Method For The Regeneration Of A Particle Filter Installed In The Exhaust Gas Train Of A Vehicular Diesel Engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

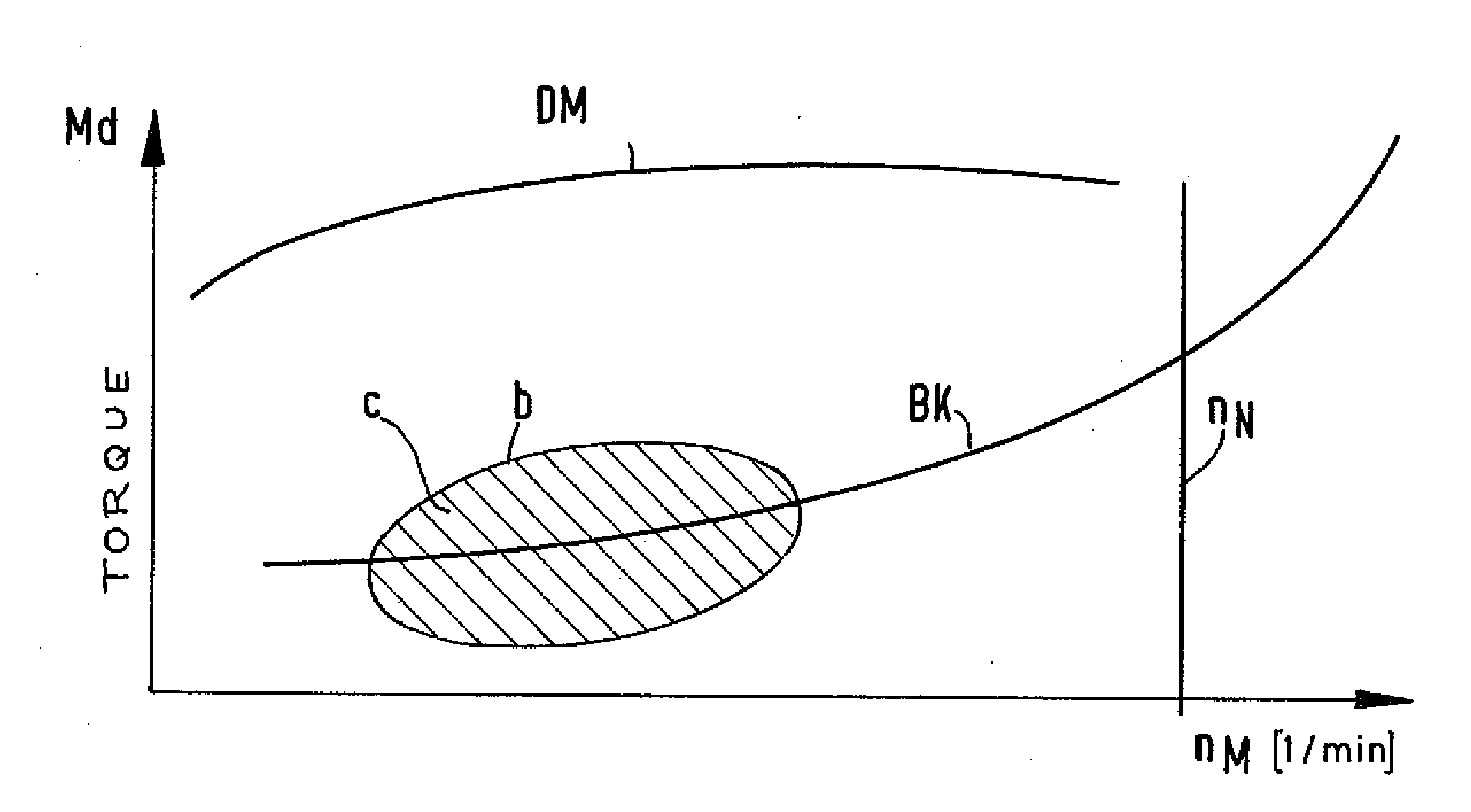

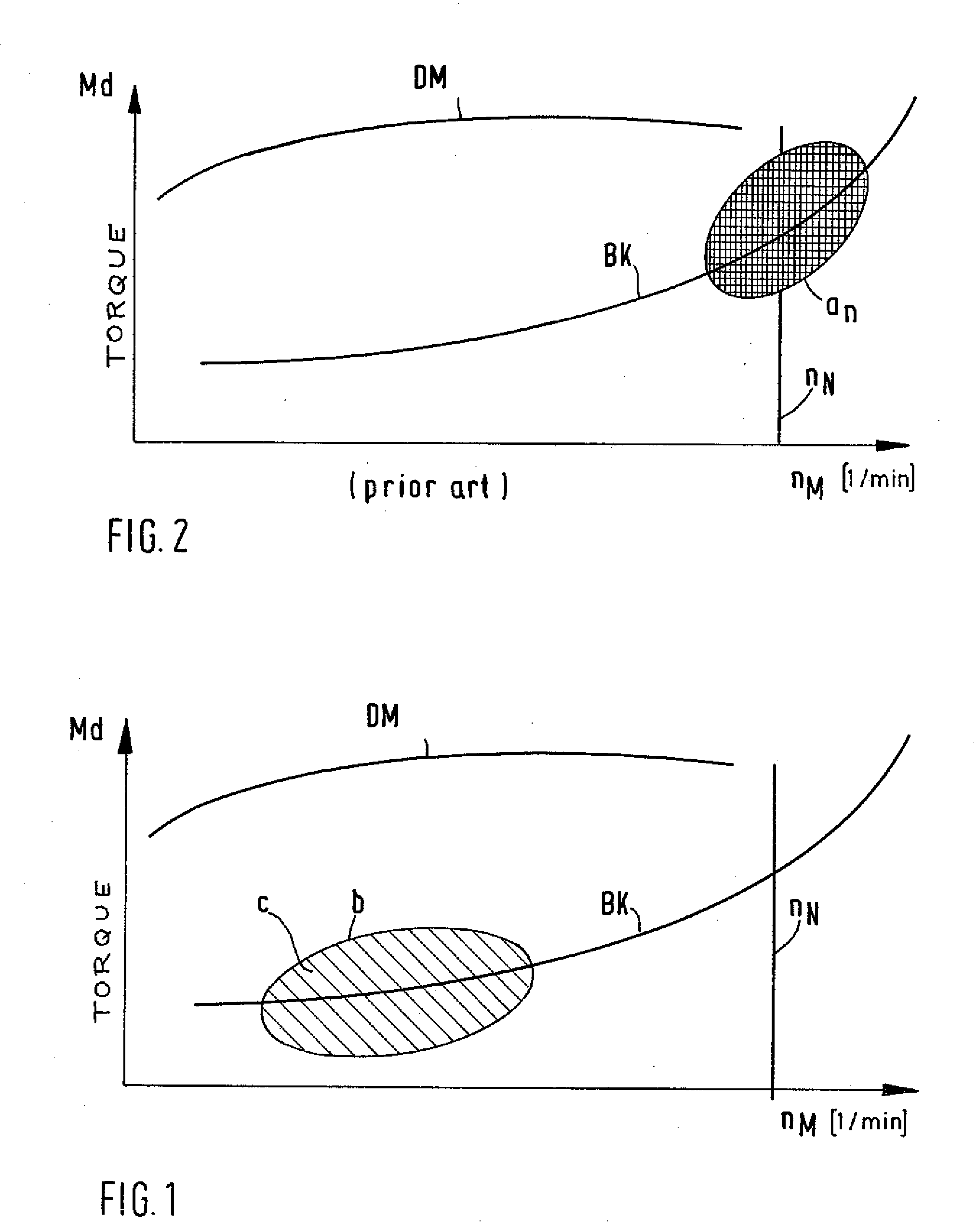

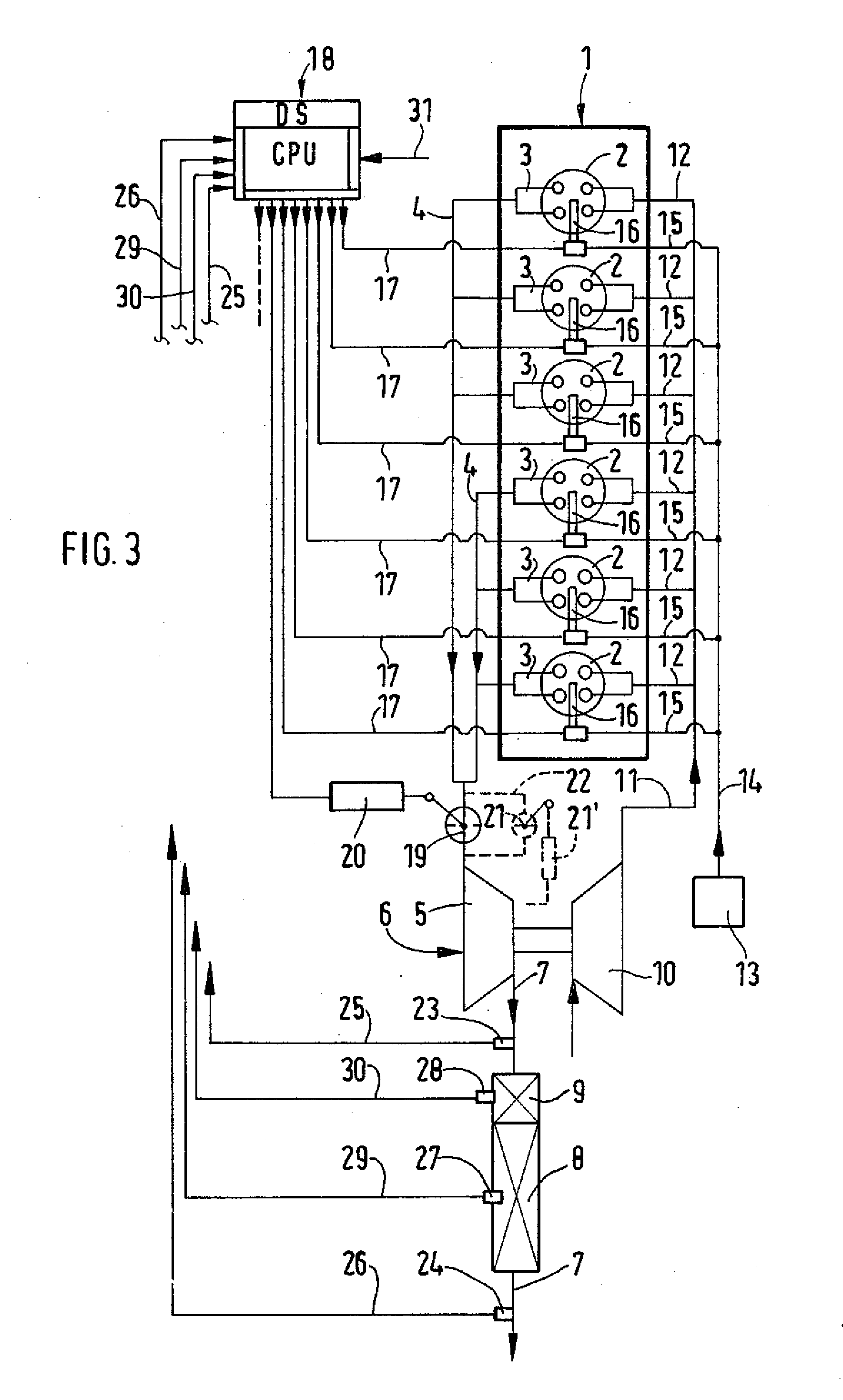

[0016]In the following, the inventive method is explained in greater detail on the basis of the diagram of FIG. 1 and a schematic diagram of a diesel engine according to FIG. 3.

[0017]FIG. 3 shows a schematic diagram of a diesel engine 1 installed in a vehicle such as a truck, bus, or other utility vehicle. Each of six cylinders 2 has two outlet valves, each of which communicates with an exhaust gas-collecting manifold 4 by way of an outlet channel 3. In the case shown here, the cylinders 2 are divided into two banks of three each, and each bank is connected to one manifold 4. Both manifolds 4 lead to the turbine 5 of an exhaust gas turbocharger 6 and are components of the exhaust gas train of the diesel engine 1, which, on the outlet side of the turbine 5, is connected to a section 7, in which a particle filter 8 is installed. In the example shown here, an oxidation catalyst 9 is installed upstream of the particle filter 8. This catalyst is responsible for producing a significant in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com