Matting coating base film and preparation method thereof

A cloth base film and matting technology, which is applied in the field of matting coating base film and its preparation, can solve the problems of increased energy consumption, solvent safety hazards, high cost, etc., achieve good matting performance and mechanical properties, improve bonding fastness, Avoid the effect of poor film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

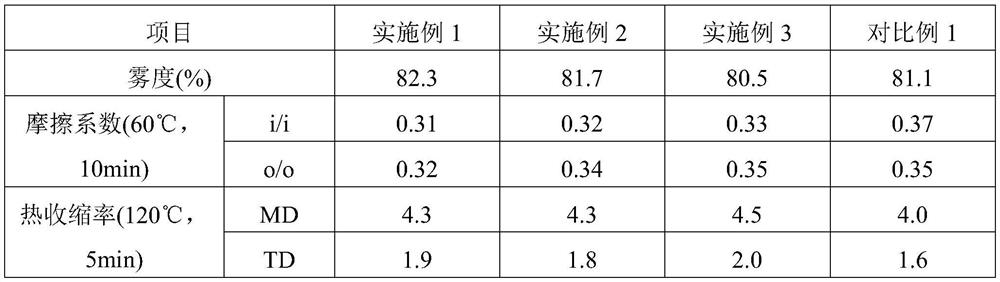

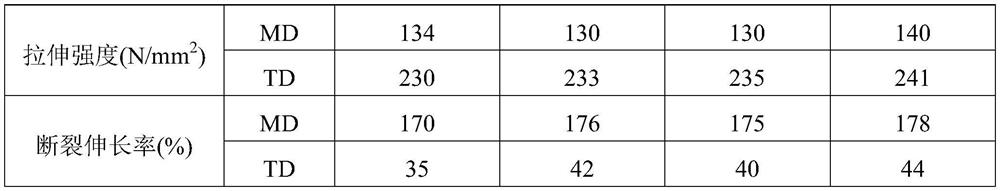

Examples

Embodiment 1

[0027] A matting coating base film, consisting of an upper surface layer, a core layer and a lower surface layer in turn; the upper surface layer is composed of the following raw materials in parts by mass: 92 parts of matting masterbatch, 6 parts of rosin resin, 2 parts of anti-tacking agent, The matting masterbatch is made of the following raw materials in parts by mass: 92 parts of polypropylene, 8 parts of silane-modified silica matting powder, and 0.4 parts of antioxidant.

[0028] The preparation method of matting masterbatch is as follows: after mixing polypropylene, silane-modified silica matting powder and antioxidant, melt extrusion at 180-220°C; the preparation of silane-modified silica matting powder The method is: add trifluoropropyltrimethoxysilane, vinyltrimethoxysilane and silica matting powder into toluene, disperse evenly, then react at 90°C for 5h, filter and dry to obtain silica The mass ratio of matting powder, trifluoropropyltrimethoxysilane and vinyltrim...

Embodiment 2

[0034] A matting coating base film, consisting of an upper surface layer, a core layer and a lower surface layer in turn; the upper surface layer is composed of the following raw materials in parts by mass: 90 parts of matting masterbatch, 7 parts of rosin resin, 3 parts of anti-tacking agent, The matting masterbatch is made of the following raw materials in parts by mass: 90 parts of polypropylene, 10 parts of silane-modified silica matting powder, and 0.1 part of antioxidant.

[0035]The preparation method of matting masterbatch is as follows: after mixing polypropylene, silane-modified silica matting powder and antioxidant, melt extrusion at 180-220°C; the preparation of silane-modified silica matting powder The method is: add trifluoropropyltrimethoxysilane, vinyltrimethoxysilane and silica matting powder into toluene, disperse evenly, then react at 80°C for 6h, filter, and dry to obtain silica The mass ratio of matting powder, trifluoropropyltrimethoxysilane and vinyltrim...

Embodiment 3

[0041] A matting coating base film, consisting of an upper surface layer, a core layer and a lower surface layer in turn; the upper surface layer is composed of the following raw materials in parts by mass: 95 parts of matting masterbatch, 4 parts of rosin resin, 1 part of anti-adhesive agent, The matting masterbatch is made of the following raw materials in parts by mass: 95 parts of polypropylene, 5 parts of silane-modified silica matting powder, and 0.5 parts of antioxidant.

[0042] The preparation method of matting masterbatch is as follows: after mixing polypropylene, silane-modified silica matting powder and antioxidant, melt extrusion at 180-220°C; the preparation of silane-modified silica matting powder The method is: add trifluoropropyltrimethoxysilane, vinyltrimethoxysilane and silica matting powder into toluene, disperse evenly, then react at 100°C for 2 hours, filter, and dry to obtain silica The mass ratio of matting powder, trifluoropropyltrimethoxysilane and vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com