Degradable unsaturated carbamide resin of polyester amide, and synthetic method

A technology of polyester amide urea and synthesis method, applied in the field of degradable unsaturated polyester amide urea resin and its synthesis, can solve the problems of high price of slow-release fertilizer, shortage of slow-release fertilizer and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

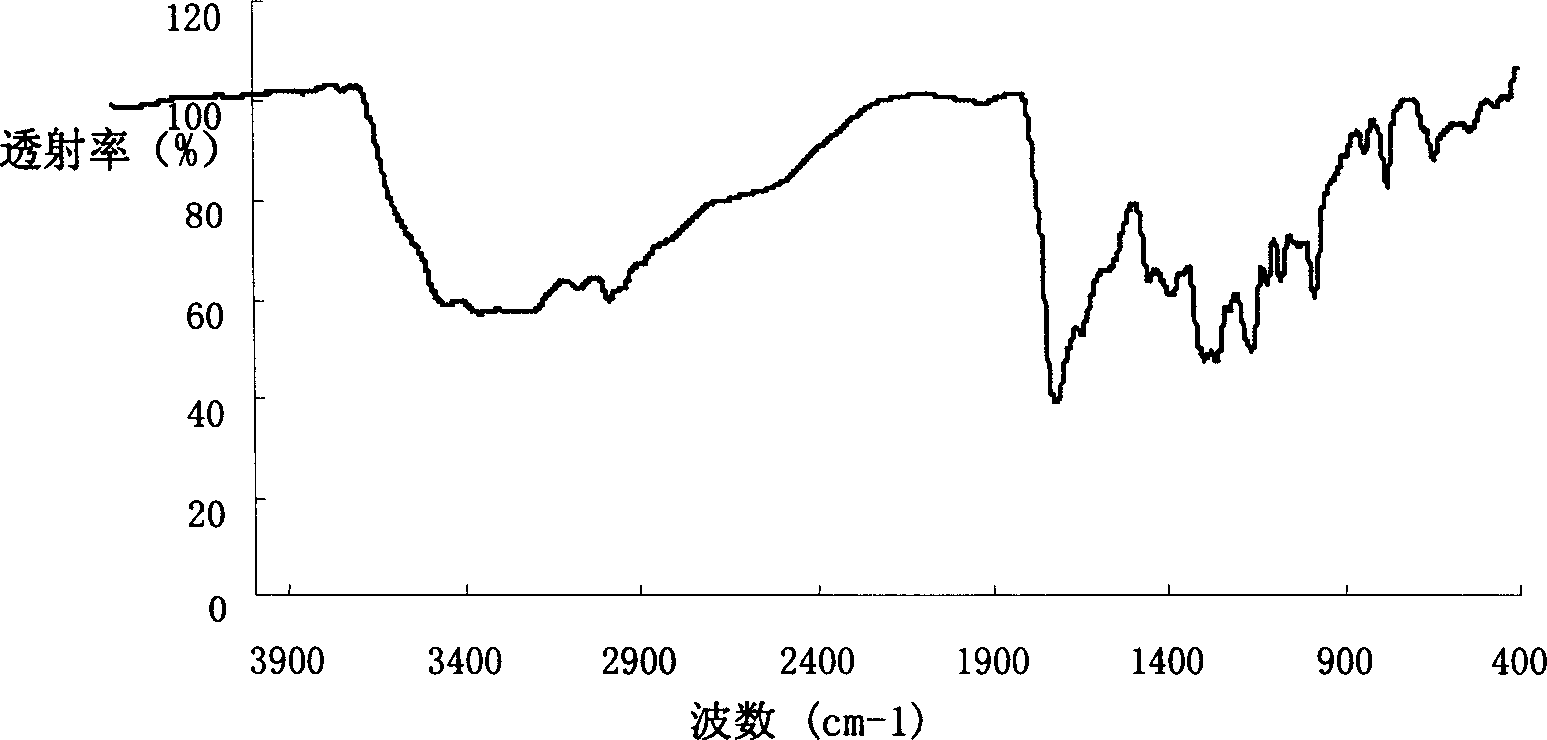

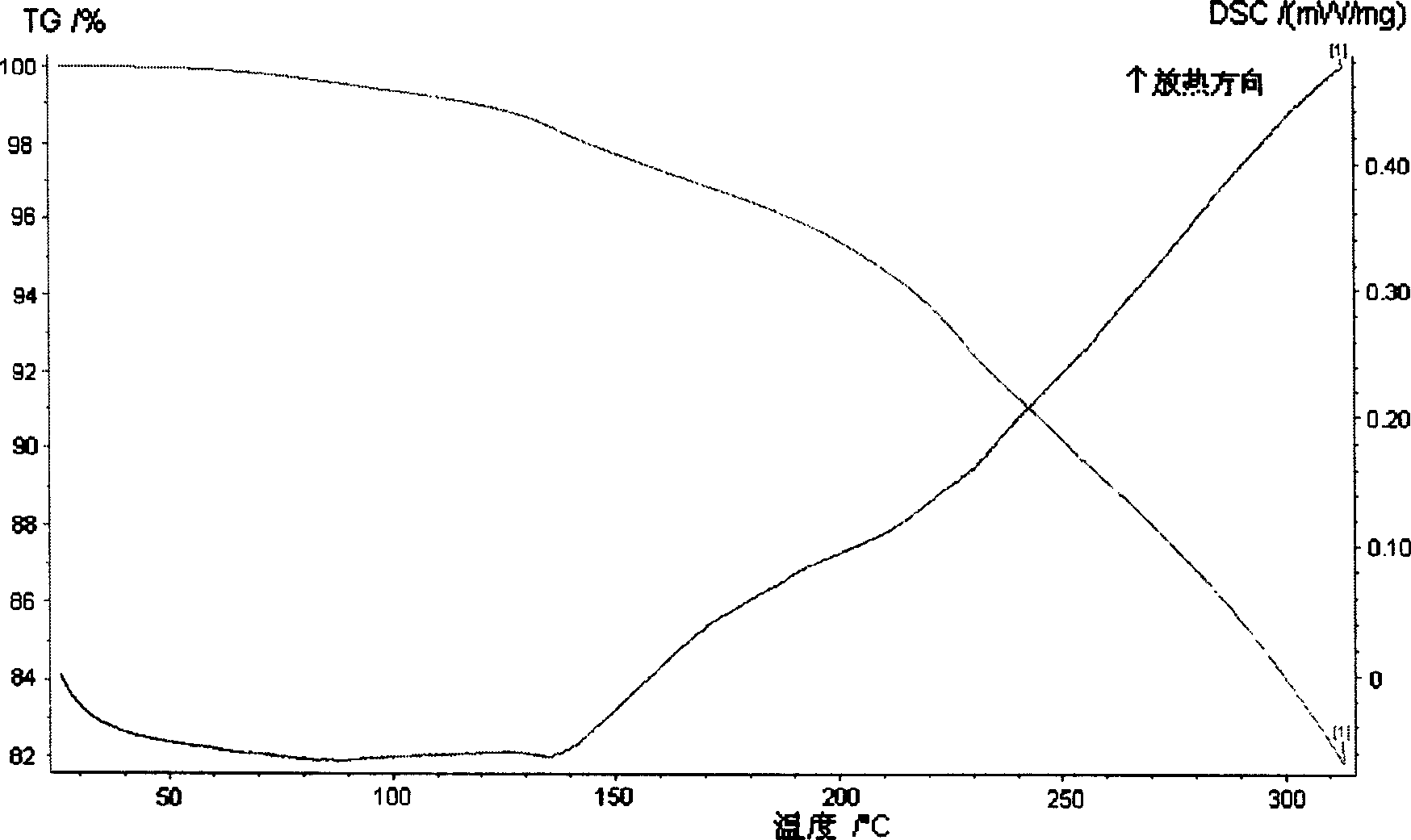

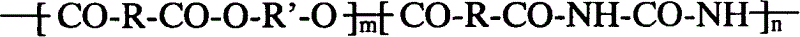

[0030] Embodiment 1: the synthesis of unsaturated polyester amide urea resin:

[0031] 19.60g maleic anhydride (0.20 mole), 3.00g urea (0.05 mole) and 9.92g ethylene glycol (0.16 mole) are mixed, put into a 250ml three-necked flask with water separator, place in a silicone oil bath, With electric stirring, react at 100°C for 20 minutes. The temperature was raised to 150°C for 40 minutes for melt polymerization in a nitrogen atmosphere, then the temperature was raised to 180°C for 120 minutes for melt polymerization in a nitrogen atmosphere, and then the temperature was raised to 200°C for melt polymerization in a nitrogen atmosphere. When the distilled reaction water reaches 80% of the theoretical amount, the polymerization is stopped, the temperature is lowered to 150° C. and poured out. After cooling, a dark brown transparent solid unsaturated polyester amide urea resin is obtained.

Embodiment 2

[0032] Embodiment 2: the synthesis of starch-filled unsaturated polyester amide urea resin:

[0033] Mix 23.20g of fumaric acid (0.20 mole), 3.00g of urea (0.05 mole) and 16.96g of ethylene glycol (0.16 mole), put it into a 250ml three-necked flask with a water separator, and place it in a silicone oil bath Medium, with electric stirring, reacted at 100°C for 20 minutes. The temperature was raised to 150°C, and melted and polymerized in a nitrogen atmosphere for 40 minutes, then raised to 180°C, melted and polymerized in a nitrogen atmosphere for 120 minutes, and then heated to 200°C, melted and polymerized in a nitrogen atmosphere for 15 minutes. When the distilled reaction water reaches 80% of the theoretical amount, add starch accounting for 50% of the total mass of the reaction system, stir well, cool down to 150°C and pour it out. After cooling, an opaque light yellow solid starch-filled unsaturated polyester is obtained. Amide urea resins.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com