requirements of self-compacting concrete, and achieve the effect of enhancing load stability, increasing strength and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

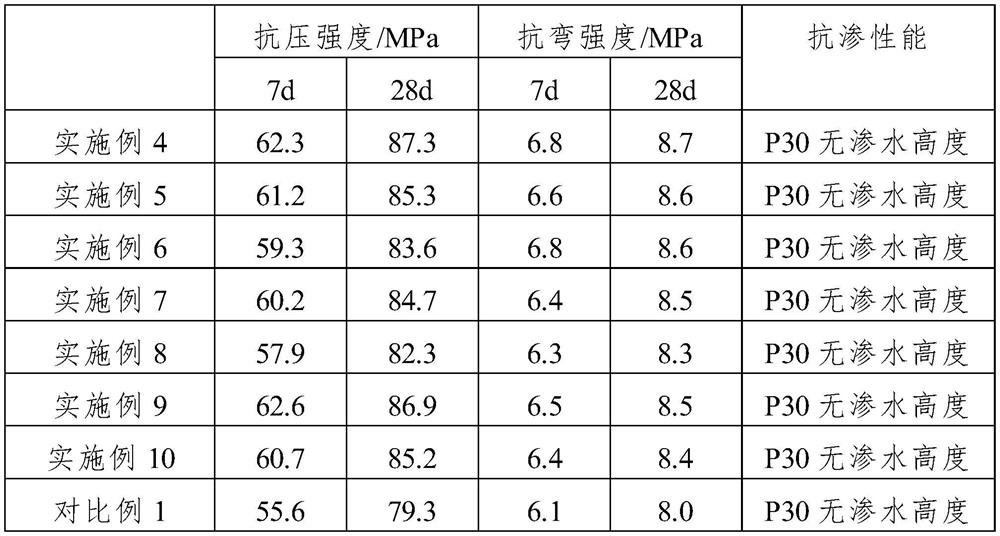

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of nano titanium dioxide / basalt rock powder composite material

[0037] A preparation method of nano titanium dioxide / basalt rock powder composite material, comprising the following steps:

[0038] (1) Pulverize the basalt to obtain basalt powder with a specific surface area of 672kg / m 2 ; Then heat up the basalt powder to 630°C and calcined for 1.5h to obtain calcined basalt powder.

[0039] (2) Add absolute ethanol and water to n-butyl titanate, stir for 15 minutes, add calcined basalt rock powder, and stir for 25 minutes to obtain a mixture; then stir and ultrasonically disperse the mixture, slowly add acetic acid, acetic acid After the addition is complete, continue to stir and ultrasonically disperse for 30 minutes; stand still for 4 hours, carry out vacuum drying at 75°C, grind after drying, then heat up to 650°C, calcinate for 4 hours, and cool to room temperature with the furnace to obtain nano-silica / Basalt stone powder compos...

Embodiment 2

[0042] Embodiment 2: the preparation of nano-titanium dioxide / basalt rock powder composite material

[0043]A preparation method of nano titanium dioxide / basalt rock powder composite material, comprising the following steps:

[0044] (1) Pulverize the basalt to obtain basalt powder with a specific surface area of 685kg / m 2 ; Then heat up the basalt powder to 600°C and calcinate for 1.5 hours to obtain calcined basalt powder.

[0045] (2) Add absolute ethanol and water to n-butyl titanate, stir for 15 minutes, add calcined basalt rock powder, and stir for 20 minutes to obtain a mixture; then stir and ultrasonically disperse the mixture, slowly add acetic acid, acetic acid After the addition is complete, continue to stir and ultrasonically disperse for 20 minutes; stand still for 4 hours, carry out vacuum drying at 70°C, grind after drying, then heat up to 620°C, calcinate for 4 hours, and cool to room temperature with the furnace to obtain nano-silica / Basalt stone powder c...

Embodiment 3

[0048] Embodiment 3: the preparation of nano titanium dioxide / basalt rock powder composite material

[0049] A preparation method of nano titanium dioxide / basalt rock powder composite material, comprising the following steps:

[0050] (1) Pulverize the basalt to obtain basalt powder with a specific surface area of 660kg / m 2 ; Then heat up the basalt powder to 650°C and calcinate for 1 hour to obtain calcined basalt powder.

[0051] (2) Add absolute ethanol and water to n-butyl titanate, stir for 10 minutes, add calcined basalt rock powder, and stir for 30 minutes to obtain a mixture; then stir and ultrasonically disperse the mixture, slowly add acetic acid, acetic acid After the addition is complete, continue to stir and ultrasonically disperse for 30 minutes; stand still for 3 hours, carry out vacuum drying at 75°C, grind after drying, then heat up to 625°C, calcinate for 4 hours, and cool to room temperature with the furnace to obtain nano-silica / Basalt stone powder com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com