Patents

Literature

187results about How to "Stable hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium-free zinc aluminum anticorrosive paint and preparation method

InactiveCN101899254AReduce microcracksImprove adhesionAnti-corrosive paintsEpoxy resin coatingsChromium freeOrganic solvent

The invention relates to a chromium-free zinc aluminum anticorrosive paint and a preparation method. The invention adopts the technical scheme that the preparation method comprises the following steps of: stirring 5 to 25 weight percent of flake zinc powder and 5 to 15 weight percent of flake aluminum powder uniformly, adding 25 to 40 weight percent of organic solvent, 1.1 to 1.8 weight percent of dispersant, 3 to 8 weight percent of corrosion inhibitor and 3 to 10 weight percent of inorganic additive into the powder, and stirring the mixture for 20 to 40 minutes to form a base material; and then stirring 5 to 15 weight percent of modified resin, 1 to 3 weight percent of organic silane coupling agent and 25 to 30 weight percent of organic solvent uniformly, and adding the mixture into the base material; or stirring the mixture for 30 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint; or stirring the mixture for 30 to 50 minutes, adding 0.05 to 0.5 weight percent of hydroxyethyl cellulose into the mixture, and stirring the mixture for 20 to 50 minutes to obtain the chromium-free zinc aluminum anticorrosive paint. The preparation method has the characteristics of environment friendliness, low energy consumption and low cost; and a coating coated by the prepared chromium-free zinc aluminum anticorrosive paint has high impact strength, good corrosion resistance, strong bonding force and high hardness.

Owner:襄阳普士利工程器材有限公司 +1

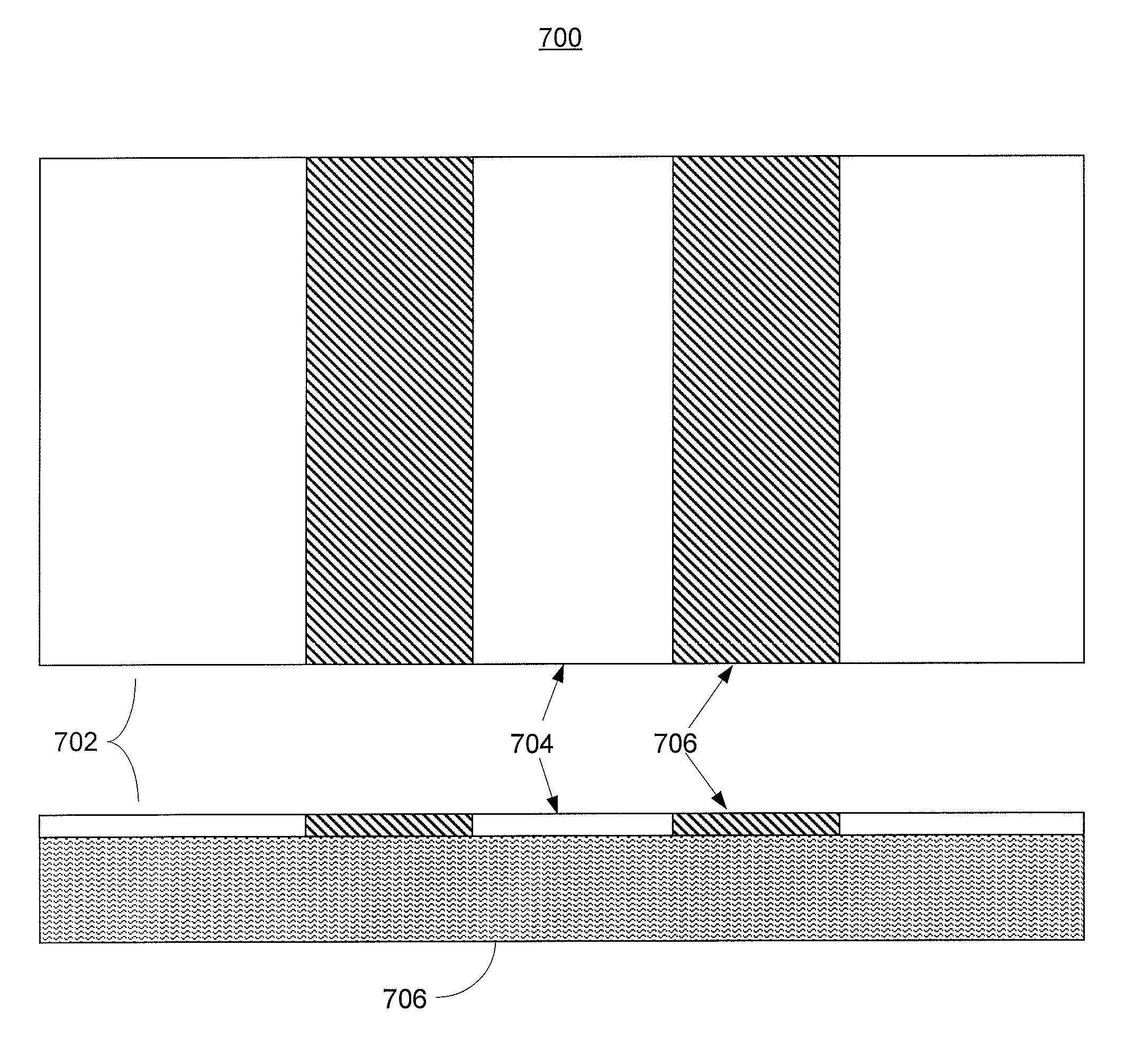

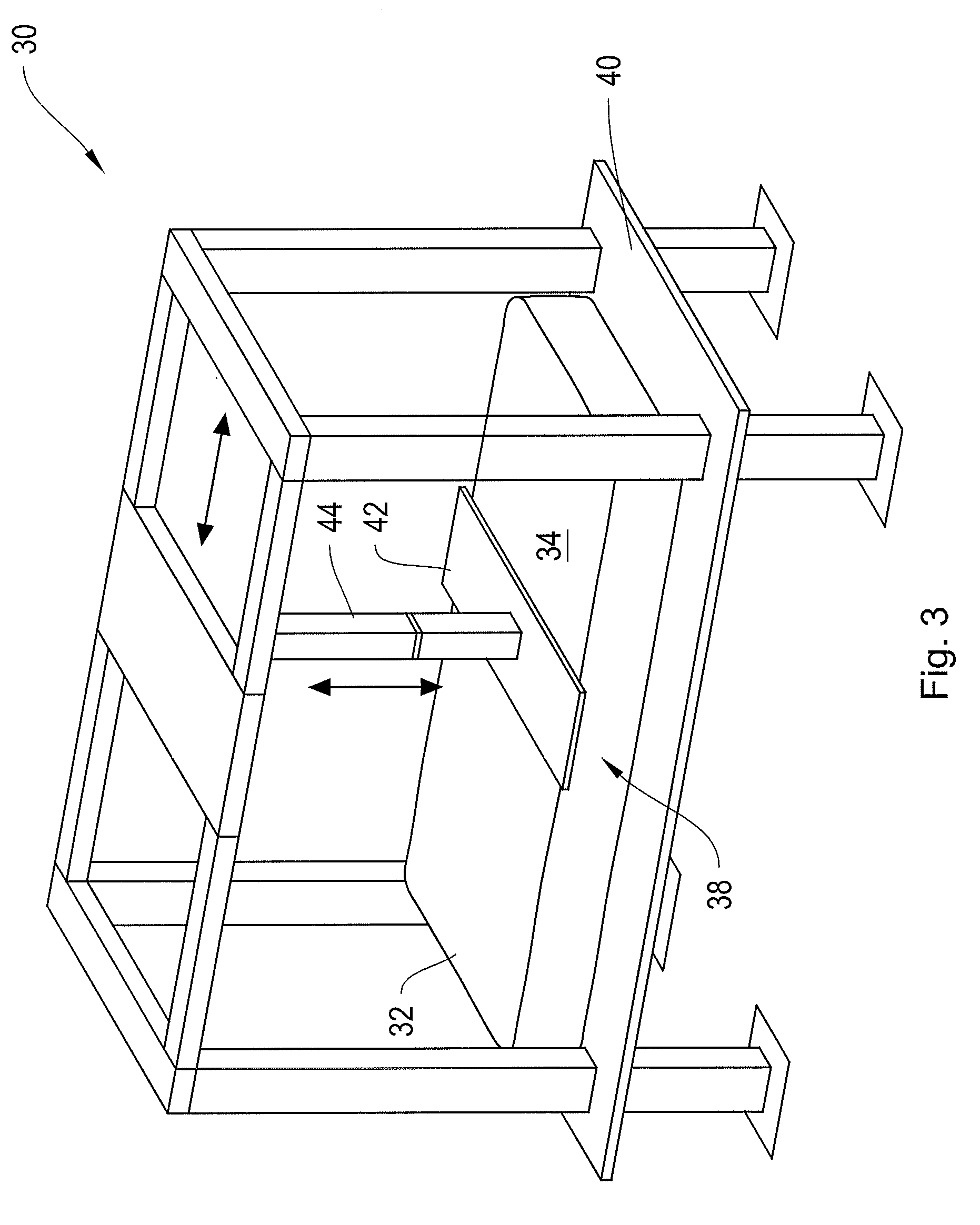

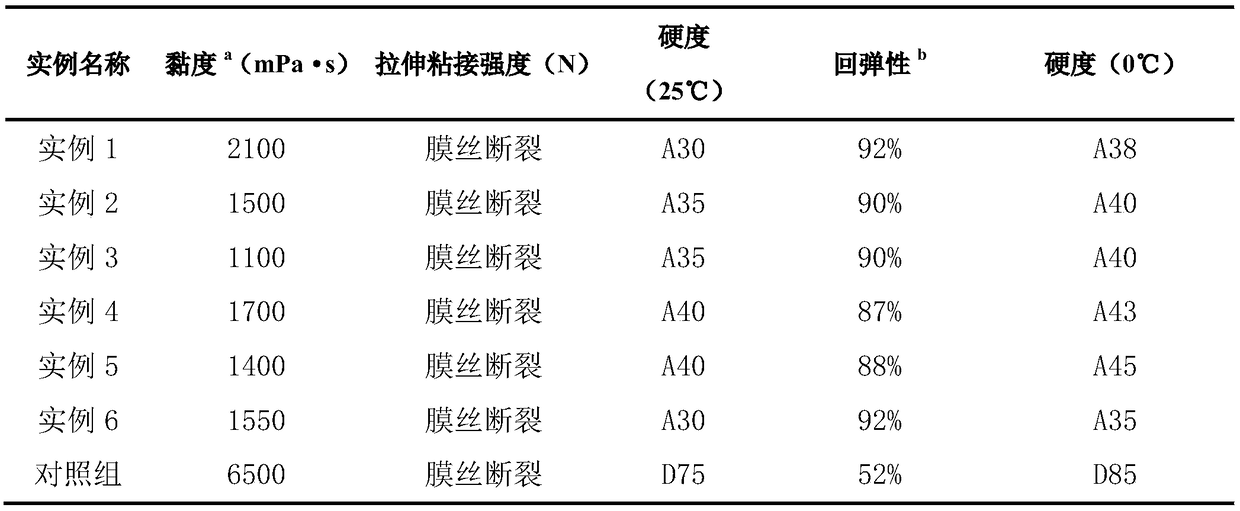

Method of manufacturing an aged mattress assembly

ActiveUS7690096B1Improve firmnessHigh hardnessUpholstery manufactureStuffed mattressesPre-conditionPre conditioning

Owner:DREAMWELL +1

Pre-conditioned foam pad

ActiveUS20100072676A1Improve firmnessHigh hardnessUpholstery manufactureStuffed mattressesPre-conditionPre conditioning

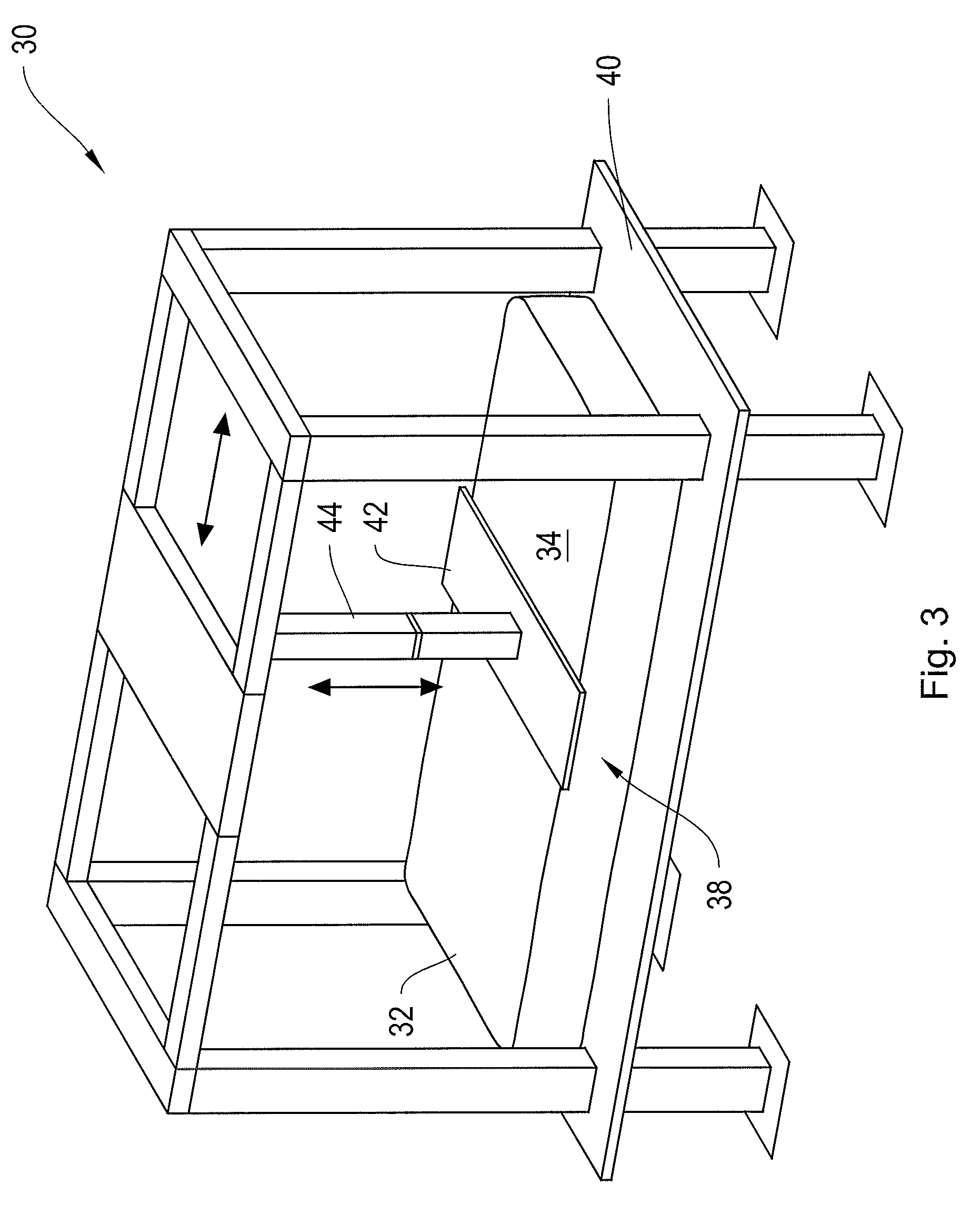

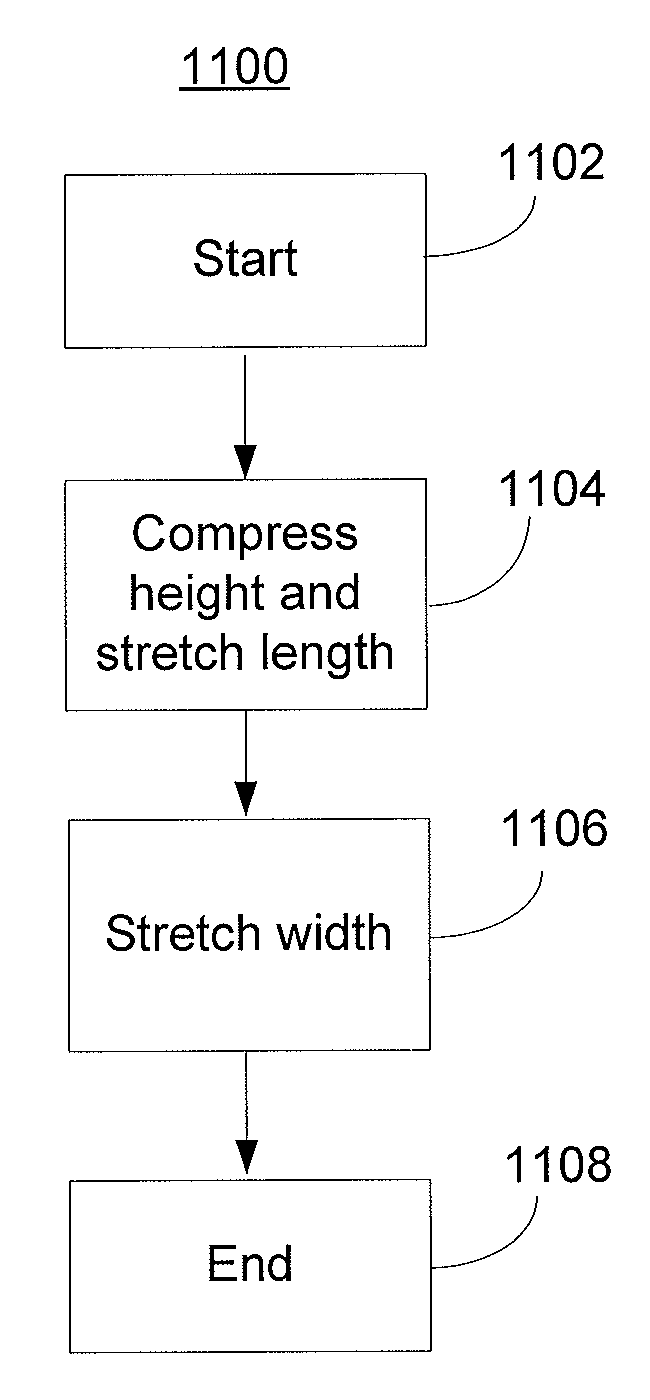

Mattresses and methods for processing a flexible foam material for use in a mattress to provide a mattress foam material that has more consistent firmness over time and area. The methods include pre-conditioning the foam pad or mattress by applying a force across a substantial portion of a major surface of the mattress to compress or stretch the height of the foam, the length of the foam, and / or the width of the foam to break or open closed cells. In certain embodiments, the force is applied by repeatedly pressing a platen against the foam pad or placing the foam pad between one or more rollers.

Owner:DREAMWELL +1

Water swelling polyurethane elastomer sealing product material and preparation method

ActiveCN101565602AStable physical and chemical propertiesStable physical and chemical properties (hardnessOther chemical processesPolyurethane elastomerPolyol

The invention relates to a water swelling polyurethane elastomer sealing product material and a preparation method. The material is prepared from the following three components (A), (B) and (C) through polymerization reaction of two steps, the elastomer material has water swelling property, and a main chain structure of material molecules absorbs water, wherein the (A) is hydrophilic polyether type polymer1polyol; the (B) is polyisocyanates; and the (C) is low-molecular polyol and amino chain-extended crosslinker. The molar ratio of the (B) to the (A) in an isocyanate end capping reaction is 1.3 to 2.8; and the molar ratio of a product of the isocyanate end capping reaction of the (A) and the (B) to the (C) in a chain-extended crosslinking reaction is 0.75 to 1.05. In the preparation method for the material, the reaction of the two steps is a reaction process of liquid polymerization, and the production of a product is an elastomer casting-molding process. The material has the characteristics of small mass variation rate and stable physical performance after the material absorbs the water repeatedly to swell, and permanent compression deformation and small stress relaxation.

Owner:NORTHWEST RUBBER & PLASTIC RES & DESIGN INST CO LTD

Super-hard middle-chrome cast grinding ball and production process thereof

InactiveCN103060667ARefined grain sizeReduce in quantityFurnace typesQuenching agentsRare earthManganese

The invention discloses a super-hard middle-chrome cast grinding ball which consists of the following chemical ingredients: 1.8-3.0% of carbon, 0.3-1.5% of silicon, 0.2-1.5% of manganese, 7.0-10.0% of chrome, 0.02-0.1% of phosphorus, 0.02-0.1% of sulfur, 0.02-0.1% of copper, 0.02-0.1% of molybdenum, 0.02-0.1% of nickel, 0.02-0.1% of tungsten, 0.1-0.2% of rare earth yttrium and 80.1-87.2% of iron. The rare earth yttrium is adopted for evolution inoculation treatment, so that a carbide is changed in shape and distribution, furthermore a net is broken, and meanwhile crystal grains are refined, the texture is compact and the flexibility is improved. By adopting an oil medium annealing and tempering thermal treatment process, eutectic carbide with martensite with the broken net is obtained, the hardness of the middle-chrome grinding ball is HRC60-69, and the toughness and the abrasion resistance of a high-chrome grinding ball are remarkably improved. On premise that the abrasion resistance and the crushing resistance of the grinding ball are further improved, the content of the noble metal chrome is reduced, and relatively the manufacturing cost of the grinding ball is lowered, and significant social benefits are achieved.

Owner:NINGGUO ZHONGYI WEAR RESISTANT MATERIALS

Enhanced polyurethane wood-imitation material and manufacturing method thereof

The invention relates to a manufacturing method of an enhanced polyurethane wood-imitation material. The material comprises components of nano cellulose, polyisocyanate, polyether polyol and additives. The components are mixed according to a certain proportion and synthesized into the enhanced polyurethane wood-imitation material through a one-step forming method. The invention adopts the nano cellulose prepared from wood machining residues to mix with polyisocyanate, polyether polyol and additives, and the mixture is synthesized into the enhanced polyurethane wood-imitation material through a one-step forming method; so the polyurethane wood-imitation material has high strength, good heat resistance, good molding ability and high strength-to-weight ratio, and is a novel engineering material. Compared with an existing polyurethane wood-imitation material, the polyurethane wood-imitation material of the invention has advantages of greatly enhanced mechanical properties and heat resistance, good size stability, high hardness, good aging resistance, effectively expanded application range, simple manufacturing process, easiness for application and low comprehensive cost.

Owner:GUANGDONG YIHUA TIMBER IND +1

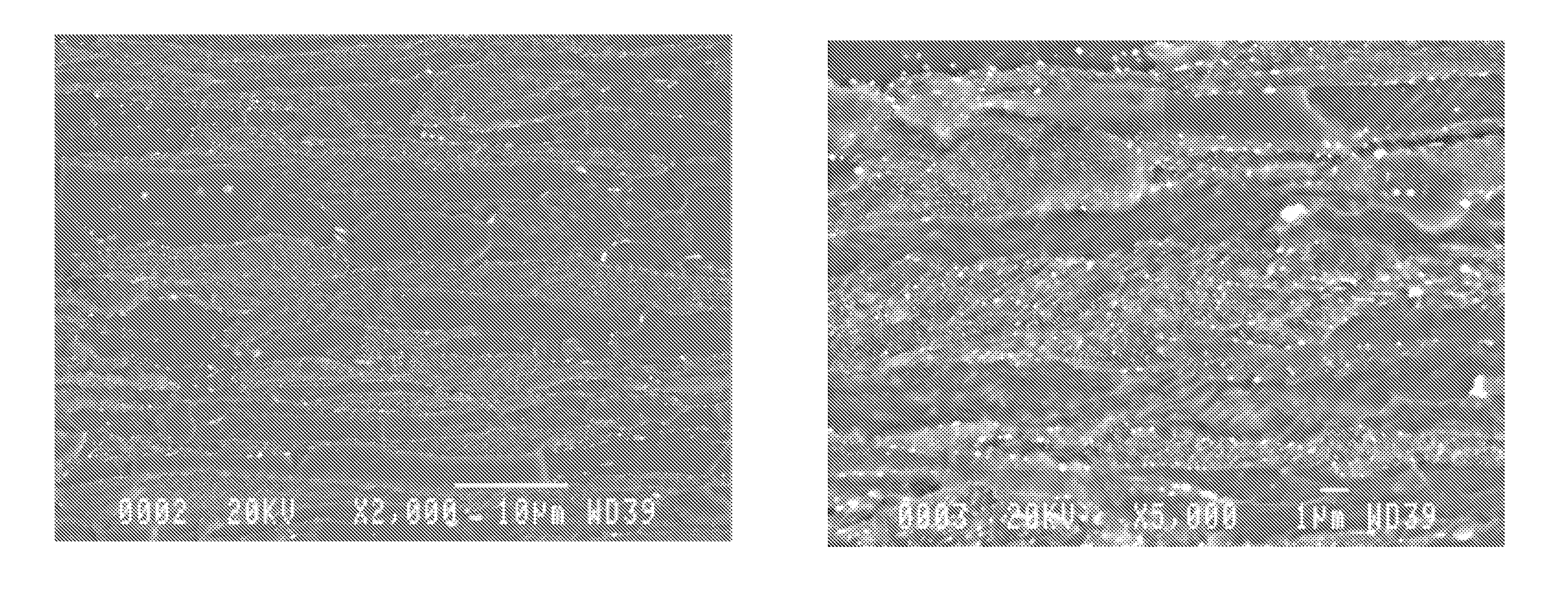

Low-hardness and high-elasticity water treatment membrane component epoxy pouring sealant preparation method and application

The invention discloses a low-hardness and high-elasticity water treatment membrane component epoxy pouring sealant preparation method and application. An epoxy pouring sealant comprises a component Aand a component B, the component A comprises, by weight, 30-70 parts of epoxy resin, 5-20 parts of activated thinners, 10-20 parts of toughening agents, 5-30 parts of fillers and 0.1-3 parts of coupling agents, the component B comprises, by weight, 20-50 parts of polyether amine, 40-70 parts of alicyclic amine and 2-15 parts of curing accelerators, and the weight ration of the component A to thecomponent B is (100:10)-(100:50). By the aid of a 'trinity' toughening modified mode of the flexible toughening agents, the activated toughening thinners and flexible curing agents, the epoxy pouringsealant is characterized of low hardness, high elasticity and stable hardness within wide temperature range, the epoxy pouring sealant has excellent adhesive performance and is low in initial viscosity, high in mold filling speed, simple and convenient to operate and applicable to the fields such as package of water treatment membrane components and flexible package of electronic devices, and theblocking efficiency of the membrane components can be greatly improved.

Owner:浙江航通舟新材料科技股份有限公司

Method for manufacturing hot stamped body having vertical wall and hot stamped body having vertical wall

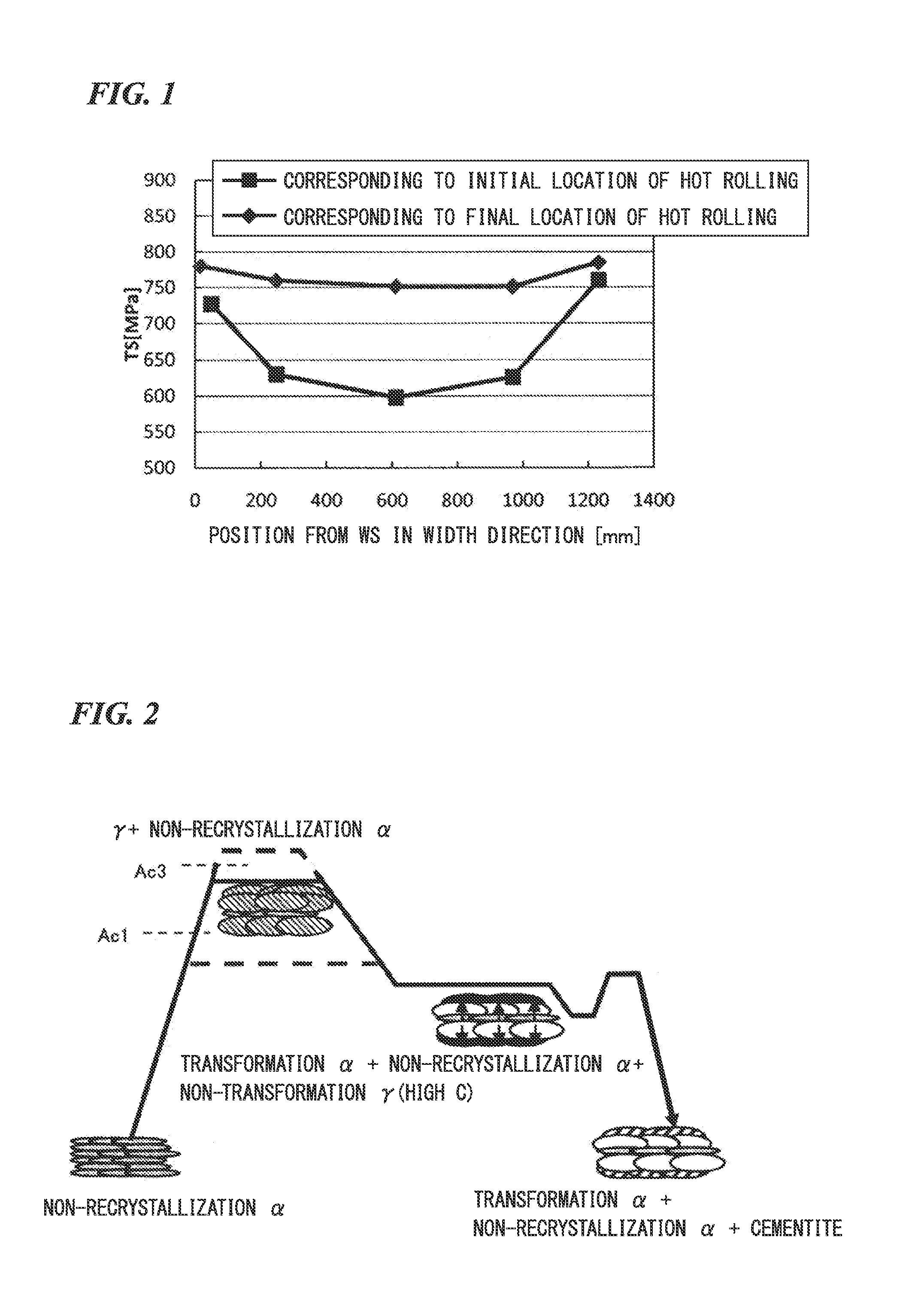

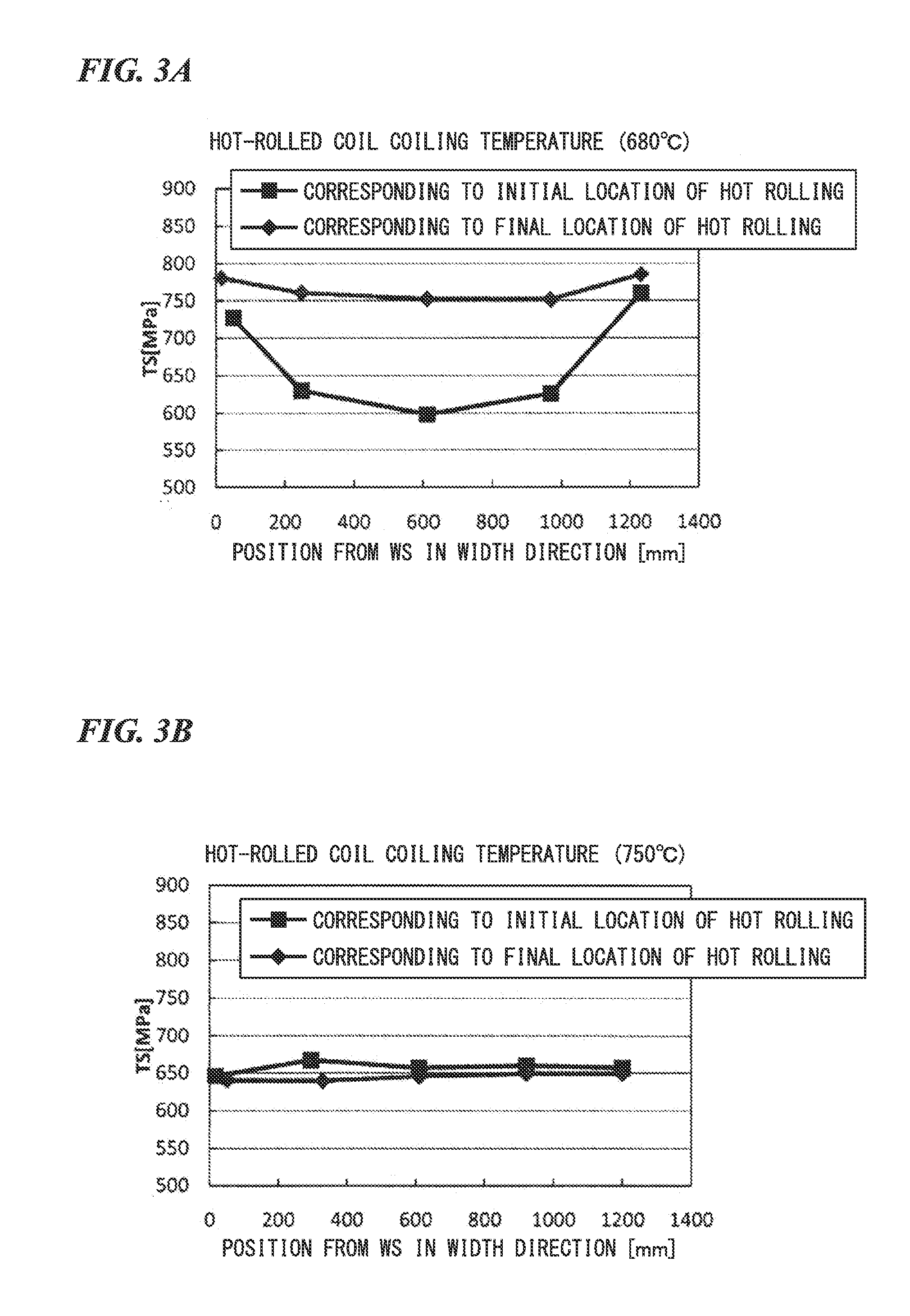

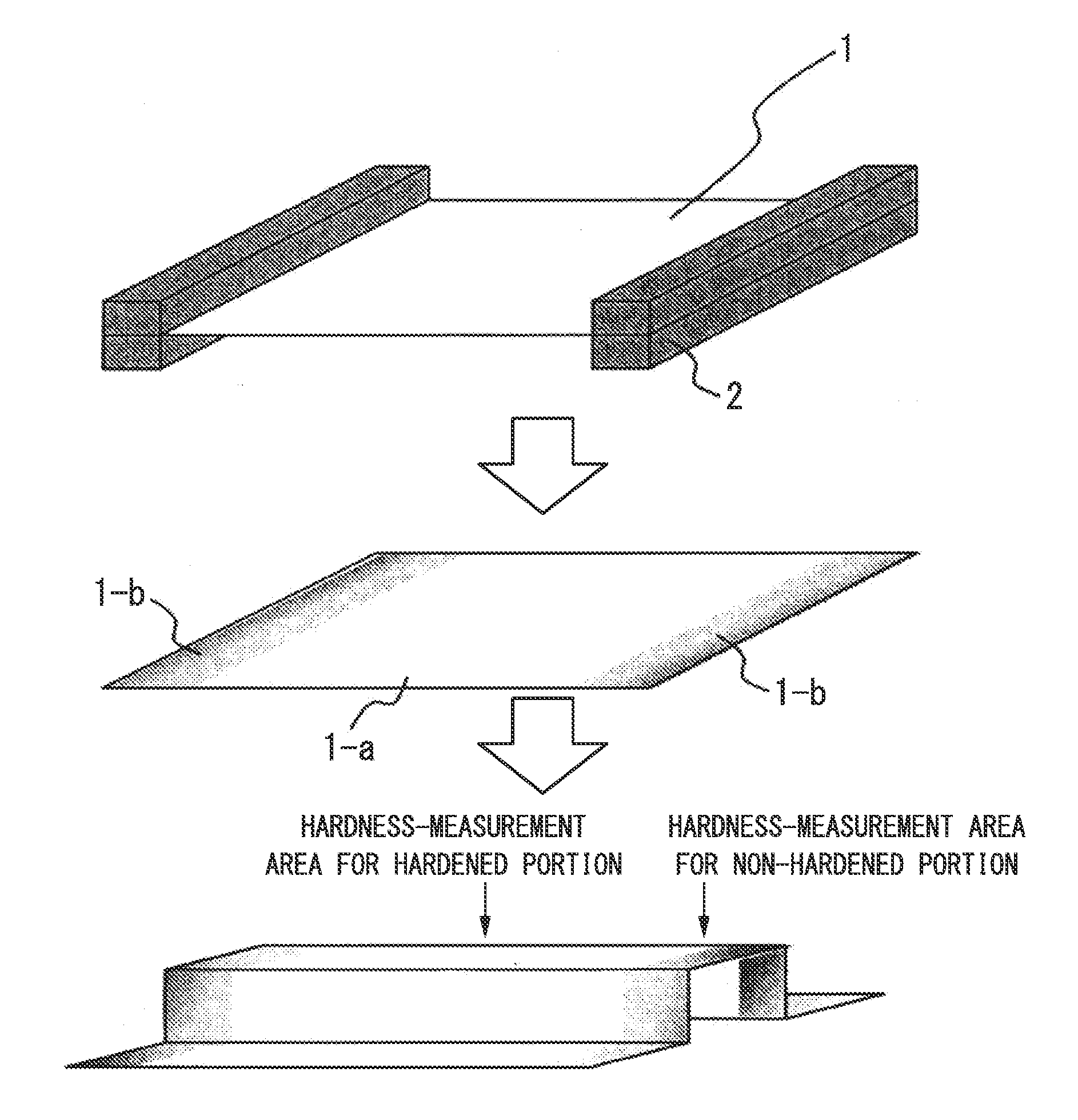

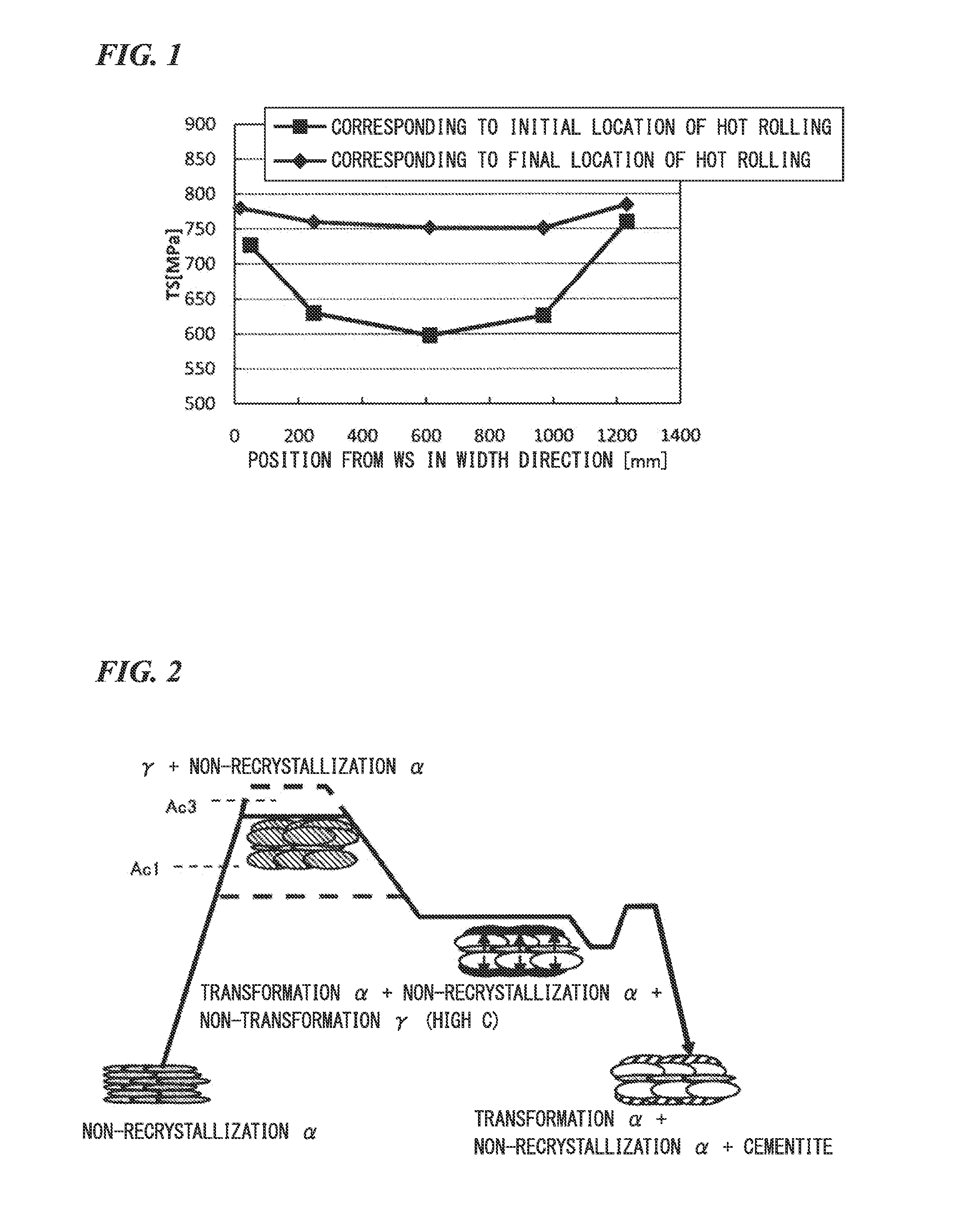

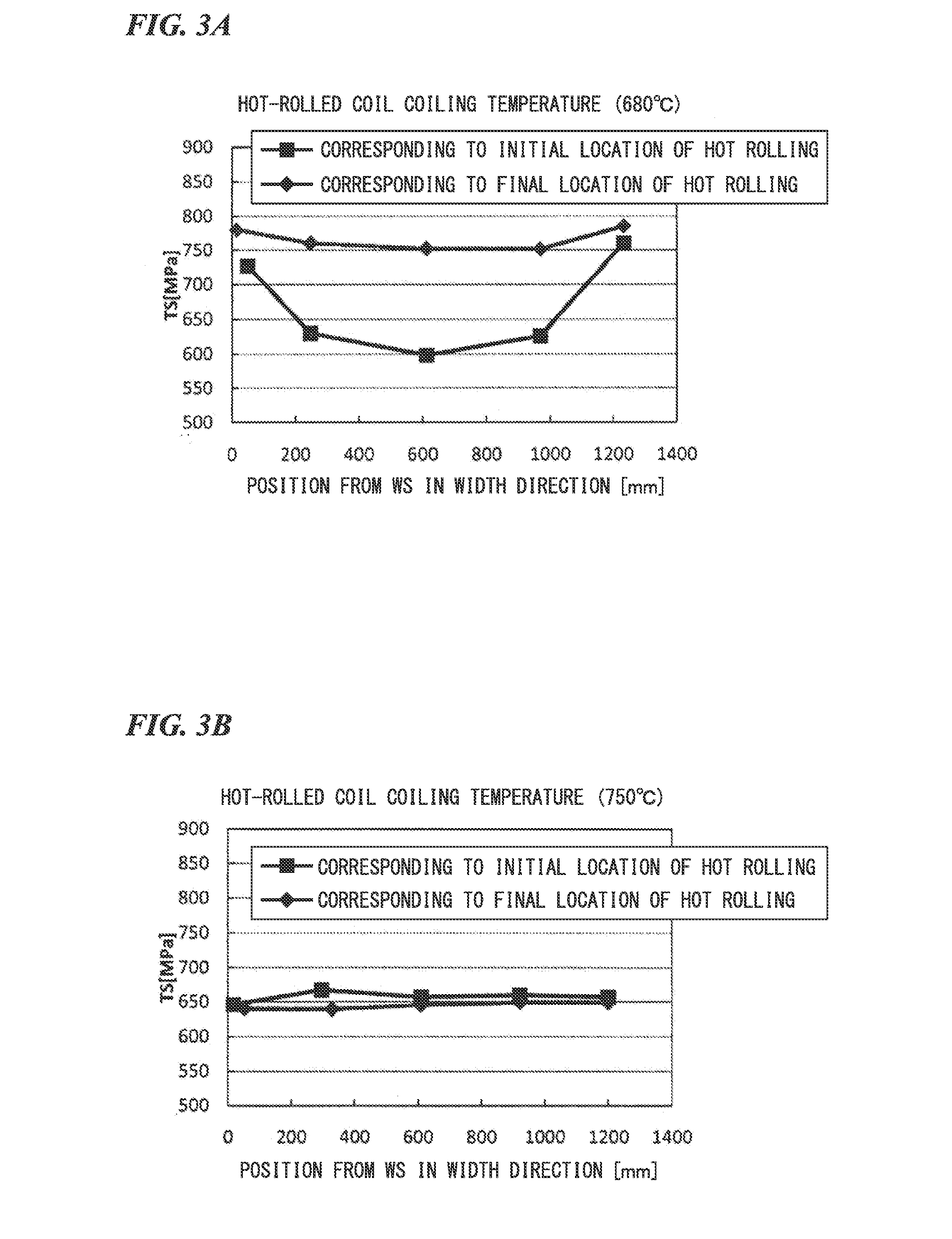

ActiveUS20130199676A1Stable hardnessGenerating scaleSurface reaction electrolytic coatingVacuum evaporation coatingHot stampingContinuous annealing

The present invention provides a method for manufacturing a hot stamped body having a vertical wall, the method including: a hot-rolling step; a coiling step; a cold-rolling step; a continuous annealing step; and a hot stamping step, in which the continuous annealing step includes a heating step of heating the cold-rolled steel sheet to a temperature range of equal to or higher than Ac1° C. and lower than Ac3° C.; a cooling step of cooling the heated cold-rolled steel sheet from the highest heating temperature to 660° C. at a cooling rate of equal to or less than 10° C. / s; and a holding step of holding the cooled cold-rolled steel sheet in a temperature range of 550° C. to 660° C. for one minute to 10 minutes.

Owner:NIPPON STEEL CORP

Method for manufacturing hot stamped body and hot stamped body

ActiveUS20130292009A1Stable hardnessGenerating scaleHot-dipping/immersion processesVacuum evaporation coatingHot stampingContinuous annealing

The present invention provides a method for manufacturing a hot stamped body, the method including: a hot-rolling step; a coiling step; a cold-rolling step; a continuous annealing step; and a hot stamping step, in which the continuous annealing step includes a heating step of heating the cold-rolled steel sheet to a temperature range of equal to or higher than Ac1° C. and lower than Ac3° C.; a cooling step of cooling the heated cold-rolled steel sheet from the highest heating temperature to 660° C. at a cooling rate of equal to or less than 10° C. / s; and a holding step of holding the cooled cold-rolled steel sheet in a temperature range of 550° C. to 660° C. for one minute to 10 minutes.

Owner:TOYOTA JIDOSHA KK +2

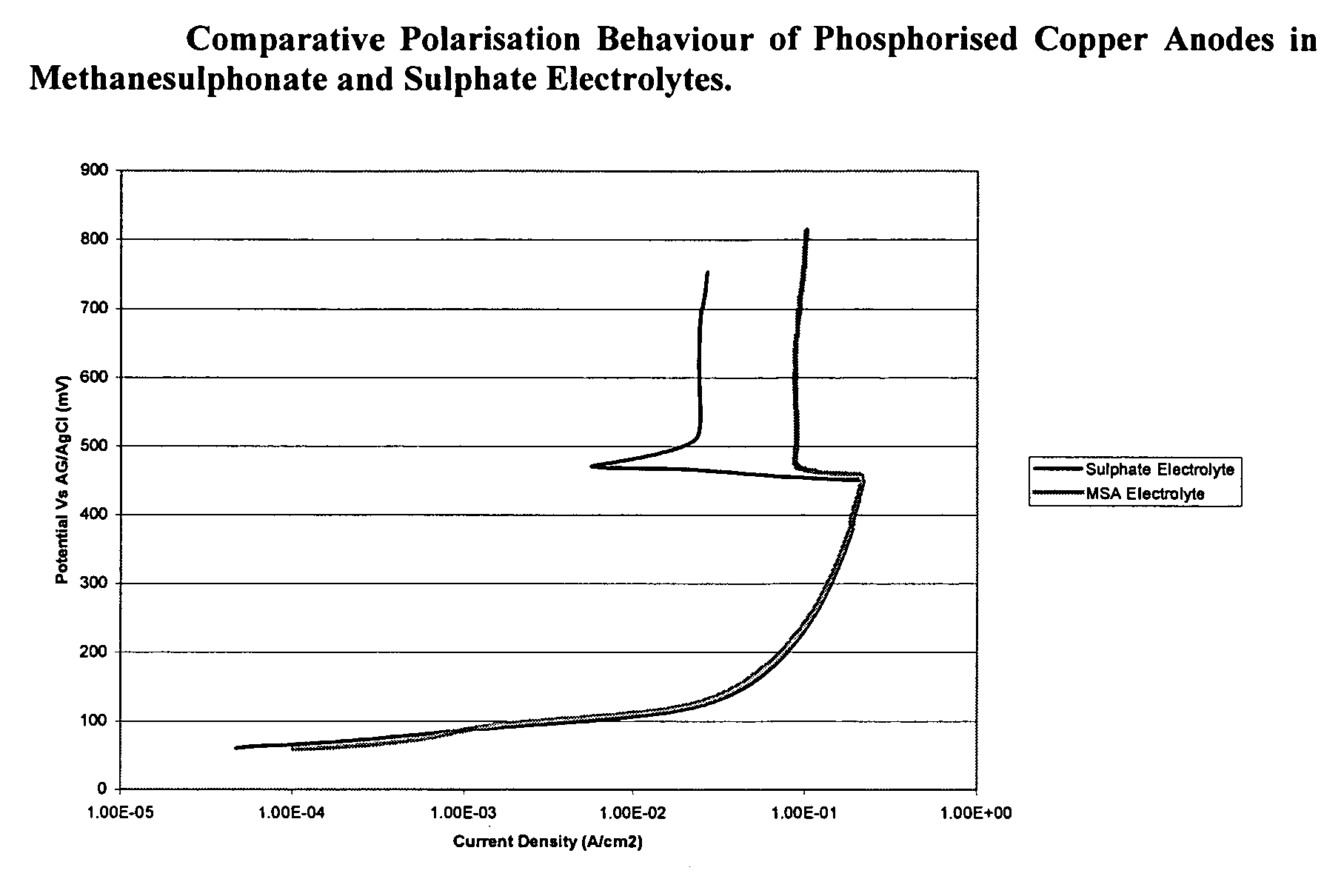

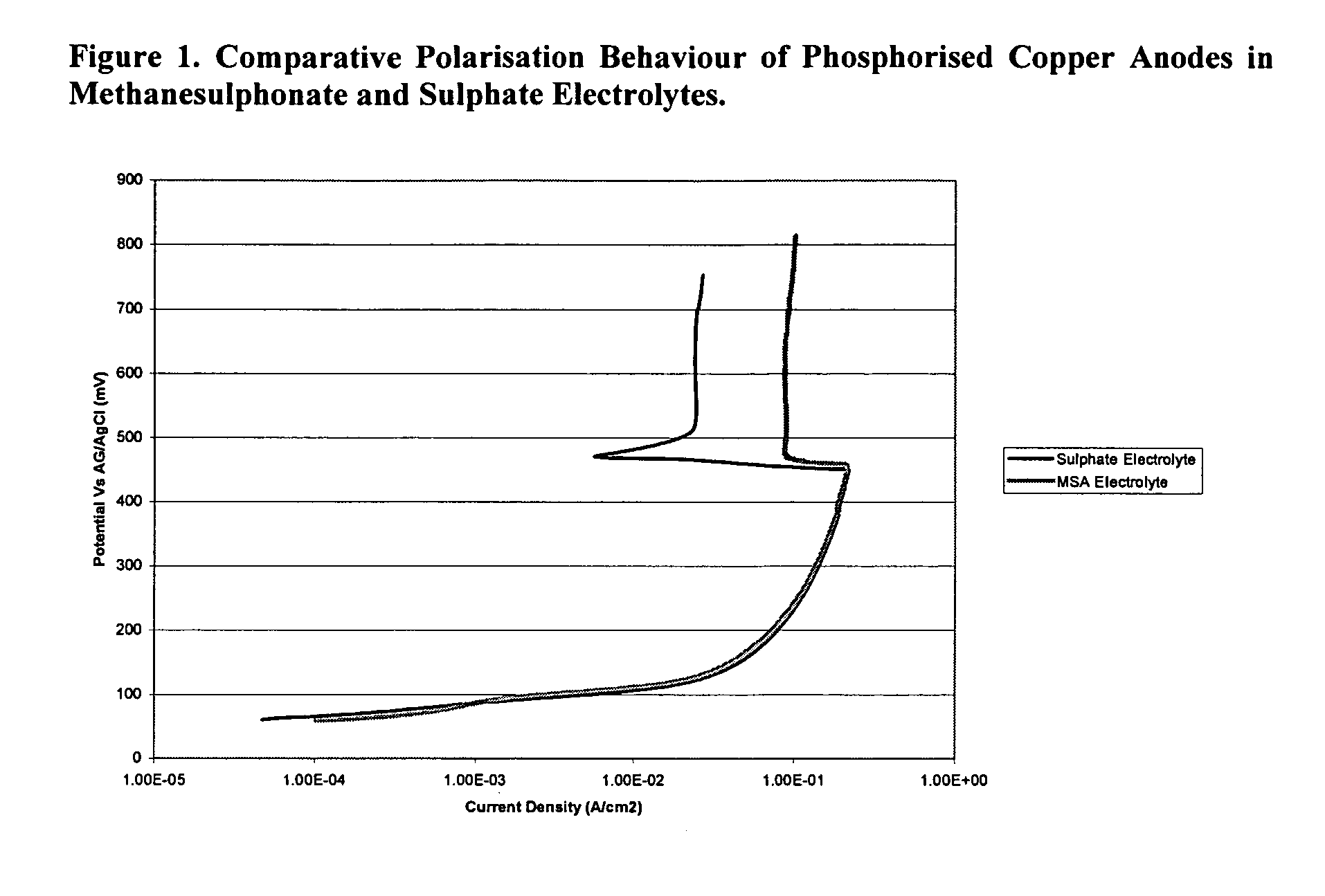

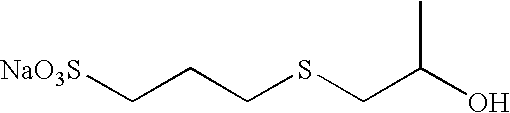

Copper electroplating of printing cylinders

The present invention is directed to an improved copper plating bath for depositing a copper layer onto a printing cylinder, the copper plating bath comprising: (a) a source of copper ions; (b) a source of methane sulphonate ions; (c) a source of chloride ions; (d) an organosulphur compound having the formula R—S—R′—SO3−X+ or X+—O3S—R′—S—R—S—R′—SO3—X+, wherein R is alkyl, hydroxyalkyl or alkyl ether, R′ is a C2–C4 alkyl group, and X+ is a cation; and (e) a polyether compound and method of using the same. The copper plating bath produces a plating deposit that has a stable hardness and is free from self-annealing during high speed plating.

Owner:MACDERMID ACUMEN INC

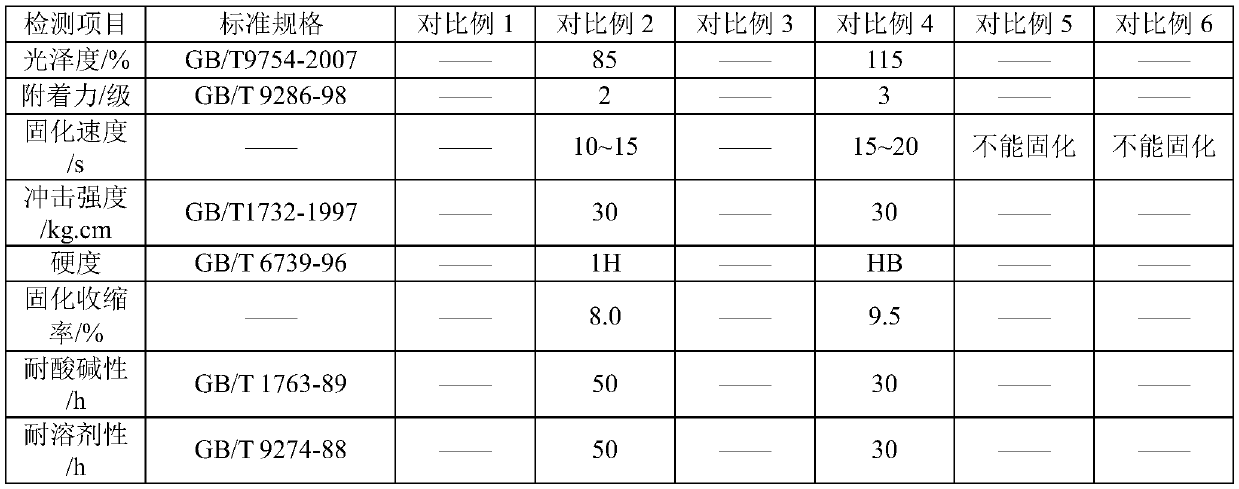

Unsaturated polyester gel coat resin capable of being subjected to UV-LED photocuring and paint preparation method thereof

ActiveCN105504245AImprove performanceImprove corrosion resistancePolyester coatingsPolyesterShrinkage rate

The invention discloses unsaturated polyester gel coat resin capable of being subjected to UV-LED photocuring and a paint preparation method thereof. The unsaturated polyester paint is prepared from 90-100 parts of unsaturated polyester gel coat resin, 10-30 parts of activated thinner, 1-5 parts of photoinitiator, 1-3 parts of coinitiator, 0-20 parts of talcum powder, 0-0.5 part of dispersing auxiliary and 0.5-3 parts of other auxiliaries. The weight ratio of photoinitiator to coinitiator is (1-5):(1-3), and unsaturated polyester gel coat resin is a mixture of acrylate-terminated unsaturated polyester and activated thinner. A coating can be prepared from the paint through the UV-LED photocuring technology, deep solidification of a film 200 micrometers thick on a woodware base material can be achieved, and the coating is low in shrinkage rate, good in acid resistance and alkaline resistance, high in luster and good in adhesive force.

Owner:GUANGDONG UNIV OF TECH +1

High temperature resistant release coating material for artificial synthetic leather release paper, and preparation method and application thereof

ActiveCN103740262AClear textureRealistic texturePolyurea/polyurethane coatingsTextiles and paperTripropylene glycolMethacrylate

The invention relates to a high temperature resistant release coating material for artificial synthetic leather release paper, and a preparation method and an application thereof. The release coating material is composed of modified urethane acrylate, modified epoxy acrylate, tripropylene glycol diacrylate, trimethylolpropane triacrylate ethoxylate, perfluoromethacrylate and gamma-methylacryloxypropyltrimethylsilane. A method for preparing the high temperature resistant release coating material for the artificial synthetic leather release paper comprises the steps of orderly putting all the components in a container, mixing and stirring so that the solid components are dissolved, and thus obtaining an even and approximately transparent coating. The release paper is clear and vivid in lines; due to the optimization of the formula, the release paper can be caused to be moderate in hardness, good and stable in release property, numerous in repeated use times, and excellent in solvent resistance and high-temperature resistance.

Owner:ZHEJIANG KAREN SPECIALTY MATERIALS

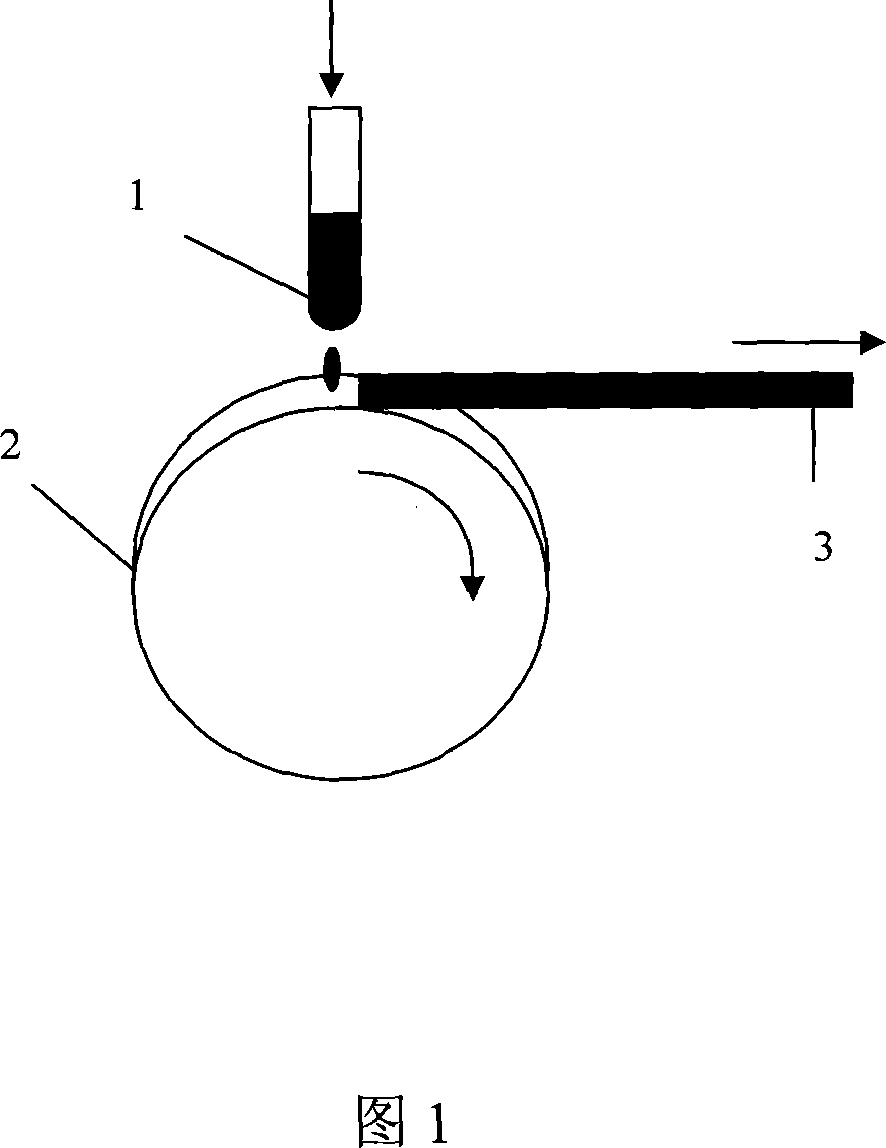

High temperature resistant silver oxide contact tip material manufacturing method

This invention relates to a manufacturing method for high temperature silver oxide contactor material including: 1, melting any 1-7 kinds of Sn, Cd, Bi, Cu, In and Fe in certain weight ratio with Ag for rest to alloy them completely to get an Ag strip with a single roller rejection rapid quenching machine, in which, the rotation speed of a cold quenching roller is 3-30m / s, 2, oxidating the Ag alloy strip for 12-24h under 0.1-10MPa and 500-750deg.C, 3, processing it to a contactor material by an ordinary method, in which, size of the metal oxide is small, hardness (HV0.3) can reach to 130 and will not be reduced along the rising of temperature and the contactor can work stably under 85deg.C.

Owner:桂林金格电工电子材料科技有限公司

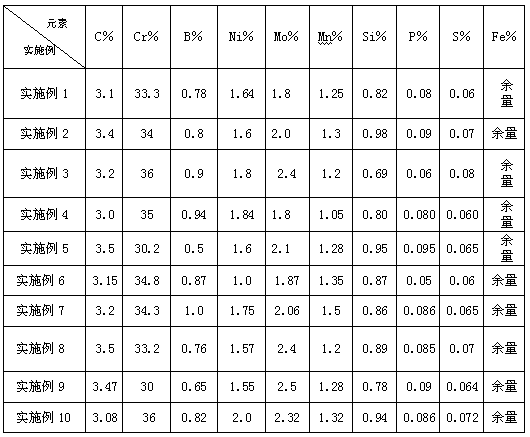

High-temperature resistant and abrasion-resistant white cast iron piece and production method

The invention discloses a high-temperature resistant and abrasion-resistant white cast iron piece and a production method to solve the problem in hardness of white cast iron. The high-temperature resistant abrasion-resistant white cast iron piece is characterized in that the white iron casting comprises the following chemical compositions by mass percent: 3.0 to 3.5 percent of C, 30 to 36 percent of Cr, 1.8 to 2.5 percent of Mo, smaller than or equal to 1 percent of Si, 1.0 to 2.0 percent of Ni, 1.05 to 1.5 percent of Mn, 0.5 to 1.0 percent of B, smaller than or equal to 0.10 percent of P, smaller than or equal to 0.08 percent of S, and Fe in balancing amount; and the chromium carbon ratio of the white cast iron is 8.5 to 12. The method comprises the steps of smelting, casting, thermal insulation and cooling. The white cast iron piece has the advantages that casting-state thermal insulation slow cooling hardness HRC is larger than or equal to 61, the hardness HRC after quench tempering is larger than or equal to 66, the hardness HRC can still keep larger than or equal to 61 at 700 DEG C, the corrosion resistance of the white cast iron piece is superior to that of the existing white cast iron piece, and the white cast iron piece is particularly suitable to serve as a wear-resistant part operating under high-temperature condition.

Owner:BAODING FENGFAN PRECISION CASTING

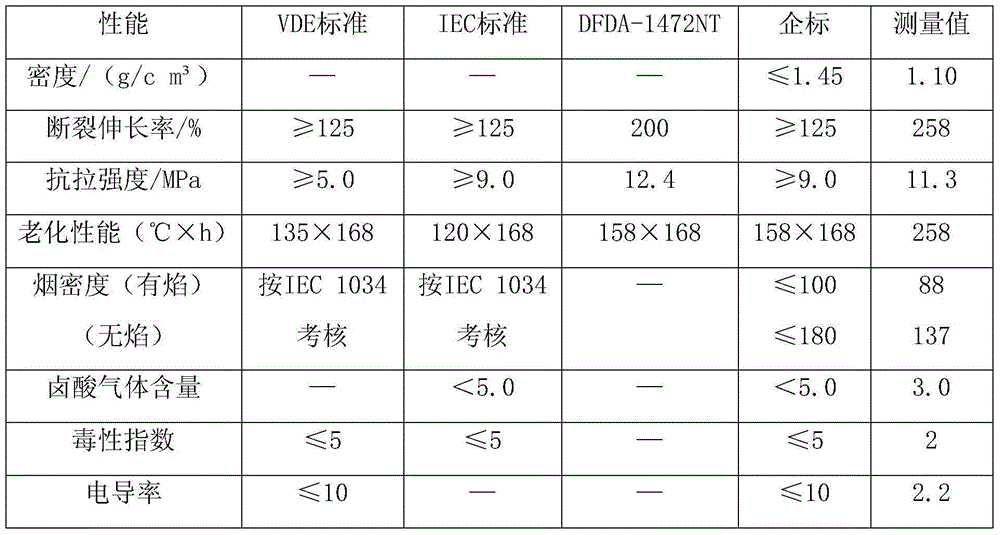

125 DEG C irradiation cross-linking low-smoke halogen-free flame-retardant polyolefin cable material

InactiveCN105086128AHigh affinityHigh tensile strengthPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolymer science

The invention discloses a 125 DEG C irradiation cross-linking low-smoke halogen-free flame-retardant polyolefin cable material, and belongs to the field of cable material formulas. The 125 DEG C irradiation cross-linking low-smoke halogen-free flame-retardant polyolefin cable material comprises 60-90 parts of EVA, 40-60 parts of HDPE, 45-60 parts of aluminum hydroxide, 45-60 parts of magnesium hydroxide, 5-10 parts of calcium-zinc compound stabilizer, 10-15 parts of softening and strengthening agents, 5-10 parts of flame retardant agents, 10-18 parts of compatibilizer, 1-1.5 parts of antioxygen OSP-1, 0.5-1 part of lubricant and 4-6 parts of cross-linking agents. The environmentally friendly cable material has the advantages of being low in smoke, free of halogen and toxin, flame retardant and resistant to high temperature, and meanwhile the mechanical property, the processing property, the flame retardant property and the high temperature resistance of the cable material all reach a higher level.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

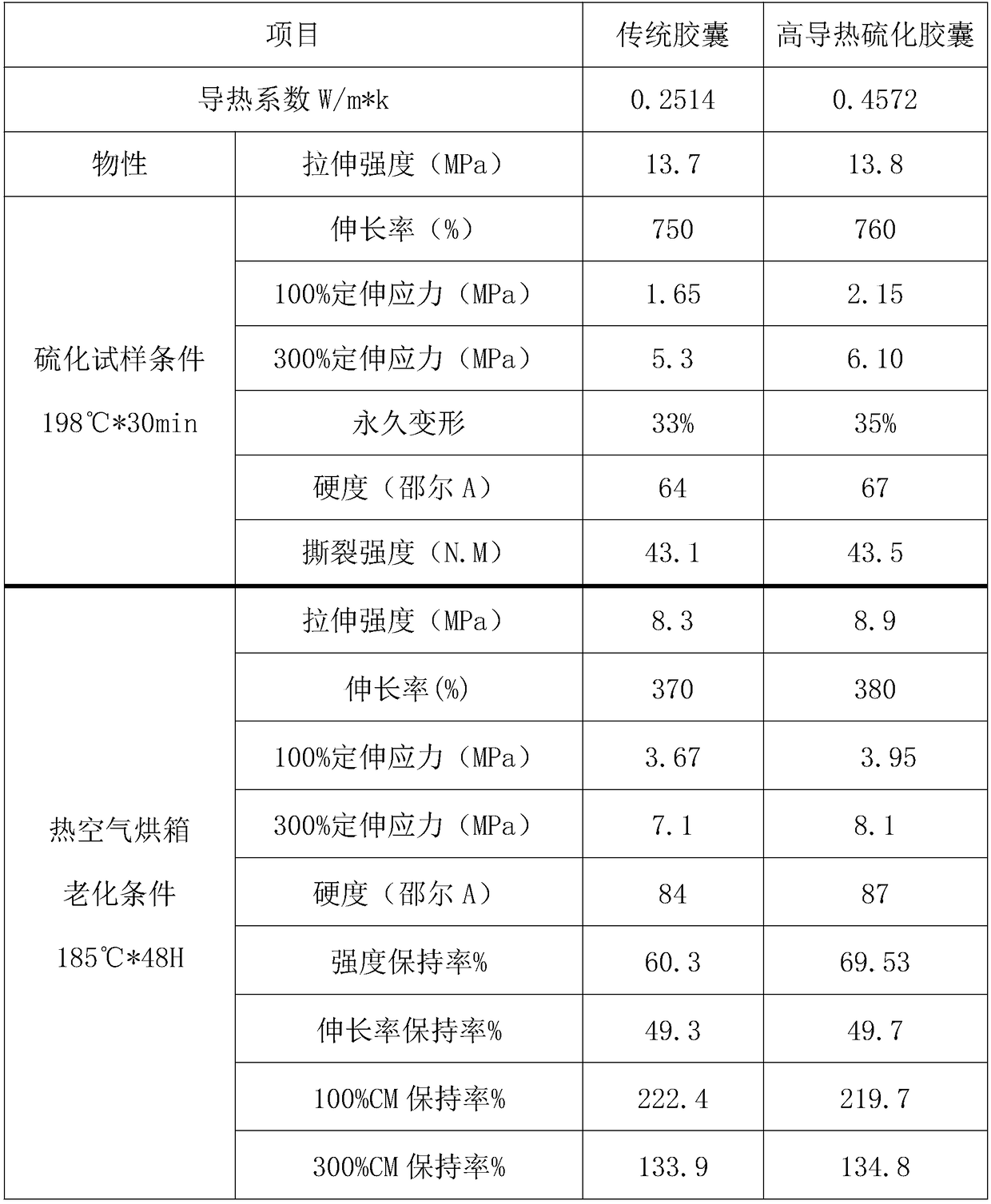

Preparation method of high-heat-conductivity type tire vulcanization capsule

The invention discloses a preparation method of a high-heat-conductivity type tire vulcanization capsule. The preparation method of the high-heat-conductivity type tire vulcanization capsule belongs to the technical field of tires, and comprises the following steps of (1) compounding the components according to the matching ratio: 95 parts of butyl rubber, 4 to 5 parts of chloroprene rubber, 15 to20 parts of N375 carbon black, 35 to 45 parts of acetylene black, 7 to 15 parts of graphene, 7 to 10 parts of alkane oil, 0.5 to 1.5 parts of stearic acid, 5 to 7 parts of zinc oxide, and 8 to 10 parts of resin; (2) primarily mixing; (3) filtering rubber; (4) secondarily mixing; (5) forming; (6) vulcanizing; (7) polishing; and (8) inspecting a finished product. According to the preparation methodof the high-heat-conductivity type tire vulcanization capsule provided by the invention, on the basis of ensuring the stability of various physical and mechanical properties, a heat conductivity coefficient is further improved, so that the aims of saving energy and reducing cost are achieved.

Owner:YONGYI RUBBER CO LTD

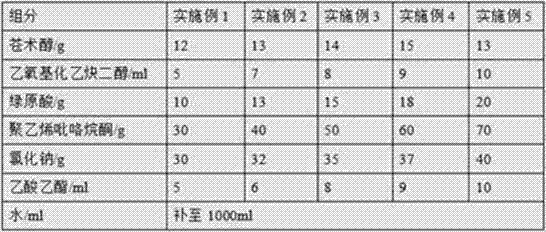

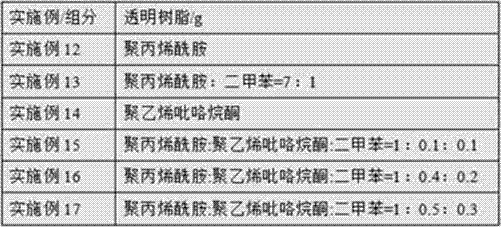

Pathological specimen processing method

InactiveCN106908294ABroad antimicrobial effectAntioxidantPreparing sample for investigationChlorogenic acidSpecimen Handling

The invention discloses a pathological specimen processing method and belongs to the field of specimen processing technology. According to the processing method, sampled pathological tissues successively undergo fixation, dehydration, transparency, wax impregnation, embedding, slicing, staining and mounting so as to obtain a pathological specimen. The fixation is to fix the pathological tissues by the use of a fixative for 4-15 h. The fixative is composed of atractylol, ethoxylated acetylenediol, chlorogenic acid, polyvinylpyrrolidone, sodium chloride, ethyl acetate and pure water. The mounting is to carry out mounting on the stained pathological tissues by the use of a mixture of polyacrylamide, polyvinylpyrrolidone and xylene. According to the invention, toxicity of reagents used in the invention is obviously reduced, the fixation effect is good, degradation and transparency degree are easy to control. Then, the tissues are not easy to deform, embrittle or harden, and mounting is complete and staining is remarkable.

Owner:LUOHE MEDICAL COLLEGE

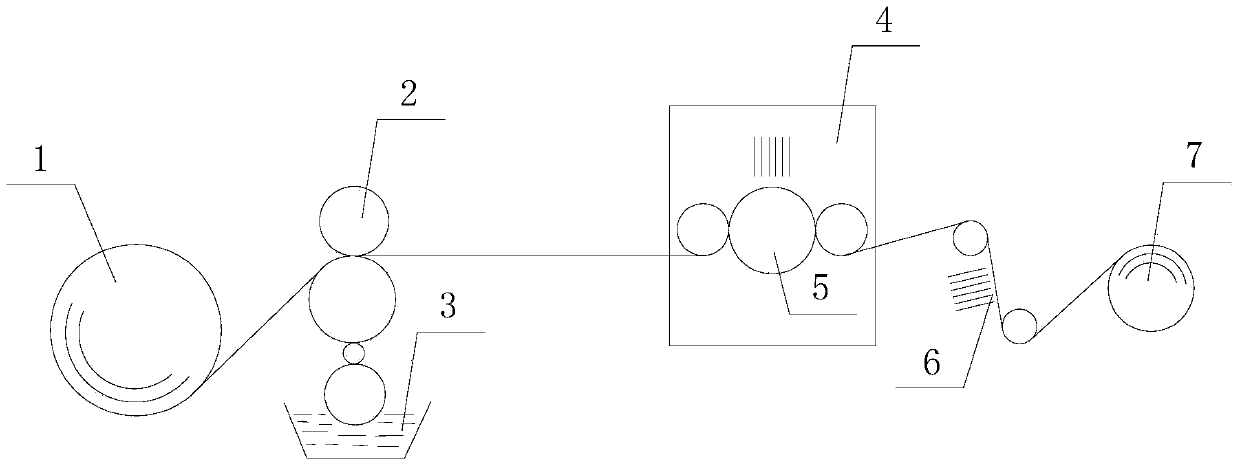

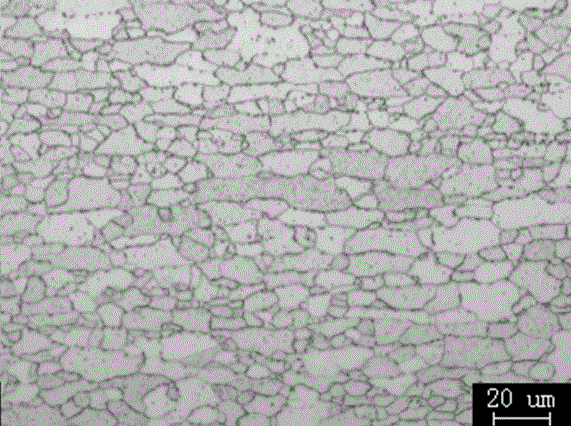

Low carbon cold-rolled steel sheet for LED lead frame and production method thereof

The invention relates to a low carbon cold-rolled steel sheet for a LED lead frame and a production method thereof, and mainly solves the technical problems that the low carbon cold-rolled steel sheet for the LED lead frame in prior art has nonuniform hardness, high surface roughness and bad aging-resistance. The production method comprises the following steps: smelting according to components, molten iron desulphurization, complex top-bottom blowing converter smelting, argon blowing from bottom of a ladle, protective casting with argon blowing in whole course, heating in a slab heating furnace, rough rolling, finish rolling, reeling for obtaining a hot-rolled steel coil, uncoiling, pickling, cold rolling, annealing in a vertical type continuous annealing furnace, flattening, and reeling for obtaining a finished product with a thickness of 0.4-0.5mm; the finishing temperature of the finish rolling is 860-900 DEG C, the reeling temperature of the hot rolling is 620-660 DEG C, the cold rolling reduction is 75-85%, the temperature scope of a soaking zone of the vertical type continuous annealing furnace for a band steel in hard rolled state after cold rolling is 710-730 DEG C, the soaking time for the band steel in the vertical type continuous annealing furnace is 105-120 s, and temper elongation is 1.0-1.4%. The low carbon cold-rolled steel sheet is mainly used for the LED lead frame.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

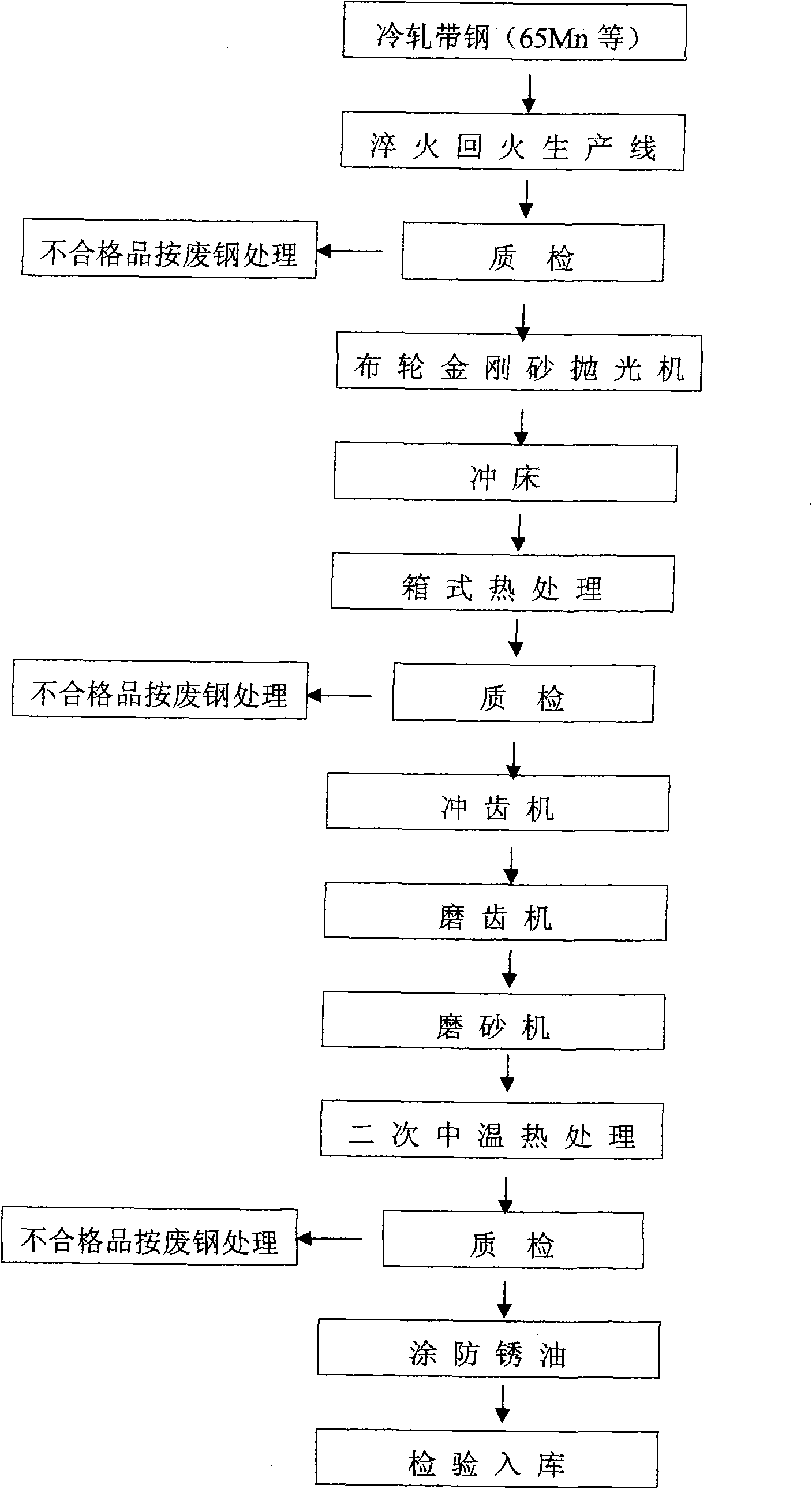

Method for producing traceless quenching and embossing saw blade

InactiveCN101333688AQuality improvementStable hardnessVegetable fibre separation from seedsMetal sawing tool makingProduction lineHardness

The invention discloses a production method of cotton ginning saw-blade, which directly uses the strip steel to firstly quench and temper and then subsequently process the strip steel. The process steps are as follows: selecting the strip, quenching the strip, inspecting the quality of the strip, polishing the surface of the strip, punching the strip into a blank of the saw-blade, heat treating the blank of the saw-blade, inspecting the quality of the blank, punching teeth on the blank by a sawtooth punching machine, grinding teeth, burring, heat treating the blank in moderate temperature, inspecting the quality of the finished product, packaging the finished product after coating antirust oil on the finished product, and inspecting and warehousing the finished product. The production method continuously produces the strip steel of 350mm and 430mm on quenching and tempering production lines, so the produced saw-blade has stable hardness, good toughness, good wear resistance and long service life.

Owner:HANDAN HANWU COTTON MACHINERY

Aluminum alloy

Owner:东莞市东兴铝业有限公司

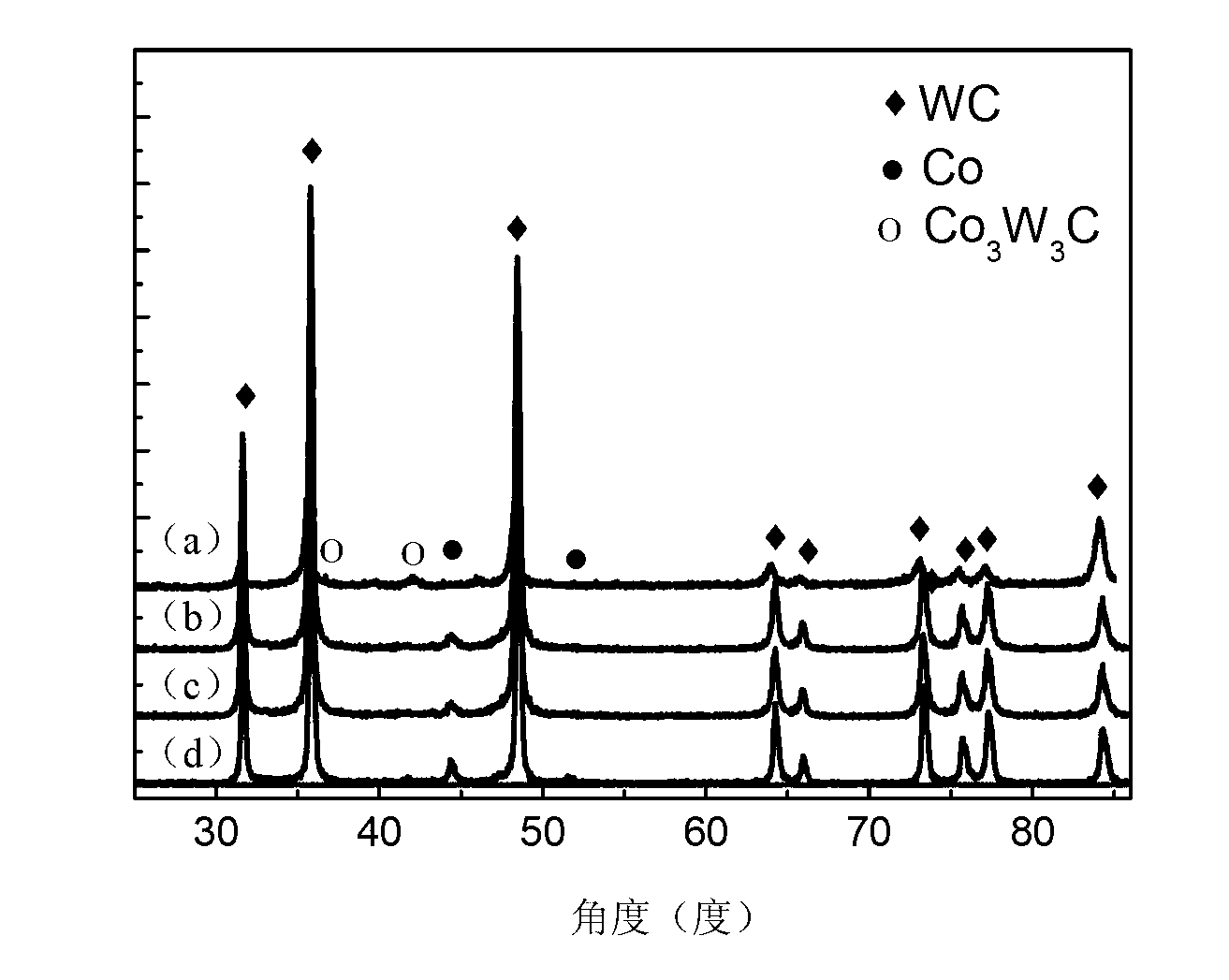

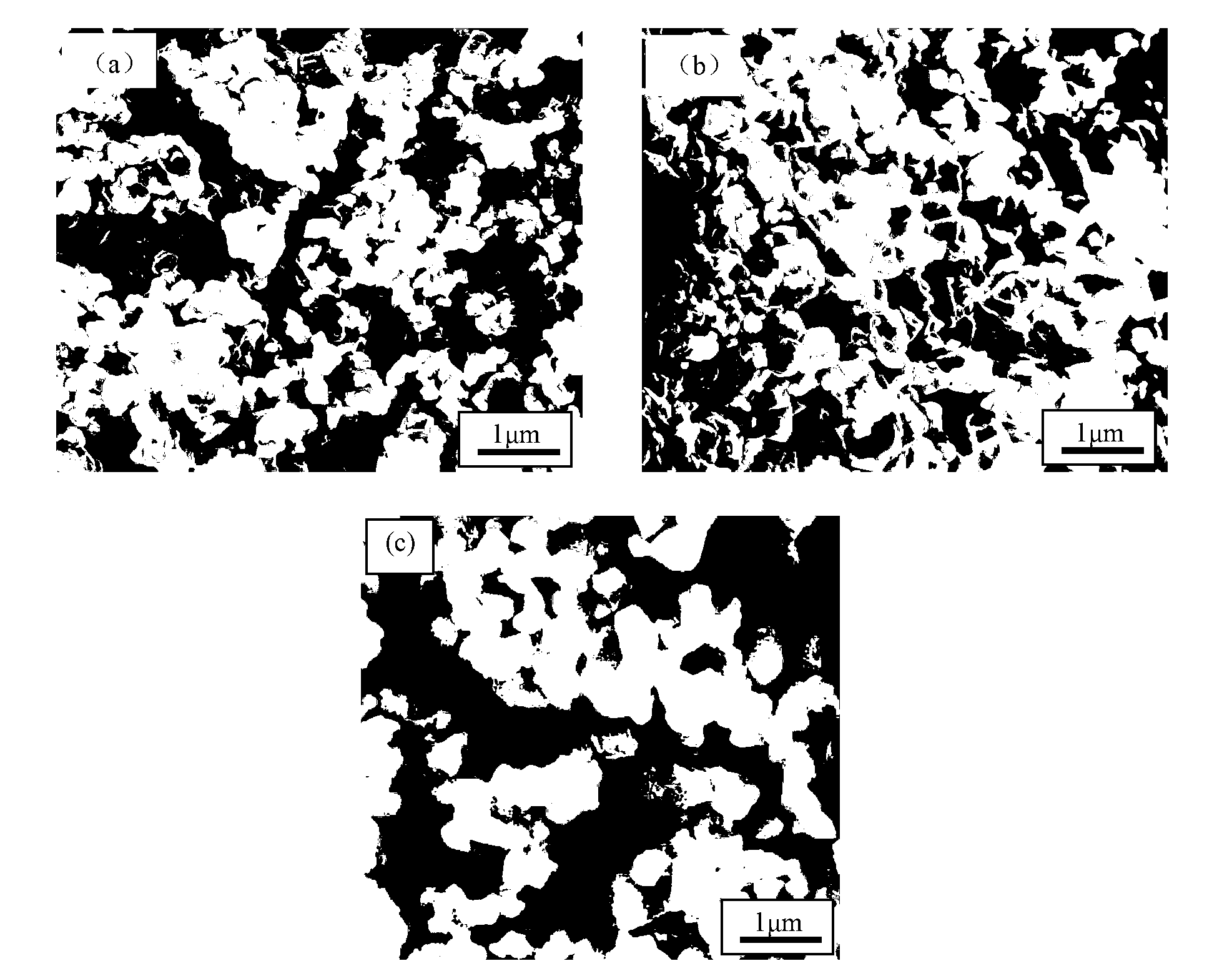

Method for synthesizing and preparing hard alloy powder by mixing original powder and regenerated powder

The invention relates to a method for synthesizing and preparing hard alloy powder by mixing original powder and regenerated powder and belongs to the technical field of the hard alloy and powder metallurgy. The method comprises the following steps of: oxidizing WC-Co waste hard alloys with different Co content to form a regenerated WC-Co oxide mixture; measuring the WO3 content in the regenerated WC-Co oxide mixture; according to the requirements of the Co content and the regenerated powder content in final state WC-Co mixed powder, adding native tungsten oxide, native cobalt oxide and carbon black required for implementing the requirement on the components of a final product into the regenerated WC-Co oxide mixture; carrying out ball mill mixing; and then performing the in-situ reduction and carburization reaction in the vacuum environment to obtain the hard alloy powder. According to the product obtained by the method disclosed by the invention, the native materials and the regenerated materials are totally and uniformly mixed, so that the stability of the product quality is improved and the components are accurate and controllable.

Owner:BEIJING UNIV OF TECH

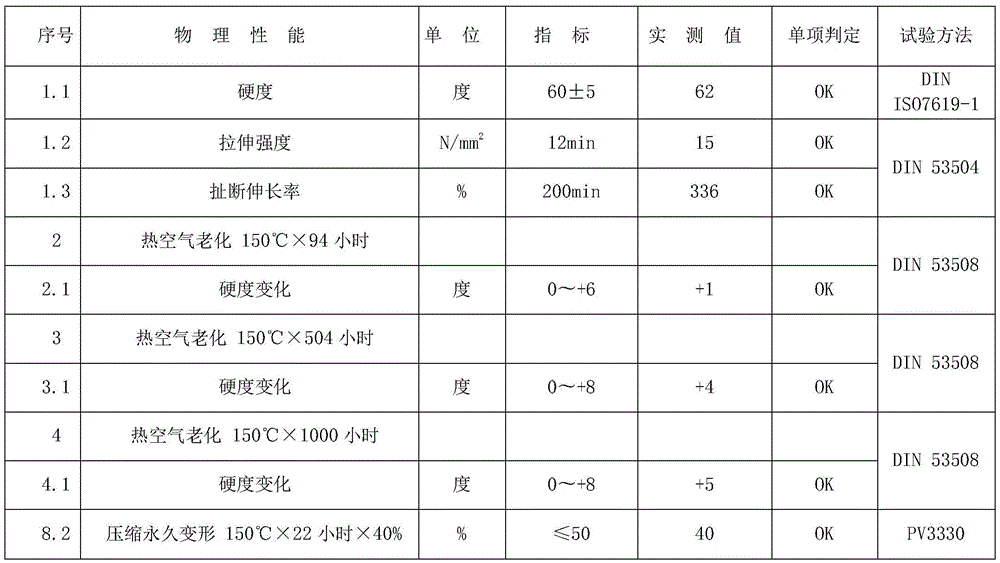

Novel anti-aging compound rubber and preparation method thereof

InactiveCN105566779AIncrease crosslink densityImprove anti-aging propertiesPolymer scienceTriallyl isocyanurate

The invention discloses an anti-aging compound rubber sealing strip. The anti-aging compound rubber sealing strip is prepared from, by weight, 50-200 parts of ethylene propylene rubber, 10-70 parts of fast extruding furnace black, 1-15 parts of indirect zinc oxide, 1-10 parts of antiager, 1-15 parts of paraffin oil, 1-10 parts of lubricant, 1-10 parts of vulcanizing agent and 1-8 parts of accelerant. The accelerant is triallyl isocyanurate and / or trifunctional acrylic ester. The invention further discloses a preparation method of the anti-aging compound rubber sealing strip. The anti-aging compound rubber sealing strip has the advantages of being long in service life, resistant to aging and pressure changes and stable in hardness, and the preparation method is simple and easy to operate.

Owner:ANHUI ZHONGDING SEALING PARTS

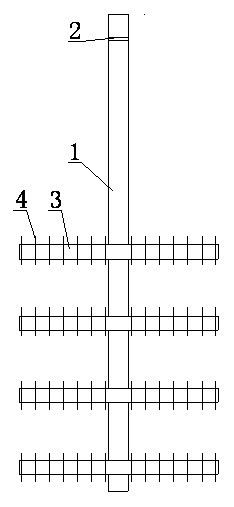

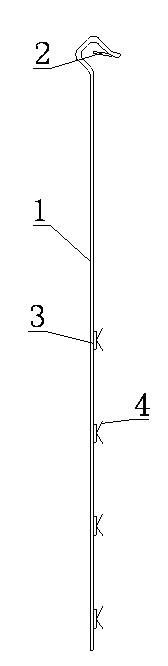

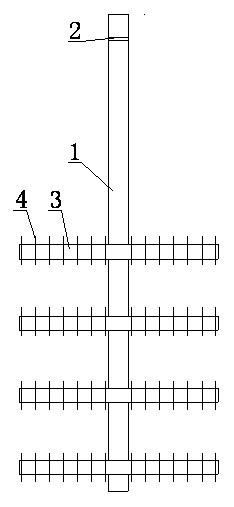

Anode special for oxidation of deep hole aluminum piece hard anode and oxidation method of deep hole aluminum piece hard anode

The invention discloses an anode special for oxidation of a deep hole aluminum piece hard anode and an oxidation method of the deep hole aluminum piece hard anode. According to a machining method of the special anode, a titanium material TA2 with both better conductivity and strength is adopted, so that good conductivity, corrosion resistance and convenience for clamping are guaranteed, and the requirements for oxidation of the deep hole piece hard anode are met. Since the oxidation of the deep hole hard anode is special, the selection of a material which has good selectivity and that a clamp can be soaked into sulfuric acid solution for long time without being easily dissolved or oxidized is particularly important. The treatment of the special clamp is that: a TA2 titanium plate or titanium wire is subjected to treatment such as welding and then used for the deep hole piece hard anode oxidation clamp. The conduction mode is that power is supplied by the anode. The anode provided by the invention is used for oxidation; the qualification rate of products at one time can be increased by over 98 percent; and the consumption and the production cost of the clamp are greatly reduced while the product quality is guaranteed.

Owner:CHONGQING JIANSHE IND GRP

Preparation method of environment-friendly and low hardness polyurethane elastomer

The invention relates to the technical field of polyurethane elastomer preparation, in particular to an environment-friendly and low hardness polyurethane elastomer without plasticizer and a preparation method thereof. The environment-friendly and low hardness polyurethane elastomer provided by the invention is composed of polyol, isocyanate, a chain extender, a hyperbranched polymer, an antioxidant, an anti-UV agent and a catalyst. Through the two steps of prepolymer synthesis and elastomer synthesis, the environment-friendly and low hardness polyurethane elastomer material can be finally obtained. The environment-friendly and low hardness polyurethane elastomer has the advantages of no toxicity, no pollution, stable structure, excellent mechanical properties, etc., and can be used in shoe materials contacting the human body, medical treatment, sports fitness and other fields.

Owner:上海优迈材料科技有限公司

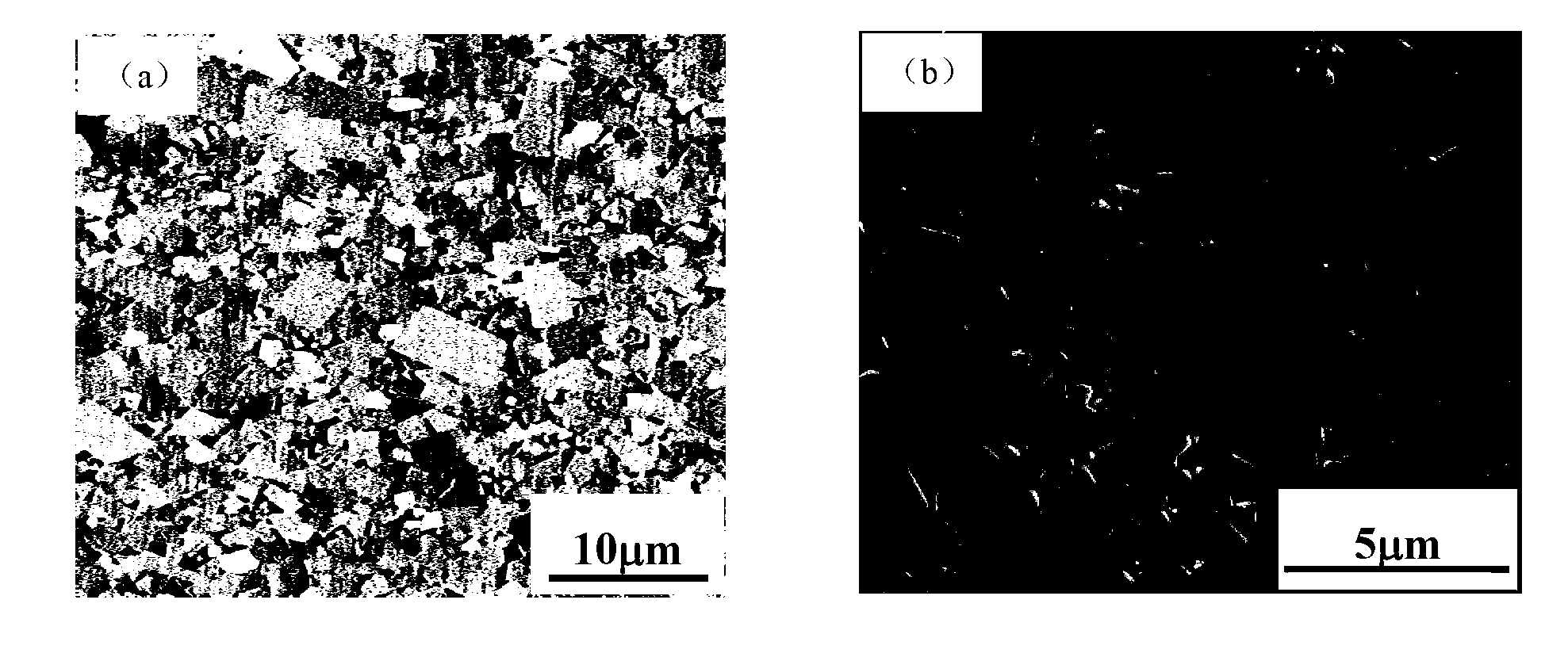

Anodic oxidation process for high-silicon high-copper die-cast aluminum and high-silicon high-copper die-cast aluminum alloy

The invention relates to an anodic oxidation process for high-silicon high-copper die-cast aluminum. According to the anodic oxidation process for the high-silicon high-copper die-cast aluminum, glycerinum, organic acid, sulfate and fluoride are added in an electrolyte, the temperature of the electrolyte is controlled to be 5-25 DEG C, and the current density of an anodic oxidation power supply is1-3 A / dm<2>. The problem that due to increase of the silicon-copper content in a high-silicon high-copper die-cast aluminum alloy, anodic oxidation becomes difficult, neither the thickness nor hardness of an oxide film can be ensured, and the performance of the oxide film is poor is solved. As for the high-silicon high-copper die-cast aluminum alloy treated by the anodic oxidation process, the thickness is stabilized to be 30 [mu]m or above and can be 50 [mu]m at most, and the hardness is stabilized to be 400-450 Hv.

Owner:SHANGHAI MIRROR METAL SURFACE TREATMENT

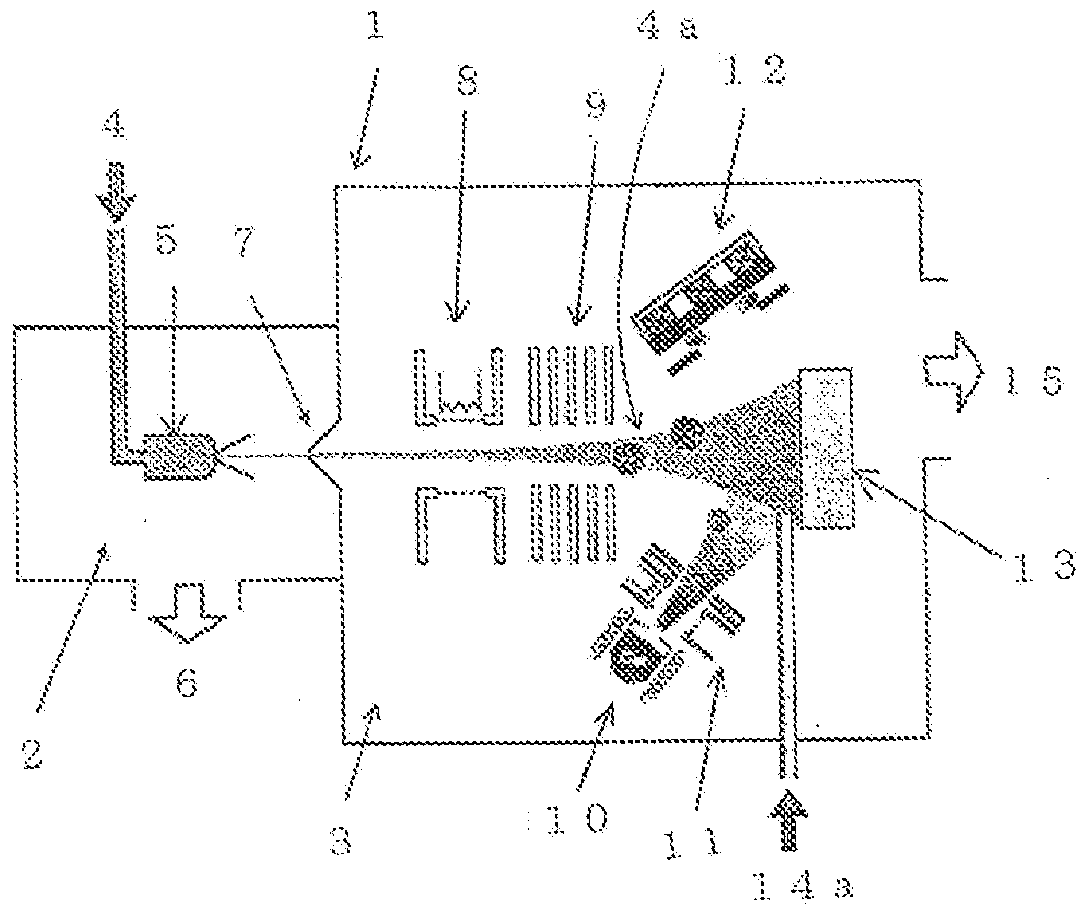

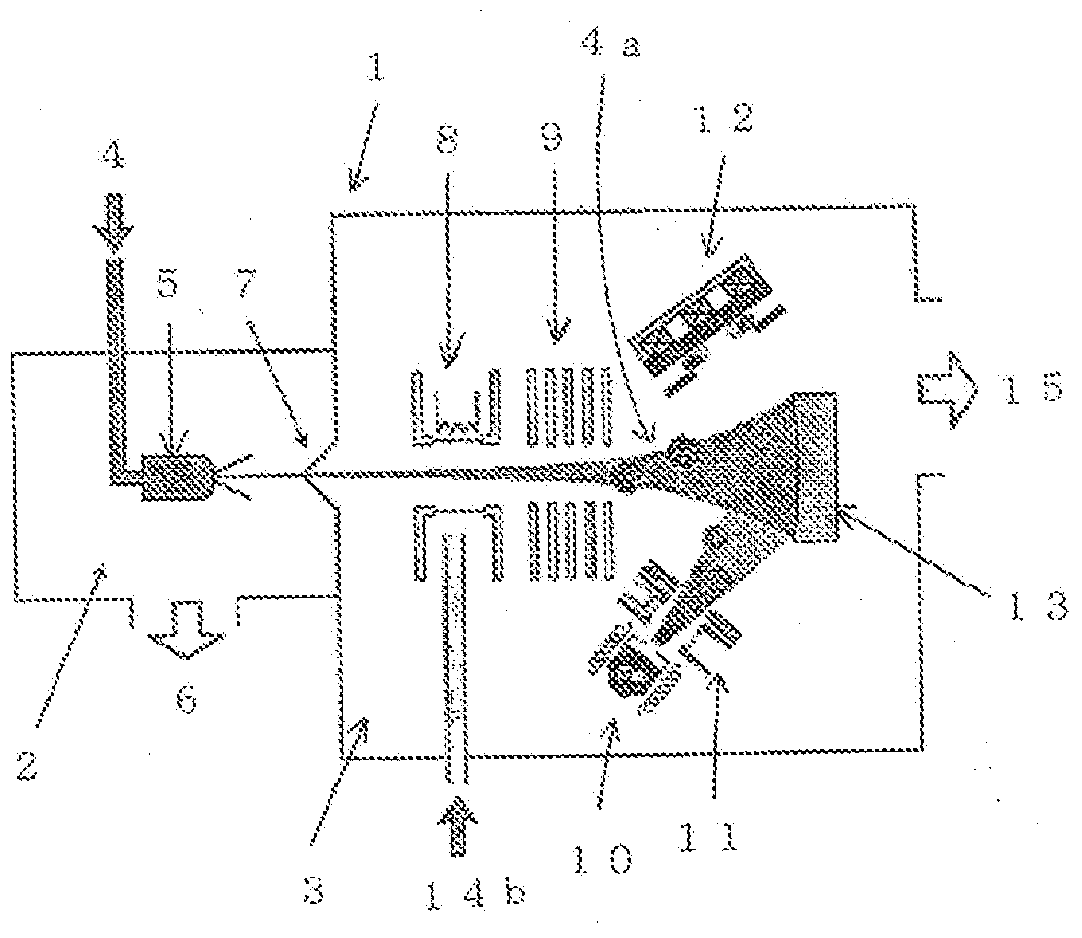

Conductive hard carbon film, and film forming method therefor

ActiveCN103210114AVolume stabilityStable hardnessElectric discharge tubesElectrical measurement instrument detailsCarbon filmHydrogen

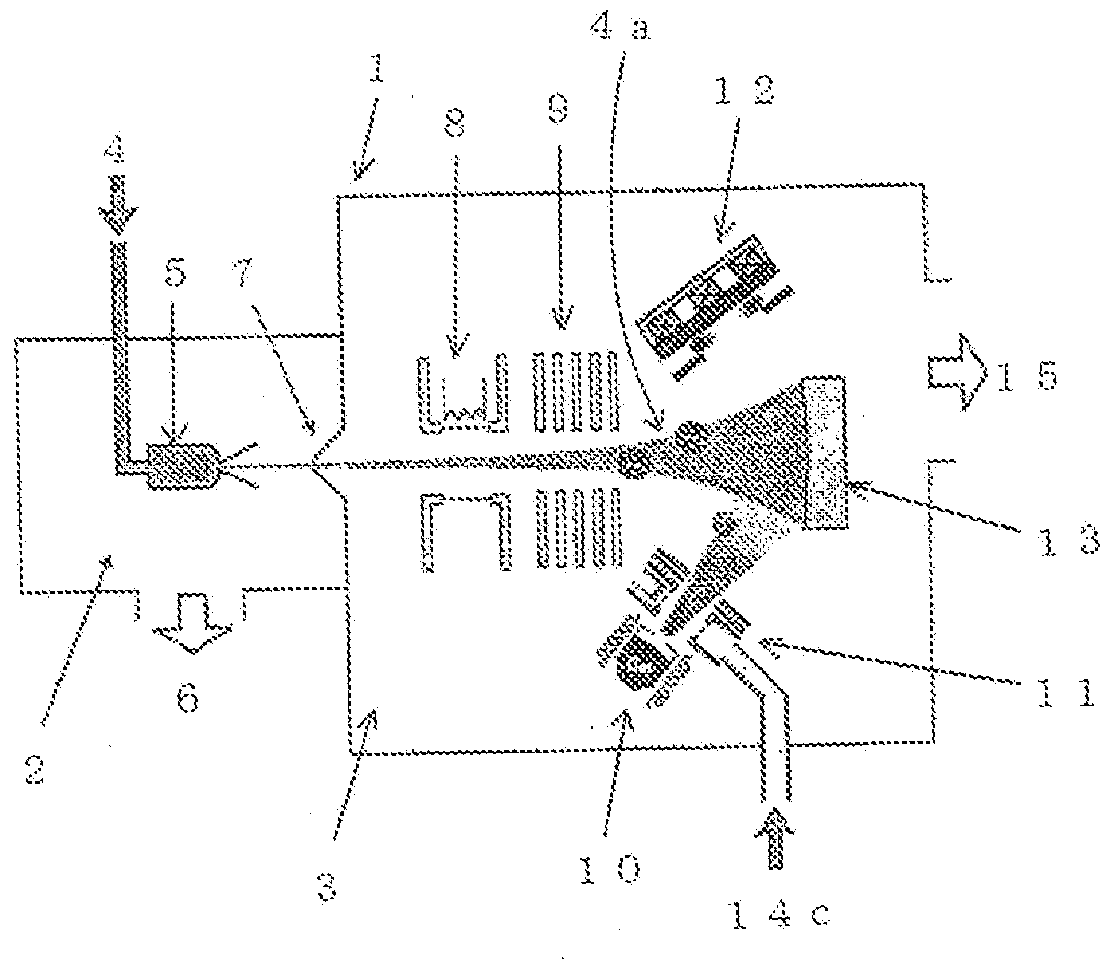

A method for forming a conductive hard carbon film in vacuum reduced pressure comprises: a step in which a gas cluster ion beam (4a) is irradiated on a substrate (13), and the substrate (13) is purified and / or flattened; a step in which an intermediate film-forming material is vaporized, the vaporization product is deposited on the surface of the substrate (13), and the gas cluster ion beam (4a) is irradiated on the intermediate film-forming material to form an intermediate film; and a step in which a carbon film-forming material containing a boron material and a carbonaceous material having substantially no hydrogen is vaporized, the vaporization product is deposited on the surface of the intermediate film, and the gas cluster ion beam (4a) is irradiated on the carbon film-forming material to form a film.

Owner:NOMURA PLATING CO LTD

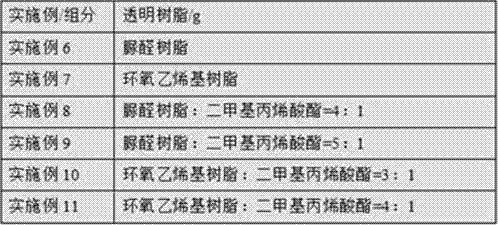

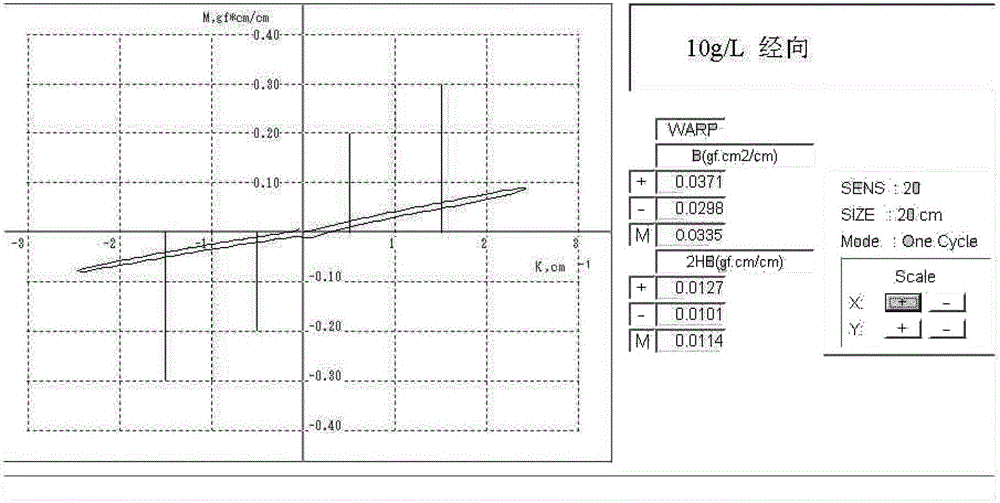

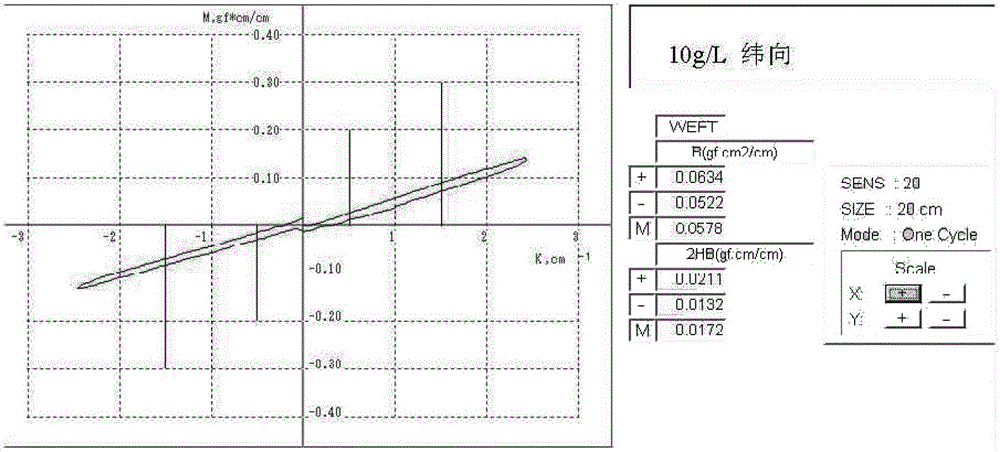

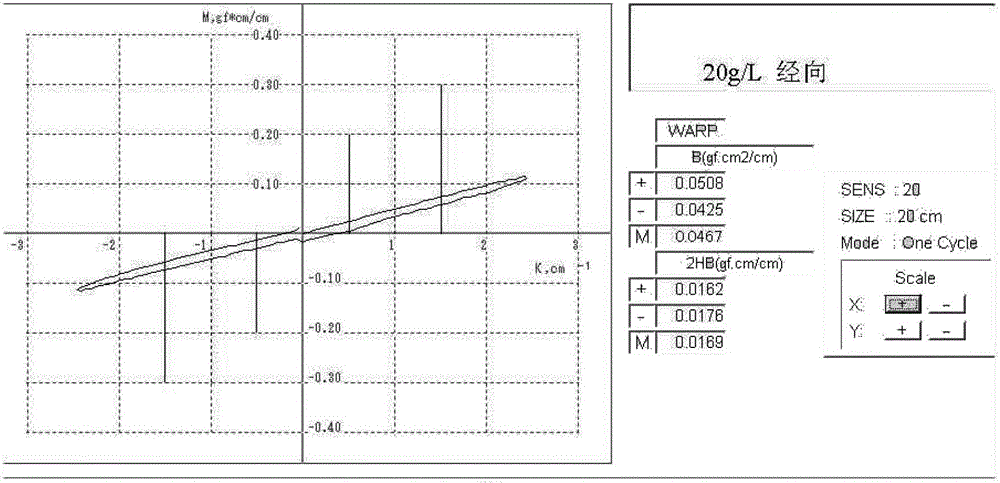

Textile frost resistance test standard sample and preparation method thereof

InactiveCN102720065AStable hardnessInspection operation is simpleFibre typesPreparing sample for investigationFrostStandard samples

The invention discloses a textile frost resistance test standard sample. The textile frost resistance test standard sample is characterized in that the textile frost resistance test standard sample is produced by utilizing hard finishing agents with different concentrations to carry out hard finishing for terylene which is taken as standard sample fabric, wherein the hard finishing agent is obtained by adding 7 parts of polyvinyl acetate into 1 part of epoxy resin finishing agent, by mass, stirring and mixing uniformly, wherein epoxy resin finishing agent is prepared from 1 part of AB-EP-20 and 0.6 part of AB-HGA, by mass; the hard finishing conditions are that the fabric is subjected to twice dipping and twice padding, mangle expression is 100%, soaking time is 1 minute, predrying is carried out at a temperature of 95 DEG C for 2 minutes, and baking is carried out at a temperature of 180 DEG C for 3 minutes; concentrations of the hard finishing agent which assists in carrying out hard finishing are 10g / l, 20g / l, 50g / L, 80g / L and 200g / L respectively. The textile frost resistance test standard sample is with permanent hardness and can be tried out as a standard sample which is used with a hand feel change degree test method at a low temperature environment.

Owner:潘葵 +3

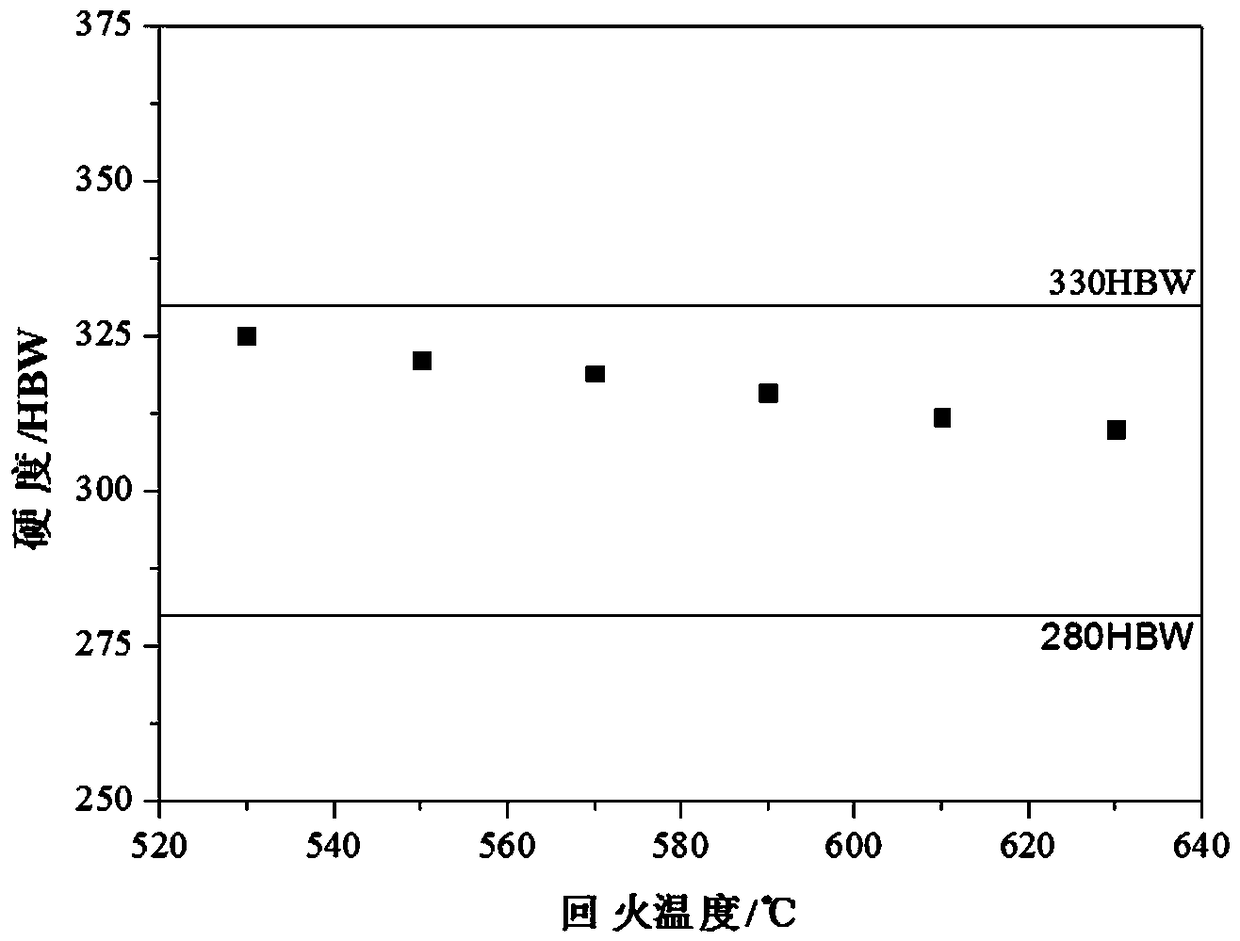

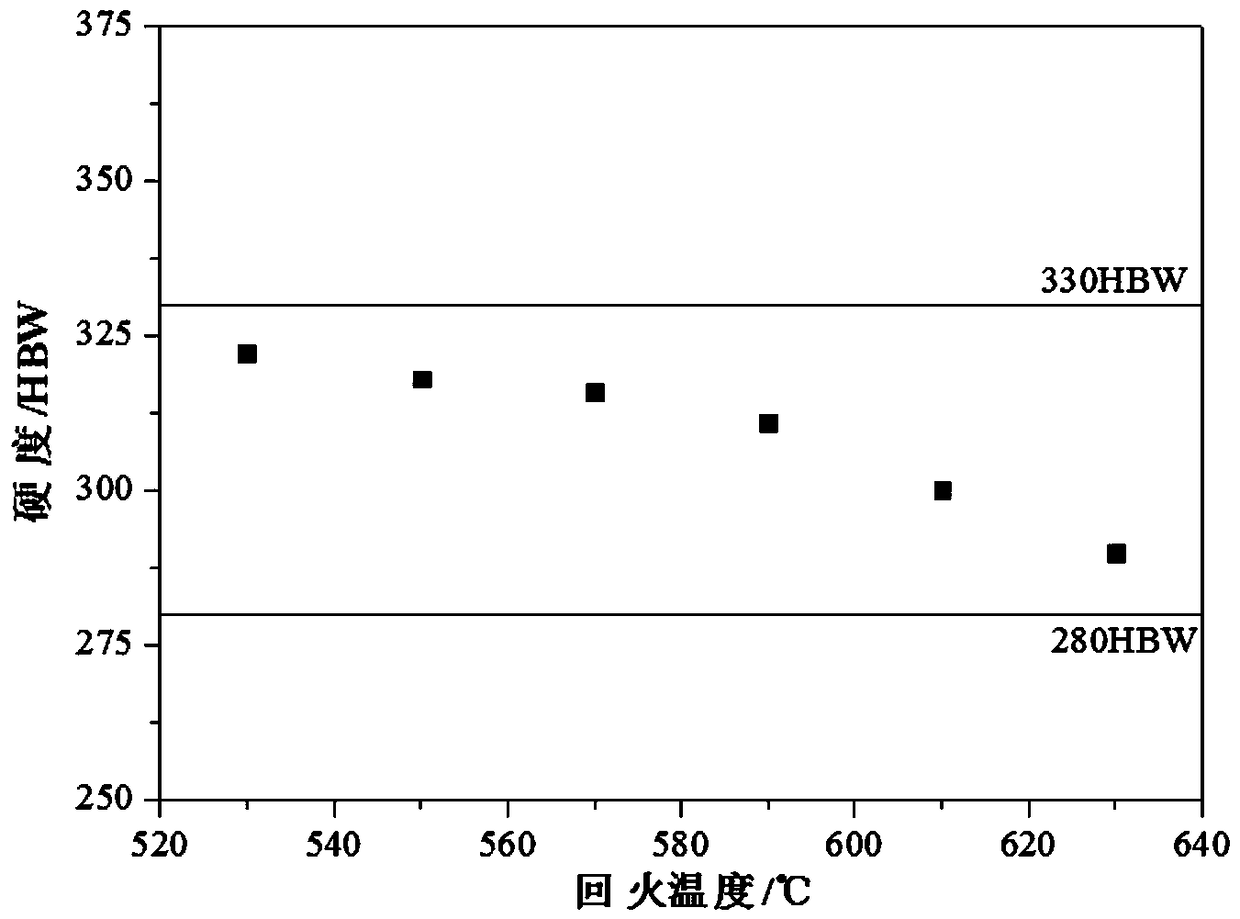

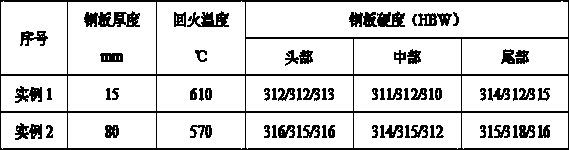

Vanadium-containing plastic mold steel plate and manufacturing method thereof

The invention relates to a manufacturing method of a vanadium-containing plastic mold steel plate. The vanadium-containing non-tempering plastic mold steel plate comprises, by weight, 0.28-0.40% of C,0.20-0.50% of Si, 1.20-1.60% of Mn, 0.030% or below of P, 0.025% or below of S, 0.80-1.20% of Cr, 0.05-0.15% of V, 0.030% or below of Ti, 0.00255 or below of B and the balance Fe and unavoidable impurities, wherein the content of Mn, Cr and V is 2.4-2.7%, the ratio of Cr to V is 9-11, and the ratio of Ti to B is equal to or higher than 8. The manufacturing method has the advantages that the alloycost is low, the tempering process window is wide, the internal quality is high, and the production process is short, and the manufacturing method can be widely used in the plastic mold manufacturingindustry.

Owner:SGIS SONGSHAN CO LTD

Production technology of polypropylene building template

InactiveCN103012958AExcellent impact resistanceExcellent deformation resistanceForming/stuttering elementsConstruction engineeringProcess engineering

The invention provides a production technology of a polypropylene building template, which is the technology for producing the building template by adopting waste plastics as the raw materials. The production technology comprises the steps of pretreating the raw materials, mixing the materials, and carrying out extrusion molding. The raw materials are treated based on a certain ratio and prepared into the product building template under a certain condition. The product building template has the characteristics that the construction quality is high, the building template can be recycled for a plurality of times, the cost is reduced, the benefit is increased, the energy conservation and environment protection are realized, and the residues can be recycled; and the product building template has a large market demand and wide prospect, and is an excellent substitute for steel templates, bamboo plywood and wood plywood.

Owner:HUNAN FENGSHUO TECH

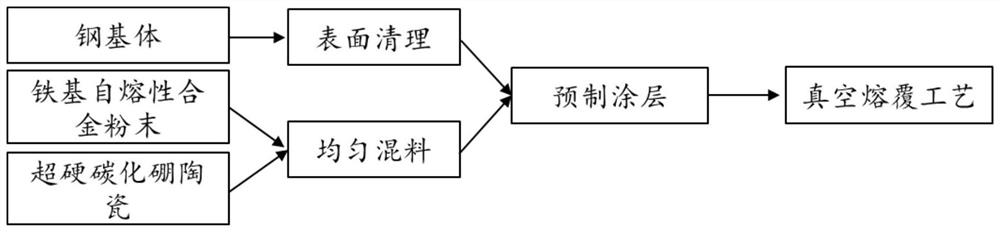

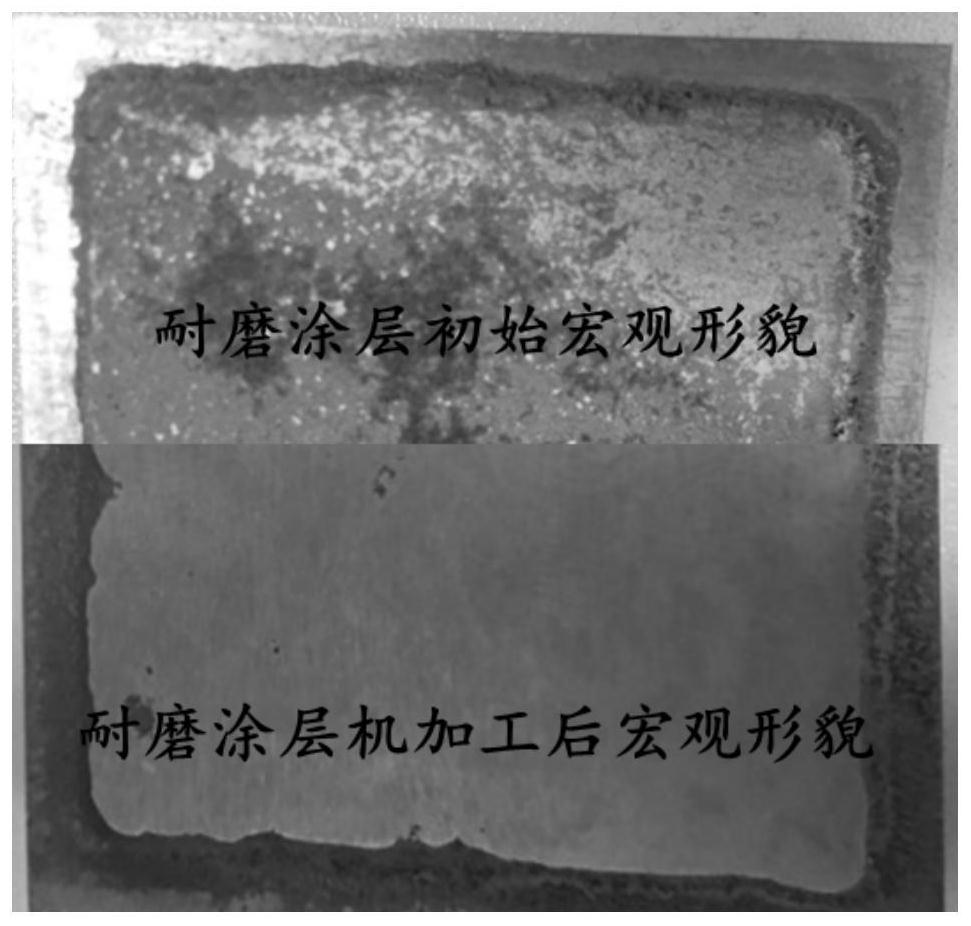

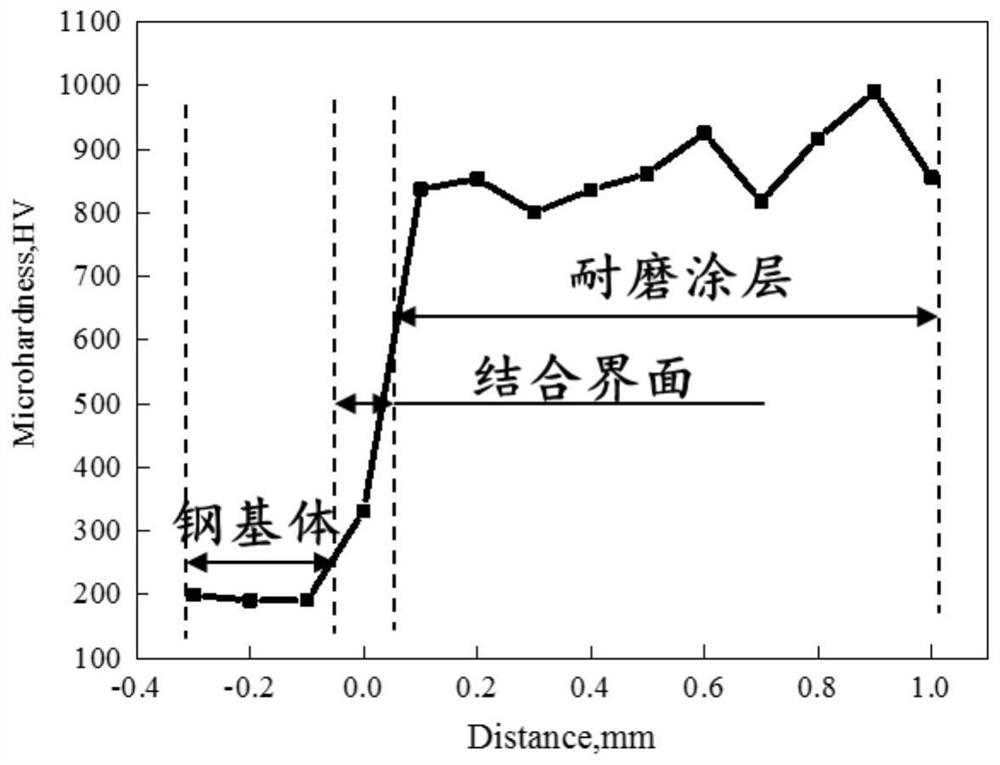

Preparation method of superhard boron carbide ceramic reinforced iron-based alloy composite wear-resistant coating

ActiveCN112708883AWide source of powderWide variety of sourcesMetallic material coating processesCrazingCeramic particle

The invention relates to a preparation method of a superhard boron carbide ceramic reinforced iron-based alloy composite wear-resistant coating. The preparation method comprises the following steps: (1) preparing boron carbide ceramic particles and iron-based self-fluxing alloy powder as raw materials; (2) preparing a steel substrate of which the surface is treated to form a surface to be cladded; (3) putting the boron carbide ceramic particles and the iron-based alloy powder into a ball mill for dry ball milling and mixing; (4) adding a binder into the mixed powder, uniformly stirring to form viscous paste, and coating the surface of the steel substrate with the viscous paste; (5) drying after air drying; and (6) carrying out vacuum cladding and then carrying out furnace cooling. The coating prepared by the method provided by the invention has no cracks and micropores penetrating through the whole thickness, is a continuous closed coating, and can significantly improve the wear resistance of mechanical parts, prolong the service life and improve the safety performance.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com