Patents

Literature

163 results about "Trans-Butenedioic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saline-alkali soil improver

InactiveCN102517030ALower pHRaise the pHOther chemical processesOrganic fertilisersCis-Butenedioic AcidFatty alcohol

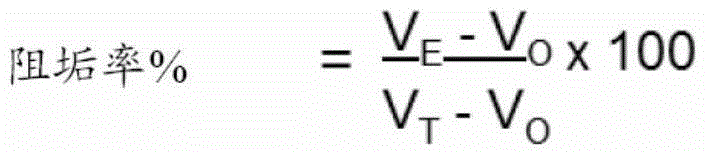

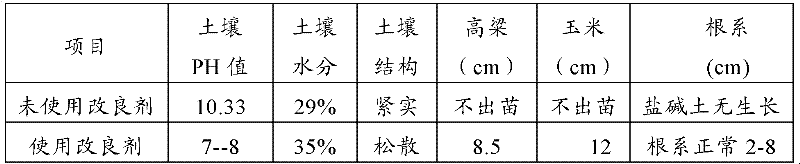

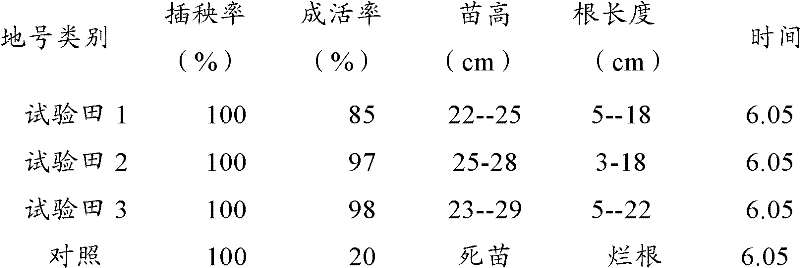

The invention relates to an improver for saline-alkali soil. The improver comprises a powder agent and a water agent, wherein the powder agent comprises the following components: organic matters, plant mycelium protein powder, active calcium, calcium superphosphate, aluminum sulfate, fatty alcohol polyoxyethylene ether ammonium sulfate, amino acid powder, bacillus subtilis and photosynthetic bacteria, and the water agent comprises the following components: citric acid, fulvic acid, humic acid, malic acid, maleic acid, fumaric acid, L-tartaric acid, pyrophosphoric acid, humic acid, lactic acid, oxalic acid, salicylic acid, sodium ion adsorbent, Tween-80 and water. The improver disclosed by the invention can improve the soil from multiple angles, namely soil structure, microorganism species, a chemical method and the like, obviously promote the release of iron and phosphorus in the soil, improve the soil structure, effectively reduce the content of sodium ions in the soil, reduce the pH value of the soil and restore land to a normal planting state after being used continuously for two years.

Owner:孙东军 +1

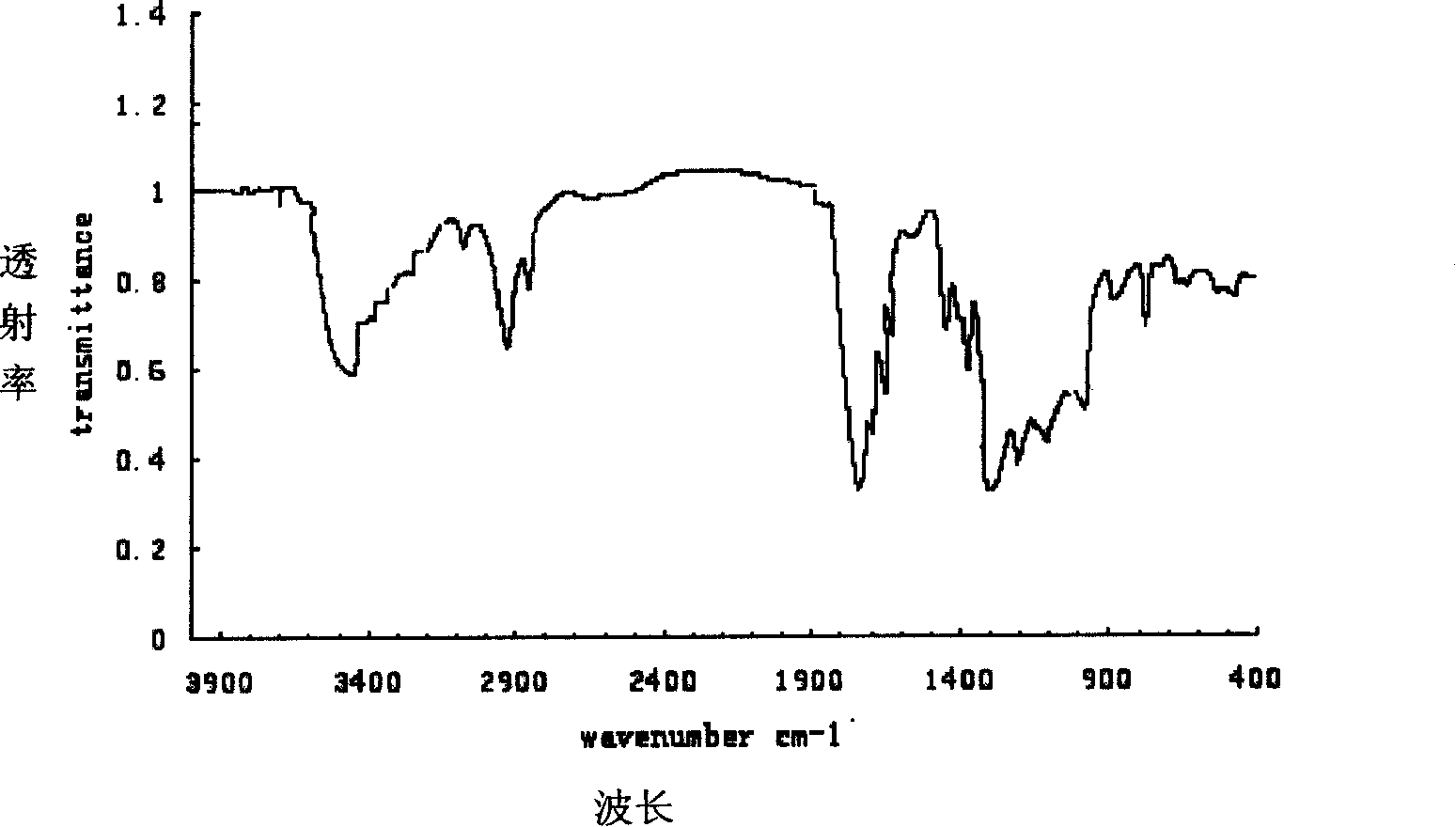

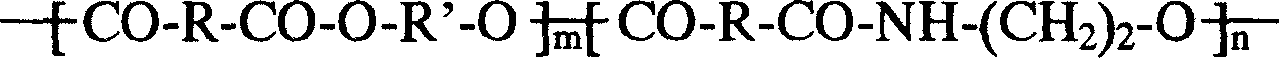

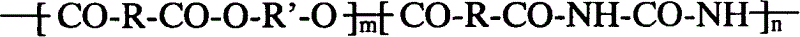

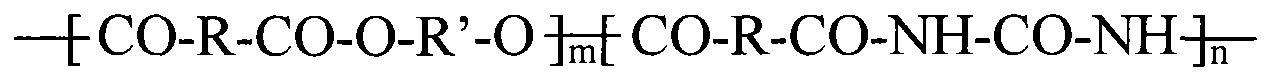

Degradable unsaturated polyesteramide resin and synthesis method thereof

The invention adopts a melt polycondensation method. A few of monomers of C2-5 aliphatic dibasic alcohol, diethylene glycol, polyglycol, fumaric acid, maleic anhydride, lactic acid, glycolic acid, ethanolamine, C2 to C12 aliphatic diamine, glutamic acid, lysine, glycine, etc. are taken as basic materials to be synthesized to obtain non toxic unsaturated polyester-amide resin with adjustable degradation rate and lower cost; wherein, the partial fumaric acid or maleic anhydride can be replaced with phthalic anhydride, isophthalic acid, or adipic acid. The resin yearns for being used as matrix resin of medical bone internal fixation material, tissue engineering scaffold material, bone tissue temporary substitutes, environmental protection type bonding agent, environmental protection type fiberglass reinforced plastics, environmental protection type coating material, disposable tableware, packing material, shopping bags, disposable bags, drug coating or capsule, drug delivery (controlled-release) material, agricultural mulching films, etc., and can be recovered to be utilized.

Owner:HUNAN UNIV

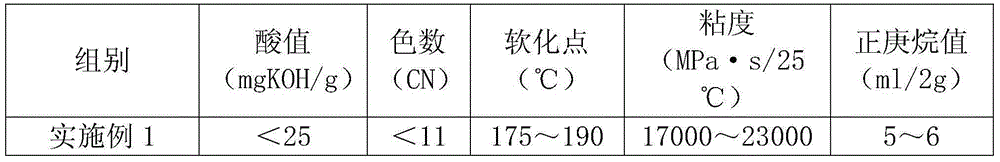

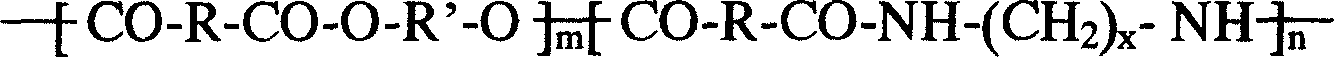

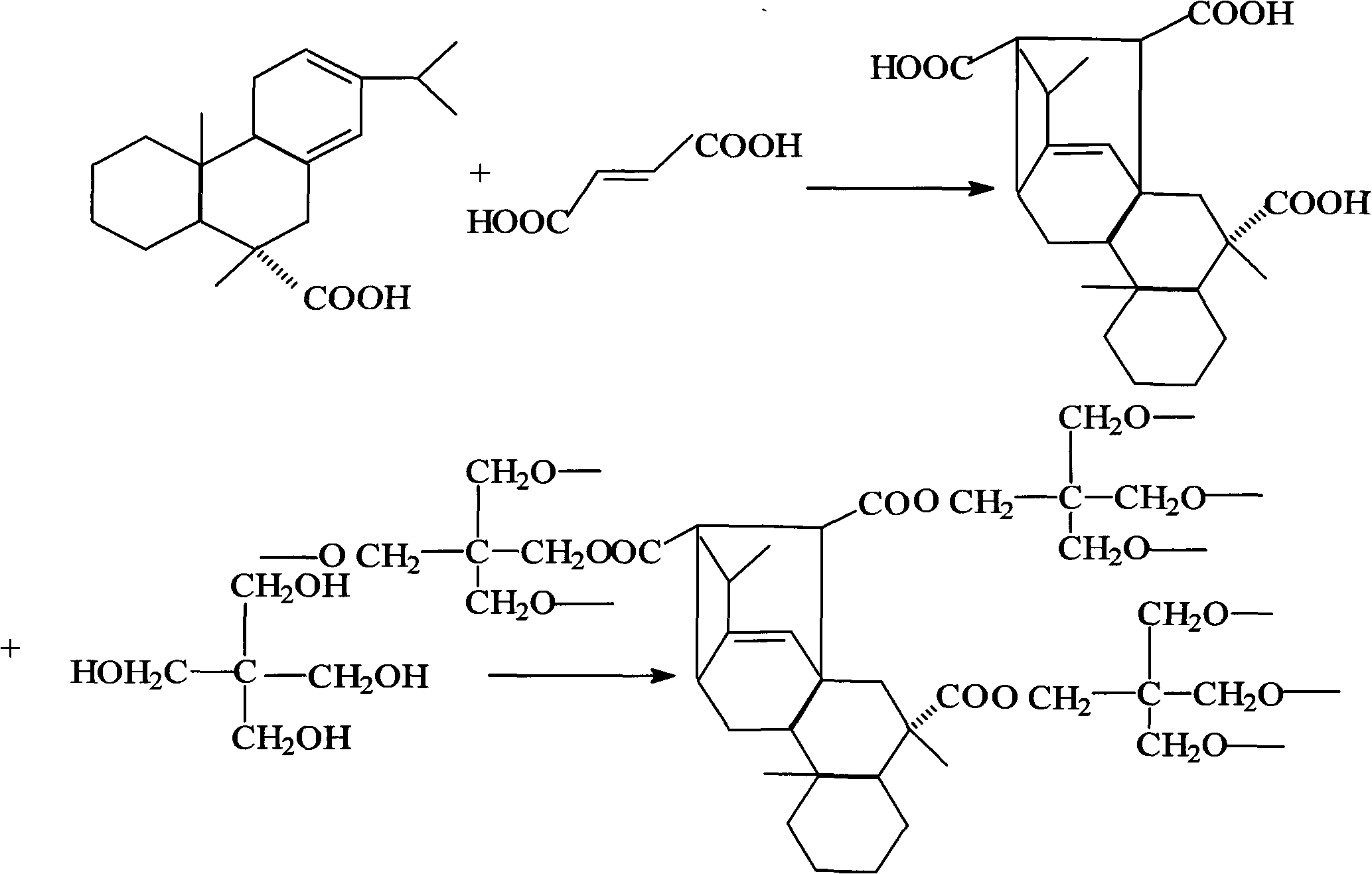

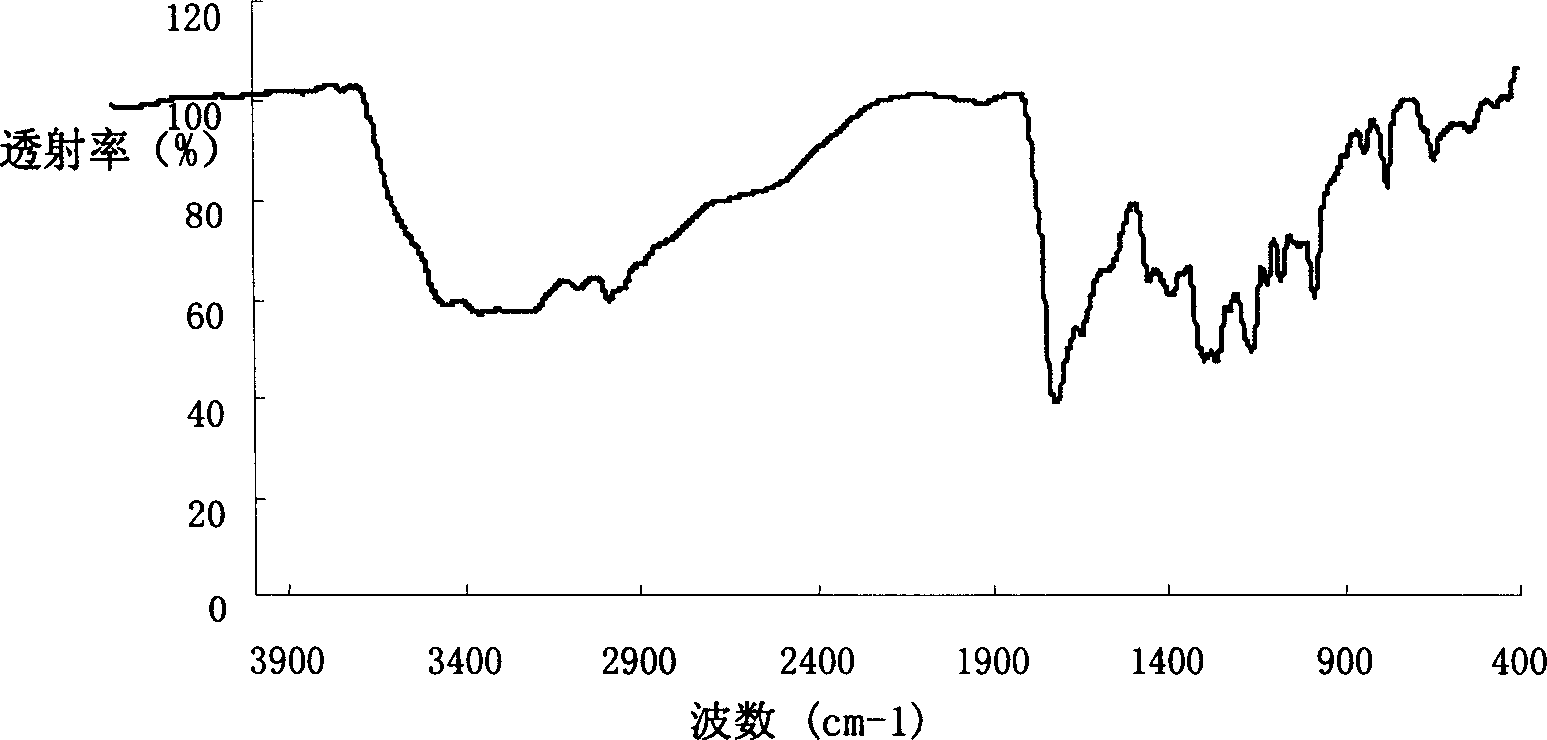

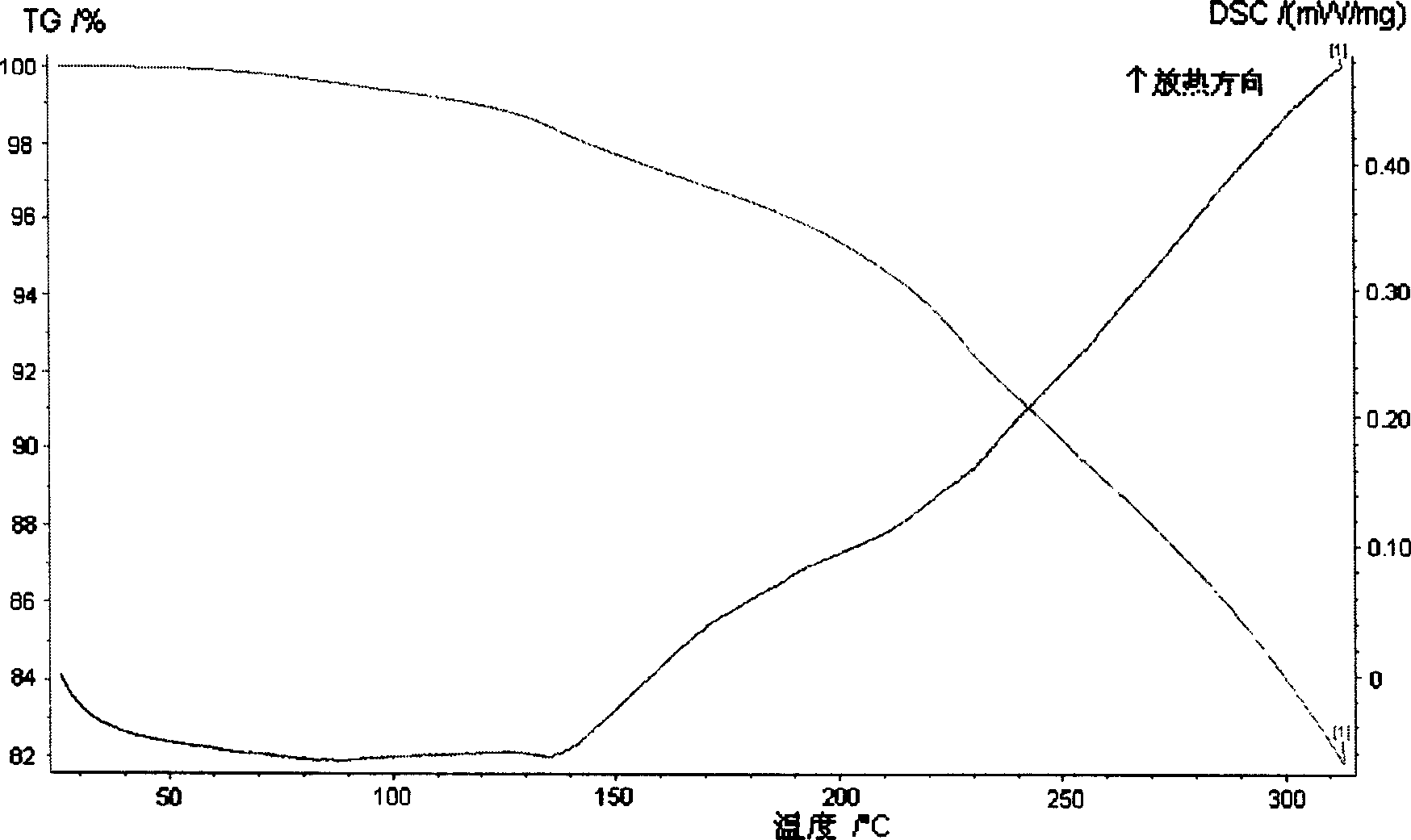

Preparation method of high-viscosity rosin resin

InactiveCN101649161AThe average molecular weight is largeMolecular structure with many branched chainsNatural resin chemical modificationPentaerythritolAdhesive

The invention discloses a preparation method of high-viscosity rosin resin which reaches higher viscosity under the condition of a lower softening point. The high-viscosity rosin resin comprises the following raw materials by weight percent: 85-86 percent of rosin, 2.0-3.0 percent of fumaric acid and 12-13 percent of pentaerythritol. The preparation method comprises the following steps: dissolvingthe rosin and then sucking the rosin into a reaction kettle; cooling to 190 DEG C to 200 DEG C; adding the fumaric acid; reacting in a heat preservation mode; when the softening point reaches 90 DEGC to 95 DEG C, adding the pentaerythritol; heating to 275 DEG C to 280 DEG C; continuing reaction; and when the acid value is smaller than or equal to 16 mg / g and the softening point reaches 110 DEG Cto 115 DEG C, performing dealcoholization and granulation to obtain a finished product. The rosin resin prepared by the preparation method can be conveniently applied to adhesives, coatings, printingink and polyamide resin products.

Owner:张家港市阳光化工有限公司

Method for promoting microbe to synthesize, 1,3-propylene glycol by adding fumaric acid from extraneous sources

A process for preparing 1,3-propanediol by adding fumaric acid to activate microns includes preparing culture media, seed culture and fermenting. It features that the fumaric acid is added to the fermentive culture medium for speeding up the utilization of glycerine by bacterial spawn.

Owner:TSINGHUA UNIV

Degradable unsaturated carbamide resin of polyester amide, and synthetic method

A degradable unsaturated polyester-amidourea resin used for disposable food container, packing material, plastic bag, medicinal coating, capsule and slow-releasing material, etc is prepared from C2-C4 binary alcohol, anti-butenedioic acid or maleic anhydride, and urea through fusing and polycondensating. It can be modified by starch or calcium carbonate powder.

Owner:郭文迅

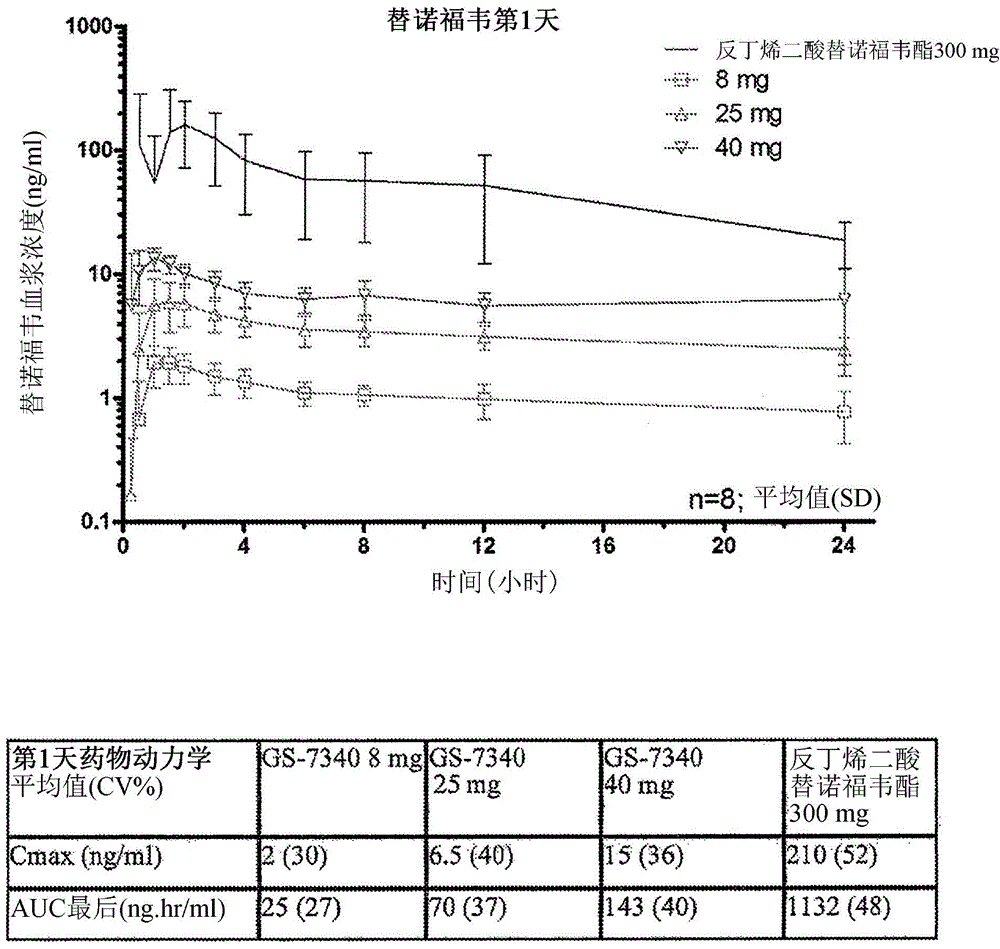

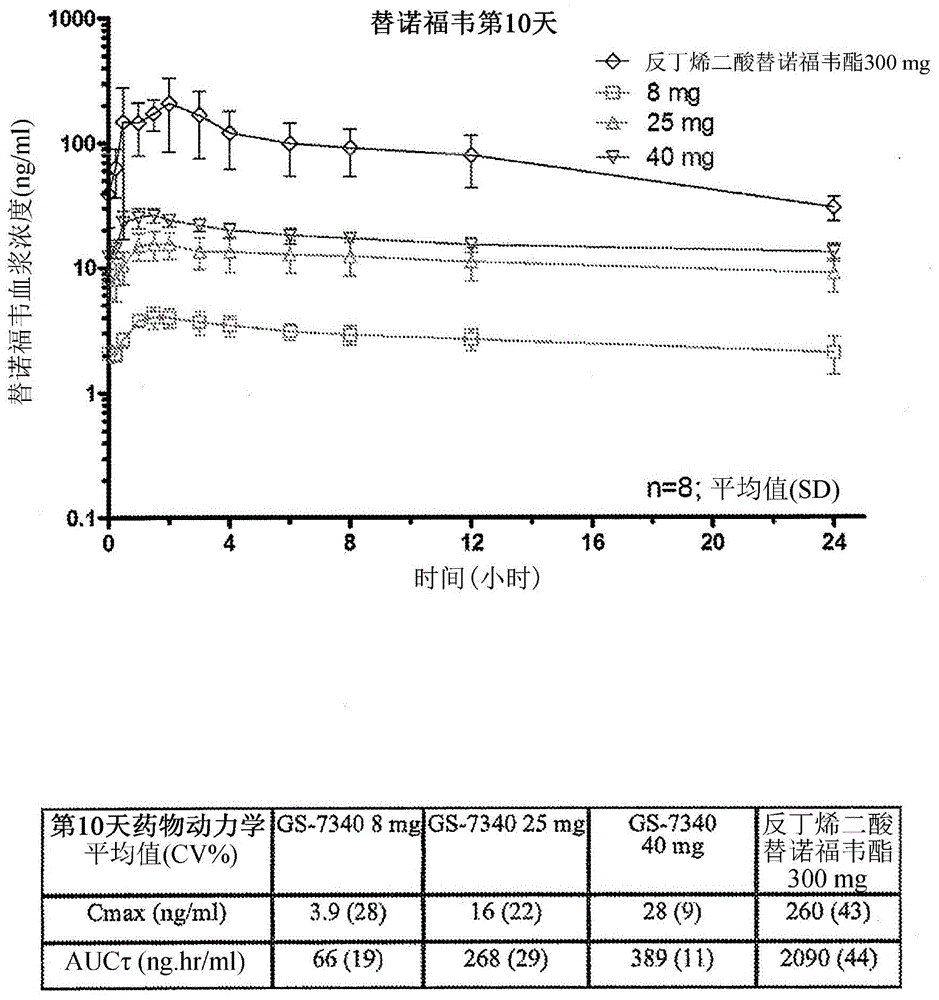

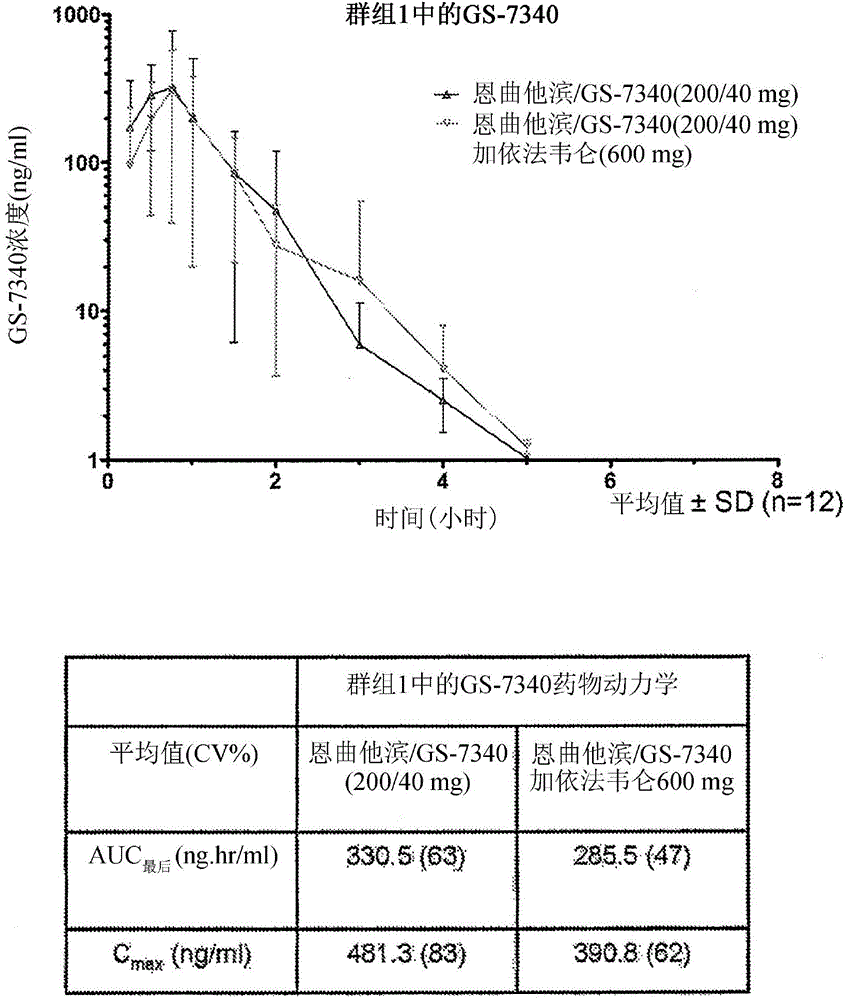

Combination therapy comprising tenofovir alafenamide hemifumarate and cobicistat for use in the treatment of viral infections

InactiveCN104105484AAntiviralsHeterocyclic compound active ingredientsEmtricitabineTenofovir alafenamide

The use of the hemifumarate form of {9-[(R)-2-[[(S)-[[(S)-l- (isopropoxycarbonyl)ethyl]amino]phenoxyphosphinyl]methoxy]propyl]adenine} (tenofovir alafenamide hemifumarate) in combination with cobicistat is disclosed. In addition, the combination of tenofovir alafenamide hemifumarate, cobicistat, emtricitabine, and elvitegravir, and the combination of tenofovir alafenamide hemifumarate, cobicistat, emtricitabine, and darunavir, are disclosed.

Owner:GILEAD SCI INC

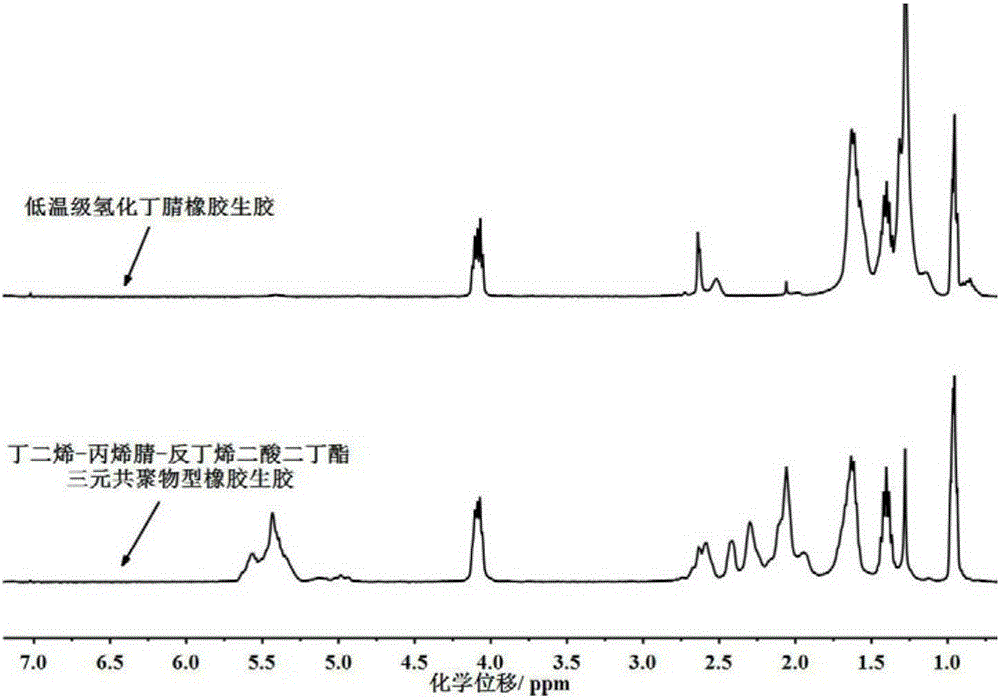

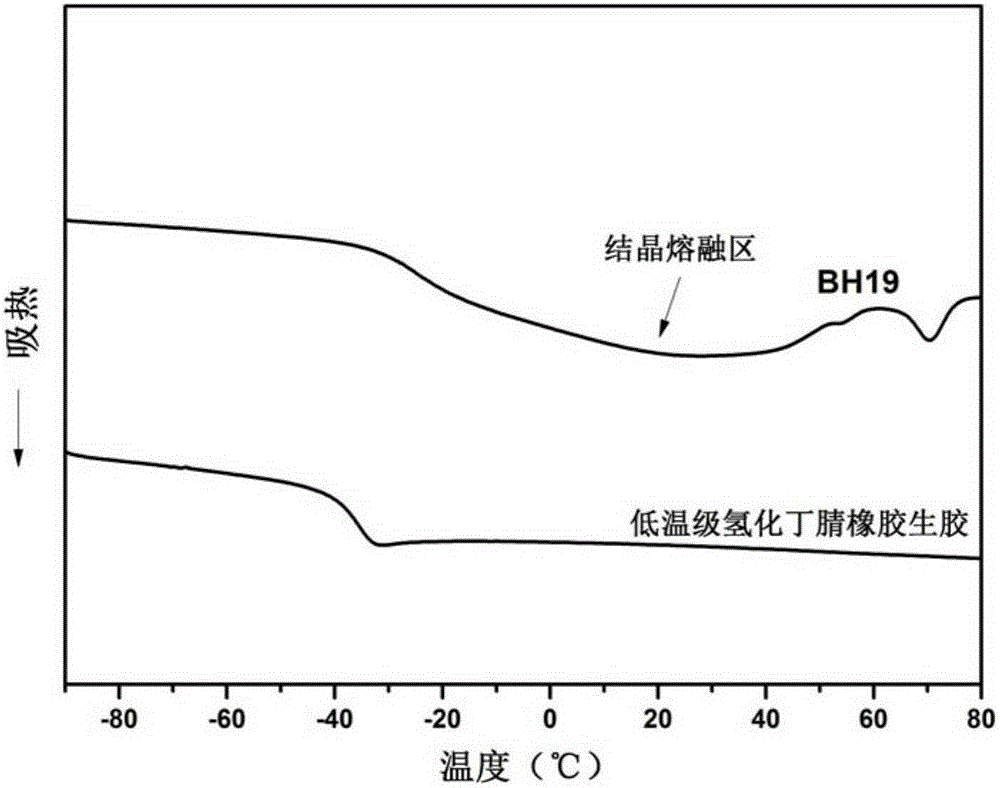

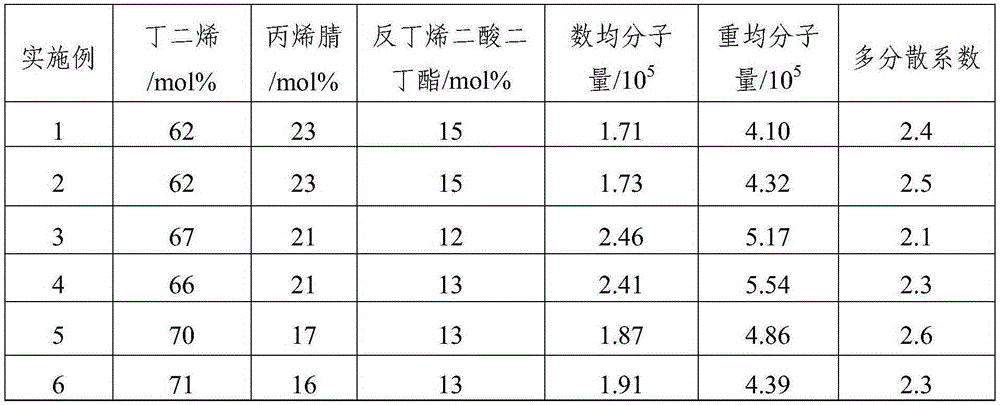

Low-temperature-level hydrogenated acrylonitrile butadiene rubber crude rubber and preparation method thereof

ActiveCN105294939ARaw rubber with high molecular weightGood oil resistancePolymer scienceAcrylonitrile

The invention provides low-temperature-level hydrogenated acrylonitrile butadiene rubber crude rubber. The low-temperature-level hydrogenated acrylonitrile butadiene rubber crude rubber is a copolymer of butadiene, acrylonitrile and dibutyl fumarate. The number-average molecular weight of the copolymer ranges from 1.05*105 to 3.25*105, the weight-average molecular weight of the copolymer ranges from 3.02*105 to 9.32*105, and the polydispersity index of the copolymer ranges from 2.0 to 2.7. The hydrogenation degree of the low-temperature-level hydrogenated acrylonitrile butadiene rubber crude rubber is more than 90%, and the glass-transition temperature ranges from -38 DEG C to -42 DEG C. The invention further provides a preparation method of the low-temperature-level hydrogenated acrylonitrile butadiene rubber crude rubber. The molecular weight of the low-temperature-level hydrogenated acrylonitrile butadiene rubber crude rubber is high, the glass-transition temperature is low, no crystallization occurs at low temperature, the content of acrylonitrile ranges from 17 mol% to 23 mol%, dibutyl fumarate containing diester-based functional groups is introduced, low-temperature resistance is excellent while good oil resistance is guaranteed, the technical barrier of low-temperature-level hydrogenated acrylonitrile butadiene rubber is broken through, high application value is achieved, and development prospects are broad.

Owner:BEIJING UNIV OF CHEM TECH

Tea preservative and preparation method and application thereof

InactiveCN101828605AGuaranteed qualityWith deoxygenationFood preservationTeaButeneSodium bicarbonate

The invention relates to a tea preservative and a preparation method and an application thereof. The preservative is prepared from the following components in percentage by weight: 20-25 parts of ferrous powder, 10-15 parts of iron dichloride, 20-25 parts of sodium bicarbonate, 5-10 parts of trans-butene diacid, 15-20 parts of zeolite and 2-5 parts of active dryer, and the dosage of the preservative is 2 percent of fresh tea in mass and is packaged with an aluminum foil bag for storage. The tea preservative has low cost, convenient preparation and little quality deterioration of tea in a storage process, and can effectively overcome the influence of external environmental conditions on tea, protect the tea quality, decrease the economic loss and increase the production benefits.

Owner:YANGZHOU UNIV

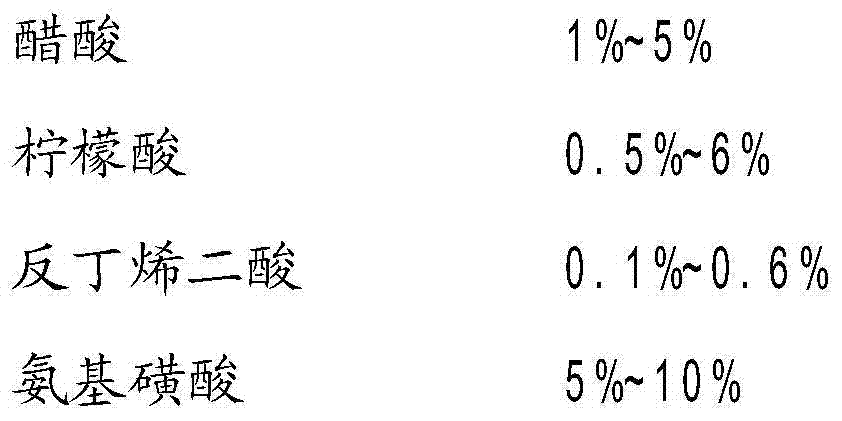

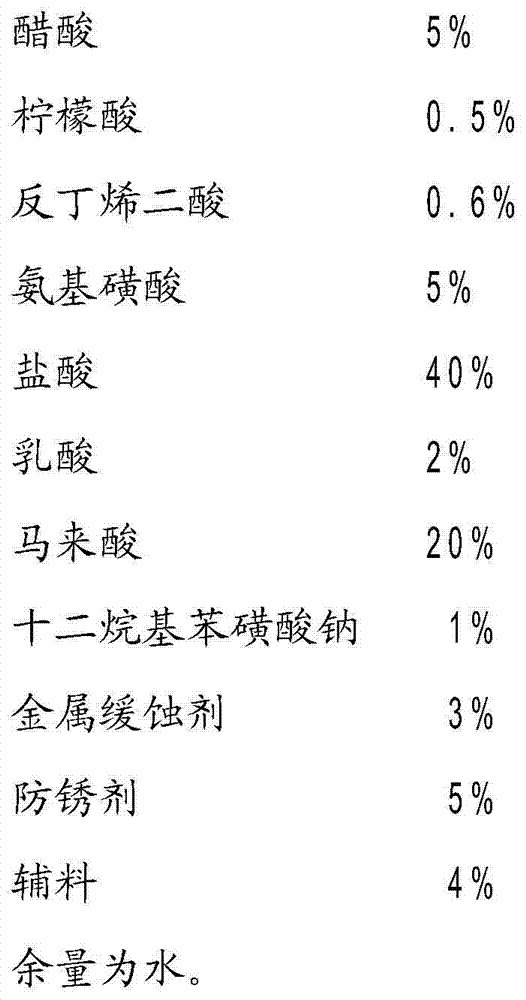

Descaling agent

InactiveCN104761065ADoes not affect healthDissolve fastSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsHuman healthSODIUM DODECYL BENZENE SULFONATE

The invention discloses a descaling agent. The descaling agent is prepared from the following components in percentage by mass: 1%-5% of acetic acid, 0.5%-6% of citric acid, 0.1%-0.6% of fumaric acid, 5%-10%o of sulfamic acid, 5%-40% of hydrochloric acid, 2%-10% of lactic acid, 1%-20% of maleic acid, 1%-3% of sodium dodecyl benzene sulfonate, 1%-3% of metal corrosion inhibitor, 5%-8% of corrosion inhibitor, 2%-4% of auxiliary materials and the balance of water. The descaling agent is non-poisonous and harmless to human bodies, capable of rapidly dissolving water scale, safe and reliable, has low corrosion to devices and mild performances, can save energy sources, does not hurt the skin and does not influence human health.

Owner:张萍

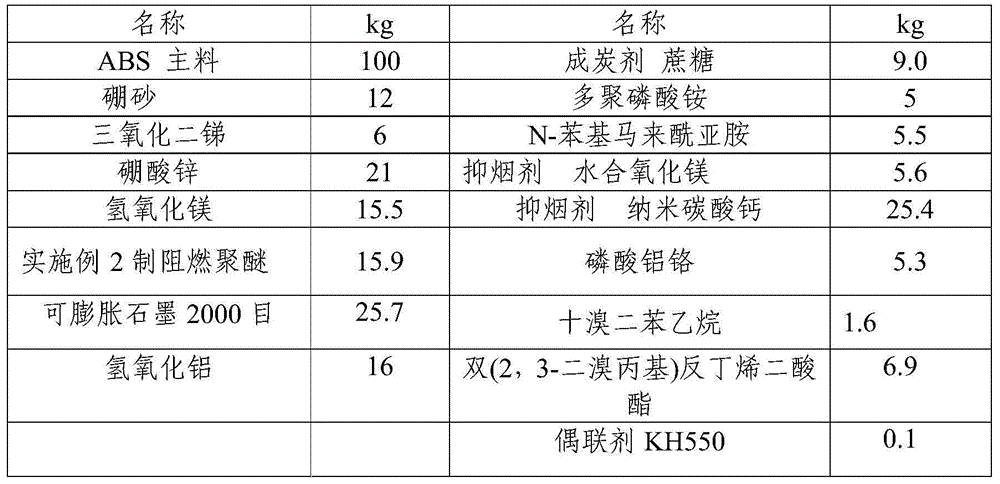

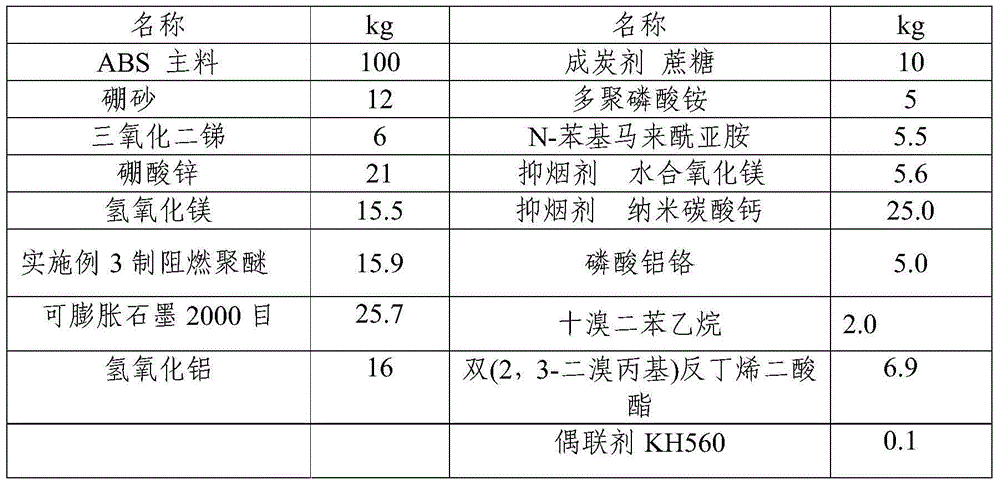

Grade-A fireproof material based on ABS (acrylonitrile-butadiene-styrene) plastic

The invention provides a Grade-A fireproof material based on ABS (acrylonitrile-butadiene-styrene) plastic, which is prepared from the following components in parts by mass: 100 parts of ABS, 8-10 parts of char forming agent, 10-15 parts of borax, 2-8 parts of ammonium polyphosphate, 4-8 parts of antimony trioxide, 4-8 parts of N-phenyl maleimide, 15-25 parts of zinc borate, 30-40 parts of smoke inhibitor, 20-40 parts of hydroxide, 10-20 parts of flame-retardant polyether, 4-8 parts of chromium aluminum phosphate, 20-30 parts of expandable graphite, 1.6-3.8 parts of decabromodiphenylethane, 5-10 parts of bis(2,3-dibromopropyl)fumarate, 0.05-0.5 part of coupling agent and 10-18 parts of coupler-treated calcium carbonate. All the indexes of the ABS plastic product satisfy the Grade-A fireproof non-inflammable standard for national construction materials, and the strength and toughness are better than those of like products.

Owner:江西合盛安泰新材料有限公司

Degradable unsaturated polyester amide urea copolymer and synthesizing method

The invention relates to a melt polycondensation method for the synthesis of unsaturated polyester amide urea resin from dipropylene glycol or neopentyl glycol or polyethylene glycol, transbutene dioic acid or maleic anhydride and urea as raw materials. The synthesized unsaturated polyester amide urea resin has the advantages of controllable degradation rate, no toxicity and low cost. The transbutene dioic acid or maleic anhydride can be partially replaced by benzene anhydride, isophthalic acid or adipic acid. The dipropylene glycol or neopentyl glycol or polyethylene glycol can be partially replaced by ethylene glycol or propylene glycol. The resin is used as matrix of fracture internal fixation material, tissue engineering scaffold, bone graft substitute, environment-friendly binder, environment-friendly glass-reinforced plastics, environment-friendly painting, disposable tableware, packaging material, shopping bag, garbage bag, pharmaceutical coating or capsule, pharmaceutical slow- / controlled-release material, agricultural mulch film, etc. furthermore, the resin is recoverable.

Owner:HUNAN UNIV

Anti-aging unsaturated polyester resin and preparation method and application thereof

The invention relates to anti-aging unsaturated polyester resin and a preparation method and application thereof. The anti-aging unsaturated polyester resin is prepared from the following reactants in percentage by weight: 28-35% of dihydric alcohol, 30-50% of dicarboxylic acid or anhydride and 25-35% of thinner, wherein the dicarboxylic acid or anhydride at least comprises 1,4-cyclohexanedicarboxylic acid, and the thinner is the combination of methyl methacrylate and styrene. The preparation method of the anti-aging unsaturated polyester resin comprises the following steps: carrying out a condensation reaction on the dihydric alcohol and the 1,4-cyclohexanedicarboxylic acid until the acid value is 20-40mgKOH / g, decreasing temperature, adding maleic anhydride or fumaric anhydride, slowly increasing temperature to carry out polycondensation reaction until the acid value is 45-55mgKOH / g, reducing pressure to carry out vacuum treatment until the acid value is 25-35mgKOH / g, adding an additive, cooling and adding the thinner. The anti-aging unsaturated polyester resin is used for making artificial stone plates, basins, sanitary ware and sheet molding compound. The content of benzene rings in the unsaturated polyester resin is greatly reduced, and anti-aging performance of the anti-aging unsaturated polyester resin is improved. The anti-aging unsaturated polyester resin has higher color and mechanical performance retention rate under the condition of coexistence of high light, oxygen and water.

Owner:上海新天和树脂有限公司 +2

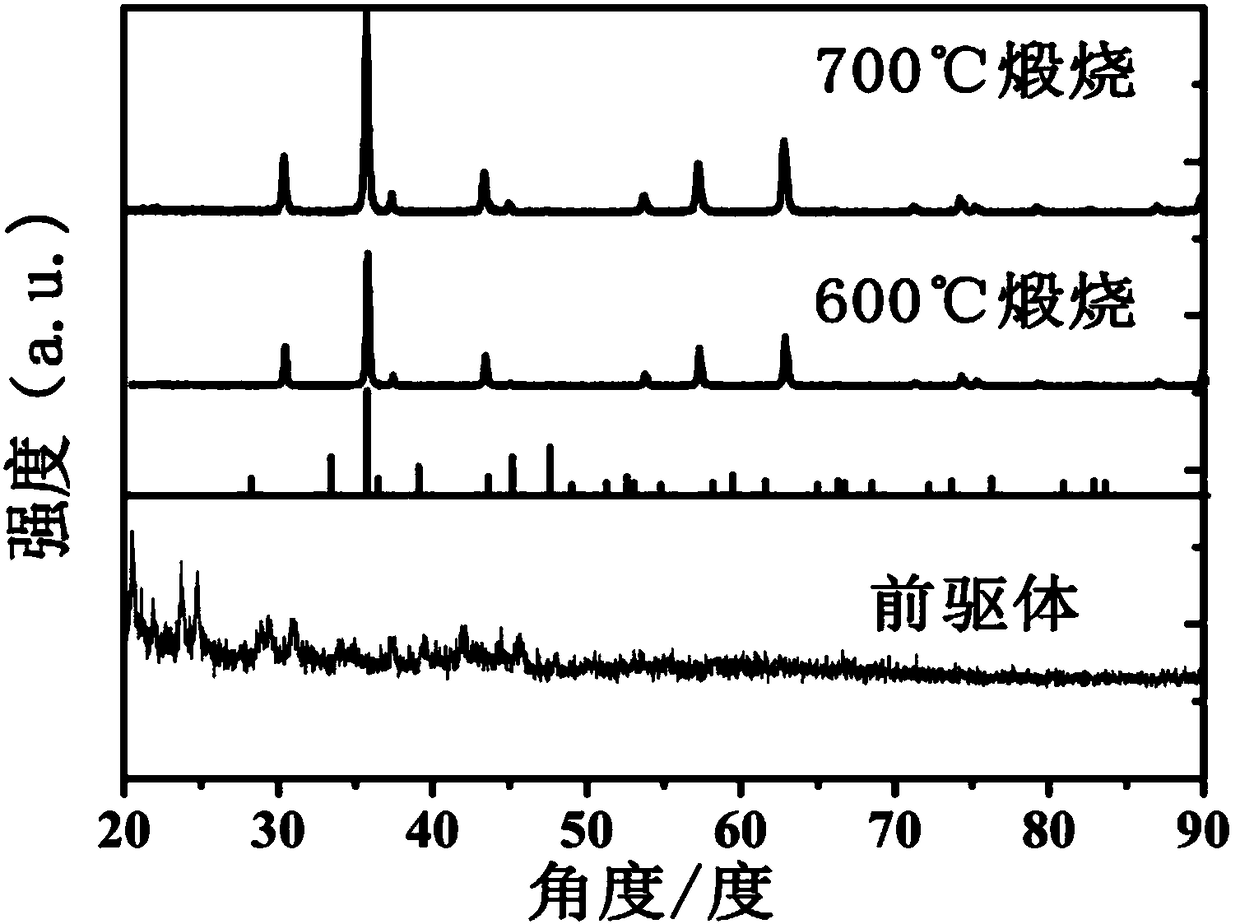

Porous ferroferric oxide/ carbon nanometer rod-shaped electromagnetic wave absorbing material and preparing method and application thereof

ActiveCN108154984AHigh saturation susceptibilityImprove coercive forceMaterial nanotechnologyMagnetic/electric field screeningAbsorbent materialOxidation resistant

The invention relates to a porous ferroferric oxide / carbon nanometer rod-shaped electromagnetic wave absorbing material and a preparing method and application thereof. The porous ferroferric oxide / carbon nanometer rod-shaped electromagnetic wave absorbing material is multi-phase nanometer composite powder composed of carbon and ferroferric oxide and a nanometer rod of a porous structure with thelength being 1.0-1.2 micrometers. The preparing method comprises the steps of dissolving raw materials like ferric trichloride hexahydrate and fumaric acid into deionized water, conducting a reactionto obtain a precursor, conducting calcination under nitrogen atmosphere and directly synthesizing the porous ferroferric oxide / carbon nanometer rod composite material. The porous ferroferric oxide / carbon nanometer rod composite material is high in stability and uniformity, has the advantages of being high in electromagnetic wave absorbing performance, wide in absorbing and covering frequency range, high in corrosion resistance and oxidation resistance and low in cost and is used for manufacturing an electromagnetism absorber.

Owner:SHANDONG UNIV

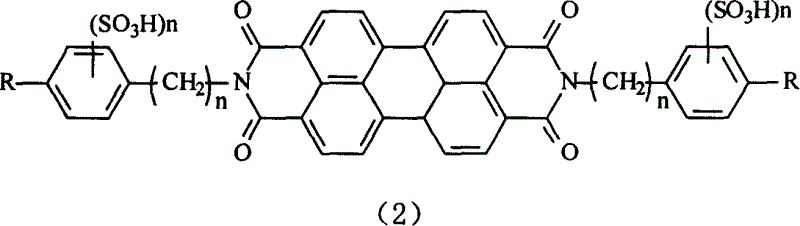

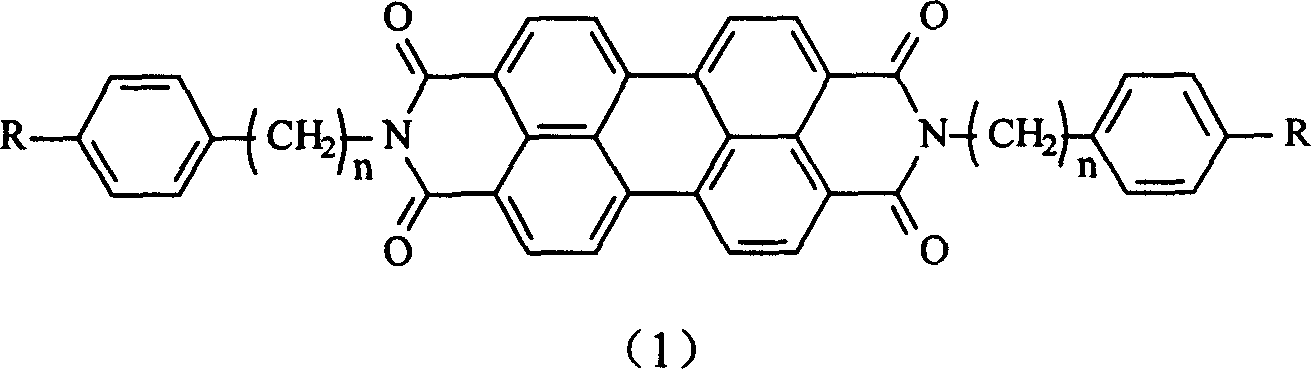

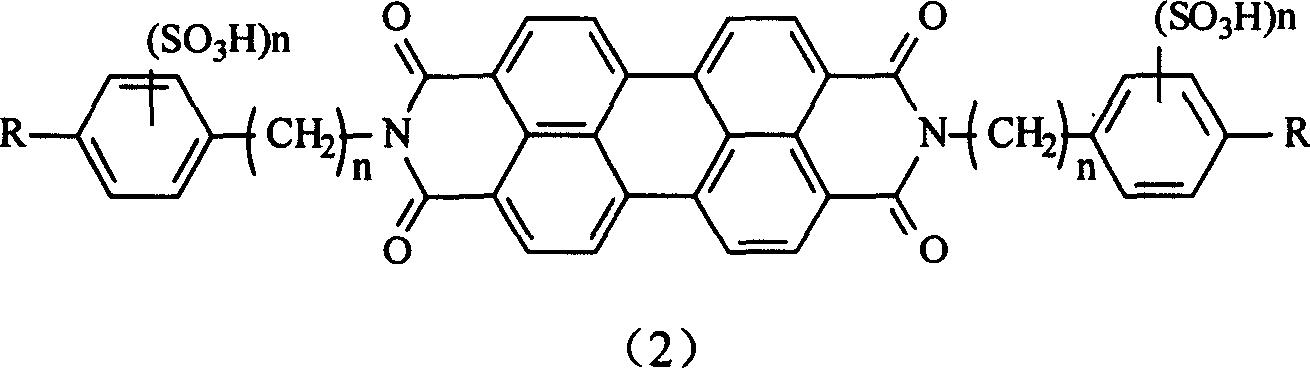

Method for preparing black perylene derivatives pigment

The present invention discloses black perylene pigment preparing process. During the preparation process, 3, 4, 9, 10-perylene tetracid dihydride is first reacted with aryl or substituent aryl aliphatic primary amine in the presence of potassium hydroxide and acetic acid to prepare coarse pigment product; the coarse pigment product is then ball milled in the presence of milling assistant, dispersant, and organic solvent, solid citric acid, maleic acid fumaric acid or calcium stearate; and the and the ball milled material is finally boiled in acid water medium containing surfactant and treated through filtering, water washing and drying to obtain the black perylene pigment. Thus prepared pigment has high black degree, high coloring capacity and easy dispersing.

Owner:EAST CHINA UNIV OF SCI & TECH +1

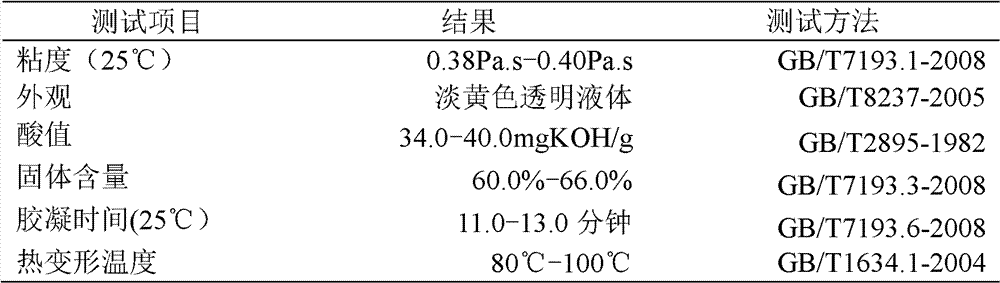

Rosin polyester resin for lithography printing ink and synthetic method thereof

The invention discloses a rosin polyester resin for lithography printing ink and a synthetic method thereof. The resin comprises, by weight, 100 portions of polymerized rosin or rosin derivatives, 1-10 portions of fumaric anhydride or maleic anhydride, 1-20 portions of vegetable oil or fatty acid, 5-20 portions of polyols and 0.1-3.0 portions of a metal oxide catalyst. Product specifications are as below: flaxseed oil viscosity of (mPa.s / 25 DEG C) 3000-10000, receiving degree (n-heptane g / 3 g) of 1-20, acid value (mgKOH / g) less than or equal to 30, softening point of 150-200 DEG C, and molecular weight (Mw) of 10000-300000. The invention has the following beneficial effects: the polyester has performances not inferior to those of the rosin modified phenolic resin, but not contains phenolic substances difficult to degrade in the environment and harmful to human body, and is an environment-friendly polyester resin compound, and applicable to harmless lithography printing ink for green printing.

Owner:广西蒙山梧华林产科技有限公司

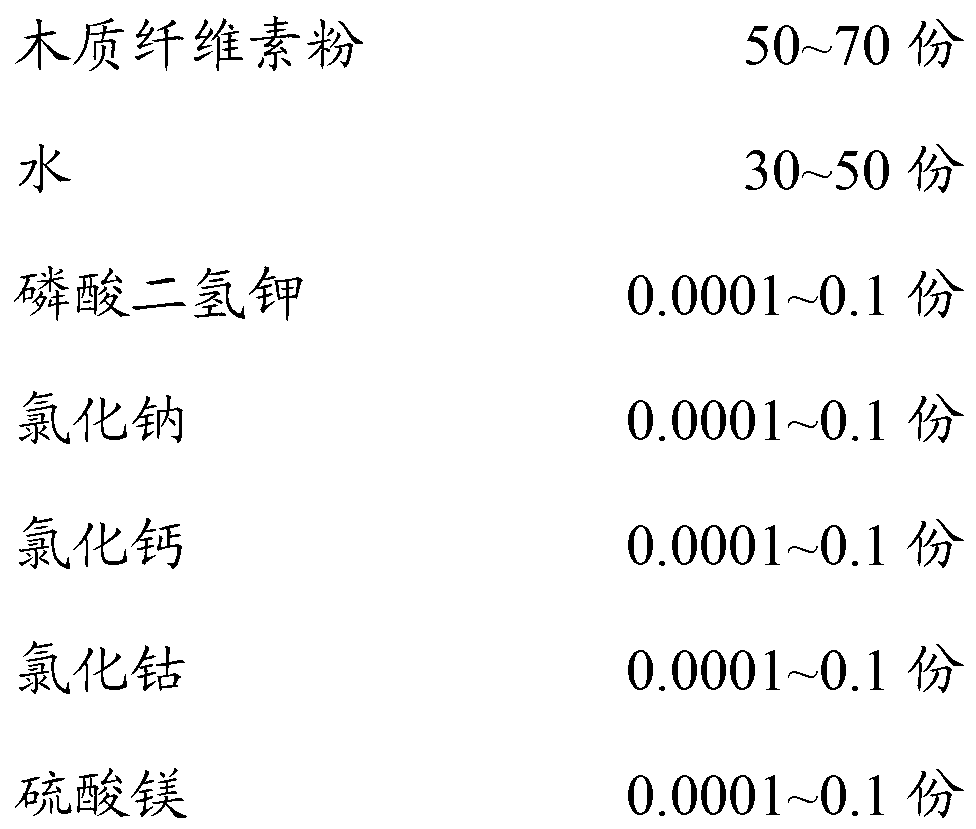

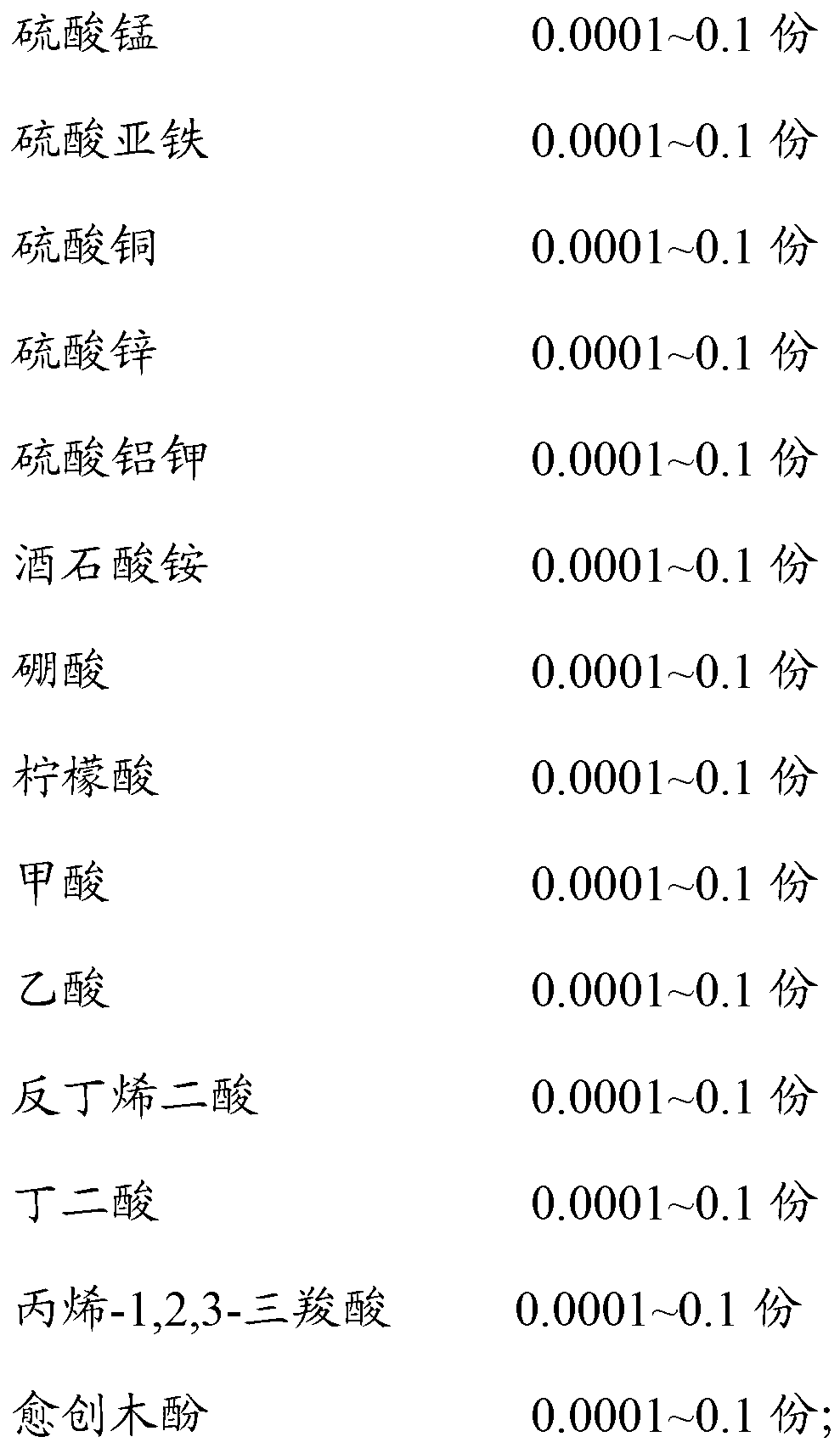

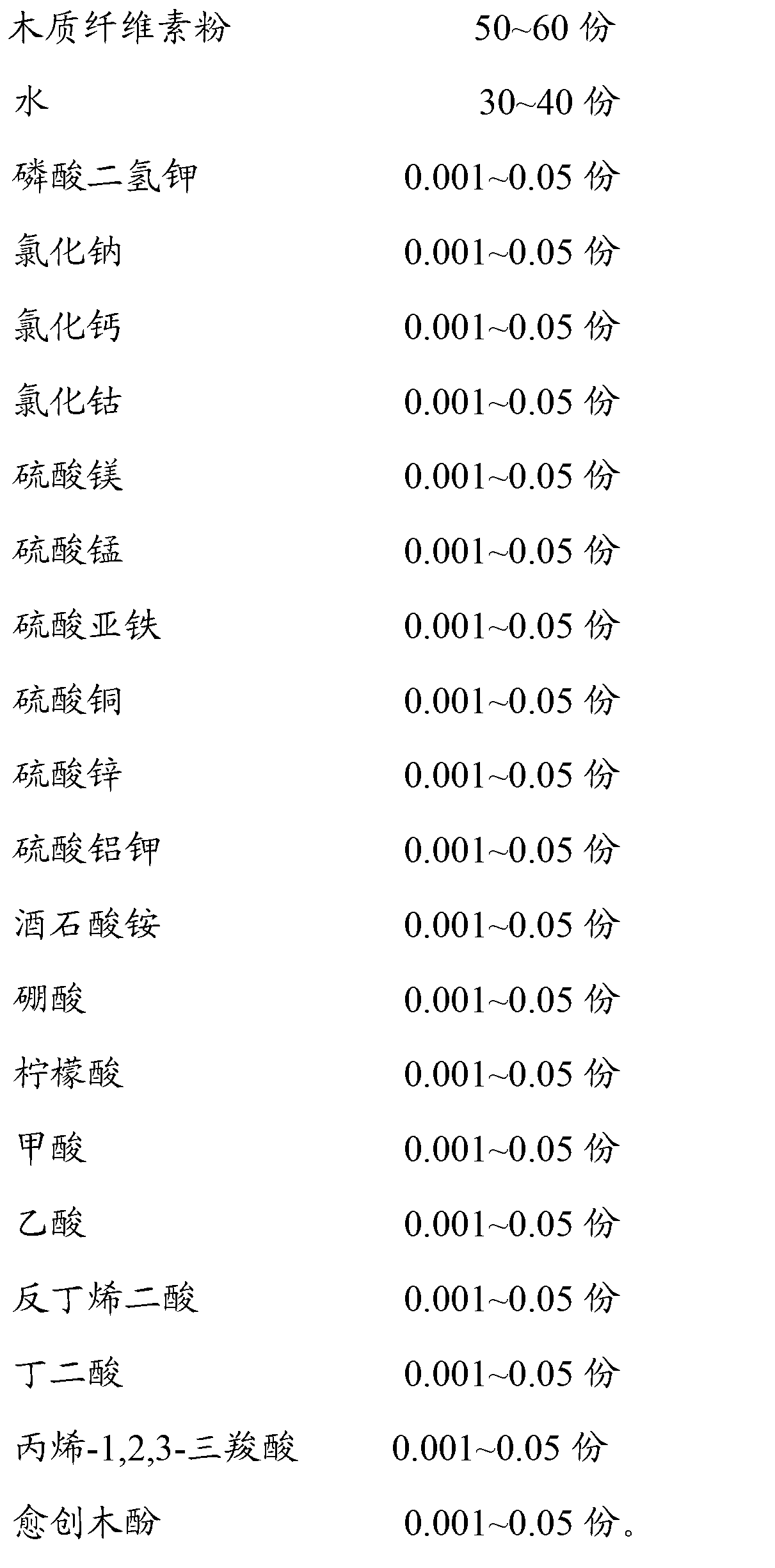

Fluid nutrient medium for large-scale cultivation of termitomyces albuminosus mycelium and application thereof

InactiveCN103172446AImprove utilizationLow costFertilizer mixturesTricarboxylic acidMonopotassium phosphate

The invention provides fluid nutrient medium for large-scale cultivation of termitomyces albuminosus mycelium and application thereof. The culture medium is prepared from the following materials in parts by weight: 50-70 parts of lignocellulose powder, 30-50 parts of water, 0.0001-0.1 part of monopotassium phosphate, 0.0001-0.1 part of sodium chloride, 0.0001-0.1 part of calcium chloride, 0.0001-0.1 part of cobalt chloride, 0.0001-0.1 part of magnesium sulfate, 0.0001-0.1 part of manganese sulfate, 0.0001-0.1 part of ferrous sulfate, 0.0001-0.1 part of copper sulfate, 0.0001-0.1 part of zinc sulfate, 0.0001-0.1 part of aluminum potassium sulfate, 0.0001-0.1 part of ammonium tartrate, 0.0001-0.1 part of boric acid, 0.0001-0.1 part of citric acid, 0.0001-0.1 part of formic acid, 0.0001-0.1 part of acetic acid, 0.0001-0.1 part of fumaric acid, 0.0001-0.1 part of succinic acid, 0.0001-0.1 part of propylene-1,2,3-tricarboxylic acid, and 0.0001-0.1 part of guaiacol. The termitomyces albuminosus of the fluid nutrient medium disclosed by the invention is customized, and can be used for large-scale indoor cultivation of termitomyces albuminosus mycelium by using lignocelluloses; and the fluid nutrient medium is low in cost and high in yield.

Owner:ZHEJIANG UNIV

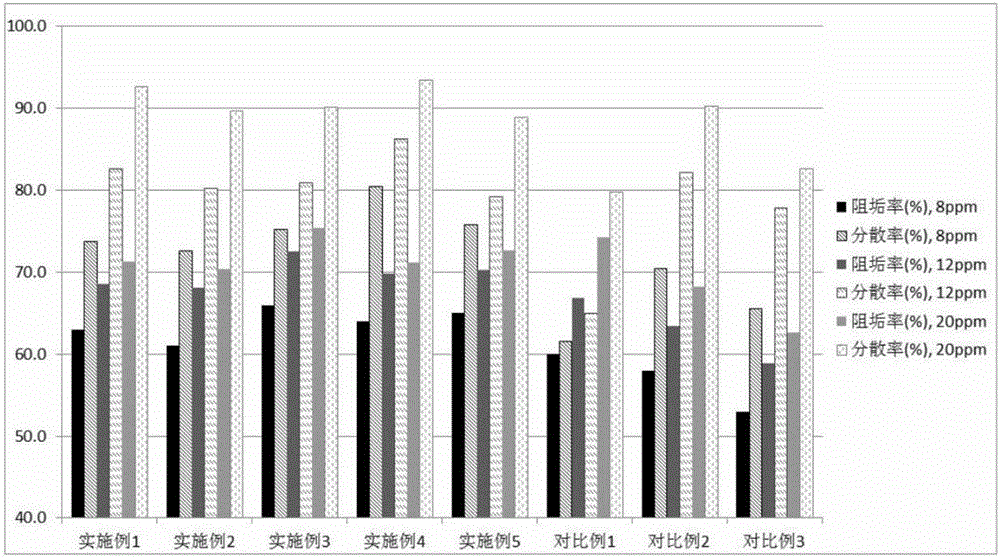

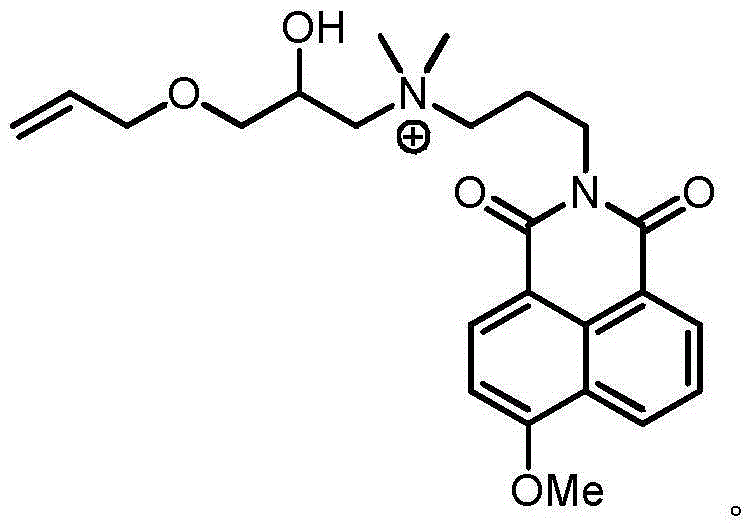

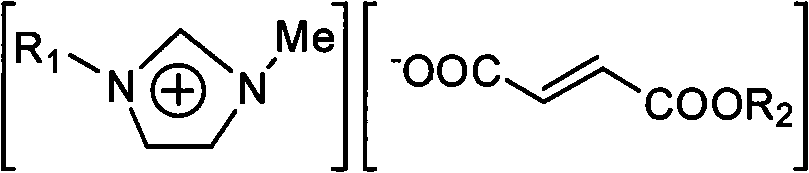

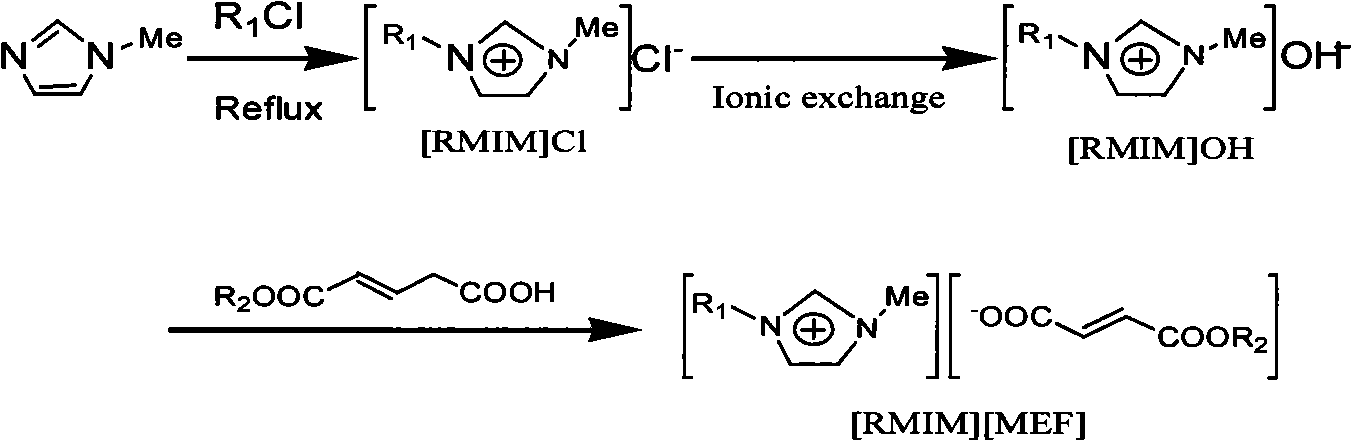

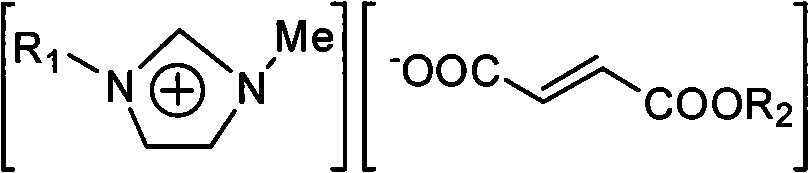

Ion liquid anti-virus activities bactericide, synthesis and application thereof

InactiveCN101341872AStrong bacteriostatic fungicide activityAntibacterial and fungicide activity is shortBiocideOrganic chemistryAnti virusSynthesis methods

The invention relates to ionic liquid bactericidal and bacteriostatic agent, and a synthetic method and the application thereof; the invention relates to ionic liquid bactericidal and bacteriostatic agent, and a synthetic method and the application thereof, in particular to a trans-butene diacid monoester anion base ionic liquid bactericidal and bacteriostatic agent and a synthetic method thereof, and the application of the trans-butene diacid monoester anion base ionic liquid bactericidal and bacteriostatic agent and the synthetic method in preparing bactericidal and bacteriostatic medicine. The invention provides novel series compound ionic liquid bactericidal and bacteriostatic agent, and a synthetic method and the application thereof. First, trans-butene diacid monoester is synthesized, and then alkyl methyl imidazole quaternary ammonium hydroxide is synthesized, and finally the ionic liquid bactericidal and bacteriostatic agent is synthesized. The ionic liquid bactericidal and bacteriostatic agent has very strong activity of bactericidal and bacteriostatic agent, and can be used to prepare anti-bacterial medicine. The synthesis route is short, the synthesis process is simple, the raw material cost is low, the environment pollution is small, the requirements for production equipment and environment conditions are not high, and the purity of the synthesized products is high, the yield is high, and the storage, transportation, packaging and use are convenient; therefore, the ionic liquid bactericidal and bacteriostatic agent is very applicable to large-scale industrialized production.

Owner:JIMEI UNIV

Prepn of isotopically labeled 15 N-L-aspartic acid and 15 N-L-alanine

InactiveCN1487087AEasy to manufactureGreat prospects for industrial implementationFermentationChemical synthesisNitrogen

The present invention is preparation process of isotopically labeled 15N-L-aspartic acid and 15N-L-alanine. Aspartase is proudced through microbial fermentation; inorganic material containing isotopic label 15N and fumaric acid are synthesized into 15N-L-aspartic acid via enzyme process. In the same time, 15N-L-aspartic acid is enzyme transformed into 15N-L-alanine. The said process is superior to available chemical synthesis process, which has low utilization of inorganic material containing isotopic label 15N, and to pure fermentation process, which has nore amino acids as side product and difficulty in separation. The present invention has 15N-L-aspartic acid concentration in ultimate reaction liquid over8%, molar conversion rate of inorganic material containing isotopic label 15N over 63 %, purity of product over 99 % and product abundance over 98.5 %.

Owner:上海新立工业微生物科技有限公司

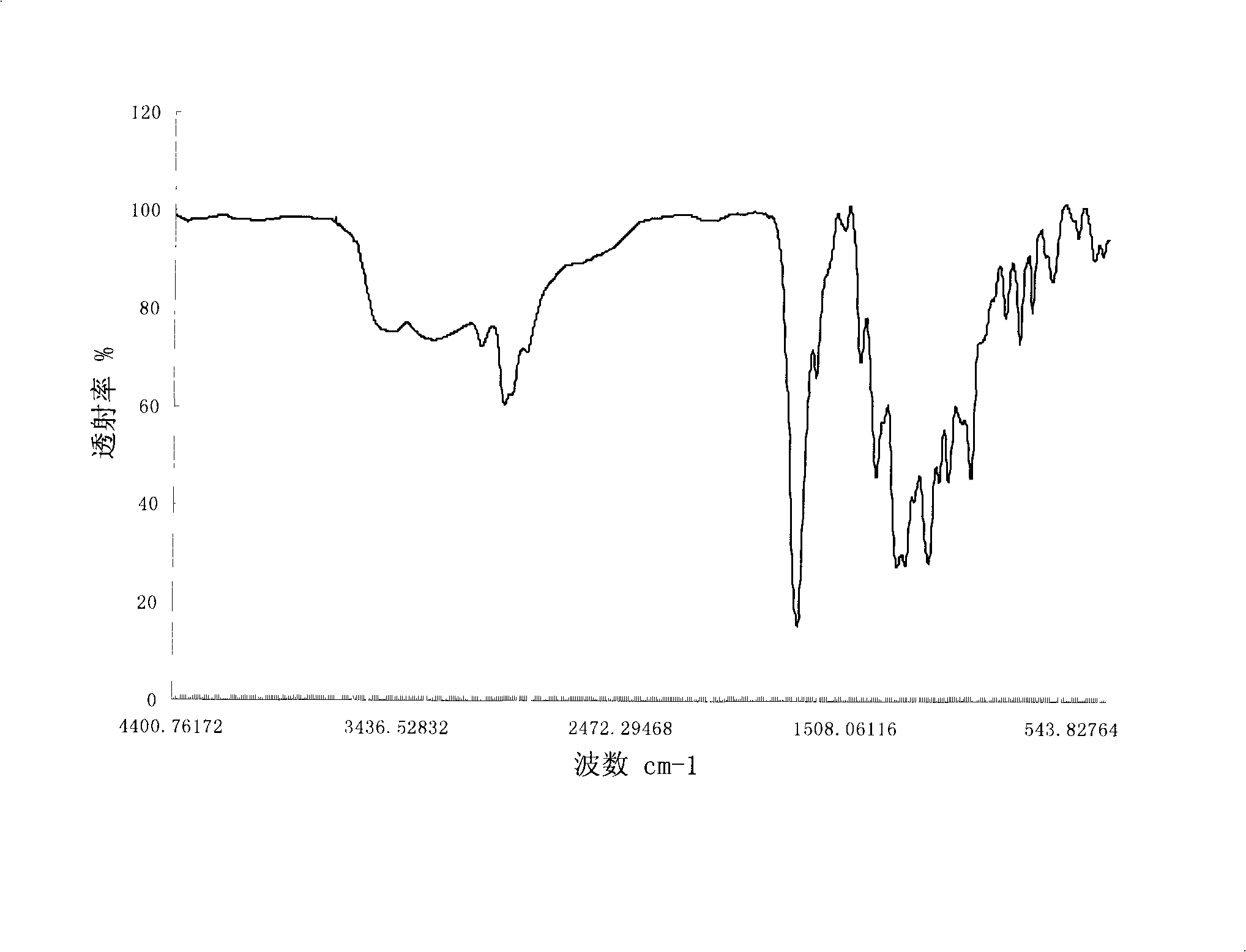

Hemifumarate salt of 1-[4-[1-(4-cyclohexyl-3-trifluoromethyl-benzyloxyimino)-ethyl]-2-ethyl-benzyl]-azetidine-3-carboxylic acid

InactiveUS20120115840A1Rapid onset of activityLow toxicityBiocideOrganic active ingredientsMedicineCarboxylic acid

This invention relates to a hemifumarate salt of 1-(4-{1-[(E)-4-cyclohexyl-3-trifluoromethyl-benzyloxyimino]-ethyl}-2-ethyl-benzyl)-azetidine-3-carboxylic acid (Compound I), to pharmaceutical compositions comprising this salt, to processes for forming this salt and to its use in medical treatment. In addition, the present invention also relates to new polymorphic forms of the hemifumarate salt form of Compound I, as well as to pharmaceutical compositions comprising these polymorphic forms, to processes for obtaining them, and their use in medical treatment.

Owner:NOVARTIS AG

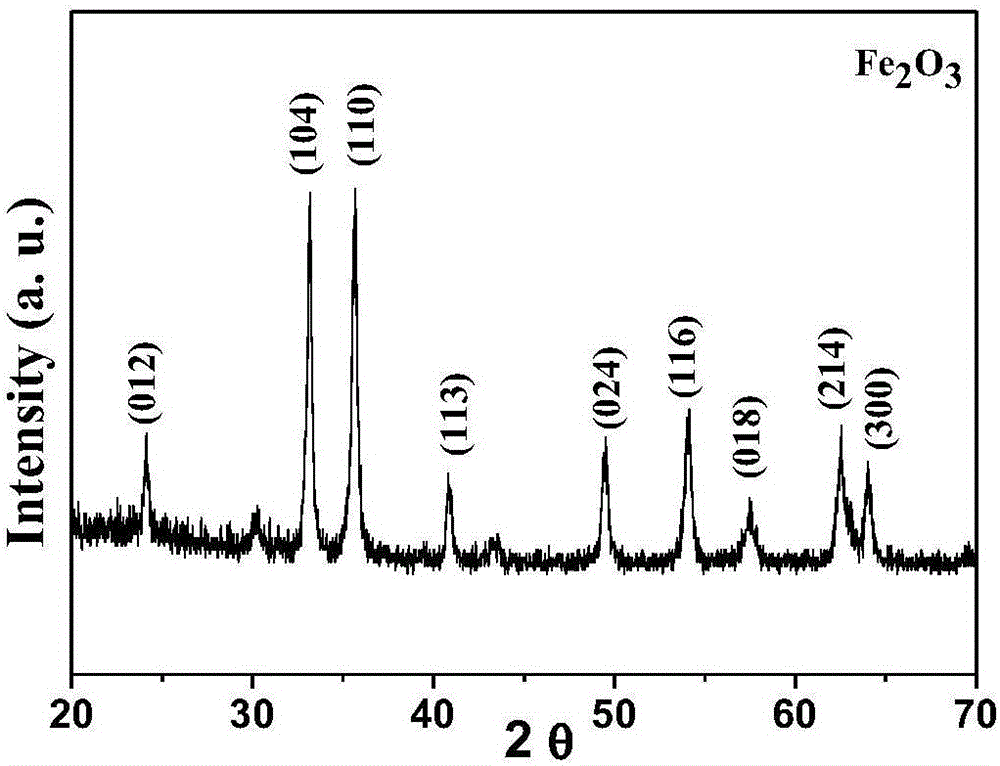

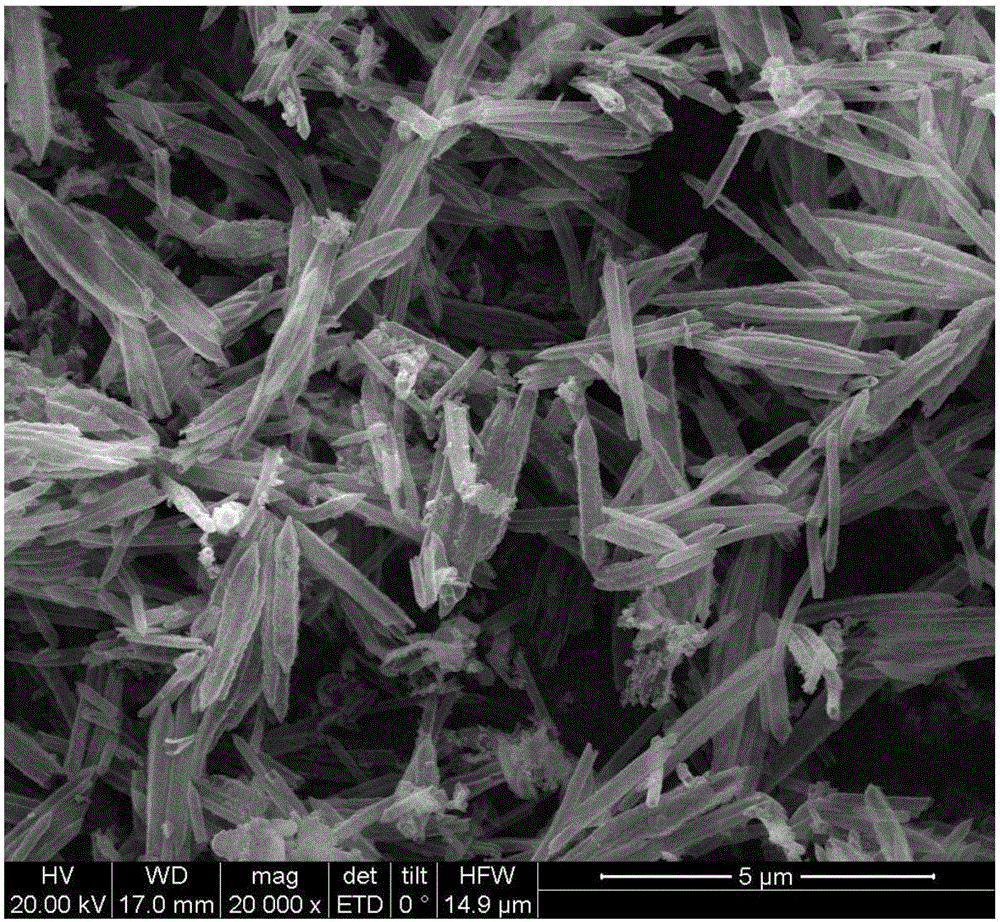

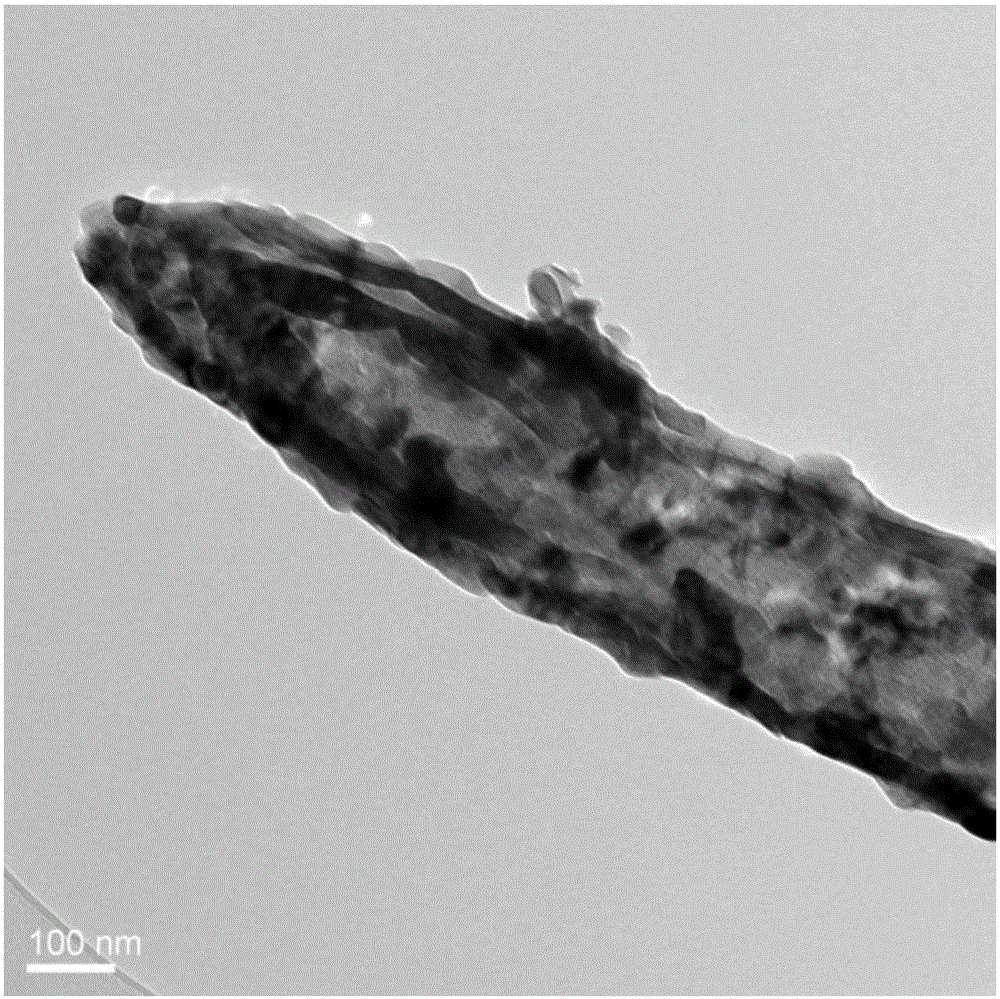

Iron sesquioxide nanotube material as well as preparation method and application thereof

ActiveCN105977484AImprove the first Coulombic efficiencyImprove efficiencyMaterial nanotechnologyFinal product manufactureShielding gasVacuum drying

The invention discloses an iron sesquioxide nanotube cathode material, which is prepared from an iron salt, fumaric acid and deionized water. A preparation method comprises the following steps of first adding a trivalent iron salt and the fumaric acid into the deionized water, and agitating an obtained aqueous solution for 2 to 6 hours at a rotational speed of 600r / min to 1,000r / min; afterwards, transferring the mixed aqueous solution into a high-pressure reaction kettle to keep the mixed aqueous solution for 12 to 24 hours at 70 DEG C to 90 DEG C; naturally cooling the mixed aqueous solution to be at a room temperature, then carrying out centrifugal separation on a precipitate, which is generated in a low-temperature hydrothermal manner, at a rotational speed of 4,000r / min to 7,000r / min, and successively washing the precipitate for three times by using ethanol and the deionized water; subsequently, carrying out vacuum drying on the precipitate in a condition of 80 DEG C to 100 DEG C, so as to obtain an iron-based metal organic framework nanofiber; finally, placing the iron-based metal organic framework nanofiber in a tube furnace, introducing an air shielding gas into the tube furnace according to an inlet gas volume of 0.2L / min to 0.8L / min, raising a temperature to 550 DEG C to 600 DEG C according to a temperature raising rate of 0.5 DEG C per minute to 2 DEG C per minute, carrying out heat preservation for 2 to 6 hours, and naturally cooling the precipitate to the room temperature, so as to obtain an iron sesquioxide nanotube material. The iron sesquioxide nanotube material prepared by the invention is applied to a lithium ion battery; the initial coulombic efficiency of a lithium battery is improved, and the cycle life of the lithium battery is prolonged; the technique is simple; the reproducibility is good; the implementation is easy.

Owner:镇江微电智能科技有限公司

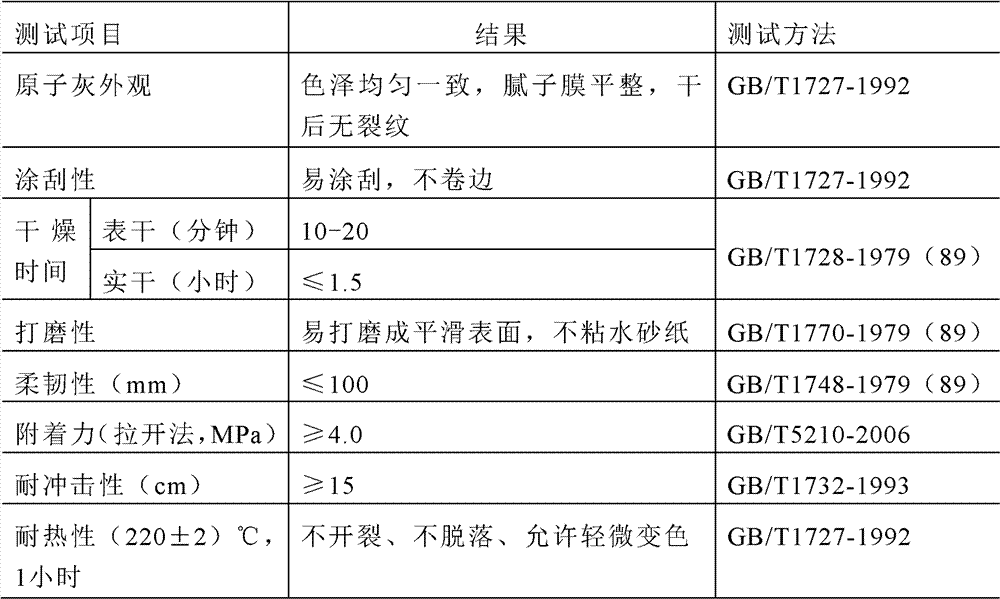

Method for preparing unsaturated polyester resin used in putty

The invention relates to a method used for preparing unsaturated polyester resin used in putty. According to the invention, an unsaturated acid and trimethylol propane are synthesized into macro-molecular air-drying alcohol; soft resin is synthesized by using monomers such as dihydric alcohol, adipic acid, isophthalic acid, maleic anhydride, and styrene; and the unsaturated polyester resin provided by the invention is prepared by using ethylene glycol, diethylene glycol, the synthesized macro-molecular air-drying alcohol, fumaric acid, tetrahydrophthalic anhydride, styrene, the synthesized soft resin, and acrylic acid. When the unsaturated polyester resin provided by the invention is prepared into putty, an adhesion force is no smaller than 4.0, an impact resistance is no smaller than 15cm, and no cracking and falling is caused after 1h of heating under a temperature of 220 DEG C (plus or minus 2 DEG C).

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS +1

Softener for bamboo product

InactiveCN104890075AImprove softening effectGood effectWood treatment detailsReed/straw treatmentWater basedAcrylic resin

The invention discloses a softener for a bamboo product. The softener for the bamboo product comprises components of raw materials in parts as follows: 10-20 parts of polyglycerol, 20-30 parts of ethylene glycol, 20-25 parts of butyl carbitol, 15-20 parts of phenoxy ethanol, 20-25 parts of diethylene glycol, 10-12 parts of ethylene glycol monomethyl ether, 8-10 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 8-12 parts of sodium alkyl benzene sulfonate, 8-15 parts of octylphenol polyoxyethylene ether, 8-10 parts of nonylphenol polyoxyethylene ether, 6-8 parts of methyl methacrylate, 15-20 parts of water-based acrylic resin, 10-15 parts of acrylic acid, 8-10 parts of methylene bis-acrylamide, 6-8 parts of ammonium persulfate, 10-12 parts of fumaric acid, 8-10 parts of succinic anhydride and 200-300 deionized water. The softener for the bamboo product has a good softening effect, is non-corrosive and has a better effect on improvement of the strength and the toughness of a softened part.

Owner:陈新棠

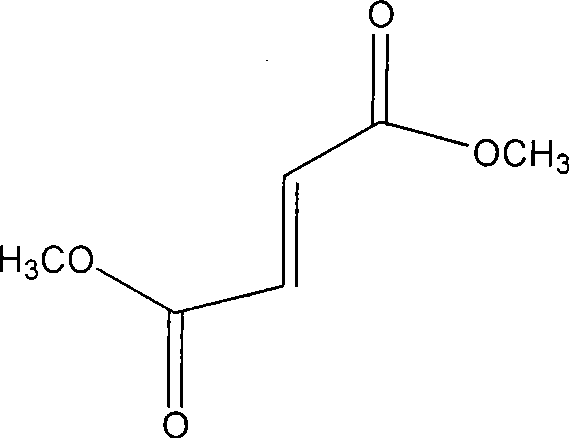

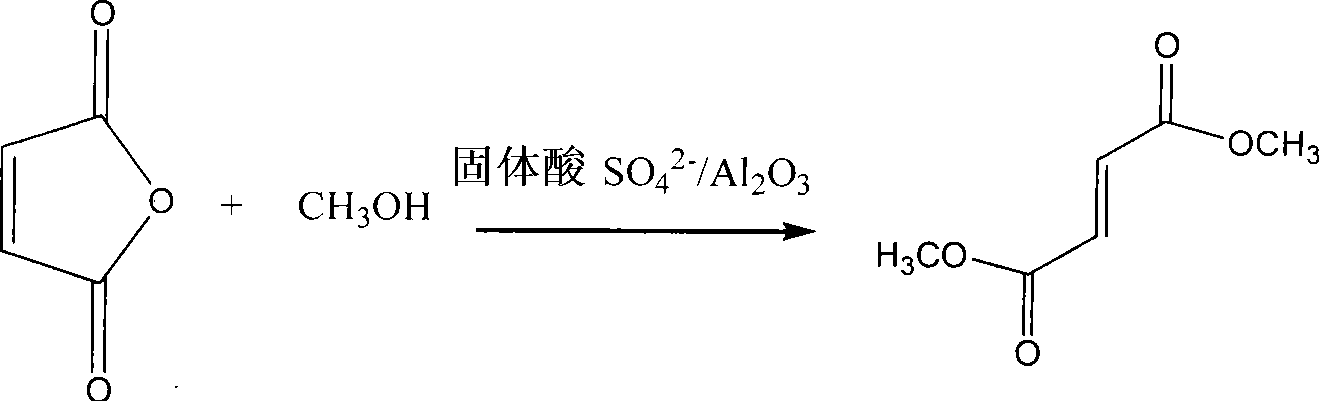

Preparation method of dimethyl fumarate

InactiveCN101475477ASimple and safe operationReduce corrosionPhysical/chemical process catalystsOrganic compound preparationSolid acidSolvent

The invention discloses a method for preparing fumaric dimethyl ester (DMF). The method comprises the steps of taking maleic anhydride as raw material and subjecting the raw material and methanol to catalytic reaction in the presence of a solid-acid SO4 / Al2O3 catalyst so as to obtain the fumaric dimethyl ester, namely a target product of the invention. The purity of the fumaric dimethyl ester obtained by the preparation method is up to over 98.5 percent, and the yield of the fumaric dimethyl ester is between 85 and 95 percent. Compared with the prior art, the method has the advantages that the method adopts the solid-acid SO4 / Al2O3 catalyst, is safe and convenient in operation, improves environment, reduces corrosion on equipment, can cyclically recycle reaction solvent and the solid-acid catalyst, reduces the three wastes, ensures stable product quality, and is suitable for industrial production.

Owner:SHANGHAI CHEM REAGENT RES INST

Solvent-free epoxy polyurethane resin floor coating

InactiveCN106366883AGood self-levelingImprove wear resistanceAntifouling/underwater paintsPaints with biocidesSolvent freeSolvent

The invention belongs to the field of preparation of epoxy coatings and particularly relates to a solvent-free epoxy polyurethane resin floor coating. The coating is prepared from a component A and a component B. The component A comprises, by weight, 40-60 parts of dicyclohexylmethylmethane-4, 20-30 parts of glycerin, 1-5 parts of fumaric acid diethyl ester diisocyanate, 1-10 parts of p-tert-butyl phenyl glycidyl ether and 0.8-1.5 parts of p-toluenesulfonyl isocyanate. The component B is prepared from, by weight, 10-15 parts of epoxy resin, 0.5-1.0 part of stannous octoate, 0.1-0.8 part of cellulose acetate butyrate and 40-45 parts of quartz sand. The mass ratio of the component A to the component B is 4:1. The coating has the advantages that the coating is good in self-leveling performance, environmentally friendly, good in abrasion resistance, resistant to heavy load, excellent in chemical resistance, high in adhesive force, resistant to mould, easy and convenient to construct, easy to maintain and good in impact resistance, and elasticity can be adjusted according to site application.

Owner:FUZHOU ROYAL FLOOR

Cooling liquid for cutting solar silicon wafer through diamond wire

InactiveCN104087406AGuaranteed Surface PropertiesGood dispersionLubricant compositionEthylenediaminePolyethylene glycol

The invention discloses a cooling liquid for cutting a solar silicon wafer through a diamond wire. The cooling liquid consists of the following raw materials in parts by weight: 2-3 parts of triethanolamine, 2-4 parts of glycerin, 2-3 parts of methoxy polyethylene glycol, 3-5 parts of hydroxyethyl acrylate, 2-3 parts of fatty alcohol-polyoxyethylene ether, 3-4 parts of p-toluenesulfonic acid, 2-5 parts of fumaric acid, 1-2 parts of phthalic anhydride, 2-4 parts of maleinimide, 1-3 parts of cis-butenedioic acid, 2-4 parts of diisopropanolamine, 2-3 parts of n-butylamine, 1-2 parts of tri-isopropanolamine, 2-3 parts of potassium sorbate, 1-3 parts of phenoxyethanol, 2-3 parts of methylparaben, 2-3 parts of ethylenediamine tetraacetic acid, 2-5 parts of titanium dioxide, 2-4 parts of methyl methacrylate, 3-5 parts of acetone, and 50-70 parts of deionized water. The cooling liquid for cutting the solar silicon wafer through the diamond wire can be well applied to cutting with the diamond wire, is good in lubrication and cooling effects, low in cost and free of pollution, can effectively reduce the breakage rate, has a good dispersion function on silicon powder and iron impurities generated in the cutting process, and ensures the surface property of the silicon wafer.

Owner:梁胜光

Electrochemical polymerization solution for preparing solid electrolyte layer for solid electrolytic capacitor

InactiveCN104064358AImprove conductivityLower ESRCapacitor electrolytes/absorbentsSuccinic acidAdipic acid

The invention provides electrochemical polymerization solution for preparing a solid electrolyte layer for a solid electrolytic capacitor. The electrochemical polymerization solution comprises a conductive macromolecule monomer, a doping agent, a solvent and weak organic acid, wherein the weak organic acid is one or combination of citric acid, adipic acid, maleic acid, fumaric acid, tartaric acid, succinic acid, malic acid or gluconic acid, the content being 0.1-1% of the total mass of the electrochemical polymerization solution. According to the electrochemical polymerization solution, ESR of the solid electrolytic capacitor products can be reduced, and reliability level of the solid electrolytic capacitor can be improved.

Owner:FUJIAN GUOGUANG ELECTRONICS SCI & TECHCO

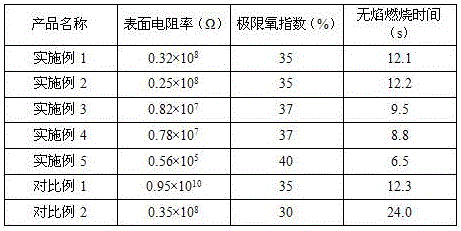

Flame-retardant antistatic rubber material for conveying belt covering layer and preparation method of rubber material

ActiveCN106243429AImprove flame retardant performanceImprove antistatic performanceRubber materialPolymer science

The invention provides a flame-retardant antistatic rubber material for a conveying belt covering layer and a preparation method of the rubber material. The rubber material is composed of chloroprene rubber, butadiene styrene rubber, sulfure, carbon black, ethyl tri-(2-methoxyethoxy)silane, zinc stearate, promoter, antiager, dicyclopentadiene resin, octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate, trihydroxyethyl methyl quaternary ammonium methyl sulfate, stearamide propyl dimethyl-beta-ethoxy ammonium dihydrogen phosphate, aluminum hydroxide, bis(2, 3-dibromopropyl)fumaric acid and 1, 2-bis(2, 4, 6-tribromophenoxy) ethane. The rubber material is prepared through plastifying, two times of mixing and vulcanization. Due to uniform dispersion and high compatibility with polymer of an antistatic agent and a flame retardant in the rubber material in a polymer substrate, flame-retardant and antistatic effects of rubber are improved obviously.

Owner:SHANDONG LONGYUAN RUBBER

Agent for improving low temp. flowability of diesel

InactiveCN1358826ASimple preparation processWell mixedLiquid carbonaceous fuelsViscous liquidTrans-Butenedioic acid

The diesel oil low-temp. flowability improving agent contains (wt%) 10-70% of ethylene-vinyl acetate copolymer, 5-50% of vinyl acetate-trans-butenedioic acid ester copolymer, 1-40% of aliphatic ester containing hydroxide radical, 1-30% of oil-soluble fatty acylamide and 1-40% of low-volatility and low-viscosity ester-like solvent. Said invented diesel oil low-temp. flowability improving agent is a yellow viscous liquid, has no volatile solvent, and is easy to be dissolved in diesel oil, its addition quality is 0.1-0.01%. It possesses good applicability for all diesel oils, can reduce solidification point of diesel oil by 5-28 deg.C and cold filtering point by 1-12 deg.C.

Owner:李鸿图

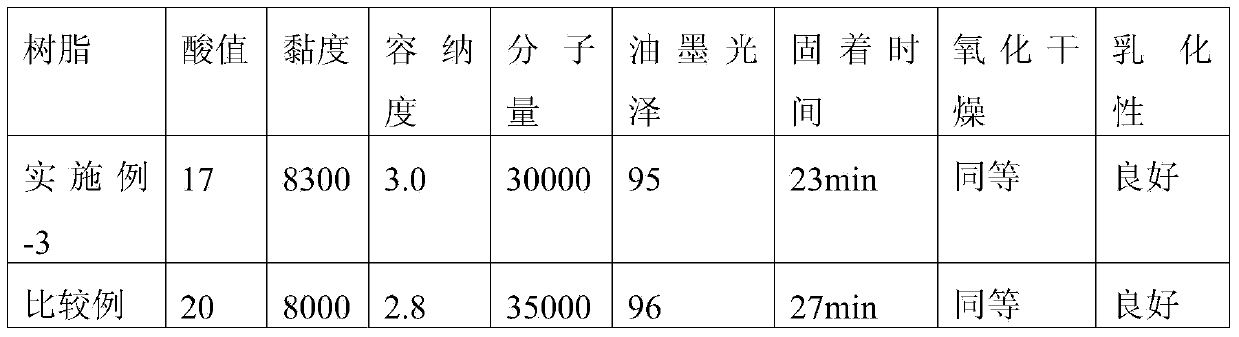

Preparation method for rosin modified phenolic resin

The invention provides a preparation method for rosin modified phenolic resin. The method comprises the following steps: 1) placing rosin into a reaction vessel, carrying out heating to 180 DEG C, adding trans-butenedioic acid, continuing heating to 210 to 215 DEG C and then carrying out heat preservation for 1 to 1.5 h, and carrying out addition reaction; 2) adding pentaerythritol and magnesium oxide into the reaction vessel, carrying out cooling to 160 to 170 DEG C, adding nonyl phenol and tert-octylphenol according to a molar ratio of 1: 1.05-1.08, then continuing cooling to 130 to 140 DEG C, adding paraformaldehyde according to a phenol-to-aldehyde molar ratio of of 1: 2.2-2.3, and carrying out heat preservation under the temperature for 1 to 2 h; and 3) raising the temperature in the reaction vessel to 260 to 270 DEG C, carrying out heat preservation and esterification reaction until an acid value is less than 25 mgKOH / g, and carrying out vaccum distillation until a low-boiling substance is distilled out, so the rosin modified phenolic resin is obtained. The resin prepared by using the method in the invention has the advantages of high viscosity, good solubility, large molecular weight, uniform distribution and applicability to offset lithographic ink.

Owner:桂林兴松林化有限责任公司

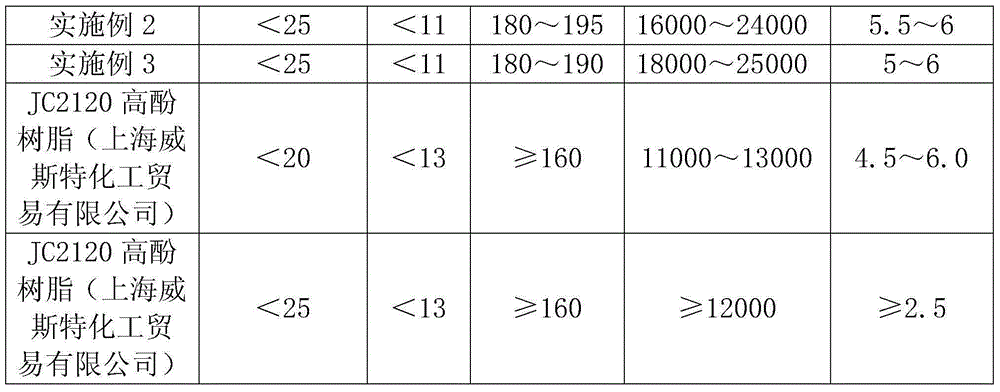

Scale inhibiting dispersant composition and use thereof

PendingCN106554091AImprove recycling efficiencyEmission reductionScale removal and water softeningNature of treatment waterFluorescenceItaconic acid

The invention discloses a composition. The composition contains a component (1) and a component (2), wherein the component (1) is selected from one or more of groups consisting of the following substances: acrylic acid, methacrylic acid, maleic acid, fumaric acid and itaconic acid monomers or homopolymers of water-soluble salts thereof or copolymers of two or more of monomers; and the component (2) is selected from one or more of groups consisting of the following substances: acrylic acid and water-soluble salts thereof and copolymers of sulfonate monomers, optional acrylamide and optional fluorescent monomers. The invention further discloses use of the composition.

Owner:ECOLAB USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Hemifumarate salt of 1-[4-[1-(4-cyclohexyl-3-trifluoromethyl-benzyloxyimino)-ethyl]-2-ethyl-benzyl]-azetidine-3-carboxylic acid Hemifumarate salt of 1-[4-[1-(4-cyclohexyl-3-trifluoromethyl-benzyloxyimino)-ethyl]-2-ethyl-benzyl]-azetidine-3-carboxylic acid](https://images-eureka.patsnap.com/patent_img/87eba999-9d69-4685-918c-2e71dad8e5c5/US20120115840A1-20120510-D00001.png)

![Hemifumarate salt of 1-[4-[1-(4-cyclohexyl-3-trifluoromethyl-benzyloxyimino)-ethyl]-2-ethyl-benzyl]-azetidine-3-carboxylic acid Hemifumarate salt of 1-[4-[1-(4-cyclohexyl-3-trifluoromethyl-benzyloxyimino)-ethyl]-2-ethyl-benzyl]-azetidine-3-carboxylic acid](https://images-eureka.patsnap.com/patent_img/87eba999-9d69-4685-918c-2e71dad8e5c5/US20120115840A1-20120510-D00002.png)

![Hemifumarate salt of 1-[4-[1-(4-cyclohexyl-3-trifluoromethyl-benzyloxyimino)-ethyl]-2-ethyl-benzyl]-azetidine-3-carboxylic acid Hemifumarate salt of 1-[4-[1-(4-cyclohexyl-3-trifluoromethyl-benzyloxyimino)-ethyl]-2-ethyl-benzyl]-azetidine-3-carboxylic acid](https://images-eureka.patsnap.com/patent_img/87eba999-9d69-4685-918c-2e71dad8e5c5/US20120115840A1-20120510-D00003.png)