High strength sand-plastic composite material

A technology of composite materials and reinforced materials, which is applied in the field of composite materials, can solve problems such as limited application range and poor mechanical strength, and achieve the effects of simple preparation process, high mechanical strength and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

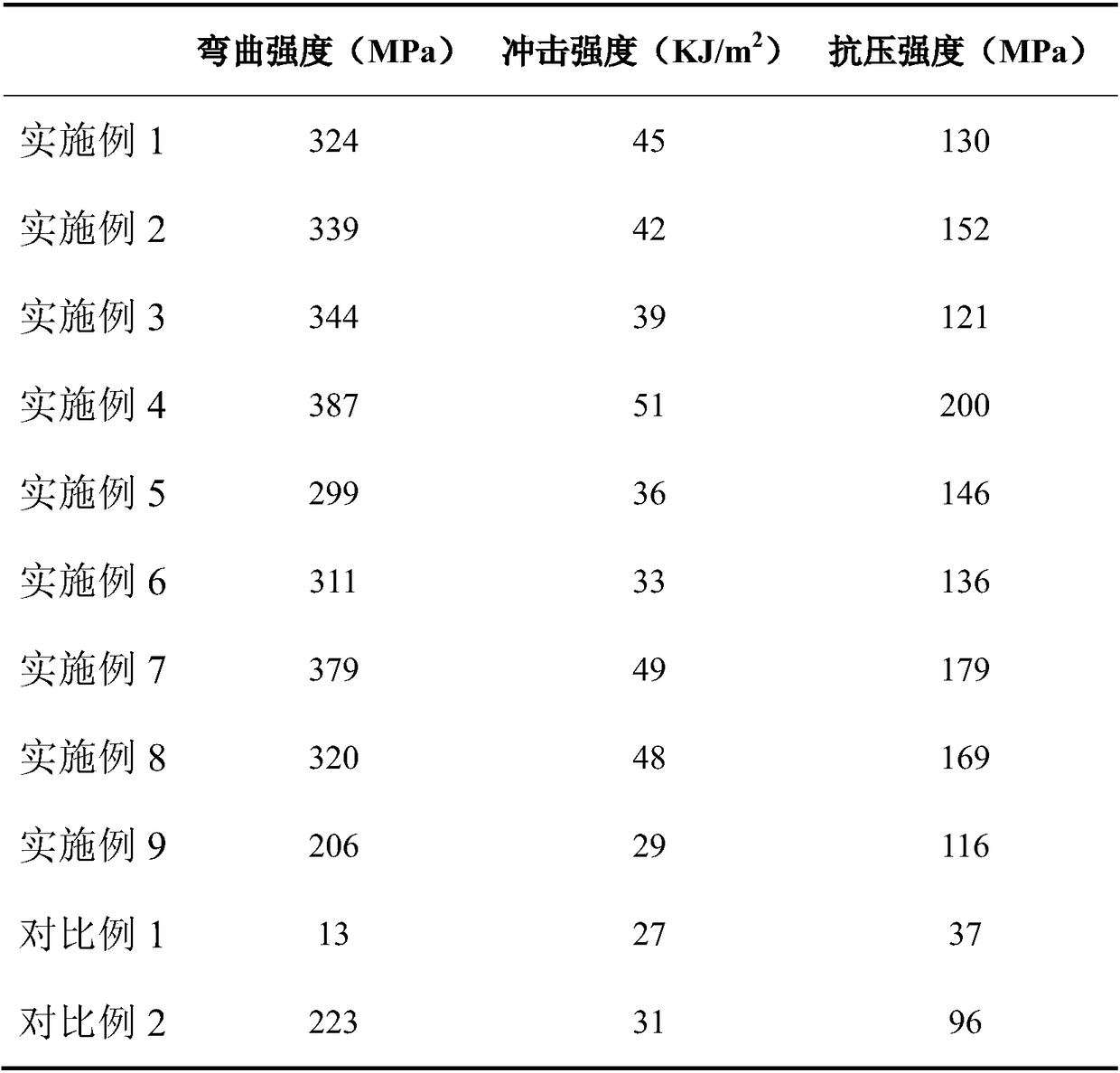

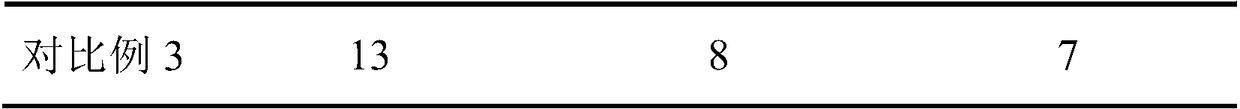

Examples

Embodiment 1

[0029] The preparation method of the sand-plastic composite material provided in this example is as follows: 60 g of 40-mesh silica sand, 0.3 g of silane coupling agent, 6 g of water glass and 0.8 g of benzoic acid are mixed and stirred evenly to make component A; Mix ethylene and 0.5g of epoxy resin AB glue to make component B; add component B and 25g of polyaramid fibers into component A while stirring at 180°C, stir well and then mold it.

Embodiment 2

[0031] The preparation method of the sand-plastic composite material provided in this example is as follows: mix 75 g of 60-mesh silica sand and 1.2 g of silane coupling agent and stir them evenly to make component A; mix 30 g of polypropylene and 0.5 g of resorcinol Mix 15g of epoxy resin adhesive to make component B; at 220°C, add component B and 7g of glass fiber into component A while stirring, and then cool and granulate after stirring.

Embodiment 3

[0033] The preparation method of the sand-plastic composite material provided in this example is as follows: mix 90 g of 100-mesh silica sand and 0.1 g of silane coupling agent and stir evenly to make component A; mix 10 g of polyvinyl chloride and organic silicon-modified diphenol Mix 7.5g of propane epoxy resin adhesive to make component B; at 220°C, add component B and 18g of graphite fiber into component A while stirring, stir well and then cool to granulate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com