Microbial agent and preparation method and application thereof

A technology of microbial agent and microbacteria, which is applied in the field of sewage biological treatment in environmental protection projects, can solve the problems of unstable treatment efficiency, long time for natural sludge cultivation and domestication, poor impact resistance, etc., and achieve simple and efficient storage, transportation and delivery , Excellent impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

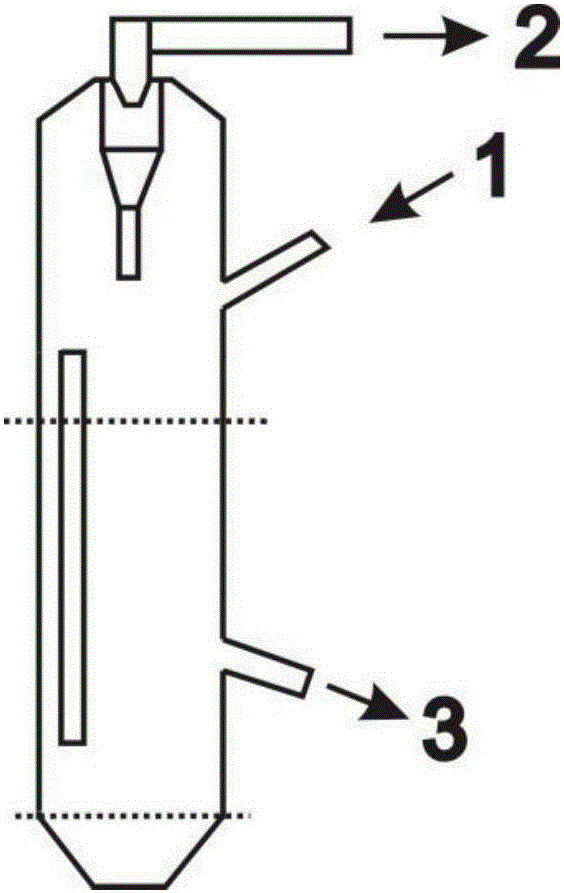

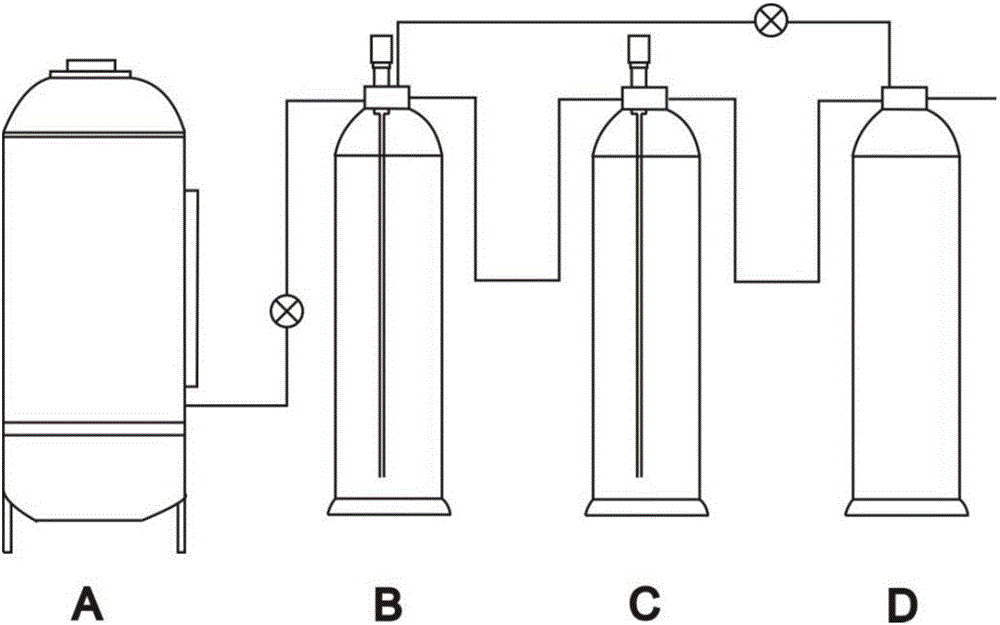

Method used

Image

Examples

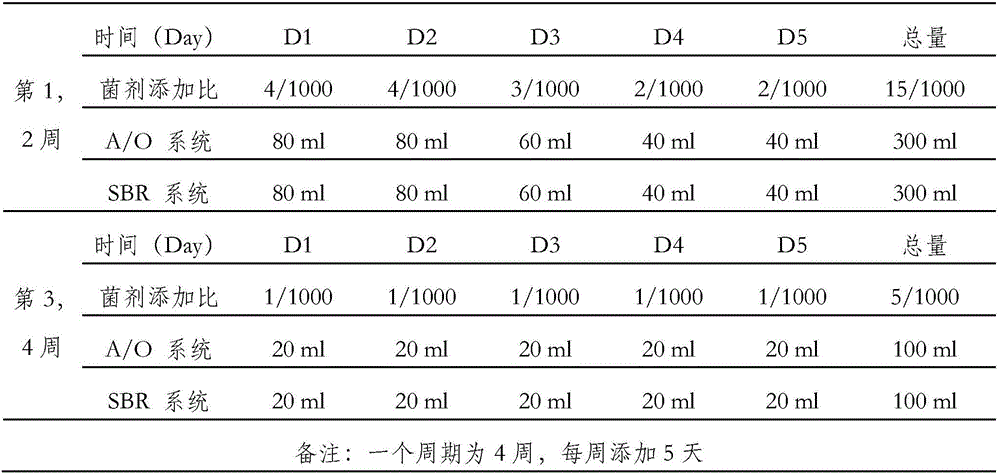

Embodiment 1

[0057] Adopt the present invention to laboratory simulation industrial waste water (adjust pH about 7.5; Main component has NH 4 Cl, molasses, yeast extract, glucose, soluble starch, other inorganic salts, etc.) to remove ammonia nitrogen. The bacterial agent is added to the SBR process according to the predetermined cycle, and the system is operated at 35°C. As a result, for the SBR system that is about to collapse (influent ammonia nitrogen is about 70mg / L, effluent ammonia nitrogen is about 20mg / L, and the removal rate is about 71%), after adding bacteria for one month and operating the system according to the predetermined parameters, the system maintains stability. In the case of about 70mg / L of ammonia nitrogen in the influent. Through the addition of bacterial agents, the ammonia nitrogen in the effluent is reduced to about 3mg / L, and the treatment rate reaches 96%.

Embodiment 2

[0059] Adopt the present invention to remove the ammonia nitrogen of laboratory simulated industrial waste water (same as embodiment 1). The bacterial agent is added to the A / O process according to the predetermined cycle, and the system is operated at 35°C. As a result, for the A / O system that is not running well (the influent ammonia nitrogen is about 70mg / L, the effluent ammonia nitrogen is about 15mg / L, and the removal rate is about 79%), the system is operated according to the predetermined parameters, and the system is maintained after one month of bacterial agent addition. After stabilization, in the case of about 70mg / L of ammonia nitrogen in the influent. With the addition of bacterial agents, the effluent drops to about 2mg / L, and the treatment rate reaches 97%.

Embodiment 3

[0061] Adopt the present invention to the printing and dyeing waste water (pre-adjusted pH is 6.5~8.5; main component: dyestuff, surfactant, polyvinyl alcohol, add appropriate amount of molasses, yeast extract, glucose, NH to Jiangnan University Textile Garment College 4 Cl and other inorganic salts to meet the necessary nutrients for microorganisms) to remove ammonia nitrogen. The bacterial agent is added to the A / O process according to the predetermined cycle, and the system is operated at 35°C. As a result, for the A / O system that is not running well (the influent ammonia nitrogen is about 70mg / L, the effluent ammonia nitrogen is about 25mg / L, and the removal rate is about 64%), the system is operated according to the predetermined parameters, and the system is maintained after one month of bacterial agent addition. After stabilization, in the case of about 70mg / L of ammonia nitrogen in the influent. With the addition of bacterial agents, the effluent drops to about 5mg / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com