Method for synthesizing unsaturated polyester resin from allyl glycidyl ether residual liquid and application

A technology of allyl glycidyl ether and polyester resin, which is applied in the field of mechanochemical synthesis technology to achieve the effects of high social value, high quality, excellent bending strength and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

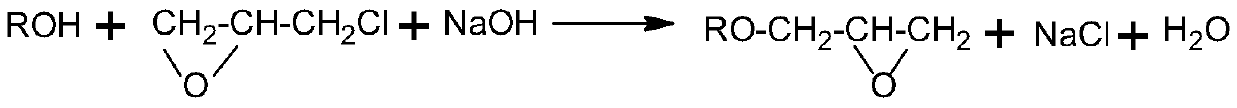

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, a kind of method utilizing allyl glycidyl ether raffinate to synthesize unsaturated polyester resin, its synthetic method comprises the following steps:

[0023] Step (1), with phthalic anhydride, terephthalic acid, isophthalic acid, maleic anhydride, fumaric acid, adipic acid, propylene glycol, neopentyl glycol, ethylene glycol, di Glycol is prepared into a mixed reaction system, and the alkyd molar ratio in the mixed reaction system is 0.5:1 to 1.5:1;

[0024] Step (2), put the mixed reaction system obtained through step (1) in the reactor, and then add the allyl glycidyl ether raffinate with an epoxy value of 0.01 to 0.6 mol / 100g into the reactor, wherein The mass fraction of the feeding amount of propyl glycidyl ether raffinate accounts for 10% to 50% of the total feeding amount of the reaction system;

[0025] Step (3), on the basis of step (2), adjust the reaction temperature in the reactor to 150-250°C, keep it warm for 2-3 hours, and measure the a...

Embodiment 2

[0029] Embodiment 2, a kind of method utilizing allyl glycidyl ether raffinate to synthesize unsaturated polyester resin, comprises the steps:

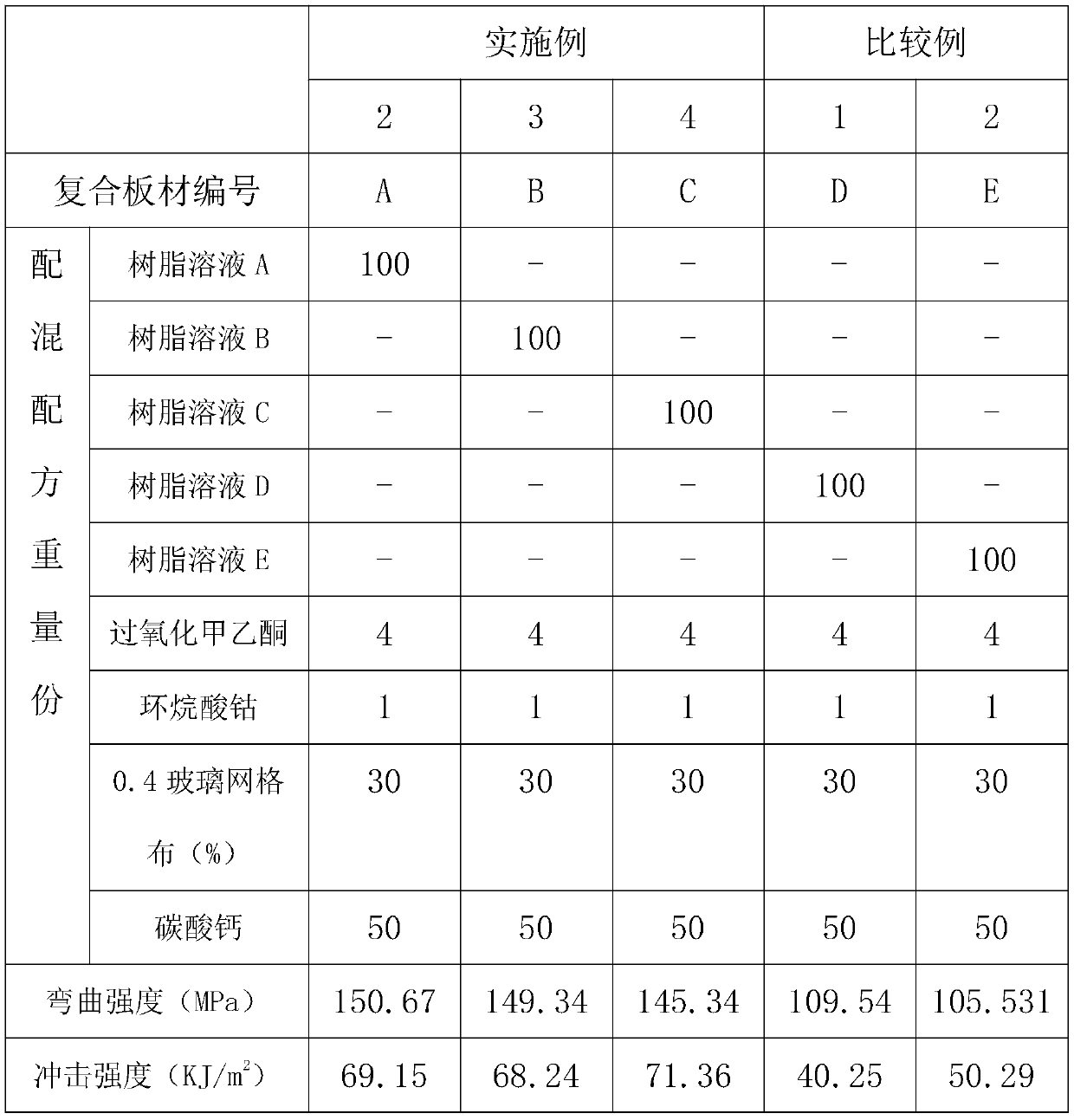

[0030] Step (1): Accurately weigh 10g of allyl glycidyl ether raffinate with an epoxy value of about 0.2eq / 100g, 30g (0.28mol) of diethylene glycol, 30g (0.39mol) of propylene glycol, and 50g of phthalic anhydride (0.3mol), maleic anhydride 25g (0.26mol), fumaric acid 25g (0.22mol), add simultaneously in the 500ml four-neck flask that is equipped with thermometer, nitrogen inlet, reflux condenser and agitator to react, The reaction temperature was gradually increased in the nitrogen flow, and was controlled at 210°C. After the reaction, the acid value of the polyester was controlled at 15 mgKOH / g, and 95 g of styrene was added. Stirring and cooling to obtain the final unsaturated polyester resin A.

[0031] Step (2): 100 parts of resin A obtained from step (1), 4 parts of methyl ethyl ketone peroxide, 1 part of cobalt naphthenate, 30...

Embodiment 3

[0034] Embodiment 3, a kind of method utilizing allyl glycidyl ether raffinate to synthesize unsaturated polyester resin, comprises the steps:

[0035] Step (1): Accurately weigh 10g of allyl glycidyl ether raffinate with an epoxy value of about 0.3eq / 100g, 30g (0.28mol) of diethylene glycol, 40g (0.52mol) of propylene glycol, and 50g of phthalic anhydride (0.3mol), maleic anhydride 30g (0.3mol), fumaric acid 25g (0.22mol), add simultaneously and react in the 500ml four-necked flask that is equipped with thermometer, nitrogen inlet, reflux condenser and stirrer , the reaction temperature is gradually increased in the nitrogen flow, controlled at 190°C, the acid value of the polyester is controlled at 30 mgKOH / g at the end of the reaction, and 80 g of styrene is added. Stir and cool to obtain the final unsaturated polyester resin product B.

[0036] Step (2): In the same manner as in Example 2, the unsaturated polyester resin B was compression-molded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com