Measuring roller and device for measuring an fibers composite

A composite fiber and roller technology, which is applied in the field of composite fiber devices and devices for measuring composite fibers, can solve the problems of measurement signal disappearance, extrusion force weakening, etc., to reduce measurement errors, avoid carrying and offset, The effect of reducing the sticking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

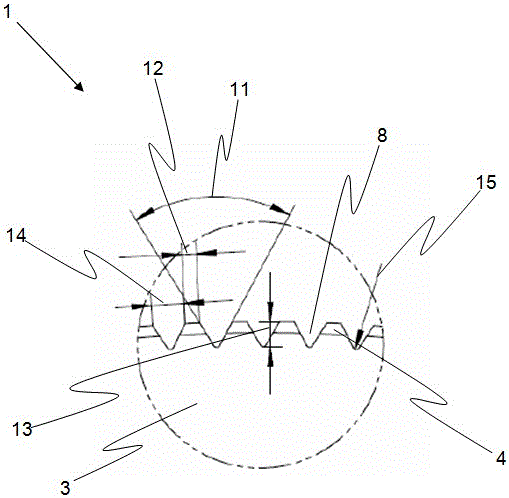

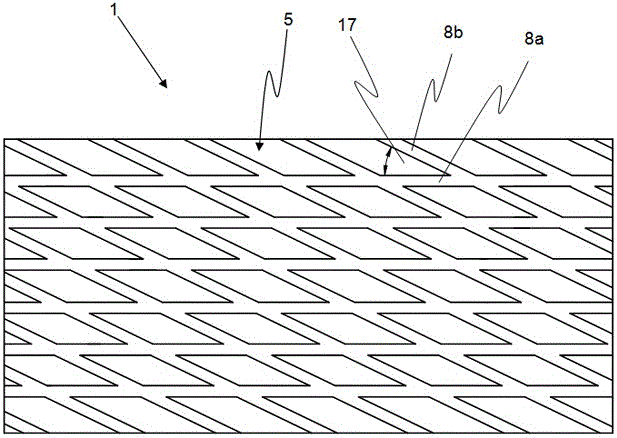

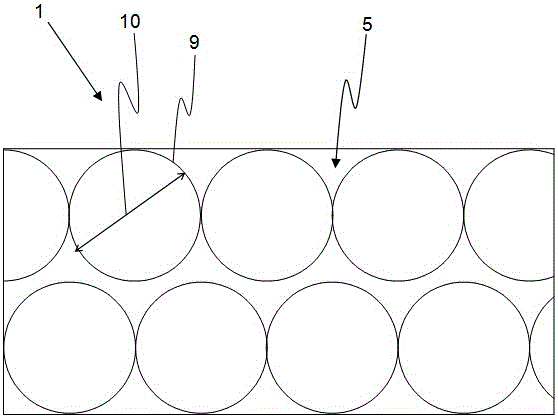

[0066] figure 1 A part of the cross-section of the measuring roll 1 is shown. The measuring roll 1 here consists of a material 3 with a low coefficient of thermal expansion. Furthermore, the outer surface 5 of the measuring roll 1 is coated with a surface coating 4 . Grooves 8 are formed in the outer surface 5 . But as an alternative or in addition to the groove 8, it is also possible to form a hole 9 (such as image 3 shown) and / or bulbous bumps 18 (as Figure 4 shown).

[0067] The surface coating 4 here only partially covers the peaks between the two grooves 8 . Therefore, only the effective surface which is in contact with the composite fiber 6 is coated. It is also conceivable that the grooves 8 are completely coated with the surface coating 4 .

[0068] In addition, the grooves 8 also have an opening angle 11 . Two adjacent grooves 8 each have a distance 12 in the circumferential direction. Likewise, the grooves 8 have a groove depth 13 and a groove width 14 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com