Patents

Literature

86results about How to "With roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

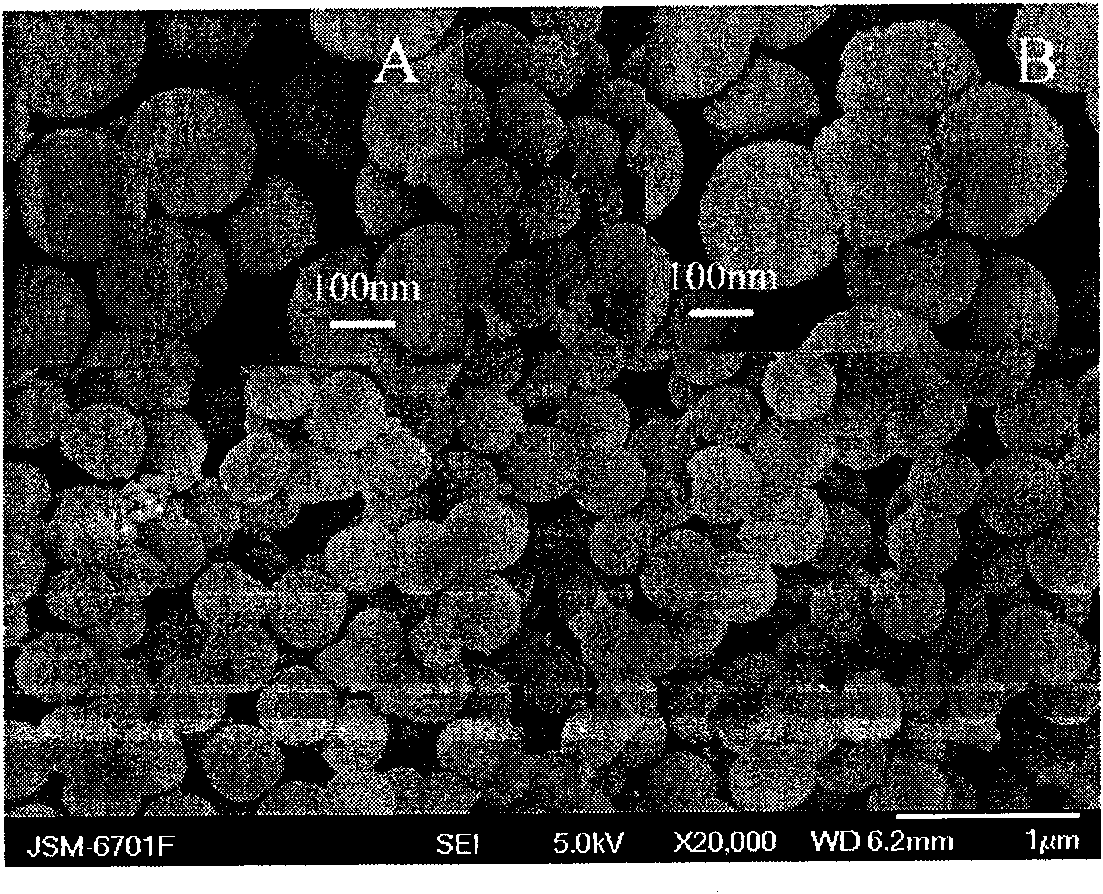

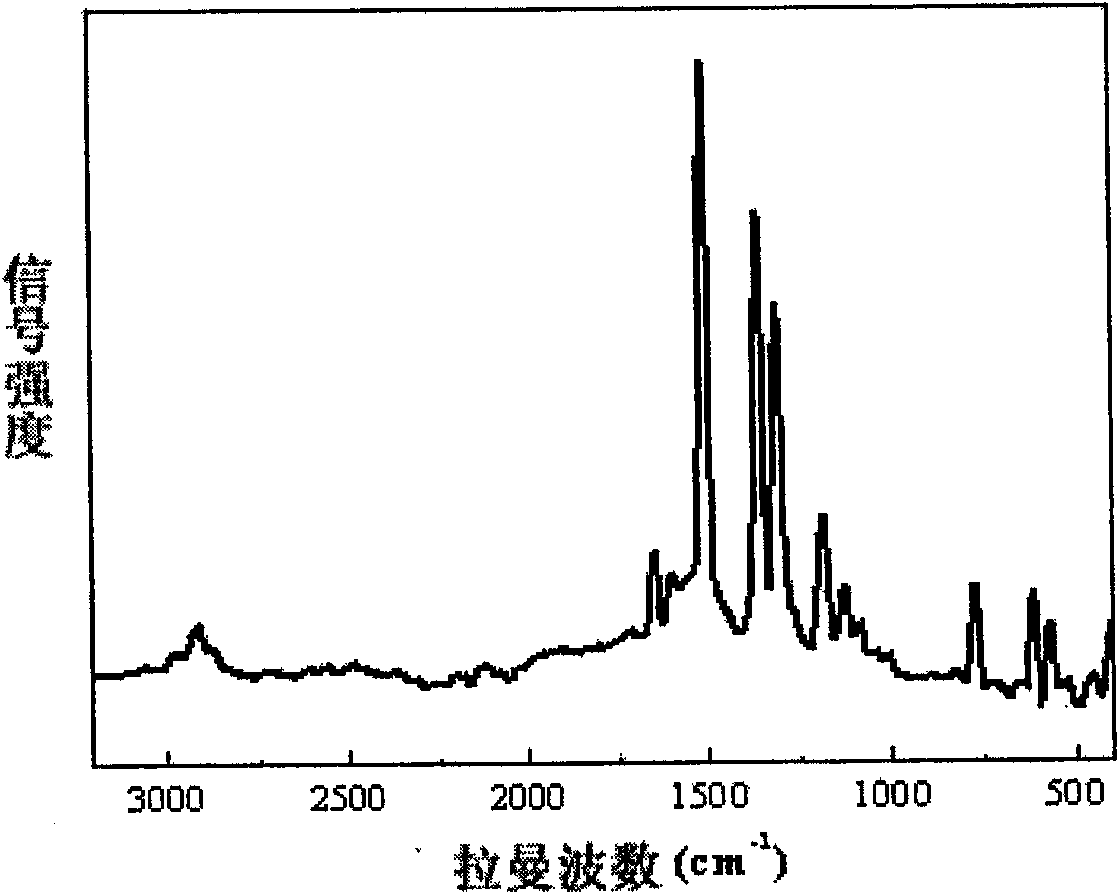

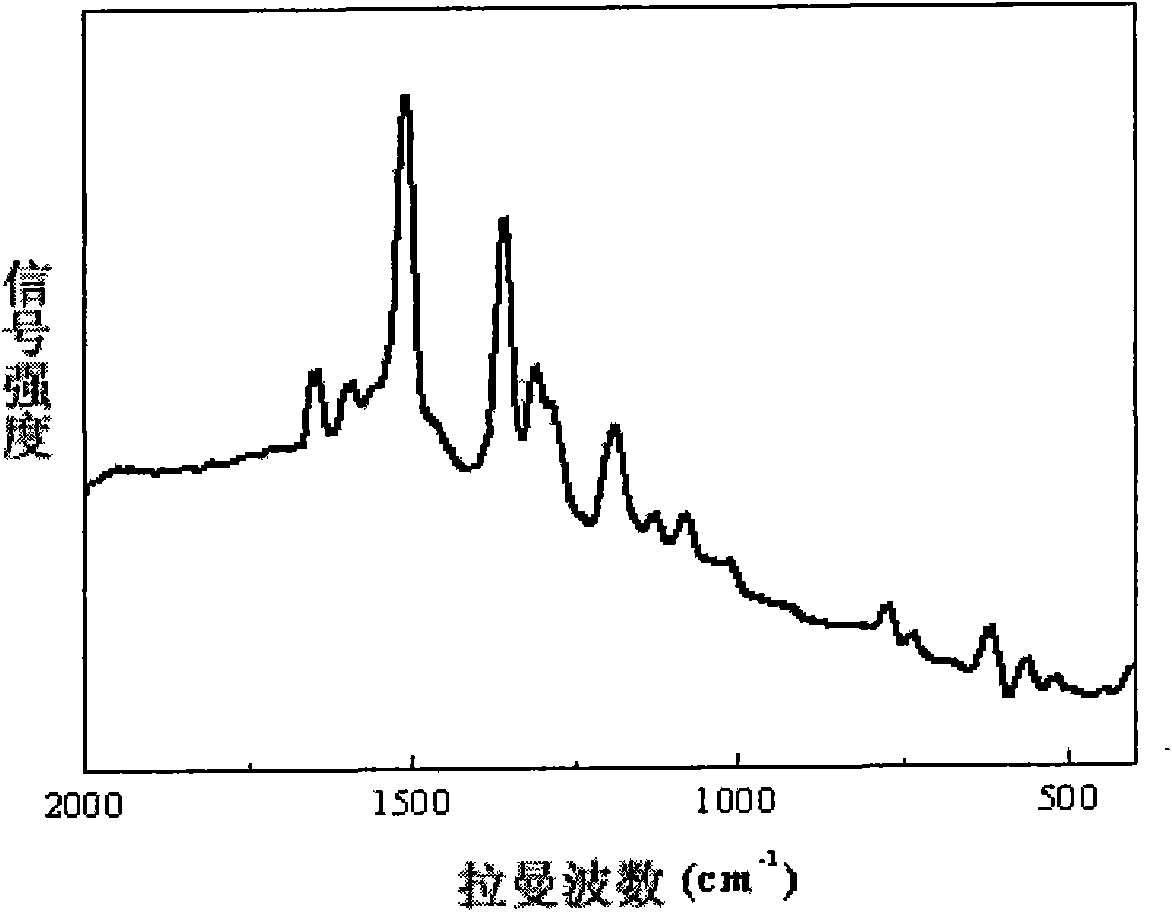

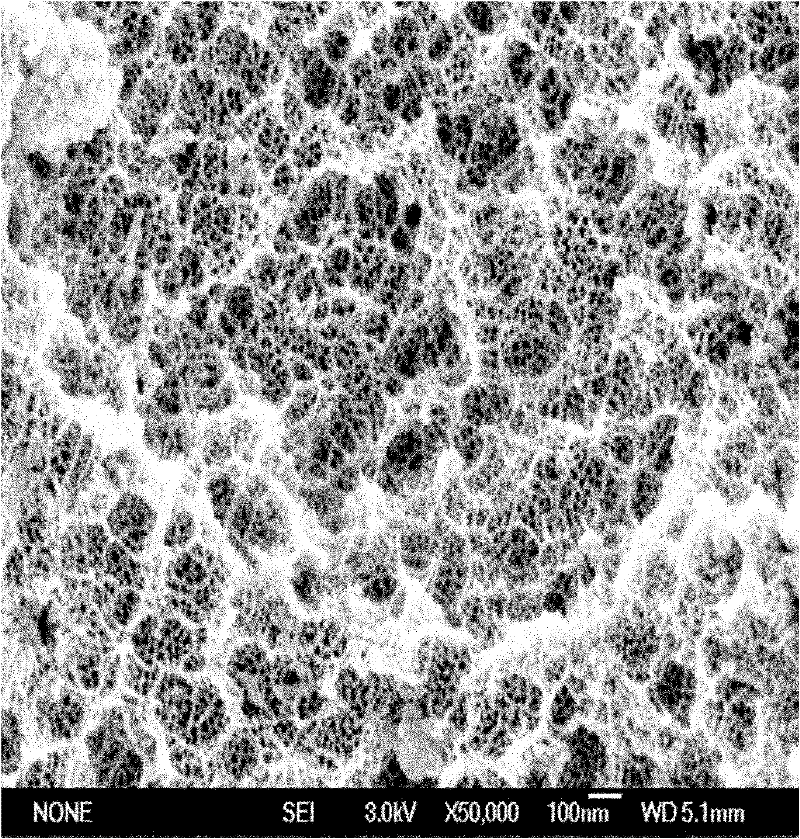

Substrate with surface-enhanced Raman scattering activity and preparation method thereof

The invention provides a substrate with surface-enhanced Raman scattering activity and a preparation method thereof, and the method comprises the following steps: the glass base surface is subjected to hydroxylation and amination treatment; catalytic hydrolysis is carried out on ethyl orthosilicate under the alkali condition by taking alcohol as a solvent; Silica microspheres with even size and smooth surface are prepared by an oscillation method; silane coupling agent of which the tail end is provided with amino is assembled on the surface of the silica microspheres; silver sol obtained by reducing sodium borohydride to silver nitrate through oscillation is assembled on the surface of SiO2-NH2NPs, and is diffused in water again after centrifugal separation and washing by distillated water; self assembly is carried out on the silver sol after being placed in SiO2@Ag NPs dispersion for 6-12h; the SERS active substrate is obtained after taking out from water and drying. In the SERS active substrate of the invention, the active particles and the substrate are combined firmly, thus being applicable to detecting unimolecular Raman signals in aqueous solution; the substrate can be used for SERS detection repeatedly, thus improving repeated utilization ratio of the substrate.

Owner:NORTHWEST NORMAL UNIVERSITY

Visual simulation shale micro-crack plugging capacity test system and method

ActiveCN103485762AIntuitive visual macro analysisImprove general applicabilityConstructionsBorehole/well accessoriesMicroscopic observationMicroscopic scale

The invention relates to a visual simulation shale micro-crack plugging capacity test system and a visual simulation shale micro-crack plugging capacity test method. Displacement evaluation experiment is performed on a single or combined micro-crack rock sample by a solution or a drilling fluid which contains the plugging agents with different concentrations and different types at different experiment conditions, such as pressure differences and times, indexes, such as the invasion depth, are compared, the formation conditions of inner mud cakes in drilling are directly described, and microscopic observation and analysis are performed on percolation substances invade into the micro-cracks by utilizing amplification imaging instruments, such as a high-definition microscope, so that the plugging mechanisms and the effects of various drilling fluid plugging agents and drilling fluids are analyzed and researched intuitively and microscopically, a proper drilling fluid plugging agent is selected preferably, a drilling fluid system formula is optimized, the problem about the experimental conditions that the visual simulation evaluation cannot be performed on shale micro-crack plugging in the past is solved, and a new evaluation experimental research means is provided for related research and production in the technical field of fractured shale strata borehole wall stability in petroleum engineering.

Owner:CHINA PETROLEUM & CHEM CORP +1

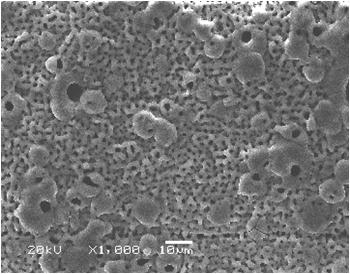

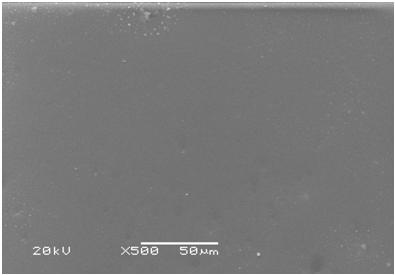

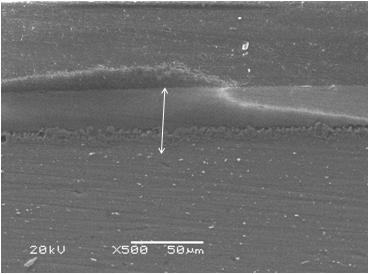

Preparation method of magnesium alloy surface micro-arc oxidation/spray coating compound film

ActiveCN101871119AHigh bonding strengthImprove corrosion resistanceAnodisationLiquid surface applicatorsMicro arc oxidationPlasma electrolytic oxidation

The invention provides a preparation method of a magnesium alloy surface micro-arc oxidation / spray coating compound film, which relates to a preparation method of a magnesium alloy surface compound film. The invention solves the problems that film layers obtained by chemical composition coating, anodic oxidation and vapor deposition in the existing magnesium alloy surface treatment method are thin and have poor corrosion resistance performance, the ion injection has high cost and is difficult to realize large-area processing, the combining force between coating layers and the magnesium alloy is poor, and organic coating layers has the defect of easy aging. The preparation method has the following steps: firstly, using micro-arc oxidation for preparing ceramic films on the surface of the magnesium alloy; then, adopting air spray coating for spraying and coating inorganic paint onto the ceramic films; and then, carrying out heat treatment to obtain the micro-arc oxidation / spray coating compound film. The method is simple, and the cost is low. The air spray coating uses porous structures of the micro-arc oxidation ceramic films, so the combination of the inorganic coating layers and the ceramic films is firm, the thickness of the compound films is between 20 and 40 mum, the self corrosion electric potential is positively moved to -1.02 V, the corrosion current density is lowered by 5 orders through being compared with that of the magnesium alloy, the magnesium alloy surface micro-arc oxidation / spray coating compound film has no damage after 72 to 144h of salt spray tests, and the corrosion resistance performance is good.

Owner:HARBIN INST OF TECH

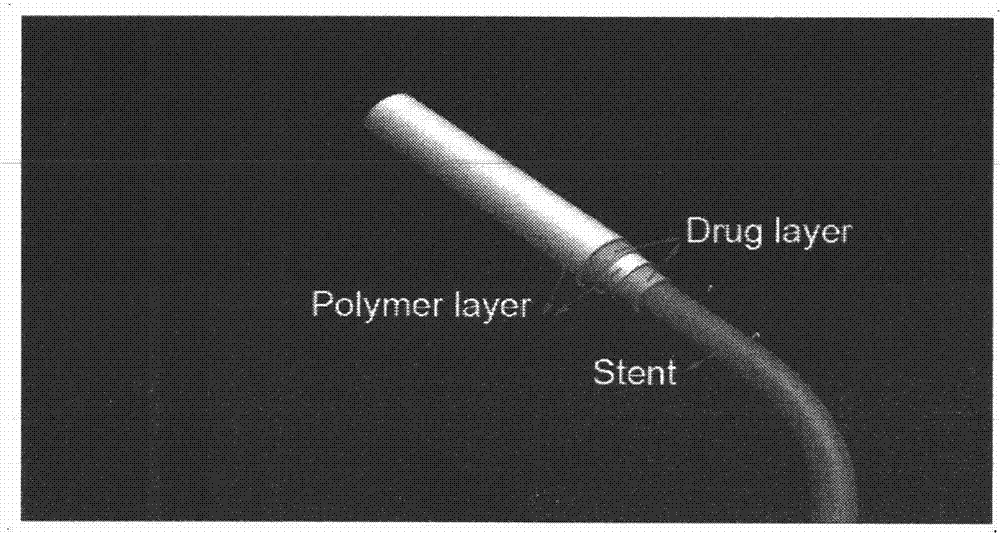

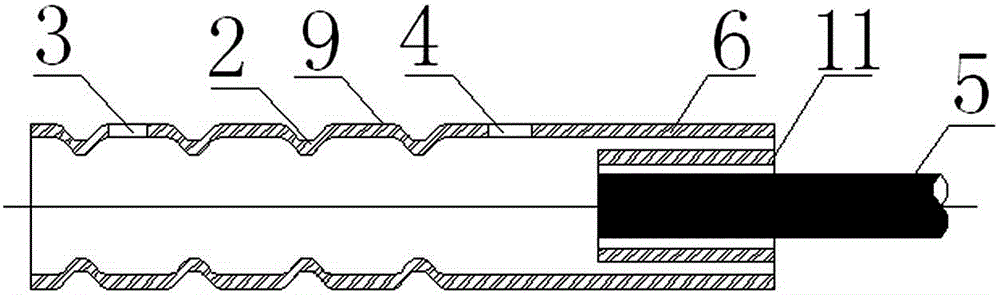

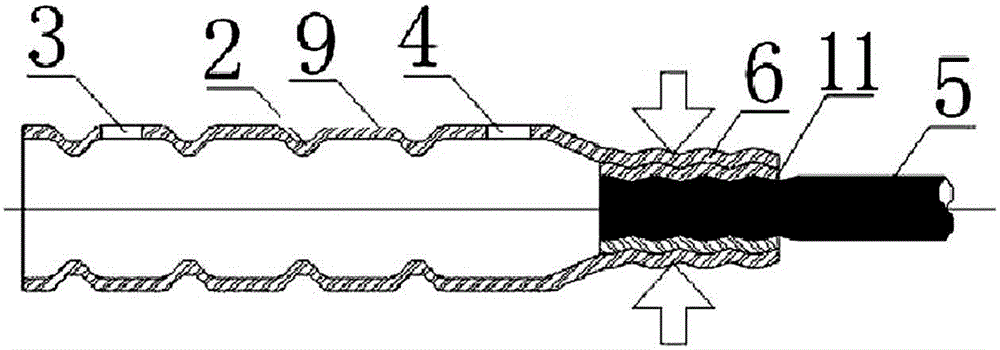

Preparation method of multi-coating drug eluting intravascular stent

The invention aims at providing a method for preparing a multi-drug multi-coating eluting intravascular stent through ultrasonic atomizing and spraying, wherein VEGF, SZ-21 and other protein drugs, taking chitosan as a drug carrier, form a first coating; the second layer is a shielding layer, which adopts a polymer poly L lactic acid (PLLA) and can be added with polyethylene glycol (PEG) in different proportions to control release speed of drug; the third layer is lipid soluble medicine, such as rapamycin, which uses PLLA as a drug carrier; and a coating at the top end of the fourth layer, same as the second layer, is a shielding layer. Two uniform drug polymer coatings can simultaneously load multiple drugs, and the release speed of the drug can be regulated and controlled by regulating a mixing proportion of the PEG and the polymer, so as to inhibit restenosis and to reduce formation of thrombus simultaneously.

Owner:CHONGQING UNIV

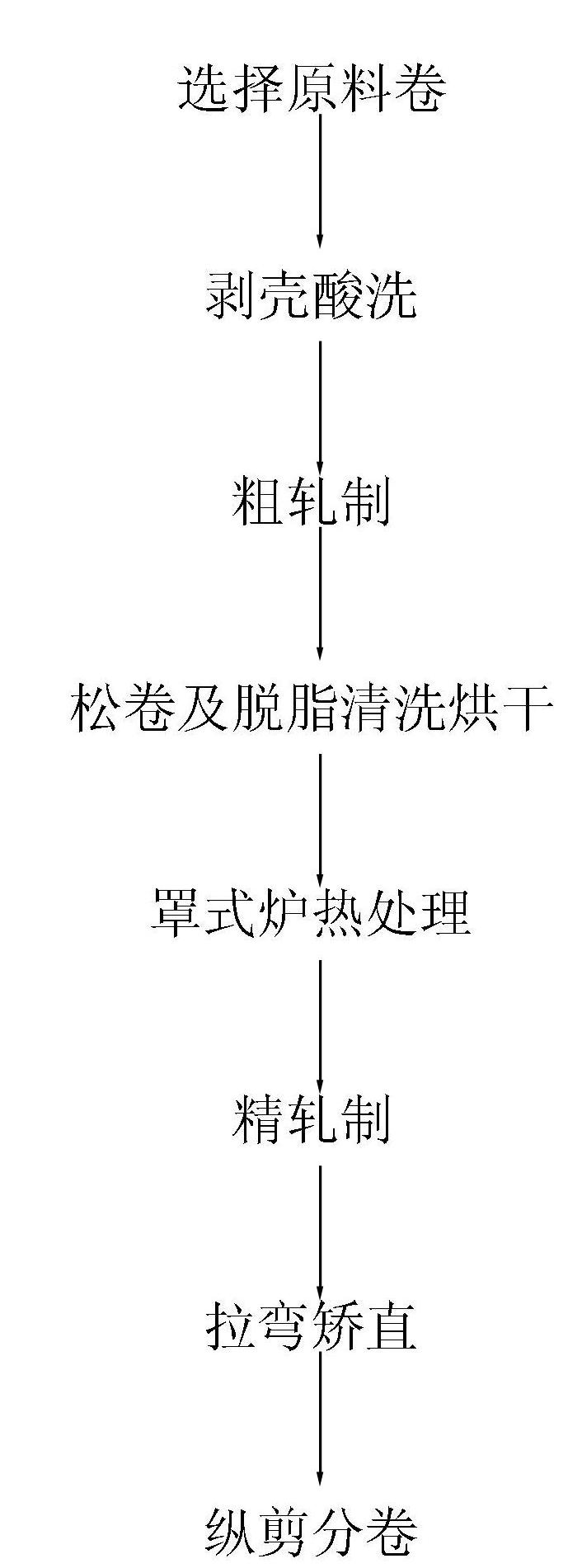

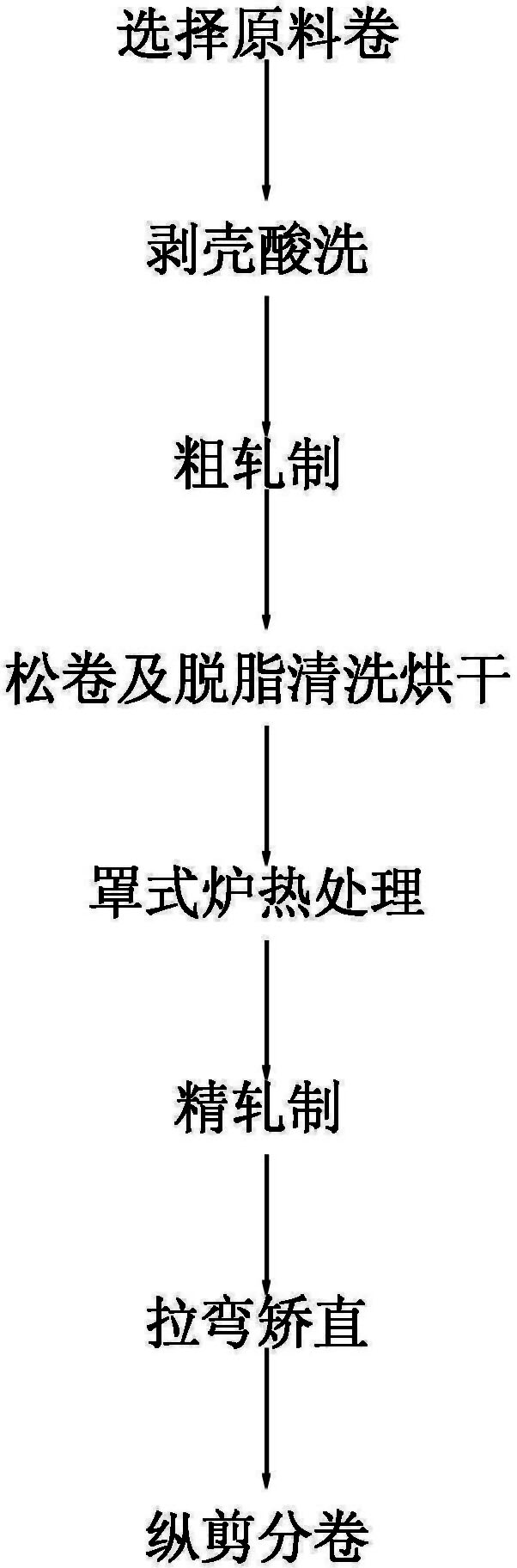

Low-carbon cold-rolled precision ultrathin steel strip for toy industry, and process method and application thereof

ActiveCN102658294ASimple production processWith roughnessWork treatment devicesMetal rolling arrangementsMetallurgyCarbon steel

The invention relates to a production process for a low-carbon cold-rolled precision ultrathin steel strip. The production process comprises pretreatment, heat treatment, finish rolling, tension leveling, and longitudinal shear and slitting to obtain a finished product. The low-carbon cold-rolled precision ultrathin steel strip produced by the process has certain roughness, and a printed layer or a protective layer on the surface of the steel strip is firm and does not fall off; the strip is high in flatness and easy to form; and the steel strip has the thickness of less than 0.08mm and even less than 0.06mm, and can be used for producing carbon steel products required to be coated with pigments or protective layers.

Owner:YONGXIN PRECISION MATERIAL WUXI

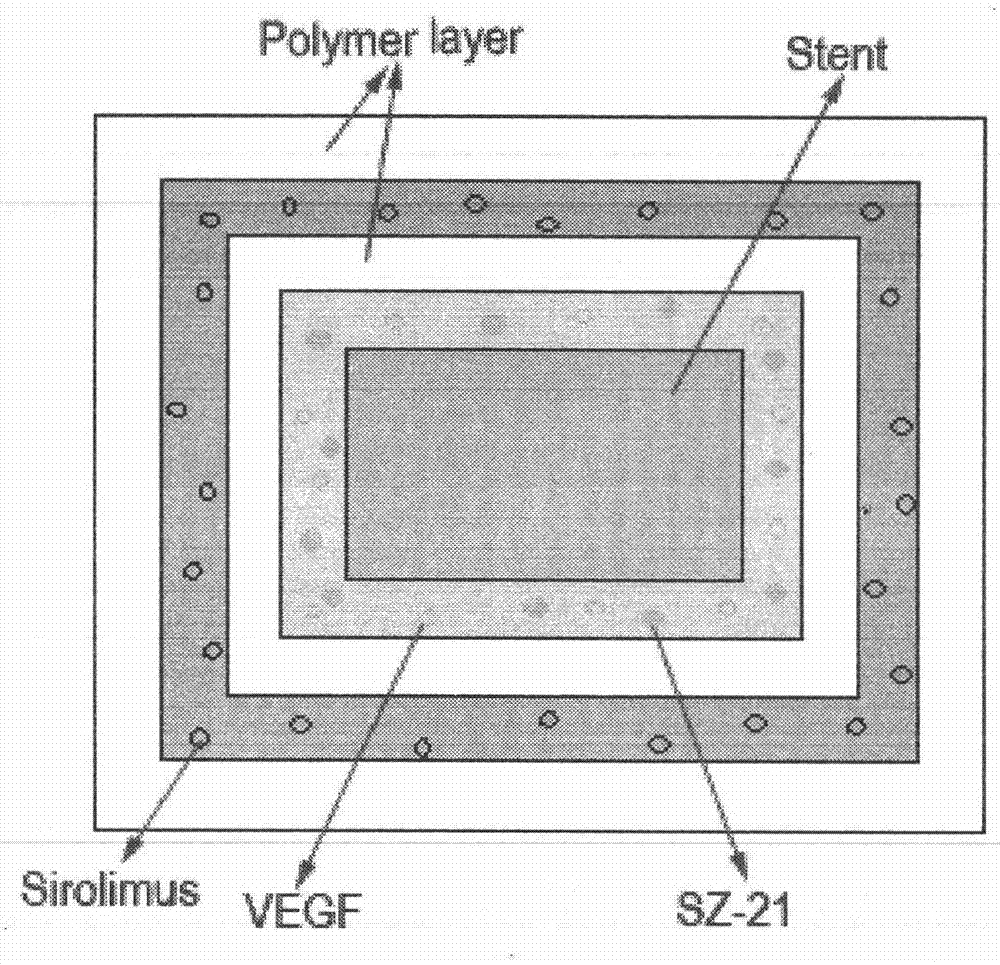

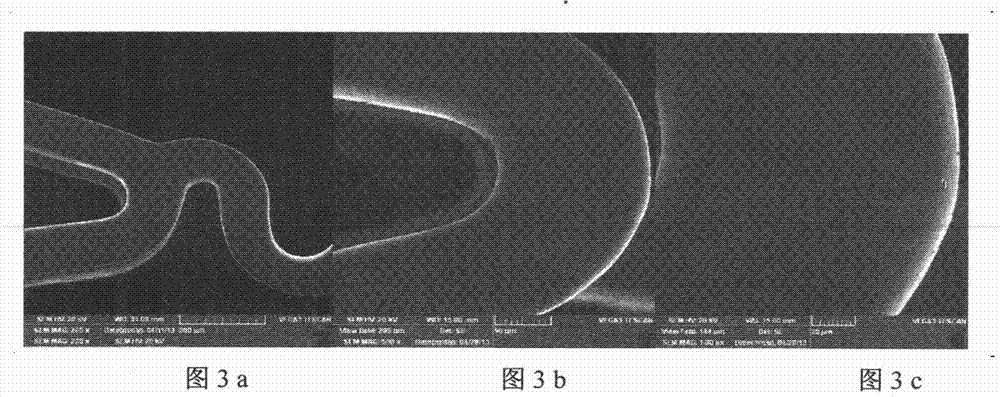

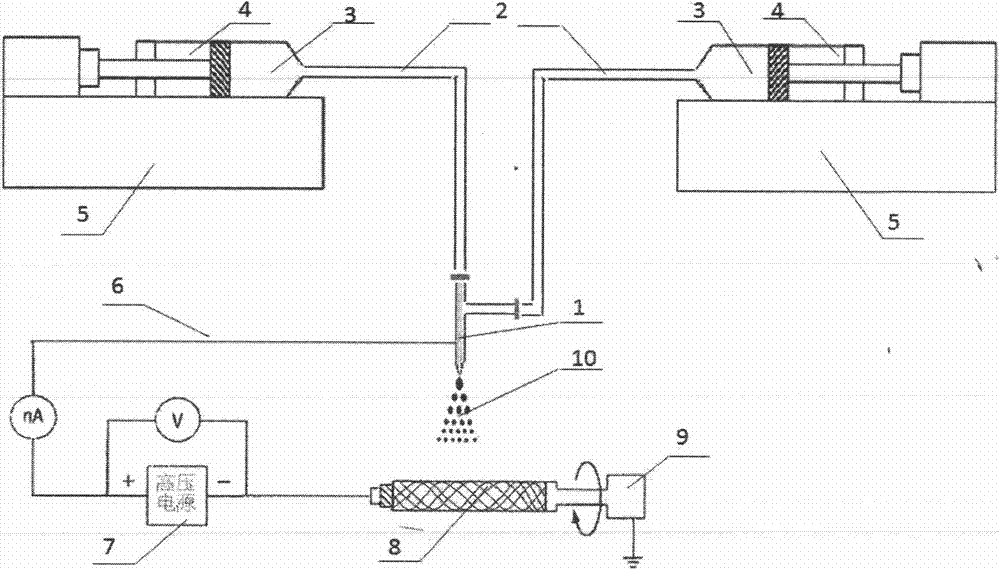

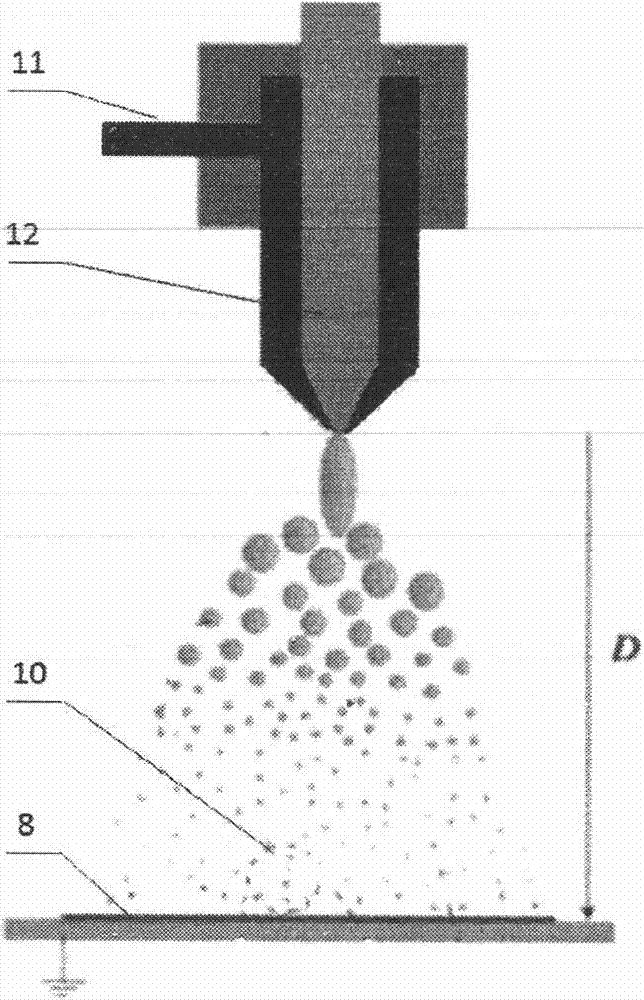

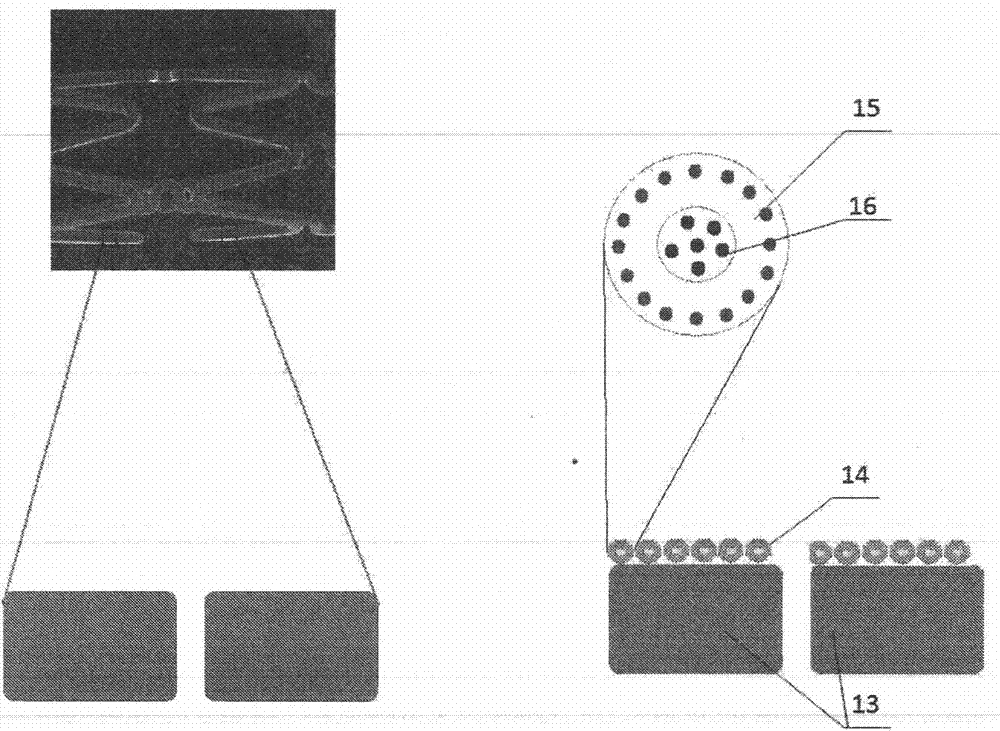

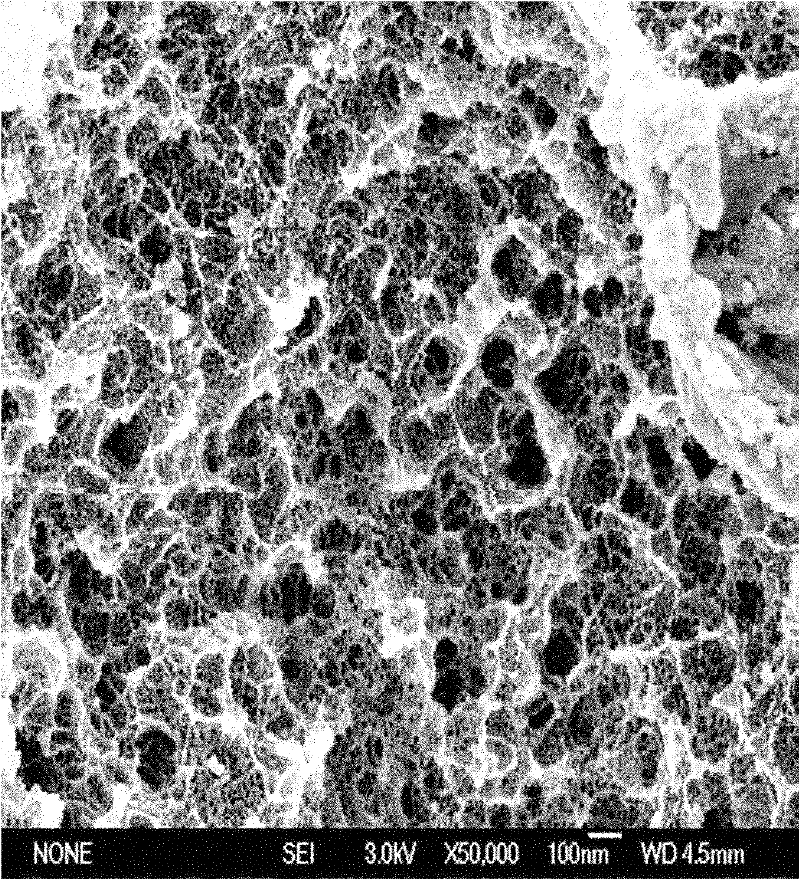

Nano-microcapsule coated intravascular stent of core-shell structure and preparation method of intravascular stent

The invention provides a nano-microcapsule coated intravascular stent of a core-shell structure and a preparation method of the nano-microcapsule coated intravascular stent, applicable to the technical field of medical instruments. Based on a coaxial electrostatic spraying technology which has characteristics of being efficient, simple and convenient, and having microspheres controlled to release and the like, a uniform nano-microcapsule coating is sprayed on a surface of a stent body part, namely the stent comprises a metal stent body part having an outer surface, having an excellent mechanical property; and a uniform drug coating, wherein the coating which is formed by uniformly depositing drug-loaded nano-microcapsules of core-shell structure, can encapsulate multiple drugs and has a good slow-release effect. The drug stent coating prepared by the invention is controllable in coating thickness, simple in preparation process, low in equipment requirement and high in preparation efficiency. Depending on curative effect of the required stent, variety of the encapsulated drugs, encapsulated drug dosage and encapsulation way can be changed to realize different release effects; and the intravascular stent is favorable for blood vessel endothelium repairing and inhibiting restenosis.

Owner:CHONGQING UNIV

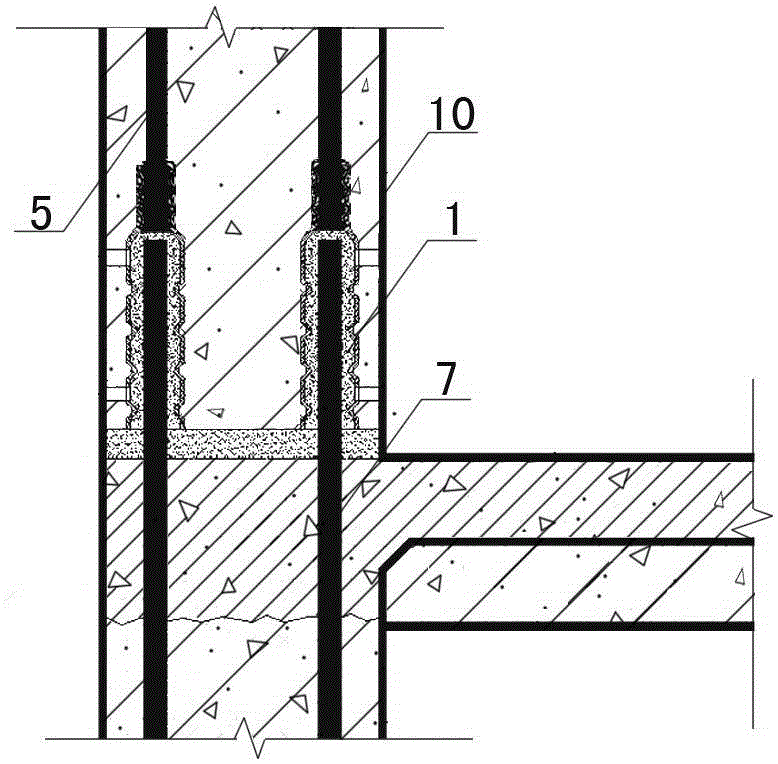

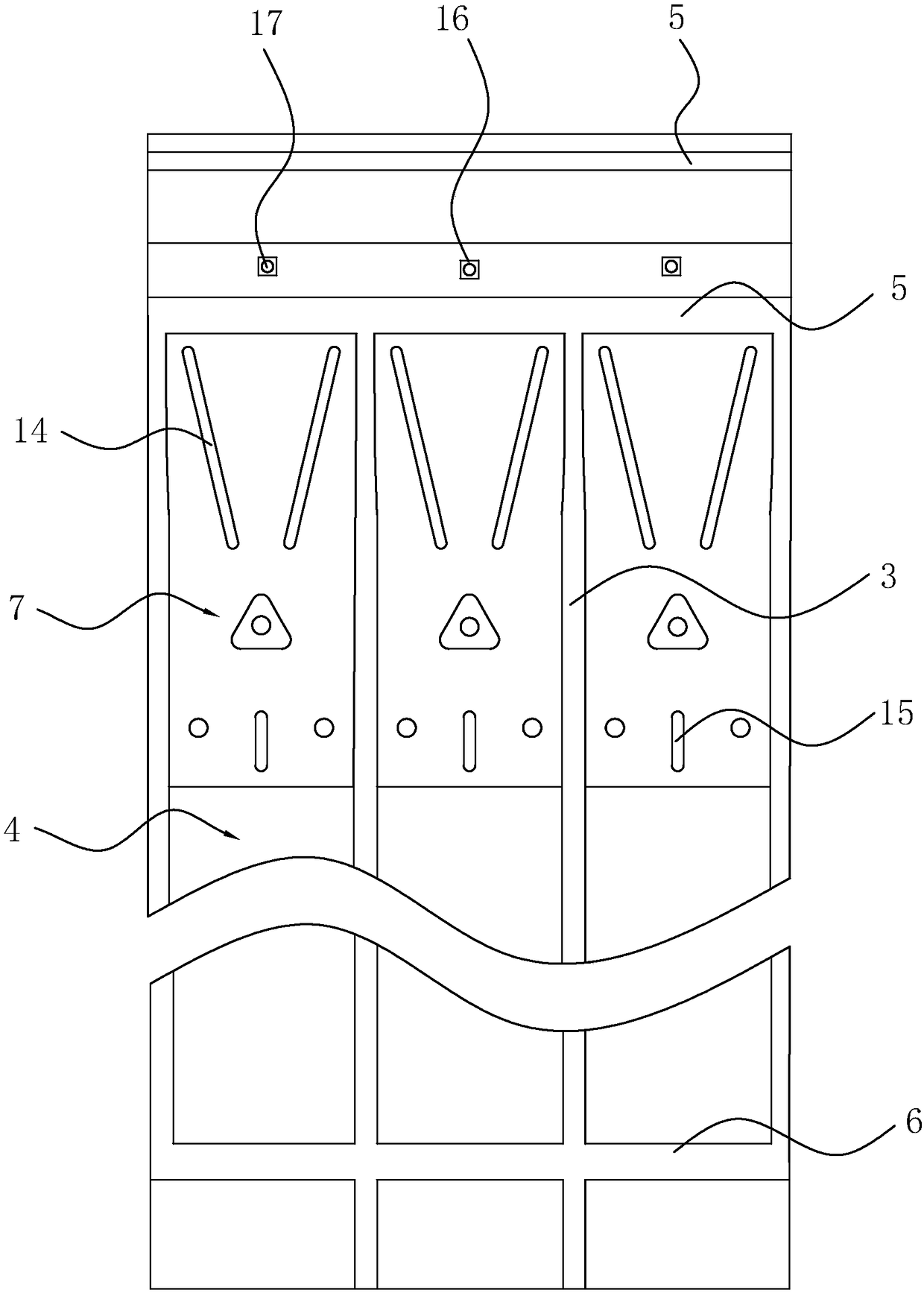

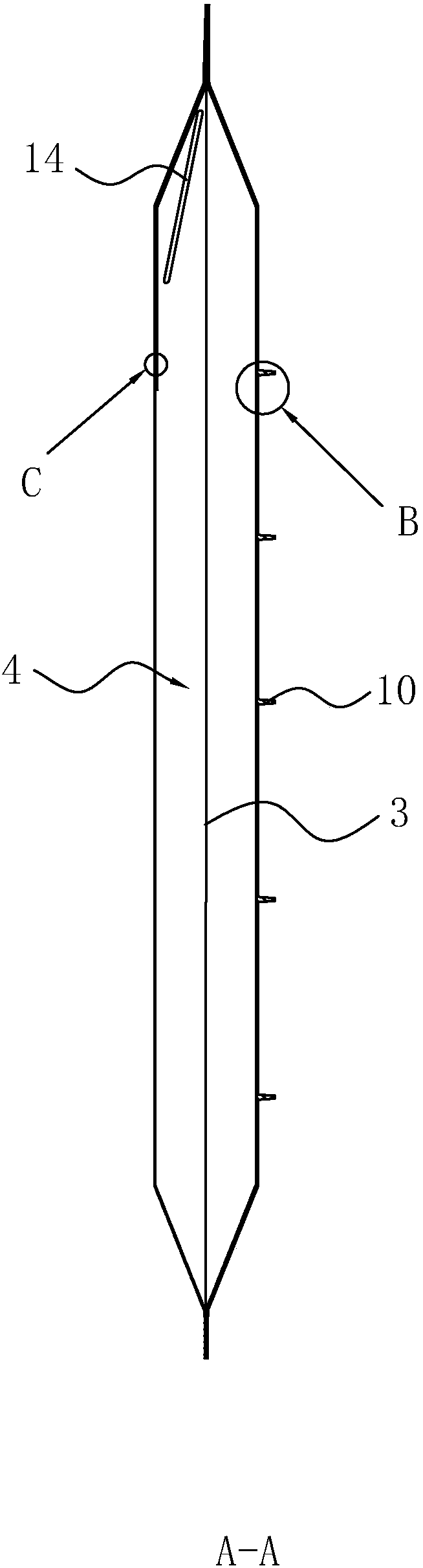

Extruded semi-grouting reinforced sleeve with built-in casing, connective structure, and construction method

InactiveCN105178516AReduce workloadImprove work efficiencyBuilding reinforcementsBuilding material handlingConcrete beamsEngineering

Disclosed are an extruded semi-grouting reinforced sleeve with a built-in casing, a connective structure, and a construction method. The sleeve is a hot-rolled seamless steel tube. The wall of the sleeve is provided with a grout inlet and a grout outlet. The sleeve is provided with circular inner projections. One end of the sleeve is an extruded end, and the rest is a grout-anchoring end. The built-in casing is arranged inside the extruded end. The inner diameter of the built-in casing is equal to the outer diameter of a rebar to be connected, and less than the inner diameter of the grout-anchoring end. All of the grout inlet, the grout outlet and the circular inner projections are located at the grout-anchoring end. By the use of the built-in casing, the deformation of the extruded end is lessened to avoid the extruded end being damaged during crimping; the sleeve is widely applicable to the rebar connection of prefabricated concrete columns in multi-storey and high-rise prefabricated assembled concrete frame structures, shear wall structures or frame shear wall structures, as well as the connection of horizontal rebars in prefabricated concrete beams, the connection of rebars in prefabricated concrete shear walls and the connection of rebars in existing reinforcement projects.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Method for improving wettability of electrode plates of lithium-ion battery

The invention discloses a method for improving wettability of electrode plates of a lithium-ion battery. The method comprises preparation of a positive electrode plate and a negative electrode plate, wherein preparation of the positive electrode plate and the negative electrode plate comprises a coating step, a drying step, a rolling step and a slitting step; a mirror grinding roller is sprayed with an anti-adhesion coating before rolling; and the anti-adhesion coating is prepared by the following methods: (1) high-temperature degreasing, namely baking the mirror grinding roller at 450-500 DEG C for 4-6 hours, and cleaning the surface with ethyl alcohol; (2) surface pretreatment, namely carrying out phosphating on the surface of the mirror grinding roller in the step (1); and (3) water curtain spraying, namely mixing teflon PTFE, silicon nitride, aluminum oxide, a curing agent VM7799 and water evenly to obtain slurry, and evenly spraying the surface of the mirror grinding roller with the slurry, wherein the ratio of the teflon PTFE to the silicon nitride to the aluminum oxide to the curing agent VM7799 to water is (20-25) to (10-12) to (10-12) to (15-20) to (40-45). The method disclosed by the invention is simple in process step and high in operability; and the wettability of the electrode plates of the lithium-ion battery can be improved.

Owner:WANXIANG 123 CO LTD +1

Preparation method for aluminum plate base for direct plate making in inkjet printing

The invention belongs to the field of printing plates and relates to a preparation method for an aluminum plate base for a printing plate and particularly relates to a preparation method for the aluminum plate base for direct plate making in inkjet printing, and the method can improve image-text resolution factor. In the invention, after an electrolyzing and anodizing treatment step and before a water washing step, the step of soaking the aluminum plate base by kalinous treatment fluid is added, so as to enable nanometer and micron coarse structures to be built on the surface of the aluminum plate base, and the high-resolution aluminum plate base for direct plate making in inkjet printing can be obtained. The nanometer and micron coarse structures can control infiltration and diffusion actions of an ink droplet on the surface of the aluminum plate base, and the obtained aluminum plate base has roughness and meanwhile has an absorbency and excellent wearing resistance. By using the direct plate making technology in inkjet printing, plate making ink is sprayed on the aluminum plate base prepared through the method provided by the invention to form an image-text region, and by adjusting the preparation technology of the aluminum plate base, the contrast between the image-text region and a non-image text region can be enhanced, and the resolving power of the obtained picture and text can be improved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

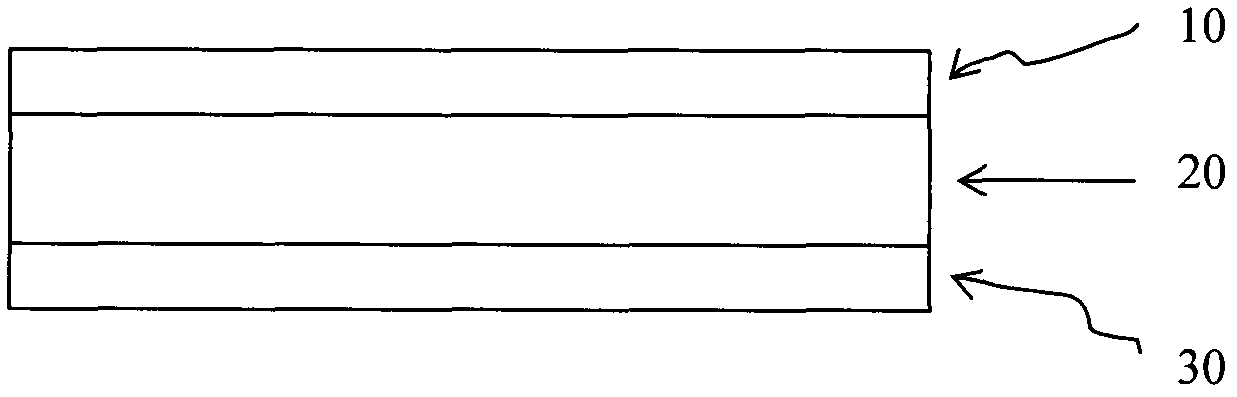

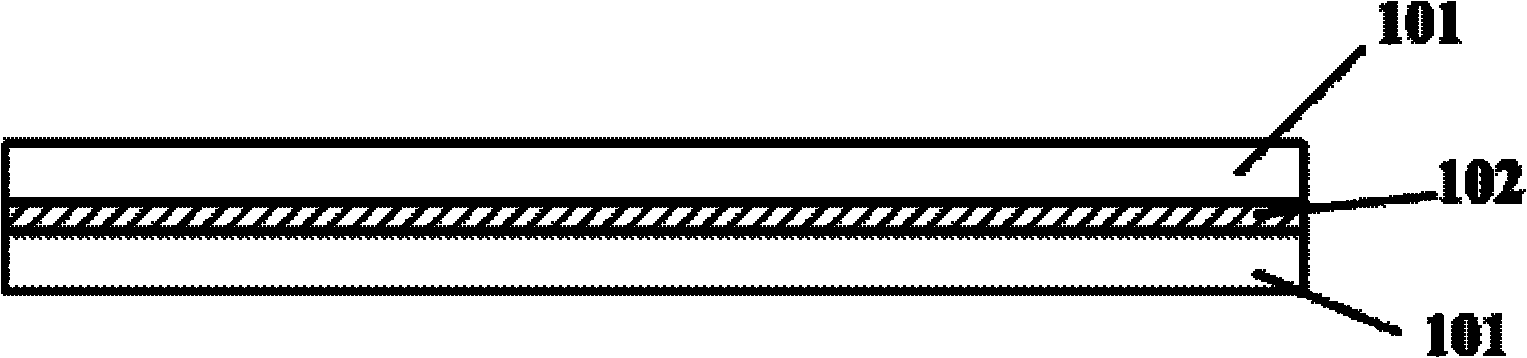

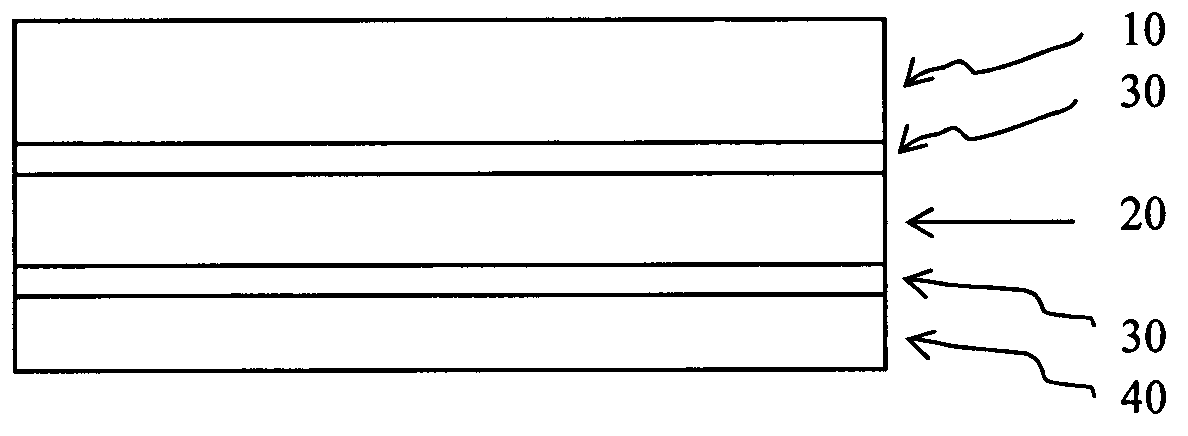

Composite film having gas barrier, heat insulation and fire resistance properties, and making method thereof

InactiveCN103203920AWith roughnessImprove thermal performanceSynthetic resin layered productsLaminationFiberAviation

The invention provides a composite film having gas barrier, heat insulation and fire resistance properties. The composite film is characterized in that the composite film is sequentially formed by an inorganic fiber cloth layer 10, an aluminum-plastic composite layer 20 and a plastic composite layer 30 from outside to inside, and a binder is bonded between each two adjacent layers. The invention also provides a making method of the composite film having gas barrier, heat insulation and fire resistance properties. The barrier film has the characteristics of low gas and water transmittance, good alkali resistance, good weather resistance, good fire resistance, good puncture resistance, and no generation of a chemical reaction with an alkaline cement mortar, and can be widely used in the fields of machines, electronics, buildings, aviations, spaceflights, automobiles and ships needing heat insulation in the cold, hot and wet environments.

Owner:周介明 +1

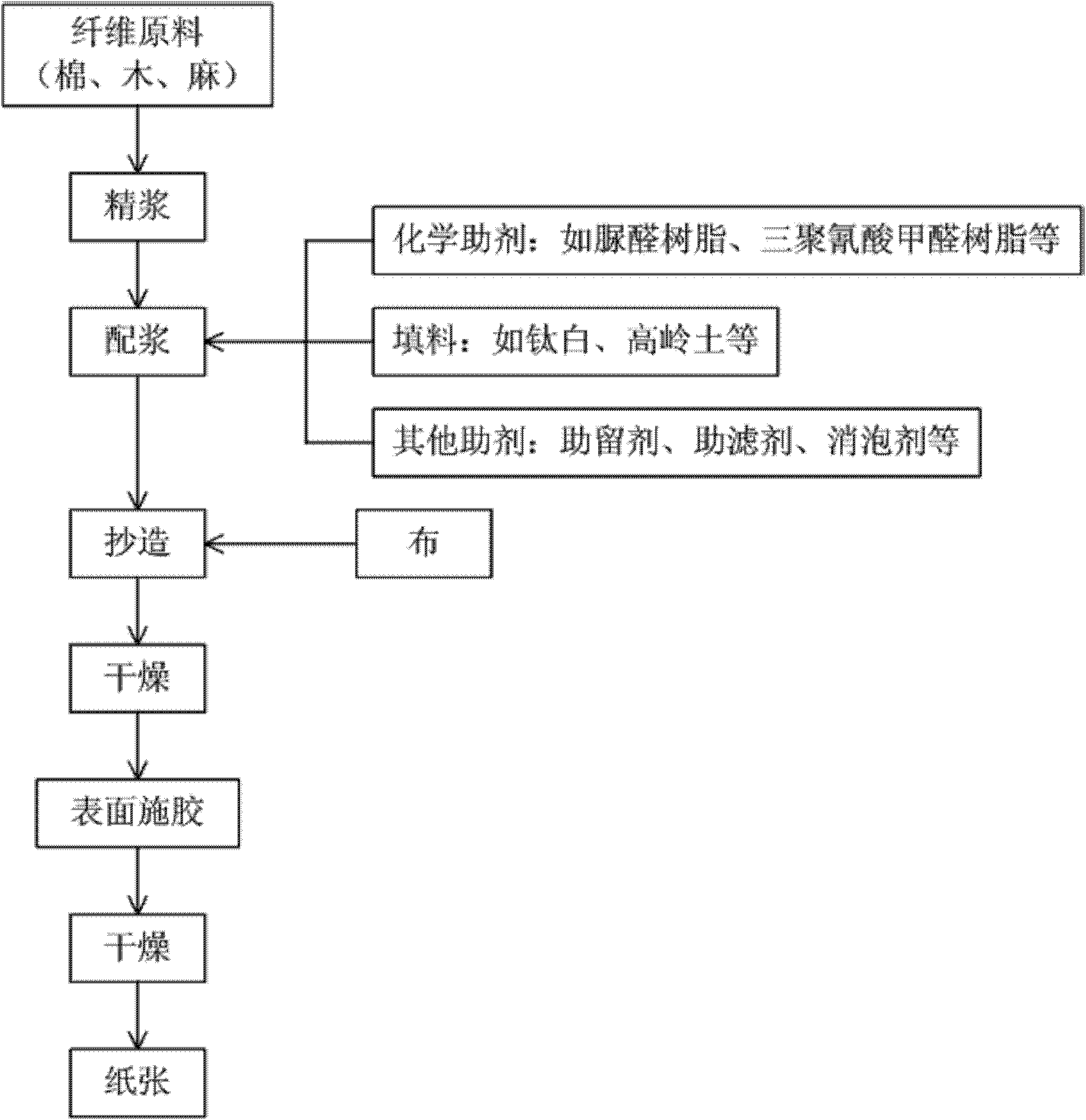

Anti-counterfeiting cloth paper and preparation method thereof

InactiveCN102277797ADehydratingImprove breathabilityNon-fibrous pulp additionSpecial paperPapermakingMachining process

The invention relates to an anti-counterfeit cloth paper and a preparation method thereof. The anti-counterfeit cloth paper has a sandwich structure composed of two layers of paper sheets and one layer of cloth. The present invention also provides a method for preparing the above-mentioned anti-counterfeit cloth paper, which includes the following steps: using a cylinder paper machine to form at least two layers of wet paper sheets with double cylinders; compounding at least one layer of cloth between the wet paper sheets on at least two sides , form a sandwich structure, and complete subsequent papermaking to obtain the anti-counterfeit cloth paper. The anti-counterfeit cloth paper of the present invention is compounded with cloth with specific properties in the middle of the paper, realizing the combination of two different technical fields of papermaking and textile, making the performance of cloth and paper complementary, enhancing the physical strength of paper, and greatly improving the physical properties of paper At the same time, it does not affect the performance of paper printing. It can also give a variety of anti-counterfeiting information during the weaving and processing of cloth, greatly improving the anti-counterfeiting performance of cloth and paper, and bringing novel expressions and effects to paper anti-counterfeiting technology.

Owner:BAODING BANKNOTE PAPER CO LTD +1

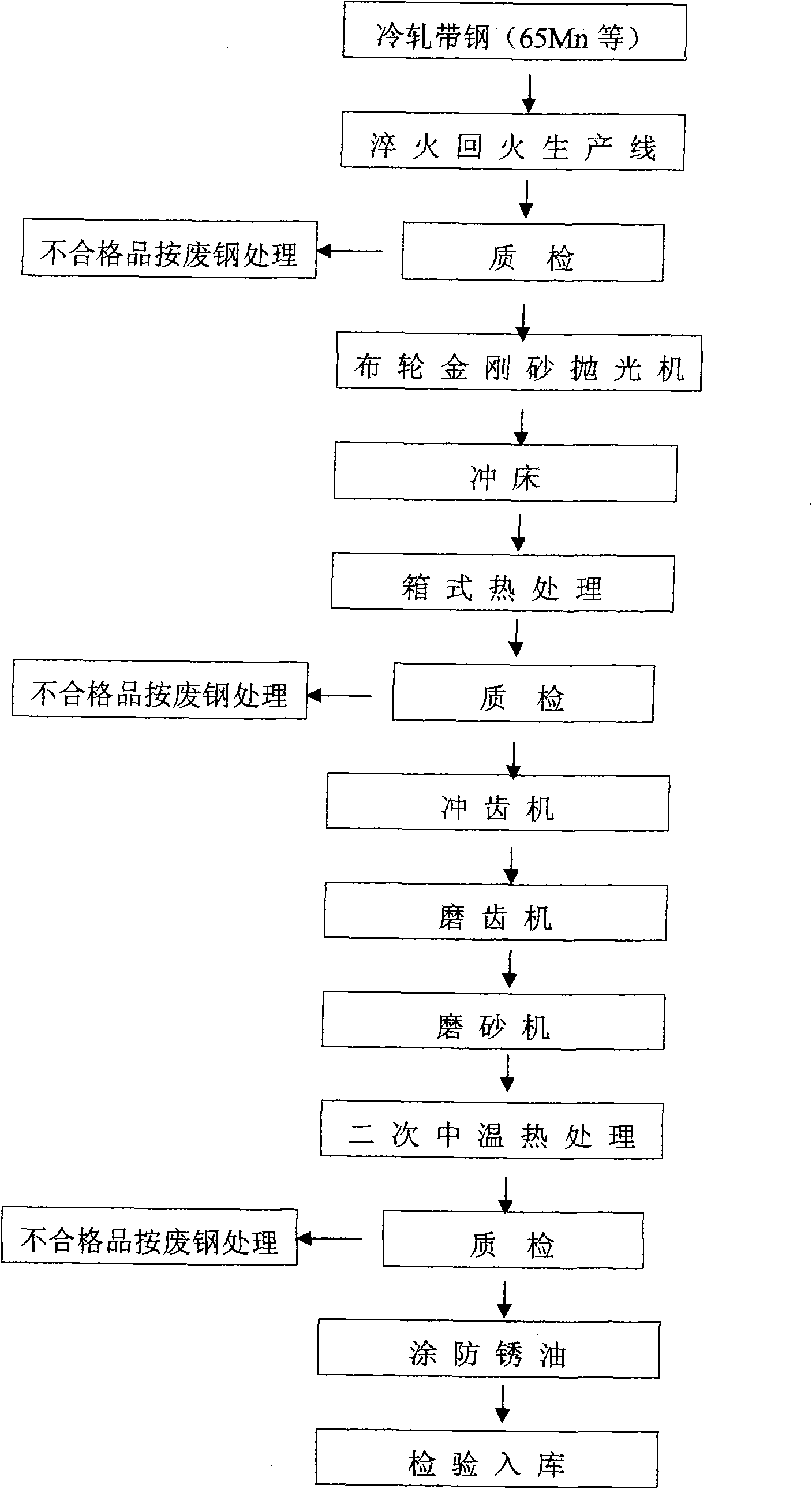

Method for producing traceless quenching and embossing saw blade

InactiveCN101333688AQuality improvementStable hardnessVegetable fibre separation from seedsMetal sawing tool makingProduction lineHardness

The invention discloses a production method of cotton ginning saw-blade, which directly uses the strip steel to firstly quench and temper and then subsequently process the strip steel. The process steps are as follows: selecting the strip, quenching the strip, inspecting the quality of the strip, polishing the surface of the strip, punching the strip into a blank of the saw-blade, heat treating the blank of the saw-blade, inspecting the quality of the blank, punching teeth on the blank by a sawtooth punching machine, grinding teeth, burring, heat treating the blank in moderate temperature, inspecting the quality of the finished product, packaging the finished product after coating antirust oil on the finished product, and inspecting and warehousing the finished product. The production method continuously produces the strip steel of 350mm and 430mm on quenching and tempering production lines, so the produced saw-blade has stable hardness, good toughness, good wear resistance and long service life.

Owner:HANDAN HANWU COTTON MACHINERY

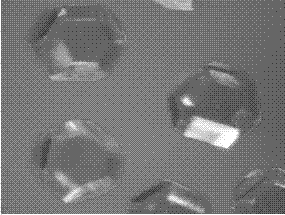

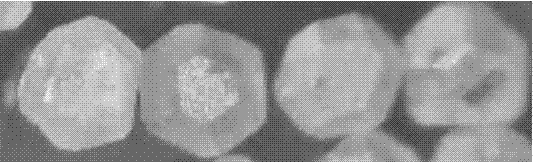

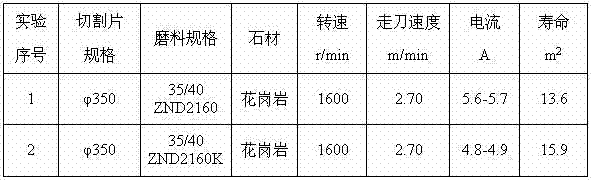

Surface roughening treatment method of diamond

ActiveCN107473768AWith roughnessReduce or interrupt exposureSurface treatment compositionsAlcoholIron oxide

The invention relates to a surface roughening treatment method of a diamond. The method comprises the following steps of: 1) preparing etching powder: uniformly mixing 60-90 parts of emery powder, 1-5 parts of potassium perchlorate and 5-20 parts of iron oxide powder to form the etching powder for future use, 2) mixing: adding the etching powder with the weight of 20-100% of that of diamond grains after wetting the surfaces of the diamond grains with alcohol and performing uniform mixing, 3) traying and heating: horizontally laying a material obtained in step 2), and performing heat preservation at 500-700 DEG C for 1-20min, and 4) screening and cleaning: screening out the etching powder after the material is cooled, washing the diamond grain with water, and performing drying. The method creates a technical condition of etching the surface of the diamond, allows dense small etching pits to be formed on the surface of the diamond and is an effective method of increasing a holding force between the diamond grains and a tool body.

Owner:ZHONGNAN DIAMOND CO LTD

Composite alloy plate and preparation method thereof

The invention provides a composite alloy plate and a preparation method thereof. The preparation method comprises the following steps of raw material inspection, surface cleaning, roughening treatment, continuous temperature compounding, diffusion annealing, scale cinder cleaning, cogging rolling, middle annealing, fine rolling, straightening and flattening, oil removal and degreasing, shearing and online whole inspection, and packaging and warehouse entering. The composite alloy plate formed by the preparation method has the advantages of high tensile intensity, high peeling intensity and thelike.

Owner:JIANGSU CHUANGTAITE STEEL PROD CO LTD

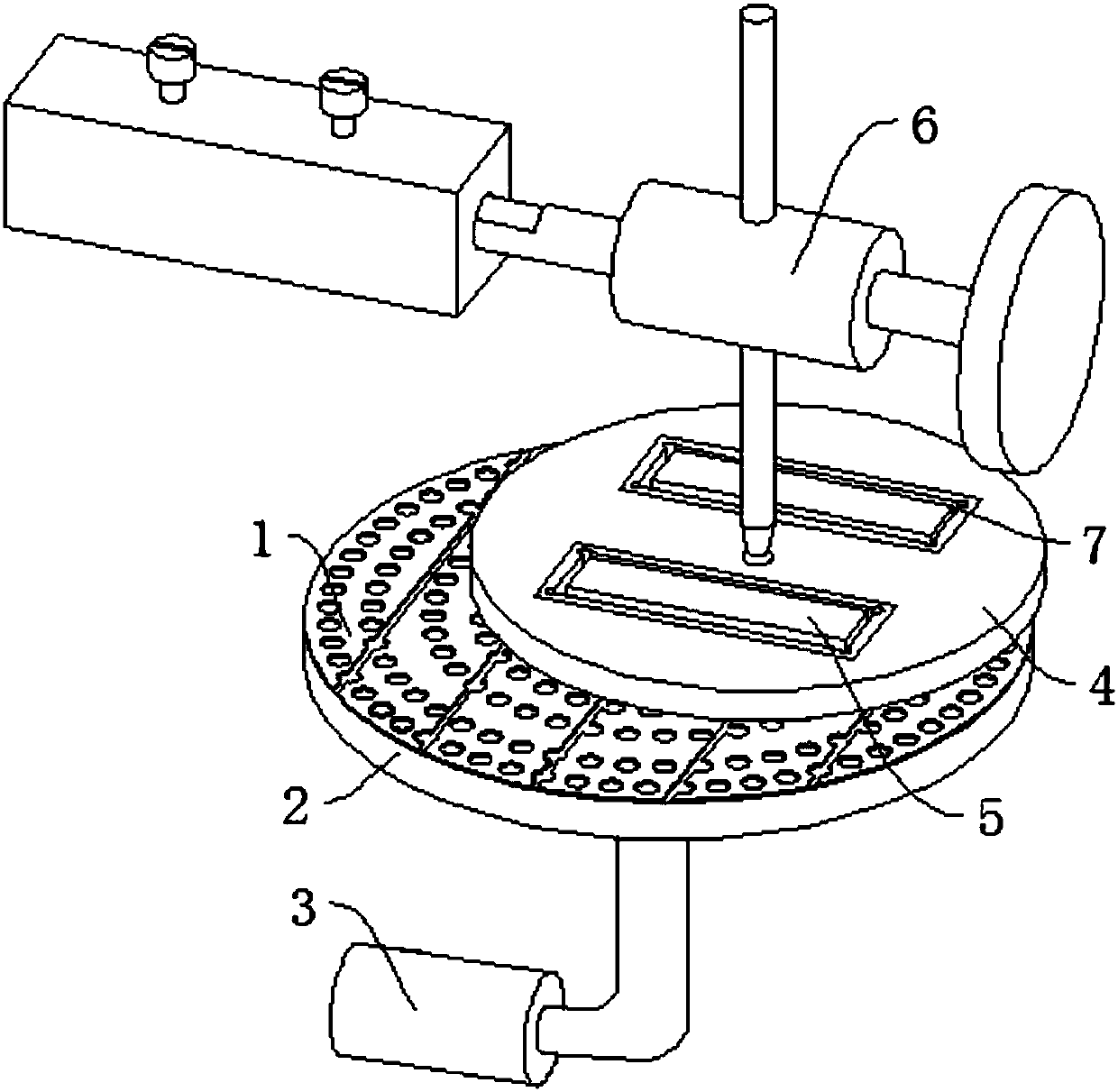

Optical lens polishing device and polishing process

InactiveCN107671605AGood suspensionGuaranteed roughnessOptical surface grinding machinesMachined surfaceEngineering

The invention discloses an optical lens polishing device. The optical lens polishing device comprises a polishing pad, a polishing pad base, a rotating driving device, a separator, pressing blocks anda polishing machine, wherein the polishing pad is arranged on the polishing pad base which is connected to the rotating driving device, the separator is arranged on the polishing pad and provided with multiple object containing grooves, the pressing blocks are arranged in the object containing grooves of the separator, a hole is formed in the middle of the separator, and the separator is connected to the polishing machine through the hole. The invention further discloses a polishing process. The polishing process particularly comprises the following steps of trimming a correction mold, trimming the polishing pad through the correction mold, cleaning the polishing pad, fixing the polishing pad to the polishing pad base, preparing a polishing solution, putting the polishing solution into apolishing solution circulating cylinder of the polishing machine, placing lenses into the object containing grooves of the separator, placing the pressing block on the lenses and starting the polishing machine and the rotating driving device for polishing. By this way, it can be guaranteed that machining faces of products are on the same plane, the products are stressed uniformly, and the polishing effect can be improved.

Owner:II VI OPTICS (SUZHOU) CO LTD

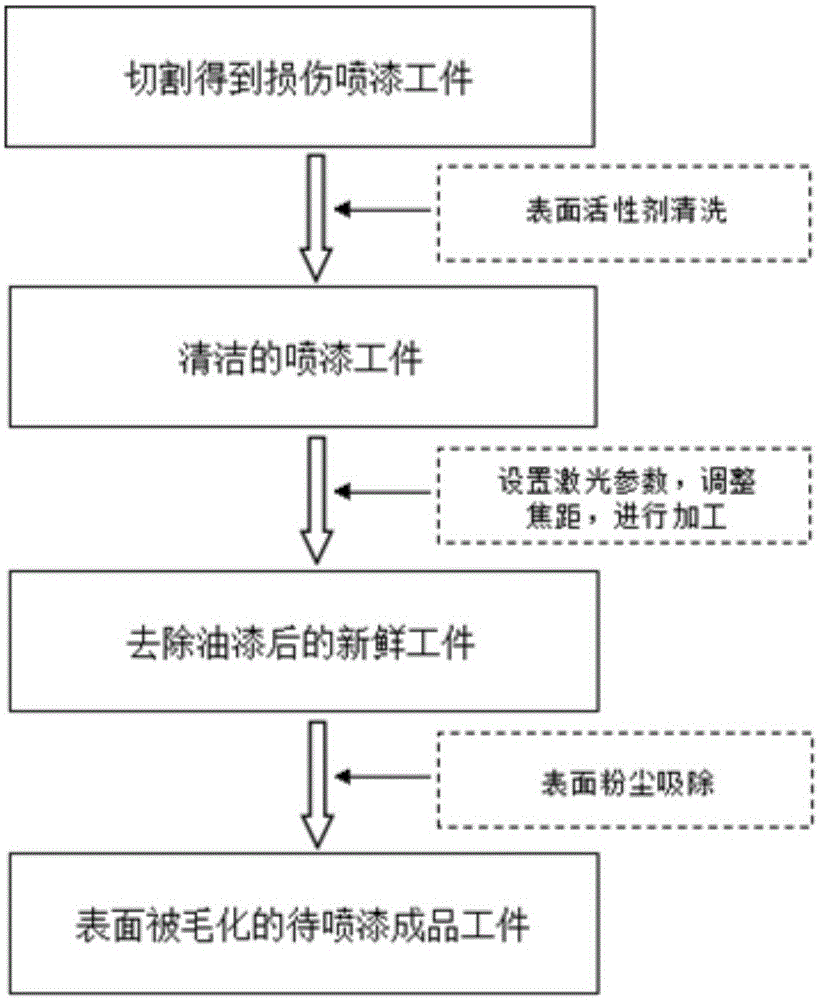

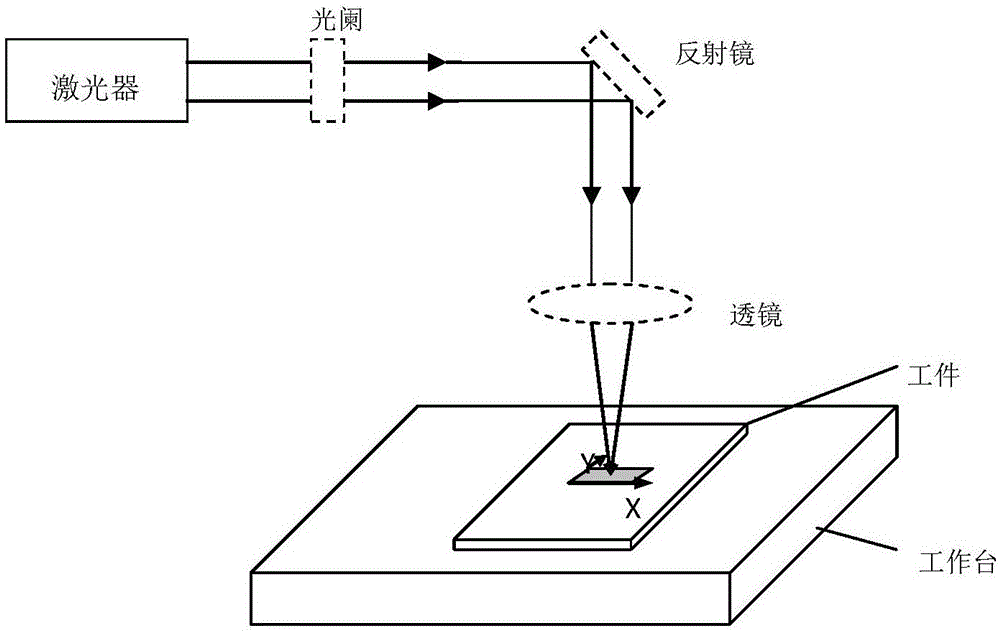

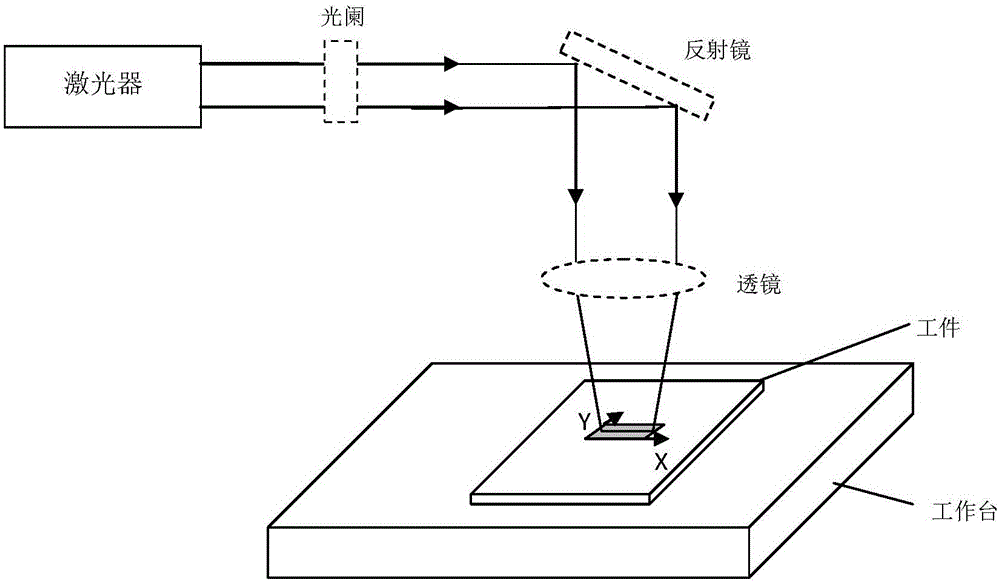

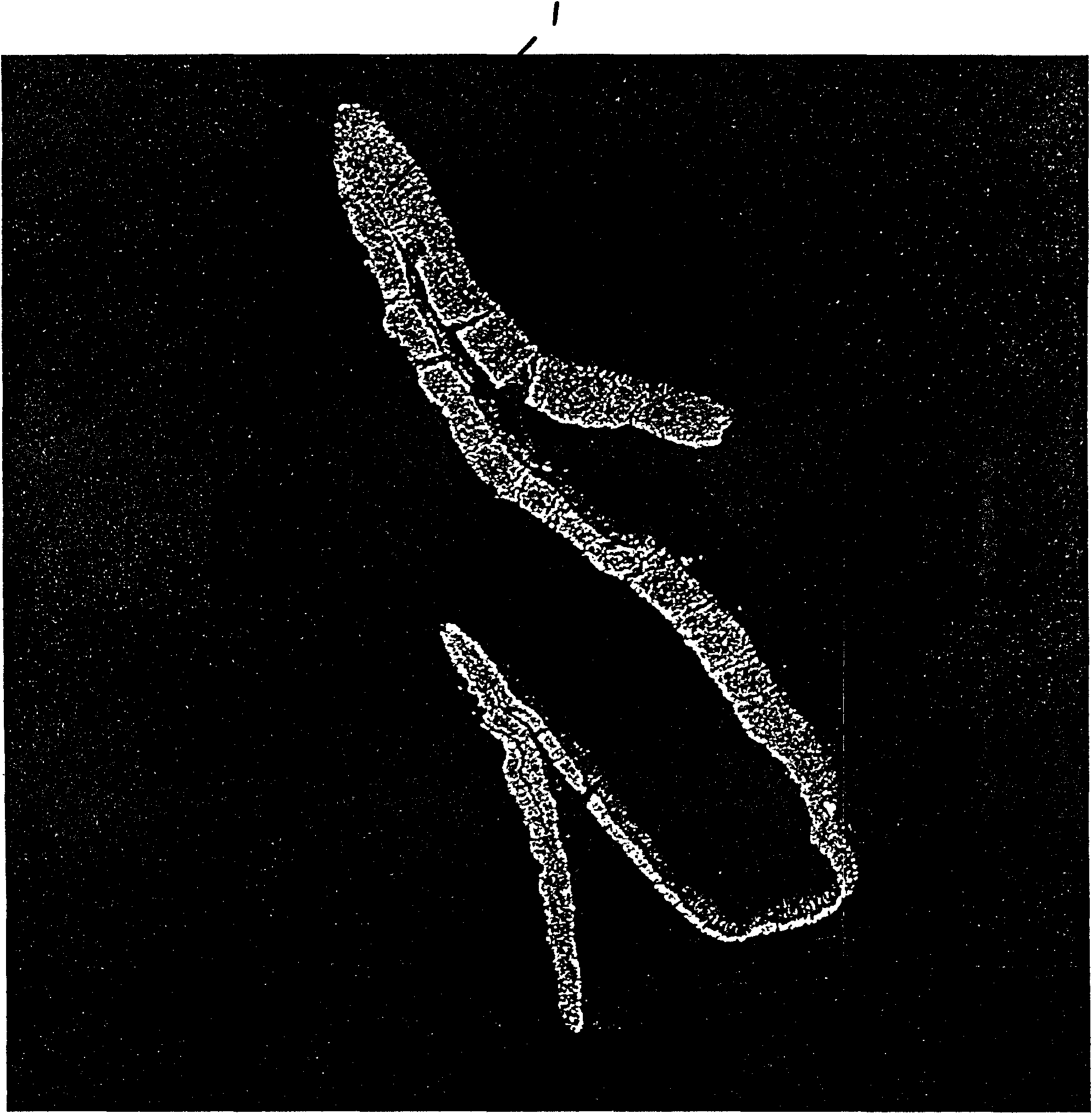

Laser method for removing paint on autobody

ActiveCN105057882ANo damageGood removal effectVehicle componentsMetal working apparatusNanosecond laserChemical solution

A laser method for removing a paint on an autobody comprises the following four steps: step 1: performing cutting to obtain an impaired painted workpiece; step 2: performing cleaning and air-drying to obtain a clean painted workpiece, particularly, sequentially cleaning the surface of the painted workpiece with a chemical solution and deionized water and performing air-drying; step 3: performing laser processing to obtain a fresh workpiece from which the paint is removed, particularly, placing the painted workpiece on a worktable of a nanosecond laser processing system, setting laser parameters, starting up the laser processing system, utilizing a vibrating mirror to scan to enable laser to scan a workpiece board at a pre-determined speed to obtain a fresh section from which the paint is removed; and step 4: performing cleaning simply to obtain a surface-textured end-product workpiece to be painted, particularly, sucking dust from the surface to obtain the surface-textured end-product workpiece to be painted. The laser method realizes semi-automatic removal of the paint on the autobody and can effectively reduce the auto beautification and maintenance cost while improving the efficiency.

Owner:BEIHANG UNIV

Polytetrafluoroethylene dental floss

A polytetrafluoroethylene dental floss comprises a floss body and is characterized in that the floss body is formed by the process that a polytetrafluoroethylene film provided with micropore is split by a film splitting blade and then is rolled up and stretched by a forming die and the transverse section of the floss body is in 'hi' (a Japanese hiragana) shape. The polytetrafluoroethylene dental floss of the invention is quick is the effect of degree of tightness when the floss body enters into slit between the teeth, is convenient to enter the slit between the teeth, and contact area of the floss body for cleaning teeth is large and is improved by 50-60% than that of the existing dental floss. The polytetrafluoroethylene dental floss can be used for cleaning teeth, repairing teeth and teeth health protection in hospitals and families.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

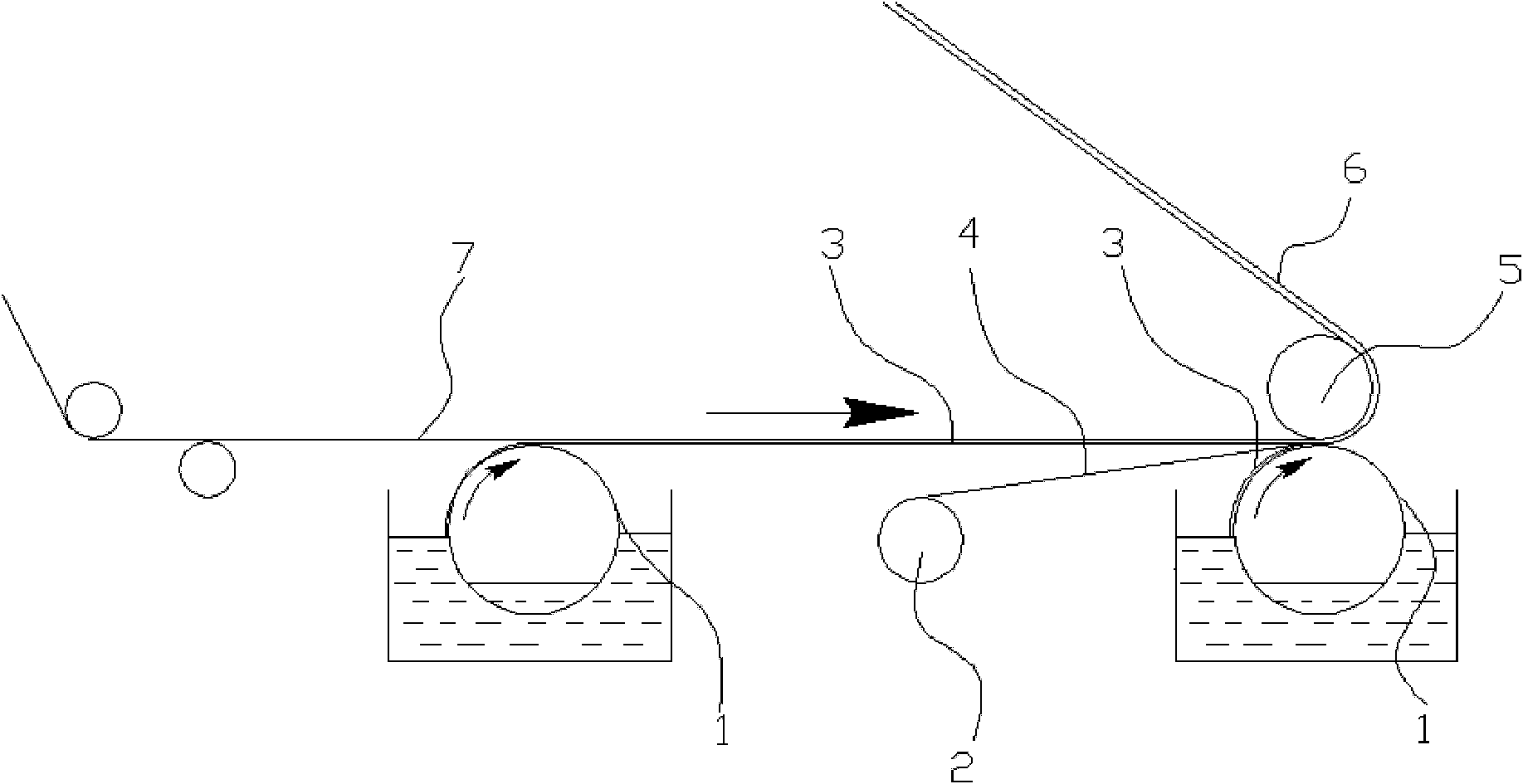

Method for compounding metal membrane by transfer-type film as well as production equipment thereof

ActiveCN103847217AImprove adhesionImprove smoothnessLamination ancillary operationsLaminationCompound aTransfer mode

The invention relates to a method for compounding a metal membrane by a transfer-type film as well as production equipment thereof. The method comprises the following steps: pretreating the surface of a plastic film; coating mucilage on the surface of a metal layer on a carrier film; drying up the carrier film; precooling the carrier film; compounding the plastic film and the carrier film by a lamination mode; carrying out hot-pressing and drying; stripping a base material layer of the carrier film. The mucilage is coated on the carrier film and is compounded with the plastic film, and finally the base material layer of the carrier film is stripped off, so that the original surface of the metal layer of the carrier film is attached to the plastic film by the mucilage, and the surface of the metal layer, which is attached to the base material layer, is converted into the surface of a metal compound film. The surface of the metal compound film after being compounded is provided with an even mirror surface, and has high metallic luster; the metal film is compounded by a transfer mode without being performed at high-temperature environments; the plastic film cannot be deformed, and the waste rate of the plastic film is reduced to be less than 0.5%; the finished product rate of the metal compound film is improved greatly.

Owner:广东东南薄膜科技股份有限公司

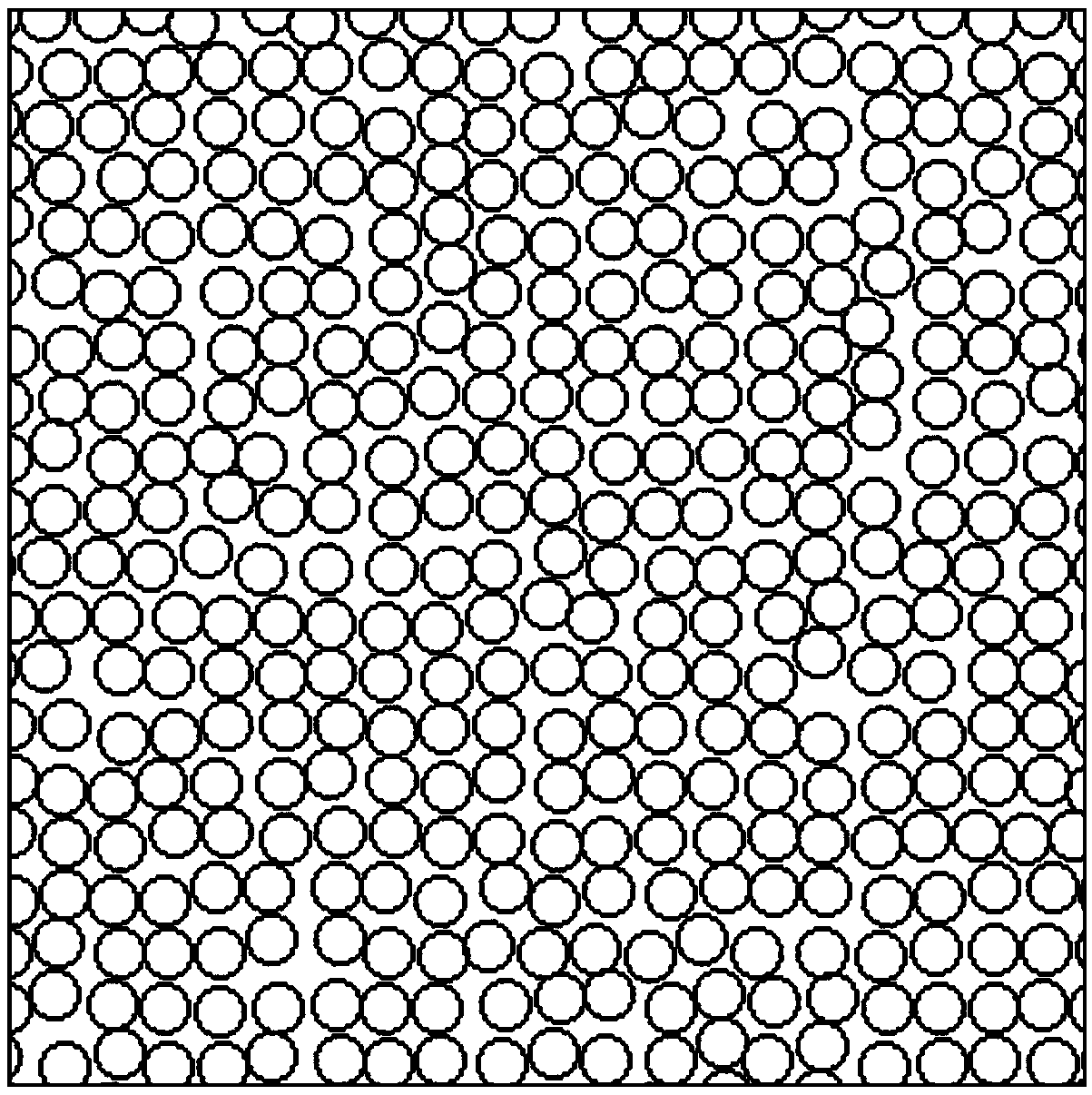

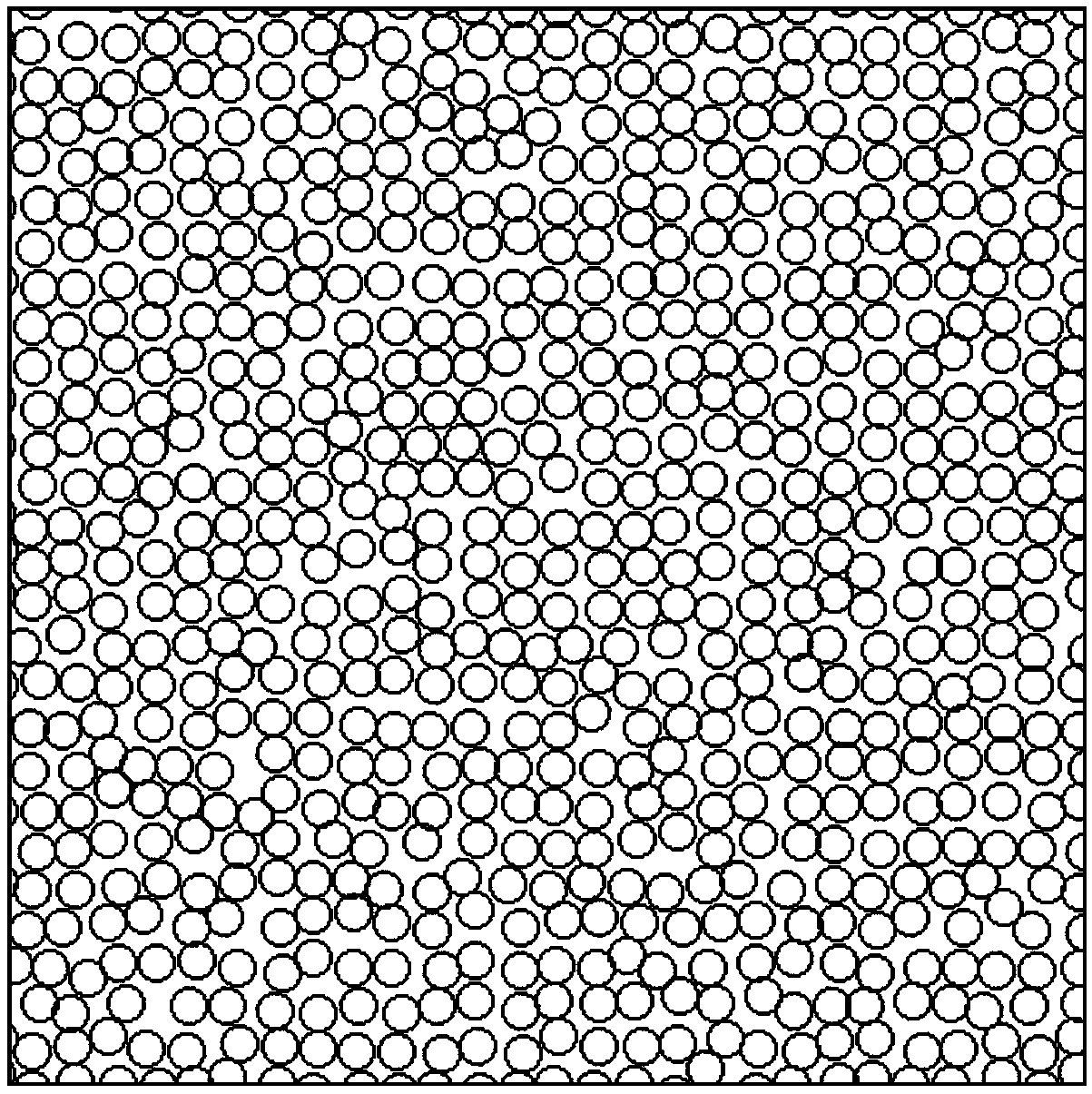

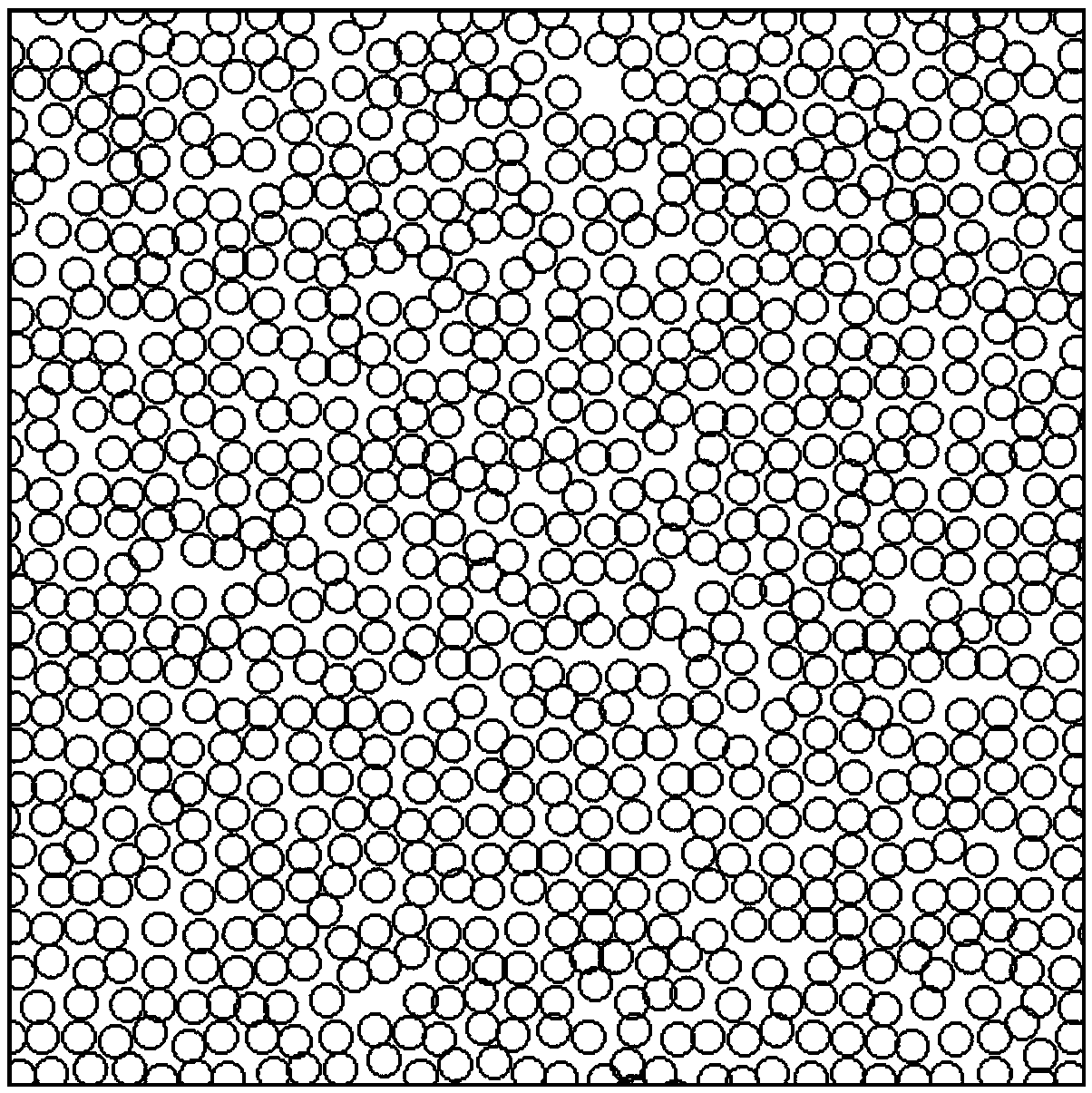

Metal material with low waviness surface and manufacturing method thereof

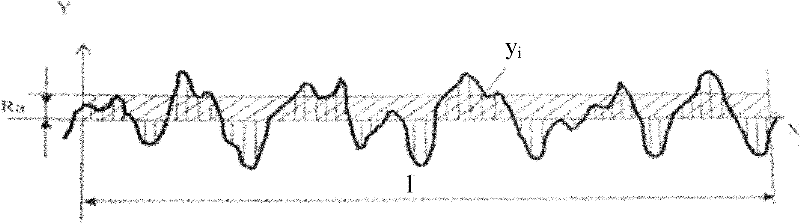

ActiveCN108927407AThe low waviness surface hasWith roughnessMetal rolling arrangementsMetallic materialsSurface roughness

The invention discloses a metal material with a low waviness surface. The surface of the metal material has a large number of roughen points, and the area of a single roughen point is 400-10,000 [mu]m<2>. The difference in size among the roughen points is less than 50%. The roughen points are disorderly distributed, and the mutual overlap amount between the roughen points is less than 10%. In addition, the invention further discloses a manufacturing method of the metal material with the low waviness surface. The manufacturing method comprises the steps that (1) a mill roll is subjected to grinding and polishing machining, the roll surface is cleaned to enable the mill roll surface roughness Ra to be less than 0.5 [mu]m, and the surface is free of oil; (2) the surface of the mill roll is subjected to roughen processing, specifically, the surface of the mill roll is irradiated with a laser pulse to form the roughen points on the surface of the mill roll; and (3) the mill roll after the roughen processing is used for rolling or leveling a metal material to obtain the metal material with the low waviness surface. The metal material is provided with the low waviness surface while havingcertain roughness on the surface of the material.

Owner:BAOSHAN IRON & STEEL CO LTD

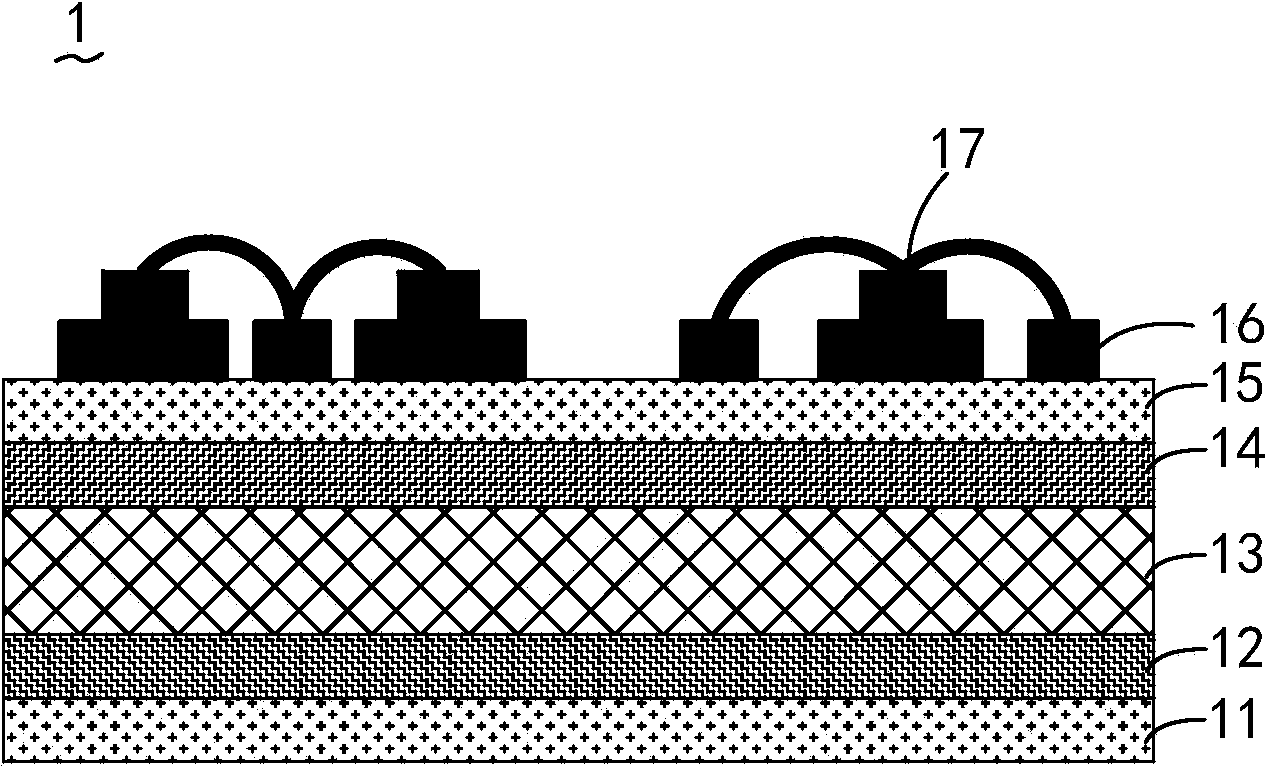

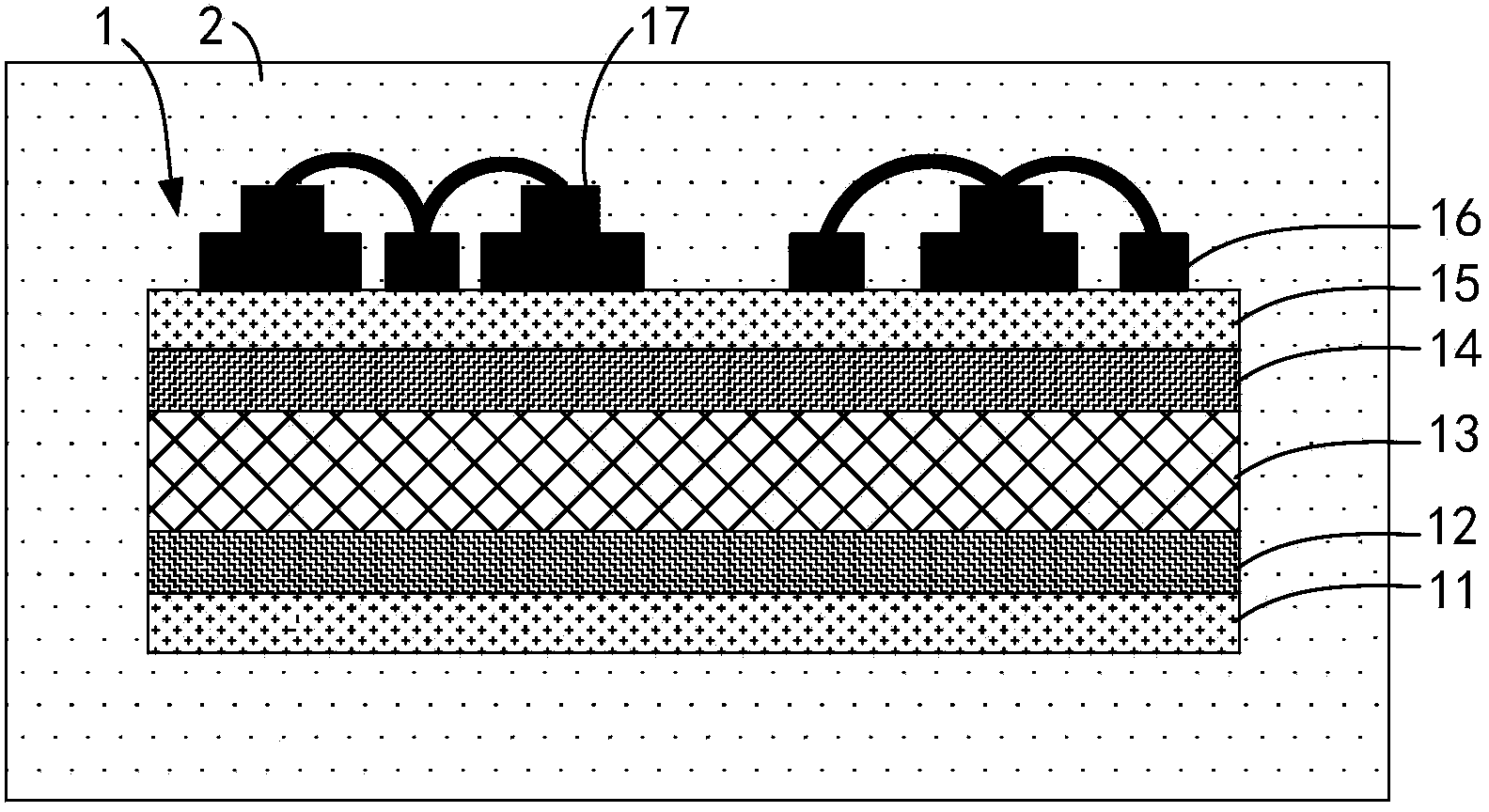

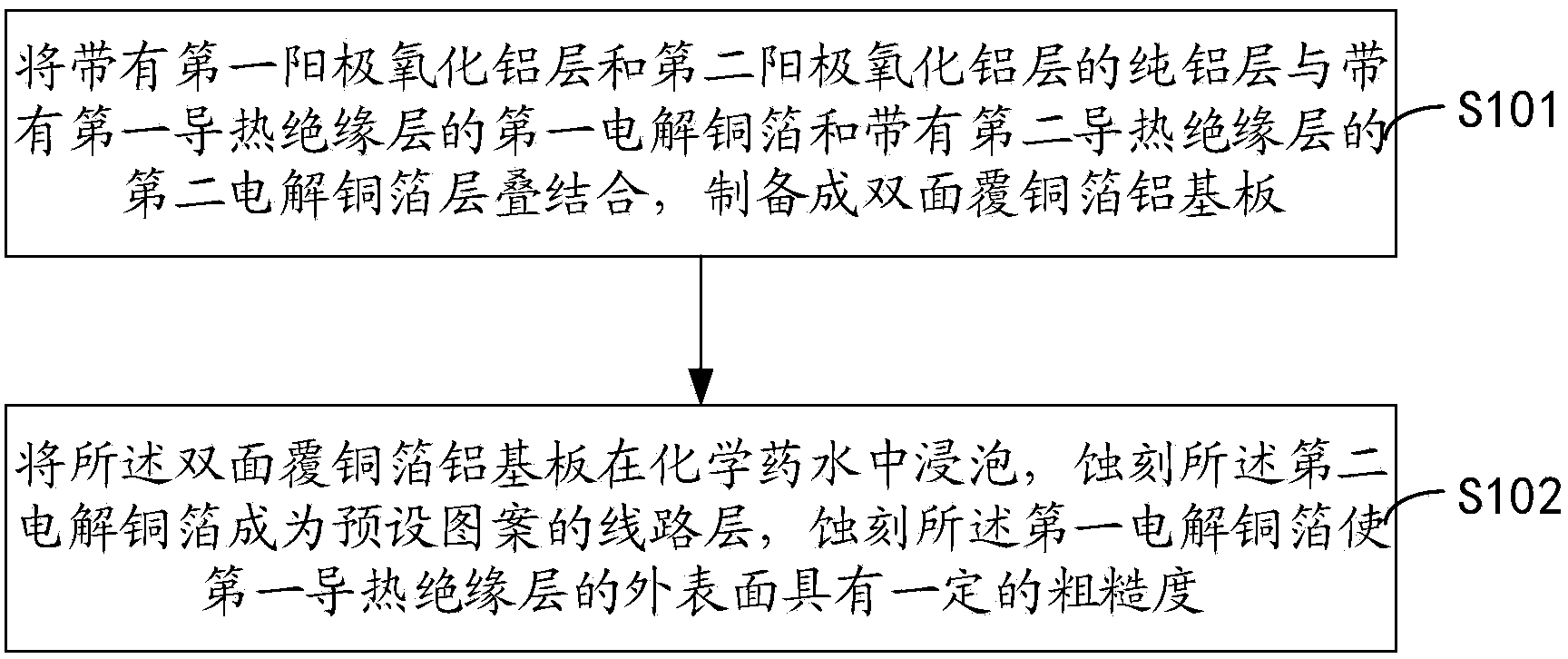

Aluminum-based circuit board and preparation method thereof, and full packaging electronic component

ActiveCN104113979AWith roughnessSimple processPrinted circuit detailsConductive material chemical/electrolytical removalHeat conductingCopper foil

Provided is an aluminum-based circuit board and a preparation method thereof, and a full packaging electronic component. The aluminum-based circuit board is used for preparing the full packaging electronic component, and comprises a first heat-conducting insulating layer, a first anode aluminum oxide layer, a pure aluminum layer, a second anode aluminum oxide layer, a second heat-conducting insulating layer and a line layer which are laminated and combined in turn. The first heat-conducting insulating layer is provided with a rough external surface. The first heat-conducting insulating layer is formed via an electrolytic copper foil etched by chemical liquid medicine so that the external surface of the first heat-conducting insulating layer has certain roughness, bonding strength between the aluminum-based circuit board and a packaging layer of the electronic component is substantially enhanced, and the structure of the aforementioned full packaging electronic component comprising the aluminum-based circuit board is enabled to be stable without de-lamination or cracking. Besides, heat radiation of the full packaging electronic component is also substantially enhanced by high bonding strength so that integrated reliability of the full packaging electronic component is enhanced.

Owner:MIDEA GRP CO LTD

Air column bag for cold chain transportation

ActiveCN108263754AFocusEasy to grabContainers to prevent mechanical damageCold chainAgricultural engineering

The invention belongs to the technical field of air column bags and discloses an air column bag for cold chain transportation. The air column bag comprises an upper film used for making contact with foods, and a lower film forming an outer surface after wrapping foods. A plurality of vertical heat seals are arranged between the upper film and the lower film and separate the upper film and the lower film into a plurality of air columns. The two ends of the multiple air columns are connected through the upper heat seals and the lower heat seals correspondingly. The ends, close to the upper heatseals, in the air columns are each provided with an air valve film. The outer surface of the lower film is provided with an antiskid structure used for preventing water in air from coagulating into asmooth ice layer. The antiskid structure is arranged, thus when the air column bag is placed in a freezing chamber, the water in the air is prevented from coagulating into the smooth ice layer, the points of force during taking of the air column bag and the foods therein are increased, and grabbing and transportation are convenient.

Owner:上海唐科新材料科技有限公司

Composite membrane and manufacturing method thereof

InactiveCN103572846AWith roughnessImprove thermal performanceSynthetic resin layered productsHeat proofingAviationFiber

The invention discloses a composite membrane. The composite membrane is characterized by being composed of an inorganic fiber mesh resin composite layer 10, an aluminum layer 20, a polyurethane adhesive layer 30 and a plastic composite layer 40. The invention further provides a manufacturing method of the composite membrane. The composite membrane has the advantages of low gas permeability and water permeability, and good alkali resistance, weather resistance, fire resistance and puncture resistance; the composite membrane and alkali cement mortar chemically react rarely, and the composite membrane can be widely applied in the fields, requiring heat insulation, of machinery, electronics, construction, aviation, aerospace, automobiles, ships in cold, hot or wet environment.

Owner:SUZHOU V I P NEW MATERIAL

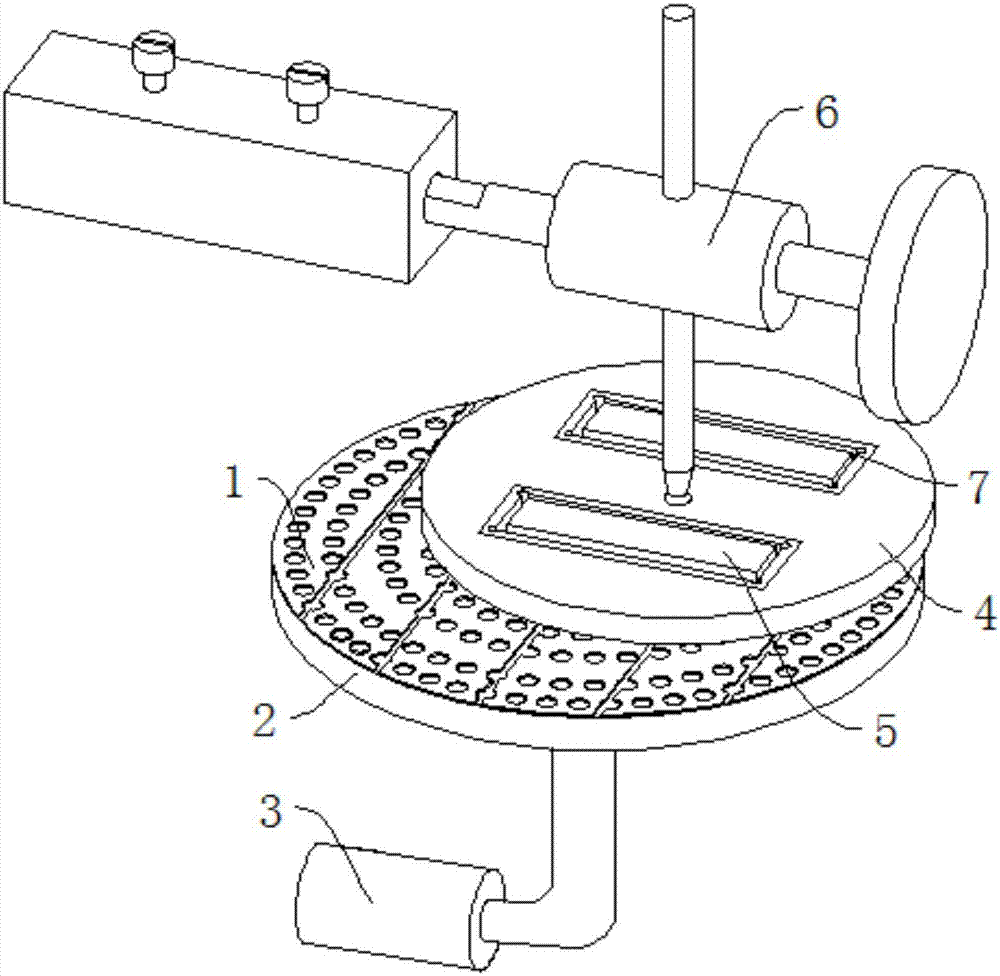

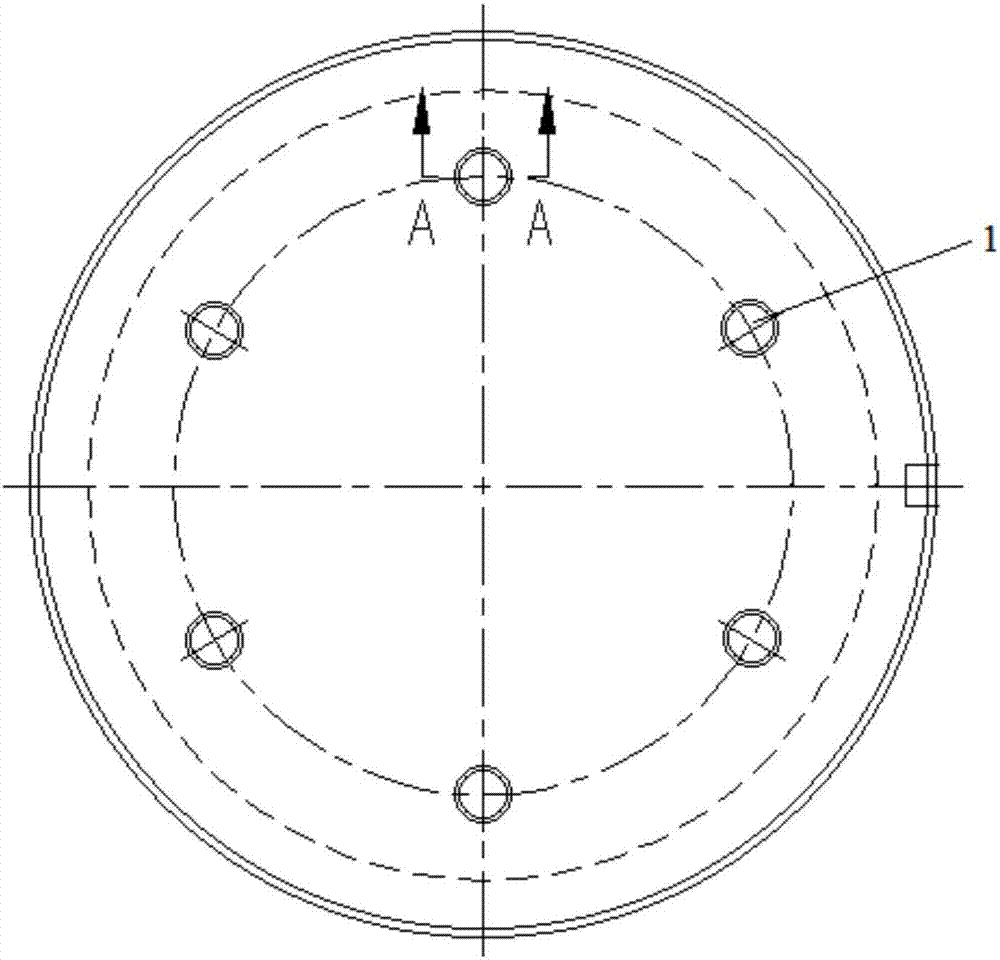

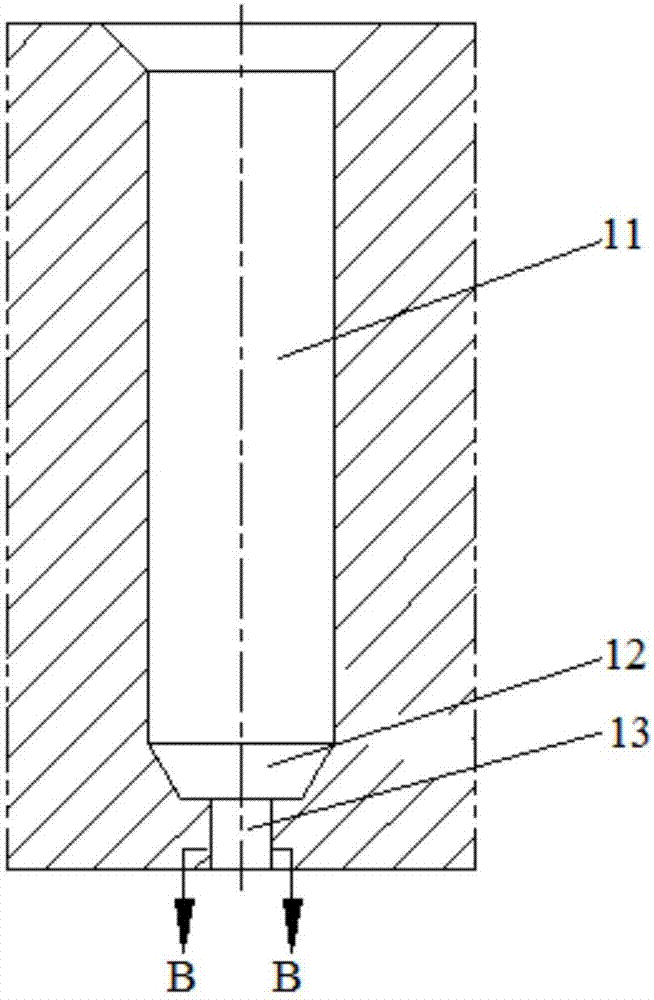

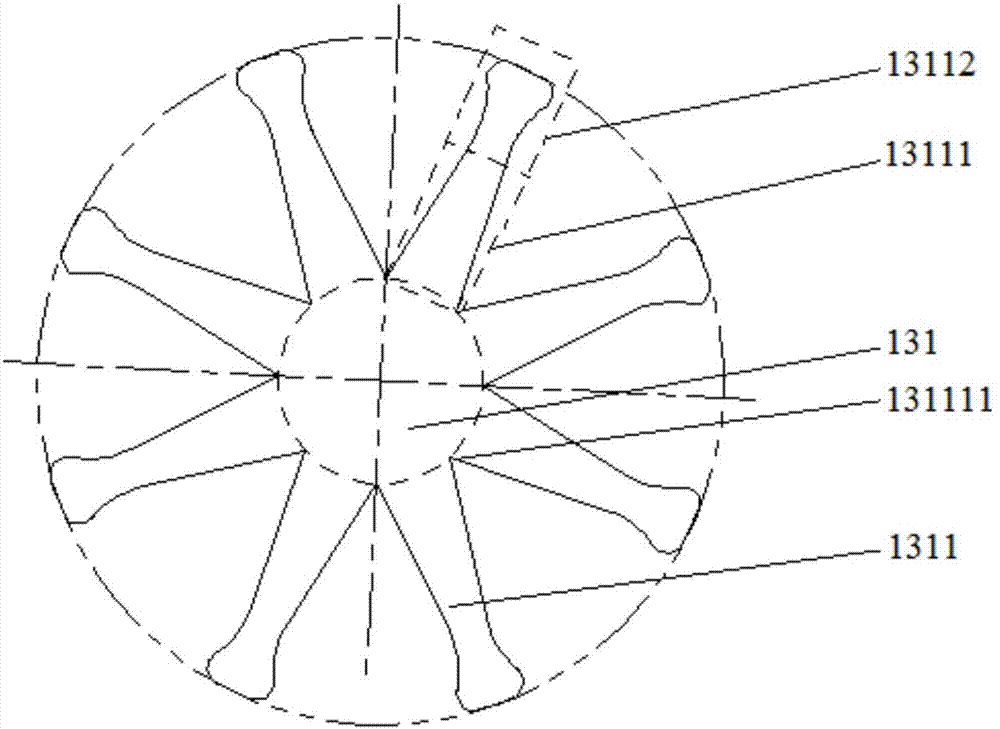

Optical lens polishing device and polishing technology

InactiveCN107253132AEven by forceImprove polishing effectLapping machinesAbrasive surface conditioning devicesEngineeringLens plate

The invention discloses an optical lens polishing device which comprises a polishing pad, a polishing pad base, a driving device, a separator, pressing blocks and a polishing machine. The polishing pad is arranged on the polishing pad base. The polishing pad base is connected to the driving device. The separator is arranged on the polishing pad. A plurality of placement grooves are formed in the separator. The pressing blocks are arranged inside the placement grooves in the separator. A hole is formed in the middle of the separator. The separator is connected to the polishing machine through a hole. The invention further discloses a polishing technology. The polishing technology comprises the specific steps of finishing a correction mold, finishing the polishing pad through the correction mold; cleaning the polishing pad; fixing the polishing pad to the polishing pad base; preparing a polishing solution; placing the polishing solution into a polishing solution circulation cylinder of the polishing machine; placing lenses into the placement grooves of the separator; placing the pressing blocks on the lenses; starting the polishing machine and the driving device for polishing. In this way, it is ensured that the product machining face is on the same plane, stress is uniform, and the polishing effect is improved.

Owner:II VI OPTICS (SUZHOU) CO LTD

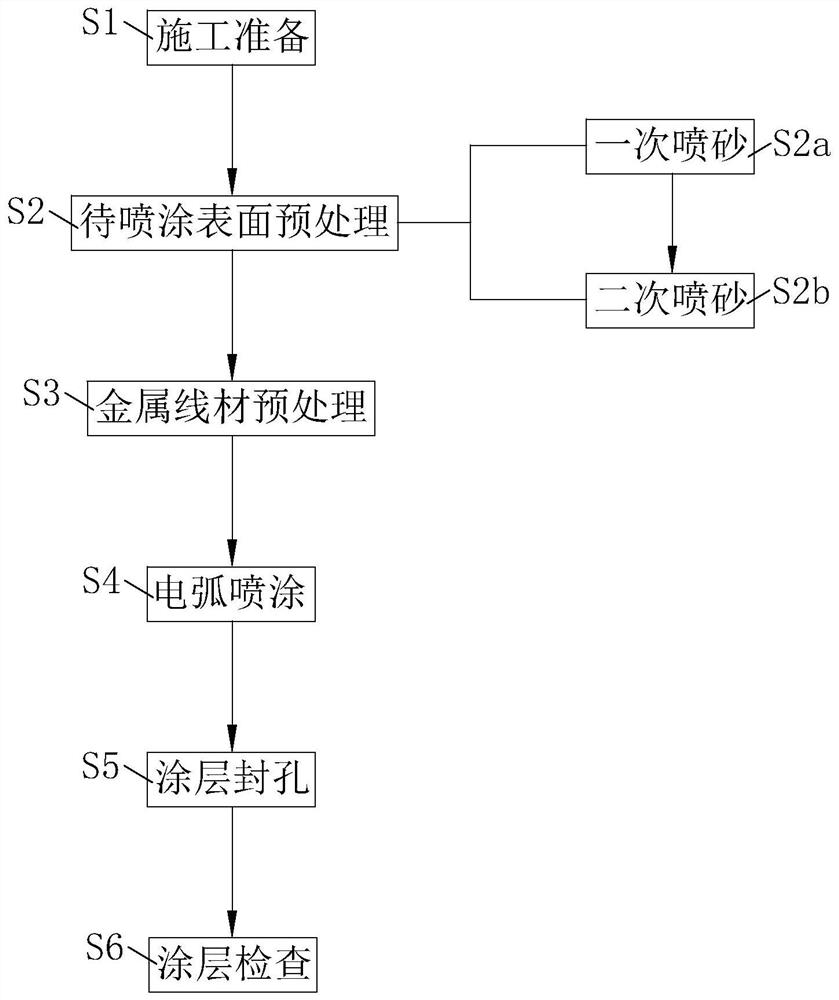

Electric arc spraying method

PendingCN112159947AHigh purityEven and dense coatingMolten spray coatingCorrosion preventionPre treatment

The invention relates to an electric arc spraying method. The electric arc spraying method comprises the following steps that S1, construction preparation is conducted; S2, pretreatment is conducted on the surface to be sprayed, specifically, sand blasting treatment is conducted on the surface of a workpiece through pneumatically-controlled sand blasting equipment, and the roughness of the workpiece reaches 90-120 microns; S3, pretreatment is conducted on a metal wire, specifically, the metal wire is cleaned through a rust remover, straightened through a straightening machine after being cleaned and dried, and polished after being straightened, so that the surface of the metal wire is smooth; S4, electric arc spraying is conducted; S5, coating hole sealing is conducted; and S6, coating inspection is conducted, specifically, the appearance surface obtained after spraying is inspected. According to the electric arc spraying method, the metal wire is cleaned, dried, straightened and polished before spraying, so that the outer surface of the workpiece obtained after spraying is smooth, a coating is uniform, flat and compact, the coating and a base body are well combined, bubbling, cracking, pitted surfaces and peeling are avoided, and accordingly the corrosion resistance and structural strength of the workpiece are improved.

Owner:上海戎实喷涂机械有限公司

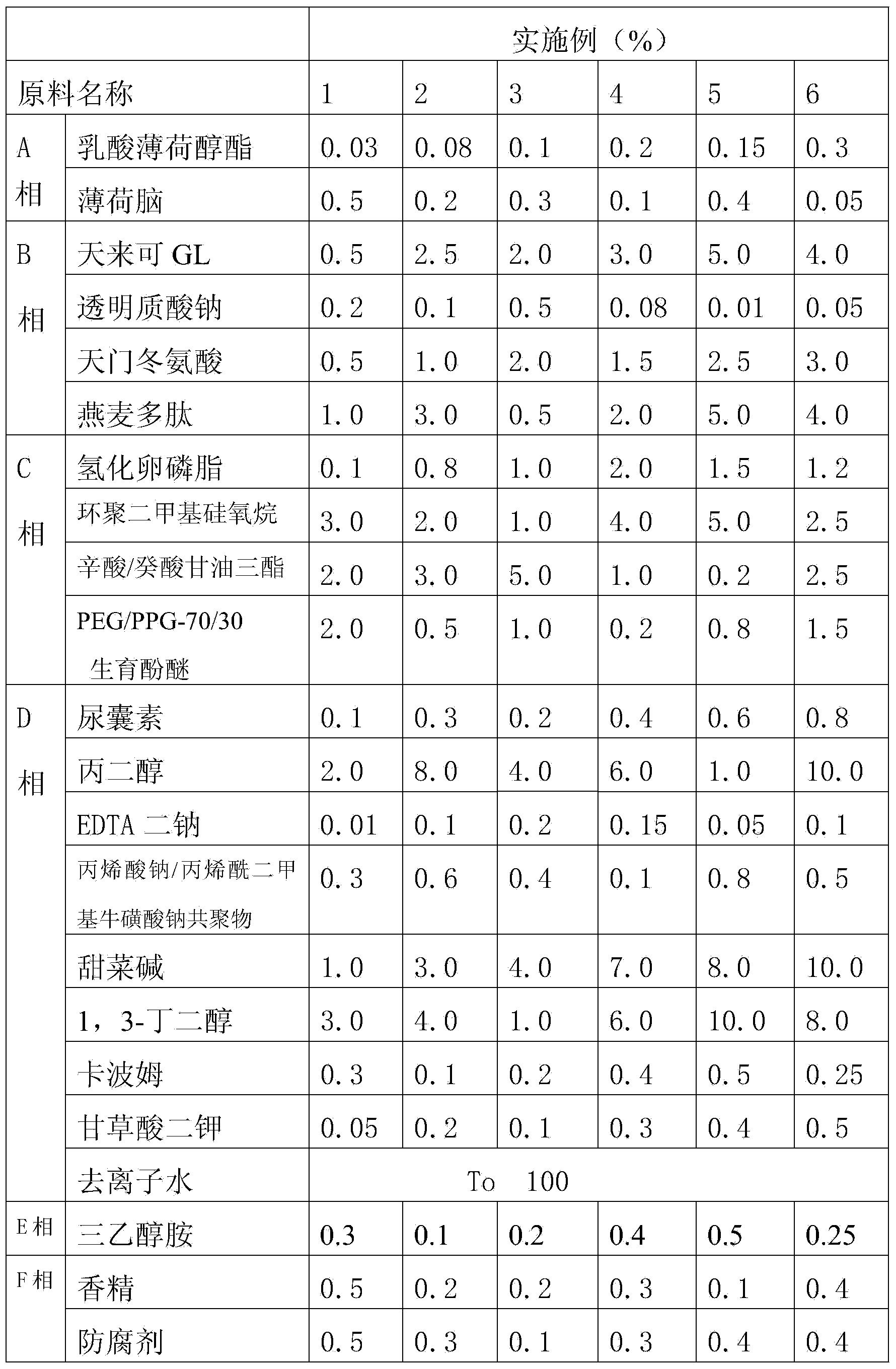

Men skin refreshing and nourishing emulsion and preparation method thereof

ActiveCN103655330APromote circulationVisible wake-up effectCosmetic preparationsToilet preparationsWrinkle skinMenthol

The invention discloses a men skin refreshing and nourishing emulsion and a preparation method thereof. The emulsion comprises lactic menthol ester, menthol, tinocare GL, sodium hyaluronate, asparaginic acid aspartic acid, oat polypeptide, an oil-phase component, a water-phase component, triethanolamine, essence and preservative. The emulsion gives a comfortable tingling and refreshed feeling to people, can be used for activating skin cells and promoting skin circulation, has a remarkable skin refreshing effect, can be used for preventing occurrence of wrinkles, enables skin to be smooth, tender and soft. The emulsion is researched and developed according to the characteristics of men skin, and can effectively improve rough skin of men and prevent skin aging.

Owner:广州市澳莱化妆品有限公司

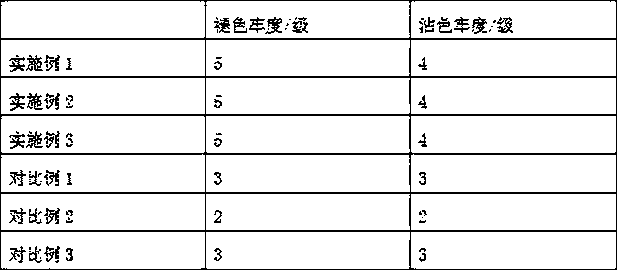

Processing method for improving colour fastness of dacron fabric

The invention discloses a processing method for improving the colour fastness of a dacron fabric and relates to the technical field of processing of clothes. The processing method comprises the following steps: (1) pretreatment; (2) plasma treatment; (3) preparation of active treating fluid; (4) modification treatment; (5) ultrasonic processing; and (6) cleaning. By virtue of performing surface low-temperature plasma treatment on the dacron fabric, the surface substantivity of the dacron fabric can be obviously improved, and the combination property of the dacron fabric with dye molecules is promoted, so that the colour fastness is improved.

Owner:阜南美凯服饰有限公司

Rough surface profiled fiber and preparation method and application thereof

ActiveCN107447272AGuaranteed use strengthImprove practicalityFilament/thread formingAbnormal shapedCorrosion

The invention discloses a rough surface profiled fiber and a preparation method and application thereof. The preparation method of the rough surface profiled fiber comprises the following steps of spinning yarns through a profiled spinneret to obtain initial fiber products; performing corrosion treatment on the obtained initial fiber products; performing washing and drying processes to obtain finished fiber products, namely, rough surface profiled fiber, wherein the process of spinning the yarns through the profiled spinneret produces the initial fiber products with the radial cross section in a star shape, then the initial fiber products are corroded, and a number of corrosive pits are formed in the surface of the obtained finished fiber products, namely, the surface obtains certain roughness to further improve condensate performance. The profiled fiber with the corrosive pits in the surface is made of polar polymers, thereby having high water absorbency, the star-shaped structure provides sliding channels for collected water, and meanwhile, the surface roughness can further improve the condensate performance of the fiber.

Owner:北京京盛国泰科技有限公司

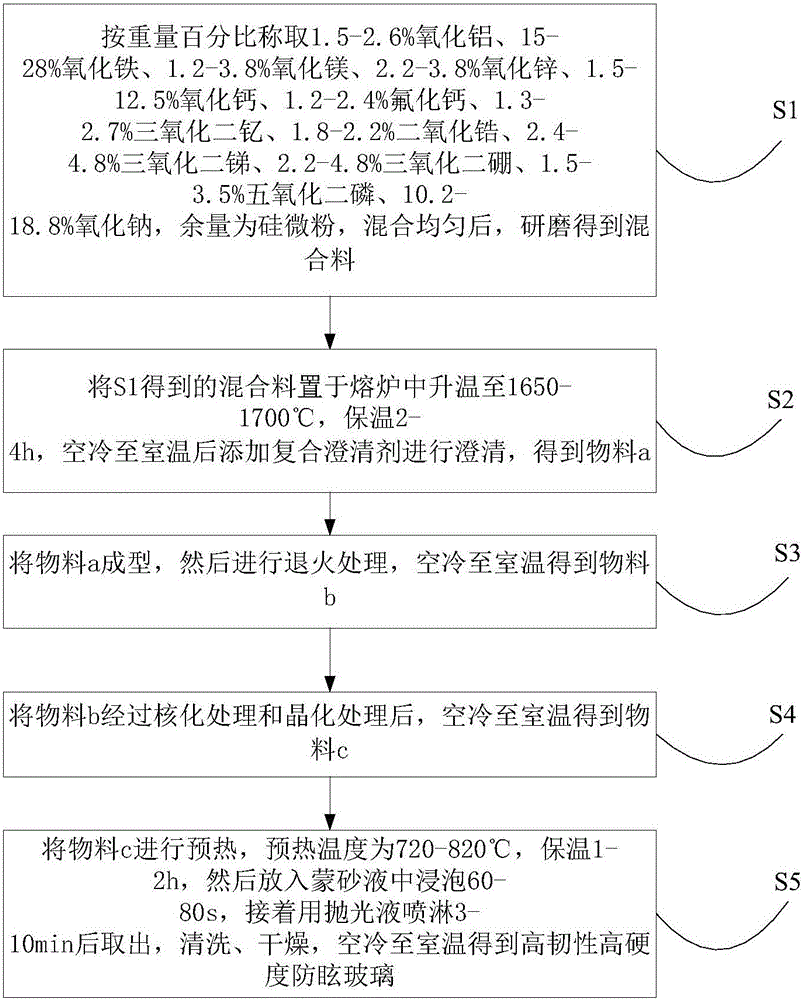

Method for preparing high-tenacity high-hardness anti-dazzle glass

The invention provides a method for preparing high-tenacity high-hardness anti-dazzle glass. The method comprises the steps that firstly, raw materials needed for manufacturing the glass are prepared, then the raw materials are evenly mixed and ground to obtain a mixture, the mixture is placed in a smelting furnace, and then composite clarifying agents are added for clarifying; the mixture is cooled to room temperature, a material a is obtained, the material a is formed, then annealing treatment is carried out, and a material b is obtained; after coring treatment and crystallization treatment are carried out on the material b, a material c is obtained; the material c is preheated, preheating temperature ranges from 720 DEG C to 820 DEG C, and heat preservation is carried out for 1-2 h; then the material c is placed in frosting liquid to be soaked for 60-80 s, a polishing solution is sprayed to the material c for 3-10 min, then the material is taken out to be washed, dried and air-cooled to room temperature, and the high-tenacity high-hardness anti-dazzle glass is obtained.

Owner:徐州高运新型材料有限公司

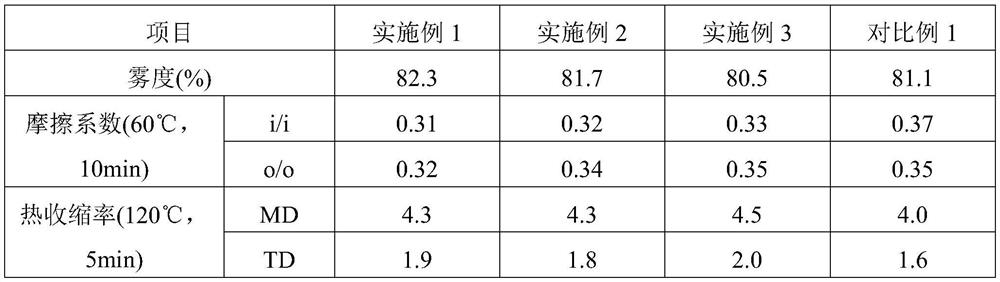

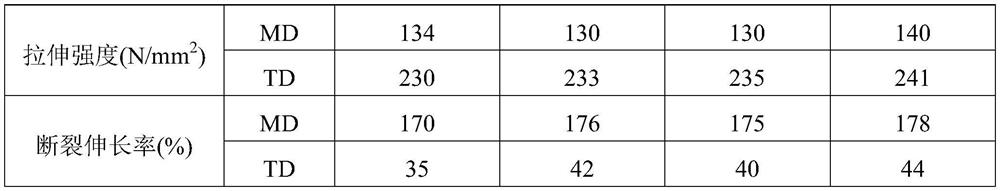

Matting coating base film and preparation method thereof

ActiveCN114161797AImprove adhesionGood compatibilitySynthetic resin layered productsFlat articlesMasterbatchRosin

The matt coating base film is sequentially composed of an upper surface layer, a core layer and a lower surface layer, the upper surface layer is prepared from the following raw materials in parts by mass: 90-95 parts of matting master batch, 4-7 parts of rosin resin and 1-3 parts of an anti-sticking agent, and the matting master batch is prepared from the following raw materials in parts by mass: 82.5-90.5 parts of polypropylene, 5-10 parts of silane modified silicon dioxide matting powder and 0.001-0.002 part of an initiator. The invention also discloses a preparation method of the matt coating base film. According to the invention, PVDC coating can be directly carried out without pre-coating primer, the cost is saved, and the packaging base material is safe and environment-friendly, has good matting performance and mechanical performance, and is a novel, green and excellent-performance packaging base material.

Owner:GETTEL GRP TONGCHENG PLASTIC IND

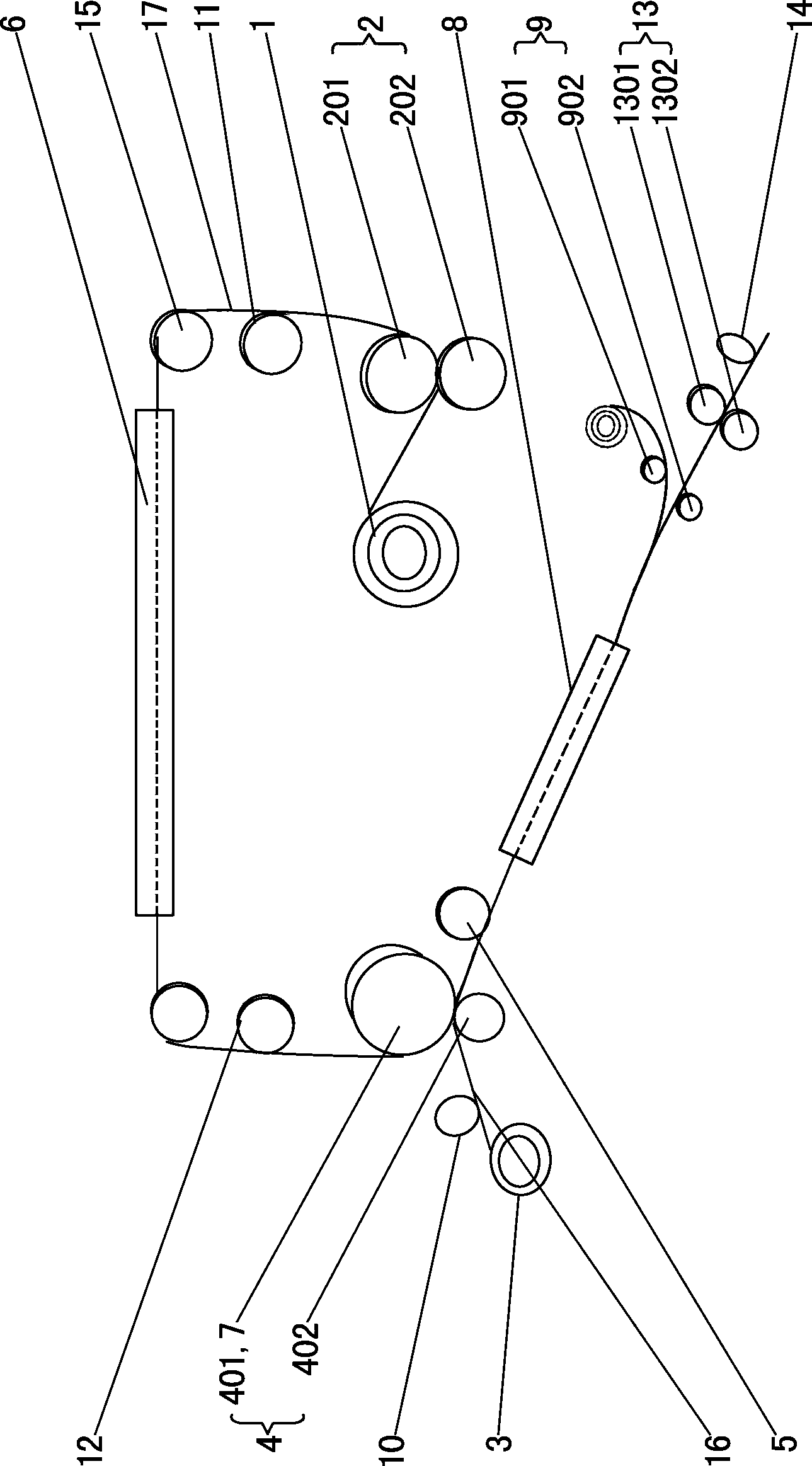

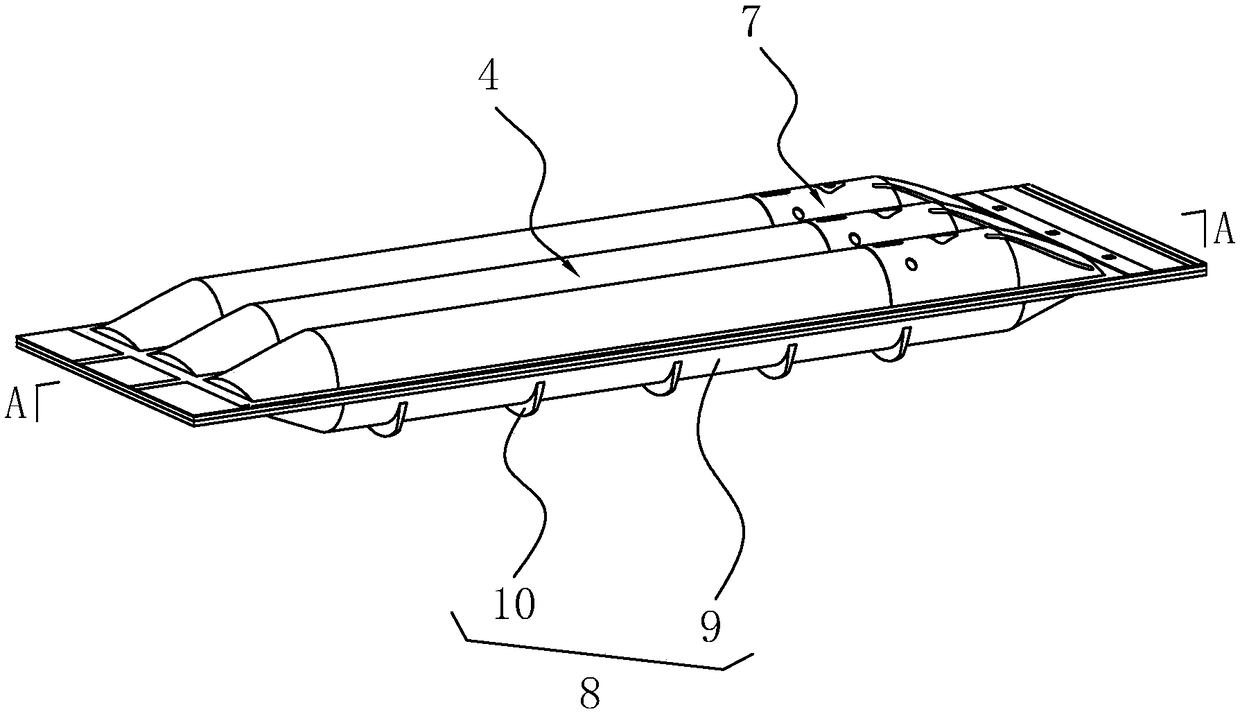

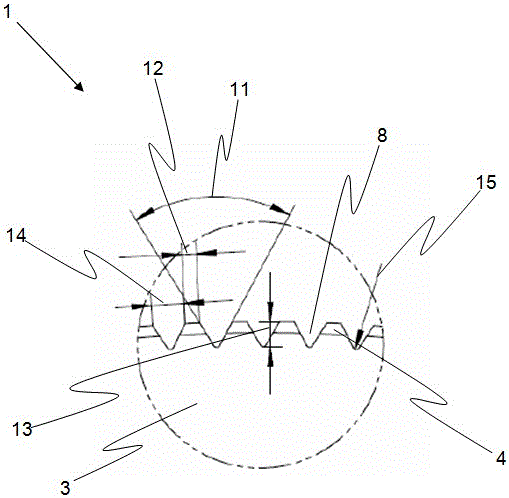

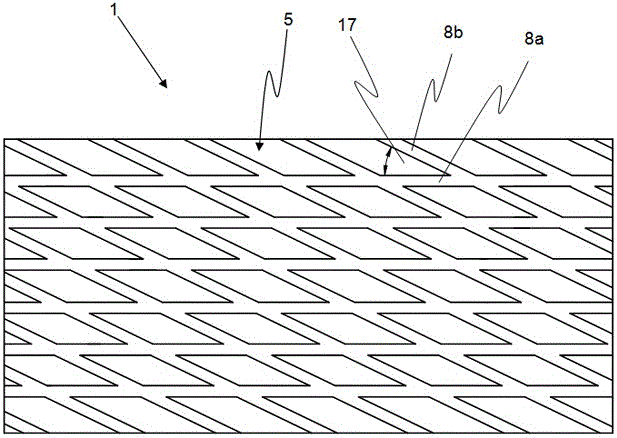

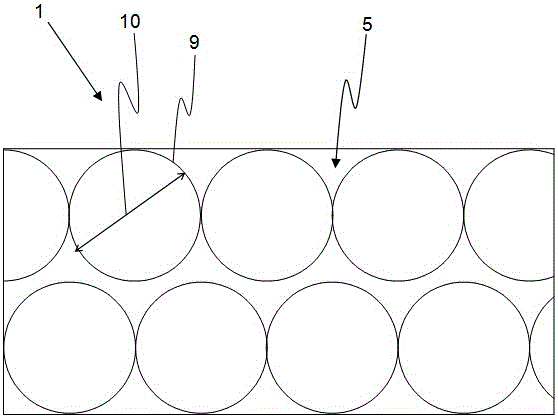

Measuring roller and device for measuring an fibers composite

The invention relates to a measuring roller for a device for measuring a fiber composite (2), in particular on a draw frame, a carding engine or a comber, made of a material of low thermal expansion (3) and having a surface coating (4), whereas the measuring roller (1) features a shell surface (5) for damping a fiber composite (6) along with a rotary axis (7). In accordance with the invention, the shell surface (5) of the measuring roller (1) features a structure forming an air buffer, made of grooves (8), boreholes (9) and / or spherical projections (18).

Owner:RIETER INGOLSTADT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com