Method and device for braking quick railway freight car

A technology for braking devices and freight cars, applied in hydraulic braking transmissions, railway car body parts, brakes, etc., can solve the problems of reducing the air pressure of the brake cylinder of an empty car, and achieve shortened braking distance, high linearity and Excellent sensitivity and anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

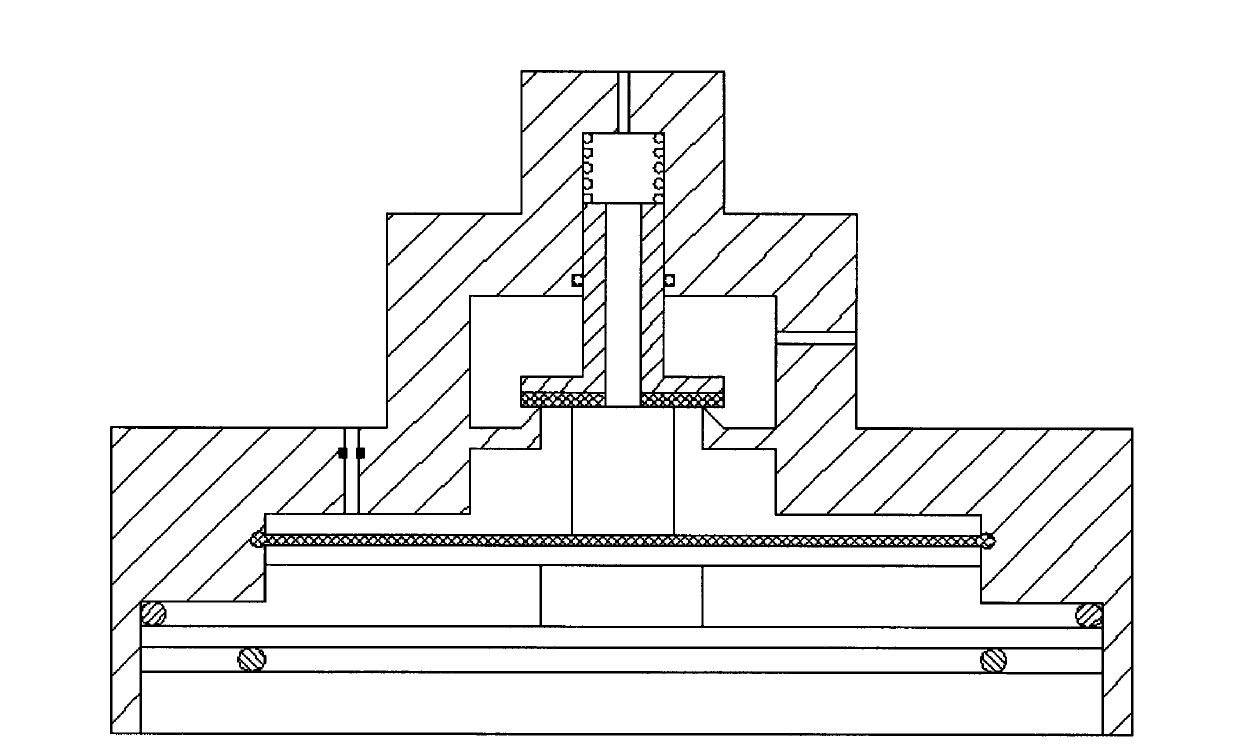

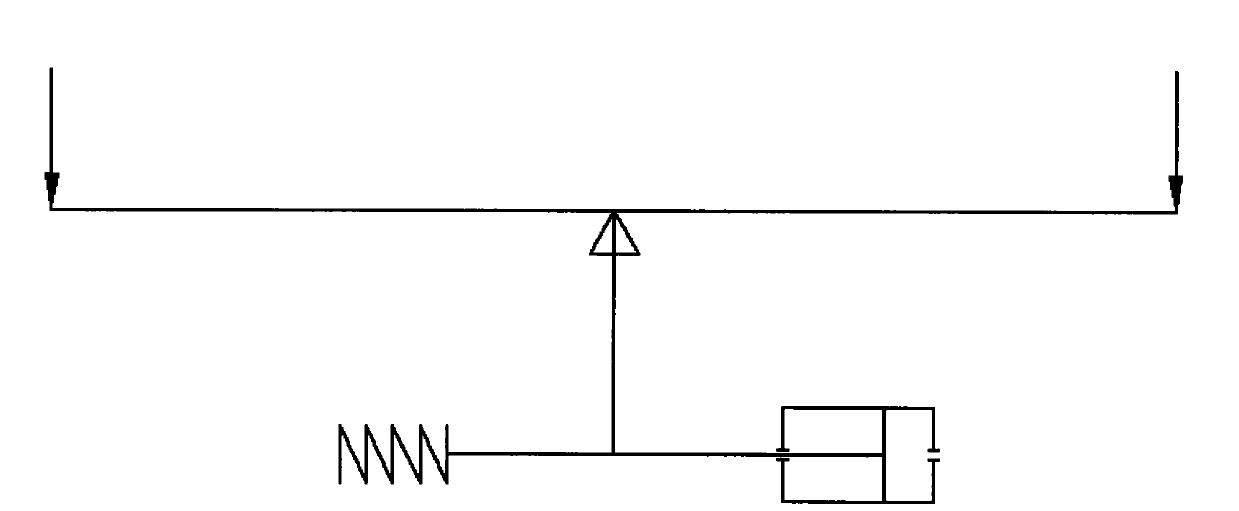

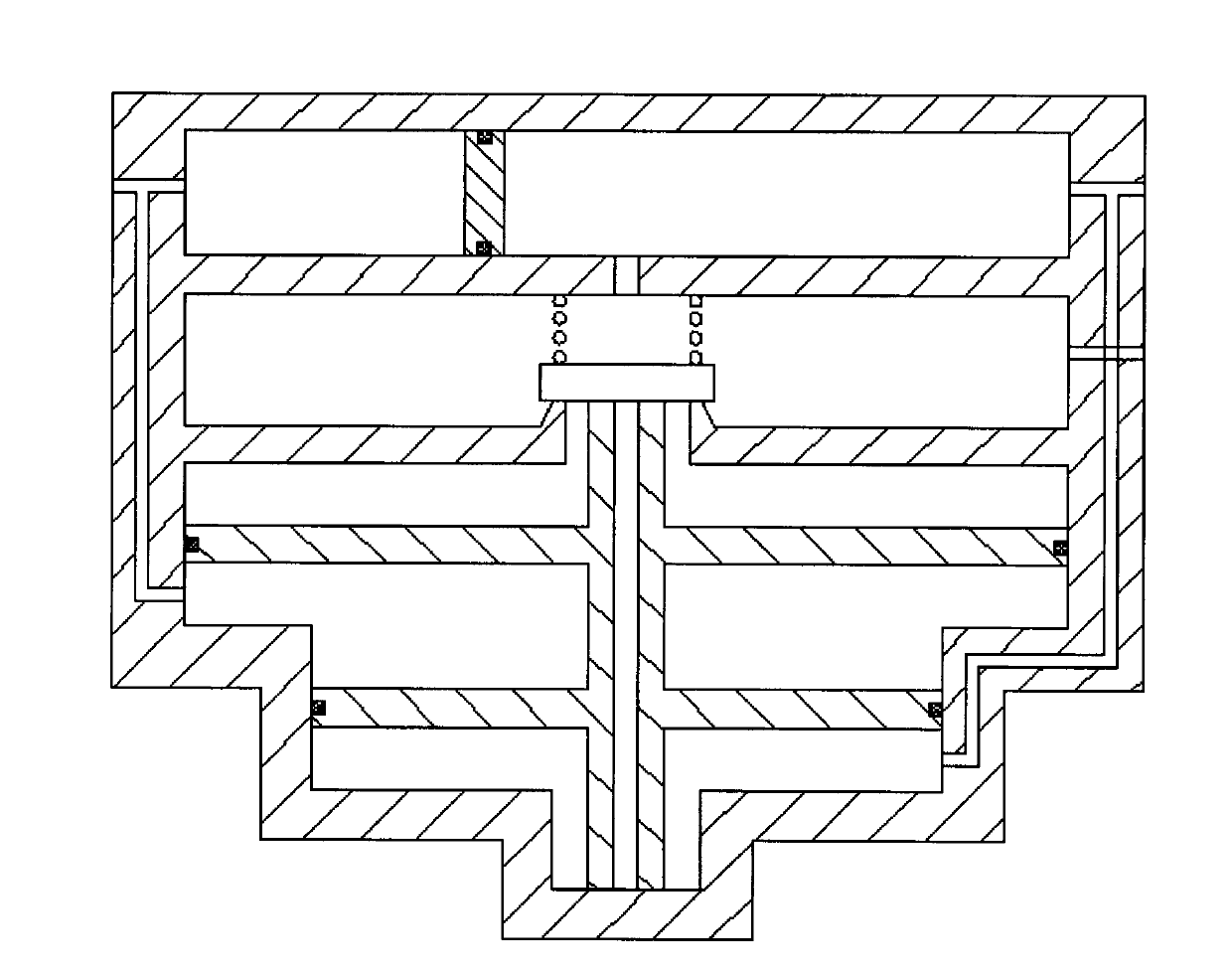

[0067] The present invention aims to provide a railway fast freight car braking method that can increase the braking force, shorten the braking distance, can arrange passenger trains, and can automatically adjust the braking force steplessly as the load of the vehicle changes. The increase and decrease of vehicle load can be automatically and steplessly changed within a certain range, and the braking rate is kept basically constant, with shorter braking idling time and higher braking force, so as to ensure safe driving braking distance. Simultaneously, the present invention also provides a railway fast freight car braking system adopting the above method, which has high reliability, good anti-vibration performance, good dynamic performance, high linearity and sensitivity, and can maintain braking rate It is basically constant and can be mixed with the braking system of passenger trains. The specific embodiments of the braking method and the braking device used in the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com