Preparation method of light self-trapping AZO (aluminium-doped zinc oxide) film glass

A thin film and glass technology, applied in the field of photovoltaic battery glass, can solve the problems of increased production costs, unreasonable consumption of AZO thin films, and increased process complexity, etc., to enhance mechanical strength, avoid unreasonable consumption, reduce costs and process stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. With the glass substrate as the substrate, the preparation temperature is maintained at 60°C, and a mixed gas of Ar and oxygen is introduced, wherein the oxygen partial pressure is 6′10 -3 Pa, Ar partial pressure is 2.1Pa, power density is 1.5W / cm 2 , using radio frequency magnetron sputtering process, using AZO ceramic target material for thin film sputtering growth, the time is 30 seconds, thus obtaining the first layer of AZO thin film;

[0022] 2. Introduce a separate Ar process gas, the pressure is 0.5Pa, and the power density is 8W / cm 2 , using radio frequency magnetron sputtering process, using AZO ceramic target material for thin film sputtering growth, the time is 600 seconds, thus obtaining the second layer of AZO thin film;

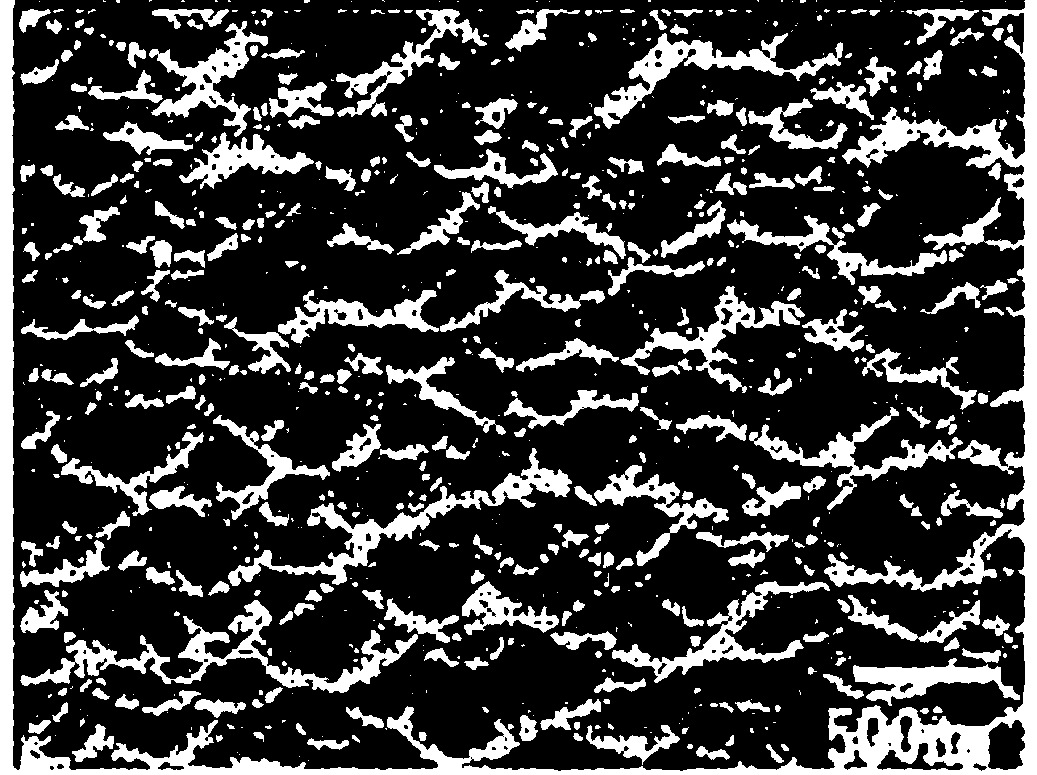

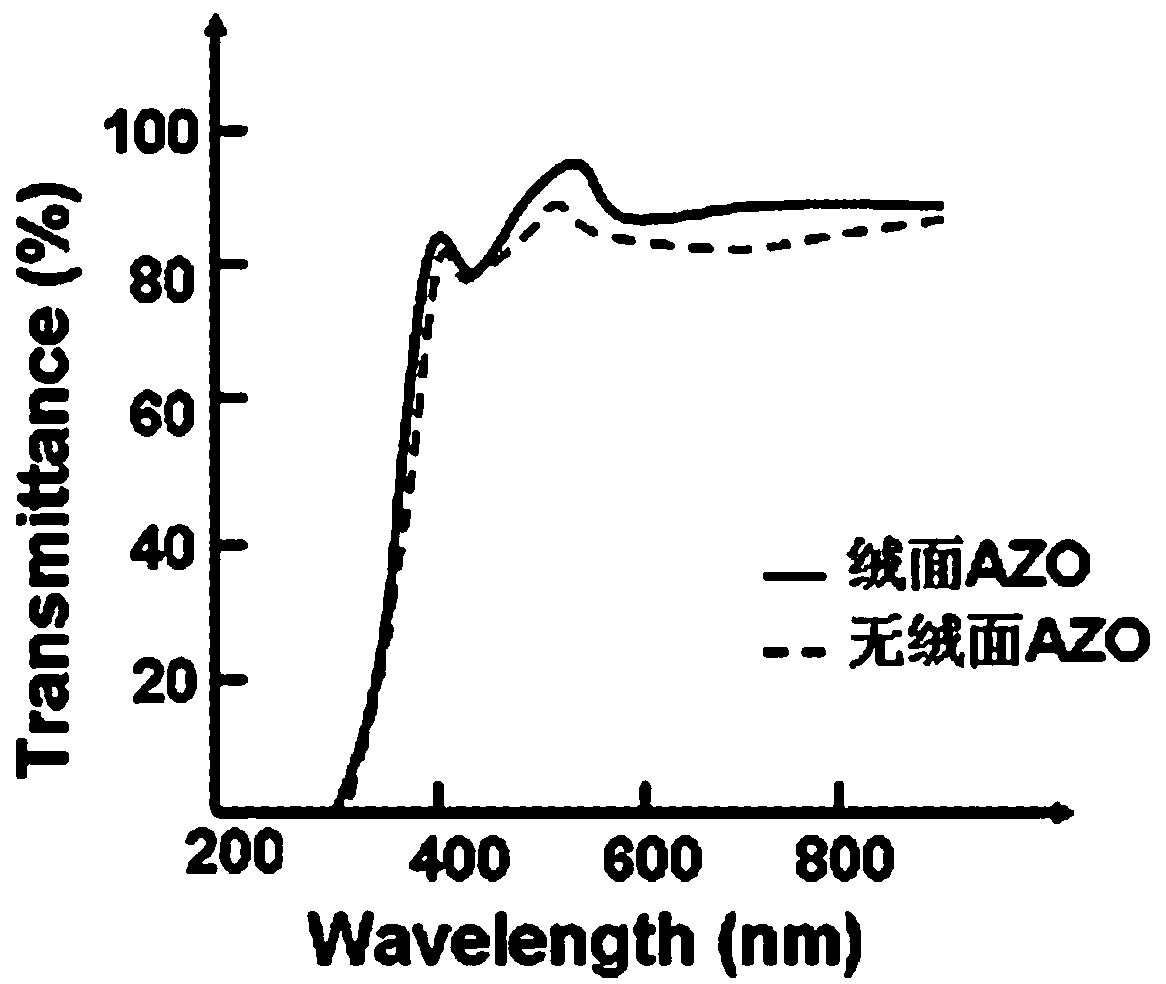

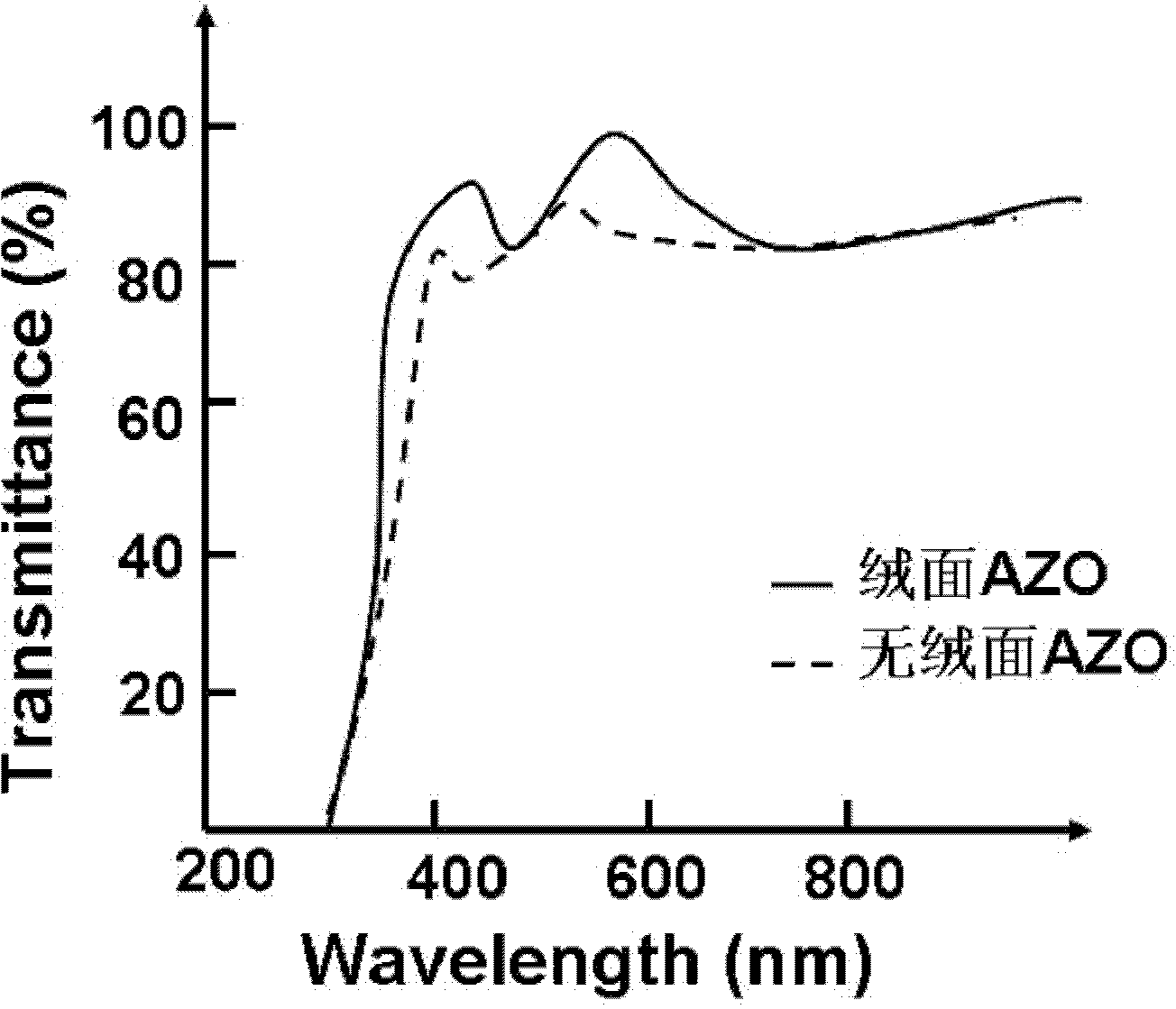

[0023] 3. The AZO film obtained above is subjected to SEM testing, such as figure 1 As shown, it can be seen from the figure that the film has a pit-like suede surface morphology, and the characteristic size of the suede is: the len...

Embodiment 2

[0026] 1. With the glass substrate as the substrate, the preparation temperature is kept at 60°C, and the mixed gas of Ar and water vapor is introduced, and the partial pressure of water vapor is 8′10 -3 Pa, Ar partial pressure is 2.4Pa, power density is 1.8W / cm 2 , using radio frequency magnetron sputtering process, using AZO ceramic target material for thin film sputtering growth, the time is 30 seconds, thus obtaining the first layer of AZO thin film;

[0027] 2. Introduce a single process gas of Ar, the pressure is 0.4Pa, and the power density is 9W / cm 2 , using radio frequency magnetron sputtering process, using AZO ceramic target material for thin film sputtering growth, the time is 600 seconds, thus obtaining the second layer of AZO thin film;

[0028] 3. The AZO film obtained above was subjected to SEM testing. The film also had pit-like suede surface morphology, and the characteristic dimensions of the suede were: about 500 nm in length and about 250 nm in depth.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com