Polyether-type urethane acrylate UV-cured adhesive and preparation method thereof

A technology of polyurethane acrylate and acrylate, which is applied in polyurea/polyurethane adhesives, adhesives, polymer adhesive additives, etc., and can solve the problems of drop resistance, poor impact resistance, heat and humidity resistance, low chemical resistance, Reduced reliability and other issues, to achieve the effect of drop resistance and vibration resistance, suitable for bonding and protection, and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

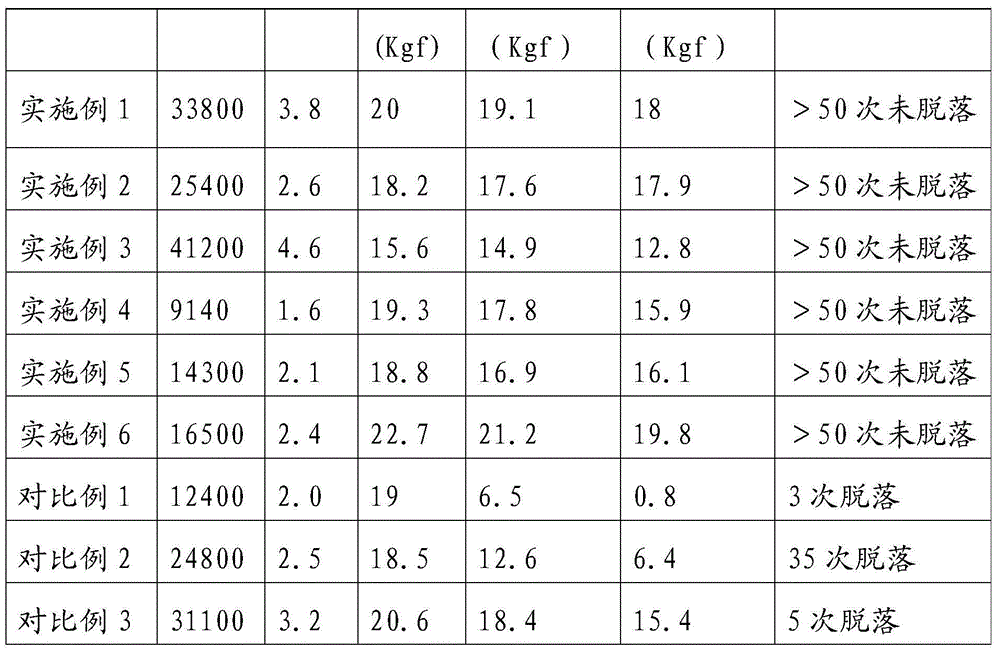

Examples

Embodiment 1

[0031] A polyether urethane acrylate UV-curable adhesive, consisting of the following raw materials in parts by weight: 30 g of polyether urethane acrylate, 30 g of epoxy acrylate, 15 g of ethylene acrylate rubber, and trimethylolpropane formal acrylate 10 g, 10 g of isobornyl acrylate, 2 g of 1-hydroxycyclohexylbenzophenone, 2 g of fumed silica, and 1 g of γ-methacryloxypropyltrimethoxysilane.

[0032] The preparation method of above-mentioned polyether type urethane acrylate ultraviolet curing adhesive, the steps are as follows:

[0033] (1) Add 120 g of polyether diol with a molecular weight between 500 and 3000 into the reactor, vacuumize and dehydrate at 110°C for 1 hour, lower the temperature to below 50°C, and add 62.1g of isophorone diisocyanate and 0.1g of dibutyltin dilaurate, react at 70°C for 3h, add 11g of hydroxyethyl methacrylate, continue to react at 75°C for 2h, take a sample and measure the infrared spectrum to confirm that the infrared absorption peak of the...

Embodiment 2

[0038] A polyether urethane acrylate UV-curable adhesive, consisting of the following raw materials in parts by weight: 40 g of polyether urethane acrylate, 20 g of urethane acrylate, 8 g of ethylene acrylate rubber, 15 g of tetrahydrofuran acrylate, and 10 g of isobornyl acrylate , 1-hydroxycyclohexyl benzophenone 2g, 2,4,6-trimethylbenzoyl diphenylphosphine oxide 1.5g, fumed silica 3g and γ-methacryloxypropyl trimethoxy Silane 0.5g.

[0039] The preparation method of above-mentioned polyether type urethane acrylate ultraviolet curing adhesive, the steps are as follows:

[0040] (1) Add 120 g of polyether diol with a molecular weight between 500 and 3000 into the reactor, vacuum dehydrate at 115°C for 1 hour, lower the temperature to below 50°C, add 26.1g of toluene diisocyanate and 0.1g Dibutyltin dilaurate, react at 75°C for 2h, add 8g of hydroxyethyl methacrylate, continue to react at 70°C for 3h, take a sample and measure the infrared spectrum to confirm that the infrare...

Embodiment 3

[0045] A polyether type urethane acrylate UV-curable adhesive, consisting of the following raw materials in parts by weight: 65 g of polyether urethane acrylate, 15 g of urethane acrylate, 5 g of ethylene acrylate rubber, 5 g of isooctyl acrylate, and 5 g of isobornyl acrylate 5g, 1.5g of 2-hydroxy-2-methyl-1-phenylacetone, 1g of 2,4,6-trimethylbenzoyl diphenylphosphine oxide, 2g of fumed silica and γ-methacryloyl 0.5 g of oxypropyltrimethoxysilane.

[0046] The preparation method of above-mentioned polyether type urethane acrylate ultraviolet curing adhesive, the steps are as follows:

[0047] (1) Add 120g of polyether diol with a molecular weight between 500 and 3000 into the reactor, vacuum dehydrate at 120°C for 1 hour, lower the temperature to below 50°C, and add 20.2g of hexamethylene diisocyanate and 0.1g of dibutyltin dilaurate, react at 80°C for 2h, add 18g of hydroxypropyl methacrylate, continue to react at 75°C for 2h, take a sample and measure the infrared spectru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com