Patents

Literature

45results about How to "Excellent impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing spray elastomer systems

InactiveUS6399736B1Improved physical propertyExcellent impact resistancePolyurea/polyurethane coatingsDiaminePolyurea

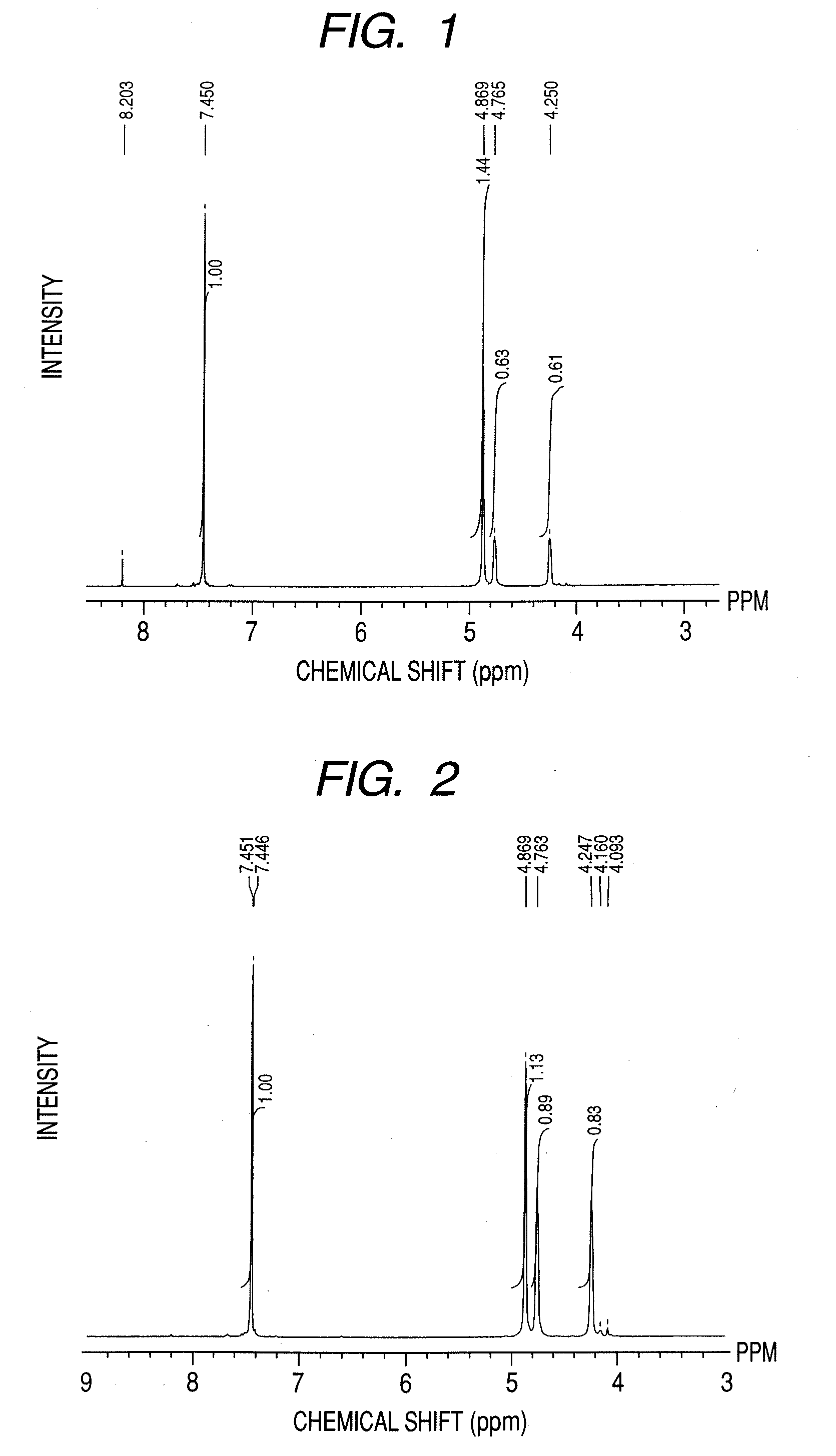

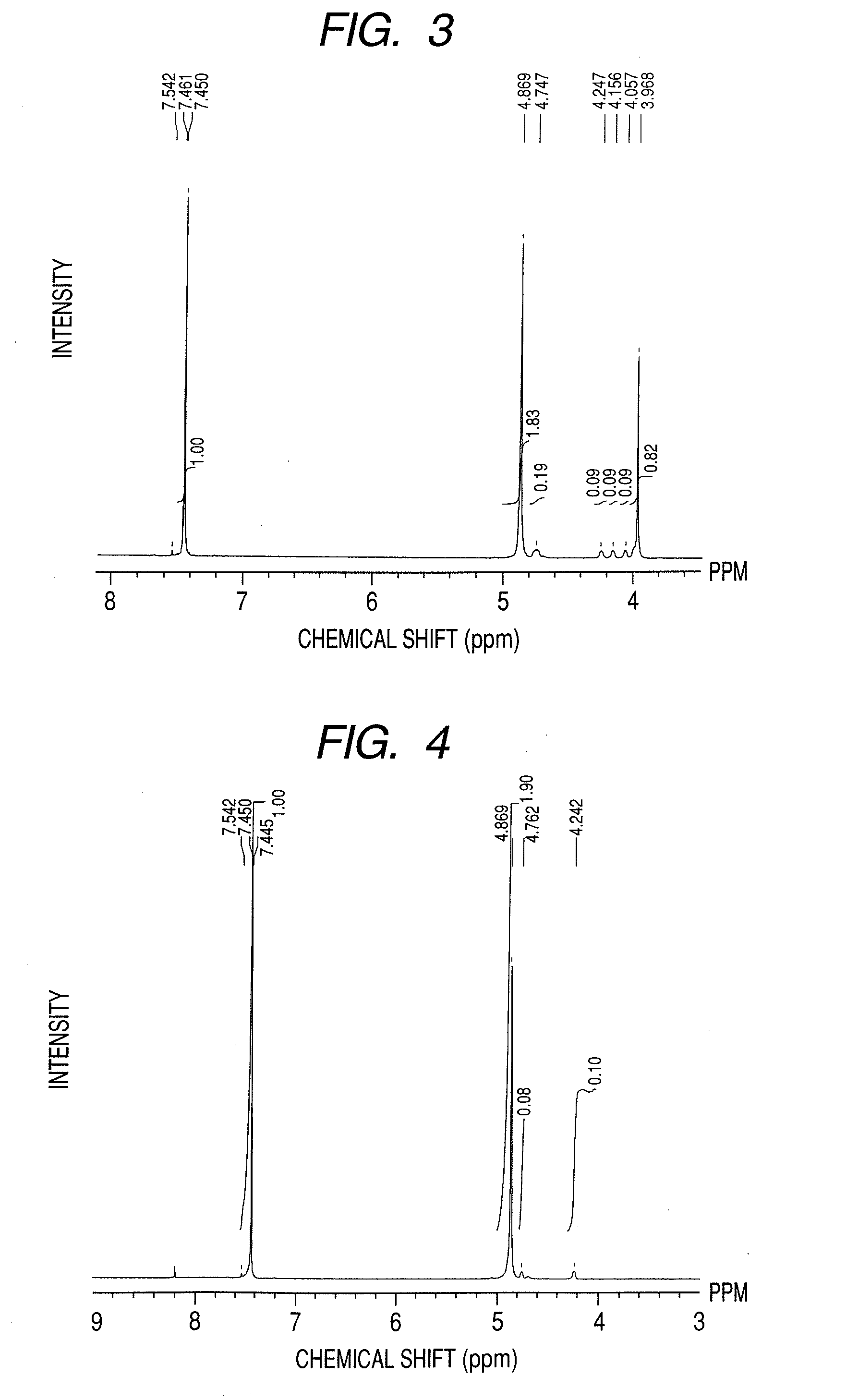

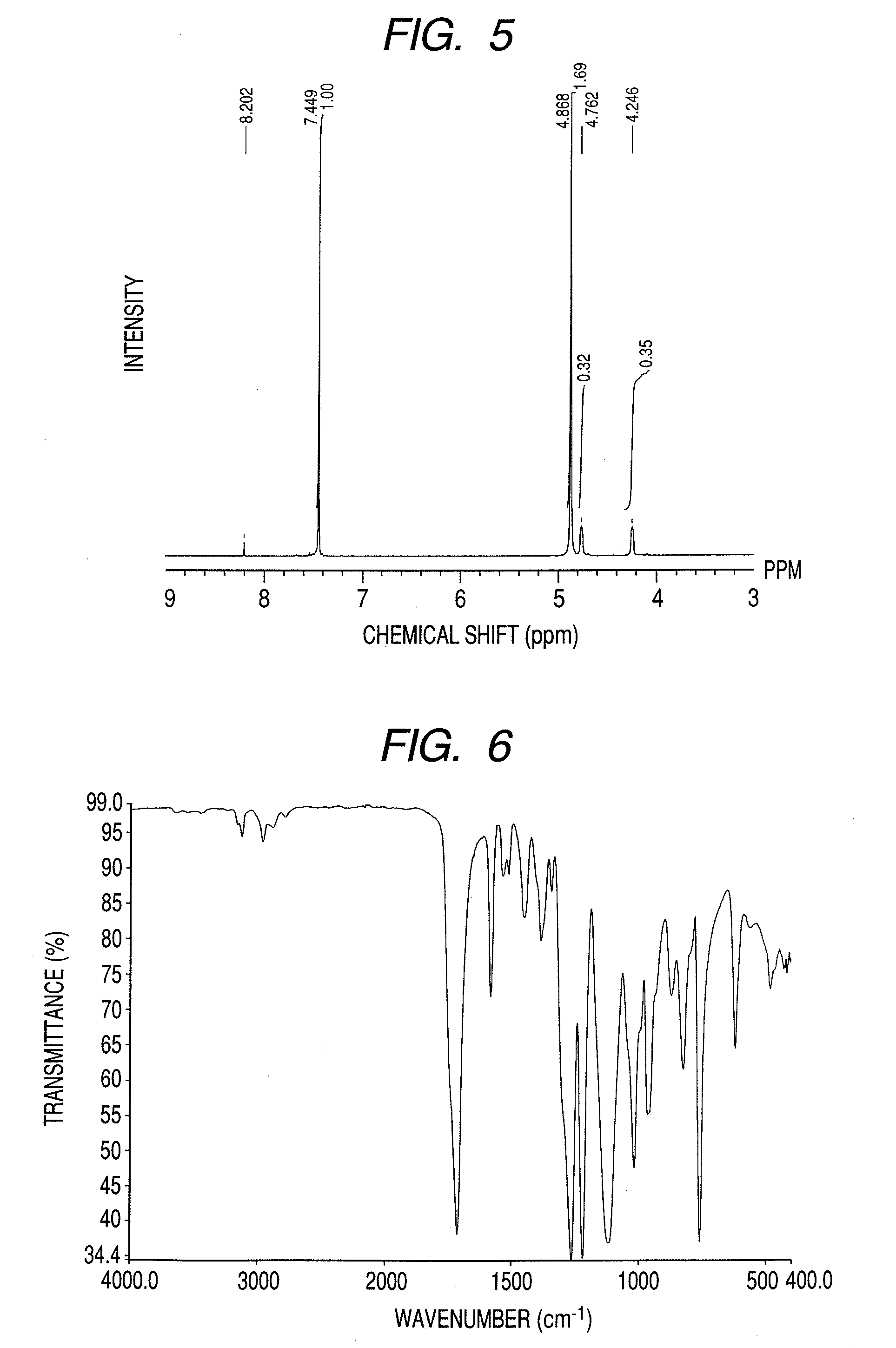

This invention concerns a method for the preparation of polyurea elastomers, comprising: (a) reacting an amine chain extender with dialkyl maleate to form an aspartic ester, wherein the chain extender has a molar amount of amine groups that is greater than the moles of dialkyl maleate; (b) blending the aspartic ester with one or more polyoxyalkyleneamines to prepare a resin blend; (c) contacting the resin blend with an isocyanate under conditions effective to form a polyurea elastomer. This invention concerns a method for the preparation of polyurethane elastomers, comprising: (a) reacting an diamine chain extender with dialkyl maleate or fumarate, wherein the mole ratio of primary amine functionality in the diamine chain extender to dialkyl maleate or fumarate is more than 1:1; (b) coating a substrate with effective film forming amounts of the product of step (a), an isocyanate, and a polyhydroxyl compound under conditions effective to form a the polyurethane elastomer.

Owner:HUNTSMAN PETROCHEMICAL LLC +1

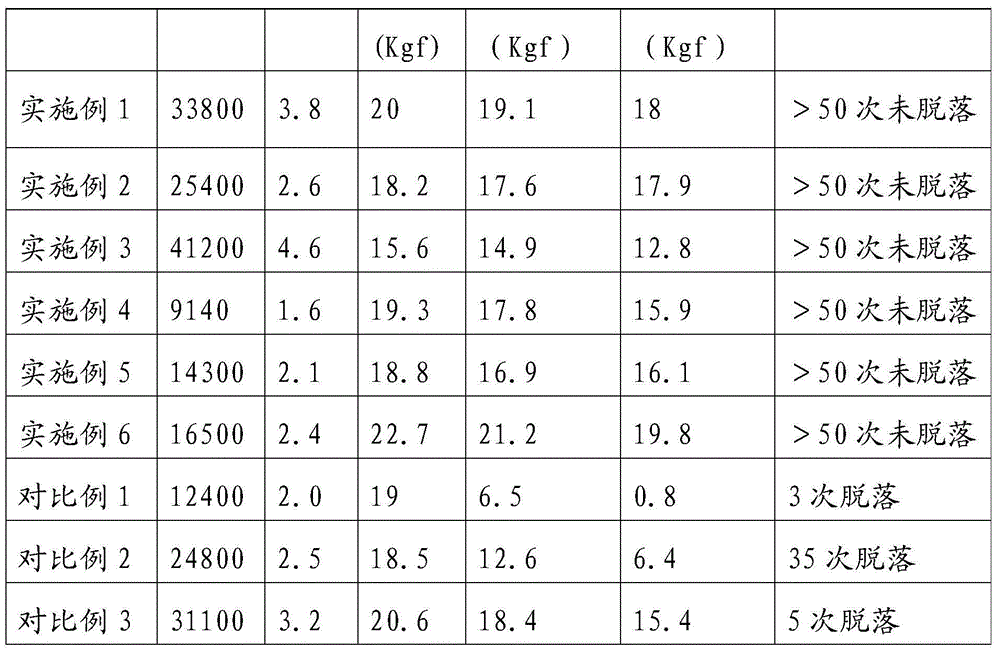

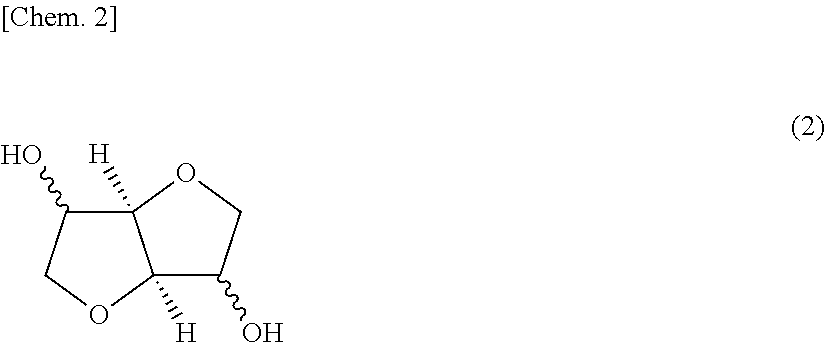

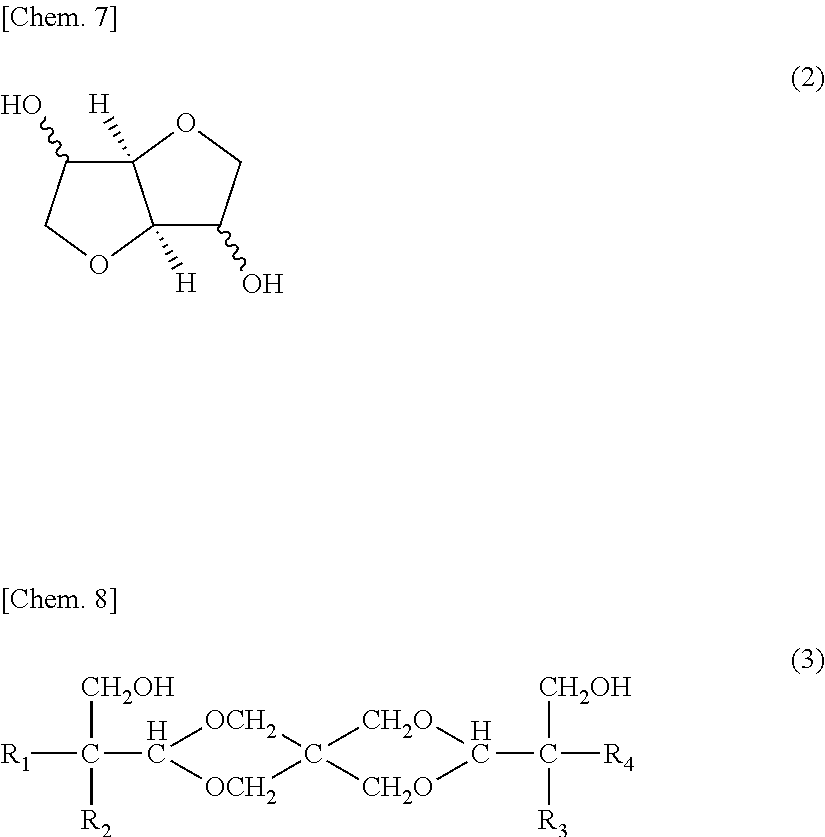

Polyester resin, method of producing the same, composition for molded article and molded article

ActiveUS20100174044A1Excellent impact resistanceImprove impact resistanceStructural unitDiethylene glycol

Provide are a novel polyester resin that can be used for producing a molded article excellent in impact resistance, and a method of producing the polyester resin. The polyester resin has structural units represented by the following general formulae (1) and (2), and contains the structural unit represented by the general formula (2) at a content of 50.1 mol % or more to 99.9 mol % or less with respect to the total of the structural units represented by the general formulae (1) and (2). The method of producing a polyester resin, includes copolymerizing a furandicarboxylic acid or an ester thereof with ethylene glycol and diethylene glycol. In the formula, R1 represents an aromatic hydrocarbon group which may be substituted, or an aliphatic hydrocarbon group which may be substituted.

Owner:CANON KK

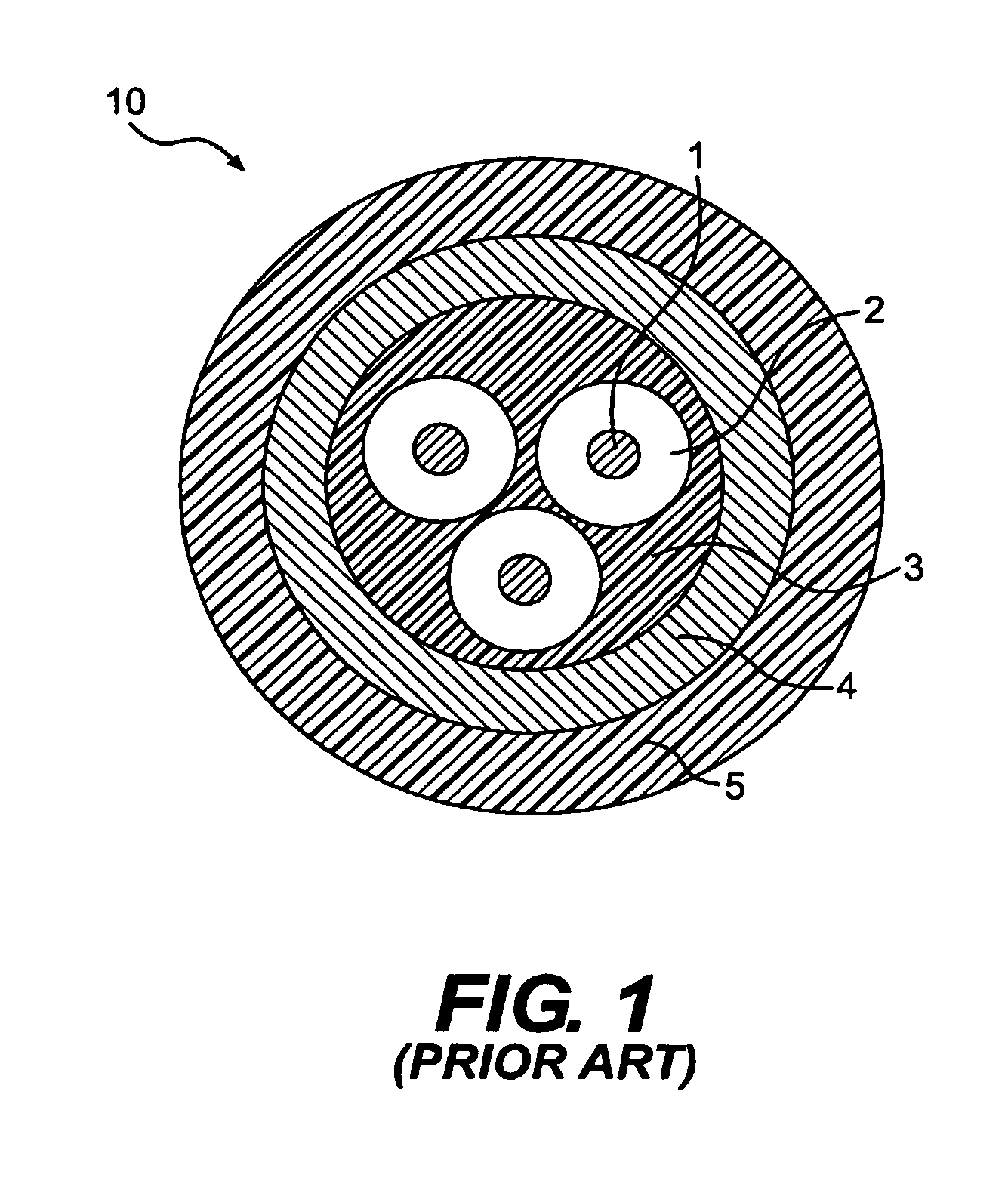

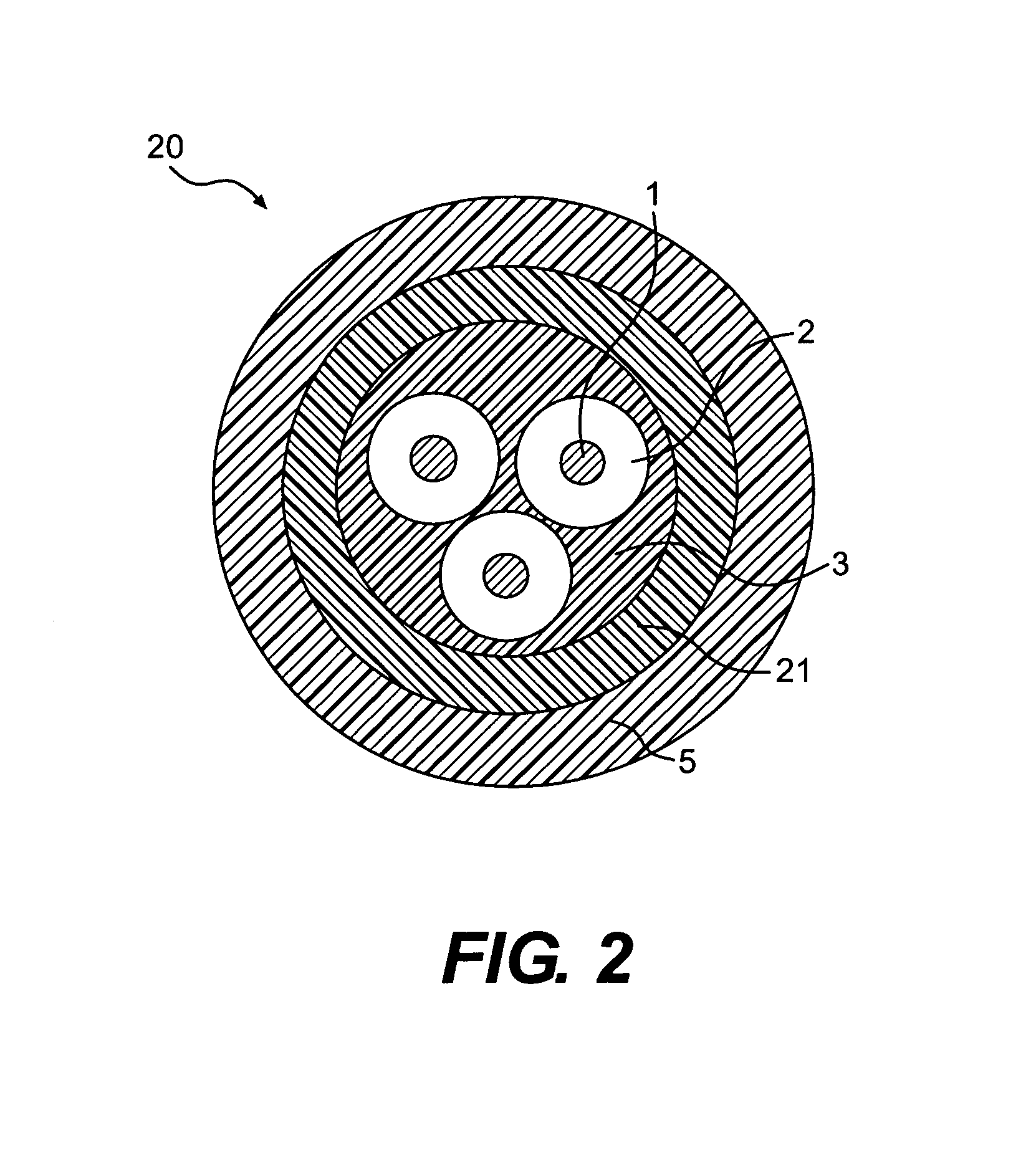

Impact-resistant self-extinguishing cable

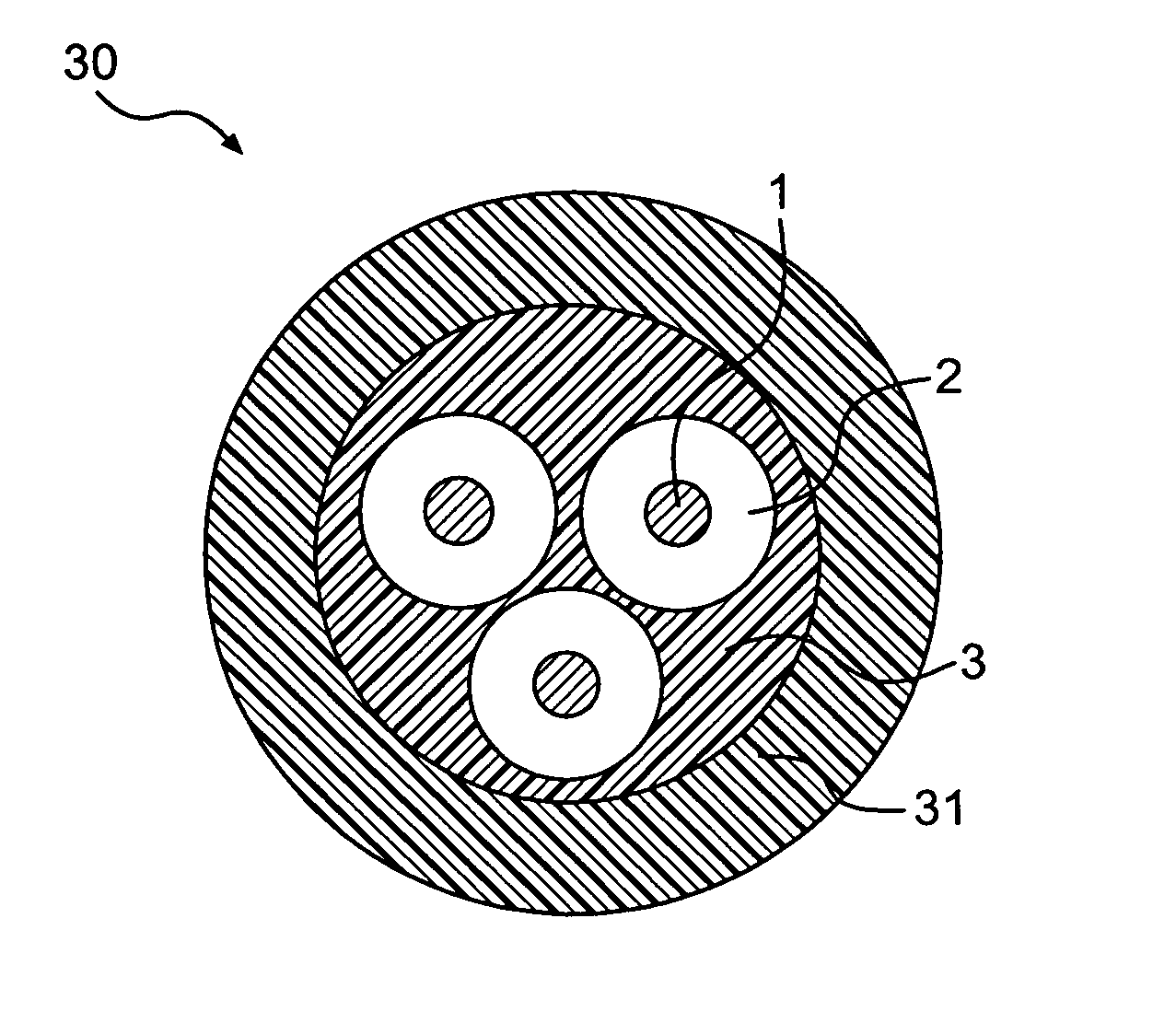

InactiveUS7049524B2High flame resistanceExcellent impact resistancePlastic/resin/waxes insulatorsInsulated cablesData transmissionEngineering

Self-extinguishing cable, in particular an electrical cable for low-voltage or medium-voltage power transmission or distribution of data transmission, having at least one conductor and at least one flame-retardant coating positioned externally to the conductor. The flame-retardant coating is produced from an expanded polymeric material which incorporates at least one intumescent agent.

Owner:PIRELLI CAVI E SISTEMI SPA +1

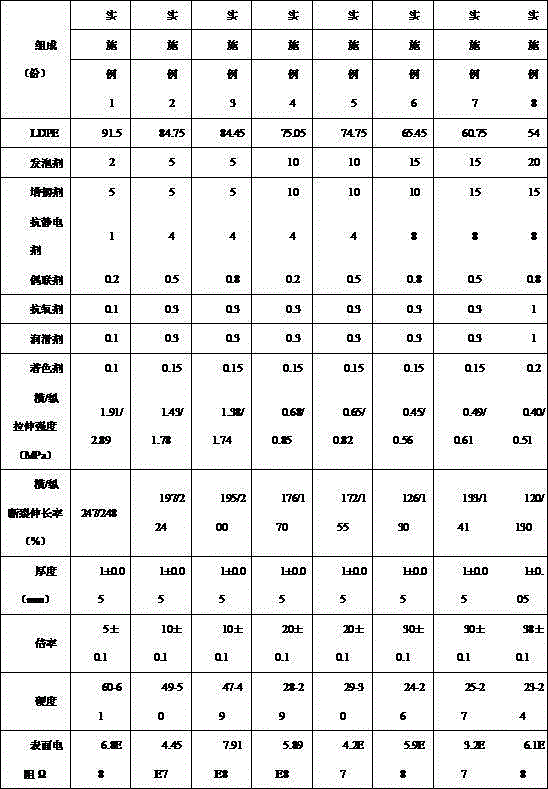

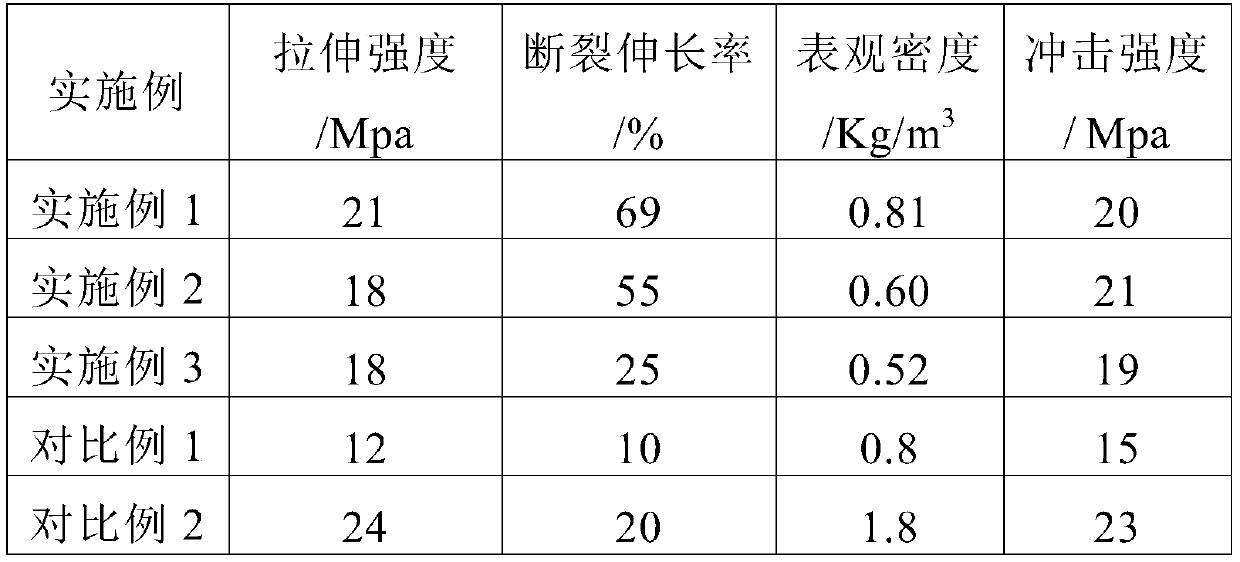

Colored high-performance and anti-static radiation cross-linked polyethylene foam material and preparation method thereof

InactiveCN104610632AExcellent impact resistanceGood anti-static performanceCross-linked polyethylenePolymer chemistry

The invention discloses a colored high-performance and anti-static radiation cross-linked polyethylene foam material and a preparation method thereof. Low-density polyethylene and a foaming agent are adopted, a toughening agent, an antistatic agent, a coupling agent, an antioxidant, a lubricating agent and a coloring agent are added for process optimizing treatment, a product has excellent impact resistance, excellent anti-static performance and a dazzling surface vision effect, changes the condition that most anti-static radiation cross-linked polyethylene foam cotton is black, fills up the blank, can completely meet the demand of the current market for the anti-static cross-linked polyethylene foam material, improves the market competitiveness, is important improvement of common anti-static foaming polyethylene materials and overcomes the defects of high cost, difficulty in process and low mechanical property of conventional anti-static polyethylene foam cotton.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

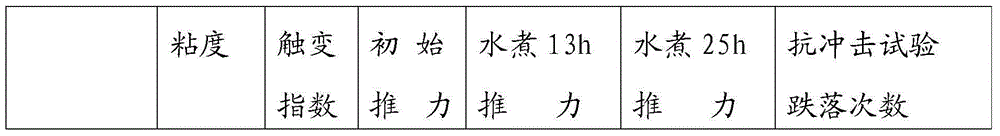

Polyether-type urethane acrylate UV-cured adhesive and preparation method thereof

ActiveCN104531041AGood flexibilityExcellent heat and humidity resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveShock resistance

The invention belongs to the technical field of adhesives and relates to a polyether-type urethane acrylate UV-cured adhesive and a preparation method thereof. The polyether-type urethane acrylate UV-cured adhesive comprises, by weight, 20-70 parts of polyether-type urethane acrylate, 10-40 parts of auxiliary resin, 5-20 parts of ethylene-acrylate rubber, 5-40 parts of an acrylate monomer, 5-35 parts of isobornyl acrylate, 1-7 parts of a photoinitiator, 1-5 parts of fumed silica and 0.5-2 parts of a silane coupling agent. Through use of the polyether-type urethane acrylate, auxiliary resin, ethylene-acrylate rubber and acrylate monomer, the polyether-type urethane acrylate UV-cured adhesive has excellent long-term high temperature resistance, low temperature resistance, high temperature and high humidity resistance, excellent shock resistance and a low cost and can be prepared by simple processes.

Owner:信泰永合(烟台)新材料有限公司

Polycarbonate resin compositions, and molded articles, films, plates, and injection-molded articles obtained therefrom

ActiveUS20130131271A1Excellent impact resistanceInferior in impact resistanceChemical recyclingPolycarbonateBuilding material

The invention is to provide a polycarbonate resin composition and a molded polycarbonate resin article which combine excellent transparency and strength and which are suitable for use in the field of building materials, electrical / electronic field, automotive field, field of optical parts, etc. The invention relates to a polycarbonate resin composition containing a polycarbonate resin and an impact strength modifier, the polycarbonate resin containing structural units which are derived from a dihydroxy compound that has the portion represented by the following general formula (1) as part of the structure thereof and having a glass transition temperature lower than 145° C. and a molded polycarbonate resin article obtained by molding the composition. The polycarbonate resin composition gives a molded object having a thickness of 3 mm which has a total light transmittance of 60% or higher.CH2—O (1)

Owner:MITSUBISHI CHEM CORP

High-strength and high-toughness polyvinyl chloride injection molded composition and preparation method thereof

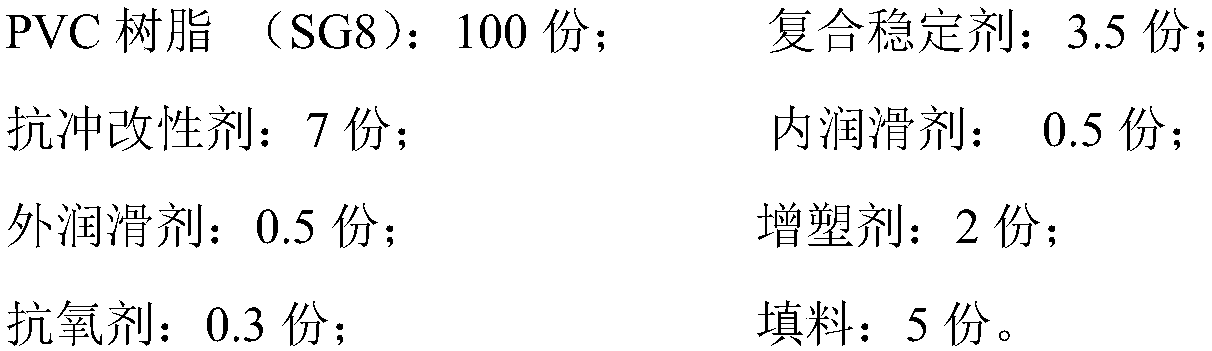

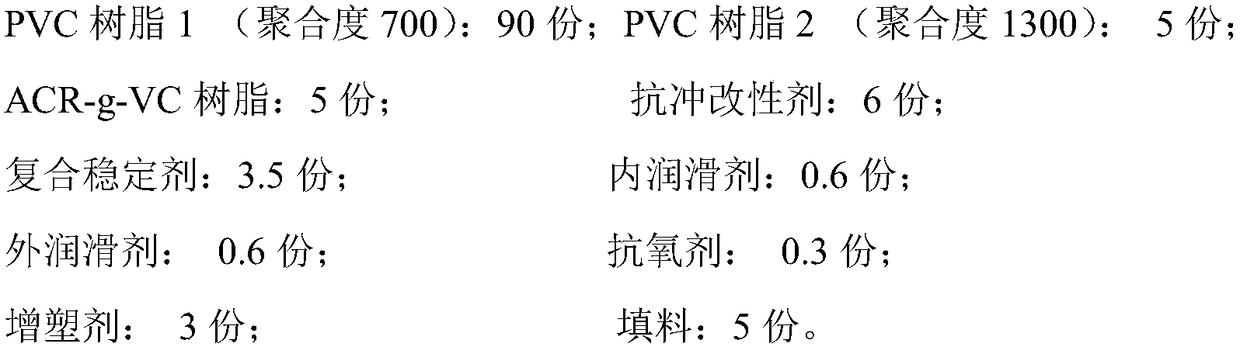

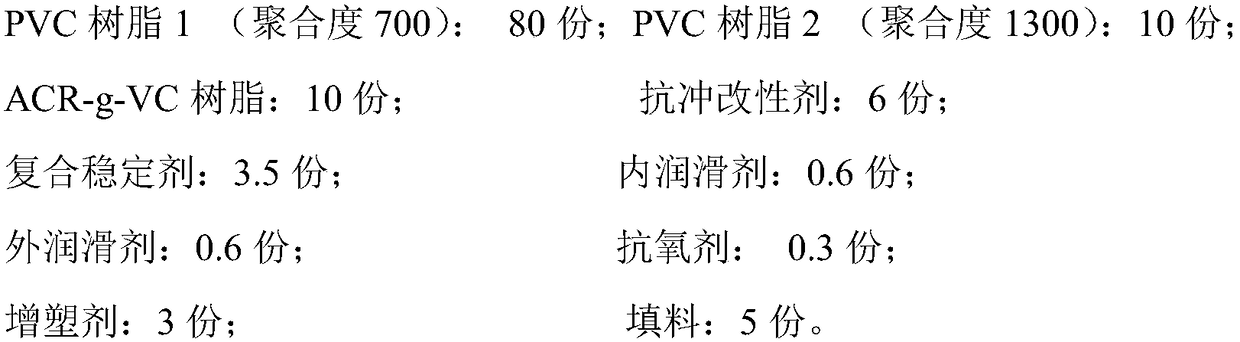

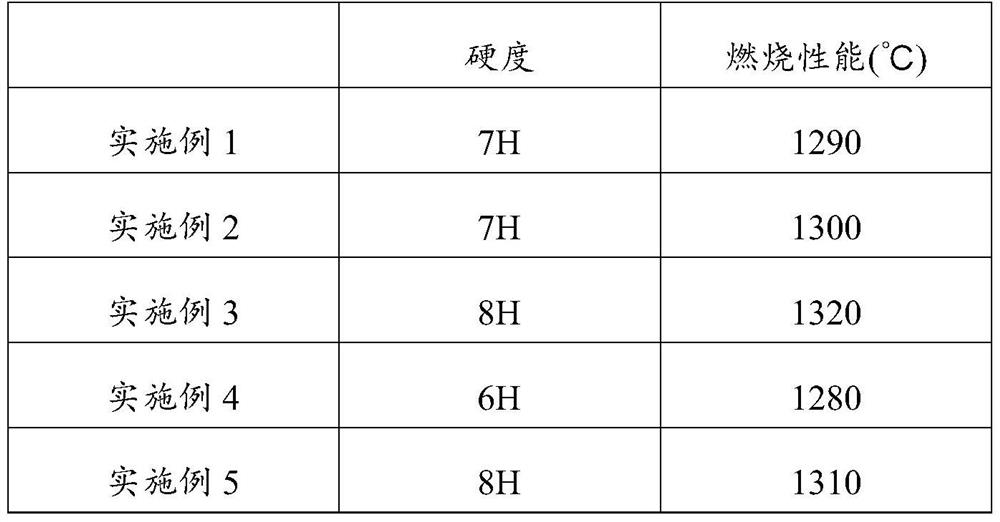

The invention discloses a high-strength and high-toughness polyvinyl chloride injection molded composition and a preparation method thereof. The composition comprises, by weight, 50-90 parts of PVC (polyvinyl chloride) resin 1, 5-20 parts of PVC resin 2, 5-40 parts of ACR-g-VC (acrylic graft vinyl chloride) resin, 3-10 parts of parts of impact modifier, 4-6 parts of compound stabilizer, 0.5-2 parts of internal lubricant, 0.5-1.2 parts of external lubricant, 1-5 parts of fillers, 1-3 parts of plasticizer and 0.1-1 part of antioxygen. The preparation method includes: weighing the ingredients according to a formula about weight ratios, placing in a high-speed mixer, mixing to obtain a polyvinyl chloride mixture, adding the polyvinyl chloride mixture into a tapered double-screw extruder, melting, extruding, pelletizing and packaging. Compared with a product prepared according to a formula adopting normal SG8 type PVC resin, the high-strength and high-toughness polyvinyl chloride injectionmolded composition has the advantages that plasticizing time can be shortened by more than 20%, and impact strength can be enhanced by more than 10 times.

Owner:YIBIN TIANYUAN GRP CO LTD

Block copolymer composition

InactiveUS6939906B2Less occurrenceExcellent impact resistanceFilm/foil adhesivesSpecial tyresIsoprenePolystyrene

Disclosed is a block copolymer composition comprising a block copolymer (I) comprising at least two polymer blocks (each polymer block (S) comprising vinyl aromatic hydrocarbon monomer units) and at least one polymer block (B) comprising isoprene monomer units and 1,3-butadiene monomer units, and a polystyrene resin (II), wherein, in the block copolymer (I), the amount of the vinyl aromatic hydrocarbon monomer units, the total amount of the isoprene monomer units and the 1,3-butadiene monomer units, and the isoprene monomer unit / 1,3-butadiene monomer unit weight ratio are within specific range, wherein the block copolymer (I) has a vinyl aromatic hydrocarbon block ratio (BL) within a specific range, and wherein the block copolymer (I) and the polystyrene resin (II) satisfy a relationship represented by the following formula (1):15+0.25BL≦Wa≦35+0.25BL (1)wherein BL represents the block ratio of the copolymer (I), and Wa represents the weight percentage, based on the total weight of the copolymer (I) and the resin (II), of the copolymer (I).

Owner:ASAHI KASEI KOGYO KK

Water-based high-temperature-resistant anti-corrosion composition

PendingCN112831252AImprove anti-corrosion performanceImprove performanceFireproof paintsAntifouling/underwater paintsAdhesive cementMischmetal

The invention discloses a water-based high-temperature-resistant anti-corrosion composition which comprises the following components in parts by weight: 45-90 parts of a polymer matrix, 15-70 parts of compact filling powder, 0.5-4 parts of rare earth metal, 5-40 parts of a dispersing agent, 2-25 parts of a flatting agent and 10-30 parts of an inorganic adhesive. The water-based high-temperature-resistant anti-corrosion composition is good in anti-corrosion performance, does not re-rust in a high-salt environment and particularly has more outstanding performance in corrosion environments such as salt mist and acid rain, the ultraviolet aging resistance is 3-5 times that of a traditional coating, the salt mist test can reach 2400 h or above, and the service life of the water-based high-temperature-resistant anti-corrosion composition meets the requirement of Centennial Project. The water-based high-temperature-resistant anti-corrosion composition disclosed by the invention is high-temperature-resistant and non-combustible, is an A-grade fireproof non-combustible material, has ultrahigh surface hardness which can reach 4-9H, particularly outstanding scratch resistance and good impact resistance, and can meet the requirements of various special environments.

Owner:烟台万华新材料技术有限公司

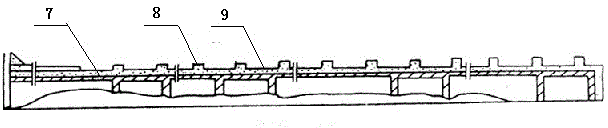

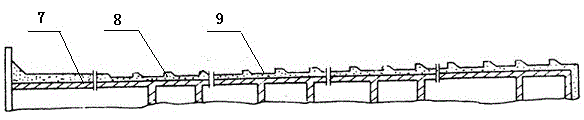

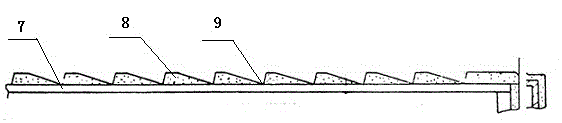

Bed-top of concentrating table

The invention relates to parts for gravity concentration equipment, in particular to a bed-top of a concentrating table. The bed-top is of novel material. By modifying the structure and material of the bed-top, the grade of finished ores is greatly increased, and the service life of the bed-top is greatly prolonged. The bed-top comprises a face plate, an ore feeding trough and a water feeding rough; the bed-top is characterized in that the face plate is provided with rifle strips, at least two deep and shallow grooves are provided between every two rifle strips, the section of the deep and shallow grooves is trapezoidal, and the ore feeding trough and the water feeding trough are made of environmental material. The bed-top is applicable to concentration of fine materials and is widely applicable to concentration of tin, tungsten, gold and silver, lead, zinc, titanium, iron, manganese, ferrotitanium, coal and the like.

Owner:江西省浩燃冶金设备有限责任公司

Production technology of polypropylene building template

InactiveCN103012958AExcellent impact resistanceExcellent deformation resistanceForming/stuttering elementsConstruction engineeringProcess engineering

The invention provides a production technology of a polypropylene building template, which is the technology for producing the building template by adopting waste plastics as the raw materials. The production technology comprises the steps of pretreating the raw materials, mixing the materials, and carrying out extrusion molding. The raw materials are treated based on a certain ratio and prepared into the product building template under a certain condition. The product building template has the characteristics that the construction quality is high, the building template can be recycled for a plurality of times, the cost is reduced, the benefit is increased, the energy conservation and environment protection are realized, and the residues can be recycled; and the product building template has a large market demand and wide prospect, and is an excellent substitute for steel templates, bamboo plywood and wood plywood.

Owner:HUNAN FENGSHUO TECH

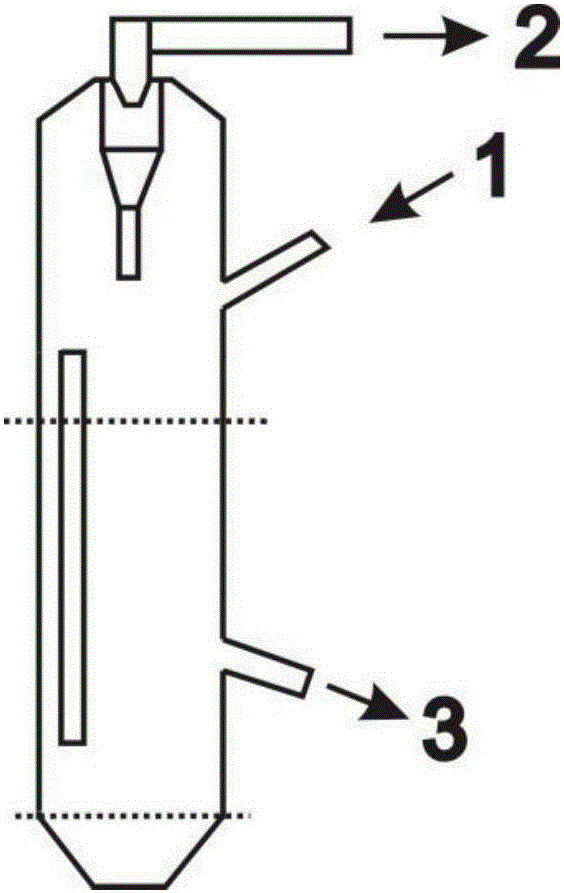

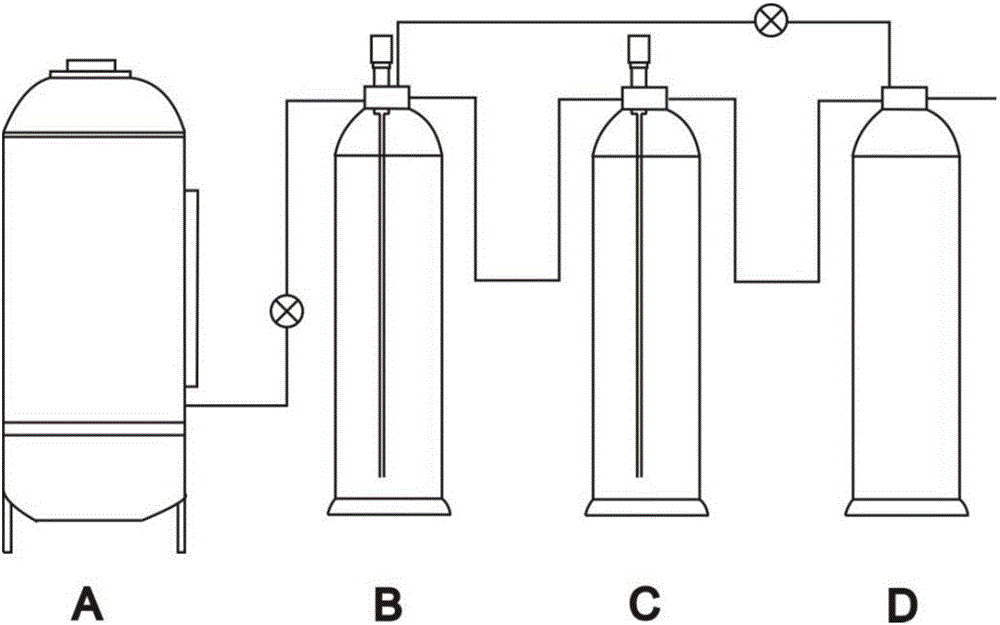

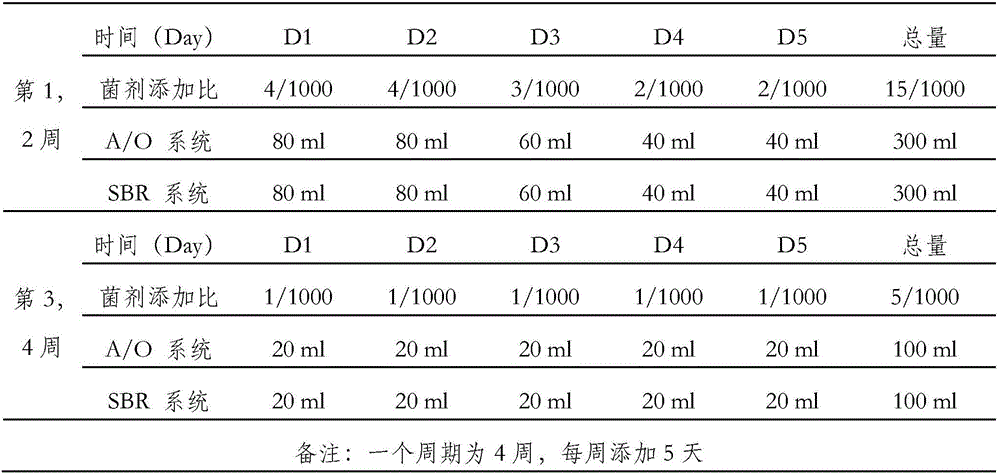

Microbial agent and preparation method and application thereof

ActiveCN105838653AExcellent impact resistanceEasy and efficient storage, transportation and releaseFungiBacteriaPathogenChemistry

The invention provides a microbial agent and a preparation method and application thereof. The microbial agent comprises the ingredients: Microbacterium sp. CICC 23615, Pseudomonas denitrificans CCTCC M91003, Deinococcus sp. CICC 10697, Bacillus sp. CICC 21937, Pichia pastoris ACCC 21021, and Aspergilus flavus CGMCC 3.2823. The microbial agent provided herein can remove ammonia and nitrogen in wastewater effectively in a biological treatment stage, up to about 97% in removal rate; in early startup stage of a system or in case of unstable operation, the microbial agent has excellent impact resistance. The microbial agent is free of pathogens, heavy metals and toxic and harmful chemicals, and solid products of the microbial agent are nontoxic and nonirritating.

Owner:ZHEJIANG HUAQINGYUAN BIOTECH CO LTD

Micro-foaming full-biodegrade polymer sheet material and preparation method thereof

The invention provides a micro-foaming full-biodegrade polymer sheet material and a preparation method thereof. The micro-foaming full-biodegrade polymer sheet material comprises, by mass, 100 parts of a full-biodegrade polymer, 3-12 parts of microsphere foaming agent master batches, 10-50 parts of a biology-based filler and 3-8 parts of glycerinum. The microsphere foaming agent master batches areprepared from, by mass, 100 parts of a polymer capable of being processed through fusion at a low temperature, 50-100 parts of a microsphere foaming agent and 5-10 parts of a compatilizer. The full-biodegrade sheet material with good mechanical properties such as a high foaming rate, low destiny, good toughness and high impact resistance can be obtained and applied to manufacturing of fast-movingconsumer goods such as food containers and has high application value and good application prospects.

Owner:江西玉源环保科技有限公司

Case-hardened steel article

ActiveCN107406943AExcellent impact resistanceReduce the amount of materialSolid state diffusion coatingGearing elementsCase hardeningHardened steel

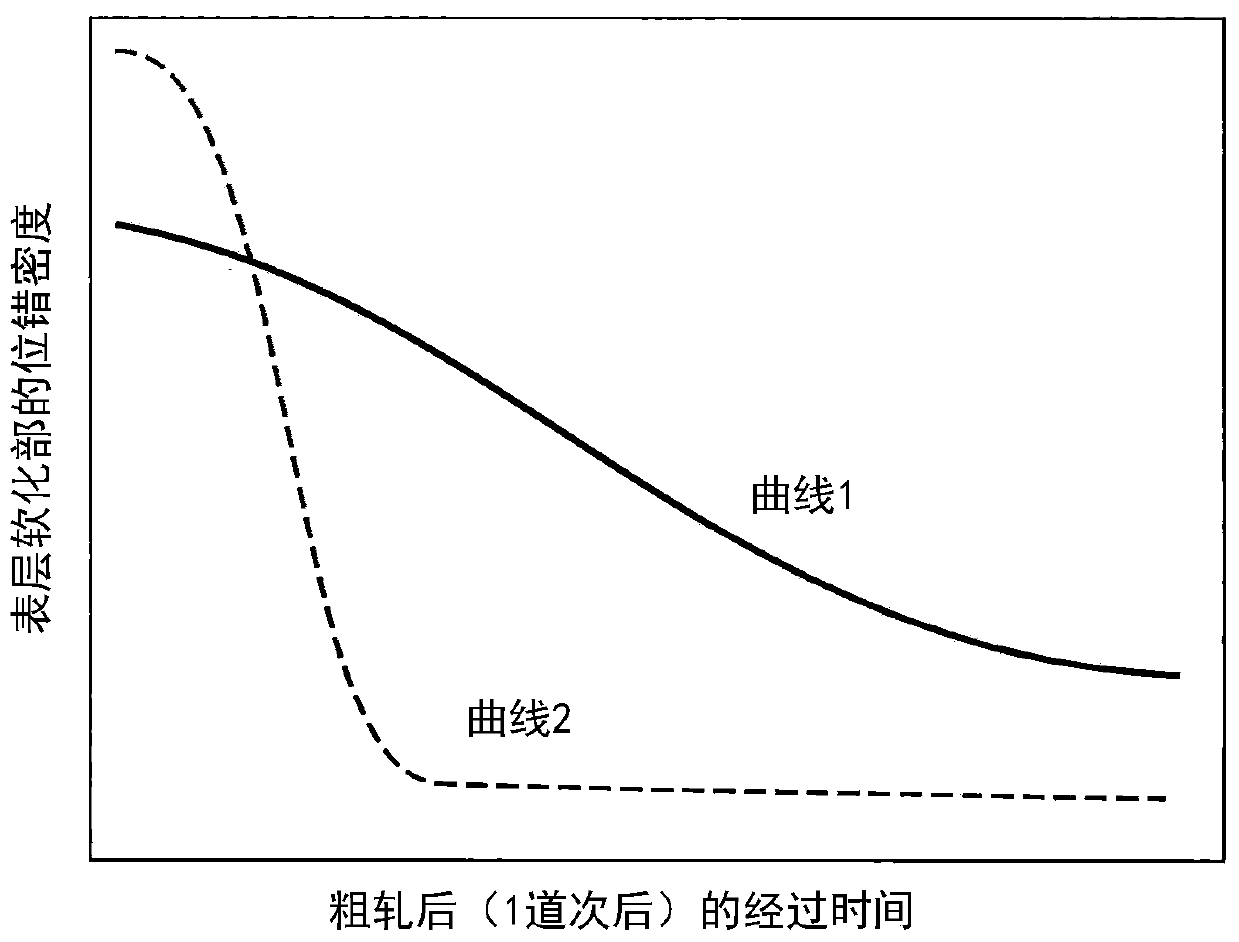

This case-hardened steel article is provided with a base metal and a carburizing layer, wherein the base metal has a predetermined chemical composition. The number density of Ti-based precipitates having a circle-equivalent diameter of 5-50 nm in a surface layer region from the surface to a depth of 0.1 mm is at least 0.5 precipitates per mu m2. The number density of AlN having a circle-equivalent diameter of 50 nm to 100 nm in said surface layer region does not exceed 0.5 AlN per mu m2.

Owner:NIPPON STEEL CORP

Flame Retardant Resin Composition and Molded Article

ActiveUS20070208114A1Excellent impact resistanceImprove impact resistanceSpecial tyresWater soluble polymersChemistry

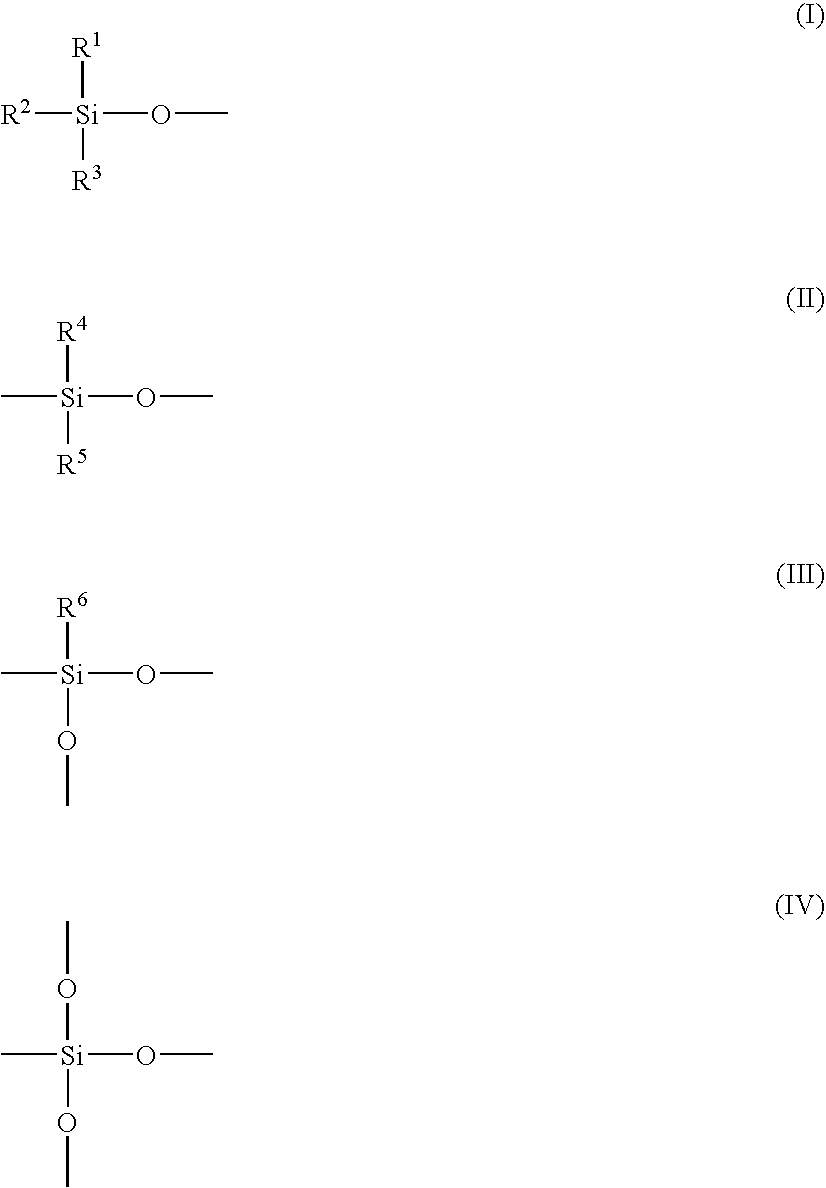

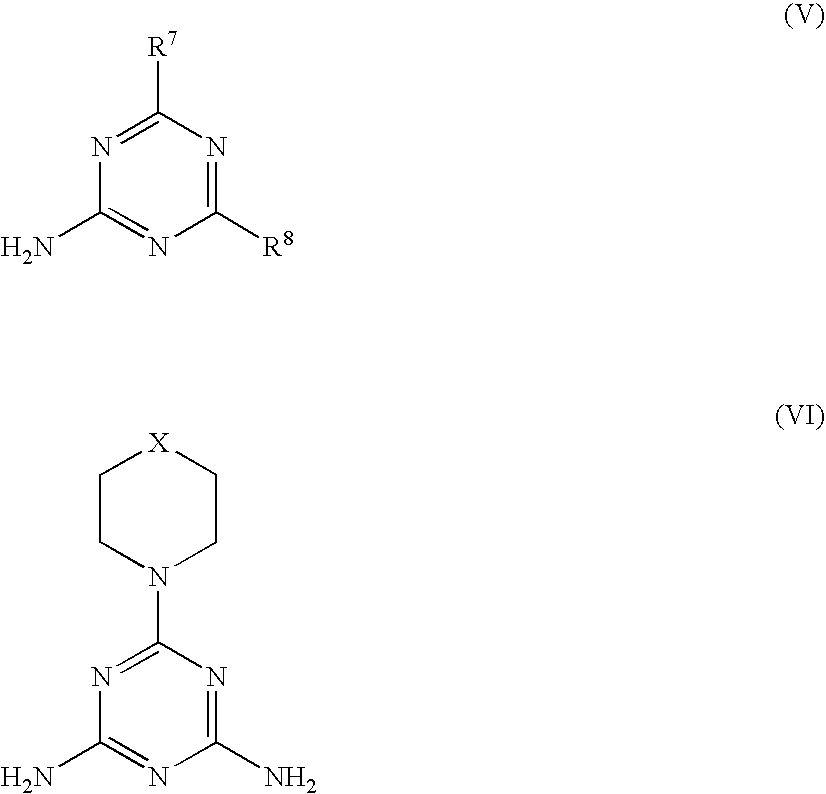

The present invention provides a flame retardant resin composition comprising the following component (A), component (B), component (C) and component (D), in which 0.1 to 50 parts by mass of the component (B), 0.001 to 30 parts by mass of the component (C) and 0.1 to 50 parts by mass of the component (D) are blended with 100 parts by mass of the component (A). Component (A): A rubber-modified styrene resin obtained by (co)polymerizing an aromatic vinyl compound or an aromatic vinyl compound and another vinyl monomer copolymerizable with the aromatic vinyl compound in a presence of a rubber-like polymer; Component (B): A thermally expandable graphite; Component (C): A layered clay material modified by a water-soluble polymer; and Component (D): At least one selected from the group consisting of silicone compounds, boron oxides, aminotriazine sulfate compounds and aminotriazine compounds. The resin composition is excellent in flame retardance and impact resistance.

Owner:LG CHEM LTD +1

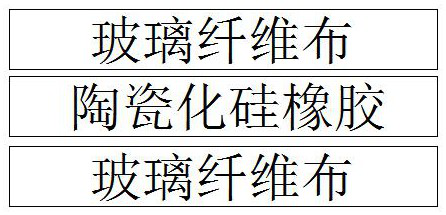

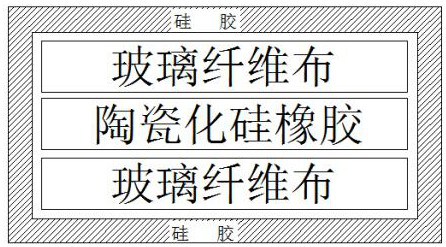

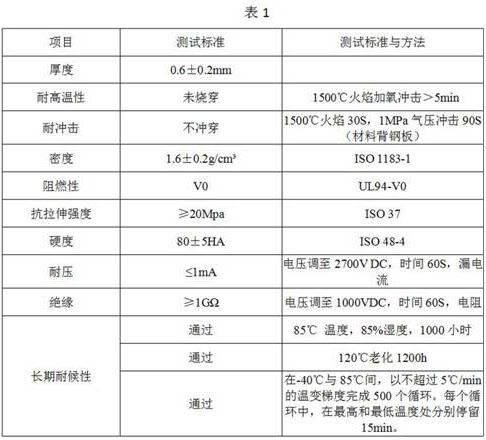

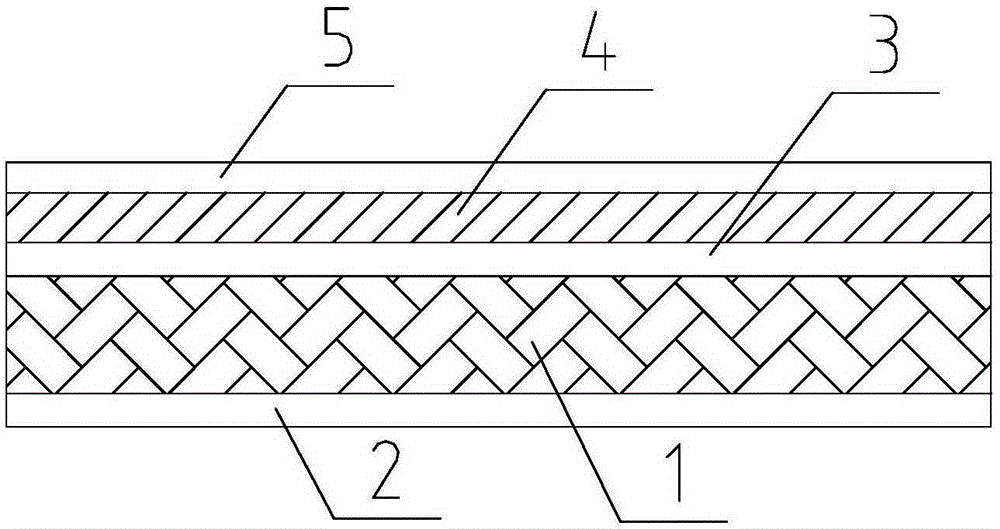

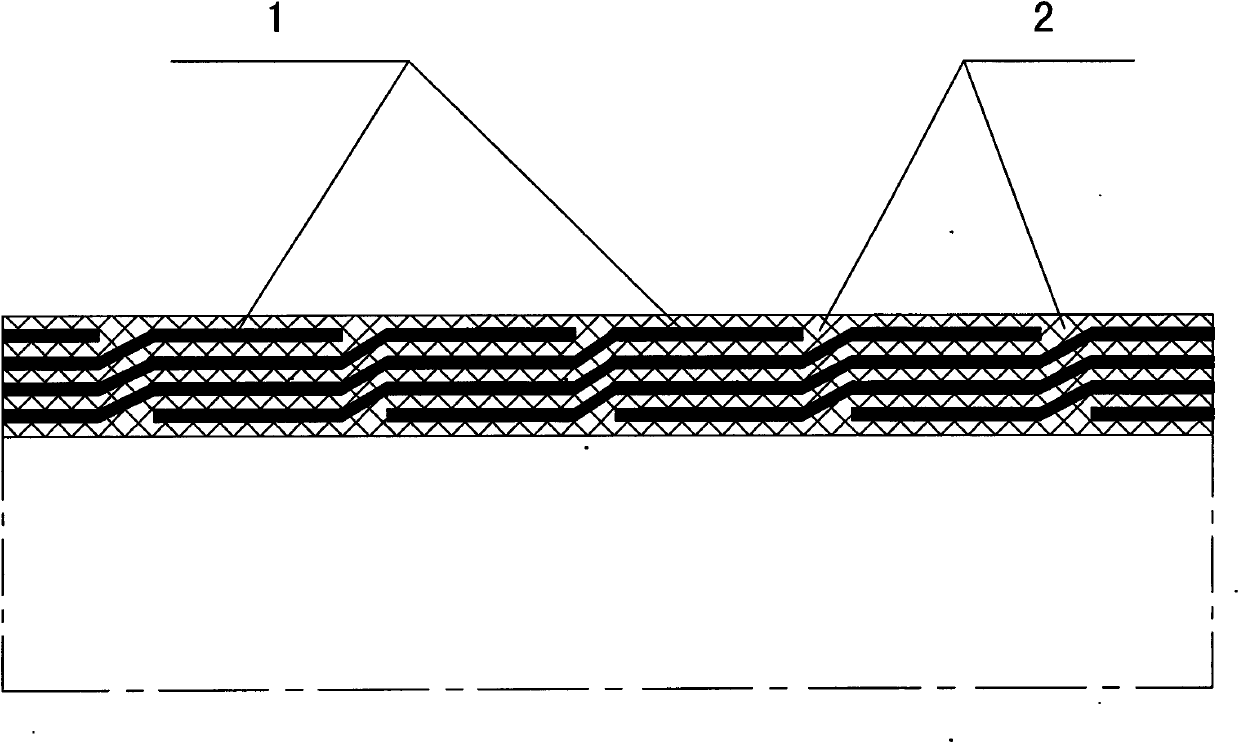

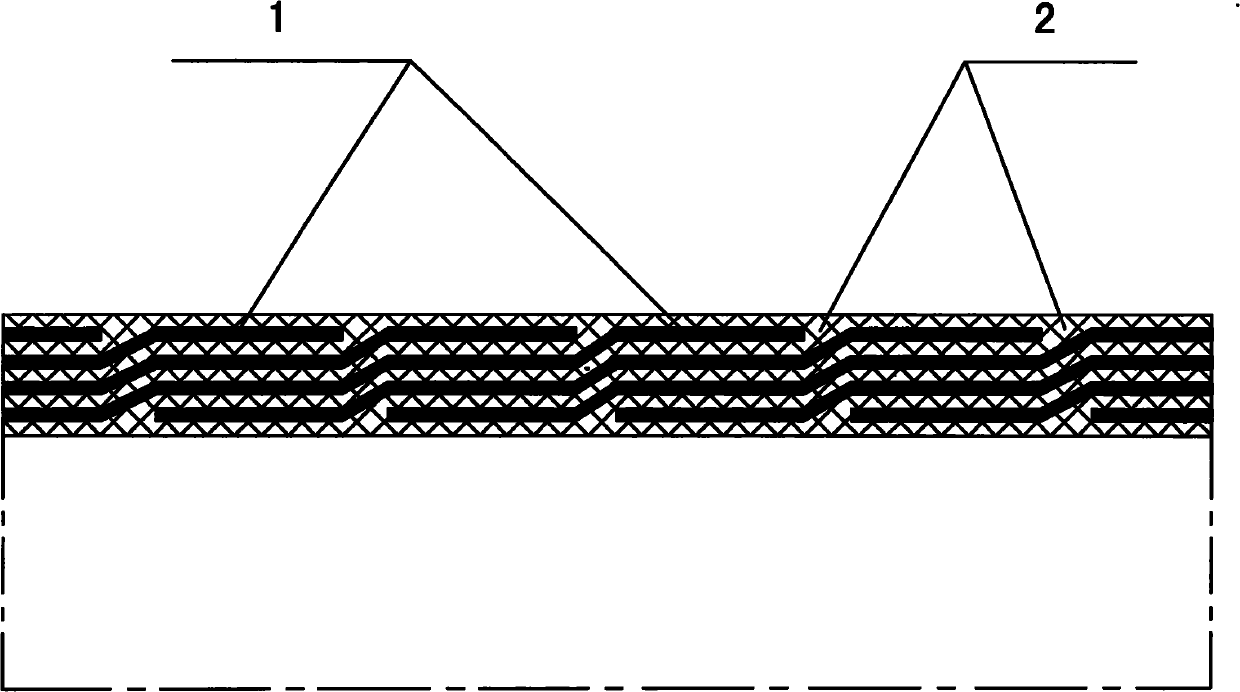

Multi-layer fireproof material for battery and manufacturing method of multi-layer fireproof material

InactiveCN112959759AAvoid shockImprove impact resistanceLamination ancillary operationsLaminationGlass fiberElectrical battery

The invention discloses a multi-layer fireproof material for a battery. The multi-layer fireproof material comprises a fireproof material body, wherein the fireproof material body is composed of two layers of glass fiber cloth and a layer of ceramic silicone rubber, the two layers of glass fiber cloth are attached to the upper surface and the lower surface of the ceramic silicone rubber respectively, and the outer surface of the fireproof material body is wrapped with silica gel. Compared with an existing fireproof material between batteries, the multi-layer structure material provided by the invention has higher impact resistance, and the impact resistance time and the impact resistance frequency of the multi-layer structure material are obviously better than the impact resistance time and the impact resistance of the existing fireproof material; and the produced material is lighter and thinner, and the silica gel wrapping the outer surface of the fireproof material body can quickly conduct heat on the surfaces of the batteries to the outside, so the heat dissipation efficiency of the battery is improved, and the thermal runaway probability of the battery is reduced.

Owner:浙江葆润应用材料有限公司

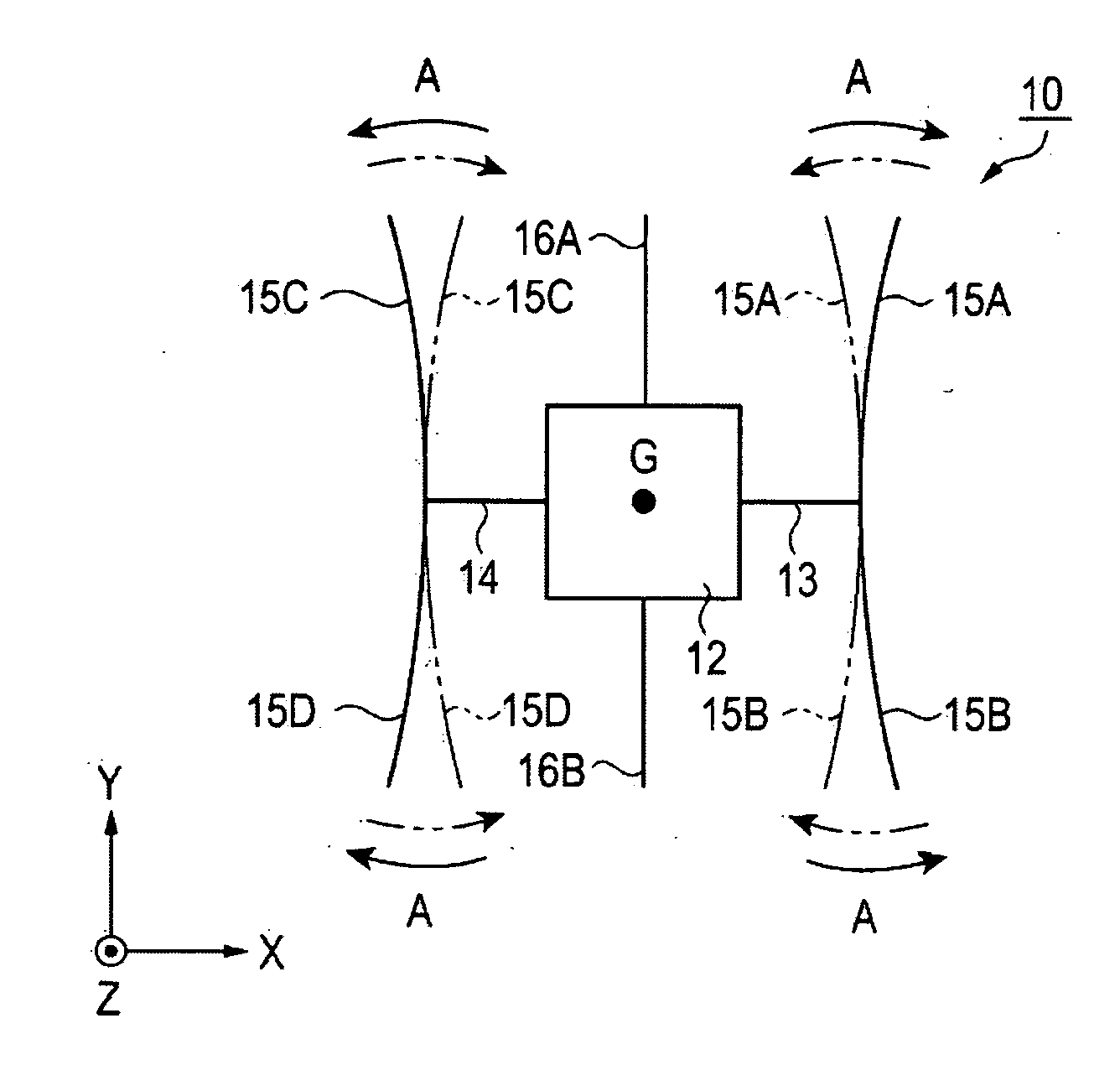

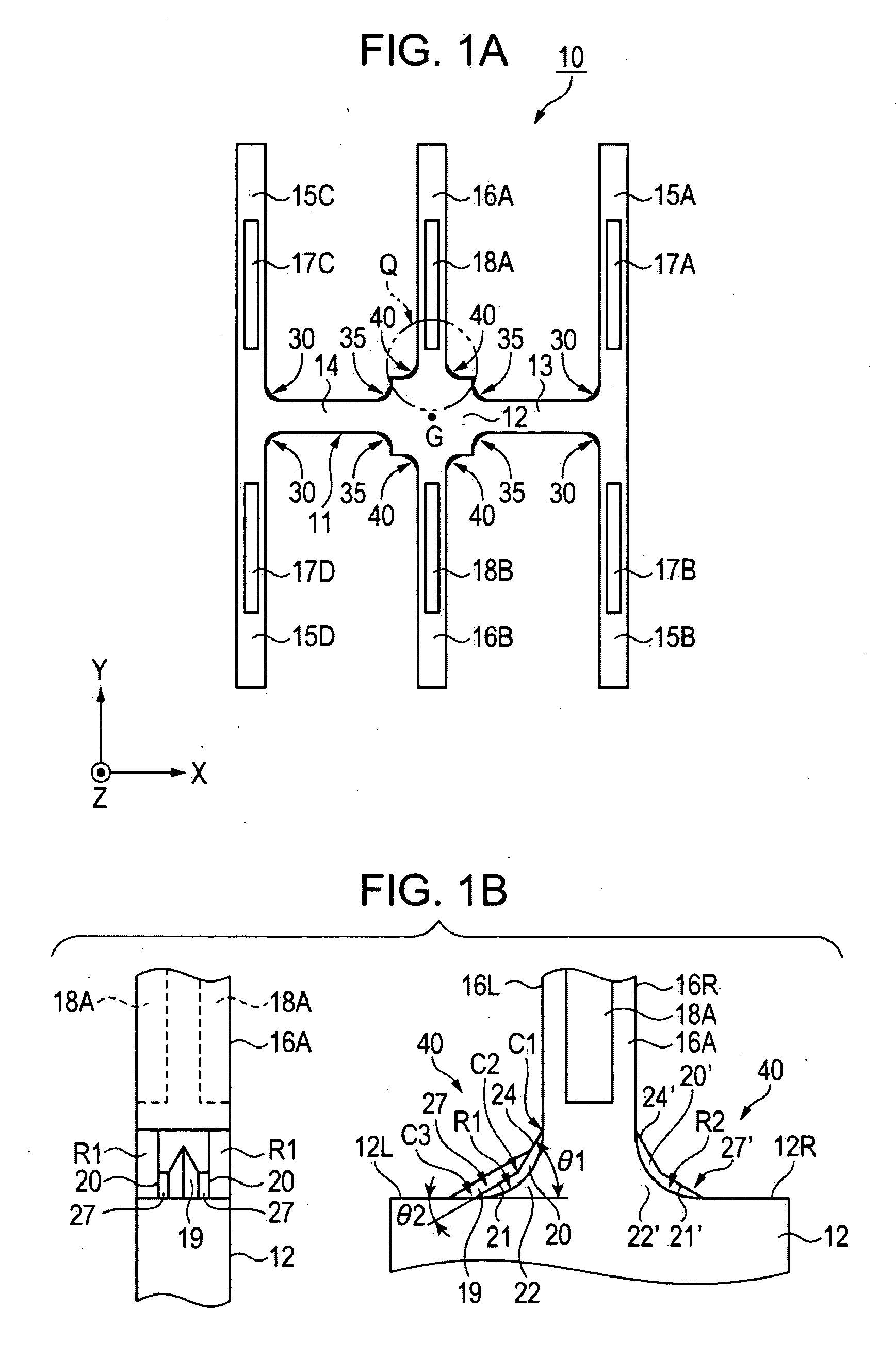

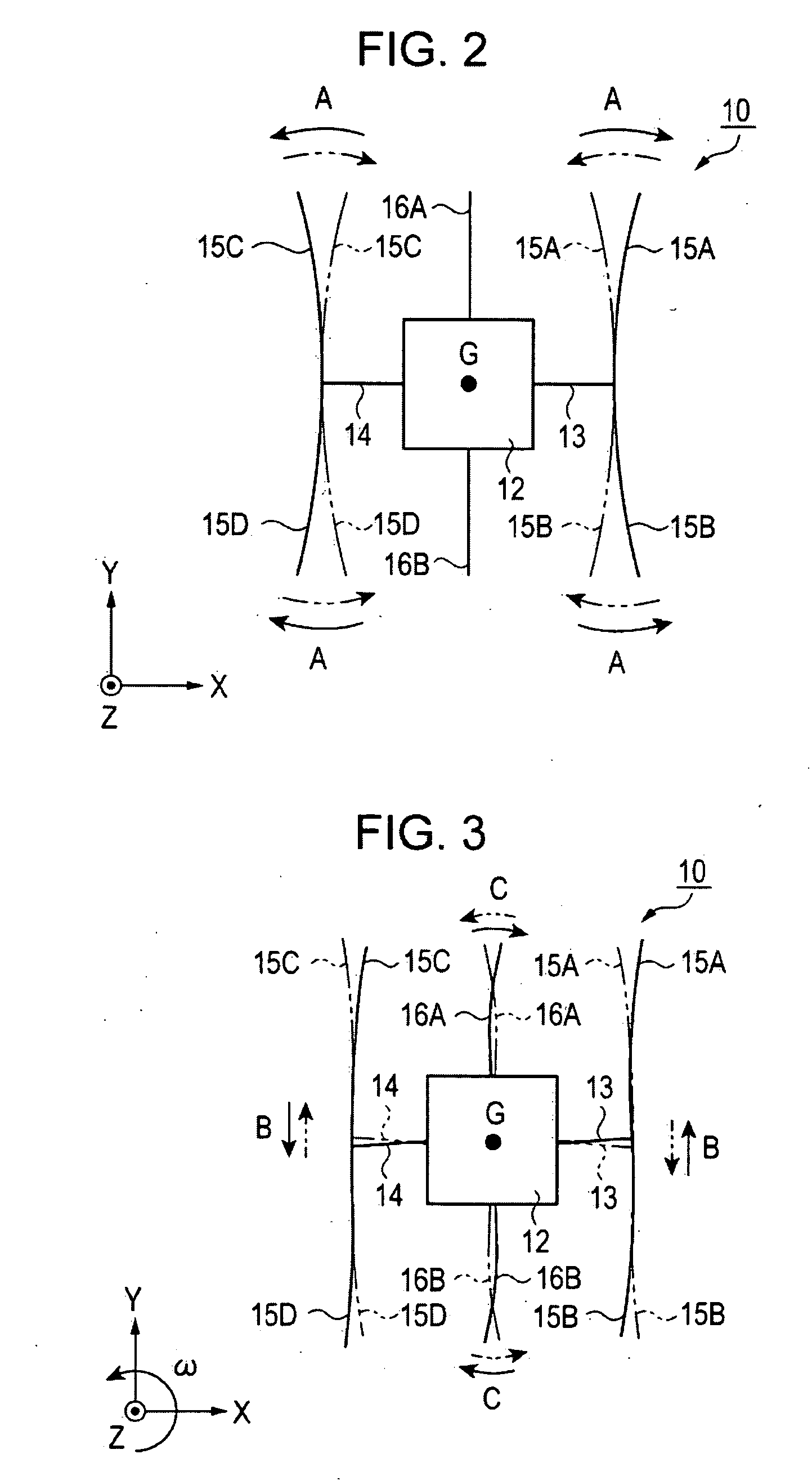

Gyro vibration piece, gyro sensor, and method of manufacturing gyro vibration piece

InactiveUS20060219007A1Excellent impact resistanceImprove impact resistancePiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesEngineeringAngular velocity

A gyro vibration piece detecting an angular velocity includes: a supporting part; a driving part connected to the supporting part and performing vibration; a detection part connected through the driving part and the supporting part and detecting detection vibration generated by Coriolis force generated by the rotation of the driving part; and a connection part including a connection portion having a plurality of steps formed between a side of a width direction of the driving part or a side of a width direction of the detection part and a side of another portion connected to the driving part or the detection part, which are continuously connected. The connection part has a first end portion which is located on an innermost side of the connection part among the connection portion and has a circular arc shaped wall portion that connects a side of a width direction of the driving part or a side of a width direction of the detection part to a side of another portion connected to the driving part or the detection part, and a bottom surface having a predetermined depth.

Owner:SEIKO EPSON CORP

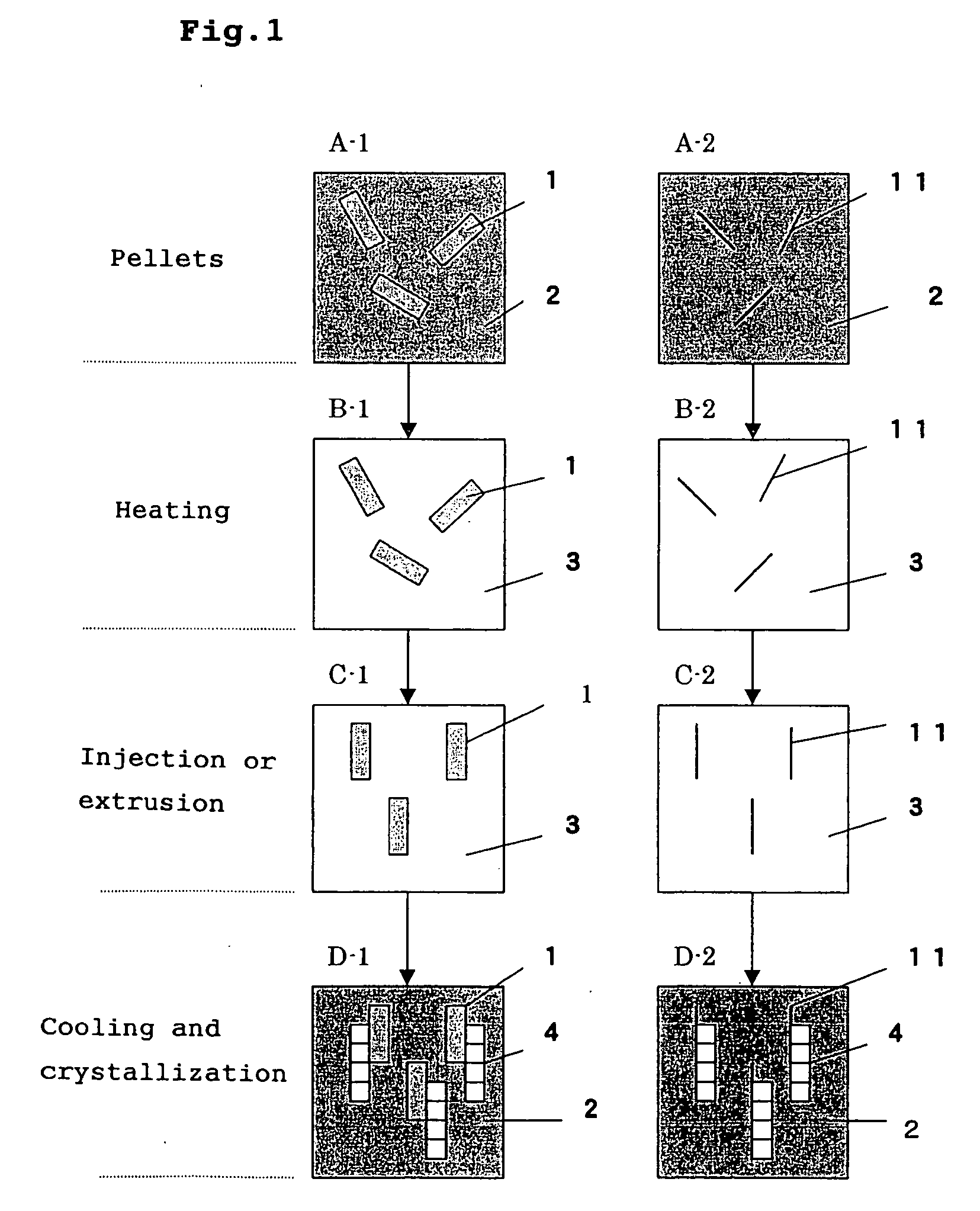

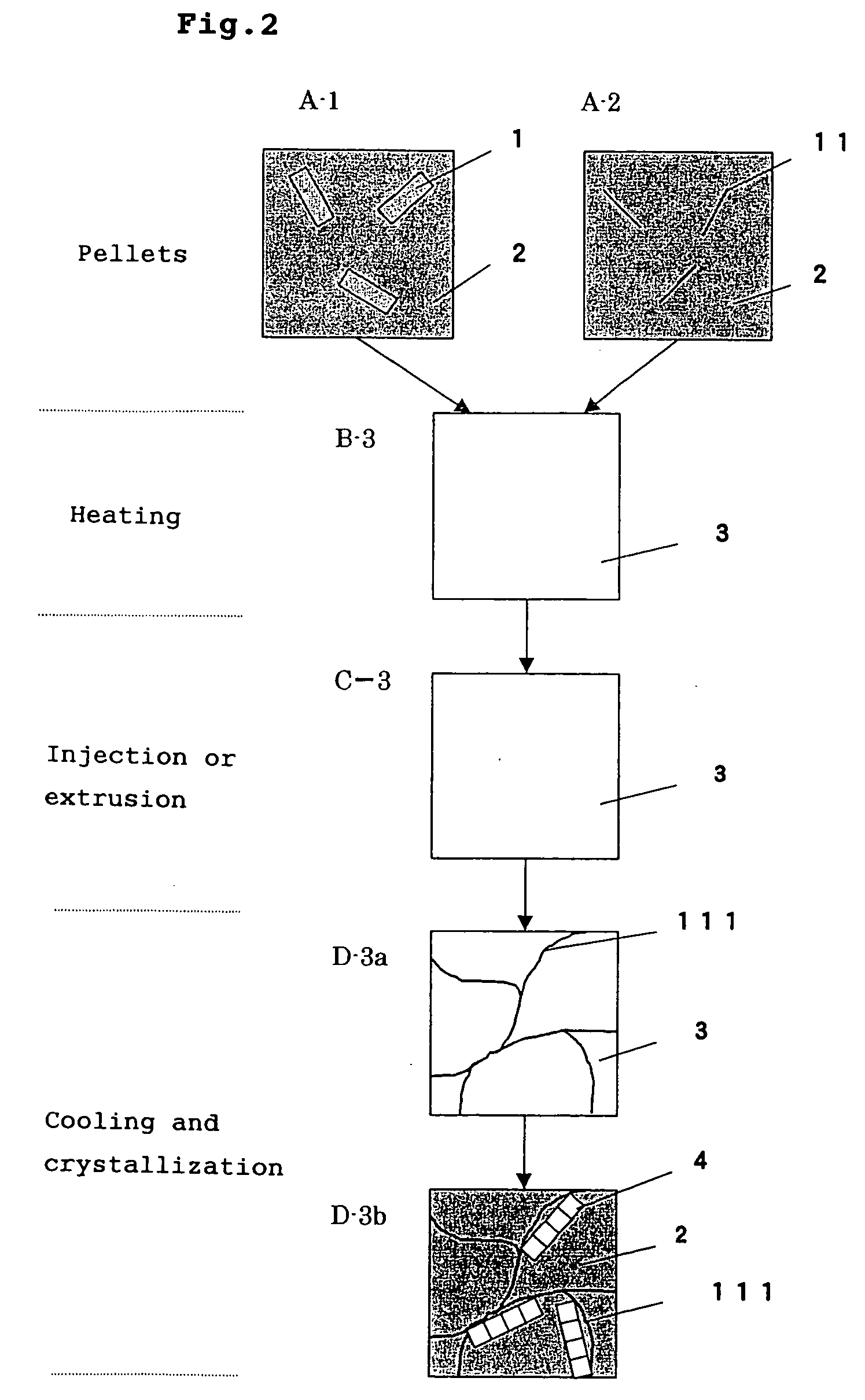

Polypropylene-based resin molded article and process for producing the same

InactiveUS20060091581A1Excellent impact resistanceHigh izod impact strengthArtifical filament manufacturePolypropyleneChemistry

The present invention provides a crystalline polypropylene-based resin molded article having an excellent impact resistance, in particular a remarkably high Izod impact strength, and a process for producing the molded article. A polypropylene-based resin molded article with an excellent impact resistance in which the β crystals of the polypropylene-based resin are unoriented can be produced by a process comprising the steps of: adding 0.01 to 0.1 parts by weight of at least one amide compound to 100 parts by weight of a polypropylene-based resin; kneading the resulting mixture at a temperature not lower than the dissolution temperature of the amide compound in the molten polypropylene-based resin until the compound dissolves in the molten polypropylene-based resin; and injecting and / or extruding the resulting melt in such a state that the amide compound has dissolved in the molten polypropylene-based resin.

Owner:NEW JAPAN CHEM CO

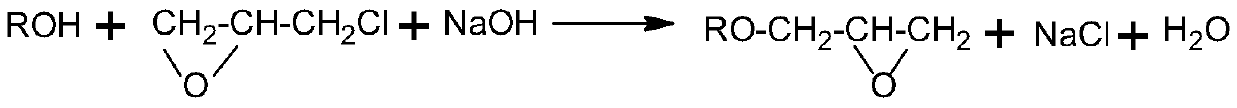

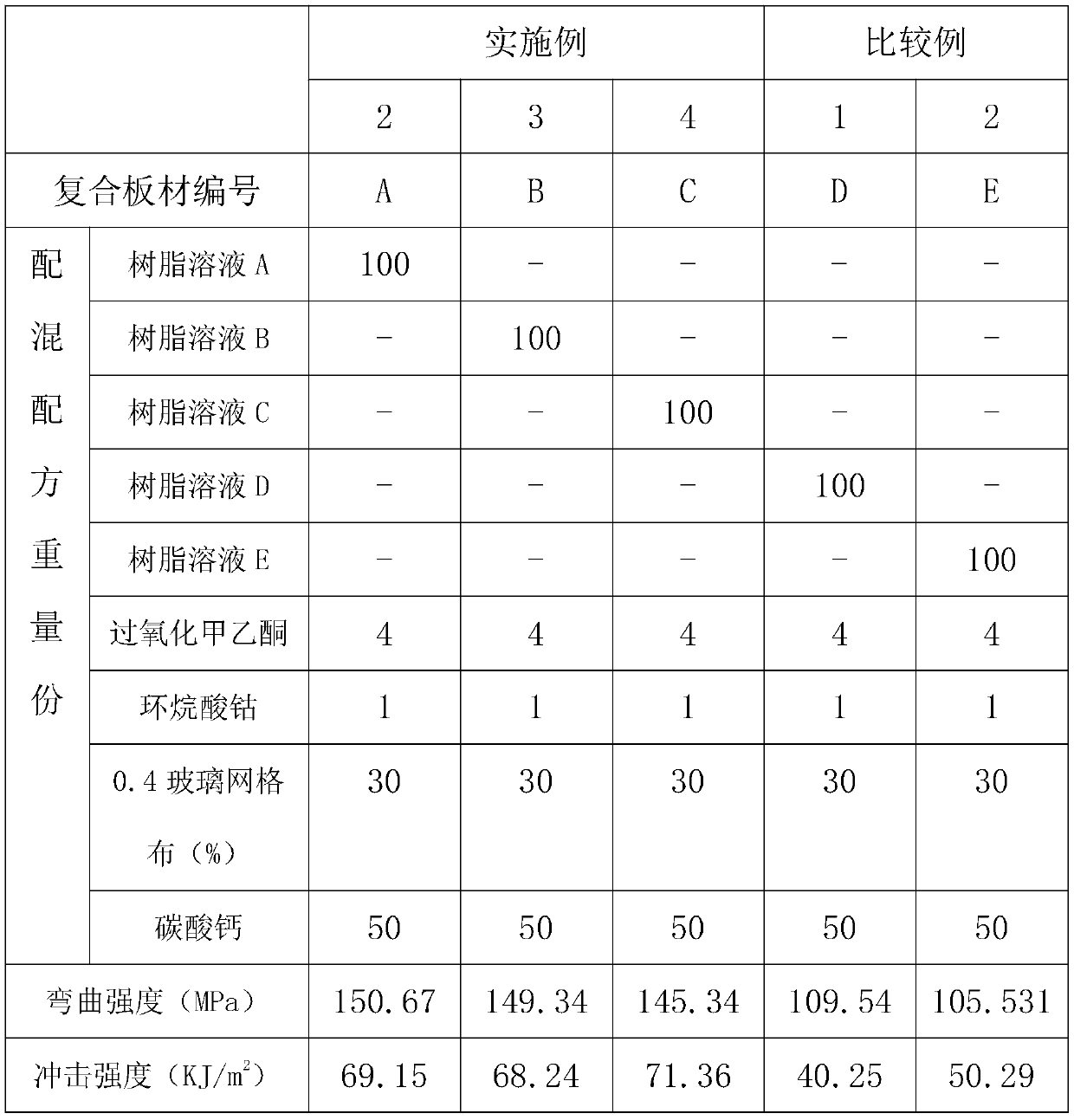

Method for synthesizing unsaturated polyester resin from allyl glycidyl ether residual liquid and application

ActiveCN110003454AExcellent bending strengthExcellent impact resistanceAdipic acidUnsaturated polyester

The invention discloses a method for synthesizing unsaturated polyester resin from an allyl glycidyl ether residual liquid. A mixed reaction system is prepared from phthalic anhydride, terephthalic acid, isophthalic acid, maleic anhydride, fumaric acid, adipic acid, propylene glycol, neopentyl glycol, ethylene glycol and diethylene glycol; the mixed reaction system is put in a reactor, the allyl glycidyl ether residual liquid is added to the reactor, and polyester is obtained after the reaction is completed; styrene and a polymerization inhibitor are added to a diluting kettle in advance and fully stirred, polyester obtained after sufficient reaction is transferred to the diluting kettle, wherein the mass of styrene is 10%-40% of the total feeding mass, and unsaturated polyester resin is obtained after sufficient and uniform mixing. According to the method for effectively synthesizing the unsaturated polyester resin from the allyl glycidyl ether residual liquid and the application, theproblem about recycling of the allyl glycidyl ether residual liquid is solved.

Owner:ANHUI XINYUAN CHEM

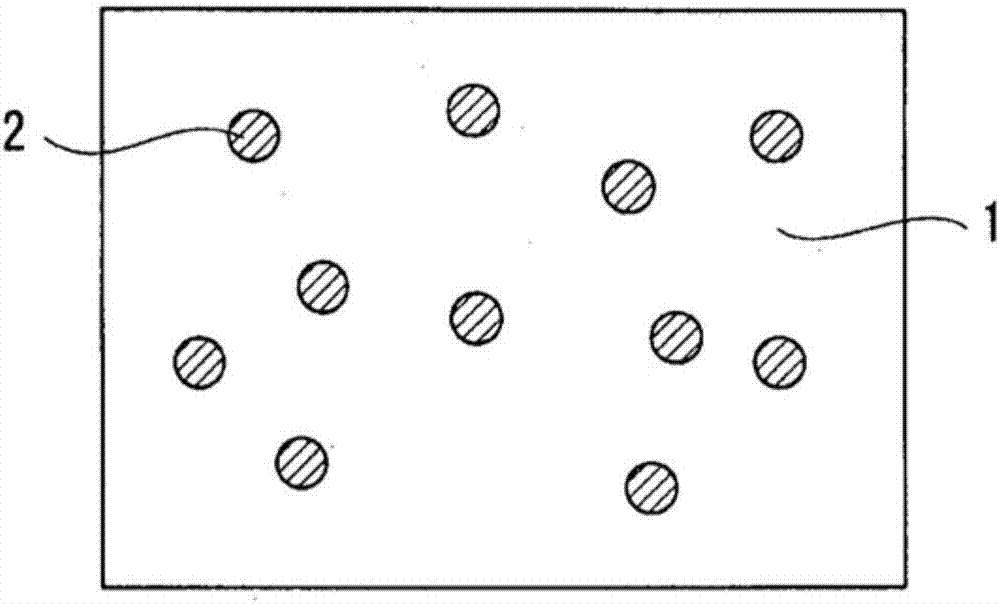

Polylactic resin composition and molding

InactiveUS20160122481A1Excellent impact resistanceMaintain in elastic modulus and strengthPolymer chemistryPolylactic acid

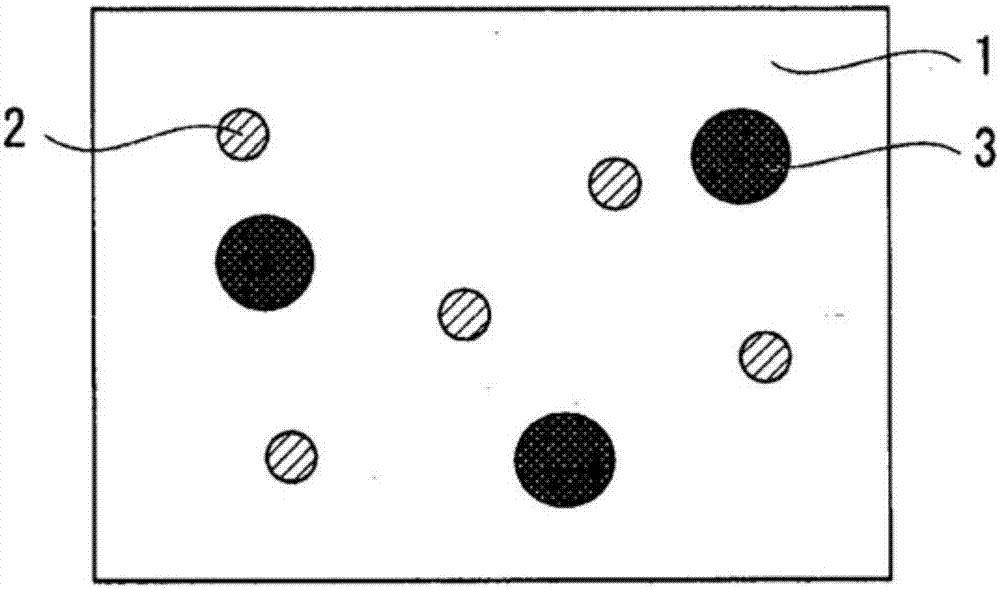

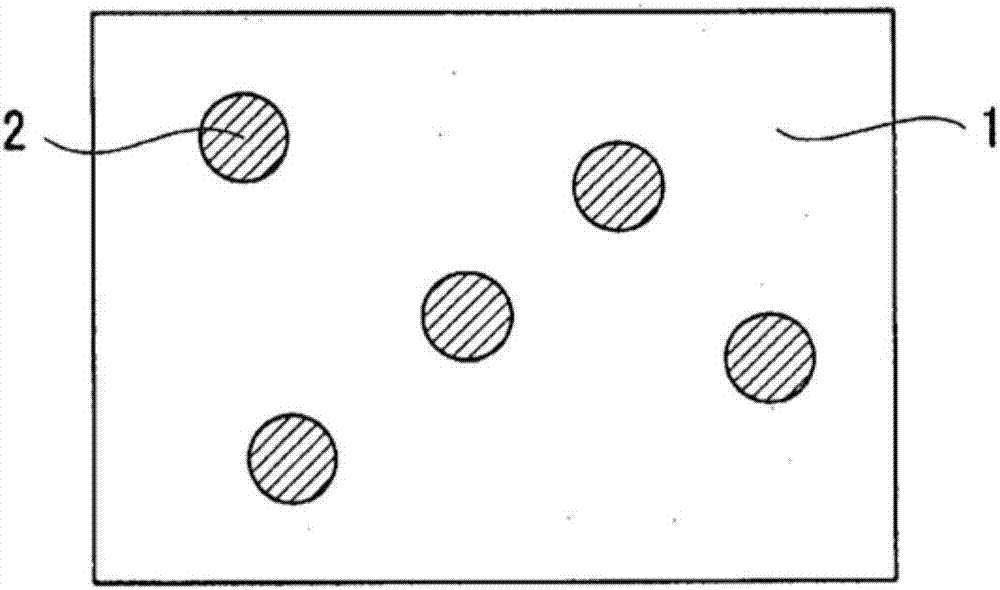

A polylactic resin composition, including: polylactic resin as main component, wherein in a binary image of the polylactic resin composition obtained by binarizing a phase image of a cross-section of the polylactic resin composition observed with an AFM in tapping mode based on intermediate value between maximum and minimum values of phase differences of the polylactic resin composition in free vibration, phases equal to or greater than intermediate value are dispersed in a phase less than intermediate value, and average equivalent circle diameter of the phases equal to or greater than intermediate value is from 0.2 μm to 1 μm, and wherein polylactic resin composition is detected to have at least one glass transition temperature (Tg) in a range of −20° C. or lower, and at least one glass transition temperature (Tg) in a range of 40° C. to 70° C. in a temperature elevating process of differential scanning calorimeter (DSC) measurement thereof.

Owner:RICOH KK

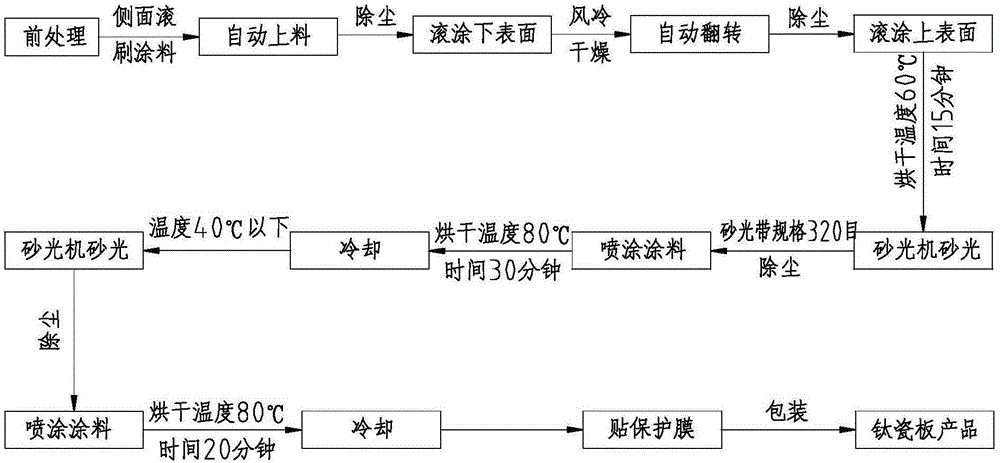

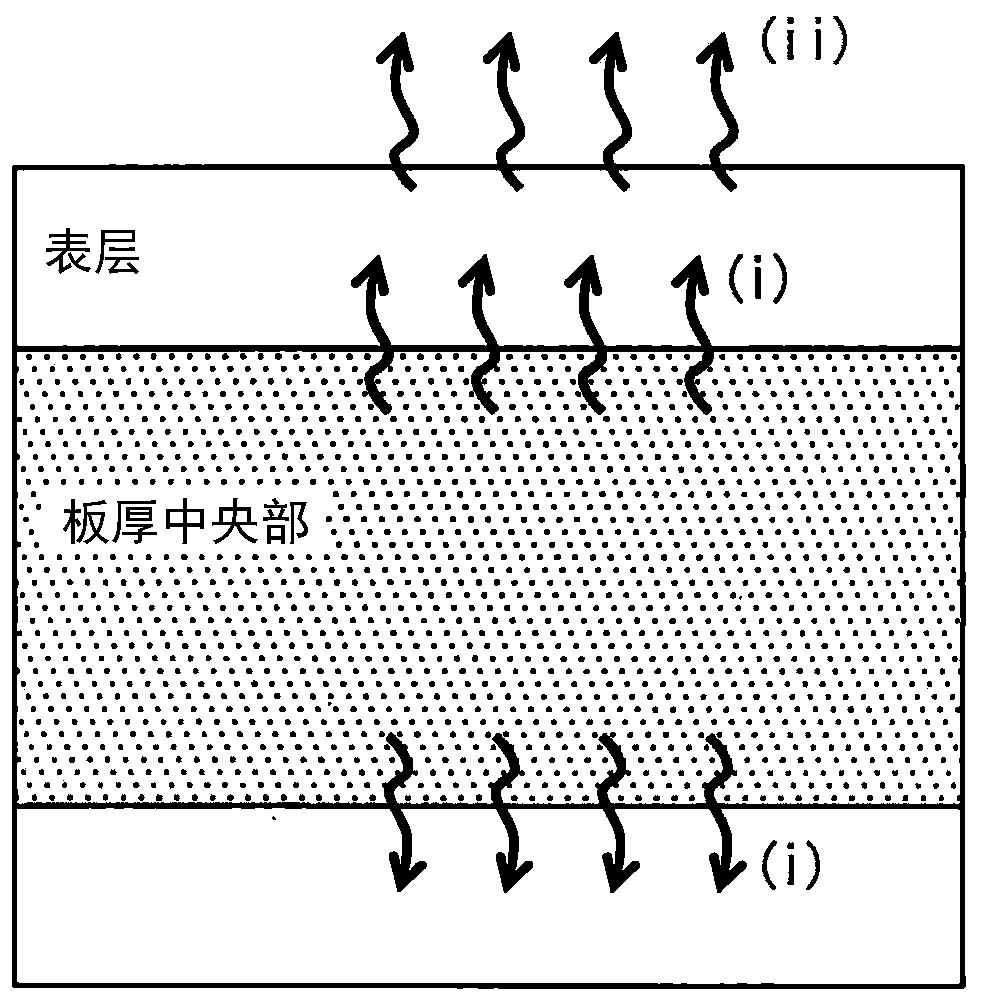

Mono-color titanium porcelain plate and processing technology thereof

InactiveCN105178539AFireproofWaterproofCovering/liningsPretreated surfacesHazardous substanceTitanium

The invention relates to a mono-color titanium porcelain plate and a processing technology thereof. The mono-color titanium porcelain plate comprises a base plate, wherein protective layers made of a titanium porcelain coating are both arranged on the upper surface and the lower surface of the base plate; and a decoration layer made of a mono-color titanium porcelain coating is arranged on the protective layer on the upper surface of the base plate; and a protective layer made of a transparent coating or a mono-color titanium porcelain coating is arranged on the decoration layer. The mono-color titanium porcelain plate is a mono-color plain plate and has the characteristics of being fireproof, waterproof, mould-proof, wear-resisting, unfading, self-cleaning, non-poisonous, environmental friendly and the like; the surface hardness of the plate can reach 3-7 H and is multiple times of the surface hardness of a paint layer on the surface of an automobile; and the plate has an excellent impact-resisting function. According to the processing technology, in the whole process of production, application and recovery, no hazardous substances are emitted; the plate is free from formaldehyde, benzene and heavy metal; and the decoration layer is painted through different ways such as spraying or roll painting, so that highlight mono-color titanium porcelain plates, semi-gloss mono-color titanium porcelain plates and matte mono-color titanium porcelain plates can be manufactured.

Owner:青岛瑞美特新材料科技有限公司

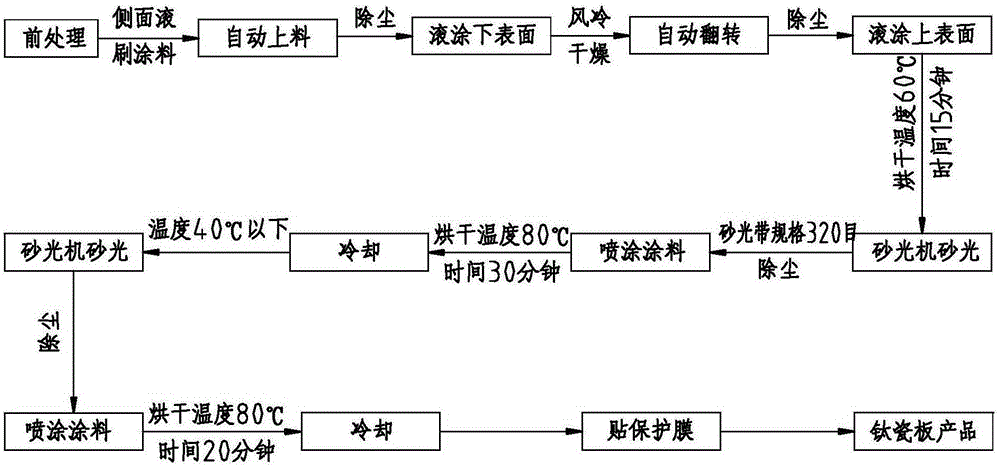

Bright alloy steel sand production process

InactiveCN109108299AStore for a long timeWith anti-oxidation layerAbrasion apparatusFurnace typesSurface layerAmmonia

The invention discloses a bright alloy steel sand production process. The bright alloy steel sand production process comprises the steps of raw material screening, heat treatment quenching, coarse crushing, graded intermediate crushing, fine crushing, bright tempering, secondary screening and packaging. According to the bright alloy steel sand production process, after alloy steel sand is subjected to bright tempering, the surface of the steel sand is made to form an anti-oxidation layer utilizing ammonia decomposition protective gases and vacuumizing treatment, and products are made to be stored longer; the alloy steel sand has the anti-oxidation layer, the surface layer is not prone to being rusted, the surface layer structure and the internal structure are stable and consistent, and thealloy steel sand is made to have more excellent impact resistance and wear resistance; the alloy steel sand has the anti-oxidation layer and durability to make the alloy steel sand be capable of replacing stainless steel grinding materials in most occasions, and the grinding material purchase cost is lowered by 30% or above; because the alloy steel sand has the anti-oxidation layer on the surface, in the process of practical application, generated dust is greatly reduced, the dust adhering to the workpiece surface is also greatly reduced, and reduction of the defective rate of workpieces is facilitated; and the surface of the alloy steel sand shows a bright metallic color.

Owner:宁波渐丰金属科技有限公司

Method for forming multilayer coating film

ActiveUS20180104718A1Excellent impact resistanceHigh low temperature impact resistancePretreated surfacesPolyurea/polyurethane coatingsIsocyanatePlastic materials

Provided is a method for forming a multilayer coating film giving excellent low temperature impact resistance to a substrate that comprises a metal material and a plastic material. The method for forming a multilayer coating film comprises sequential steps of forming an uncured primer coating film, an uncured first colored coating film, an uncured second colored coating film and an uncured clear coating film on a substrate; and heating the same so as to simultaneously cure these 4 coating films, wherein the aqueous first colored paint and aqueous second colored paint are each a 1-package type paint composition containing a specific hydroxyl group-containing resin and a specific blocked polyisocyanate compound.

Owner:KANSAI PAINT CO LTD

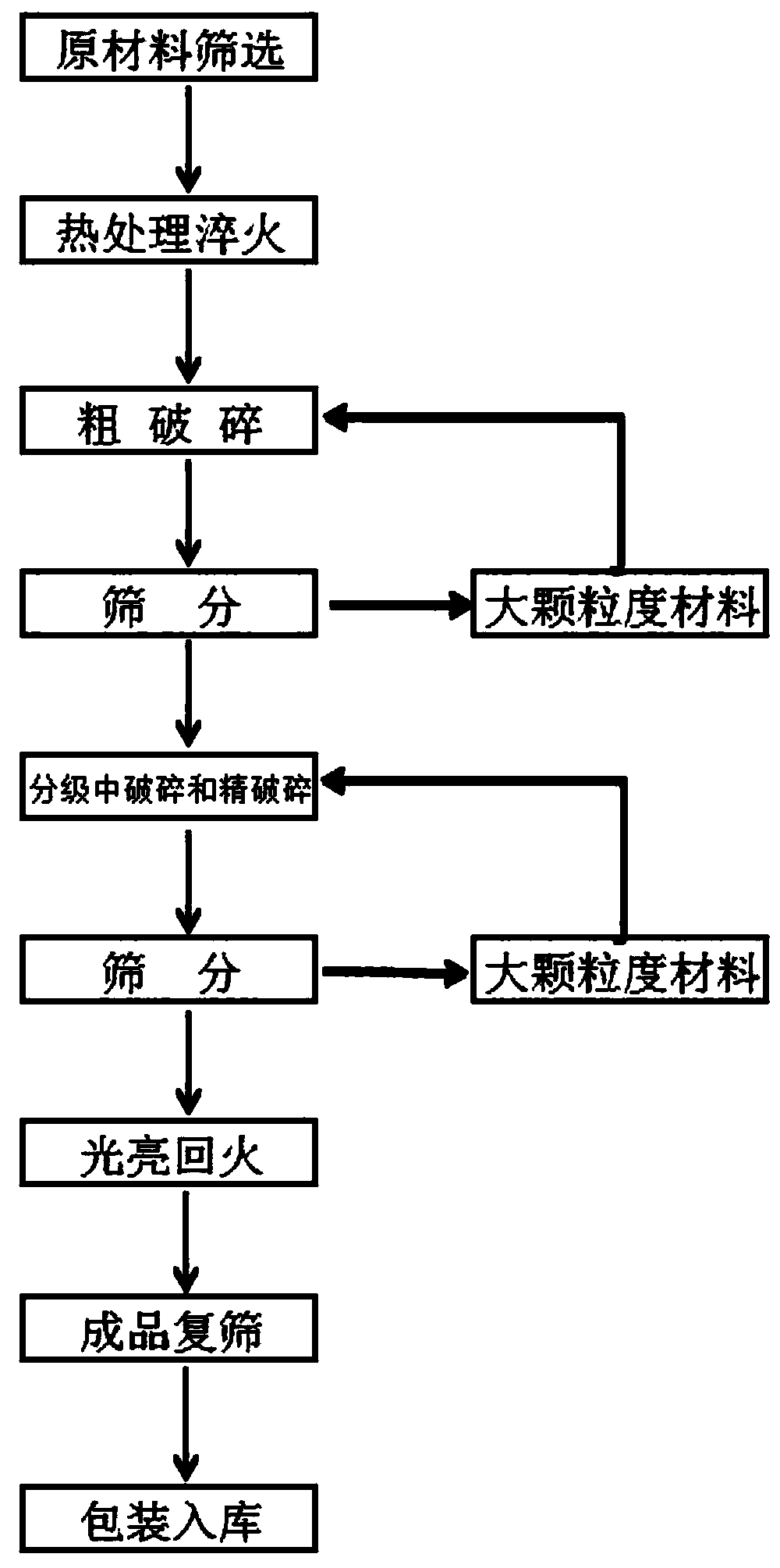

Hot stamp moulded body

InactiveCN110199046AGood flexibilityExcellent impact resistanceHot-dipping/immersion processesSolid state diffusion coatingComposite materialMaterials science

Provided is a hot stamp moulded body which is characterized by: including a plate thickness central portion, and a surface layer provided to one or both sides of the plate thickness central portion; and further including intermediate layers formed next to and between the plate thickness central portion and the respective surface layers. The hot stamp moulded body is further characterized in that:the plate thickness central portion has a prescribed composition; the hardness of the plate thickness central portion is at least 500 Hv, but not more than 800 Hv; the variation delta H1 in hardness in the surface layers in the plate thickness direction is at least 10 Hv, but less than 200 Hv; and the variation delta H2 in hardness in the intermediate layers in the plate thickness direction is atleast 50 Hv, but less than 200 Hv.

Owner:NIPPON STEEL CORP

Reinforced plastics spiral tubular product of composite steel strip

InactiveCN102022586AExcellent impact resistanceExcellent dimensional stabilityRigid pipesCold formedSteel frame

The invention discloses a reinforced plastics spiral tubular product of a composite steel strip, belonging to the field of steel and plastic tubular products. The reinforced plastics spiral tubular product is characterized in that a composite steel frame is used as a support, polyvinyl resin and a cold rolled steel strip which is subjected to oil and rust removal and is coated with adhesive resin are rolled into the steel frame with an approximate stair step shape through a cold forming sectional steel mill, and the steel frame is compounded and adhered with polyethylene to be made into a sectional bar for a steel and plastic structure pipe through a plastic extruder; and the reinforced plastics spiral tubular product of the composite steel strip is produced through helical winding and forming machine equipment by adopting a plastic resin melting mode.

Owner:杨显

Construction method of epoxy resin self-leveling terrace

InactiveCN110670843AExcellent flexibilityExcellent impact resistanceFilling pastesEpoxy resin coatingsEpoxyGlass fiber

The invention relates to a construction method of an epoxy resin self-leveling terrace. The method comprises the following steps that a to-be-constructed terrace is subjected to defect-free treatment;the pre-treatment terrace is subjected to surface grinding to obtain a to-be-painted terrace; a primer is twice brushed onto the to-be-painted terrace, after the primer is solidified, curing is carried out again, and the terrace to be laid mat is obtained; an epoxy resin binder is applied to the surface of the terrace to be laid mat, and a glass fiber chopped strand mat coiled material in an unwinding state is adhered to the surface of the epoxy resin binder, and curing is carried out to obtain the mat terrace; the surface of the mat terrace is coated with epoxy resin mortar to obtain a to-be-puttied terrace; whether surface closure is good or not is carried out on the to-be-puttied terrace, sand holes and air holes, found in the examination, on the to-be-puttied are puttied, after puttyis cured, the puttied parts are polished and modified so as to obtain the to-be-troweled terrace; and the to-be-troweled terrace is coated with self-leveling paint through troweling to obtain the epoxy resin self-leveling terrace. Flexibility, impact resistance, and crack resistance of the terrace is ideal.

Owner:苏州华亭建设工程有限公司

Polyamide resin composition and molded article using same

The present invention provides a polyamide resin composition containing a polyamide resin (A) in which a diamine constituent unit thereof includes a constituent unit derived from a xylylenediamine (a-1), and a dicarboxylic acid constituent unit thereof includes a constituent unit derived from an α,ω-linear aliphatic dicarboxylic acid (a-2) having from 4 to 20 carbon atoms; and a polyether polyamide (B) in which a diamine constituent unit thereof includes constituent units derived from a polyether diamine compound (b-1) represented by a specified structural formula and a xylylenediamine (b-2), and a dicarboxylic acid constituent unit thereof includes a constituent unit derived from an α,ω-linear aliphatic dicarboxylic acid (b-3) having from 4 to 20 carbon atoms.

Owner:MITSUBISHI GAS CHEM CO INC

Intrinsically wear-resistant titanium alloy and preparation method thereof

The invention discloses an intrinsically wear-resistant titanium alloy and a preparation method thereof. The titanium alloy is prepared by the following steps: with TC17 as an original intrinsic body,performing vacuum evaporation-solidification treatment, and smelting and sintering under argon protection; after that, quickly cooling, and performing hot isostatic pressing treatment to finally obtain the titanium alloy. The intrinsically wear-resistant titanium alloy disclosed by the invention has the advantages of high wear resistance, good machining property, strong impact resistance, simultaneous action with any surface strengthening technology, and wide application range.

Owner:宁波俐辰新能源有限公司

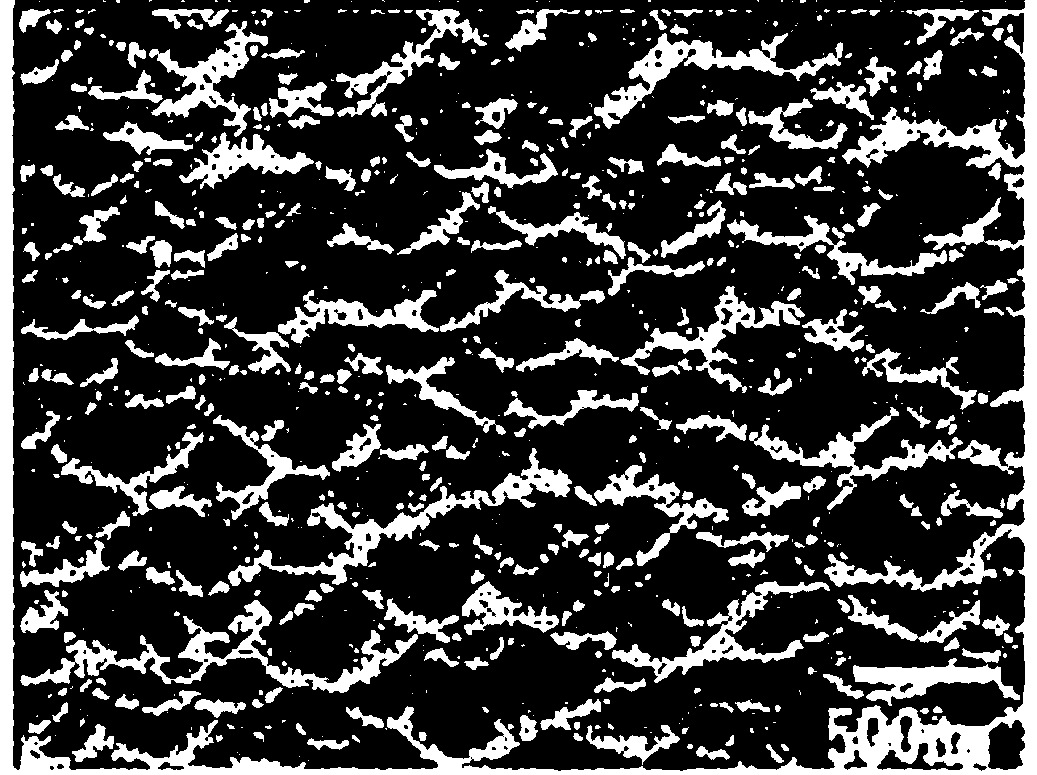

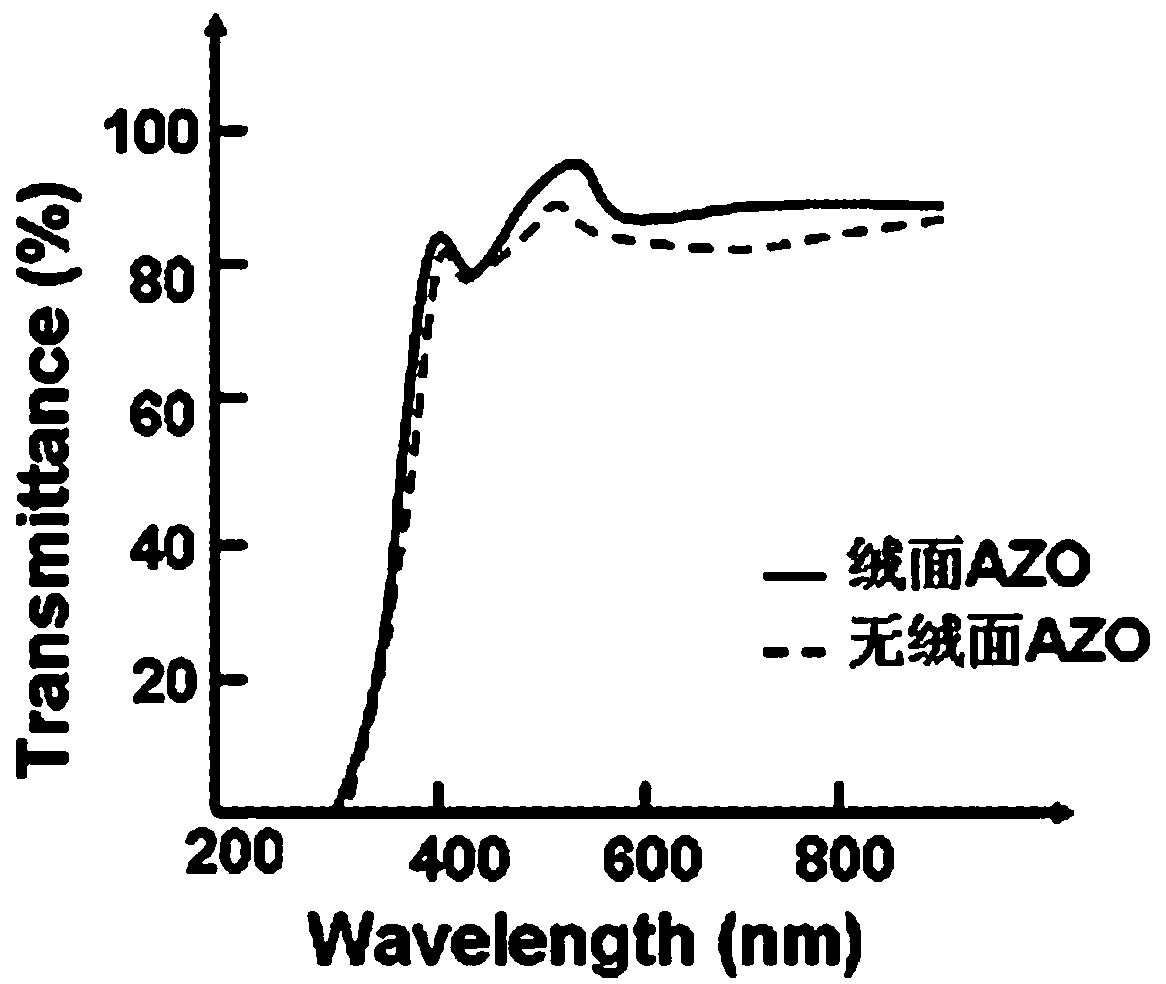

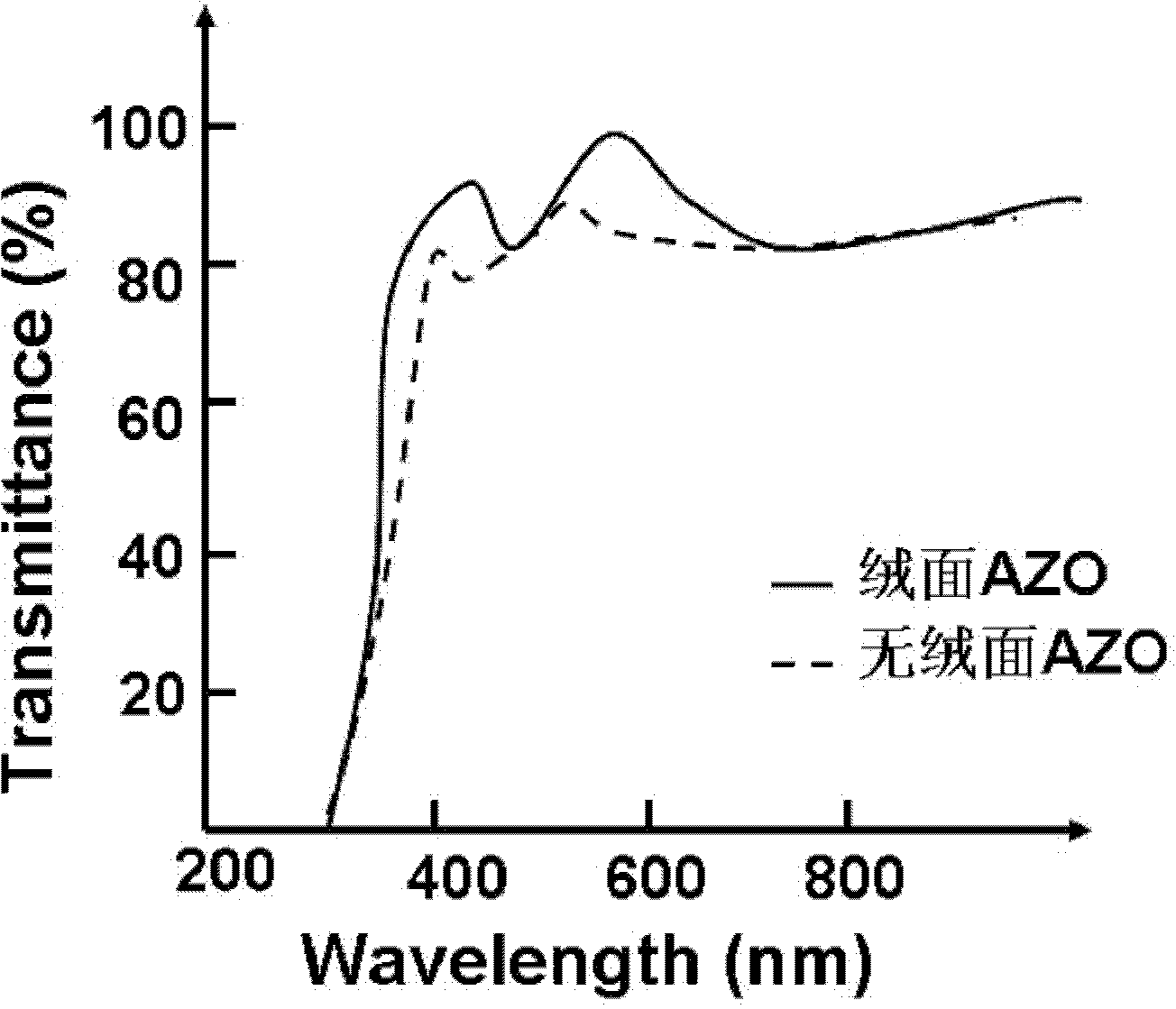

Preparation method of light self-trapping AZO (aluminium-doped zinc oxide) film glass

The invention discloses a preparation method of light self-trapping AZO (aluminium-doped zinc oxide) film glass. The preparation method comprises the following steps of growing a layer of AZO film with a thickness of 50-100 nm at a high speed by virtue of the mixed plasma of Ar and oxygen or Ar and vapour at first, and then further growing the AZO film with a thickness of 500-600 nm at a growth speed slower than the previous speed by virtue of an independent Ar plasma and a higher ion equivalent, wherein the obtained AZO film with a total thickness of 600-700 nm has texture structure and morphology; an acid etching link in a conventional AZO texturization process is avoided; the thickness, and production and manufacturing costs needed by the AZO film are effectively reduced.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Fiber composite-reinforced anti-corrosion anti-collision wall for bridge and preparation method of wall

PendingCN113882298AStrong impact resistanceExcellent impact resistanceBridge structural detailsRoadway safety arrangementsCorrosion preventionCrumb rubber

The invention discloses a fiber composite-reinforced anti-corrosion anti-collision wall for a bridge and a preparation method of the wall. According to the anti-collision wall, a reinforcing layer is arranged on base concrete, and the base concrete is anti-collision wall concrete of an original bridge; and the reinforcing layer comprises a metal plate, fiber reinforced cloth 1, fiber reinforced cloth 2 and surface damping particles in sequence. The fiber reinforced cloth adopted by the invention has higher impact resistance and can effectively resist impact; and the fiber reinforced cloth is combined with a bottom metal plate and the surface rubber particles, so the impact resistance of the anti-collision wall can be effectively improved. The fiber reinforced cloth and the metal plate are directly bonded through the impregnating adhesive, an impregnating system is an epoxy resin adhesive system, and a cured material of the impregnating adhesive is excellent in mechanical property, high in density and excellent in corrosion resistance. The anti-collision wall has excellent impact resistance and corrosion resistance at the same time, and the durability and safety of the bridge can be effectively improved.

Owner:山西省交通科技研发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com