Method for preparing high-tenacity high-hardness anti-dazzle glass

An anti-glare glass, high hardness technology, applied in the field of glass preparation, can solve the problems of unsatisfactory toughness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

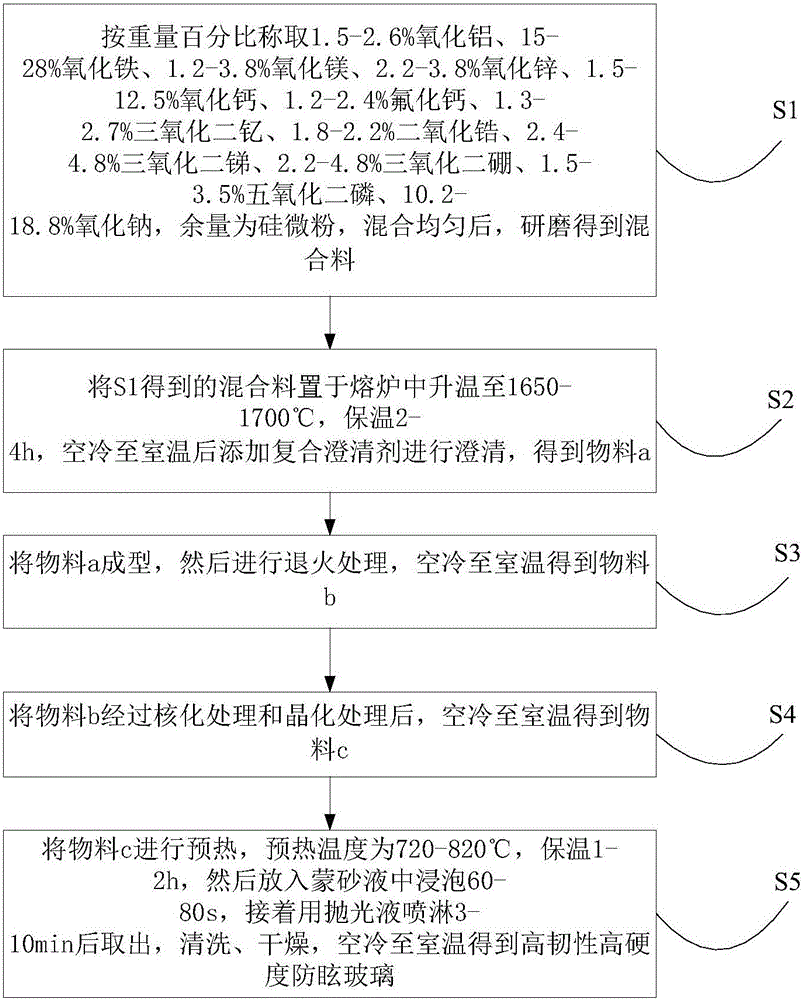

[0021] refer to figure 1 , the present invention proposes a method for preparing anti-glare glass with high toughness and high hardness, comprising the following steps:

[0022] S1. Weigh 1.5-2.6% aluminum oxide, 15-28% iron oxide, 1.2-3.8% magnesium oxide, 2.2-3.8% zinc oxide, 1.5-12.5% calcium oxide, 1.2-2.4% calcium fluoride, 1.3-2.7% yttrium trioxide, 1.8-2.2% zirconia, 2.4-4.8% antimony trioxide, 2.2-4.8% boron trioxide, 1.5-3.5% phosphorus pentoxide, 10.2-18.8% sodium oxide , the balance is silica powder, after mixing evenly, grind to obtain the mixture;

[0023] S2. Put the mixed material obtained in S1 into a melting furnace to heat up to 1650-1700° C., keep it warm for 2-4 hours, and add a composite clarifier to clarify after air cooling to room temperature to obtain material a;

[0024] S3, forming material a, then performing annealing treatment, and air cooling to room temperature to obtain material b;

[0025] S4. After the material b is subjected to nucleatio...

Embodiment 1

[0028] The present invention proposes a method for preparing anti-glare glass with high toughness and high hardness, comprising the following steps:

[0029] S1. Weigh 2.05% aluminum oxide, 21.5% iron oxide, 2.5% magnesium oxide, 3.0% zinc oxide, 7.0% calcium oxide, 1.8% calcium fluoride, 2.0% yttrium trioxide, 2.0% zirconium dioxide by weight percentage , 3.6% antimony trioxide, 3.5% diboron trioxide, 2.5% phosphorus pentoxide, 14.5% sodium oxide, the balance is silicon micropowder, after mixing evenly, grind to obtain the mixture;

[0030] S2. Put the mixed material obtained in S1 in a melting furnace and heat it up to 1675° C., keep it warm for 3 hours, cool it to room temperature in air, add a sodium antimonate solution with a concentration of 37 wt% for clarification, and obtain material a;

[0031] S3. Form material a, then heat up to 195°C, keep warm for 55min, air cool to room temperature, then heat up to 260°C, keep warm for 55min, air cool to room temperature, then h...

Embodiment 2

[0035] The present invention proposes a method for preparing anti-glare glass with high toughness and high hardness, comprising the following steps:

[0036] S1. Weigh 1.5% alumina, 28% iron oxide, 1.2% magnesium oxide, 3.8% zinc oxide, 1.5% calcium oxide, 2.4% calcium fluoride, 1.3% yttrium trioxide, 2.2% zirconium dioxide by weight percentage , 2.4% antimony trioxide, 4.8% diboron trioxide, 1.5% phosphorus pentoxide, 18.8% sodium oxide, and the balance is silicon micropowder. After mixing evenly, grind to obtain a mixture;

[0037] S2. Put the mixture obtained in S1 in a melting furnace to heat up to 1700° C., keep it warm for 2 hours, cool it to room temperature in air, and then add a sodium antimonate solution with a concentration of 42 wt% for clarification to obtain material a;

[0038] S3. Mold material a, then heat up to 210°C, keep warm for 40 minutes, air cool to room temperature, then heat up to 210°C, keep warm for 70 minutes, air cool to room temperature, then hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com