Sand plastic floor and manufacturing method and paving structure thereof

A production method and sand-plastic technology, applied in chemical instruments and methods, lamination devices, building structures, etc., can solve the problem of low strength of wood-plastic flooring and achieve high strength and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

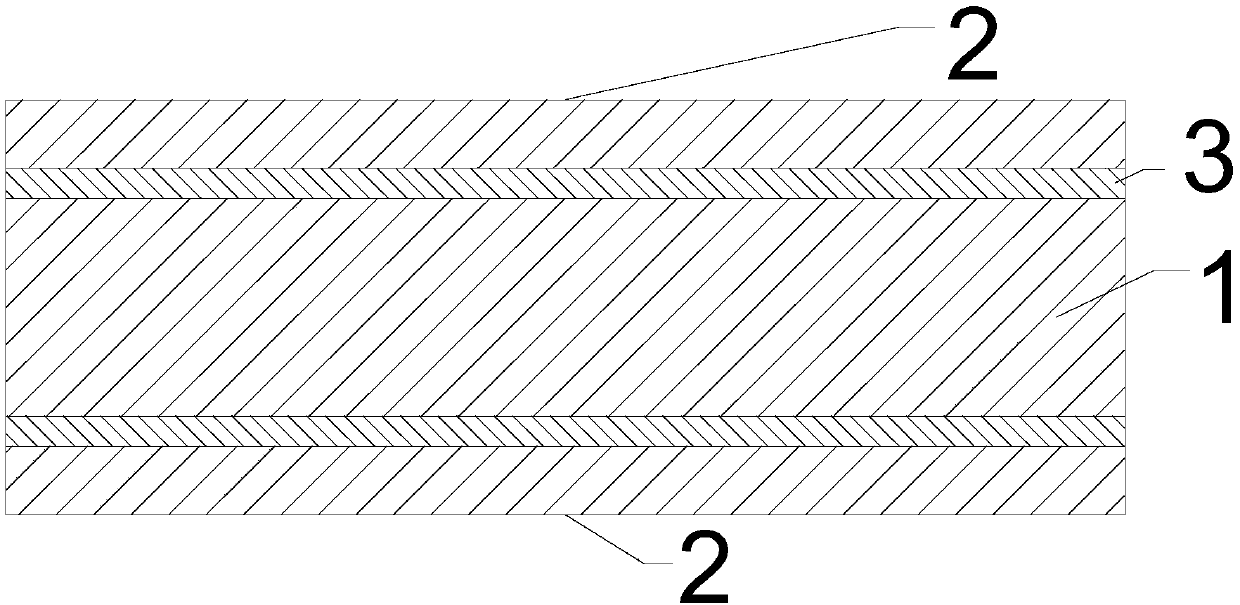

Image

Examples

Embodiment 1

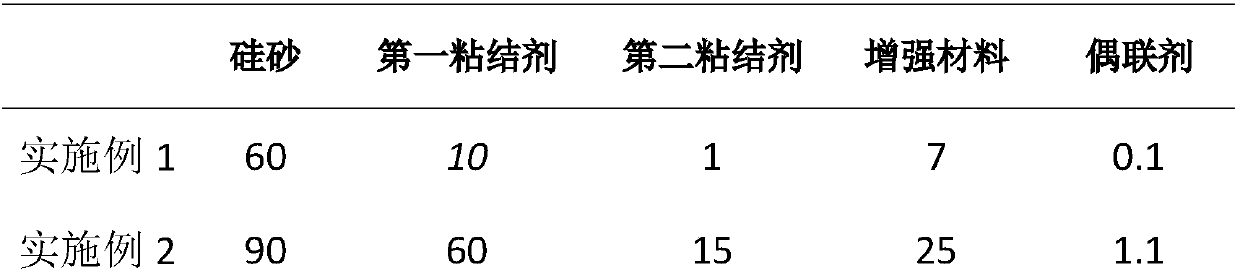

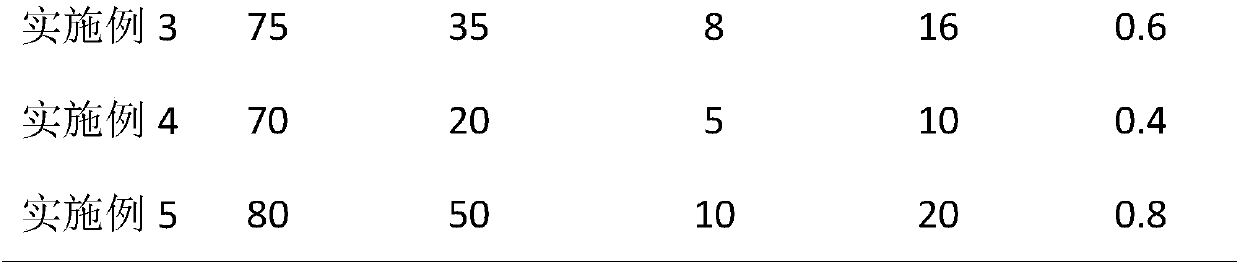

[0038] This embodiment provides a sand-plastic floor, including: a base layer; an anti-impact layer connected to the upper and lower sides of the base layer, the anti-impact layer is made of sand-plastic composite material, and the sand-plastic composite material is In parts by weight, it includes: 60 parts of silica sand; 10 parts of the first binder; 1 part of the second binder; 7 parts of reinforcing material; and 0.1 part of coupling agent.

[0039] In this implementation, green silica sand is used as the main material, and other components are also commonly available materials. The sand-plastic composite material has simple preparation process, low cost and easy industrial production. At the same time, silica sand has a wide range of production areas and can be obtained locally.

[0040] At the same time, in order to improve the connection strength between the impact prevention layer and the base layer, an adhesive layer is provided between the impact prevention layer and the...

Embodiment 2

[0045] This embodiment is made on the basis of embodiment 1, and specifically provides a sand plastic floor, including: a base layer; an anti-impact layer connected to the upper and lower sides of the base layer, and the anti-impact layer is made of sand It is made of plastic composite material. The sand-plastic composite material includes 90 parts by weight of silica sand; 60 parts of first binder; 15 parts of second binder; 25 parts of reinforcing material; 1.1 parts of coupling agent.

Embodiment 3

[0047] This embodiment is made on the basis of embodiment 1, and specifically provides a sand plastic floor, including: a base layer; an anti-impact layer connected to the upper and lower sides of the base layer, and the anti-impact layer is made of sand It is made of a plastic composite material, and the sand-plastic composite material comprises 75 parts by weight of silica sand; 35 parts of a first binder; 8 parts of a second binder; 16 parts of a reinforcing material; and 0.6 parts of a coupling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com