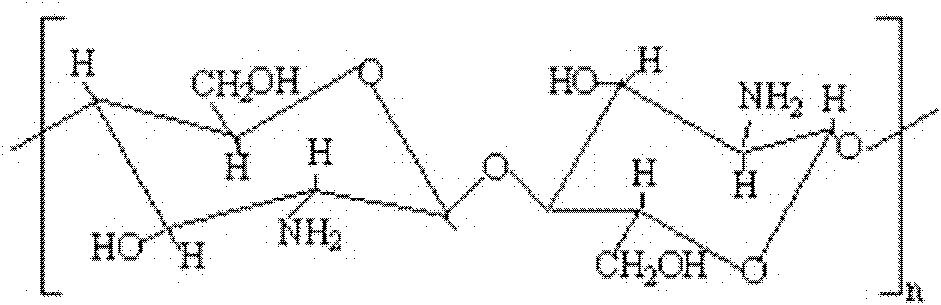

Chitosan nano fibrous membrane adsorbing material and preparation method thereof

A technology of chitosan nano and adsorption materials, applied in fiber treatment, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of high cost of non-selective adsorption and regeneration, limiting the wide application of activated carbon, and low hydrophilic performance , to achieve the effect of low cost, increased contact area and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

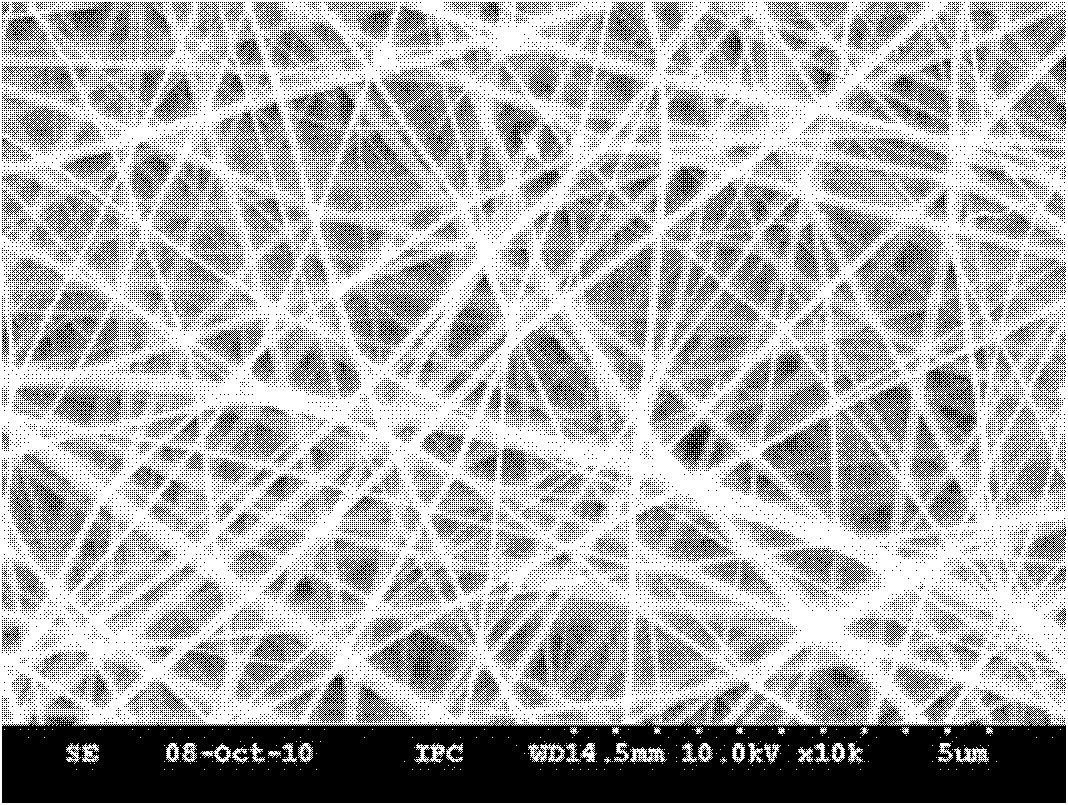

Embodiment 1

[0041] 1g of CS was dissolved in 24g of pure trifluoroacetic acid to obtain a CS solution with a concentration of 4wt%. After magnetic stirring at room temperature for 24 hours, a transparent CS spinning solution was obtained, and then stood for defoaming. Adjust the distance between the spinneret connected to the injector and the upper surface of the drum receiver to be 10 cm, set the rotation speed of the drum receiver to 5 rpm, and apply a voltage of 20 kV between the spinneret and the grounded drum receiver. At room temperature, the humidity is 50-80%. Add the CS spinning solution to the syringe of the electrospinning equipment. The CS spinning solution is injected into the spinneret at a flow rate of 0.4ml / h under the action of the syringe pump. The CS nanofiber film is obtained on the receiver, and then dried, for example, in a drying oven at 60-100° C. for 12 hours. The obtained CS nanofibrous membrane was dissolved in an alkaline solution such as sodium carbonate Na at a...

Embodiment 2

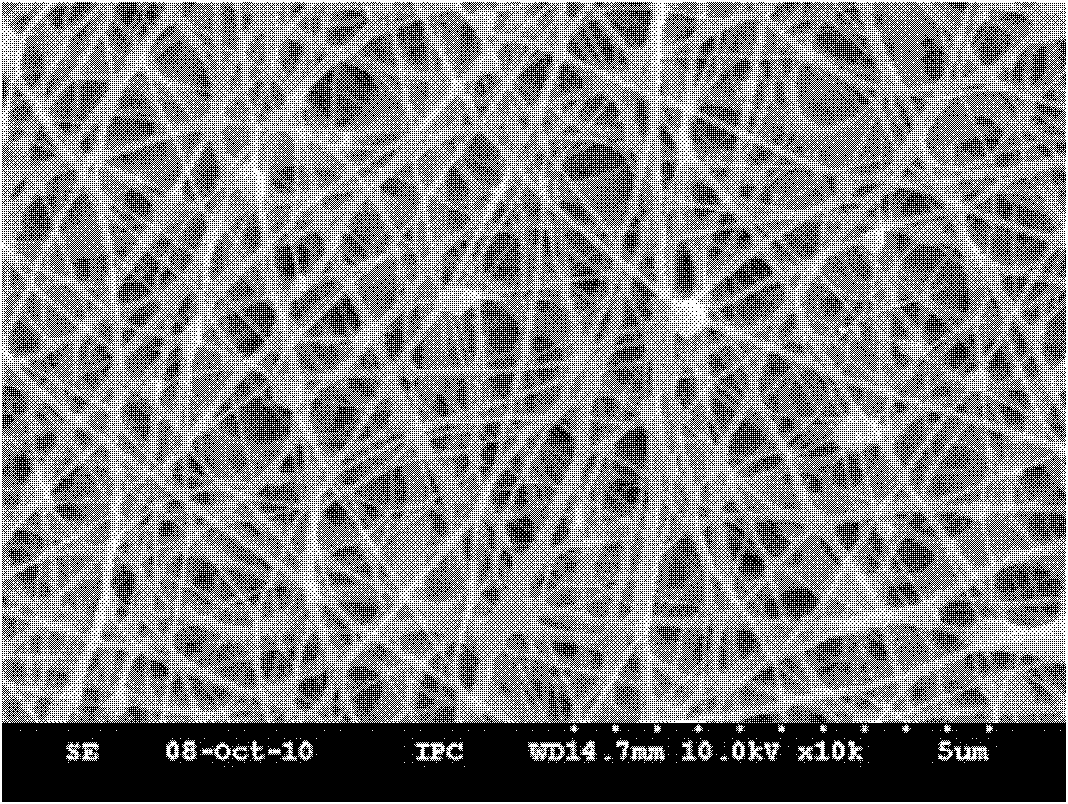

[0045] 0.8g of CS was dissolved in 19.2g of pure trifluoroacetic acid to obtain a CS solution with a concentration of 4wt%. After magnetic stirring at room temperature for 24 hours, a transparent CS spinning solution was obtained, and then stood for defoaming. Adjust the distance between the spinneret connected to the injector and the upper surface of the drum receiver to be 15 cm, set the rotation speed of the drum receiver to 5 rpm, and apply a voltage of 25 kV between the spinneret and the grounded drum receiver. At room temperature, the humidity is 50-80%. Add the CS spinning solution to the syringe of the electrospinning equipment. The CS spinning solution is injected into the spinneret at a flow rate of 0.4ml / h under the action of the syringe pump. The CS nanofiber film is obtained on the receiver, and then dried, for example, in a drying oven at 60-100° C. for 12 hours. The obtained CS nanofibrous membrane was dissolved in an alkaline solution such as sodium carbonate N...

Embodiment 3

[0049] 0.8g of CS was dissolved in 19.2g of pure trifluoroacetic acid to obtain a CS solution with a concentration of 4wt%. After magnetic stirring at room temperature for 24 hours, a transparent CS spinning solution was obtained, and then stood for defoaming. Adjust the distance between the spinneret connected to the injector and the upper surface of the drum receiver to be 15 cm, set the rotation speed of the drum receiver to 5 rpm, and apply a voltage of 10 kV between the spinneret and the grounded drum receiver. At room temperature, the humidity is 50-80%. Add the CS spinning solution to the syringe of the electrospinning equipment. The CS spinning solution is injected into the spinneret at a flow rate of 0.1ml / h under the action of the syringe pump. The CS nanofiber film is obtained on the receiver, and then dried, for example, in a drying oven at 60-100° C. for 12 hours. The obtained CS nanofibrous membrane was dissolved in an alkaline solution such as sodium carbonate N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com