Phase change energy storage microcapsule material and its preparation method

A phase-change energy storage and phase-change material technology, which is applied in the field of phase-change energy storage microcapsule materials and their preparation, can solve problems such as affecting the environment and human health, volatile formaldehyde, and restricting the application of phase-change materials, and achieves compactness. Excellent, fast reaction speed, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1, weigh 10 g of n-dodecyl alcohol, 4 g of methyl methacrylate, 1 g of acrylic acid, 0.4 g of Span-60, 0.6 g of Tween-80, 0.05 g of azobisisobutyronitrile, and 100 g of deionized water;

[0022] Step 2: Add n-dodecyl alcohol to deionized water, add emulsifiers Span-60 and Tween-80, mix, stir evenly, heat to 65°C, and use ultrasonic emulsification for 10 minutes;

[0023] Step 3, after ultrasonic emulsification for 10 minutes, transfer the obtained mixture solution to a four-neck flask including mechanical stirring, condenser, nitrogen inlet and feeding port, heat in a water bath to 65°C, and mechanically stir for 20 minutes;

[0024] Step 4: Add methyl methacrylate to the solution in Step 3, pass nitrogen gas to deoxygenate for 0.5 h, heat in a water bath to 80°C, slowly add azobisisobutyronitrile to initiate polymerization of methyl methacrylate, and react at constant temperature for 2 h Finally, add acrylic acid, and continue to keep the water bath at 80°C for 3 ...

Embodiment 2

[0027] Step 1, weigh 5g of n-dodecyl alcohol, 4g of methyl methacrylate, 1g of acrylic acid, 1g of OP-10, 0.1g of potassium persulfate, and 100g of deionized water;

[0028] Step 2: Add n-dodecyl alcohol to deionized water, add emulsifier OP-10, mix, stir evenly, heat to 65°C, and use ultrasonic emulsification for 10 minutes;

[0029] Step 3, after ultrasonic emulsification for 10 minutes, transfer the obtained mixture solution to a four-neck flask including mechanical stirring, condenser, nitrogen inlet and feeding port, heat in a water bath to 65°C, and mechanically stir for 15 minutes;

[0030] Step 4: Add methyl methacrylate to the solution in Step 3, pass nitrogen gas to deoxygenate for 0.5 h, heat in a water bath to 80°C, slowly add potassium persulfate to initiate methyl methacrylate polymerization, react at constant temperature for 2 h, and then Add acrylic acid, and continue to keep the water bath at 80°C for 3 hours;

[0031] Step 5: After the polymerization reactio...

Embodiment 3

[0033] Step 1, weigh 15g of n-dodecyl alcohol, 4g of methyl methacrylate, 1g of acrylic acid, 0.4g of Span-60, 0.6g of Tween-80, 0.1g of ammonium persulfate, and 100g of deionized water;

[0034] Step 2: Add n-dodecyl alcohol to deionized water, add emulsifiers Span-60 and Tween-80, mix, stir evenly, heat to 65°C, and use ultrasonic emulsification for 10 minutes;

[0035] Step 3, after ultrasonic emulsification for 10 minutes, transfer the obtained mixture solution to a four-neck flask including mechanical stirring, condenser, nitrogen inlet and feeding port, heat in a water bath to 65°C, and mechanically stir for 10 minutes;

[0036] Step 4: Add methyl methacrylate to the solution in Step 3, pass nitrogen gas to deoxygenate for 0.5 h, heat in a water bath to 80°C, slowly add ammonium persulfate to initiate methyl methacrylate polymerization, react at constant temperature for 2 h, and then Add acrylic acid, and continue to keep the water bath at 80°C for 3 hours;

[0037] Ste...

PUM

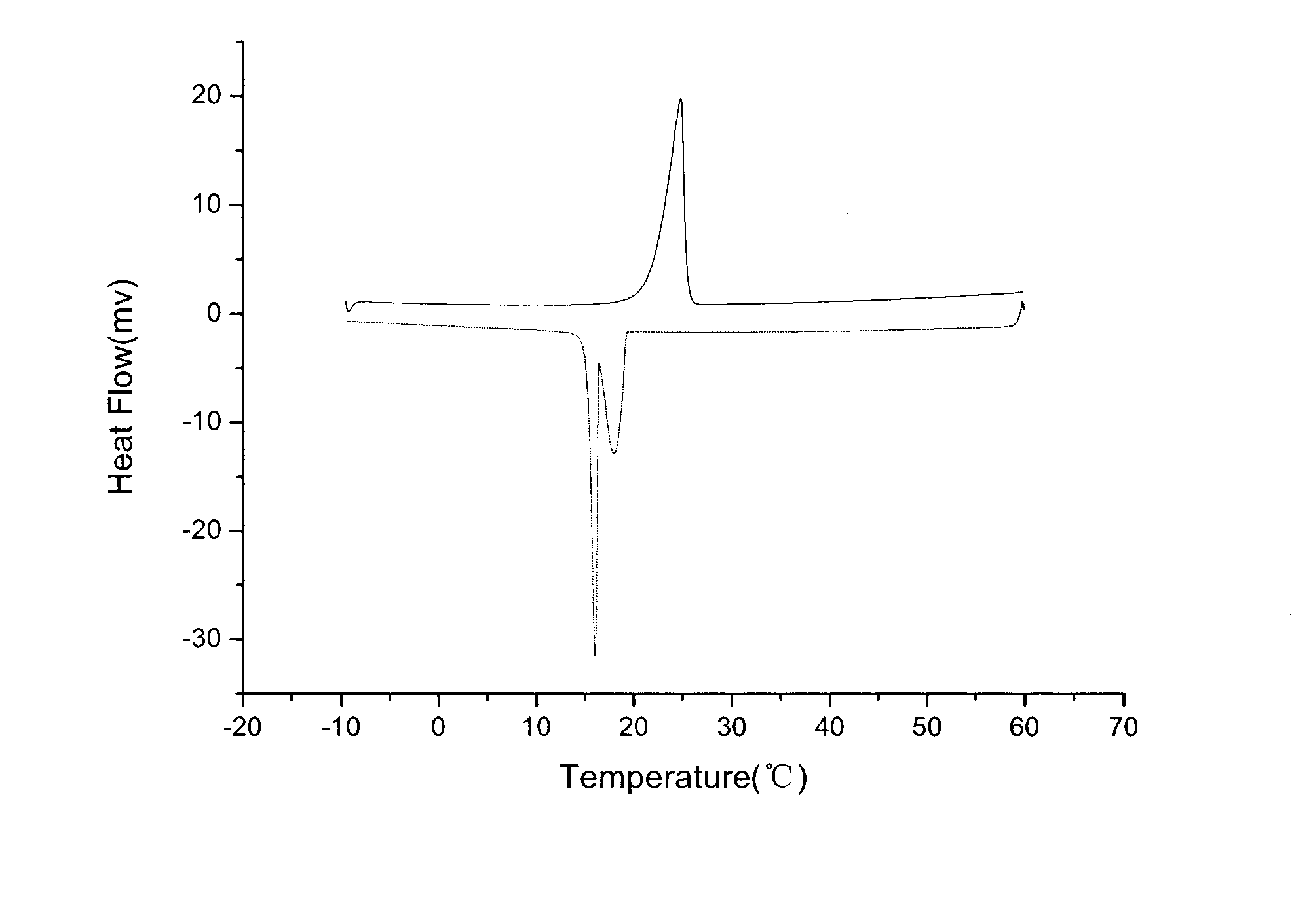

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com