Vanadium-containing plastic mold steel plate and manufacturing method thereof

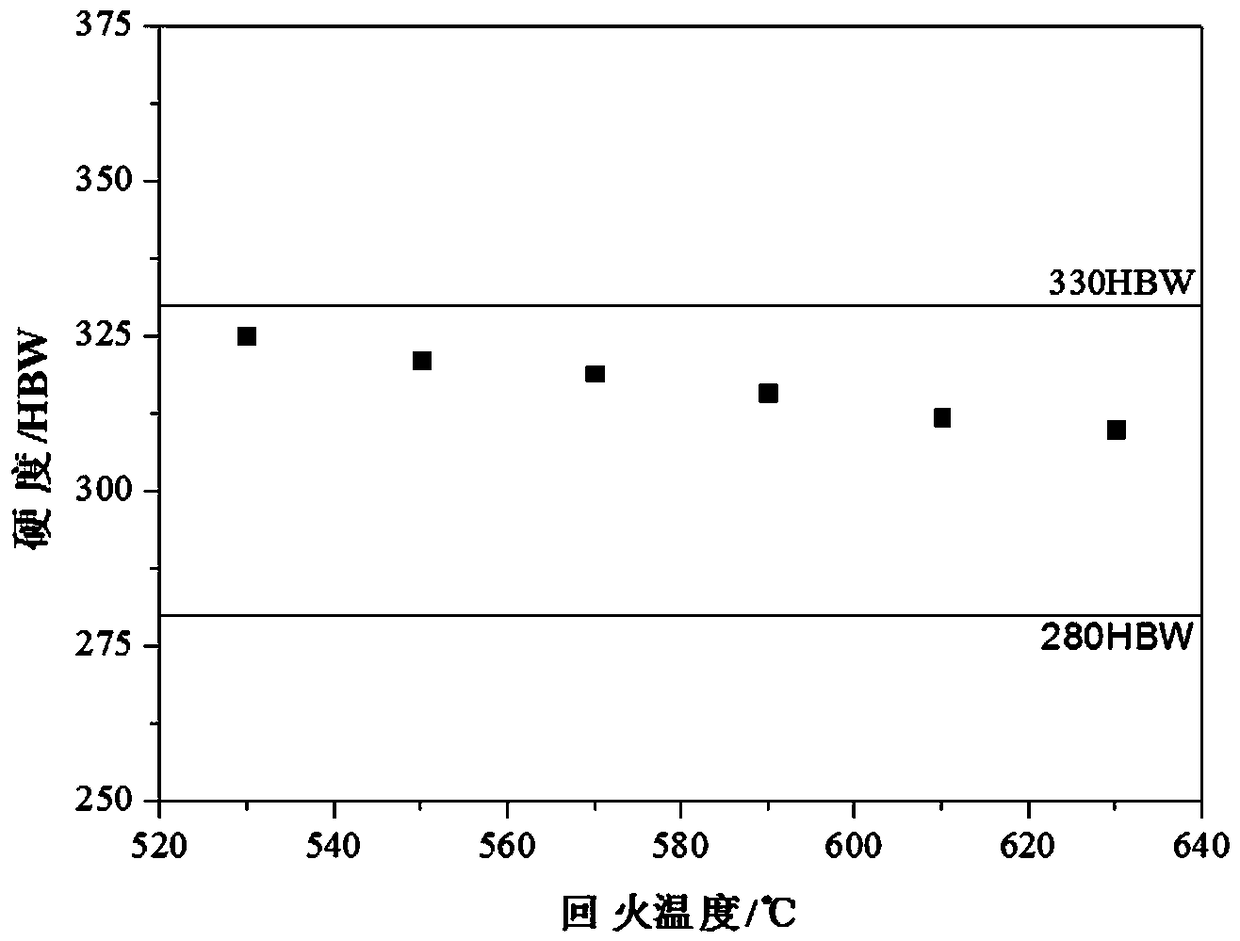

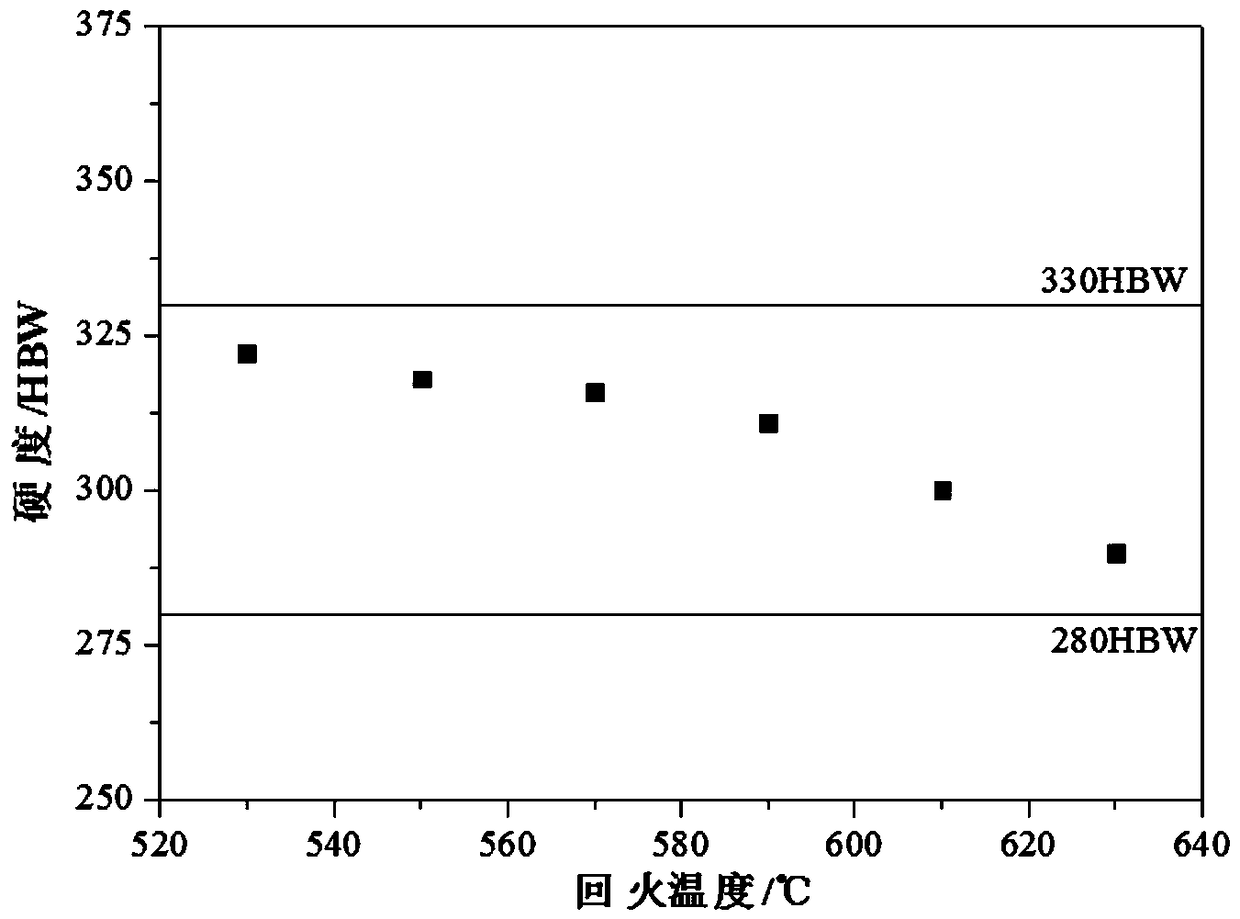

A technology for a plastic mold and a manufacturing method, applied in the field of vanadium-containing non-quenched and tempered plastic mold steel plate and its manufacturing, can solve the problems of complex process, high alloy cost, affecting the internal quality and machinability of the mold steel, and achieve the production process flow. The effect of simplicity, low alloy cost, and wide tempering process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

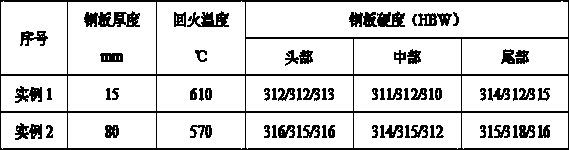

Embodiment 1

[0026] The chemical composition of the steel is C: 0.38%, Si: 0.41%, Mn: 1.45%, P: 0.013%, S: 0.005%, Cr: 0.80-1.20%, V: 0.05-0.15%, Ti: ≤ 0.03%, B: 0.0017%, the balance is Fe and inevitable inclusions, of which Mn+Cr+V is 2.4~2.7%, Cr / V is 9-11, Ti / B≥8.

[0027] (1) Smelting: Smelting according to the above chemical composition. 120-ton converter smelting, LF refining in ladle furnace, RH refining in vacuum degassing furnace, calcium treatment after ladle out of RH furnace, soft blowing of Ar gas from the bottom of the ladle to molten steel, blowing Ar gas time ≥ 10 minutes;

[0028] (2) Pouring: Ladle to tundish adopts long nozzle to protect steel tapping, tundish to crystallizer adopts submerged nozzle to protect pouring, superheat of molten steel in tundish is controlled at ≤30°C; total light reduction in continuous casting process ≥5mm , the secondary cooling electromagnetic stirring is put into the whole process, and the continuous casting slab with a thickness of 270mm...

Embodiment 2

[0032] The chemical composition of the steel is C: 0.38%, Si: 0.40%, Mn: 1.55%, P: 0.013%, S: 0.005%, Cr: 0.80-1.20%, V: 0.05-0.15%, Ti: ≤ 0.03%, B: 0.0017%, the balance is Fe and inevitable inclusions, of which Mn+Cr+V is 2.4~2.7%, Cr / V is 9~11, Ti / B≥8.

[0033] (1) Smelting: Smelting according to the above chemical composition. 120-ton converter smelting, LF refining in ladle furnace, RH refining in vacuum degassing furnace, calcium treatment after ladle out of RH furnace, soft blowing of Ar gas from the bottom of the ladle to molten steel, blowing Ar gas time ≥ 10 minutes;

[0034] (2) Pouring: Ladle to tundish adopts long nozzle to protect steel tapping, tundish to crystallizer adopts submerged nozzle to protect pouring, superheat of molten steel in tundish is controlled at ≤30°C; total light reduction in continuous casting process ≥5mm , the secondary cooling electromagnetic stirring is put into the whole process, and the continuous casting slab with a thickness of 270mm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com